P1PE P5200BC User Manual

1

FOR YOUR SAFETY

You must read and understand

this manual before use.

Keep this manual for future reference.

2

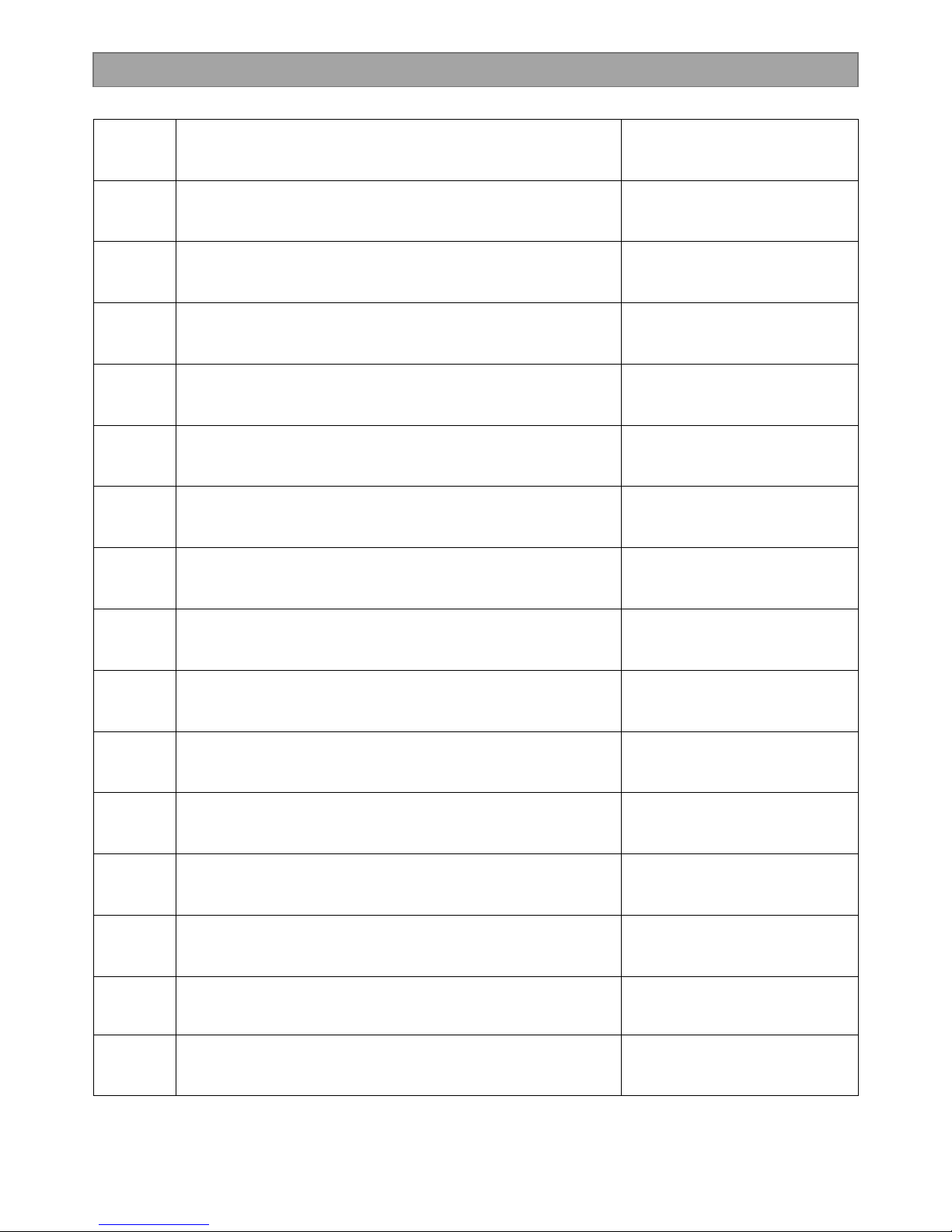

CONTENTS

PAGE NO.S

1

SAFETY 3 - 7

2

MACHINE SPECIFIC SAFETY

7 - 8

3

PART LOCATIONS

9

4

MACHINE ASSEMBLY

10 - 11

5

STARTING PROCEDURE

12 - 16

6

STOPPING PROCEDURE

16

7

OPERATING INSTRUCTIONS

17 - 19

8

MAINTENANCE

20 - 26

9

TROUBLESHOOTING

27

10

TRANSPORTING

28

11

DECLARATION OF CONFORMITY

28

12

RECYCLING & PRODUCT DISPOSAL

29

13

MANUAL UPDATES

30

14

WARRANTY 30

15

CONTACT DETAILS

30

INDEX

3

1. SAFETY

1.1

General Safety Notes.

1.2

The operator of the machine is responsible for, and has a duty of care in making sure

that the machine is operated safely and in accordance with the instructions in this

user manual. Keep the manual safe and pass it on if the machine is loaned or sold to

another user.

1.3

Please note the following safety points.

1.4

The machine should never be left it in a condition which would allow an untrained or

unauthorised person/s to operate this machine.

1.5

All due care and diligence should be taken by the operator for the safety of and with

regard to those around whilst using the machine.

