Ozito PCS-406A Instruction Manual

1

PETROL

CHAINSAW

41cc - 406mm

INSTRUCTION MANUAL

SPECIFICATIONS

Engine: 41cc 2 Stroke

Power: 1.5 kW

Bar Type: Oregon 406mm (16”)

Chain Pitch: 9.53mm (3/8”)

No Load Speed: 11000/min

Chain Speed: 21 m/s

Fuel Mix 40:1

Fuel Tank Capacity: 260ml

Chain Oil Tank Capacity: 210ml

Weight: 5.40 kg

PCS-406A

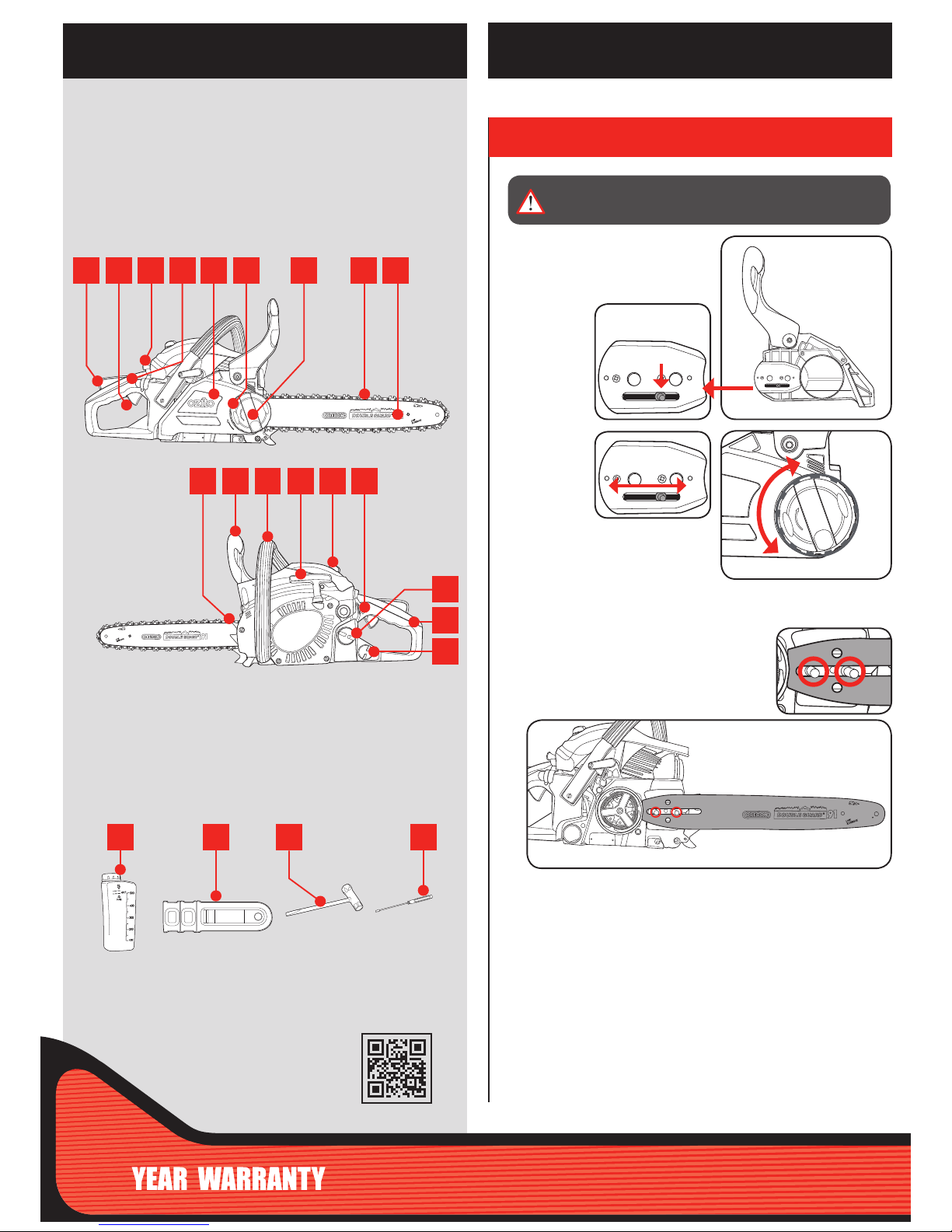

WHAT’S IN THE BOX

ozito.com.au

Chain Saw

Side Cover

Chain

Chain Bar Cover

Guide Bar

Spark Plug Wrench Screwdriver

Fuel Mixing

Bottle

1

ONLINE MANUAL

Scan this QR Code with your

mobile device to take you to

the online manual.

1. The rst step is to correctly position

the chain tensioning pin on the

inside of the side cover.

2. The chain

tensioning

pin can be

adjusted

by turning

the chain

tension dial.

When the dial is turned ANTI

CLOCKWISE, the pin moves

towards the rear of the chainsaw.

When the dial is turned

CLOCKWISE, the pin moves towards the front of the chainsaw.

3. Fit the open end of the guide bar

over the die bar pins.

KNOW YOUR PRODUCT

ASSEMBLY

1. Throttle Safety Lock

2. Throttle Trigger

3. Choke Control

4. Priming Bulb

5. Side Cover

6. Chain Tension Dial

7. Side Cover Locking Lever

8. Chain

9. Guide Bar

1. FITTING THE CHAIN BAR

PETROL CHAINSAW

ACCESSORIES

1

10 11 12 13 14 15

16

17

18

2 3 4 5 6 7 8 9

WARNING!: DO NOT START THE ENGINE UNTIL THE

CHAINSAW IS FULLY ASSEMBLED.

