Ozito SDR-003 User Manual

Cordless Trio Driver

3.6V Lithium Ion

SDR-003

CAUTION: Read this operation manual before using this tool.

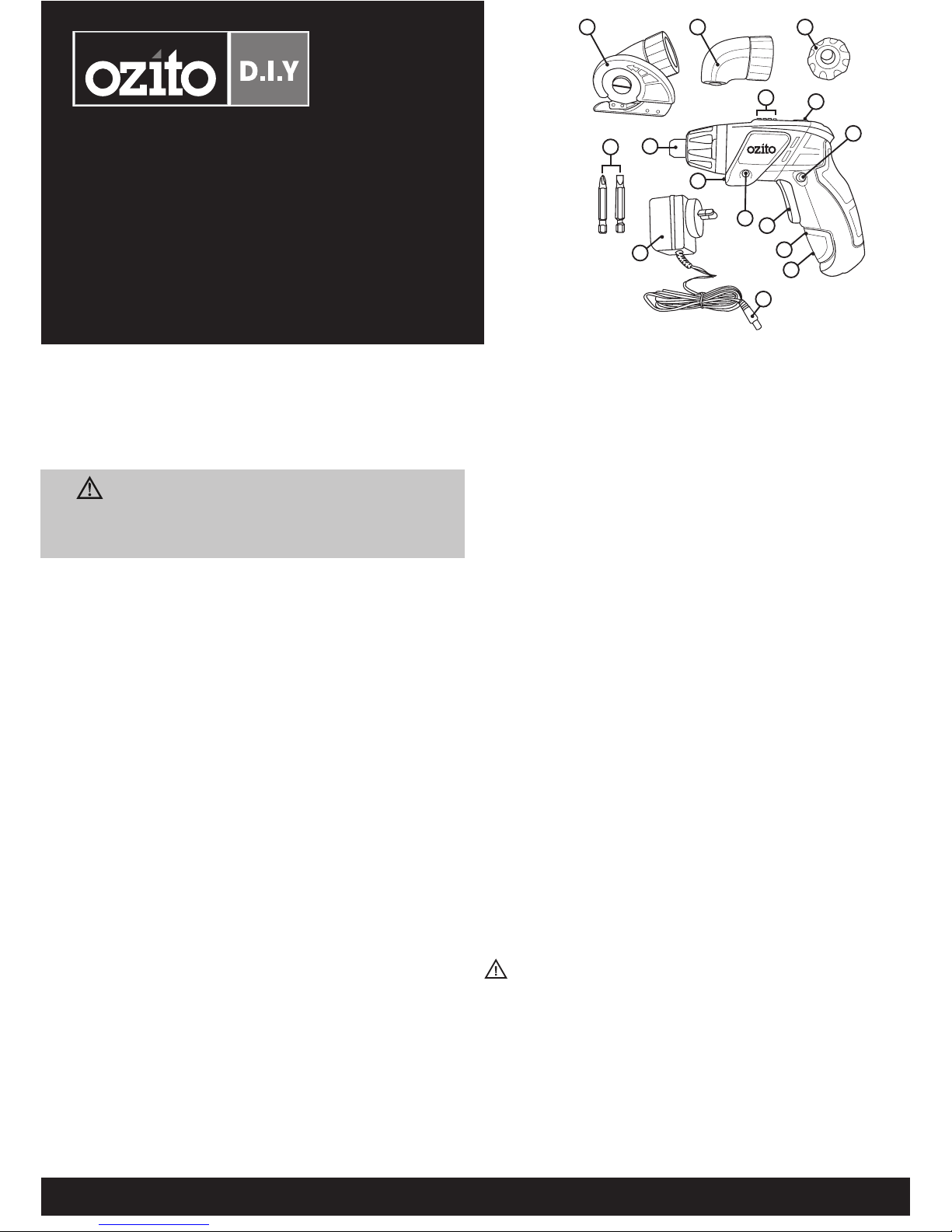

1. Cutting Head Attachment

2. Right Angle Attachment

3. Protective Rubber Nose Piece

4. Driver Bit Accessories

5. ¼” Magnetic Bit Holder

6. Battery Level Indicator

7. Rear Rotating Handle Lock Button

8. Forward/Reverse Switch

9. LED Charge Indicator

10. Charging Socket

11. ON/OFF Trigger Switch

12. LED Light On/Off Button

13. LED Light

14. Charger Plug

15. 240V Charger Adaptor

Specifications

Motor: 3.6 Volt

Charger input: 240V ~ 50Hz

Charger output: 6V DC 300mA

No load speed: 200rpm

To view the full range visit: www.ozito.com.au

0312

Additional Safety Instructions For Chargers And

Batteries

Danger! If the battery pack case is cracked or damaged, do not insert into

charger. There is a danger of electric shock or electrocution.

