Page 1

xF

User Manual

Covers RT3000 v3 and

RT500 v1 models

The inertial experts.

RT

GNSS-aided

inertial

measurement

systems

Page 2

2

Oxford Technical Solutions

Legal Notices

Information furnished is believed to be accurate and reliable. However, Oxford

Technical Solutions Limited assumes no responsibility for the consequences of use of

such information nor for any infringement of patents or other rights of third parties which

may result from its use. No licence is granted by implication or otherwise under any

patent or patent rights of Oxford Technical Solutions Limited. Specifications mentioned

in this publication are subject to change without notice and do not represent a

commitment on the part of Oxford Technical Solutions Limited. This publication

supersedes and replaces all information previously supplied. Oxford Technical Solutions

Limited products are not authorised for use as critical components in life support devices

or systems without express written approval of Oxford Technical Solutions Limited.

All brand names are trademarks of their respective holders.

The software is provided by the contributors “as is” and any express or implied

warranties, including, but not limited to, the implied warranties of merchantability and

fitness for a particular purpose are disclaimed. In no event shall the contributors be liable

for any direct, indirect, incidental, special, exemplary, or consequential damages

(including, but not limited to, procurement of substitute goods or services; loss of use,

data, or profits; or business interruption) however caused and on any theory of liability,

whether in contract, strict liability, or tort (including negligence or otherwise) arising in

any way out of the use of this software, even if advised of the possibility of such damage.

Copyright Notice

© Copyright 2019, Oxford Technical Solutions.

Revision

Document Revision: 190902 (See Revision History for detailed information).

Contact Details

Oxford Technical Solutions Limited

Park Farm Business Centre

Middleton Stoney

Oxfordshire

OX25 4AL

United Kingdom

Tel: +44 (0) 1869 814 253

Fax: +44 (0) 1869 251 764

Web: http://www.oxts.com

Email: support@oxts.com

Page 3

RT User Manual

Revision: 190902

3

Warranty

Oxford Technical Solutions Limited warrants its products to be free of defects in

materials and workmanship, subject to the conditions set forth below, for a period of one

year from the Date of Sale.

“Date of Sale” shall mean the date of the Oxford Technical Solutions Limited invoice

issued on delivery of the product. The responsibility of Oxford Technical Solutions

Limited in respect of this warranty is limited solely to product replacement or product

repair at an authorised location only. Determination of replacement or repair will be made

by Oxford Technical Solutions Limited personnel or by personnel expressly authorised

by Oxford Technical Solutions Limited for this purpose.

In no event will Oxford Technical Solutions Limited be liable for any indirect, incidental,

special or consequential damages whether through tort, contract or otherwise. This

warranty is expressly in lieu of all other warranties, expressed or implied, including

without limitation the implied warranties of merchantability or fitness for a particular

purpose. The foregoing states the entire liability of Oxford Technical Solutions Limited

with respect to the products herein.

Any use of misuse of the RT in a manner not intended may impar the protection

provided. Please contact OxTS if you believe any service of repair is required on

your RT.

Page 4

4

Oxford Technical Solutions

Table of contents

Legal Notices __________________________________________________________________ 2

Copyright Notice _______________________________________________________________ 2

Revision ______________________________________________________________________ 2

Contact Details ________________________________________________________________ 2

Table of contents ______________________________________________________________ 4

Introduction __________________________________________________________________ 7

Easy operation ______________________________________________________________________ 9

Self-correcting ______________________________________________________________________ 9

Interchangeable _____________________________________________________________________ 9

Advanced processing _________________________________________________________________ 9

Related documents ____________________________________________________________ 10

RT product family _____________________________________________________________ 11

• RT500s (v1) ___________________________________________________________________ 11

• RT3000s (v3) __________________________________________________________________ 11

Single antenna _____________________________________________________________________ 11

Dual antenna ______________________________________________________________________ 11

GLONASS _________________________________________________________________________ 12

BeiDou ___________________________________________________________________________ 12

250 Hz ___________________________________________________________________________ 12

Satellite differential corrections ________________________________________________________ 12

Scope of delivery ______________________________________________________________ 13

RT500 and RT3000 system components __________________________________________________ 13

Specification _________________________________________________________________ 14

Common specifications ______________________________________________________________ 16

Notes on specifications ______________________________________________________________ 16

Heading accuracy ___________________________________________________________________ 16

Environmental protection _____________________________________________________________ 17

Export control classification number ____________________________________________________ 17

Conformance notices __________________________________________________________ 18

Regulator testing standards ___________________________________________________________ 18

Software installation __________________________________________________________ 19

Page 5

RT User Manual

Revision: 190902

5

Hardware installation__________________________________________________________ 21

RT orientation and alignment __________________________________________________________ 21

Antenna placement and orientation _____________________________________________________ 21

Operation ___________________________________________________________________ 23

Front panel layout __________________________________________________________________ 23

Co-ordinate frame conventions_________________________________________________________ 26

Ethernet configuration _______________________________________________________________ 33

Wi-Fi configuration __________________________________________________________________ 36

Dual antenna systems _______________________________________________________________ 38

Inputs and outputs ____________________________________________________________ 41

Digital inputs and outputs_____________________________________________________________ 42

Configuring the RT ____________________________________________________________ 45

Overview _________________________________________________________________________ 45

Working through NAVconfig ___________________________________________________________ 46

NAVconfig Home section in NAVconfig __________________________________________________ 46

Start/Read Configuration section in NAVconfig ____________________________________________ 47

Read Configuration section ___________________________________________________________ 48

Hardware Setup section in NAVconfig ___________________________________________________ 49

IMU orientation tab __________________________________________________________________ 49

Primary antenna tab _________________________________________________________________ 51

Secondary Antenna tab ______________________________________________________________ 53

GNSS Differential Corrections tab_______________________________________________________ 58

Interfaces section in NAVconfig ________________________________________________________ 62

