PRM-8

™

PAGE ROUTING MODULE

Installation

&

Operation

Manual

TABLE OF CONTENTS

PRM-8 INTRODUCTION .................................................................................................................. 1

PRM-8 CALLOUTS .......................................................................................................................... 2

PRM-8 BLOCK DIAGRAM ................................................................................................................ 3

PRM-8 SET-UP ................................................................................................................................ 4

PRM-8 SET-UP (CONTINUED) ......................................................................................................... 5

PRM-8 CONNECTIONS ................................................................................................................... 6

PRM-8 CONNECTIONS (CONTINUED) ............................................................................................. 7

PRM-8 PROGRAMMING .................................................................................................................. 8

PRM-8 PROGRAMMING (CONTINUED)............................................................................................ 9

PRM-8 PROGRAMMING (CONTINUED)........................................................................................... 10

TYPICAL PAGING CONTROL PANEL ............................................................................................... 11

PRM-8 SET-UP NOTES ................................................................................................................... 12

PRM-8 SPECIFICATIONS ............................................................................................................... 13

OXMOOR FACTORY SERVICE ......................................................................................................... 14

OXMOOR TWO YEAR LIMITED WARRANTY ..................................................................................... 14

CONTACT OXMOOR ....................................................................................................................... 14

PRM-8 INTRODUCTION

•Multi-channel zone-page feature

• All-page capability

• Eight program channels

•Mic/line selectable page input

• Second line-level page input

• Individual channel page-level controls

• Adjustable program ducking

• Individual channel ramp-up/down adjustments

• Zone selection control by momentary or maintained closure

• PA-422 serial control capability

• Provision for real-time LED tally indicators

• Removable terminal blocks for easy wiring

The eight-channel PRM-8 Page Routing Module simplifies page routing within multiple-zone sound systems.

Page inputs are easily routed to any one, or any combination, of the module’s eight program channels.

Upon initiation of a page, program audio at each selected channel is automatically faded to a user-determined level and mixed with the page signal. Upon

completion of a page the program audio on each channel is ramped smoothly back to its original level.

Each of the two PRM-8 page inputs may function as a

Zone Page and/or an All Page input as determined by

internal dip switches. An input assigned the All Page

function takes priority over the Zone Page input.

Accessed through the control port, the Zone Page Enable control routes the zone page input to the selected

program channels. During this page, the program audio

of each selected channel is ducked as determined by the

Duck Level.

Similarly, the All Page Enable control routes the All

Page input to all program channels. During this page,

the program audio of all channels is ducked as determined by the Duck Level.

to its original level upon completion of a page. Page

Level gain controls provide independent page level settings for each program channel.

Controls on the rear of the PRM-8 include a "Mic, Line"

switch for configuring the page Mic/Line input to accept

either a microphone source or a line-level source and

screwdriver-adjustable attenuators for both page inputs.

A Control Port allows the use of contact closures, momentary or maintained (user selectable), for zone page

selection and zone page clear. Zone page enable and all

page enable always require a maintained closure. DC

power is also present for adding LED tally indicators for

all control functions.

The PRM-8 is ideally suited to solving the complex

patching requirements of paging within room combining

systems. When linked to Oxmoor’s MCS Room Combining System through PA-422 ports, the Page Module

tracks room combining changes. As a result, a page

routed to one channel within a combined group will go

to all channels in the group. Besides allowing communication between the PRM-8 and the MCS-Mainframe, the

PA-422 ports make possible the utilization of an alternative controller.

In some installations it is desirable to prevent the All

Page signal from being heard in certain zones. An All

Page Source dip switch removes the All Page source

from selected channels during an All Page function. All

channels will continue to duck and ramp the program

source during an All Page.