CORRECT

POSITION

10. Bucking Spikes

11. Chain Brake

12. Handle

13. Recoil Starter

14. Filter Cover Knob

15. Ignition Switch

16. Fuel Tank Cap

17. Rear Handle

18. Chain Bar Oil Cap

19. Fuel Mixing Bottle

20. Chain Bar Cover

21. Spark Plug Wrench

22. Screwdriver

19 20 21 22

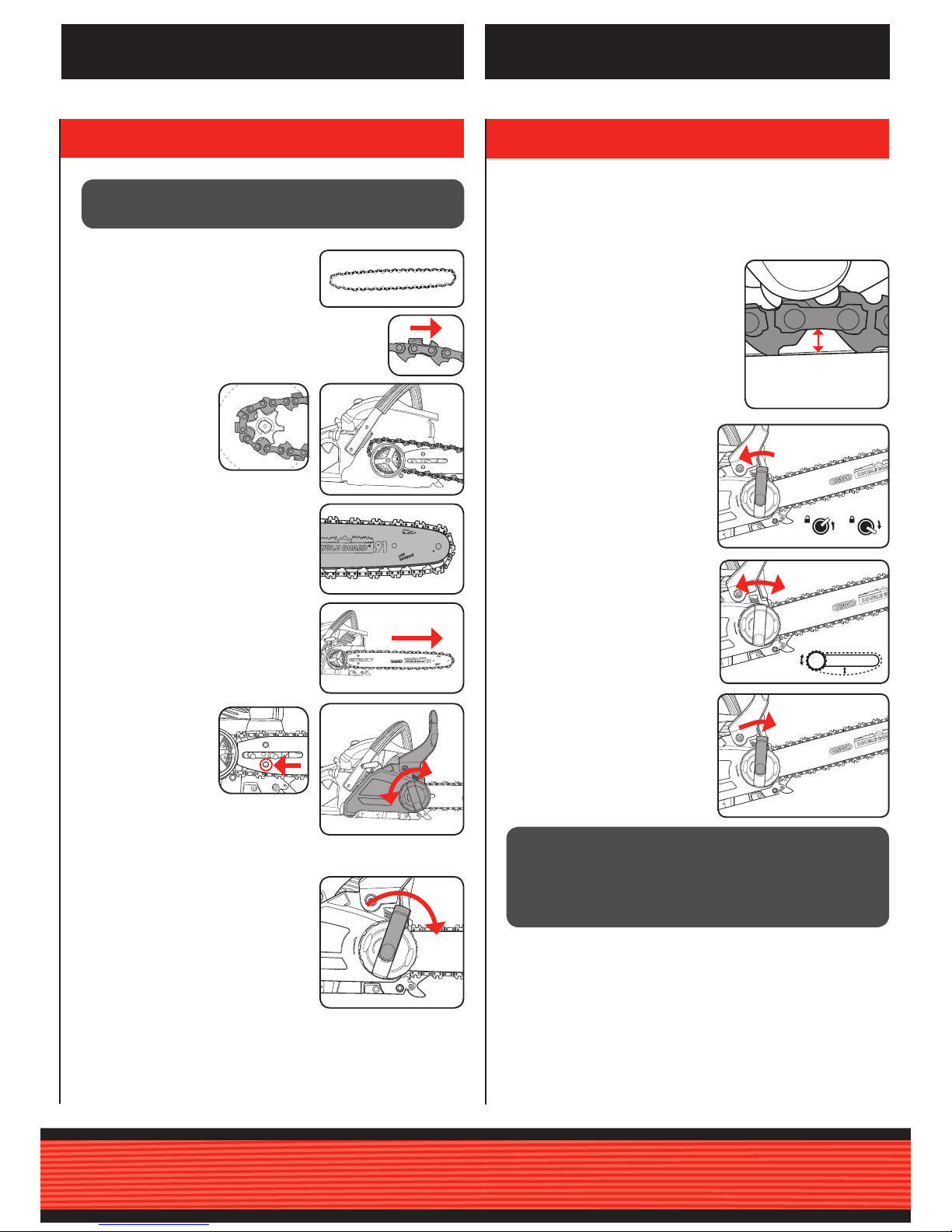

2. INSTALLING THE CHAIN

3. ADJUSTING THE CHAIN TENSION

1. Spread the chain out in a loop with the

cutting edges pointing CLOCKWISE

around loop.

2. Slip the chain behind

the clutch and around

the sprocket. Make

sure that the links t

between the sprocket

teeth.

3. Guide the drive links into the groove and

around the end of the bar.

Note: The chain may droop slightly on the

lower part of bar. This is normal.

4. Pull the chain bar forward until the chain

is closely seated. Make sure that all the

drive links are in the groove of the bar.

5. Place the side cover

onto the chainsaw.

Make sure that the

chain tensioning pin

ts into the chain bar.

If it does not t, it can

be adjusted slightly

with the chain tensioning dial.

The chain must not slip off the bar when

you do this.

6. Pull out the side cover locking lever

and turn it in a clockwise direction. This

action will x the side cover in place.

