P1PE P72800A, P73200A, PGP200PWA, P73200T, PGX200PWT User Manual

PETROL PRESSURE WASHER

Models P72800A, P73200A, P73200T, PGP200PWA

& PGX200PWT

User Manual

Page 2

First edition - April 2017

Page 3

First edition - April 2017

CONTENTS

4 - 6

7 - 12

13 - 14

15

16 - 18

19 - 24

25

26

27

28

29

29

29

1. SAFETY

2. QUICK START

3. STARTING PROCEDURE

4. STOPPING - SHUTDOWN PROCEDURE

5. USING THE MACHINE

6. MAINTENANCE

7. TROUBLESHOOTING

8. SPECIFICATION

9. PART LOCATIONS

10. DECLARATIONS OF CONFORMITY

11. RECYCLING & PRODUCT DISPOSAL

12. CONTACT DETAILS

13. MANUAL UPDATES

14. WARRANTY 29

1. SAFETY

1.1. General safety notes.

1.1.1. The operator of the machine is

responsible for, and has a duty of care in

making sure that the machine is operated

safely and in accordance with the instructions

in this user manual. Keep the manual safe and

pass it on if the machine is loaned or sold to

another user.

1.1.2. Please note the following safety

points.

1.1.2.1. The machine should never be left it in

a condition which would allow an untrained or

unauthorised person/s to operate this

machine.

1.1.2.1.1. All due care and diligence

should be taken by the operator for the safety

of, and with regard to those around whilst

using the machine.