Screwdriver-adjustable controls on the front panel of the

compact, 1U chassis include Duck Level for setting the

level to which program audio is attenuated during a

Zone Page and All Page. Fade In adjusts the time required for the program audio to reach the duck level

upon initiation of a page. Fade Out adjustment determines the time required for the program audio to return

All PRM-8 audio inputs and outputs are electronically

balanced and accommodate either balanced or unbalanced lines. Terminal block connectors insure easy installation and solid mechanical connection for the eight

program channel inputs and outputs as well as the linelevel page input. The page Mic/Line connection is

through a standard female XLR-type connector.

The PRM-8 Page Module brings simplicity to system design, installation and operation, along with the uncompromising performance and reliability for which

Oxmoor products are well known and respected.

Page 1

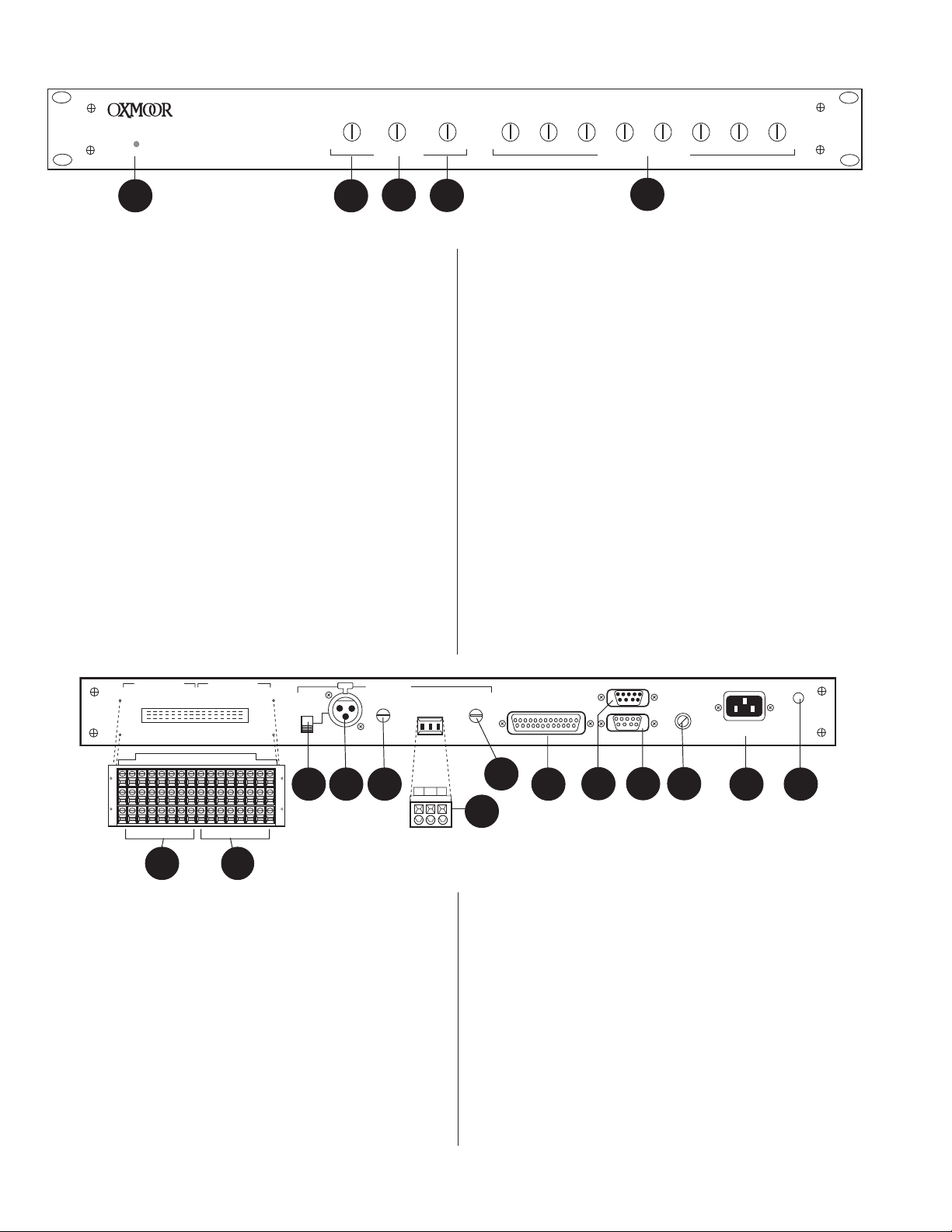

PRM-8 CALLOUTS

PRM-8 PAGE ROUTING MODULE

POWER

1

LEVEL FADE IN FADE OUT

0-80 0 5 0 5

DUCK

2

3

Figure 1.0: Front Panel View

1. POWER STATUS LED - Indicator for AC Power On.

2. DUCK LEVEL - Duck level control pot, accessed through the

front panel with a small flat-blade screwdriver, adjusts the

level to which program material is attenuated during a

page. Range is from 0 (no ducking) to -80 dB.

3. FADE IN - Accessed through the front panel with a small

flat-blade screwdriver, sets the time required, during a

page, for the program material to be attenuated to the

level established by the DUCK LEVEL control.

4. FADE OUT - Accessed through the front panel with a small

flat-blade screwdriver, sets the time required for the

program material to return to its prior level upon

cessation of a page.

5. PAGE LEVEL - Accessed through the front panel with a

small flat-blade screwdriver, these attenuators adjust

page level, from 0 to -80 dB, in each zone individually.

6. PROGRAM OUTPUTS - Audio outputs, terminal block

connections with mating connector, electronically

balanced, accommodate balanced or unbalanced lines.

Recommended load impedance is 600 ohms or greater.

Maximum output level is +24 dBu.