1.6

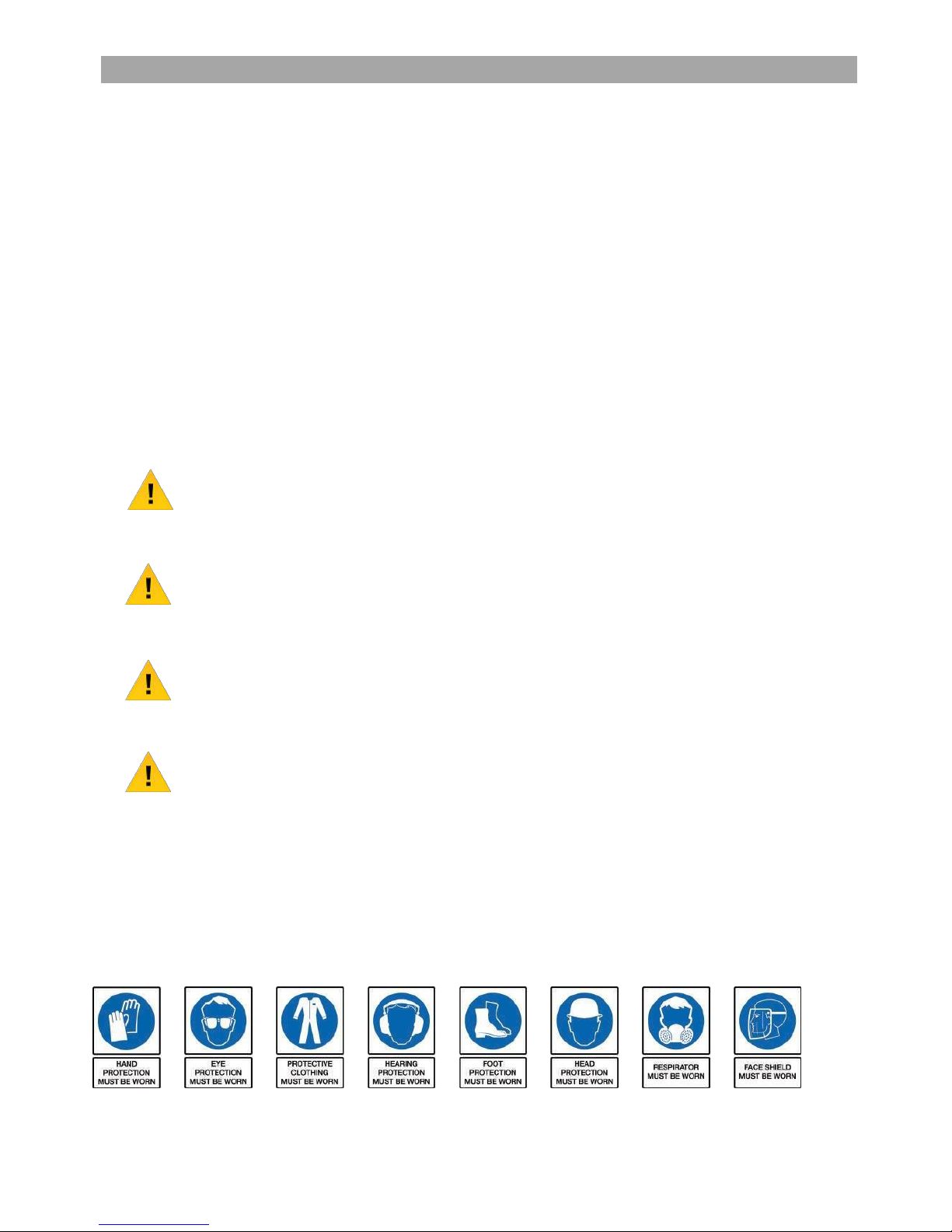

Some or all of the following - warning signs, symbols and/or PPE pictograms may

appear throughout this manual. You MUST adhere to their warnings. Failure to do

so may result in personal injury to yourself or those around you.

DANGER

Indicates a hazard, which, if not avoided, could result in serious injury or death.

WARNING

Indicates a hazard, which, if not avoided, could result in serious injury.

CAUTION

Indicates a hazard which, if not avoided, might result in minor or moderate injury.

NOTE

Indicates a situation that could easily result in equipment damage.

READ and keep the manual safe and pass it on if the machine is loaned or sold to another user.

You MUST fully understand all instructions to ensure you use and operate the machine safely.

Appropriate Personal Protective Equipment (PPE), MUST be worn at all times when operating or

repairing the machine.

4

1.10

Carbon Monoxide (where applicable).

1.11

Carbon monoxide is a colourless and odourless gas. Inhaling this gas can cause

death as well as serious long term health problems such as brain damage.

1.12

The symptoms of carbon monoxide poisoning can include but are not limited to the

following;

Headaches, dizziness, nausea, breathlessness, collapsing or loss of consciousness.

1.13

Carbon monoxide poisoning symptoms are similar to flue, food poisoning, viral

infections and simply tiredness. It is quite common for people to mistake this very

dangerous poisoning for something else.

1.14

