Ozito SCMS-10STAND User Manual

SLIDING

WHAT’S IN THE BOX

COMPOUND

MITRE SAW

254mm (10”)

INSTRUCTION MANUAL

SPECIFICATIONS

Motor: 1900W

No Load Speed: 4,800/min

Blade: Ø254mm x Ø25.4 x 48T

Mitre Angle: 0-45° left & right

Bevel Angle: 0-45° left

Max. Cutting Capacity:

Mitre 0° x Bevel 90°: 70 x 310mm

Mitre 45°x Bevel 90°: 70 x 210mm

Mitre 0°x Bevel 45°: 40 x 310mm

Mitre 45°x Bevel 45°: 40 x 210mm

ozito.com.au

Compound Mitre Saw

Dust Bag

Material Support Bar x 2

Material Clamp

Hex Key

SCMS-10STAND

WARRANTY

IN ORDER TO MAKE A CLAIM UNDER THIS

WARRANTY YOU MUST RETURN THE PRODUCT

TO YOUR NEAREST BUNNINGS WAREHOUSE WITH

YOUR BUNNINGS REGISTER RECEIPT. PRIOR TO

RETURNING YOUR PRODUCT FOR WARRANTY

PLEASE TELEPHONE OUR CUSTOMER SERVICE

HELPLINE:

Australia 1800 069 486

New Zealand 0508 069 486

TO ENSURE A SPEEDY RESPONSE PLEASE

HAVE THE MODEL NUMBER AND DATE OF

PURCHASE AVAILABLE. A CUSTOMER SERVICE

REPRESENTATIVE WILL TAKE YOUR CALL

AND ANSWER ANY QUESTIONS YOU MAY

HAVE RELATING TO THE WARRANTY POLICY

OR PROCEDURE.

The benefits provided under this warranty are in addition

to other rights and remedies which are available to you at law.

Our goods come with guarantees that cannot be excluded

at law. You are entitled to a replacement or refund for a major

failure and for compensation for any other reasonably foreseeable

loss or damage. You are also entitled to have the goods repaired

or replaced if the goods fail to be of acceptable quality and the

failure does not amount to a major failure.

Generally you will be responsible for all costs associated with

a claim under this warranty, however, where you have suffered

any additional direct loss as a result of a defective product you

may be able to claim such expenses by contacting our customer

service helpline above.

3 YEAR REPLACEMENT WARRANTY

Your product is guaranteed for a period of 36 months from the

original date of purchase and is intended for DIY (Do It Yourself) use

only. If a product is defective it will be replaced in accordance with

the terms of this warranty. Warranty excludes consumable parts, for

example: blade, carbon brushes and dust bag.

WARNING

The following actions will result in the warranty being void.

• If the tool has been operated on a supply voltage other

than that specified on the tool.

• If the tool shows signs of damage or defects caused

by or resulting from abuse, accidents or alterations.

• Failure to perform maintenance as set out within the instruction

manual.

• If the tool is disassembled or tampered with in any way.

• Professional, industrial or high frequency use.

OZITO

Australia/New Zealand (Head Office) 1-23 Letcon Drive, Bangholme, Victoria, Australia 3175.