CH1 CH 2 CH 3 CH 4 CH 5 CH 6 CH 7 CH 8

-800-800-800-800-800-800-800-80

4

PAGE LEVEL

5

10. MIC/LINE LEVEL - Accessed through the back panel with a

small flat-blade screwdriver, adjusts the MIC/LINE input

for varying input signal levels.

11. LINE IN - Page input, terminal block connections with

mating connector, electronically balanced input, accepts

balanced or unbalanced signals from line-level devices.

Normal input level is +4 dBu with a maximum input level

of +24 dBu.

12. LINE LEVEL - Accessed through the back panel with a small

flat-blade screwdriver, adjusts the LINE input for varying

input signal levels.

13. CONTROL PORT - Female, 25-pin, standard D-sub connector.

Provides connections for external switching of: Zones for

zone paging, Zone Page Enable, All Page Enable, and Zone

Page Clear. Also provides tally connections for all control

functions.

14. PA-422 IN - Male, 9-pin D-sub connector. This port

connects to the PA-422 OUT of the MCS-MCP Master

Control Panel, an MCS-IB Interface Box or other PA-422

control devices.

0

PROGRAM OUTPUTS

8765432187654321

+

–

S

6

PROGRAM INPUTS

7

LINE

MIC

8

PUSH

MIC/LINE

9 10

PAGE INPUTS

LEVEL

+–

Figure 1.1: Rear Panel View

7. PROGRAM INPUTS - Audio inputs, terminal block

connections with mating connector, electronically balanced,

accept balanced or unbalanced signals from line-level

devices. Normal input level is +4 dBu with a maximum input

level of +24 dBu.

8. MIC, LINE - Switch configures the MIC/LINE input to

accept either a microphone-level or a line-level source.

9. MIC/LINE - Page input, XLR-F type, Pin 2 positive,

electronically balanced, accepts balanced or unbalanced

signals. Normal input level is dependent on the MIC,

LINE switch setting. Microphone input level is -50 dBu

with a maximum input level of -20 dBu. Line input level

is +4 dBu with a maximum input level of +24 dBu.

OXMOOR

MADE IN USA BY

OXMOOR CORPORATION

12

BIRMINGHAM, ALABAMA

CONTROL PORT

13

LINEMIC/LINE

LINE

LEVEL

S

14

PA-422 IN

PA-422 OUT

15

FUSE

16

POWER

17

CHASSIS

SERIAL #

18

11

15. PA-422 OUT - Female, 9-pin D-sub connector. It is used to

carry the PA-422 data to the next PA-422 device.

