INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

INTRODUCTION

Description of the System

The Mueller PAC Fre-Heater Model AL is designed to recover heat

removed by refrigeration or air conditioning systems and to utilize that

heat for heating water. It is a heat recovery system which heats and

stores hot water all in one unit. It is easily connected to an existing

refrigeration unit, either air or water cooled. PAC Fre-Heater is a desuperheater which removes most or all of the latent heat of the hot

discharged gas from the compressor and uses the existing condenser to

remove the remaining heat and condense the refrigerant . It is not

intended to and should not be used to totally replace the normal air- or

water-cooled condenser.

PAC water tanks are rated for 150 psi working pressure and refrigeration

circuits are rated for a maximum working pressure of 400 psi.

PAC have a placement for supporting heater by the placement of this

element located in the under of the tank. The placement of this element

allows the maximum utilization of the refrigerant heat recovery system

and minimizes the usage of electricity in directly heating the water.

The outer jacket of all PAC Fre-Heaters is highly corrosion-resistant

stainless steel and will remain bright and rust-free with a minimu m

of care . Do no t us e ab r a si v e c l ea ni n g ma t er i al s or compounds on the

outer jacket as they will scratch the surface. After using any cleaning

compounds always rinse with clear water. In coastal areas where the

air contains a high salt content, the bright appearance of the Fre-Heater

can be maintained by rubbing it with oil or a light grease as soon as it is

installed.

Capacity

PAC Fre-Heater is designed for use with air- or water-cooled

refrigeration units. The size of the units and refrigeration systems on

which each model may be used are shown in Table 1.

2

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Table 1 - PAC Technical Specifications

Model

Water

Connection

Sizes

No. of

Refrig.

Circuits

Water

Connection

Sizes

(inch)

Refrig.

Connection

Sizes

(inch)

Dimension

(cm..)

Weight

(kilogram)

AL-0252P 25 1

1/2”

THREAD

3/8” FLARE 38x44 12

AL-0502P 50 1

1/2”

THREAD

3/8” FLARE 45x53 16

AL-0502PS 50 2

1/2”

THREAD

3/8” FLARE 45x53 16

AL-0752P 75 1

1/2”

THREAD

3/8” FLARE 45x77 21

AL-0752PS 75 2

1/2”

THREAD

3/8” FLARE 45x77 21

AL-1002P 100 1

3/4”

THREAD

3/8” FLARE 52x79 25

AL-1002PS 100 2

3/4”

THREAD

3/8” FLARE 52x79 25

AL-1502P 150 1

3/4”

THREAD

3/8” FLARE 52x110 27

AL-1502PS 150 2

3/4”

THREAD

3/8” FLARE 52x110 27

Fre-Heater Location

The Fre-Heater should be located inside. If it is necessary to locate the FreHeater outside, it must be under a cover. The Fre-Heater must be

protected from water dripping or spraying, or in any way collecting on the

top surface, as this can result in the failure of the heat exchanger. When

selecting a location for PAC Fre-Heater, the ability of that location to bear

the loaded weight of the Fre-Heater should be a prime consideration. The

loaded weights of all PAC Fre-Heaters are listed in Table 1.

PAC Fre-Heater should be located as near as practical to the refrigeration

unit(s). The Fre-Heater should not be located where cooling tower or

evaporative condenser water will be in continual direct contact with the

exterior surface. Careful planning of the Fre-Heater location and plumbing

can reduce installation costs and save time during installation and on

maintenance in the future.

3

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Figure 1 : PAC Fre-heater Model AL-0252P

Front Side

Back Suspension

4

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Figure 2 : PAC Fre-Heater Model AL-0502P, AL-0502PS

Front Side

Back Suspension

5

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Figure 3 : PAC Fre-Heater Model AL-0752P, AL-0752PS

Front Side

Back Suspension

6

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Figure 4 : PAC Fre-Heater Model AL-1002P, AL-1002PS

Front Side

Back Suspension

7

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Figure 5 : PAC Fre-Heater Model AL-1502P, AL-1502PS

Front Side

Back Suspension

8

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Figure 6 : PAC Connections Model AL-0252P

9

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Figure 7: PAC Connections Model AL-0502P

Figure 8 : PAC Connections Model AL-0502PS

10

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Figure 9 : PAC Connections Model AL-0752P

Figure 10 : PAC Connections Model AL-0752PS

11

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Figure 11 : PAC Connections Model AL-1002P

Figure 12 : PAC Connections Model AL-1002PS

12

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Figure 13 : PAC Connections Model AL-1502P