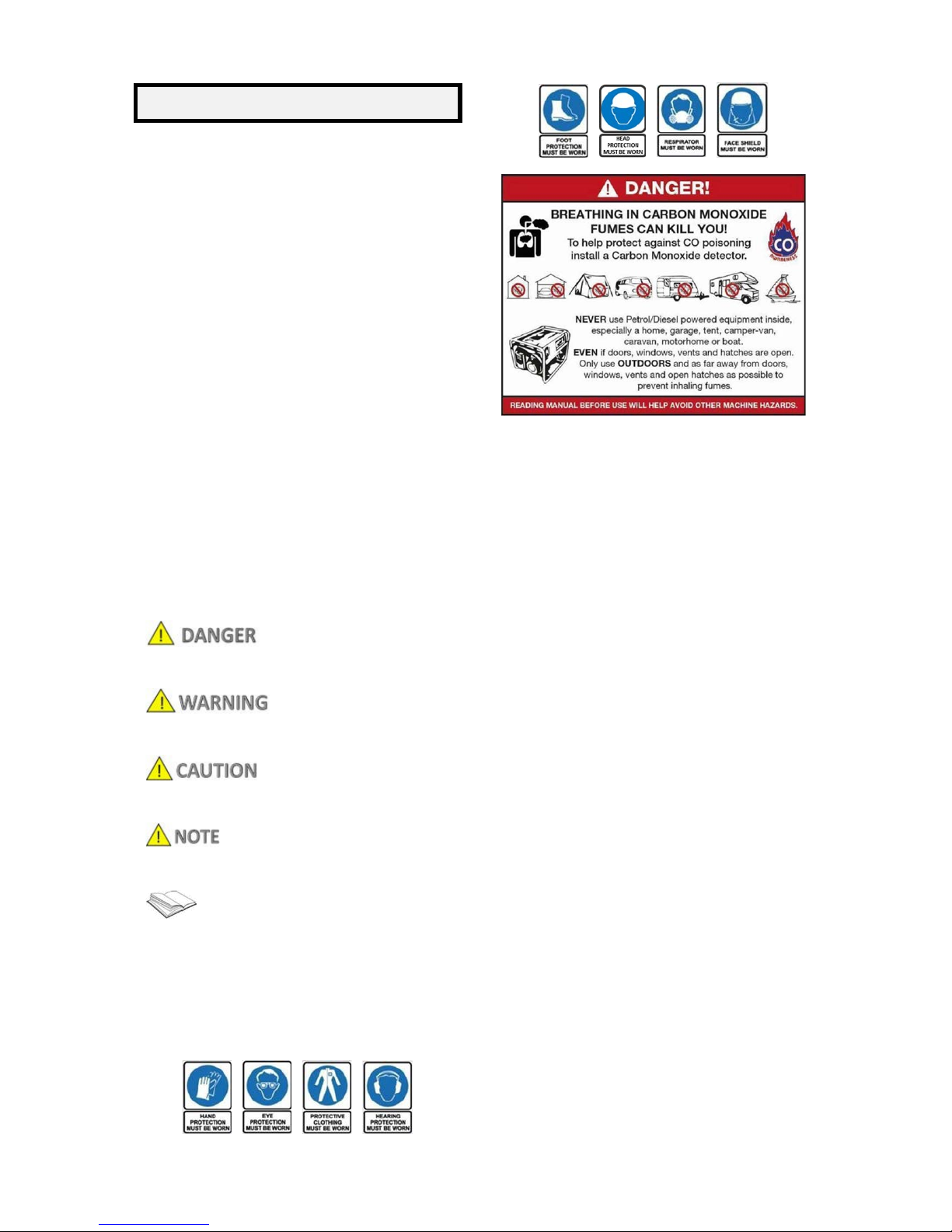

1.1.2.1.2. Some or all of the following warning signs, symbols and/or PPE pictograms

may appear throughout this manual. You

MUST adhere to their warning/s. Failure to do

so may result in personal injury to yourself or

those around you.

Ind

icates a hazard, which, if not avoided, could

result in serious injury or death.

Indicates a hazard, which, if not avoided, could

result in serious injury.

Ind

icates a hazard which, if not avoided, might

result in minor or moderate injury.

Ind

icates a situation that could easily result in

equipment damage.

READ a

nd keep the manual safe and pass it on

if the machine is loaned or sold to another

user. You MUST fully read instructions to make

sure you use and operate machine safely.

Appropriate Personal Protective Equipment

(PPE), MUST be worn at all times when

Machine is in use or being repaired.

1.2. Carbon monoxide (where applicable).

1.2.1. Carbon monoxide is a colourless and

odourless gas. Inhaling this gas can cause

death as well as serious long term health

problems such as brain damage.

1.2.2. The symptoms of carbon monoxide

poisoning can include but are not limited to

the following; Headaches, dizziness, nausea,

breathlessness, collapsing or loss of

consciousness.

1.2.2.1. Carbon monoxide poisoning

symptoms are similar to flu, food poisoning,

viral infections and simply tiredness. It is quite

common for people to mistake this very

dangerous poisoning for something else.

1.2.2.2. To avoid carbon monoxide poisoning

DO NOT use Petrol/Diesel- powered

equipment inside any of the following; Home,

garage, tent, camper van, mobile home,

caravan or boat.

This list is not exhaustive and if you are in any

doubt contact your dealer.

1.2.3. If you think you have or someone

around you has been affected by carbon

monoxide poisoning;

1.2.3.1. Get them fresh air immediately, by

leaving the affected area or by opening doors

and windows. If safe and practical to do so

make sure that the machine is turned off. DO

NOT enter a room you suspect of having

carbon monoxide present – instead call the

emergency services.

1.2.3.2. Contact a doctor immediately or go to

hospital - let them know that you suspect

carbon monoxide poisoning.

Page 4

First edition - April 2017

1.2.4 DO NOT use in an enclosed area or a

moving vehicle.

1.3. General fuel safety.

ALL FUELS ARE FLAMMABLE

1.3.1. Fire hazard - keep fuel away from all

sources of ignition for example heaters, lamps,

sparks from grinding or welding.

1.3.2. D

O NOT carry out hot work on tanks

that have contained fuel it is extremely

dangerous.

1.3.3. ALWAYS keep work area clean and

tidy.