To avoid carbon monoxide poisoning DO NOT use Petrol/Diesel powered equipment

inside any of the following; Home, garage, tent, camper van, mobile home, caravan

or boat. This is not exhaustive and if you are in any doubt contact your dealer.

1.15

If you think you have or someone around you has been affected by carbon monoxide

poisoning;

1.16

Get them fresh air immediately, by leaving the affected area or by opening doors and

windows. If safe and practical to do so make sure that the machine is turned off.

DO NOT enter a room you suspect of having carbon monoxide present – instead call

the emergency services.

1.17

Contact a Doctor immediately or go to Hospital – let them know that you suspect

carbon monoxide poisoning.

1.18

DO NOT use in an enclosed area or moving vehicle.

1.20

General Fuel Safety (where applicable).

CAUTION

ALL FUELS ARE FLAMABLE

1.21

Fire Hazard – keep fuel away from all sources of ignition for example heaters.

Lamps, sparks from grinding or welding.

1.22

DO NOT carry out hot work on tanks that have contained fuel.

1.23

ALWAYS keep the work area tidy.

5

1.24

ALWAYS clean up spills promptly using absorbent granules and a lidded bin.

1.25

ALWAYS dispose of waste fuels correctly.

1.30

Fueling/De-fueling (where applicable).

CAUTION

ALL FUELS ARE FLAMABLE

1.31

ALWAYS fuel and defuel in a well ventilated area outside of buildings.

1.32

ALWAYS wear correct, suitable and fit for purpose Personal Protective Equipment

(PPE), suggested items are but not limited to safety gloves, overalls.