Figure 13 : PAC Connections Model AL-1502PS

13

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

SECTION 2.0 - INSTALLATION

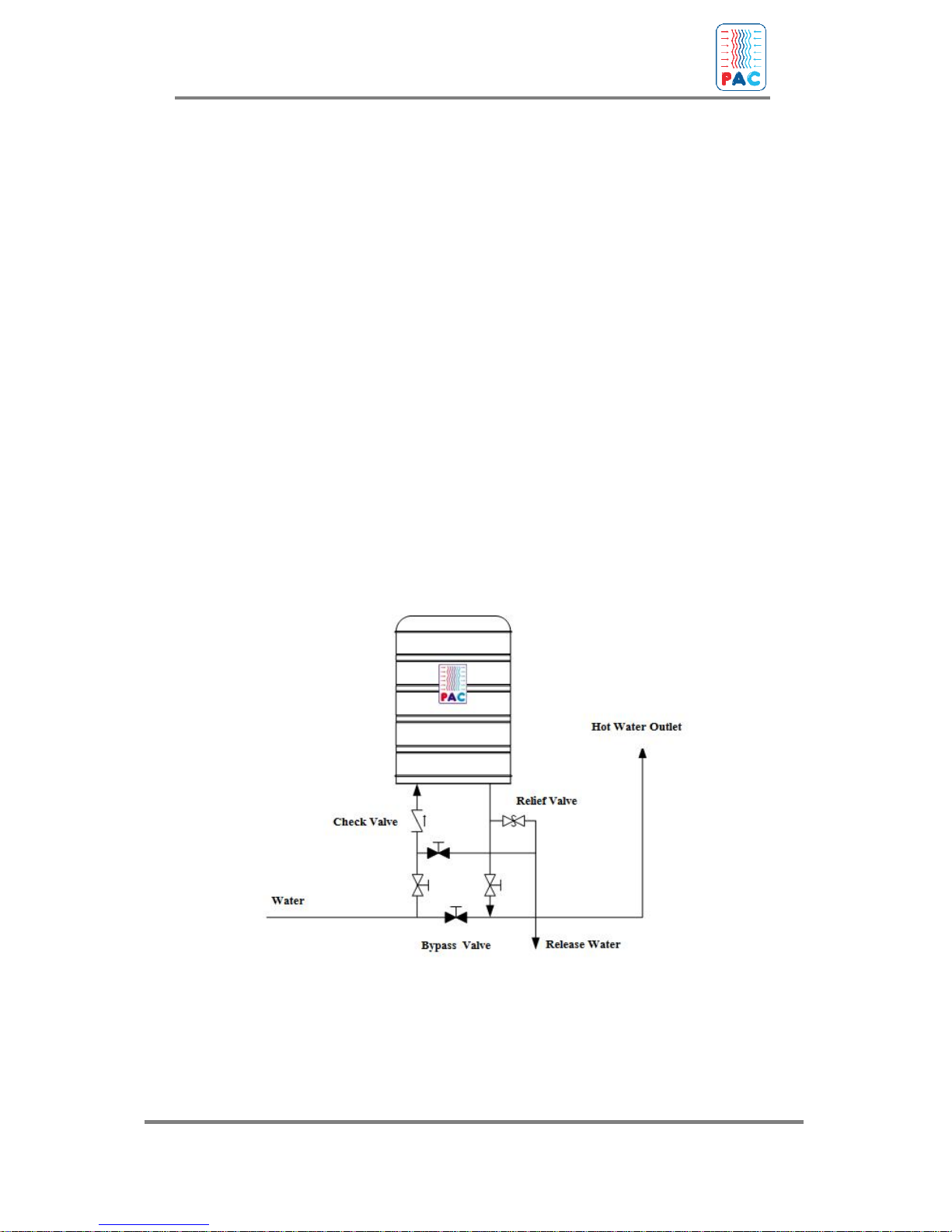

2.1 Installing Water Piping

PAC Fre-Heater is equipped with 3/4" or 11/2" connections for cold water

inlet and hot water outlet, depending on the specific model

The water inlet connection is labeled “Cold” and the outlet connection is

labeled “Hot”

The pipe from the “Hot” outlet should go to the conventional water heating

system if one is used. See Figures.

A water bypass line should always be provided so the Fre-Heater(s) can be

bypassed for service without shutting down the total water heating system.

NOTE: Be sure there are no leaks at the water connections which might cause

the insulation to become wet.