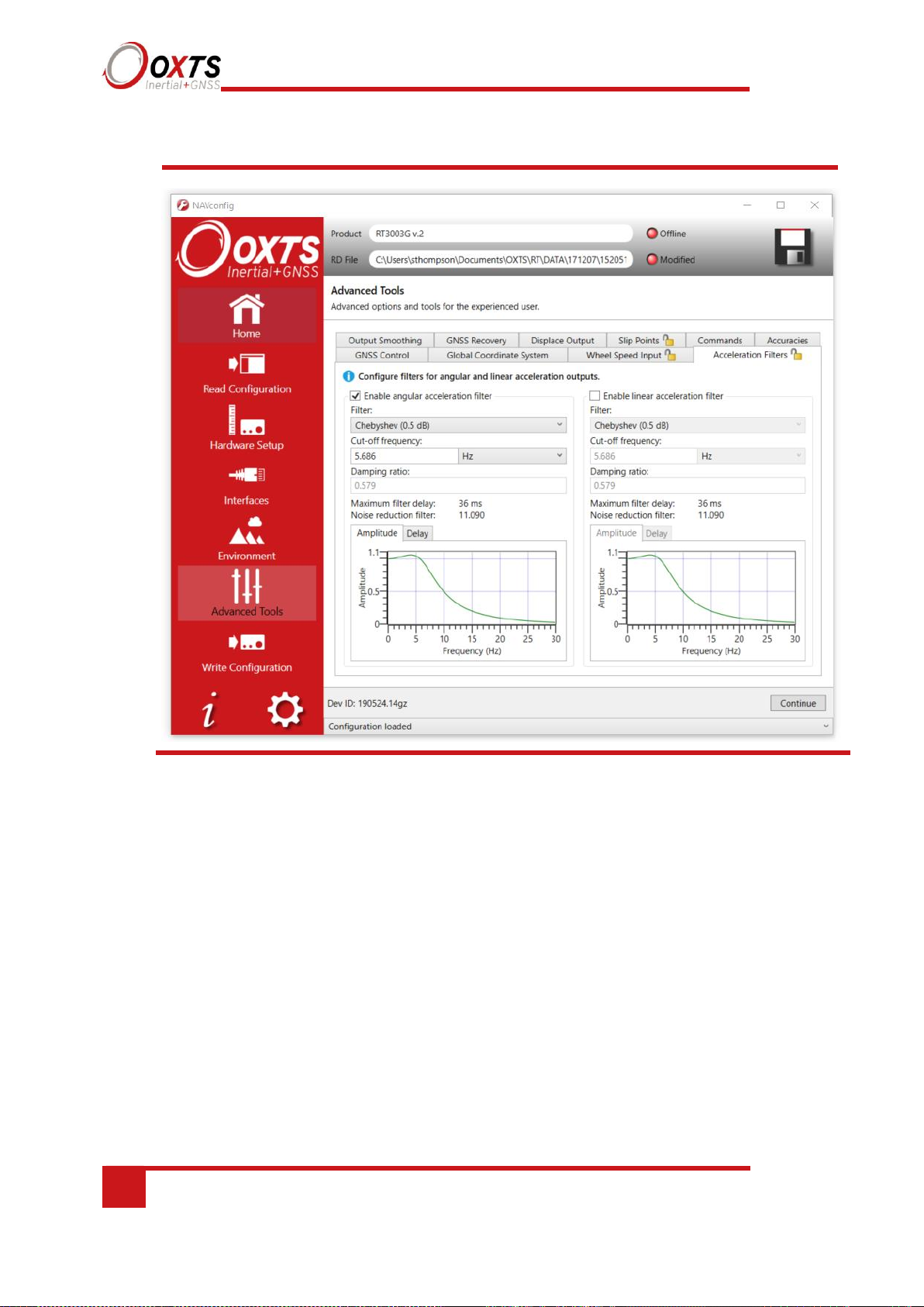

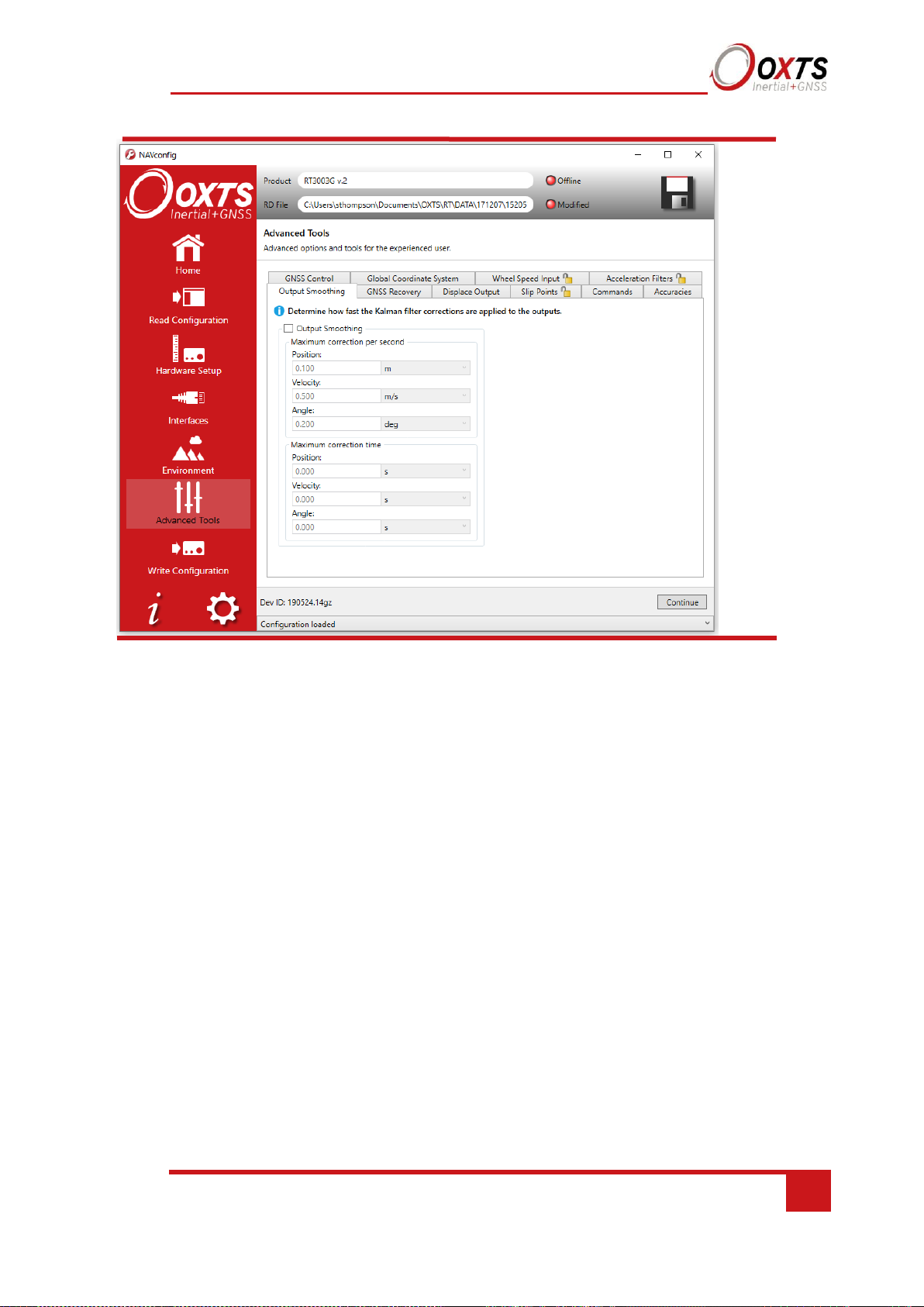

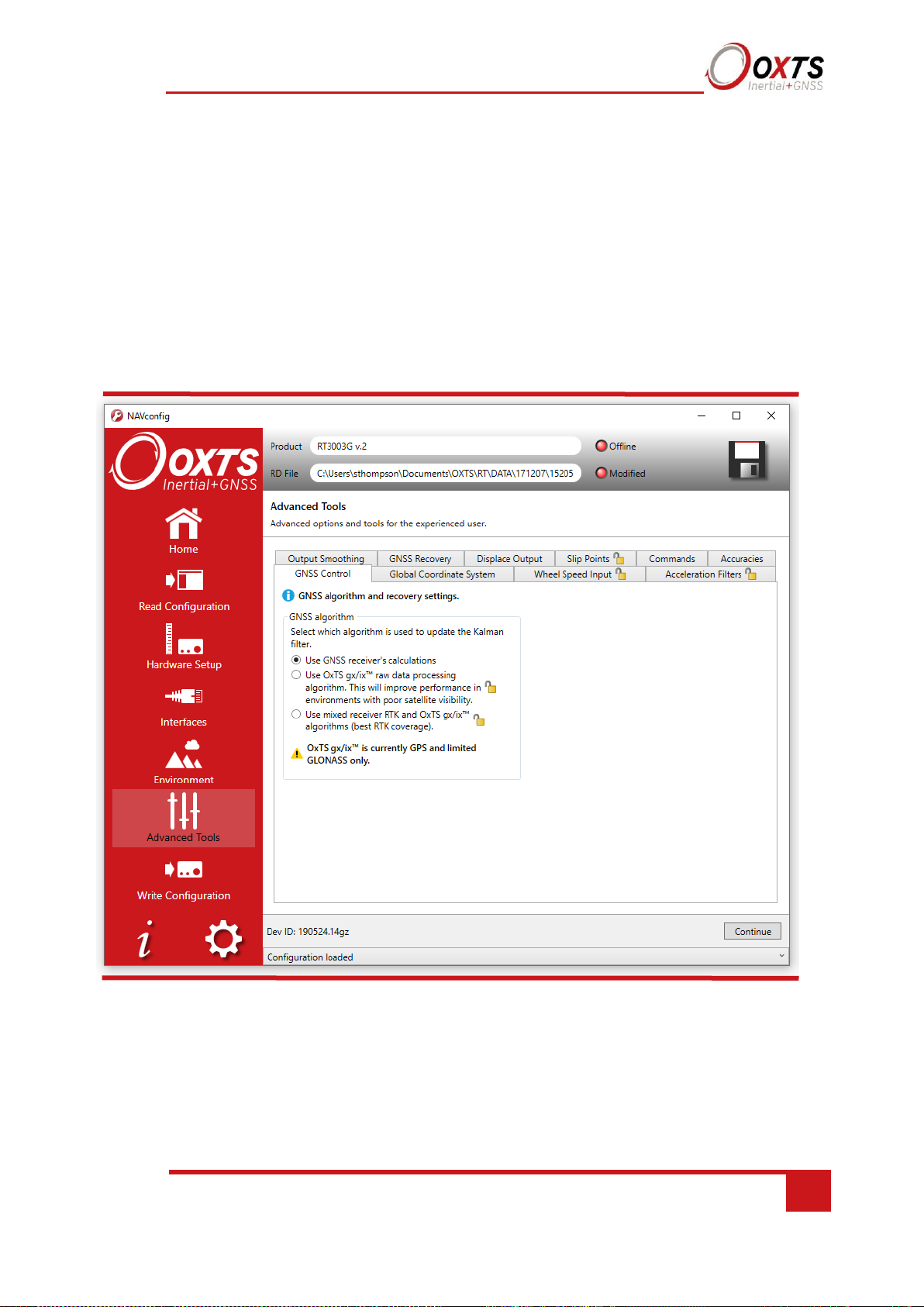

Advanced Tools section _____________________________________________________________ 75

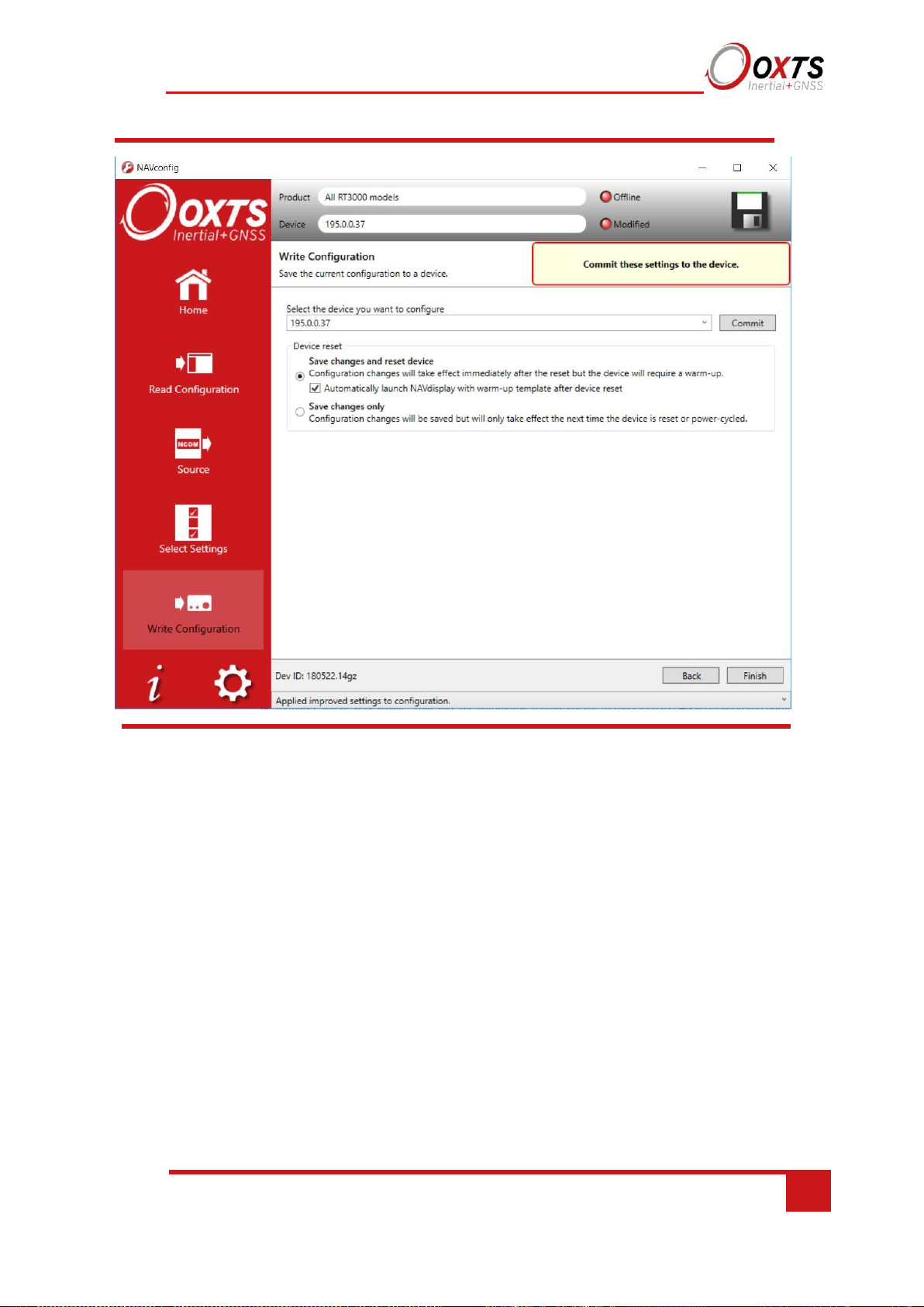

The Write Configuration section of NAVconfig _____________________________________________ 86

Setting up the base station _____________________________________________________ 87

Using the RT-Base S _________________________________________________________________ 87

Initialisation process ___________________________________________________________ 88

Real-time outputs ___________________________________________________________________ 88

Warm-up period ____________________________________________________________________ 89

Improving the configuration after a warm-up____________________________________________ 92

Committing the configuration to the RT __________________________________________________ 92

Post-processing data __________________________________________________________ 97

Laboratory testing ____________________________________________________________ 98

Page 6

6

Oxford Technical Solutions

Accelerometer test procedure__________________________________________________________ 98

Gyro test procedure _________________________________________________________________ 98

Testing the internal GNSS and other circuitry _____________________________________________ 100

Using the orientation measurements ____________________________________________ 101

Operating principles __________________________________________________________ 102

Internal components ________________________________________________________________ 102

Strapdown navigator _______________________________________________________________ 103

Kalman filter ______________________________________________________________________ 104

CAN messages and signals _____________________________________________________ 106

Termination resistor ________________________________________________________________ 106

CAN-DBC file _____________________________________________________________________ 106

CAN bus messages ________________________________________________________________ 106

Table heading definitions ____________________________________________________________ 109

Signals __________________________________________________________________________ 110

Revision history ______________________________________________________________ 128

Drawing list _________________________________________________________________ 129

Page 7

RT User Manual

Revision: 190902

7

Introduction

The RT family of inertial navigation system (INS) devices are instruments for making

precision measurements of motion in real time.

There are three divisions within the RT family – RT500s (v1) RT3000s (v3) and

RT1003s (v1) – and each division has performance options. The RT500 and RT3000

products are covered in this manual. The RT1003 product has its own manual, which

can be downloaded from the OxTS Support Site here.

From September 2019 the RT3000 became v3 with new functionality. v2 devices are

now end of life and include: RT2000s, RT3000s (v2), and RT4000s. The RT1003 is

unchanged.

The “RT-Range Hunter” is a variant of the RT3000 v3 that runs the OxTS RT-Range

processing engine for vehicle-to-vehicle and vehicle-to-lane testing inside the RT

itself. This functionality used to be available from the RT-Range S Hunter accessory

but now runs on board the RT3000 v3 as an optional feature. If you are configuring an

RT-Range S Hunter for ADAS testing then you will need to refer to the RT-Range

user manual – available to download at support.oxts.com.

To obtain high-precision measurements, the RT uses mathematical algorithms

developed for use in fighter aircraft navigation systems. An inertial sensor block with

three accelerometers and three gyros (angular rate sensors) is used to compute all the

outputs. A WGS 84 modelled strapdown navigator algorithm compensates for earth

curvature, rotation and Coriolis accelerations, while measurements from high-grade

kinematic GNSS receivers update the position and velocity navigated by the inertial

sensors. This innovative approach gives the RT several distinct advantages over

systems that only use GNSS:

• The RT has a high (100 Hz, 200 Hz or 250 Hz) update rate and a wide bandwidth.

• The outputs are available with low, 1 ms latency.

• All outputs remain available continuously during GNSS blackouts when, for

example, the vehicle drives under a bridge.

• The RT recognises jumps in GNSS position and ignores them.

• The position and velocity measurements the GNSS makes are smoothed to reduce

the high-frequency noise.

• The RT makes many measurements GNSS cannot, for example acceleration, angular

rate, pitch and roll.

Page 8

8

Oxford Technical Solutions

An RT system processes data in real time. The real-time results are output via an

RS232 serial port, over 10/100 Base-T Ethernet using a UDP broadcast and on CAN

bus. Outputs are time-stamped and refer to GPS time; a 1PPS timing sync can be used

to give accurate timing synchronisation between systems. The inertial measurements

are synchronised to the GPS clock.

Page 9

RT User Manual

Revision: 190902

9

Internal data logging enables the data to be reprocessed post-mission. Data can be

collected in the unit, downloaded using “ftp”, processed on a PC and viewed using the

NAVdisplay.

Easy operation

There is minimal configuration required to use the system. The configuration can be

saved to the RT so it can operate autonomously without user intervention. A lot of work

has been put into the initialisation of the inertial algorithms so the RT can reliably start

to navigate in the vast majority of situations.

The single unit contains inertial sensors, GNSS receiver, data storage and CPU. One or

two antennas need to be mounted outside the vehicle where they have a clear view of the

sky. A 10–50 V dc power supply can be obtained from most vehicles. A laptop computer

allows real-time viewing of the results.