1.3.4. ALWAYS clean up all spills promptly

using correct methods i.e. absorbent granules

and a lidded bin.

1.3.5. ALWAYS dispose of waste fuels

correctly.

1.4. Fueling/De-fueling.

ALL F

UELS ARE FLAMMABLE

1.4.1. ALWAYS fuel and defuel in a wellventilated area outside of buildings.

1.4.2. ALWAYS wear correct, suitable and fit

for purpose Personal Protective Equipment

(PPE), suggested items are but not limited to

safety gloves and overalls.

1.4.3. W

hen fueling/de-fueling ALWAYS

avoid inhaling fumes

1.4.4. When de-fueling ALWAYS use a

propriety fuel retriever.

1.4.5. ALWAYS carry fuel in the correct and

clearly marked container.

1.5. El

ectrical safety.

1.5.1. E

lectricity can kill - NEVER use

pressure washer jet to come into contact with

LIVE or ENERGISED equipment. It can also

cause severe burns.

1.5.2. NEVER work on or near electricity with

wet hands, wet clothing, and wet gloves.

1.6. Vibrations.

1.6.1. Prolonged use of hand held (operated)

machines will cause the user to feel the effects

of/from vibrations. These vibrations can lead

to white finger (Raynaud's phenomenon) or

carpal tunnel syndrome. This condition

reduces the ability of the hand to feel and

regulate temperature, causing numbness and

heat sensations and may cause nerve damage

and circulatory tissue death.

1.6.2. Not all factors that lead to white finger

disease are known, but cold weather, smoking

and other diseases that affect blood vessels

and blood circulation as well as large and longlasting impact of shocks are considered factors

in the formation of white finger. Note the

following to reduce the risk the white finger

and carpal tunnel syndrome:

1.6.2.1. Wear gloves and keep your hands

warm

1.6.2.2. Take regular breaks

1.6.3. All of the above precautions may help

reduce the risk of white finger disease but not

rule out carpal tunnel syndrome. Long-term

and regular users are therefore recommended

to observe the condition of your hands and

fingers. Seek medical attention immediately if

any of the above symptoms should occur.

1.8. Noise.

1.8.1. The operating noise of the machine

can damage your hearing. Wear hearing

protection such as earplugs or ear defenders

to protect your hearing. Long- term and

regular users are advised to have hearing

checked regularly. Be especially vigilant and

cautious when wearing hearing protection

because your ability to hear alarm warnings

will be reduced.

1.8.2. Noise emissions for this equipment is

unavoidable. Carry out noisy work at approved

times and for certain periods. Limit the

working time to a minimum. For your personal

protection and protection of people working

nearby it is also advisable for them to wear

hearing protection.

Page 5

First edition - April 2017

1.8.3. See CERTIFICATE of CONFORMITY

section for Outdoor Noise declaration of

conformity.

1.9. Ma

chine specific safety.

1.9.1. N

EVER direct the outlet of the

pressure washer jet towards anyone, which

includes adults, children, all pets and livestock

or other objects that can be damaged.

1.9.2. You MUST know how to STOP the

machine quickly. You MUST also know how to

safely bleed the built up pressure.

1.9.3. To reduce the risk of injury, close

supervision is necessary when a product is

used near children.

1.9.4. You MUST be thoroughly familiar with

the controls.

1.9.5. Stay alert – watch what you are doing.

1.9.6. DO NOT operate the product when

fatigued or under the influence of alcohol or

drugs.

1.9.7. Keep operating area clear of all

persons not involved in the pressure washing

process.

1.9.8. DO NOT overreach or stand on

unstable support. You MUST maintain good

footing and balance at all times. Be careful

that you do not slip on any water residue. You

MUST keep working surface free of excess

water

1.9.9. Follow the maintenance instructions

specified in the manual.

1.9.10. DO NOT leave the pump running for

longer than 1 minute without using the pump

will overheat. Damaged caused in this way will

invalidate any warranty.