IMPORTANT NOTE: To reduce the risk of excessive temperatures and pressures

in this water heater, a pressure/temperature relief valve has been installed by the

manufacturer and should not be removed. This valve should be provided with a

3

/4" drain line oriented so that any discharge from the valve will exit within 6"

above or at any distance below the structural floor and cannot contact any live

electrical part. The discharge opening must not be blocked or reduced in size

under any circumstances. Any additional protective equipment required by

local codes must also be installed. In the event that the pressure/temperature

relief valve is damaged or otherwise needs replacement, a combination

temperature and pressure relief valve, certified by a nationally recognized

testing laboratory that maintains periodic inspection of production of listed

equipment, as meeting the requirements for Relief Valves and Automatic Gas

Shut-Off Devices for Hot Water Supply Systems, ANSIZ 2 1.22-1971, should be

installed. The valve must be marked with a maximum set pressure of 150 psig

for use on all PAC Fre-Heaters.

!

14

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

If a water mixing valve is installed in the system, make sure that check valves are in both

hot and cold water lines. If this precaution is not taken, hot water may be drawn into the

cold water system under certain system operating conditions.

In many multi-unit installations, it is advantageous to install a circulating pump and form

a loop plumbing circuit through the Fre-Heaters. This will usually increase the heat

recovery efficiency of the system by keeping the total system water volume at a uniform

temperature and picking up the most available heat from any refrigeration units which may

be running. Consult a plumbing supply house for a hot water circulating pump suitable for

your particular installation. All pumps used in a Fre-Heater water circulation system must

be suitable for potable water use. . Multiple Fre-Heater installations may be piped in parallel if

care is taken to assure equal flow through all of the Fre-Heaters. Parallel plumbing is usually

reserved for installations having a common refrigeration compressor on all of the FreHeaters. Refer to in the Figure.

Under certain circumstances, it may be necessary to operate a high temperature or

booster heater loop at temperatures above those attainable or desirable in the Fre-Heater. At

those times a piping scheme should be used. This allows the Fre-Heater to operate at its

optimum heat reclaim while the system temperature is at a higher level.

Figure 14 : Installing Water Piping

15

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Figure 15 : Installing PAC Fre-Heater (through one circuit into another)

Figure 16 : Installing PAC Fre-Heater in parallel series

16

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Refrigeration Connections

Mueller Fre-Heaters are shipped with a dry nitrogen holding charge that

must be removed from the Fre-Heater piping before installation of

refrigerant piping.

Good refrigeration practices must be used while installing the Fre-Heater.

These practices are of common knowledge to the experienced refrigeration

serviceman, and only a certified, experienced refrigeration serviceman should

undertake the refrigeration connection portion of a Fre-Heater installation.

Inlet and outlet stubs are copper tube for Freon applications and stainless

steel male pipe thread for ammonia applications. The sizes of refrigeration

connections for various PAC Fre-Heaters are shown in Table 1.

On runs 8 metres or less, refrigeration lines to and from the Fre-Heater

should be the same size as the compressor discharge line.

Avoid long runs whenever possible. However, if necessary to have runs of

more than 8 metres, the lines should be upsized by one tube size. Should

there be any question about refrigeration line sizing, the equipment

manufacturer’s recommendation should be followed.

In most instances, refrigeration line runs of over 16 metres should not be

used. If they are, particular care must be taken to avoid oil traps and excessive

pressure drop in the lines.

The refrigeration lines going to and from PAC Fre-Heaters could reach

temperatures of 150°C. The refrigeration lines must be insulated to prevent a

burn hazard for personal injury or combustible substances. The insulation will

also add to the efficient operation of the Fre-Heater.

If in making tubing connections, it is necessary to cut openings into the

air-conditioning or refrigeration cabinet, the following must be observed

and provided for. Particular care must be taken if the equipment is located

outdoors.

ท

Integrity and rain tightness of the cabinet must be maintained.

ท Do not cut into a control box or enclosure containing live

mechanical parts or electrical wiring. Make openings below any

enclosures containing live mechanical parts or electrical wiring.

ท Tubing must be protected against mechanical damage by the

cabinet. The use of protective bushings is recommended.

ท Tubing connections must be made by means of high-

temperature soldering or brazing.

17

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

ท Tubing must be routed such that no possibility of contacting

moving parts occurs.

ท Provide protection for tubing if the likelihood of accidental

damage occurring exists.

ท Always use a gear-type tubing bender when making bends

tubes. A conduit bender will flatten the tubing and restrict

the flow of refrigerant.

ท When installing tubing through walls or along a structural

member, be sure the tubing is isolated from these members

to avoid any transmissions or vibrations that might occur.

Table 1 for the per circuit condensing unit capacity range of the various

PAC Fre-Heater units. To assure proper condensing unit operation, stay

within the capacity range specified.

A refrigeration unit exceeding the single circuit capacity of a specific PAC

Fre-Heater may be connected to two or more Fre-Heater circuits on one

or more F re -H ea te rs ha vi ng a combined circuit capacity equal to the

refrigeration unit

When making multiple Fre-Heater circuit connections to a single

refrigeration unit, the piping to the Fre-Heater circuits should be in parallel.