16. FUSE HOLDER - Replace only with approved type of fuse

in a rating appropriate to the mains voltage, as indicated

on back panel. (See SPECIFICATIONS).

17. POWER CONNECTOR - Standard IEC 3-pin connector for

AC power cord. Use only with grounded (3-wire) outlets.

Cord sets are available for all world connection

standards.

18. CHASSIS GROUND POST - A screw with a star washer

enables the installer to secure a ground wire to the

chassis.

Page 2

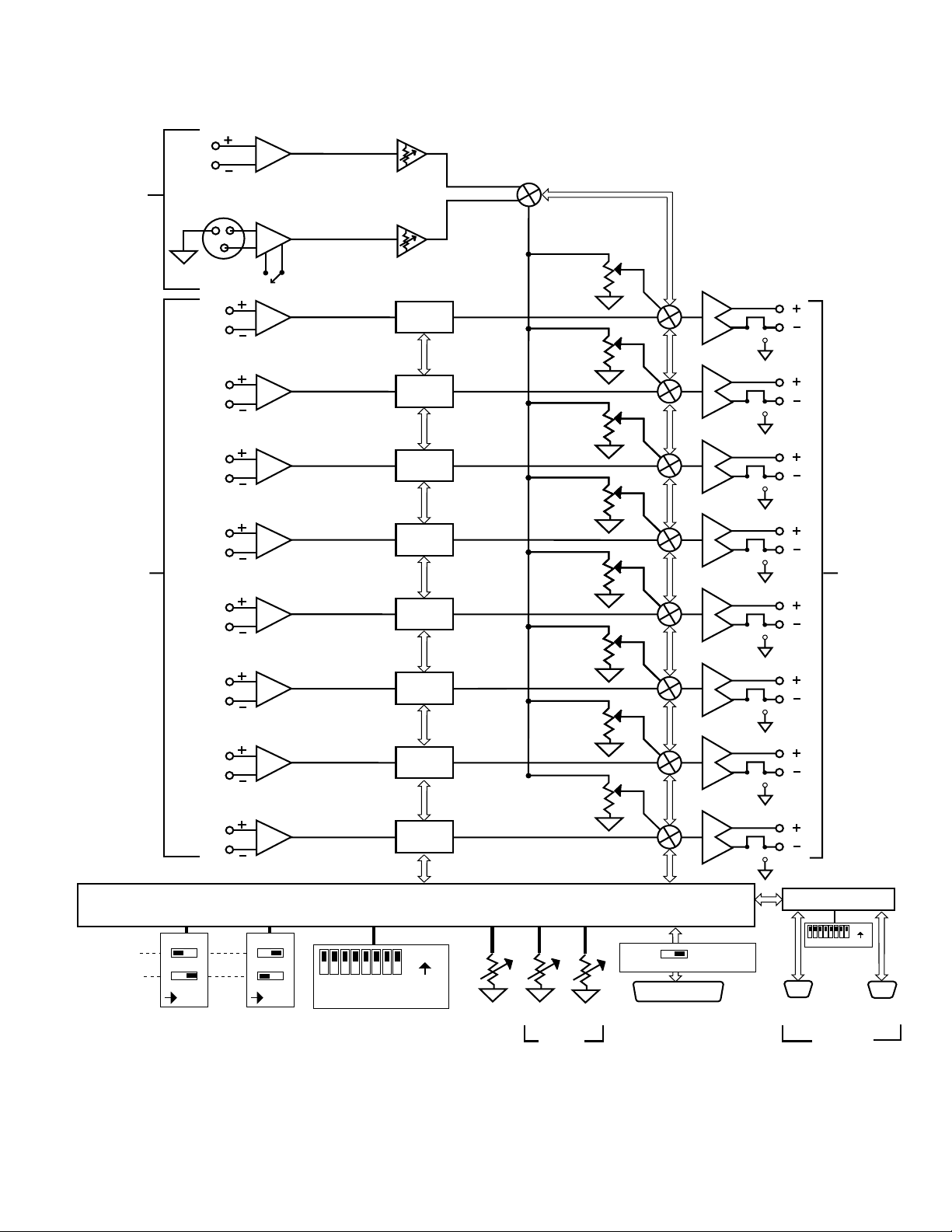

Page

Inputs

PRM-8 BLOCK DIAGRAM

Line

21

Mic/Line

Program

Inputs

3

Mic/Line Switch

Page

Level

CH. 1

Duck

Page

Level

CH. 2

Duck

Page

Level

CH. 3

Duck

Page

Level

CH. 4

CH. 5

Duck

Duck

Page

Level

Program

Outputs

Page

Level

CH. 6

Duck

Page

Level

CH. 7

Duck

Line

Mic/Line

ON ON

Zone Page

Input

SW1SW1

All Page

Input

CH. 8

12345678

SW3

All Page

Source

Page

Level

Duck

On–Board Microprocessor

ON

CH.

In

Level

Figure 1.3: Block Diagram

Page 3

Out

Toggle

SW1

••••••••••••••••••••

•••••••••••••••••••

Control

Port

Maintained

Send/Receive

ON

CH.

SW2

•••••

••••

12345678

In

PA-422Duck Fade

•••••

••••

Out

PRM-8 SET-UP

OXMOOR CORPORATION

MADE IN USA

PRM-8

COPYRIGHT 1994

PCB # 1300129

REVISION A

SW2 SW3

SW1

230

ON

12345678

ON

12345678ON12345678

SW6

POWER LED

SW 1

SW 3

SW 2

AC POWER TRANSFORMER

PRM-8 SET-UP OVERVIEW

(Refer to Figure 2.1)

The PRM-8 has three internal dip switches that may be used to

configure its operation for different system requirements. Before

installing the PRM-8, refer to the switch function description

below to determine the switch positions best suited to your

system requirements. Refer to page 10 for a typical control panel

configuration and its operation.

CAUTION!

Hazardous voltages are present inside the chassis.

Before opening the case to gain access to the printed

circuit board, always remove the power from the unit by