Self-correcting

Unlike conventional inertial navigation systems, the RT uses GNSS to correct all its

measurements. GNSS makes measurements of position, velocity and (for dual antenna

systems) heading. Using these measurements, the RT is able to keep other measurements,

such as roll and pitch, accurate. Tight coupling of the GNSS and inertial measurements

means the raw GNSS data can also be used. There is no drift from the RT in any of the

measurements while GNSS is present.

Interchangeable

The RT500 (v1) and RT3000 (v3) products have identical output capabilities. The serial

port, Ethernet, Wi-Fi and CAN bus are the same on RT500 and RT3000 devices including

the data formats. Each device comes with two user cables which house the connections

needed for data transfer from the RT to other devices e.g. laptop, Data Acquisition

system, LiDAR etc.

Advanced processing

In poor GNSS environments, drift times can be halved by using the combined results of

processing forwards and backwards in time. Our proprietary gx/ix™ processing engine

can further improve performance with single satellite aiding algorithms and tight

coupling of the inertial and GNSS measurements, meaning position updates even with

fewer than four satellites in view.

Page 10

10

Oxford Technical Solutions

Related documents

This manual covers the installation and operation of RT systems, but it is beyond its

scope to provide details on service or repair. Contact OxTS support or your local

representative for customer service related inquiries.

Additional manuals provide further information on some of the software and

communication types mentioned in this manual. Table 1 lists related manuals and where

to find them.

Table 1. Supplementary manuals

Manual

Description

NAVdisplay

Manual

For viewing real-time information from an RT. https://support.oxts.com/hc/en-

us/articles/115002433285-NAVdisplay-Online-manual

NAVgraph

Manual

For plotting and exporting captured data.

https://support.oxts.com/hc/en-us/articles/115002433465-NAVgraph-Online-manual

NCOM

Manual

For decoding and using the NCOM format.

www.oxts.com/Downloads/Support/NCOM Manual and Code

Drivers/ncomman.pdf

NCOM C

Code Drivers

A collection of C functions that can be used to decode the binary protocols from the

RT.

www.oxts.com/Downloads/Support/NCOM Manual and Code Drivers/ncomrx.zip

NMEA 0183

Description

NMEA description manual for the NMEA outputs.

www.oxts.com/Downloads/Support/NMEA/nmeaman.pdf

NAVsolve

Manual

Explains how to use our post-processing application. https://support.oxts.com/hc/en-

us/articles/360000225449-NAVsolve-manual

Page 11

RT User Manual

Revision: 190902

11

RT product family

The RT product family is split into three device types (one of which is the RT1003

which has its own manual, available to download at support.oxts.com). The other two

product device types are:

• RT500s (v1)

Fitted with lower-cost GNSS receivers. The RT500 is a dual antenna model and is

GLONASS enabled. 100 Hz and 250 Hz versions are available. An optional BeiDou

upgrade is available.

• RT3000s (v3)

Survey-grade GNSS receivers provide high-precision position and velocity

measurements even in high multipath environments. Can be GLONASS and BeiDou

enabled. The RT3000 L1 only mode is single antenna only and does not provide RTK

position accuracy. The RT3000 with RTK support is dual antenna. 100 Hz and 250 Hz

versions are available. The RT3000 is also able to run the OxTS RT-Range Hunter

feature codes for ADAS testing.

The options contained within each device type are listed in the “Specification” section

on page 16.

Single antenna

An advanced algorithm in the RT software means most road vehicle customers are able

to use a single antenna system. The Heading lock and Advanced slip features allow RT

devices to maintain an accurate heading while stationary and while driving with low

vehicle dynamics.

Single antenna systems can experience reduced heading accuracy on aircraft, boats or

in low-speed land vehicles.

Dual antenna

Dual antenna systems provide high accuracy heading information and almost constant

heading performance under all conditions.

For aircraft or marine applications, or road vehicle applications on low-friction surfaces

(e.g. ice), a dual antenna system is recommended to maintain high accuracy heading.

Advanced processing in the RT allows relock to occur after five seconds of a skyobstruction – unlike GNSS-only systems which can take several minutes; in this time

the RT’s heading will not have significantly degraded. The fast relock time is made

possible because the RT’s own heading is used to resolve the ambiguities in the GNSS

measurements. Resolution of these ambiguities is what normally takes several minutes.

Page 12

12

Oxford Technical Solutions

The heading software in the RT enables significantly better performance and coverage

compared to GNSS-only solutions.

GLONASS

GLONASS capability adds the ability to utilise the Russian satellite constellation

GLONASS as well as the American constellation GPS. This means an extra 24 satellites

are available for the RT to lock on to and obtain position and velocity updates from.

In open sky conditions, the addition of GLONASS capability is of little benefit as the

GPS signals are unlikely to be interrupted and full accuracy can be achieved almost 100%

of the time. However, in open-road testing situations there are likely to be bridges, trees,

and tall buildings that can block the view of satellites or cause multipath effect errors. In

these situations, GPS and GLONASS receivers are able to maintain 1 cm accurate RTK

positioning mode at times when GPS-only receivers are not. They are also able to reestablish RTK lock and resolve its ambiguities after an obstruction faster.

BeiDou

BeiDou capability adds the ability to utilise the Chinese satellite constellation BeiDou as

well as the American constellation GPS and Russian constellation GLONASS. This

means an extra 34 satellites are available for the RT to lock on to and obtain position and

velocity updates from.

250 Hz

1. All products (including the RT1003) have the option of coming with a 250 Hz version

of the inertial measurement unit (IMU).

Satellite differential corrections

To improve the positioning accuracy of standard GNSS, two satellite-based differential

correction services are available. These are SBAS and TerraStar.

Services such as WAAS and EGNOS, are wide-area differential corrections provided for

free. They can provide an accuracy of better than 1 m CEP. WAAS is available in North

America; EGNOS is available in Europe; MSAS is available in Japan; GAGAN is

available in India; SDCM is available in Russia. Other parts of the world are not covered

and cannot use this service.

TerraStar is a subscription service. RT systems that have TerraStar capability include the

necessary hardware to receive corrections. It is necessary to pay a licence fee to activate these

corrections. Capable RT systems will use the TERRASTAR-D service which can provide better

than 10 cm position accuracy. TerraStar is available on all continents. Marine versions also exist.

For more information, see TerraStar’s website: http://www.terrastar.net.

Page 13

RT User Manual

Revision: 190902

13

Scope of delivery

RT products are supplied complete with users cables, an Ethernet cable and crossover, a

Wi-Fi antenna, software, a calibration certificate, a tape measure, and a quick start guide.

RT500 and RT3000 system components

Table 2 lists all items that are delivered with each standard RT500 and RT3000 model.

Table 2. Summary of RT500 and RT3000 system components

Description

RT500 and RT3000

RT500 or RT3000 unit

Power cable 77C0002B

14P0038 user cable

Aux user cable

Ethernet cable (cross-over)

USB stick with manual and software

Tape measure

Calibration certificate

Quick start guide

The RT3000 product that is RTK capable requires the correct differential corrections in

order to work to full specification. Differential corrections can be supplied by an RTBase S, GPS-Base, NTRIP or other suitable differential correction source.

In addition to the components supplied, the user will require a laptop computer or other

logging system

Page 14

14

Oxford Technical Solutions

Specification

Specifications for RT products can be found in Table 3 and Table 4. These specifications are

listed for operation of the system under the following conditions:

• After a warm-up period of 15 minutes’ continuous operation.

• Open-sky environment, free from cover by trees, bridges, buildings or other

obstructions. The vehicle must have remained in open sky for at least five minutes for

full accuracy.

• The vehicle must exhibit some motion behaviour. Acceleration of the unit in different

directions is required so the Kalman filter can estimate any errors in the sensors.

Without this estimation, some of the specifications degrade.

• The distance from the RT measurement point to the primary GNSS antenna must be

known by the system to a precision of five millimetres or better. The vibration of the

system relative to the vehicle cannot allow this to change by more than five

millimetres. The system will estimate this value itself in dynamic conditions.

• For dual antenna systems, the system must know the relative orientation of the two

antennas to 0.05° or better. The system will estimate this value itself under dynamic

conditions.

• For single antenna systems, the heading accuracy is only achieved under dynamic

conditions. Under benign conditions, such as motorway driving, the performance will

degrade. The performance is undefined when stationary for prolonged periods of time.

Optionally, extended measurement ranges covering 30 g acceleration and 300°/s

angular rate may be requested. The specification using the extended measurement

range sensors can be marginally worse than those listed here.

Page 15

RT User Manual

Revision: 190902

15

Table 3. RT500 and RT3000 specifications

Parameter

RT500 v1

(Dual

antenna)

RT3000 v3

L1 only

(single

antenna)

RT3000 v3

(Dual

antenna)

Positioning

GPS L1

GLONASS

L1

GPS L1

GLONASS

L1

BeiDou L11

GPS L1, L2

GLONASS L1,

L2

BeiDou L1, L21

Position accuracy

2

2.0 m CEP SPS

2.0 m CEP SPS

1.5 m CEP SPS

1.0 m CEP SBAS

1.0 m CEP SBAS

0.6 m CEP SBAS

0.5 m CEP DGPS

0.4 m CEP DGPS

0.4 m CEP DGPS

0.1 m CEP PPP

0.2 m 1 L1

0.01 m 1 L1/L2

Velocity accuracy

0.1 km/h RMS

0.1 km/h RMS

0.05 km/h RMS

Roll/pitch

0.05° 1

0.05° 1

0.03° 1

Heading

0.15° 1

0.15° 1

0.1° 1

Acceleration

– Bias stability

5 μg 1σ

5 μg 1σ

5 μg 1σ

– Linearity

0.01% 1

0.01% 1

0.01%

– Scale factor

0.1% 1

0.1% 1

0.1% 1

– Range

100 m/s

2

100 m/s

2

100 m/s

2

Angular rate

– Bias

0.01°/s 1

0.01°/s 1

0.01°/s 1

– Scale factor

0.1% 1

0.1% 1

0.1% 1

– Range

100°/s

100°/s

100°/s

Track (at 50 km/h)

0.15° 1

0.15° 1

0.07° 1

Slip angle (at

50 km/h)

0.25° 1

0.2° 1

0.15° 1

Lateral velocity

0.5% 1

0.4% 1

0.2% 1

Update rate

100 Hz / 250 Hz

100 Hz / 250 Hz

100 Hz / 250 Hz

Input voltage

4

10–48 V dc

10–48 V dc

10–48 V dc

Power

12 W

14 W

14 W

consumption

Dimensions

184 × 120 × 71 mm

184 × 120 × 71 mm

184 × 120 × 71 mm

Mass

1.5 kg

1.5 kg

1.5 kg

1

Optional upgrade.

2

To achieve specification, relevant differential corrections from a base station, NTRIP or

TerraStar subscription are required.

3

With two-meter antenna separation. Wider separation will improve accuracy (supports up to

five-meter separation).

4

Voltage range of connected devices such as radio modems must be considered.

Page 16

16

Oxford Technical Solutions

Common specifications

Table 4. RT common specifications

Parameter

Specification

Calculation

latency

1 ms

Operating

temperature

1

-40° to 70 °C

Vibration

0.1 g2/Hz 5–500 Hz

Shock survival

100 g, 11 ms

Internal storage

32 GB

Notes on specifications

To achieve full accuracy in real time, the RT products will require appropriate differential

corrections where applicable, either from a base station or with a TerraStar licence.

Alternatively, a RINEX file can be downloaded post-mission and used to post-process

the data to full accuracy.

For the TerraStar service, at least 30 minutes of open-sky condition may be required

before full accuracy is achieved. This service can easily achieve this accuracy in airborne

applications.

The “1” specification has been used for parameters where offset cannot be measured by

the RT, for example position (the offset of the base station cannot be found by the RT

alone). The “RMS” specification was used where the offset is known, for example

velocity. For angles and measurements derived from the angles, the “1” specification is

used because the mounting of the RT compared to the vehicle gives an offset the RT

cannot measure.

The accuracy of the product will depend on the operating mode of the GNSS. For

example, an RT3000 operating without differential corrections enabled will have the

specifications of the RT3000 L1 only.

Heading accuracy

The heading accuracy that can be achieved by the dual antenna system in the RTs in Table

5 is 0.2° 1σ per metre of separation in ideal, open sky conditions. The system can provide

these accuracies in static and dynamic conditions. A four-metre separation is required to

reach the accuracy listed in Table 5. The maximum recommended separation is five

metres, at which it may be possible to achieve better accuracy than that listed if the

structure is rigid, including temperature variation.

Page 17

RT User Manual

Revision: 190902

17

For single antenna systems, the heading is calculated from the inertial measurements.