1.33

When fueling/de-fueling ALWAYS avoid inhaling fumes.

1.34

When de-fueling ALWAYS use a proper fuel retriever.

1.35

ALWAYS carry fuel in the correct and clearly marked container.

1.40

Electrical Safety )where applicable).

1.41

Electricity can kill – NEVER work on LIVE/ENERGISED equipment.

1.42

Prior to carrying out any maintenance work you MUST identify electrical isolation

methods and isolate all electrical supplies.

1.43

Prior to use and with all electrical supplies isolated, you MUST check all electrical

cables, plugs and connectors for the following;

1.44

Are intact and have no signs of damage, to include but not limited to bare wires,

chaffing, cuts and loose wiring.

1.45

If there are any signs of damage, the damage item MUST be taken out of service

until the damage has been repaired by an electrically competent person.

1.46

All trailing cables should be routed so as not to cause any kind of trip hazard.

1.47

NEVER work on or near electricity with wet hands, wet clothing and wet gloves.

6

1.50

Batteries (where present).

1.51

Batteries present a risk if they become damaged by the possible leaking of

electrolyte. This electrolyte is an acid and can cause serious burn injuries. Care

should be taken when working on or near them. NOTE the electrolyte may be in

a liquid or gel form.

1.52

Should you come in to contact with electrolyte you should;

1.53

Remove all clothing contaminated with electrolyte. If you cannot remove then

saturate them in water.

1.54

Get medical assistance as soon as possible. You must advise the medical staff of

the type of acid.

1.55

Lead/acid battery = dilute sulphuric acid.

1.56

Nickel/cadmium = potassium hydroxide alkali electrolyte.

1.57

Use fresh running water to wash off excess electrolyte, continue this until medical

assistance arrives. Make sure that you do not was the electrolyte to another part of

your body or face.

1.58

If electrolyte comes in to contact with Eyes the electrolyte needs to be immediately

washed away with large amounts of water. Make sure that you do not wash the

electrolyte to another part of your face or body.

1.59

Gasses from charging batteries are highly flammable and great care should be taken

to charge in well ventilated areas.

1.59.1 There is an explosion risk if the battery terminals are short circuited, when

connecting/disconnecting ALWAYS exercise great care so that the terminals or

battery leads are NOT allowed to touch and cause a spark. ALWAYS use suitable

insulated tools.

1.60

Vibrations (where applicable).

1.61

Prolonged use of hand held (operated) machines will cause the user to feel the

effects of/from vibrations. These vibrations can lead to white finger (Raynaud’s

phenomenon) or carpal tunnel syndrome. This condition reduces the ability of the

hand to feel and regulate temperature, causing numbness and heat sensations and

may cause never damage and circulatory tissue death.

1.62

Not all factors that lead to white finger disease are known, but cold weather, smoking

and other diseases that affect blood vessels and blood circulation as well as large

and long-lasting impact of shocks are considered factors in the formation of white

finger. Note the following to reduce the risk of white finger and carpal tunnel

syndrome;

1.63

Wear gloves and keep your hands warm.

1.64

Take regular breaks.

1.65

All of the above precautions may help reduce the risk of white finger disease but not

rule out the carpal tunnel syndrome. Long-term and regular users are therefore

recommended to observe the condition of your hands and fingers. Seek medical

attention immediately if any of the above symptoms should occur.

1.70

Noise (where applicable).

7

1.71

The operating noise of the machine can damage your hearing. Wear hearing

protection such as earplugs or ear defenders to protect your hearing. Long-term

and regular users are advised to have hearing checked regularly. Be especially

vigilant and cautious when hearing ear protection because your ability to hear alarm

warnings will be reduced.

1.72

Noise emissions for this equipment is unavoidable. Carry out noisy work at approved

times and for certain periods. Limit the working time to a minimum. For your personal

protection and protection of people working nearby it is also advisable for them to

wear hearing protection.