disconnecting the AC power cord.

If changes are required:

1. Disconnect the AC power cord.

2. Remove the screws that secure the top cover and set the cover

aside.

3. Use the front panel Power LED and the AC Power

Transformer as reference points to locate SW1, SW2 and SW3

which are located on the component side of the PRM's printed

circuit board

SW1 SET-UP PROCEDURE

(Refer to Figure 2.0)

Switch SW1 determines if: A manual Zone Page Clear line is to

be used; The system is to store the Zone Page selections after a

zone page; The Channel Select is to operate with momentary or

maintained closures; The Page inputs are to be used as All Page,

Zone Page or both

SW1

ON

12345678

.

.

SW1: Shipped from factory configured as shown.

Note: The Zone Page Clear function can be used only

if the Control Port is set for MOMENTARY

operation (#4 ON).

Figure 2.1: SW1, SW2 and SW3 Location on Printed Circuit Board

SW2 SET-UP PROCEDURE

(Refer to Figure 2.2)

Switch SW2 determines the PA-422 address. When the PA422 port is to be used, the PRM-8's PA-422 address should be

set to the same address as the controlling device. PA-422

requires that a device's address be between 1 and 250.

SW2

ON

12345678

1

2

4

8

16

32

64

128

SW2: Shipped from factory with

PA -422 set to address 2.

PA-422 Address

Figure 2.2: Factory Set-Up for SW2

1*Off = Not used, set to Off position

2*Off = Not used, set to Off position

3 Off = Zone Page selection is NOT stored

*On=Zone Page selection is stored

4*Off = Channel Select set for MAINTAINED closures

On = Channel Select set for MOMENTARY closures

5*Off = Mic/Line input NOT used as All Page

On = Mic/Line input used as All Page

6 Off = Line input NOT used as All Page

*On=Line input used as All Page

7 Off = Mic/Line input NOT used as Zone Page

*On=Mic/Line input used as Zone Page

8*Off = Line input NOT used as Zone Page

On = Line input used as Zone Page

* Indicates factory settings.