The accuracies listed in Table 3 are achievable under dynamic conditions. Under static

conditions the heading accuracy of single antenna systems will degrade.

Non-ideal mounting of the GNSS antennas will reduce the heading accuracy,

particularly for dual antenna systems.

Environmental protection

The RT500 and RT3000 products are rated to IP65. To achieve IP65 it is necessary to

have connectors fitted to both TNC antenna connectors and to use self-amalgamating

tape over the TNC connectors.

Export control classification number

Export control regulations change, and so the classification number of the RT may also

change. The information presented here was correct when the manual was published.

RT products can fall under two different export control categories depending on the

type of accelerometer fitted internally. The type of accelerometer does not affect the

specification of the product, only the export control classification number (ECCN).

Table 5 lists the ECCN for the products.

Table 5. ECCN for RT products

Product

Serial number

ECCN

RT500

7A003d

RT3000 v3 L1

Only

Either 7A003d or 7A103a1, see invoice or delivery note

or contact support at OxTS. Some products will have

codes that relate to export control on their labels.

EXCT-1—7A003d

EXCT-2—7A103a1

RT3000

v3

7A003d

Page 18

18

Oxford Technical Solutions

Conformance notices

The RT complies with the radiated emission limits for 47 CFR 15.109:2010 class A of

Part 15 subpart B of the FCC rules, and with the emission and immunity limits for class

A of EN 55022. These limits are designed to provide reasonable protection against

harmful interference in business, commercial and industrial uses. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following:

o Re-orient or relocate the receiving antenna.

o Increase the separation between the equipment and the receiver.

The RT incorporates a GNSS receiver. No GNSS receiver will be able to track satellites

in the presence of strong RF radiations within 70 MHz of either the L1 GPS frequency

(1575 MHz) or L2 1228 MHz.

The RT conforms to the requirements for CE.

Regulator testing standards

RT500 and RT3000 products

o 47 CFR 15.109:2010 class A (radiated emissions).

o EN 61000-4 criterion A according to standard EN 301 489-1:2008 (-2:2009 electrostatic

discharge), (-3:2006+A2:2010 radiated immunity), (-4:2012 electrical fast transients),

(-5:2006 voltage surge) and (-6:2009 conducted radio frequency immunity).

o EN 55022:2010 class A according to standard EN 301 489-1:2008 (Radiated

electromagnetic emissions) and (conducted emissions).

o EN 55011:2009+A1:2010 class A according to standard EN 301 489- 1:2008 (Radiated

electromagnetic emissions).

Page 19

RT User Manual

Revision: 190902

19

Software installation

Included with every RT is a USB stick containing the software package NAVsuite. This

package contains several programs required to take full advantage of the RT’s capabilities.

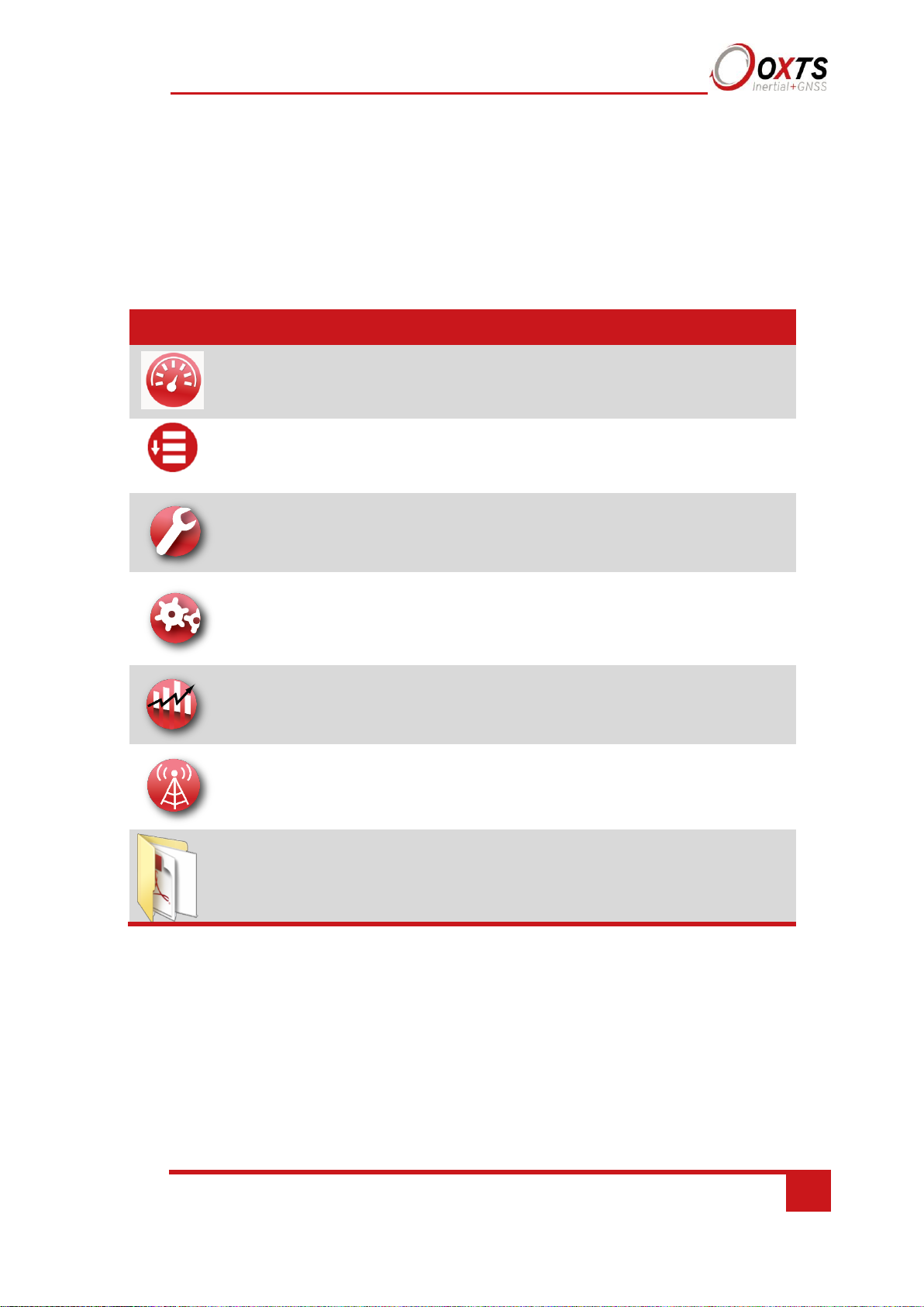

Table 6 lists the contents of NAVsuite.

Table 6. NAVsuite components

Icon

Software

Description

NAVdisplay

Used to view real-time data from OxTS products via

Ethernet or a serial port. It can also be used to transmit

special commands and replay logged data.

NAVstart

A menu from which you can navigate between OxTS

applications. This opens automatically when you are

connected to a unit.

NAVconfig

Used to create, send, and receive configurations from OxTS

products. As configurations vary between products there is

no manual for NAVconfig.

NAVsolve

Used to download raw data files from the RT and postprocess the data. The configuration can be changed and

differential corrections can be applied before the data is

reprocessed. It can export NCOM, XCOM and CSV file

formats.

NAVgraph

Used to graph NCOM, XCOM and RCOM files created in

post-process. It can display graphs, cursor tables and map

plots and data can be exported in CSV or KML (Google

Earth) format.

NAVbase

Used to configure and manage RT-Base S and GPS-Base

base stations, which can be used to achieve RTK integer

level position accuracy.

Manuals

This folder contains PDF versions of relevant OxTS

manuals. Other manuals can be downloaded from the

OxTS website.

To install NAVsuite, insert the USB stick and run NAVsetup.exe. Follow the onscreen

instructions to install the software. By default, the installer creates the program files in

C:\Program Files (x86)\OxTS on 64 bit operating systems or C:\Program Files\OxTS on 32 bit

operating systems.

The first time some OxTS applications are run, a firewall warning message similar to that shown

in Figure 1 may be triggered. This is because the program is attempting to listen for, and

communicate with, OxTS devices on the network. The firewall must be configured to allow

each program to talk on the network, or programs will not work as intended.

Page 20

20

Oxford Technical Solutions

Figure 1. Windows Firewall warning message

Ensure both Private and Public networks are selected to ensure the software can continue functioning

when moving from one type to another.

Page 21

RT User Manual

Revision: 190902

21

Hardware installation

It is essential to install the RT rigidly in the vehicle. The RT should not be able to move

or rotate compared to either GNSS antenna, otherwise the performance will be reduced.

In most circumstances the RT should be mounted directly to the chassis of the vehicle. If

the vehicle experiences high shocks, then vibration mounts may be required.

The RT is compatible with the RT-Strut product from OxTS to provide a quick and secure

vehicle mounting solution.

Do not install the RT where it is in direct sunlight as, in hot countries, this may cause the

case to exceed the maximum temperature specification.

RT orientation and alignment

The orientation of the RT in the vehicle is normally specified using three consecutive

rotations that rotate the RT to the vehicle’s co-ordinate frame. The order of the rotations

is heading (z-axis rotation), then pitch (y-axis rotation), then roll (x-axis rotation). It is

important to get the order of the rotations correct.

In the default configuration the RT expects its y-axis to be pointing right and its z-axis

pointing down relative to the host vehicle. There are times however when installing an

RT in the default configuration is not possible, for example when using the RT-Strut. The

RT can be mounted at any angle in the vehicle as long as the configuration is described

to the RT using NAVconfig. This allows the outputs to be rotated based on the settings

entered to transform the measurements to the vehicle frame.

For ease of use, it is best to try and mount the RT so its axes are aligned with the vehicle

axes. This saves the offsets having to be measured by the user. If the system must be

mounted misaligned with the vehicle and the user cannot accurately measure the angle

offsets, the RT has some functions to measure these offsets itself. The heading offset can

be measured if the vehicle has a non-steered axle. The Improve Configuration wizard in

NAVconfig should be used for this. Roll and pitch offsets can be measured using the

Surface tilt utility in NAVdisplay.

Antenna placement and orientation

For optimal performance it is essential for the GNSS antenna(s) to be mounted where

they have a clear, uninterrupted view of the sky and on a suitable ground plane, such as

the roof of a vehicle. For good multipath rejection the antennas must be mounted on a

metal surface using the magnetic mounts provided; no additional gap may be used.

The antennas cannot be mounted on non-conducting materials or near the edges of

conducting materials. If the antennas are to be mounted with no conductor below them

Page 22

22

Oxford Technical Solutions

then different antennas must be used. It is recommended to mount the antennas at least

30 cm from any edge where possible.

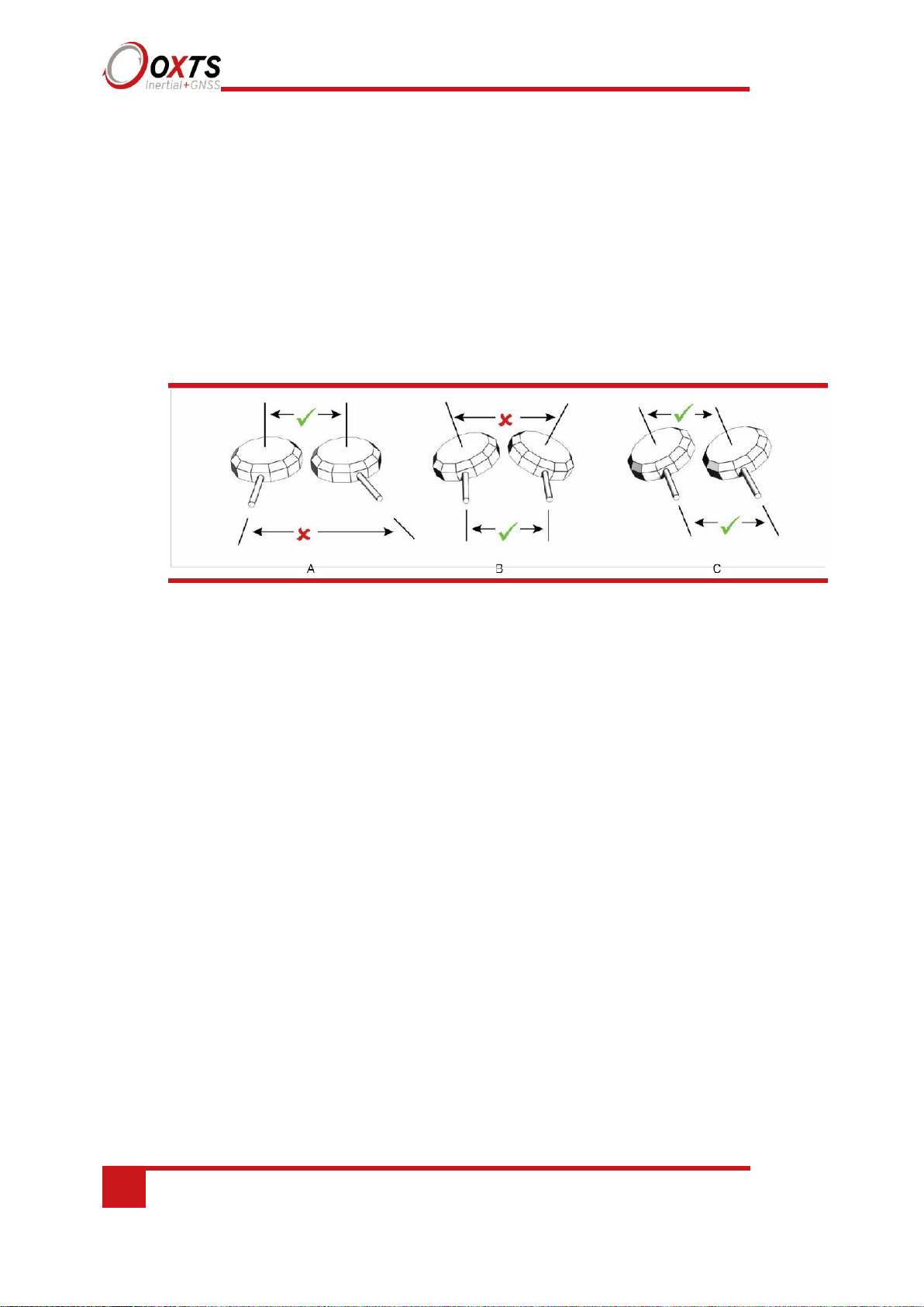

For dual antenna systems, the secondary antenna should be mounted in the same

orientation as the primary antenna, as shown in Figure 2. The antenna baseline should