1.9.11. DO NOT let the unit freeze. You MUST

always empty the machine of all water after

use and before storage – this is especially

important in very cold weather or at times

when the weather gets down to freezing

temperatures.

1.9.12. Only operate the machine outdoors.

1.9.13. NEVER use the pressure washer to

spray dangerous liquids such as petrol, acids

etc.

1.9.14. The exhaust will be HOT during and

shortly after use – You MUST keep all body

parts and flammable materials clear of the

exhaust at all times.

1.9.15. NEVER under any circumstance

attempt to repair the high pressure hose. You

MUST instead replace any damaged hose or

other high pressure components.

1.9.16. Under NO circumstances should you

modify or alter the Pressure Washer in any

way. Modifications can create serious safety

hazards and will also void the warranty.

Page 6

First edition - April 2017

2. QUICK START

2.1. This guide is meant to serve as a quick reference for operating your Pressure washer it is for

convenience and the user should read the safety section first.

FOR OUTDOOR USE ONLY.

This Pressure washer produces carbon monoxide - a poisonous, colourless & odourless gas that can

cause death or serious injury. Petrol is highly flammable, always handle with extreme care and in a

well ventilated area.

Always remove HT lead from spark plug when checking machine or changing parts.

2.2. This product comes partially assembled and carefully packaged and should include, 2 x rubber

feet, 2 x Fixed wheels, 2 x Axles, 2 x Large flange nuts, 1 x Spanner set, 1 x Bracket, 4 x Flange bolts, 4

x Small flange nuts, 1 x Spray gun, 1 x Lance c/w 5 nozzles, 4 x Large washers, 1 x High pressure hose,

User manual, Warranty registration form.

2.3. At this

point, check that you have all of the included items listed above. If any are missing or

damaged, call 01646 687 880 or email service@genpower.co.uk.

