Ozito MWR-135, MWR-090 Instruction Manual

WHAT’S IN THE BOX

MIG

WELDER

120 Amp

INSTRUCTION MANUAL

SPECIFICATIONS

Input Voltage: 230-240V ~ 50Hz

Welding Current: 40 - 120A

Welding Wire Size: 0.6-0.8mm General Wire,

0.8-0.9mm Flux-Cored Wire

Duty Cycle: 60%@40A, 10%@120A

Insulation Type: Earthed Appliance (Class I)

Wire Spool Weight: 0.2kg to 5kg

Weight (tool only): 22.2kg

ozito.com.au

MIG Welder

Welding Mask

Chipping Hammer /

Wire Brush

Earth Clamp

Terminal Spanner

WARRANTY

IN ORDER TO MAKE A CLAIM UNDER THIS

WARRANTY YOU MUST RETURN THE PRODUCT

TO YOUR NEAREST BUNNINGS WAREHOUSE WITH

YOUR BUNNINGS REGISTER RECEIPT. PRIOR TO

RETURNING YOUR PRODUCT FOR WARRANTY

PLEASE TELEPHONE OUR CUSTOMER SERVICE

HELPLINE:

Australia 1800 069 486

New Zealand 0508 069 486

TO ENSURE A SPEEDY RESPONSE PLEASE

HAVE THE MODEL NUMBER AND DATE OF

PURCHASE AVAILABLE. A CUSTOMER SERVICE

REPRESENTATIVE WILL TAKE YOUR CALL

AND ANSWER ANY QUESTIONS YOU MAY

HAVE RELATING TO THE WARRANTY POLICY

OR PROCEDURE.

MWR-135

The benefits provided under this warranty are in addition

to other rights and remedies which are available to you at law.

Our goods come with guarantees that cannot be excluded

at law. You are entitled to a replacement or refund for a major

failure and for compensation for any other reasonably foreseeable

loss or damage. You are also entitled to have the goods repaired

or replaced if the goods fail to be of acceptable quality and the

failure does not amount to a major failure.

Generally you will be responsible for all costs associated with

a claim under this warranty, however, where you have suffered

any additional direct loss as a result of a defective product you

may be able to claim such expenses by contacting our customer

service helpline above.

3 YEAR REPLACEMENT WARRANTY

Your product is guaranteed for a period of 36 months from

the original date of purchase. If a product is defective it will

be replaced in accordance with the terms of this warranty.

Warranty excludes consumable parts, for example: welding masks

and combination wire brush and chipping hammers.

WARNING

The following actions will result in the warranty being void.

• If the tool has been operated on a supply voltage other

than that specified on the tool.

• If the tool shows signs of damage or defects caused

by or resulting from abuse, accidents or alterations.

• Failure to perform maintenance as set out within the

instruction manual.

• If the tool is disassembled or tampered with in any way.

• Professional, industrial or high frequency use.

OZITO Australia/New Zealand (Head Office) 1-23 Letcon Drive, Bangholme, Victoria, Australia 3175.