WARNING! Don’t allow any liquid to get inside charger. Electric shock

may result.

To facilitate cooling of the battery pack after use, avoid placing the charger

or battery pack in a warm environment such as in a metal shed, or an

un-insulated trailer.

• Before using the charger, read all instructions and cautionary markings on

charger, battery pack and product using the battery pack.

• Do not place any object on top of the charger or place the charger on a

soft surface that may result in excessive internal heat. Place the charger in a

position away from any heat source.

• To reduce risk of damage to the electric plug and cord, pull by the plug

rather than the cord when disconnecting the charger.

• Make sure cord is located so that it will not be stepped on, tripped over, or

otherwise subjected to damage or stress.

• An extension cord should not be used unless absolutely necessary. Use of

an improper extension cord could result in the risk of fire, electric shock

or electrocution.

1 2

3

8

12

10

9

15

5

4

7

11

13

14

6

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and safer at the

rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any

power tool that cannot be controlled with the switch is dangerous and

must be repaired.

c) Disconnect the plug from the power source and/or the battery pack

from the power tool before making any adjustments, changing

accessories, or storing power tools. Such preventive safety measures

reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow

persons unfamiliar with the power tool or these instructions to operate

the power tool. Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect the

power tool’s operation. If damaged, have the power tool repaired

before use. Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools

with sharp cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with

these instructions, taking into account the working conditions and the

work to be performed. Use of the power tool for operations different from

those intended could result in a hazardous situation.

5) Battery tool use and care

a) Recharge only with the charger specified by the manufacturer. A

charger that is suitable for one type of battery pack may create a risk of

fire when used with another battery pack.

b) Use power tools only with specifically designated battery packs. Use of

any other battery packs may create a risk of injury and fire.

c) When battery pack is not in use, keep it away from other metal

objects, like paper clips, coins, keys, nails, screws or other small

metal objects, that can make a connection from one terminal to

another. Shorting the battery terminals together may cause burns or a fire.

d) Under abusive conditions, liquid may be ejected from the battery;

avoid contact. If contact accidentally occurs, flush with water. If

liquid contacts eyes, additionally seek medical help. Liquid ejected

from the battery may cause irritation or burns.

6) Service

a) Have your power tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power

tool is maintained.

b) If the supply cord is damaged, it must be replaced by the manufacturer,

its service agent or similarly qualified persons in order to avoid a hazard.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any

way. Do not use any adapter plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled cords increase the risk of

electric shock.

e) When operating a power tool outdoors, use an extension cord suitable

for outdoor use. Use of a cord suitable for outdoor use reduces the risk of

electric shock.

f) If operating a power tool in a damp location is unavoidable, use a

residual current device (RCD) protected supply. Use of an RCD reduces

the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication. A moment of

inattention while operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position

before connecting to power source and/or battery pack, picking up or

carrying the tool. Carrying power tools with your finger on the switch or

energising power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on.

A wrench or a key left attached to a rotating part of the power tool may

result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This

enables better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly used. Use

of dust collection can reduce dust-related hazards.

Save all warnings and instructions for future reference.

The term “power tool” in all of the warnings refers to your mains-operated

(corded) power tool or battery-operated (cordless) power tool.

WARNING! Read all safety warnings and all instructions. Failure

to follow the warnings and instructions may result in electric

shock, fire and/or serious injury.

General Power Tools Safety Warnings

Battery: 3.6V DC 1300mAh

Rotation: Forward & Reverse

Gearbox: Single Speed

Weight: 0.52kg

• Do not operate charger if it has received a sharp blow, been dropped or

otherwise damaged in any way. Have it checked by an electrician or

power tool repairer.

• Do not disassemble charger. Take it to an electrician or power tool

repairer when service or repair is required. Incorrect reassembling may

result in a risk of electric shock, electrocution or fire.

• To reduce risk of electric shock, unplug charger from the outlet before

attempting any cleaning. Removing the battery pack will not reduce

this risk.

• Never attempt to connect 2 chargers together.

• DO NOT store or use the tool and battery pack in locations where the

temperature may reach or exceed 40ºC (such as outside sheds or metal

buildings in summer).

• The charger is designed to operate on standard household electrical

power (240 Volts). Do not attempt to use it on any other voltage!

The battery pack is not fully charged out of the carton. First read the

safety instructions and then follow the charging notes and procedures.

• The longest life and best performance can be obtained if the battery

pack is charged when the air temperature is between 18 - 24ºC. Do not

charge the battery pack in an air temperature below 10o C or above

40ºC. This is important and will prevent damage to the battery pack.