also be aligned with one of the vehicle axes where possible, either inline or perpendicular

to the vehicle’s forward axis. In the default configuration the primary antenna should be

at the front of the vehicle and the secondary antenna should be at the rear.

Figure 2. Dual antenna orientations

A)

The bases of the antennas are parallel, but the cables exit in different directions. B) The cables

exit in the same direction but the bases of the antennas are not parallel. C) The bases of the antennas are

parallel and the cables exit in the same direction. This configuration will achieve the best results.

It is best to mount the two antennas on the top of the vehicle. Although it is possible to

mount one on the roof and one on the bonnet (hood), the multipath reflections from the

windscreen will degrade the performance of the system.

Multipath affects dual antenna systems on stationary vehicles more than moving vehicles

and it can lead to heading errors of more than 0.5° RMS if the antennas are mounted

poorly.

It is critical to have the RT mounted securely in the vehicle. If the angle of the RT can

change relative to the vehicle, then the dual antenna system will not work correctly. This

is far more critical for dual antenna systems than for single antenna systems. The user

should aim to have no more than 0.05° of mounting angle change throughout the testing.

(If the RT is shock mounted then the RT mounting will change by more than 0.05°; this

is acceptable, but the hysteresis of the mounting may not exceed 0.05°.)

For both single and dual antenna systems it is essential that the supplied GNSS antenna

cables are used and not extended, shortened or replaced. This is even more critical for

dual antenna systems and the two antenna cables must be of the same specification. Do

not, for example, use a 5 m antenna cable for one antenna and a 15 m antenna cable for

the other. Do not extend the cable, even using special GNSS signal repeaters that are

designed to accurately repeat the GNSS signal. Cable length options are available in 5 m

and 15 m lengths.

Page 23

RT User Manual

Revision: 190902

23

Operation

The top label and LEDs convey some basic information that aids configuration and

troubleshooting. Once power is applied, the RT requires no further input from the user to

start logging and outputting data.

This section covers some basic information required for operation of the RT.

Front panel layout

Figure 3 shows the layout of the RT500 and RT3000 front panel. Table 7 lists the parts

of the front panel labelled in Figure 3. For single antenna models, the secondary

antenna connector is not connected internally.

Figure 3. RT500/RT3000 front panel layout

Page 24

24

Oxford Technical Solutions

Table 7. RT3000 v3 RT500 v1 front panel descriptions

1 Power LED

3 GNSS LED

5 Second user cable connector

7 Secondary GNSS antenna connector

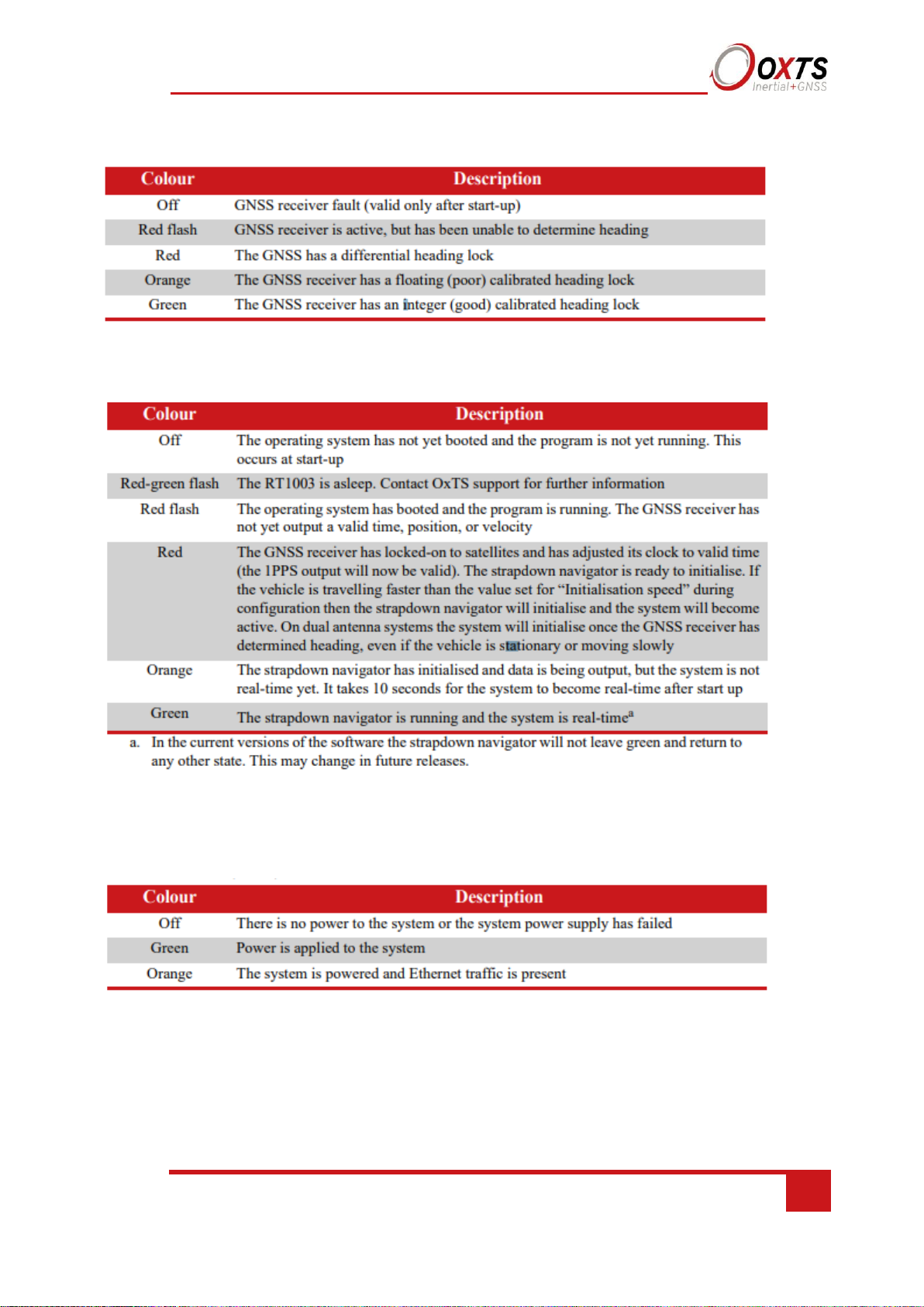

LED definitions

The LEDs on the connector panel provide information about the current system state, but it

is not possible for the LEDs to communicate everything the product is capable of measuring.

Instead, they provide a snapshot of the current status and are useful for at-a-glance checks

without the need for a portable PC. The tables below describe the behaviour of each LED.

Status LED

6 Primary GNSS antenna connector

4 User cable main connector

Label no. Description

8 WI-Fi antenna connector

Page 25

RT User Manual

Revision: 190902

25

Table 8. GNSS LED states

Table 9. Status LED states

Table 10. Power (PWR) states

Page 26

26

Oxford Technical Solutions

Co-ordinate frame conventions

Measurements made by the INS are available in a number of different reference frames

for use in different applications.

IMU frame

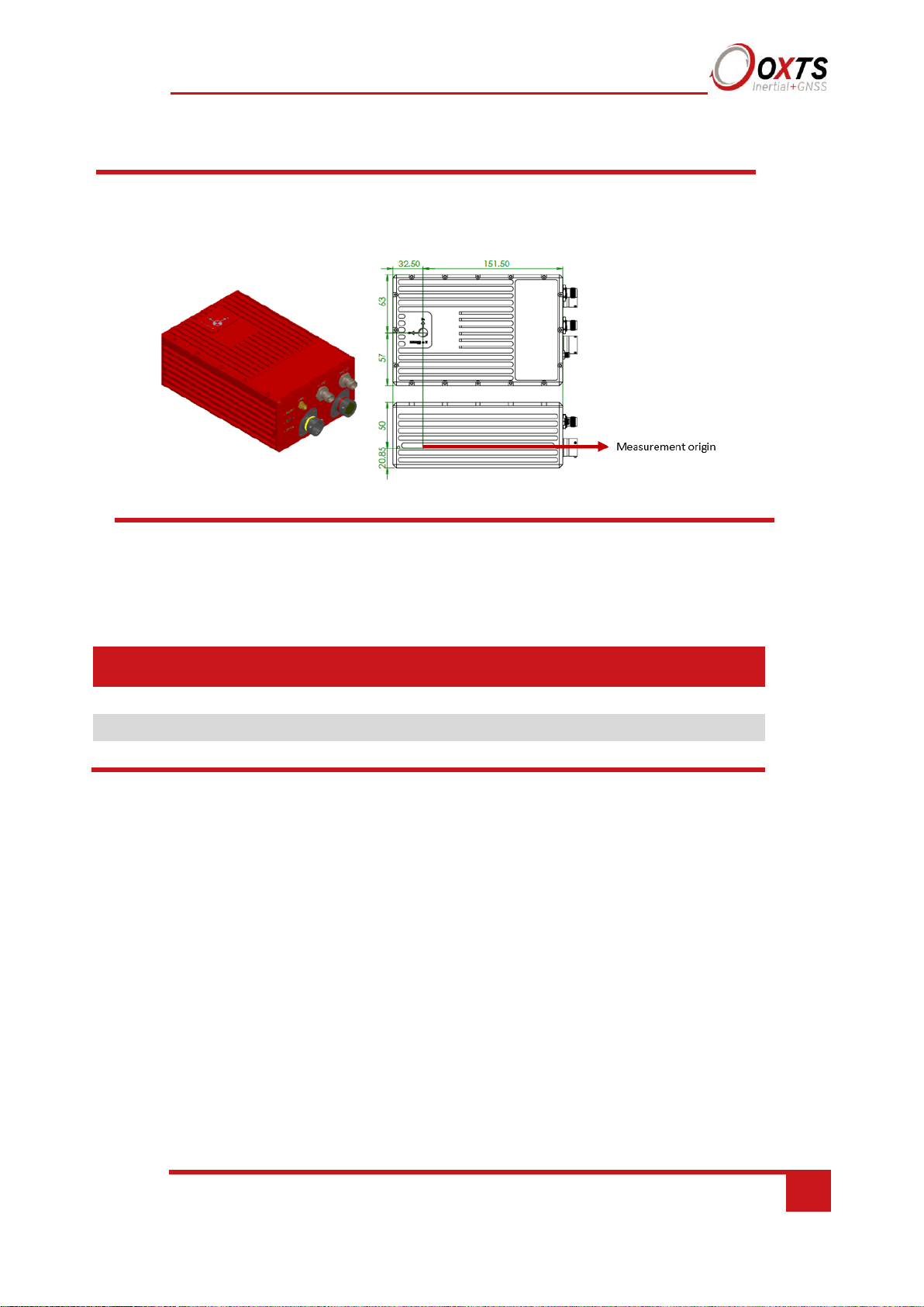

The IMU reference frame used by the RT (shown in Figure 4), is popular with navigation

systems – where the positive X-axis points forwards, the positive Y-axis points right and

the positive Z-axis points down.