1014

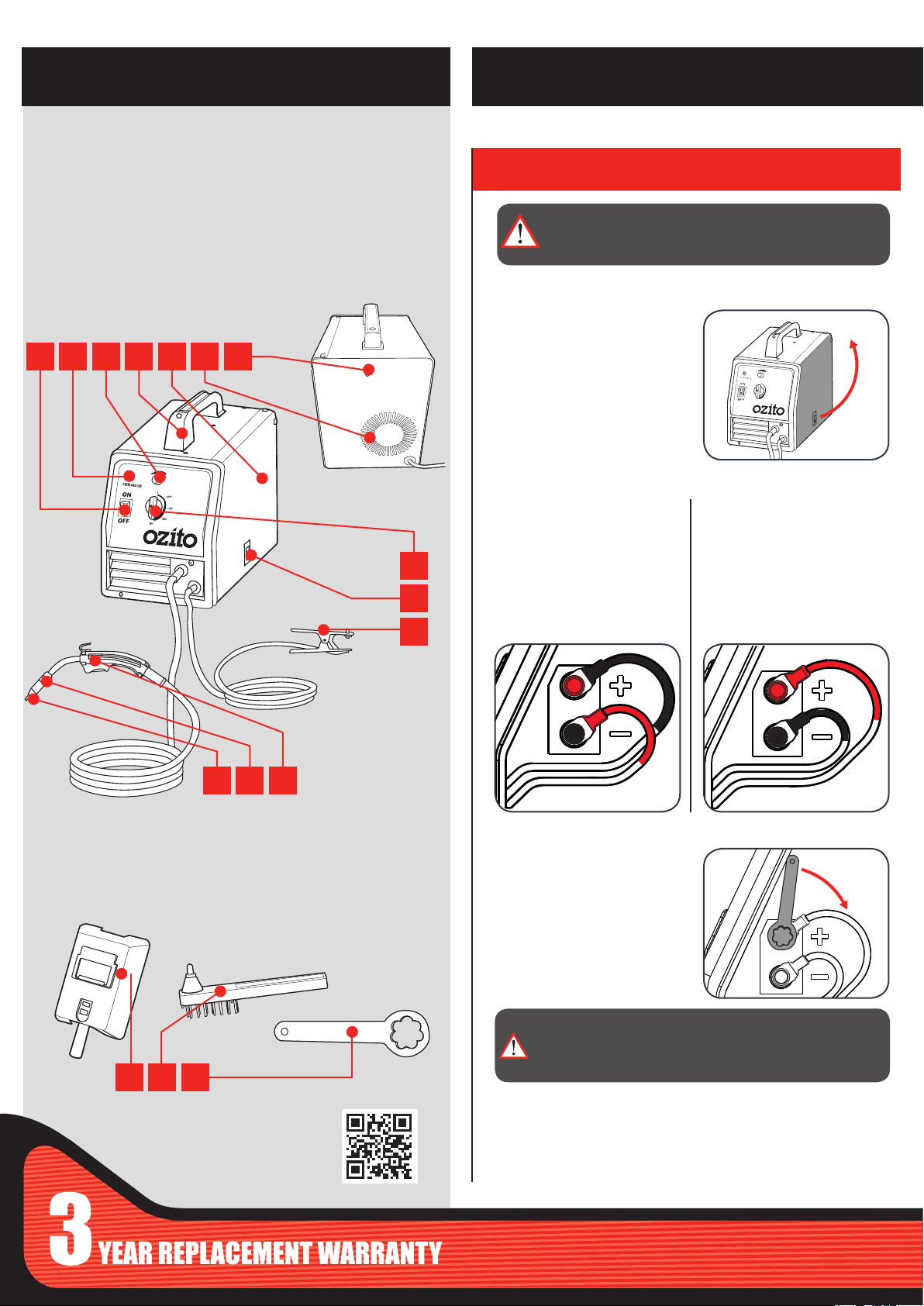

KNOW YOUR PRODUCT

SETUP & PREPARATION

MIG WELDER

1 On/Off Switch

2 Overload Protection LED

3 Wire Feed Speed

4 Carry Handle

5 Side Cover

6 Internal Cooling Fan

7 Welder Gas Intake Barb

1 2 3 4 5 6 7

8 Output Voltage Control Dial

9 Side Cover Release Lever

10 Earth Clamp

11 Torch Tip

12 Shroud

13 MIG Torch

8

9

10

1. TERMINAL CONFIGURATION

WARNING: ENSURE THE TOOL IS SWITCHED OFF AND

DISCONNECTED FROM THE POWER SUPPLY BEFORE

PERFORMING ANY OF THE FOLLOWING STEPS.

Setting the Welding Current for Gasless or Gas Shielded

1 Open the side cover by

raising the side cover

release lever.

Gasless Welding Mode Gas Shielded Welding Mode

2 Connect the positive

welding cable (red) to the

negative terminal and the

negative welding cable

(black) to the positive

terminal.

2 Connect the positive

welding cable (red) to the

positive terminal and the

negative welding cable

(black) to the negative

terminal.

ACCESSORIES

14 Welding Mask

15 Chipping Hammer / Wire

Brush

14 15 16

ONLINE MANUAL

Scan this QR Code with your

mobile device to take you to

the online manual.

11

12 13

16 Terminal Spanner

3 Ensure that the terminals

are secure by tightening

the terminal knobs using

the terminal spanner.

WARNING: TERMINAL KNOBS MUST BE SECURELY

TIGHTENED PRIOR TO OPERATION. LOOSE OR

INCORRECT FASTENING MAY CAUSE THE CONNECTION

TO OVERHEAT OR BURN.