1.73

See CERTIFICATE of CONFORMITY section for Outdoor Noise declaration of

conformity.

2. MACHINE SPECIFIC SAFETY

WARNING

DO NOT modify the unit in any way.

Only use the tool for the job for which it is intended.

ALWAYS remove the HT lead from the spark plug when checking the machine or

changing parts.

2.0

Inspect the tool before each use.

2.1

Replace any damaged parts before operation.

2.2

Check for fuel leaks and make sure all fasteners are secure and in place.

2.3

Make sure the safety guard is properly attached.

2.4

Use only recommended accessories and parts approved by the manufacturer.

Non approved attachments may cause damage to the machine or harm to the user

and will also void the machines warranty.

2.5

Under no circumstances should you ever take the product apart or alter it any way

even if the item if faulty.

You may damage or cause further harm by taking the products apart and you will

void the warranty in doing so.

2.6

This unit is designed to cut fresh brush with a thickness smaller than 10mm.

DO NOT attempt to cut brush with a thickness greater than 10mm.

2.7

Blunt blades increase the risk of kickback, so check the blade carefully

before each use.

ALWAYS replace a blunt blade.

2.8

This brush cutter is designed exclusively for cutting garden areas in private domestic

settings. Using it for any purpose other than those intended qualify as improper

use.

The operator is solely responsible for assuming all risks.

2.9

DO NOT overload the machine.

8

CAUTION

Blade thrust can cause serious personal injury.

Carefully study this section.

It is important that you understand what causes blade thrust, how you can reduce

the chance of blade thrust and how you can remain in control of the unit if blade

thrust does occur.

2.10

Blade thrust can occur when the moving blade comes in to contact with an object it

cannot cut.

This contact causes the blade to stop for an instant then suddenly move or ‘bounce’

away from the object that it hit.

The operator can lose control of the unit and the blade can cause serious personal

injury to the operator or any person nearby if the blade contacts any part of the body.

2.11

By understanding and knowing about blade bounce, you can help eliminate the

element of surprise.

2.12

Cut fibrous weeds and grass ONLY.

2.13

DO NOT let the blade contact materials it cannot cut, such as hard wood, vines,

fences, metal, rocks etc.

2.14

Be extra prepared for bounce if you cut where you cannot see the blade

making contact, such as in areas of dense growth.

2.15

Keep the blade sharp.

A dull blade increases the chance of bounce.

2.16

Avoid feeding the blade into grass too rapidly.

The blade can bounce away from material being cut if the blade is fed in faster than

it’s cutting capacity.

2.17

Cut only from your right to left.

2.18

Keep the path of advance clear of material that has been cut and other debris.

2.19

Keep a good firm grip on the unit with both hands.

A firm grip can neutralize bounce.

2.20

Keep both feet spread apart in a comfortable stance and yet braced for the

possibility that the unit could bounce.

2.21

DO NOT overreach. Keep a firm footing and balance.