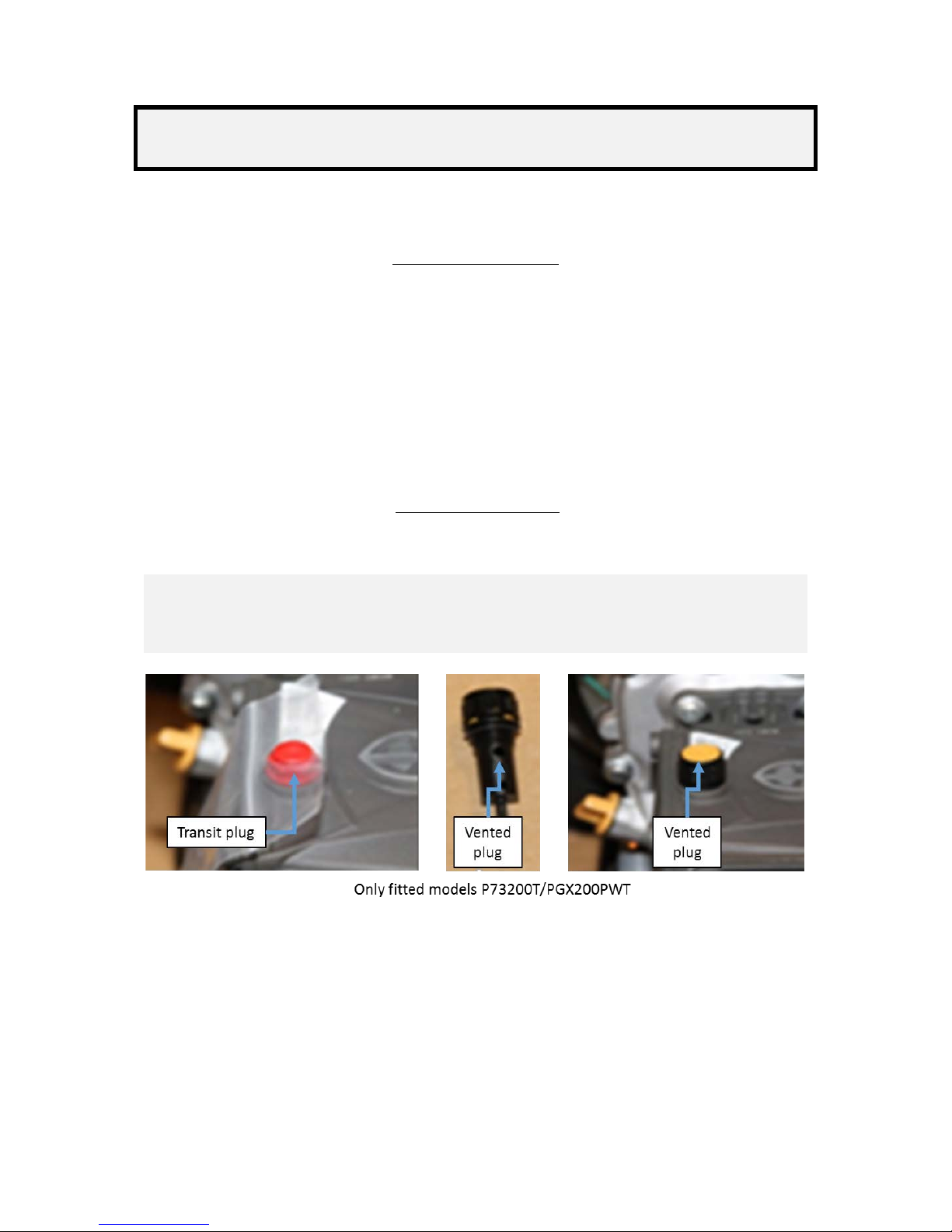

2.4. Shipping plug.

Important, do not run the pump with the red transit plug installed, this will void

your warranty!

Remove the red shipping plug (fitted on pump) and install the vented operating plug.

Using a 11/16 inch/18mm spanner carefully remove the red shipping plug from the pump as shown.

Remove the vented plug from the bag attached to the red shipping plug. Install the vented plug as

shown. Install by hand and secure finger tight.

Page 7

First edition - April 2017

2.5. Rubber feet assembly.

Using the bolts supplied attach the brackets with the rubber feet on to the frame. Insert the bolts from

the outside of the unit towards the inside and secure the bolts with the cap nuts provided using 10mm

wrenches. Do not over-tighten. A second person should steady the frame for this step. Repeat the

process for both feet.

2.6. Axle and wheel assembly.

Place large diameter washer on to the axle shaft and insert the axle into the wheel/tyre assembly as

shown, you may have to use a rubber mallet to tap the axle through the wheel opening.

Slide the axle wheel assembly onto the frame assembly and place a washer onto the axle and

secure with a supplied nut. Tighten using suitable spanner and socket. Tighten securely but DO NOT

overtighten. A second person should steady the frame for this step.