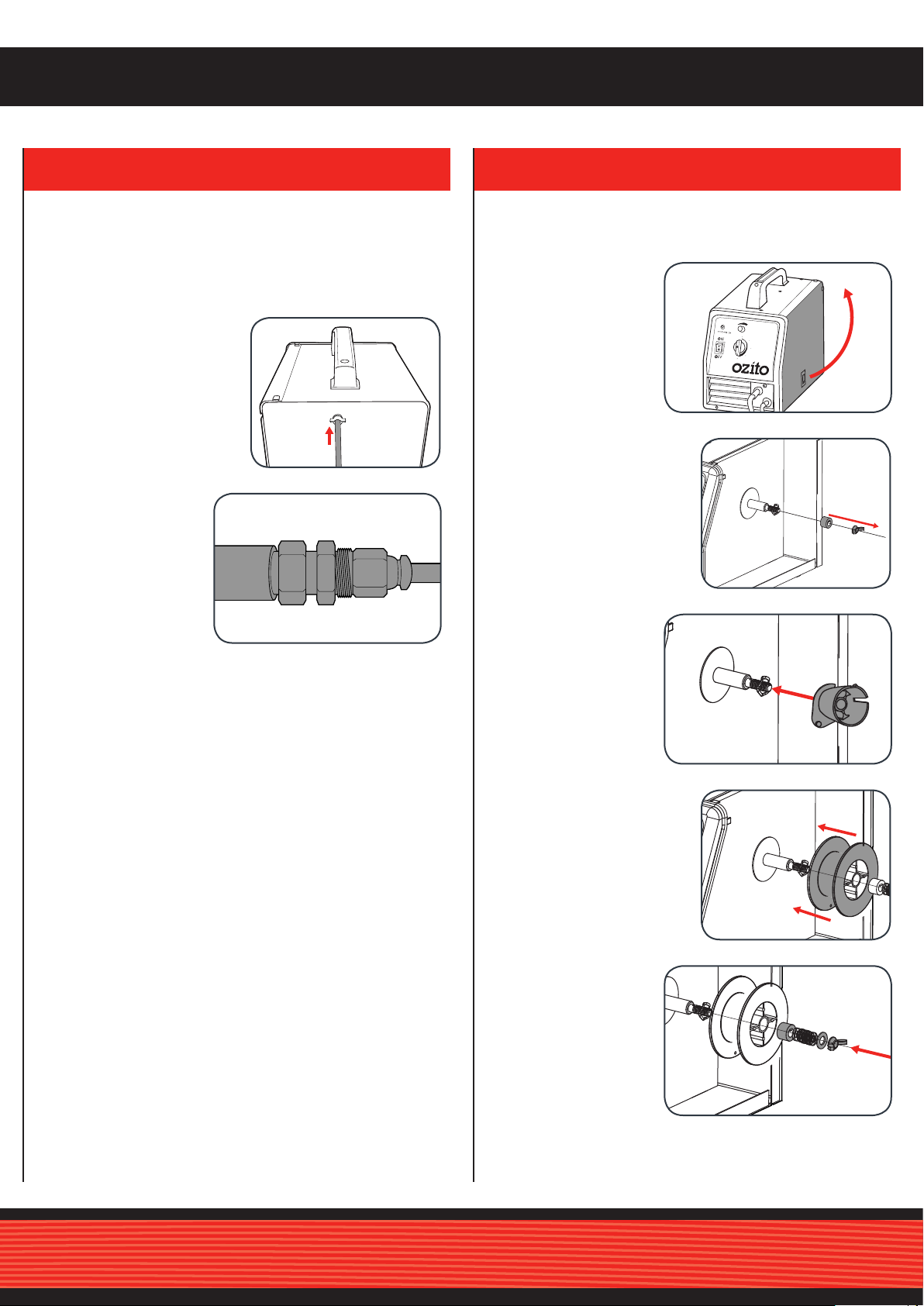

2. SHIELDED GAS WELDING SETUP 3. FITTING THE WELDING WIRE COIL

Drive

washer (c)

Drive

shaft (a)

5.0kg Coil

adaptor (e)

Drive

washer (c)

Drive

shaft (a)

5.0kg Coil

adaptor (e)

Attaching the Shielding Gas Hose and Regulator

When using a shielding gas with the MIG welder, you will

require additional hoses and gauges. These additional

accessories are available at your local gas supplier and are not

included with your MIG welder.

1 Connect the hose to the

welder gas intake barb

and secure in place with

the appropriate hose

clamp.

2 When using a

shielding gas with

a disposable argon

gas bottle, you may

need to purchase

a hose reducing

adaptor from your

gas supplier.

• Check with your local gas supplier for their recommendations

of the required gas mixture and ow rate for your MIG welder.

• Check all of the connections to the gauges and the shielding

gas bottle for leaks prior to commencing to weld.

The MIG welder is supplied with a 0.2kg coil of 0.8mm gasless

welding wire. Welding wire up to 5kg can be tted to this welder

using the 5kg coil adaptor.

1 Open the side cover

by lifting the side

cover release lever.

2 Remove the wing nut by

rotating anti-clockwise and

remove the drive washer.

3 If a 5kg wire coil is

to be tted, slide the

coil adaptor onto

the wire drive shaft.

Note: This step can

be skipped if a smaller

wire coil is to be tted.

4 Slide the welding wire coil

onto the shaft.

5 Align the drive

washer lug with

the slot in the drive

shaft and secure

with the wing nut

but do not over

tighten.

Note: Over tightening of the wing nut will restrict the wire feed

rate and can cause damage to the wire feed motor or irregular

welding.

Loading...

Loading...