When making measurements required in the configuration files, measurements should be

made between the point of interest and the measurement origin shown in Figure 4. The

axes and measurement origin point are the same for all RT models.

Page 27

RT User Manual

Revision: 190902

27

Figure 4. IMU co-ordinate frame and measurement origin

Table 11 lists the directions that the axes should point for zero heading, pitch and roll

outputs when the default mounting orientation is used.

Table 11. Direction of axes for zero heading, pitch and roll outputs

Axis

Direction

Vehicle axis

X North

Forward

Y East

Right

Z Down

Down

Once installed, if the RT axes and the vehicle axes are not the same as those listed in

Table 12, they can be aligned by reconfiguring the RT for a different mounting

orientation using the NAVconfig software.

Page 28

28

Oxford Technical Solutions

If the RT-Strut is being used to mount the RT in the vehicle then NAVconfig will have

to be used to configure the orientation or the RT will not work correctly.

OxTS NED navigation frame

Table 12. OxTS NED navigation frame definition

North The north axis (N) is perpendicular to the gravity vector and in the direction of the

North Pole along the earth’s surface.

Down The down axis (D) is along the gravity vector.

Figure 5. OxTS NED navigation frame definition

The OxTS navigation frame is attached to the vehicle but does not rotate with it. The down axis is

always aligned to the gravity vector and north always points north.

The east axis (E) is perpendicular to gravity, perpendicular to the north axis and is in

the east direction.

East

Axis Description

Page 29

RT User Manual

Revision: 190902

29

ISO 8855 ENU earth-fixed system

Table 13. ISO 8855 ENU earth-fixed system

Axis

Description

East

The east axis (E) is perpendicular to gravity, perpendicular to the north axis and is in

the east direction.

North

The north axis (N) is perpendicular to the gravity vector and in the direction of the

north pole along the earth’s surface.

Up

The up axis (U) is co-axial with the gravity vector, and positive in the up direction.

Figure 6. ISO 8855 ENU earth-fixed system

The ISO earth-fixed system is attached to the vehicle but does not rotate with it. The north and east axes

are perpendicular to the gravity vector and north always points north.

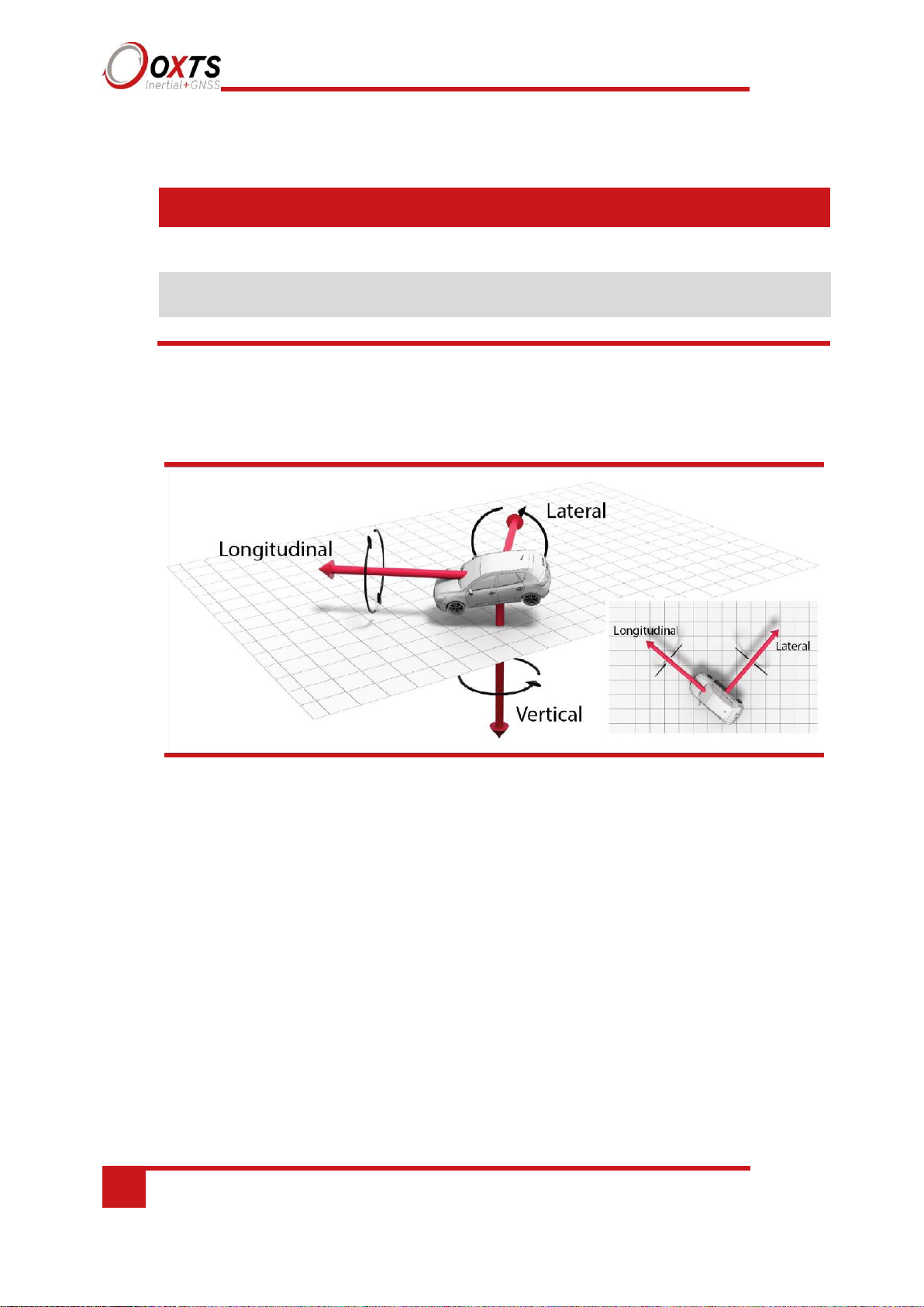

OxTS horizontal frame

The OxTS horizontal frame (sometimes called the level frame) is attached to the vehicle

but does not rotate with the roll and pitch of the vehicle. It rotates by the heading of the

vehicle. The definition of the OxTS Horizontal frame is listed in Table 14 and shown in

Figure 7.

Page 30

30

Oxford Technical Solutions

Table 14. OxTS Horizontal frame definition

Forward This is the longitudinal (forward) direction of the vehicle, projected in to the

horizontal plane.

Down This is the vertical (down) direction of the vehicle, along the gravity vector.

Figure 7. OxTS horizontal frame definition

The OxTS horizontal frame is attached to the vehicle. The longitudinal and lateral axes remain parallel to

a horizontal plane. The longitudinal axis is also parallel to the vehicle’s heading when viewed from above.

ISO 8855 intermediate system

The ISO 8855 intermediate system is attached to the vehicle but the X- and Y-axis both

remain parallel to the ground plane. The X-axis is also aligned with the vertical projection

of the vehicle heading. The definition of the ISO 8855 intermediate system is listed in

Table 15. ISO 8855 intermediate system and shown in Figure 8.

This is the lateral direction of the vehicle, pointing to the right, projected in to the

horizontal plane.

Lateral

Axis Description

Page 31

RT User Manual

Revision: 190902

31

Figure 8. ISO 8855 intermediate system

The ISO intermediate system is attached to the vehicle. The X- and Y-axes remain parallel to a

horizontal plane. The X-axis is also parallel to the vehicle’s heading when viewed from above.

Table 15. ISO 8855 intermediate system

X This is the forward direction of the vehicle, projected into the horizontal plane.

Z This is the vertical direction of the vehicle, pointing up.

OxTS vehicle frame

The OxTS vehicle frame is attached to the body of the vehicle. It is related to the INS

through the rotations in the Orientation page of NAVconfig. It can be changed while the

INS is running using the Quick Config tool of NAVdisplay. The definitions of the vehicle

frame are listed in Table 16 and shown in Figure 9.

Table 16. Vehicle frame definition

Axis

Description

X

This is the forward direction of the car.

Y

This is the right direction of the car.

Z

This is the down direction of the car.

This is the lateral direction of the vehicle, pointing to the left, projected in to the

horizontal plane.

Axis Description

Page 32

32

Oxford Technical Solutions

Figure 9. Vehicle frame definition

The OxTS vehicle frame is attached to the vehicle and rotates with it in all three axes. The X-axis remains

parallel to the vehicle’s heading, while the Y-axis points to the right and is perpendicular to the vehicle’s

vertical plane of symmetry

ISO 8855 vehicle system

The ISO 8855 vehicle system is attached to the body of the vehicle. At rest, the X-axis

points forwards horizontally and is parallel to the vehicle’s longitudinal axis. The Y-axis

is perpendicular to the longitudinal axis and points left. The Z-axis is orthogonal to the

X- and Y-axes. Definitions are listed in Table 17 and shown in Figure 10.

Table 17. ISO 8855 vehicle system

Axis

Description

X

This is the forward direction of the car.

Y

This is the left direction of the car.

Z

This is the up direction of the car.

Page 33

RT User Manual

Revision: 190902

33

Figure 10. ISO 8855 vehicle system

The ISO vehicle frame is attached to the vehicle and rotates with it in all three axes. The X-axis remains

parallel to the vehicle’s heading, while the Y-axis points to the left and is perpendicular to the vehicle’s

vertical plane of symmetry.

Ethernet configuration

To configure the RT for unrestricted data transmission it is necessary to use the Ethernet

connection. The RT 500 and RT3000 v3 also support Wi-Fi data transmission and the

setup of WiFi is covered later in this manual. The operating system at the heart of the RT

products allows connection to the unit via FTP. The use of FTP allows the user to manage

the data logged to the unit; files can be downloaded for reprocessing and deleted to make

space for future files. Configuration files for alternative configurations require FTP to

put the configuration files on to the RT. The default username and password are both

“user”.

The RT outputs its data over Ethernet using a UDP broadcast. The use of a UDP

broadcast allows everyone on the network to receive the data sent by the RT. The data

rate of the UDP broadcast is 100 Hz or 250 Hz.

In order to communicate via Ethernet each RT is configured with a static IP address that

is shown on the delivery note. If the delivery note is unavailable, the default IP address

normally takes the form 195.0.0.sn, where sn is the last two digits of the RT’s serial

number. The serial number can be found on the top of the RT or on the delivery note.

The IP address of the computer being used to communicate with the RT may need to be

changed so it matches the subnet. For example, 195.0.0.200 should be available since

this IP address is never used by the RT by default.

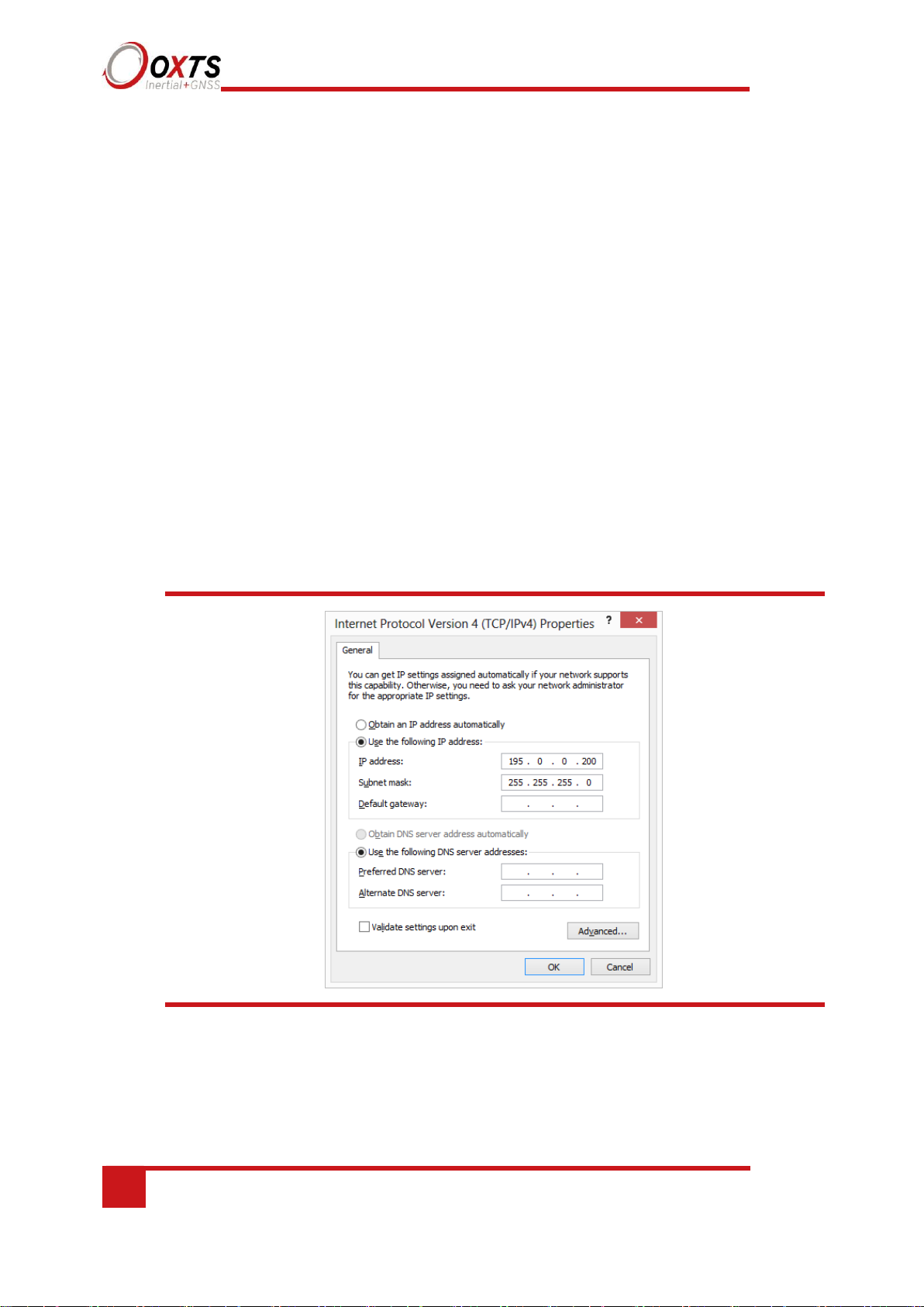

To change the IP address of the computer, follow these steps (applies to Windows

Vista/7/8/10):

Page 34

34

Oxford Technical Solutions

1. Open the ‘Control Panel’ from the Start menu.

2. In category view, select ‘Network and Internet’ and then ‘Network and Sharing

Centre’.