Figure 2.0: Factory Set-Up for SW1

Page 4

SW3 SET-UP PROCEDURE

(Refer to Figure 2.3)

SW3 allows individual channels to NOT receive the All

Page source. Those channels switched OFF will continue to

mute and ramp the program source during an All Page, but

will not receive the All Page source.

SW3

ON

12345678

1

2

3

4

5

6

7

8

SW3: Shipped from factory with all

channels set to receive the All

Page source (all channels ON).

PRM-8 Program Channels

Figure 2.3: Factory Set-Up for SW3

PRM-8 SET-UP (CONTINUED)

SW3

ON

12345678

1

2

3

4

5

6

7

8

PRM-8 Program Channels

SW2

ON

12345678

1

2

4

8

16

32

64

128

PA-422 Address

SW1

ON

12345678

DIRECT MODE SET-UP

The PRM-8 can be programmed to allow page routing to any

channel without the use of the Zone Page Enable control line. In

this mode the Fade In and Fade Out settings are ignored and any

combination of channels may be selected at any time. When a

program channel is selected (using a Channel Select control line)

the program audio is immediately ducked to the Duck Level

setting and the PRM's Zone Page input is routed to the selected

channel(s).

To program the PRM-8 for the Direct Mode operation:

A. Remove the AC power from the unit.

B. Set SW1, switch number 4 to the off (MAINTAINED)

position.

C. Hard-wire the Zone Page Clear line (pin 14 on the Control

Port) to common.

D. Restore the AC power to the unit.

PROGRAM OUTPUT BALANCED/UNBALANCED SET-UP

(Refer to Figure 2.4)

The PRM-8 is configured from the factory for balanced audio

outputs. A jumper is provided for each channel to allow easy

conversion to an unbalanced configuration.

CUSTOM SET-UP

(Refer to Figures 2.6, 2.7, 2.8 and 2.9)

Use the templates below to record custom set-ups of the

PRM-8:

Figure 2.6: SW1 Set-Up Template

BALANCED SET UP

Arrows Pointing To Rear Panel Of PRM-8

UNBALANCED SET UP

Figure 2.4: Program Output Jumper Set-Up

PROGRAM OUTPUT FACTORY SET-UP

(Refer to Figure 2.5)

Located next to the PRM-8's Program Output connector on the

circuit board, the jumpers are labeled as follows:

P9 = Channel 1

P16 = Channel 2

P11 = Channel 3

P10 = Channel 4

P13 = Channel 5

The diagram below illustrates the factory set-up for the

balanced/unbalanced jumpers.

P12 = Channel 6

P14 = Channel 7

P15 = Channel 8

Program Output Jumpers

P15

P14

P12

P13

P10

P11

P16

Figure 2.7: SW2 Set-Up Template

Figure 2.8: SW3 Set-Up Template

Program Output Jumpers

P15

P14

P12

CH: 8

CH: 7

CH: 6

CH: 5

P13

P10

CH: 4

P11

CH: 3

P16

CH: 2P9CH: 1

CH: 8

Figure 2.9: Program Output Jumpers Set-Up Template

CH: 7

CH: 6

CH: 5

CH: 4

CH: 3

CH: 2P9CH: 1

Figure 2.5: Factory Set-Up for Output Jumpers

Page 5

PROGRAM OUTPUTS PROGRAM INPUTS

8765432187654321

+

–

PRM-8 CONNECTIONS

LINE

PUSH

PAGE INPUTS

LEVEL

LINEMIC/LINE

S

+–

LINE

LEVEL

S

Figure 3.0: Program Inputs and Outputs View

PROGRAM INPUT AND OUTPUT CONNECTIONS

(Refer to Figure 3.0)

The PRM-8 Page Module provides connections for eight

program channels. Upon initiation of a page, the page inputs

are routed to any one, or any combination, of these program

channels.