Series (through one circuit into another) piping of the Fre-Heater should not

be used.

A refrigerant line discharge muffler is not necessary for proper operation

or warranty coverage in a Fre-Heater installation. However, if the Fre-Heater

is to be installed in an area where any machine noise would be

objectionable, a discharge muffler should be considered as a method of

eliminating the normal compressor pulsation noise present in all

refrigeration systems.

Typical refrigeration unit piping is shown in Figures

If there is a hot gas defrost valve, an oil separator, and/or a discharge

muffler in the compressor discharge line, the Fre-Heater must be installed

downstream of it/them. See Figure for an illustration of this.

In the event of extended compressor operation with little or no water

usage, it is possible to generate water temperatures which exceed the

100°C setting of the pressure-temperature relief valve. This will result in

repeated dumping of hot water through the relief valve.

18

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

To avoid the repeated release of hot water by the pressure/temperature

relief valve, should be installed. Installation and operation instructions

for the above bypass system are included with these instructions for your

reference and the port size is large enough to allow unrestricted refrigerant

flow.

For maximum refrigeration unit efficiency and Fre-Heater heat

recovery, head pressure controls must be used.

On air-cooled refrigeration units, you must install head-pressureoperated fan controls; and on water-cooled refrigeration units, you must

install a head-pressure-operated water valve, if they are not already on the

refrigeration units. On many low temperature applications, an auxiliary

cooling fan must be installed on the compressor if the condenser fan is

cycled to maintain head pressure. Consult the compressor manufacturer for

their recommendation if you are in doubt of sufficient air flow for compressor

cooling.

Refrigerant Charge

It may be necessary to add additional charge in some refrigeration

systems. Check the sight glass and, if necessary, add refrigerant to clear

the sight glass. Final charging of the system must be done after the water

in the Fre-Heater becomes warm.

Test Run

Turn on the water supply and fill the Model PAC Fre-Heater with

water. Ensure that all water and refrigeration connections are leakfree. The unit is then ready for use. Refrigerant charge should be

checked after the system has achieved normal operating conditions.

Be sure to check for proper operation of any and all controls, valves,

etc., installed with or changed during the installation of the FreHeater, both in the refrigeration and water systems.

19

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Figure 17 : Installing Refrigerant Charge with Air-Condition

Fig ure 18 : Typical Refrigeration Connections for Single

Refrigeration Unit and Single-Circuit Piping

20

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Figure 18 : Typical Dual Refrigeration Unit Piping

21

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Figure 19 : Fre-Heater Location with Hot Gas Defrost Valve, Oil

Separator, and/or Discharge Muffler in System

22

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Figure 20 : Installing Refrigerant Charge by Heat-Exchanger

23

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Maintenance

In order to achieve the maximum life from your PAC Fre-Heaters the following

should be done annually:

1. Remove and check at least one of the two anode rods. Both anode

rods should be replaced

2. Check the operation of the pressure/temperature relief valve by

manually operating it to see that it will freely flow water should it be

required to do so. If there is any doubt that it will not function

properly, replace it.

3. Check all water fittings, valves, etc. to be sure there are no water

leaks. Repair as necessary.

4. Check the operation of all controls such as the hot gas bypass valve

aquastat, electric element controls, refrigeration head pressure

controls, or any other controls necessary for the proper operation of

the Fre-Heater and the refrigeration and/or air conditioning systems it

is connected to.

24

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Efficiency

Figure 21 :

Result of Electric Power of Compressor with out PAC

25

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Figure 22 : Result of Electric Power of Air-condition and Temperature of

Refrigerant by PAC setting have water in but not flow out

Figure 23 : Result of Electric Power of Air-condition and Temperature of

Refrigerant by PAC setting and water flow out

26

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

Figure 24 : Temperature of water flow out from the Mueller

27

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

APPENDIX

THE COLUMN TOWER

28

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

THE COLUMN TOWER

- If you would like to open an effluent from PAC, you

should turn off the water in and out, then turn on the

effluent drain from the tank.

- If the temperature in PAC are between 35-36

Celsius, then there are some water flow out from

Pressure Relief Valve. You should adapt to Pressure

Relief Valve for flow out the water that higher

temperature.

- If the temperature in PAC is more than 80 Celsius

but there are not the effluent flow out from Pressure

Relief Valve, you should unscrew for release water

in the temperature that you want.

- If the Pressure Relief Valve can not set for that

period so should change a new Pressure Relief

Valve.

29

INSTALLATION AND OPERATION MANUAL

PAC HEAT RECOVERY WATER HEATER

30

Loading...

Loading...