0917

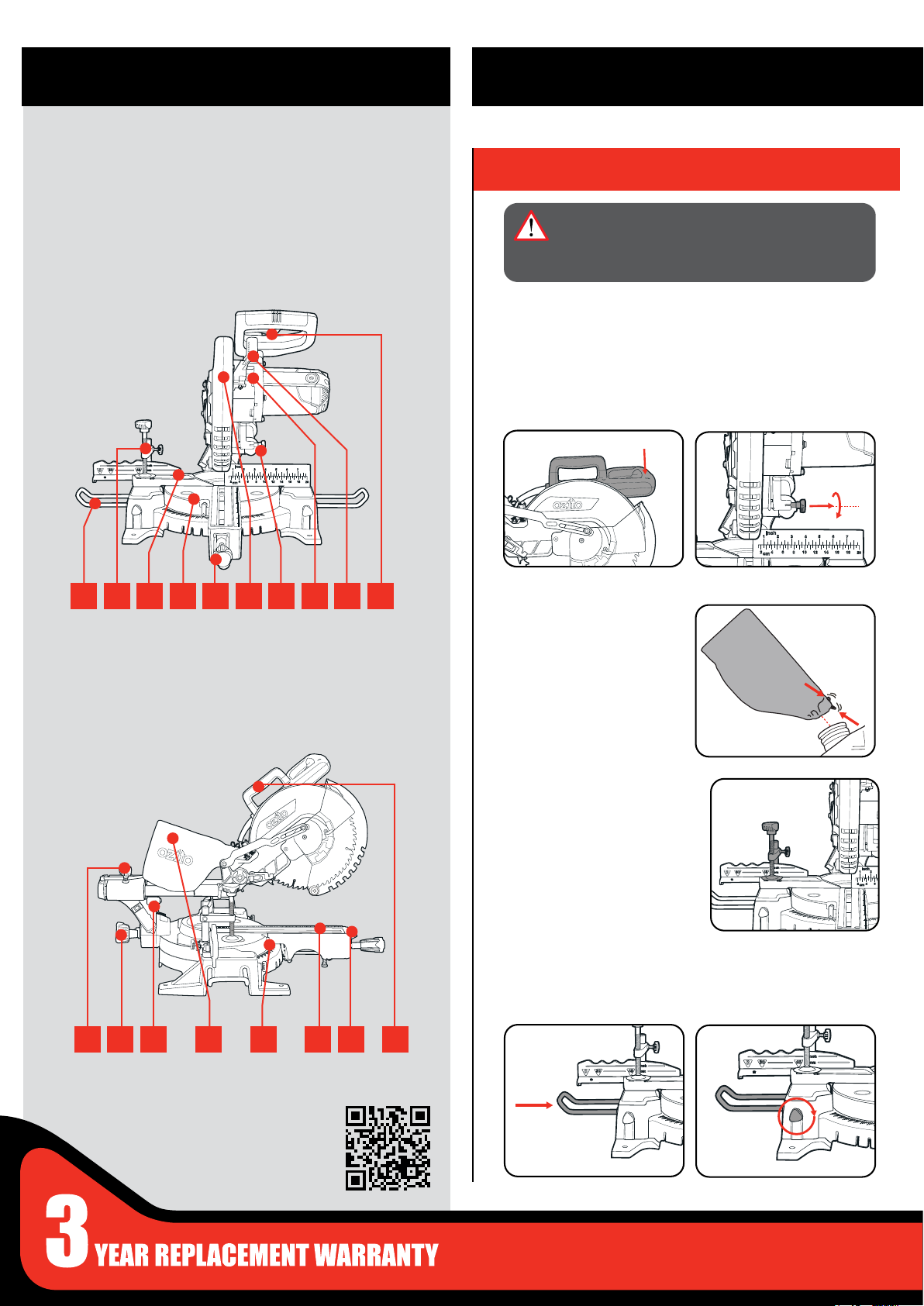

KNOW YOUR PRODUCT

SETUP & PREPARATION

MITRE SAW

1 Material Support Bar

2 Material Clamp

3 Fence

4 Mitre Table

5 Mitre Table Lock

1

2 3 4 5 6 7 8 9 10

11 Slide Lock

12 Bevel Lock

14 Dust Bag

13 Laser Guide

6 Retractable Safety Guard

7 Lock Down Pin

8 Spindle Lock Button

9 Release Lever

10 Trigger

15 Mitre Angle Pointer

16 Table Insert

17 Mitre Release

18 Carry Handle

1. ASSEMBLY

WARNING! ENSURE THE TOOL IS SWITCHED

OFF AND DISCONNECTED FROM THE POWER

SUPPLY BEFORE PERFORMING ANY OF THE

FOLLOWING PROCEDURES.

Unpacking

1. Remove foam packaging materials and using the carry handle,

carefully lift the mitre saw from its box and place it on a level

work surface.

2. Release cutting head from its transport position. While holding

the head of the saw down release the lock down pin by rotating

it 90 degrees.

Dust Bag

1. Squeeze the clamp at the

end of the dust bag, place

over the dust extraction

port.

11 12 13 14 15 16 17 18

ONLINE MANUAL

Scan this QR Code with your

mobile device to take you to

the online manual.

Material Clamp

Material clamp will assist

securing timber when making

cuts.

Note: The clamp can be

mounted on either the left or

right side of the blade.

Material Support Bars

1. Insert each bar into the

two holes located on

both sides of the base.

2. Tighten screw when in

place.