• Do not incinerate the battery pack even if it is seriously damaged or is

completely worn out. The battery can explode in a fire.

• Never attempt to open the battery pack for any reason. If the plastic

housing of the battery pack breaks or cracks, immediately discontinue

use and do not recharge.

This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for

their safety.

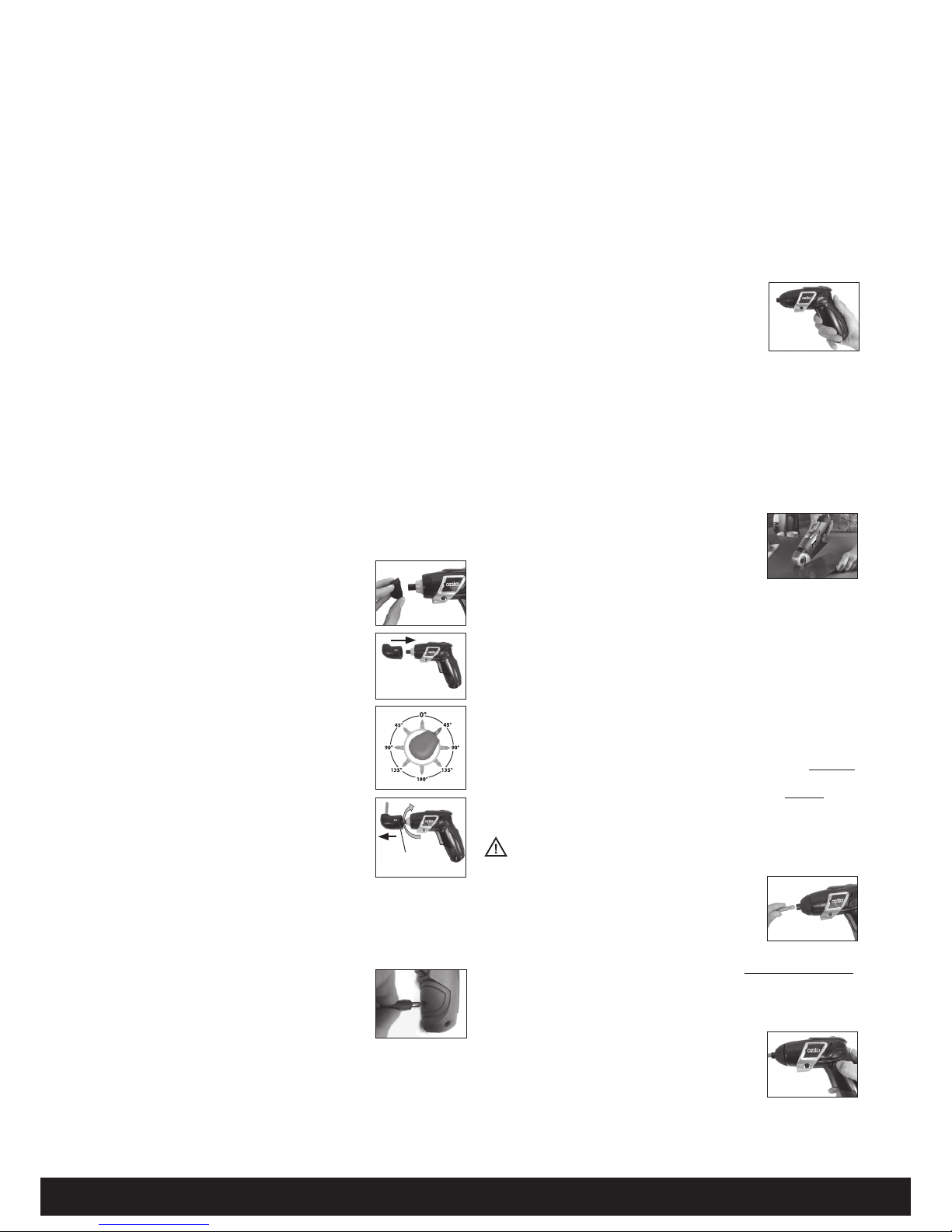

Installing the Cutting Head Attachment /Right Angle Attachment

1. Remove the protective rubber nose piece (3) of the

Trio Driver by pulling gently at the lip (Fig.1).

2. Select the desired attachment and angle position

and click onto the Trio Driver (Fig.2).

3. The cutting head and right angle attachments can

be positioned in 8 different angle positions to suit

any required job (Fig.3).

4. To remove the attachments slightly twist the spring

loaded lock collar in the direction of the arrow

until released.