3. Select ‘Change adapter settings’ in the side panel.

4. Right-click the Ethernet option and select ‘Properties’.

5. In the window that opens, navigate the list to find Internet Protocol Version 4

(TCP/IPv4). Select it and click ‘Properties’.

6. In the TCP/IPv4 Properties window (Figure 11), select ‘Use the following IP

address’ and enter the IP address and subnet mask to use.

7. Click ‘OK’ when finished.

Figure 11. Configuring the computer’s IP address for Ethernet data

transmission

Once the computer is configured the IP address of an RT can be found by running

NAVdisplay software; this will display the IP address of any RT connected.

Note that it is possible to change the IP address of RT systems. If the IP address has been

changed then NAVdisplay should still be able to identify the address that the RT is using,

as long as the PC has a valid IP address and this is not the same as the RT’s.

Page 35

RT User Manual

Revision: 190902

35

Connection details for Ethernet configuration

The RJ-45 connector on the 14C0038x user cable is designed to be connected directly to

a network hub. To extend the cable it is necessary to use an in-line coupler. This is two

RJ-45 sockets wired together in a straight-through configuration. Following the in-line

coupler, a normal, straight UDP Cat 5e cable can be used to connect the coupler to the

hub.

The RT can be connected directly to an Ethernet card in a computer. To do this a crossed

in-line coupler must be used. The connections in the crossed coupler are given in Table

18. Note that this is not the normal configuration sold and it may be necessary to modify

an existing coupler to suit.

Table 18. In-line coupler connections

Socket 1

Straight socket 2

Crossed socket 2

Pin 1

Pin 1

Pin 6

Pin 2

Pin 2

Pin 3

Pin 3

Pin 3

Pin 2

Pin 4

Pin 4

–

Pin 5

Pin 5

–

Pin 6

Pin 6

Pin 1

Pin 7

Pin 7

–

Pin 8

Pin 8

–

A typical in-line coupler is shown in Figure 12.

Figure 12. In-line RJ-45 coupler

Page 36

36

Oxford Technical Solutions

Wi-Fi configuration

The RT can be configured via a Wi-Fi connection using the Wi-Fi access point inside the

RT itself. Like Ethernet, the use of FTP via a Wi-Fi connection allows the user to manage

the data logged to the unit; files can be downloaded for reprocessing and deleted to make

space for future files. Configuration files for alternative configurations require FTP to put

the configuration files on to the RT.

The RT outputs its data over Wi-Fi to each device connected to its access point as a UDP

unicast message.

In order to communicate via Wi-Fi, each RT is configured with a static IP address that is

shown on the delivery note. If the delivery note is unavailable, the default IP address

normally takes the form 195.0.0.sn, where sn is the last two digits of the RT’s serial

number. The serial number can be found on the front panel of the RT or on the delivery

note.

Once you are on the same IP range as the RT you can connect to the RT via

Wi-Fi. Via your PC’s network settings you should be able to select the ‘RT as

a Wi-Fi network’. The RT that you wish to connect to can be identified by its

serial number. See Fig 14 below.

Page 37

RT User Manual

Revision: 190902

37

Figure 13. Connect to the Wi-Fi module in the RT

Wi-Fi settings are configured using NAVconfig and this process is explained

later in this manual.

Page 38

38

Oxford Technical Solutions

Dual antenna systems

It is often useful to have an understanding of how the RT uses the measurements from the dual

antenna system. This can lead to improvements in the results obtained.

1.

To use the measurements properly the RT needs to know the angle of the GNSS antennas

compared to the angle of the RT. This is very difficult to measure accurately without

specialised equipment, therefore the RT needs to measure this itself as part of the warmup process.

2.

The RT will lock on to satellites, but it cannot estimate heading so it cannot start. Either

motion or static initialisation can be used to initialise the RT.

3.

When the vehicle drives forward and reaches the initialisation speed, the RT assumes that

the heading and track are similar and initialises heading to track angle.

If the RT is mounted in the vehicle with a large heading offset then the initial value of

heading will be incorrect. This can also happen if the RT is initialised in a turn. This can

lead to problems later.

4.

When the combined accuracy of heading plus the orientation accuracy figure for the

secondary antenna is sufficiently accurate then the RT will solve the RTK Integer problem

using the inertial heading. There is no need for the RT to solve the RTK Integer problem

by searching.

If the antenna angle is offset from the RT by a lot then the RTK Integer solution that is

solved will be incorrect. For a 2 m antenna separation the RT orientation and the secondary

antenna orientation should be known to within 5°. For wider separations the secondary

antenna orientation angle needs to be more accurate.

5.

Once the RTK Integer solution is available, the RT can start to use the dual antenna solution

to improve heading. The level of correction that can be applied depends on how accurately

the angle of the secondary antenna is known compared to the inertial sensors.

6.

The Kalman filter tries to estimate the angle between the inertial sensors and the secondary

antenna. The default value used in the configuration software (5°) is not accurate enough

so that the RT can improve the heading using this value. If you want the vehicle heading

to 0.1°, but the angle of the two GNSS antennas is only known to 5°, then the measurements

from the antenna are not going to be able to improve the heading of the vehicle.

Driving a normal warm-up, with stops, starts and turns, helps the Kalman filter improve

the accuracy of the secondary antenna angle. The accuracy of this angle is available in the

verified in NAVdisplay.

Page 39

RT User Manual

Revision: 190902

39

7.

In the unlikely event that the RTK Integer solution is incorrect at the start then the

Kalman filter can update the secondary antenna orientation incorrectly. If this

happens then things start to go wrong. The Kalman filter becomes more convinced

that it is correct, so it resolves faster, but it always solves incorrectly. Solving

incorrectly makes the situation worse.

To avoid the Kalman filter from getting things wrong it is possible to drive a

calibration run, then use the Improve configuration wizard within NAVconfig. This

tells the Kalman filter it has already estimated the angle of the secondary antenna in

the past and it will be much less likely to get it wrong or change it. This step should

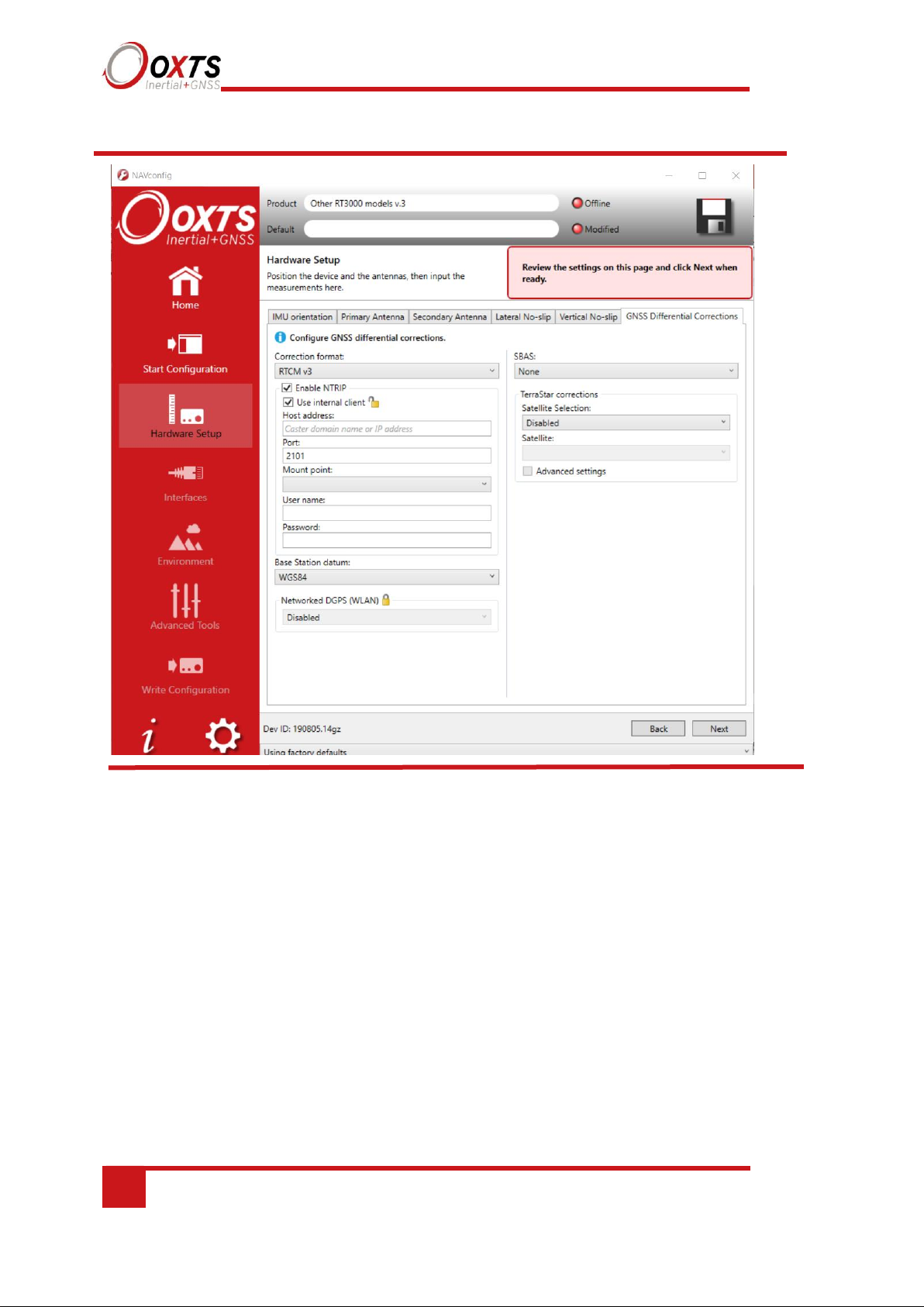

only be done if the RT is permanently mounted in a vehicle and the antennas are

bolted on. Any movement of either the RT or the antennas will upset the algorithms.

Multipath effects on dual antenna systems

Dual antenna systems are very susceptible to the errors caused by multipath. This can

be from buildings, trees, roof-bars, etc. Multipath is where the signal from the satellite

has a direct path and one or more reflected paths. Because the reflected paths are not

the same length as the direct path, the GNSS receiver cannot track the satellite signal

as accurately.

The dual antenna system in the RT works by comparing the carrier-phase

measurements at the two antennas. This tells the system the relative distance between

the two antennas and which way they are pointing (the heading). For the heading to be

accurate the GNSS receivers must measure the relative position to about 3 mm. The

level of accuracy can only be achieved if there is little or no multipath.

In an ideal environment, with no surrounding buildings, trees, road signs or other

reflective surfaces, the only multipath received is from the vehicle’s roof. The antennas

supplied with the RT are designed to minimise multipath from the vehicle’s roof when

the roof is made of metal. For use on non-metallic roofs a different type of antenna is

required.

When stationary the heading from the RT will show some error; the size of the error

depends on the multipath in the environment. Table 19 lists the errors to be expected

when stationary with a 1 m base-line.