9

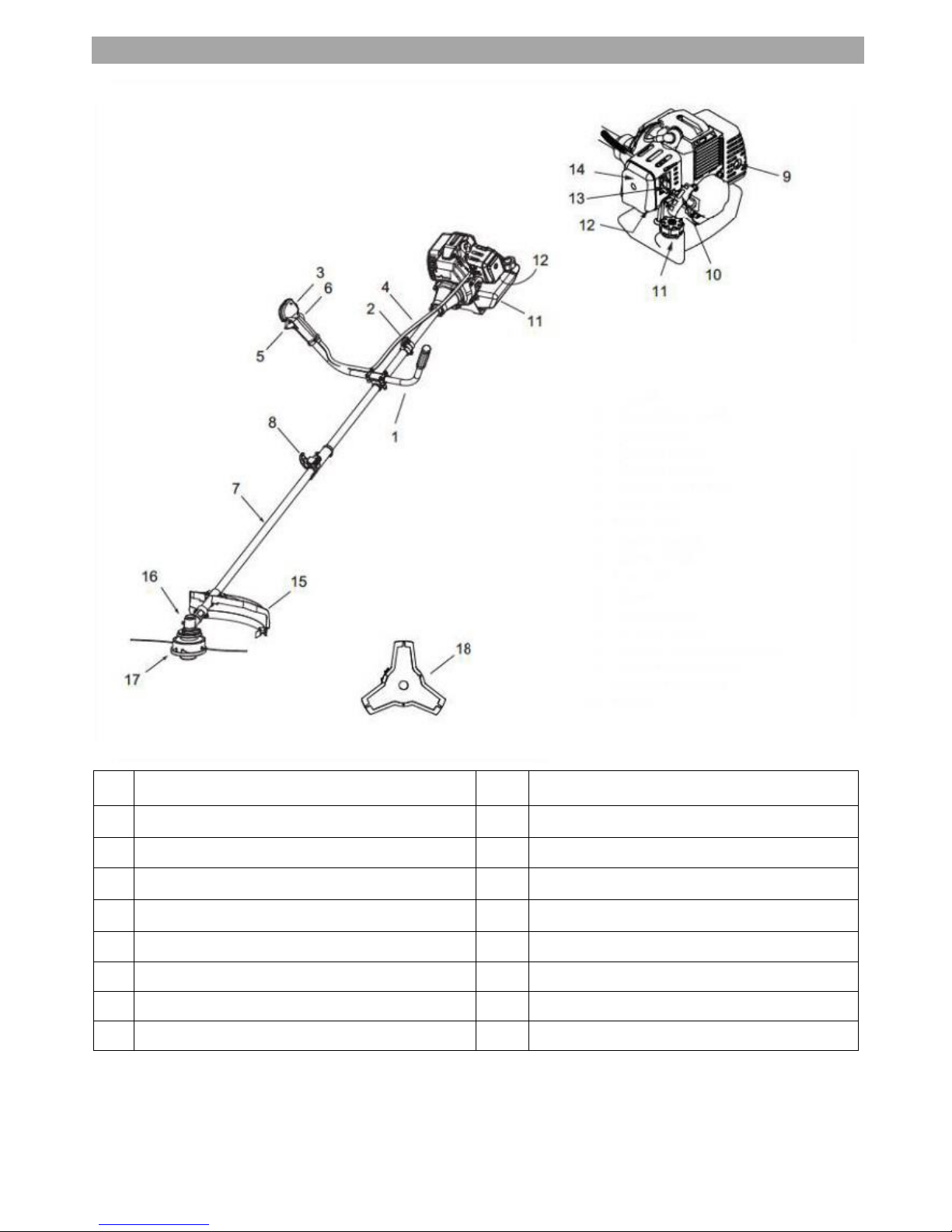

3. PART LOCATIONS

1

Handle

10

Recoil Starter Handle

2

Suspension Point

11

Fuel Tank

3

Start / Stop Switch

12

Primer Bulb

4

Throttle Cable

13

Choke Lever

5

Throttle Trigger

14

Air Filter Cover

6

Throttle Set Button

15 Cutting Attachment Guard

7

Main Shaft

16

Gearbox

8

Shaft Bolt

17

Trimming Head

9

Exhaust / Muffler

18

Brush Cutter Blade

10

4. MACHINE ASSEMBLY

3.0

Loosen the 4 bolts on the upper clamp and insert the handle. Retighten the bolts.

3.1

Put the throttle assembly onto the handle and tighten the nut and bolt securely.

3.2

Place the cutting attachment guard on the gearbox and attach it with the hardware

provided.