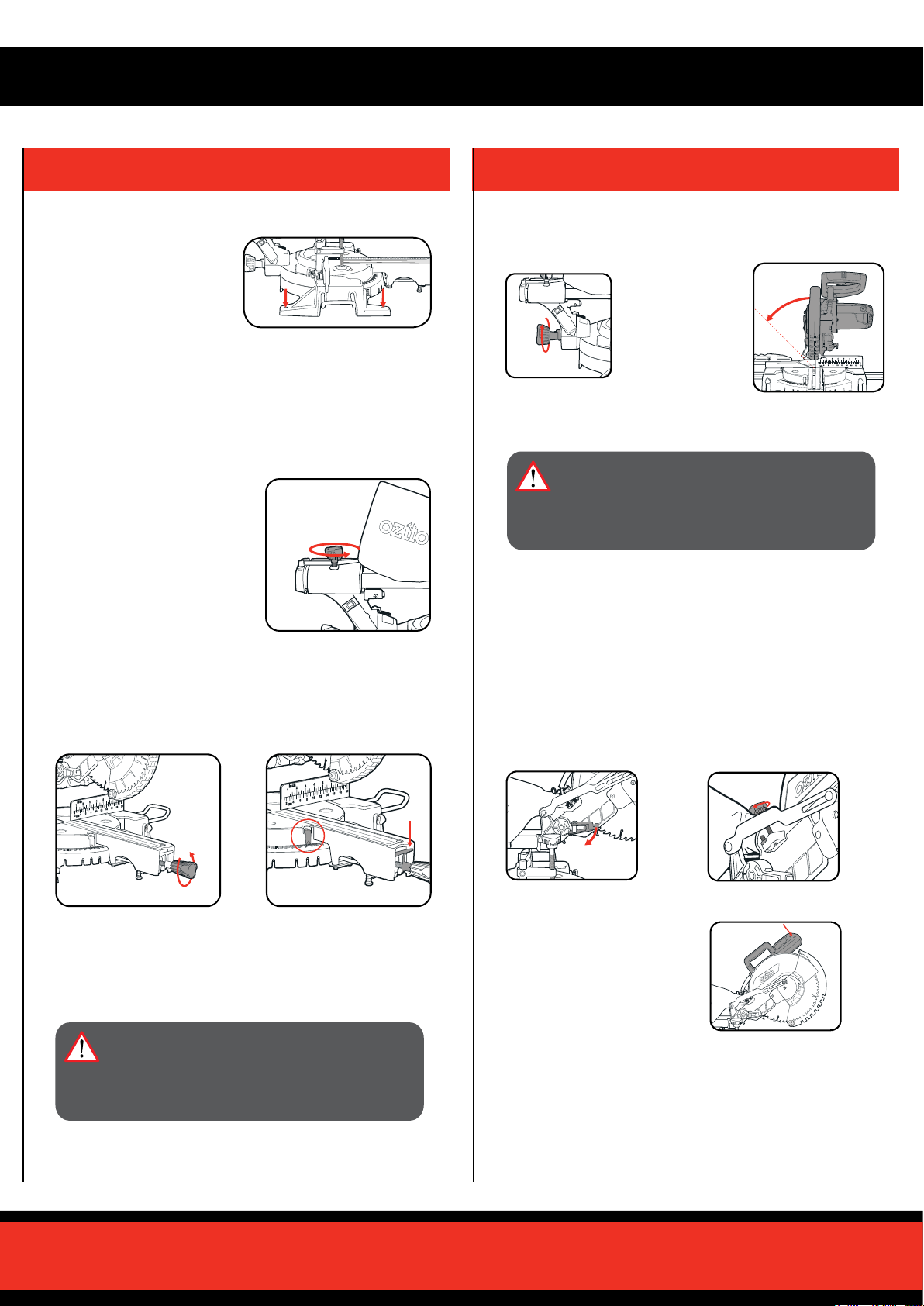

2. SET-UP AND ADJUSTMENTS

Bench Mounting

The base of the saw has

bench mounting holes that

can be used to mount it to a

workbench or mitre saw stand.

Use screws or bolts to secure.

Note: If required, the Mitre Saw can be mounted onto a 13mm piece

(or thicker) of plywood which can then be clamped to the work bench

or mitre saw stand. This provides the exibility to transport the Mitre

Saw to other work areas

Slide Lock

When cutting a narrow piece of

wood it is not necessary to use

the slide mechanism. In these

circumstances, push back the

cutting head and ensure the slide

locking knob is tight to prevent the

cutting head from sliding.

Mitre Angle Adjustment

1. Loosen mitre table lock

2. While pulling the mitre

release set the desired mitre

angle (left or right) as shown

by the mitre angle pointer

Bevel Angle Adjustment

1. Loosen bevel

lock.

3. Tighten bevel lock at selected angle.

Ensure the upper fence is moved out of the path of the blade.

WARNING!: ENSURE THE BEVEL LOCK IS

TIGHT BEFORE MAKING A CUT. FAILURE TO

DO SO MAY RESULT IN THE CUTTING HEAD

MOVING DURING OPERATION AND CAUSE

SERIOUS PERSONAL INJURY.

2. Tilt the cutting head to the desired

bevel angle

left as shown

by the bevel

angle pointer.

Trenching

Trenching refers to restricting the depth of cut and permits a “trench”

to be cut in the workpiece.

1. Ensure the cutting head is

raised, pull the trenching

stop out as far as it will go.

2. To adjust the trenching

depth rotate the trenching

depth adjustment screw.

Note: The mitre table features positive click stops at 0°, 15°, 22.5°,

31.6° and 45° for quick setting of common mitre angles.

3. Tighten mitre table lock at selected angle

WARNING! ENSURE THE MITRE TABLE LOCK

IS TIGHT BEFORE MAKING A CUT. FAILURE

TO DO SO MAY RESULT IN THE MITRE TABLE

MOVING DURING OPERATION AND CAUSE

SERIOUS PERSONAL INJURY.

3. To check that the blade

stops at the desired position,

lower the cutting head

until the trenching stop

adjustment screw touches

the trenching stop.

Loading...

Loading...