SETUP & PREPARATION

Note. Proper tension of the chain is extremely important and must be

checked before starting, as well as during any cutting operation.

Taking the time to make adjustments to the chain will result in

improved cutting performance and prolonged chain life.

Correct tension

For the correct chain tension, pull up on

the chain from the top and middle of the

exposed guide bar. The bottom tip of the

links should only just stay in the track.

Adjusting tension

1. Loosen the side cover locking dial

slightly.

2. Hold the nose of guide bar

up and turn the adjustment

dial CLOCKWISE to increase

chain tension. Turning dial

COUNTERCLOCKWISE will

decrease amount of tension on the

chain. Ensure the chain ts snugly

all the way around the guide bar.

3. After making the adjustment, and

while still holding nose of bar in the

uppermost position, tighten the side

cover locking dial securely.

CAUTION!: WEAR PROTECTIVE GLOVES AT ALL TIMES

WHEN HANDLING THE CHAIN.

CAUTION!: RECHECK THE TENSION AFTER A FEW

MINUTES OF CUTTING AS THE CHAIN MAY STRETCH

AFTER INITIAL USE. A LOOSE CHAIN MAY CAUSE

WEAR TO BOTH THE CHAIN AND THE GUIDE BAR AND

BECOME A MAJOR SAFETY HAZARD.

5 - 6mm gap is

the ideal tension

Loading...

Loading...