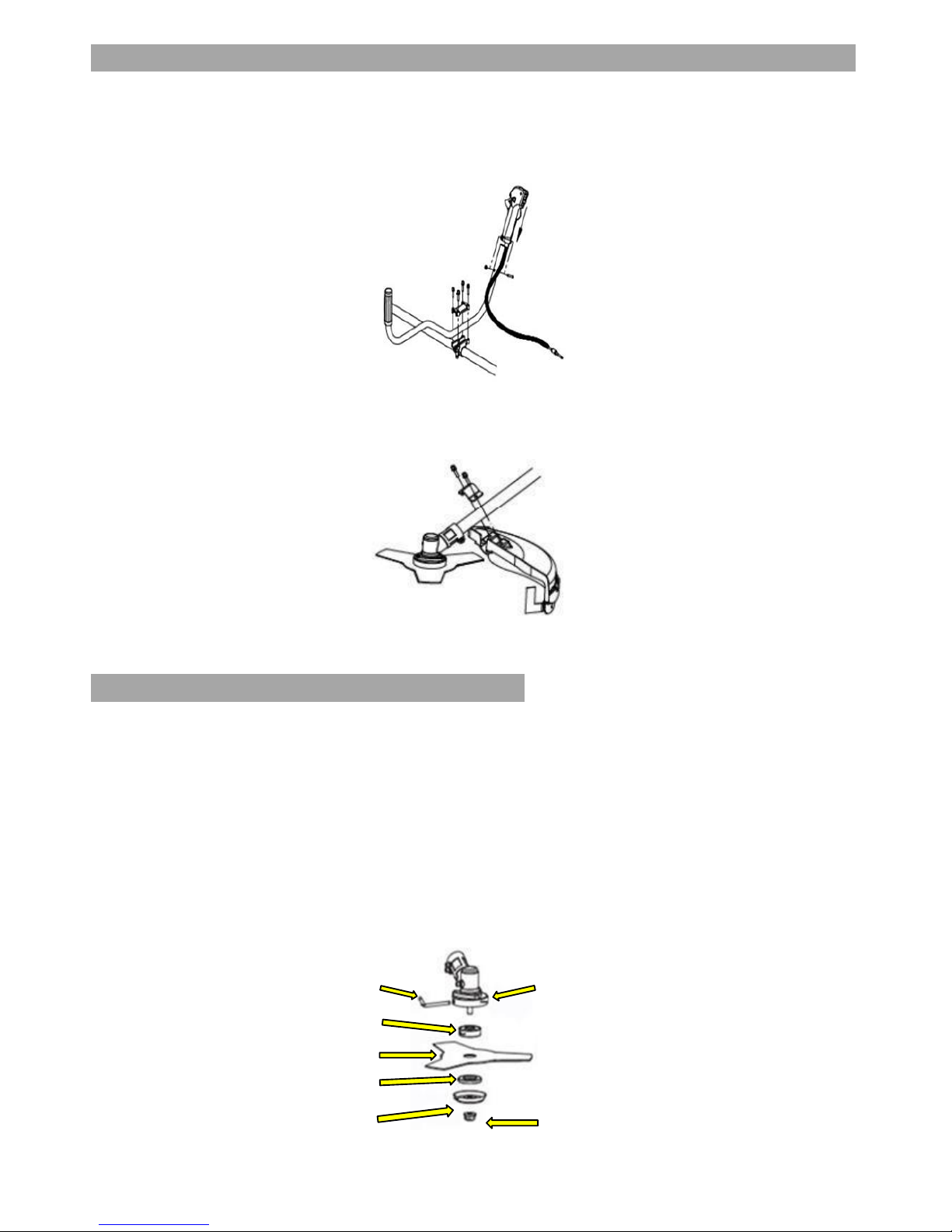

INSTALLING THE BRUSH CUTTER

3.3

Place the collar ring (3) on the shaft thread (2).

3.4

Insert the allen key provided (1) into the gear case locking hole to prevent the shaft

from rotating.

3.5

Secure the metal blade (4) between the collar ring (3) and washer (5).

Be careful and check that it is centrally located on the collar.

3.6

Insert the lower washer (6).

3.7

Hold the allen key (1) firmly in the gear case locking hole and tighten using the

nut (7).

(1)

(2)

(3) (4)

(5)

(6)

(7)

Loading...

Loading...