5. Always ensure the protective rubber nose piece (3) is replaced when

you are not using any of the attachments. The rubber protective rubber

nose piece needs to be used on the Trio Driver in a driving, drilling mode.

Charging the Battery

This tool has been shipped in a low charge condition

and should be fully charged prior to use.

Plug the 240V charger adaptor (15) into an appropriate

AC power outlet and switch on.

Connect the charger plug (14) of the AC adaptor into

the charging socket (10) of the screwdriver.

The red charge indication LED (9) will illuminate.

The batteries will take 3-5 hours to charge. This may vary up to 7 hours due

to the level of charge left in the batteries and also the ambient temperature.

Note: The charge indicator LED (9) will turn off when the Trio Driver is fully

charged, the charger adaptor (15) LED power indicator will always be

illuminated when the charger is plugged in and turned on!

Additional Safety Instructions For Chargers

And Batteries (cont.)

Operation

To view the full range visit: www.ozito.com.au

Initial Charge

Charge your battery for 5-7 hours then use it until it runs down and only

slowly operates. Recharge for 5-7 hours again.

Once again run your tool until only a small amount of charge remains.

Repeat the above cycle about 4 or 5 times, this should set the battery

“memory”, then charge as earlier stated.

Caution: This charger does not automatically turn off when the battery is

fully charged. Please take care not to leave the tool on the charger turned

on for excessive periods of time.

Switch off the charger at mains when charging is complete.

Note: The charge indicator LED (9) will be illuminated when the charger

is plugged and charging the screwdriver. The charge indicator LED (9) will

turn off when the screwdriver is fully charged.

Operation

Starting Operation

Switching On and Off

• To operate on the Trio Driver press the On/Off trigger

switch (11) (Fig.6).

• To turn off the Trio Driver, release the On/Off trigger

switch (11).

Cutting operation

Do not force the Trio Driver. Let the accessory do the cutting, or premature

stalling will occur.

The cutting performance of the Trio Driver depends on the materials that are

being cut and the level of battery charge.

If too much force is applied to the Trio Driver, the battery overload protection

will be activated resulting in the product to stop functioning. The trigger then

must released and reactivated to resume cutting.

Depending on the batteries level of charge, excessive feed considerably

reduces the performance capability.

Always keep the blade free and clean of material debris.

The guide edge of the cutting head attachment (1)

must be aligned parallel to the cutting surface (Fig.7)

thin materials, such as fabrics, can be pulled into the

Trio Driver during cutting and become jammed.

Therefore, do not apply too much pressure with fabric

materials in order to achieve good cutting results.

During cutting, apply sufficient tension while holding fabrics and cut slowly.

Cutting Capacity

The Trio Driver cutting head has the capacity to cut the following:

- 6mm thick cardboard

- 6mm thick carpet

- 1mm plastic

The cutting head is not capable of cutting anything thicker than the above.

The life of the blade will be determined by what type of material is cut

and how often. Cutting thicker materials on a regular basis will reduce the

blades sharpness and affect the cutting performance.

Replacement Blade

If the blade becomes worn and/or damaged contact your local Bunnings

store for a replacement cutting head attachment.

Caution: If fabric become tangled around the cutting wheel DO NOT pull.

Remove the cutting wheel from the machine and gently try and remove.

Inserting Driver Bits

WARNING! Always unplug the charger and make sure the forward/

reverse switch (8) is in the lock position. Refer to the forward/reverse in

the coming instructions.

The Trio Driver has a ¼”magnetic bit holder (5) which

holds all your driver bits securely. To either insert or

extract the driver bits simply insert the shank of the

driver bit into the ¼” magnetic bit holder (5) and ensure

the bit is secure.

When using the right angle attachment (2) simply

insert into the chuck of the right angle attachment (2) (Fig.8).

Replacement Driver Bits can be purchased at any Bunnings Warehouse.

Always ensure you only use single ended 50mm driver bits as shorter driver

bits may become stuck or hard to remove from the screwdriver.

Forward / Reverse Lever

To select forward /reverse switch (8) on the Trio Driver

simply push forward/reverse switch (8) to the right side

for reverse (L) or the left side for forward (R).

To lock the Trio Driver simply ensure that the

forward/reverse switch (8) is placed in between forward

and reverse position (Fig.9).

Pre Drilling your Material

It is recommended to pre drill holes, (pilot hole) in the material you are

about to screw into. Pre drilling holes will assist the screwdriver when driving screws and enable your tool to operate efficiently.

Fig.1

Fig.2

Fig.3

Fig.4

Fig.5

Fig.6

Fig.7

Fig.8

Fig.9

Operation (cont.)

Spring Loaded

Collar

Loading...

Loading...