Page 40

40

Oxford Technical Solutions

Table 19. Typical heading error for when stationary in different environments

Environment

Typical error (3σ)

Complete open-sky

0.6° (0.2° 1σ)

Near trees, buildings

1°

Next to trees, buildings

2°

Typical figures using a 1 m base-line. For accuracy specification of 0.1° RMS a 2 m separation is required.

Using a 2 m base-line can halve the figures shown here.

Page 41

RT User Manual

Revision: 190902

41

Inputs and outputs

RTs have two connectors for their inputs and outputs. The J1 connector of the 14C0038

user cable connects to the primary user cable and connectors J2–J7 provide connections

for the inputs and outputs. The J1 connector on the Aux user cable (secondary) provides

three additional inputs and outputs. See the user cable drawings located at the back of

this manual for more details on the connectors and pin assignments. The main connectors

are keyed so the user cable must be correctly aligned for it to connect.

The system can output data on the serial port, over Ethernet and over CAN bus. The

standard serial output of the RT is a proprietary binary format, referred to as NCOM.

OxTS offers C and C++ code that will interpret the packet. This can be used freely in

users’ programs to interpret the output of the RT. More information about NCOM can

be found in the NCOM description manual.

It is also possible to output a standard NMEA string from the RT to mimic the output of

standard GNSS receivers.

OxTS offers a service to tailor the serial output format to the customer’s specification.

Contact Oxford Technical Solutions for details of this service

Page 42

42

Oxford Technical Solutions

Digital inputs and outputs

Table 20 describes each of the signals on the digital I/O connector J5 of the 14C0038X

user cable. A more detailed explanation of each signal can be found below.

Table 20. Digital I/O signals

1PPS output

The 1PPS (J5-1) output is a pulse generated by the GNSS receiver. The output is active even

when the GNSS receiver has no valid position measurement. The falling edge of the pulse is

the exact transition from one second to the next in GPS time. The pulse is low for 1 ms, then

high for 999 ms and repeats every second. The output is a low-voltage CMOS output, with

0.8 V or less representing a low and 2.4 V or more representing a high. No more than 10 mA

should be drawn from this output.

Figure 14. 1PPS waveform

Page 43

RT User Manual

Revision: 190902

43

Trigger 1 and 2

Trigger 1 (J5-2) and Trigger 2 (J5-4) can be used to generate events within the RT for

purposes of identifying external events, or to output a time/distance-based signal for the

purpose of driving external events. Both Triggers are independently configurable in the

Options page of NAVconfig.

In input mode, the trigger waits for a signal from an external device such as a camera or

switch. When a signal is detected, a time-stamped measurement is generated by the INS in

addition to the normal measurements being generated. The trigger inputs have a pull-up

resistor so they can be used with a switch or as a CMOS input.

Input signal characteristics:

• 0 V and 5 V input

• low < 0.6 V

• high > 2.6 V

In output mode, the trigger generates pulses based on distance or in synchronisation with the

IMU clock rate. The pulse width of the distance-based signal is 1 ms, whereas the IMU sync

signal has a duty cycle of approximately 50%.

Output signal characteristics:

• 0 V and 5 V output

• low <= 0.8 V

• high >= 2.4 V

Camera mode is a software condition that is automatically entered when the PPM distance

output is configured as less than 1 PPM. It exists in order to generate time-stamped INS

measurements synchronised with distance-based output triggers. The output is called camera

mode as it’s often used to trigger image recording equipment, which can then be matched to

the position measurements at the precise moment of the trigger. Camera mode provides a

method of achieving this.

To enter camera mode, configure a trigger as an output, and set the distance to less than one

pulse per metre. A signal will be generated according to the specifications above at the

distance interval defined by the PPM settings. At the same moment the trigger signal is

output, a position measurement will be internally generated and logged alongside

the regular measurement data. To generate a real-time message in relation to the

camera trigger, it is necessary to select the ‘Output on camera trigger option’ on

the Ethernet configuration window.

Page 44

44

Oxford Technical Solutions

Wheel speed input

The wheel speed 1A input (J5-3) accepts TTL pulses from an encoder on a single wheel.

An encoder from a gearbox should not be used, and simulated TTL pulses (e.g. converted

from the CAN bus) should not be used either. The timing of the wheel speed input pulses

is critical and nothing should cause any delay to them.

The RT also accepts signals from quadrature wheel speed sensors. When using quadrature

sensors, connect one channel from the quadrature sensor to wheel speed 1A, and the other

to wheel speed 1B input (J5-5). The odometer input should be configured as per a normal

wheel speed sensor – the RT will automatically detect the use of the quadrature sensor.

The wheel speed input requires less than 0.8 V for a low pulse and more than 2.4 V for a

high pulse. Limited protection is provided on this port, however the input voltage should

not exceed 12 V.

Wheel speed input signal characteristics:

• 0 V to 12 V

• low < 0.8 V

• high > 2.4 V

The wheel that is used should not steer the vehicle. The RT will assume the wheel travels

straight.

IMU sync output pulse

The synchronising edge of the PPS is configurable in NAVconfig.

Page 45

RT User Manual

Revision: 190902

45

Configuring the RT

To obtain the best results from your RT it will be necessary to configure the RT to suit

the installation and application before using it. The program NAVconfig can be used to

do this. This section describes how to use NAVconfig and gives additional explanations

on the meanings of some of the terms used.

It is only possible to change the RT configuration using Ethernet or WiFi. It is necessary

to have the Ethernet and Wi-Fi adaptor settings on your computer configured correctly

in order to communicate with the RT and change the settings. See the sections “Ethernet

configuration” and “WiFi configuration” on pages 36 and 37 for

more information.

Overview

In order to give the best possible performance, the RT needs to know the following

things:

• The orientation of the RT as it is mounted in the vehicle.

• The position of the primary GNSS antenna compared to the RT.

• The orientation of dual antennas (if applicable) compared to the RT.

• The position of the rear wheels (or non-steering wheels) compared to the RT.

• Some environment parameters.

The RT can work out many of these parameters by itself, but this takes time. Measuring

the parameters yourself and configuring the RT reduces the time taken to achieve full

specification.

RT products can calculate the position of the GNSS antenna. This works well when using

a base station to achieve 1 cm accuracy, but can take hours with less accurate positioning

modes. It is best to measure the position of the GNSS antenna to an accuracy of 10 cm

or better.

If the RT has been running for some time, it will have improved the measurements. It is

possible to read these improved measurements into NAVconfig, commit them to the RT,

then use them next time you start the system. If you move the RT from one vehicle to

another it is essential you create a new configuration rather than using parameters that

have been tuned for a different vehicle.

Page 46

46

Oxford Technical Solutions

Working through NAVconfig

NAVconfig is split into seven sections. Each section contains several tabs with settings

that can be applied to the device. The sections are: Home, Ready Configuration,

Hardware Setup, Interfaces, Environment, Advanced Tools and Write Configuration.

When a device is connected via WiFi or Ethernet, the product name (including serial

number) will be displayed at the top of the application. By clicking on the ‘Save’ icon at

the top right of the application you can save your configuration process to a destination

on your computer. This can be done at any stage.

NAVconfig supports English and Chinese (simplified) languages.. You can switch

language in NAVconfig by clicking on the ‘Settings’ button at the bottom left of the

window and choosing your preferred language from the options.

If you are connected to a device or editing a configuration file from an RD file then it is

possible to view information related to the device in NAVconfig. Click the ‘i’ icon in the

bottom left of the window to see a list of features related to your device.

NAVconfig Home section in NAVconfig

NAVconfig is a universal tool that is used to configure many different devices. The first

step is to choose whether you are starting a new configuration, modifying an existing

configuration or improving a configuration after a device warm-up.

When you select ‘New configuration’ you must then go through each step of the

configuration wizard in order before committing a new configuration to the device.

When you select ‘Modify configuration’ you can jump in and edit the configuration,

navigating through all the options in any order before committing the changes.

Selecting “Improve configuration” sets up a different workflow within NAVconfig for

users who have completed a device warm-up and want to apply improved settings to the

device and recommit these settings.

Page 47

RT User Manual

Revision: 190902

47

Figure 15. NAVconfig Home section

Start/Read Configuration section in NAVconfig

Figure 16. NAVconfig Start/Read Configuration section

Page 48

48

Oxford Technical Solutions

This section becomes available when you choose “New configuration” or “Modify

configuration” from the Home section. It is important to ensure the correct Product type

and version is selected. The settings available in NAVconfig vary depending on the

product type and version chosen.

The product model and generation (version) can be found on the label on your product.

Read Configuration section

The Read Configuration choice tells NAVconfig where to read the initial configuration

from (see Figure 18).

Figure 17. NAVconfig Read Configuration section

Read settings from a folder: It is possible to store a configuration in a folder. The

configuration comprises several files, so it is tidier to keep it in a folder by itself. To read

the configuration from a folder, select this option and then specify a folder by clicking

the ‘Browse…’ button.

Page 49

RT User Manual

Revision: 190902

49

‘Read settings from a raw data (RD) file:’ The RT writes the configuration it is using to

the internally stored RD file. This option extracts the configuration used and loads it into

the configuration wizard. Specify an RD file by clicking the ‘Browse’… button.

Read initial settings from device: If the RT is connected to the computer via Ethernet or

WiFi it is possible to read the initial settings directly from the RT. The settings loaded are

the settings that were last committed to the RT using NAVconfig or the factory default

settings applied at manufacture stage. Select this option and enter the correct IP address of

your RT or select it from the dropdown list.

You must also specify the type of vehicle that the device is being installed in. This will

tailor the settings available to edit in NAVconfig.

Hardware Setup section in NAVconfig

This section contains settings related to the position and orientation of the RT in the vehicle

and the GNSS antennas as well as the profile of the vehicle in which the RT is being

installed (position of axles). It is broken up into tabs and it is recommended that you work

through each tab in order.

IMU orientation tab

The IMU orientation tab is used to define the vehicle co-ordinate frame relative to the

RT’s co-ordinate frame. It is important to get the orientation correct as although settings

entered on this page do not affect the accuracy of the RT, if the outputs are not properly

rotated to the vehicle frame then the measurements will appear incorrect.

When using an RT-Strut, the orientation will need to be changed. Figure 19 shows an RT

mounted on an RT-Strut in a vehicle. In this configuration, the y-axis points left and the

z-axis points forwards. Other configurations are possible with the RT-Strut.

Page 50

50

Oxford Technical Solutions

Figure 18. An RT device mounted on our RT-Strut

Use the Y axis points and the Z axis points box to specify which way the RT’s axes point

in the vehicle. Figure 4 shows the RT axes’ directions. The IMU orientation tab of the

configuration wizard, also has illustrations to visualise the orientation of the RT in a vehicle

based on the settings input. The advanced settings will change to show the three rotations

associated with orientation input, even when unavailable.

Page 51

RT User Manual

Revision: 190902

51

Figure 19. NAVconfig IMU orientation tab in the Hardware Setup section

For correct initialisation, it is necessary to get the heading orientation correct.

The RT gets its initial heading by assuming the vehicle is travelling forwards in

a straight line. If the definition of the vehicle’s x-axis (forward direction) is

incorrect in the RT then it will not initialise correctly when the vehicle drives

forwards.

If the vehicle level option is used, then the pitch and roll orientations must also

be correct.

To make small adjustments, select the ‘Specify exact angles’ checkbox to enable

the rotations for editing. This allows any slip angle, pitch or roll offsets to be

zeroed.

Primary antenna tab

The RT can calculate the position of the primary antenna itself. However, this takes time

and better results can be achieved sooner if the user measures the distance accurately.

Getting these measurements wrong is one of the main reasons for poor results from the

RT, so it is important to be careful. It is recommended to measure the GNSS antenna

position to an accuracy of 10 cm or better. Figure 21 shows the Primary Antenna page.

Page 52

52

Oxford Technical Solutions

Figure 20. NAVconfig Primary Antenna tab

It is necessary to tell the RT the distance between its measurement origin (shown in Figure

4) and the GNSS antenna’s measurement point. This should be entered in the vehicle’s

co-ordinate frame.

The RT will try to improve the position of the primary GNSS antenna during use. To use

the values the RT has estimated use the “Improve configuration” wizard after your warmup on the Orientation utility page.

Page 53

RT User Manual

Revision: 190902

53

Secondary Antenna tab

If your system has two antennas, click the ‘Secondary GNSS antenna’ checkbox on the

Secondary Antenna page (Figure 22) to allow the configuration to be entered. If it is not

enabled, the RT will ignore the secondary antenna and will not use it to compute a

heading solution.

Enter the antenna separation and select to position of the secondary antenna relative to

the primary antenna from the dropdown list. The illustrations will change according to

the settings you choose to help visualise the configuration of the antennas.

Figure 21. NAVconfig Secondary Antenna tab in the Hardware Setup section

Page 54

54