Page 8

First edition - April 2017

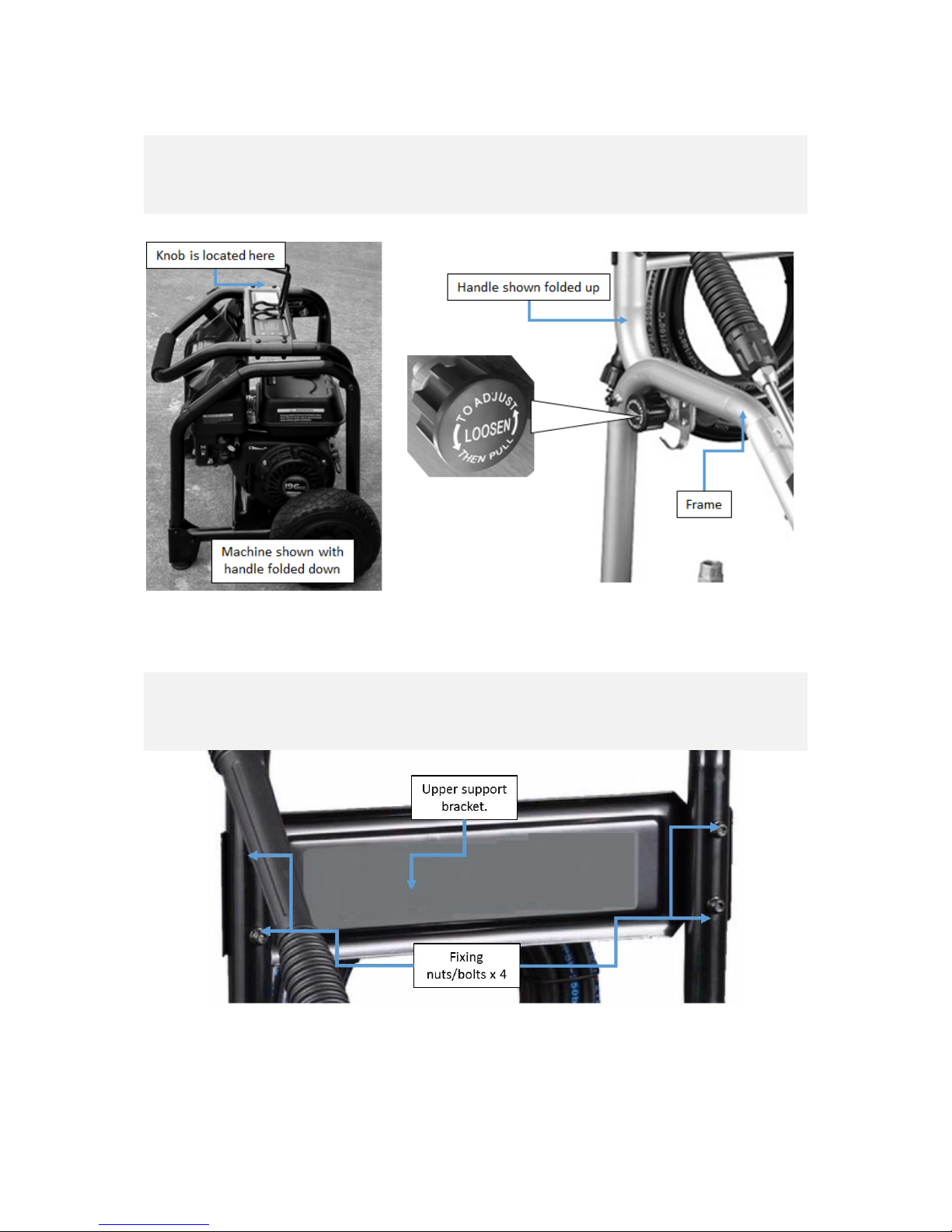

2.7. Handle assembly.

The handle assembly is folded down for transportation, pull handle upwards and lock into position using

the knob on the right hand side of the machine as viewed from the rear of machine. To undo knob pull

outwards, raise the handle and release knob so that it locates the hole in frame.

2.8. Upper support assembly.

Using the 4 bolts provided, insert the bolts through the front of the frame handle support. Next hold

the Upper support against the back of the frame handle support and secure the bolts using a large

Phillips head screwdriver into the Upper Support. Be careful to make sure the bolt does not cross-

thread into the upper support. Do not over-tighten.

Page 9

First edition - April 2017

2.9. Wand/Gun – trigger assembly.

Attach the wand into the handle as shown below. Start off gently so that you do not cross thread the

attachments. Screw into place in a clockwise direction. Tighten using a suitable spanner but DO NOT

over tighten.

Attach the high pressure hose to gun/trigger as shown below. Start off gently so that you do not cross

thread the attachments. Screw into place in a clockwise direction. Tighten by hand, DO NOT over

tighten.

Attach the high pressure hose to the pump as shown below. Start off gently so that you do not cross

thread the attachments. Screw into place in a clockwise direction. Tighten by hand, DO NOT over

tighten.

Page 10

First edition - April 2017

Loading...

Loading...