The Program Input and Output connections are made through

a 48-pin screw terminal block mating connector. NOTE: Make

sure that the two mounting screws (shipped with the connector) are

used to secure the 48-pin screw terminal to the enclosure.

1. PROGRAM INPUTS: (S) = Shield, (+) = High, (–) = Low,

electronically balanced input, accepts balanced or

unbalanced signals from line-level devices. Nominal input

level is +4 dBu with maximum input level of + 24 dBu.

2. PROGRAM OUTPUTS: (S) = Shield, (+) = High, (–) = Low,

electronically balanced output accommodates balanced or

unbalanced lines. Recommended load impedance is 600

ohms or greater. Maximum output level is +26 dBu.

MIC/LINE

MIC

Figure 3.3: Page Inputs View

PAGE INPUT CONNECTIONS

(Refer to Figure 3.3)

The PRM-8 Page Module provides connections for two page

inputs. Page inputs are easily routed to any one, or any

combination, of the module's eight program channels.

1. MIC/LINE: XLR input, Pin 1 = Shield, 2 = High, 3 = Low,

accepts balanced or unbalanced signals from mic-level or

line-level audio devices.

MIC, LINE: Set switch to MIC position for mic-level or LINE

position for line-level source.

MIC/LINE LEVEL: Use a small flat-blade screwdriver to

adjust the MIC/LINE input for various input signal levels.

2. LINE: (S) = Shield, (+) = High, (–) = Low, accepts balanced

or unbalanced signals from line-level audio devices. The

connections are made through a 3-pin cage-clamp

connector. The cage-clamp spring clamps the wire

providing quick and easy termination.

PROGRAM INPUT AND OUTPUT WIRING SCHEMES

(Refer to Figures 3.1 and 3.2)

The diagrams below illustrate the correct wiring of balanced

and unbalanced program inputs and outputs.

BALANCEDBALANCED

BALANCED

BALANCEDBALANCED

UNBALANCEDUNBALANCED

UNBALANCED

UNBALANCEDUNBALANCED

+

–

S

+

–

S

+

–

S

+

–

S

Figure 3.1: Program Input Wiring Schemes

BALANCEDBALANCED

BALANCED

BALANCEDBALANCED

HIGH

LOW

SHIELD

UNBALANCEDUNBALANCED

UNBALANCED

UNBALANCEDUNBALANCED

NC

HIGH

LOW

Figure 3.2: Program Output Wiring Schemes

HIGH

LOW

SHIELD

HIGH

LOW

NC

NOTE: The unbalanced

output configuration

is valid ONLY if the

Balanced/Unbalanced

output jumper block

has been set to the

unbalanced position.

See page 6, Figure 2.4.

LINE LEVEL: Use a small flat-blade screwdriver to adjust the

LINE input for various input signal levels.

PAGE INPUT WIRING SCHEMES

(Refer to Figure 3.4)

The diagram below illustrates the correct wiring of balanced

and unbalanced page inputs.

LINE IN

MIC/LINE IN

LINE IN

MIC/LINE IN

–

3

S

1

+

2

–

3

S

1

+

2

Figure 3.4: Page Input Wiring Schemes

BALANCEDBALANCED

BALANCED

BALANCEDBALANCED

UNBALANCEDUNBALANCED

UNBALANCED

UNBALANCEDUNBALANCED

LOW

SHIELD

HIGH

LOW

NC

HIGH

Page 6

PRM-8 CONNECTIONS (CONTINUED)

N

LINE

LEVEL

Pin 25Pin 25

Pin 25

Pin 25Pin 25

OXMOOR

MADE IN USA BY

OXMOOR CORPORATION

BIRMINGHAM, ALABAMA

CONTROL PORT

PA-422 OUT

Pin 1Pin 1

Pin 1

Pin 1Pin 1

PA-422 IN

Figure 3.5: Control Port View

CONTROL PORT CONNECTIONS

(Refer to Figures 3.5, 3.6 and 3.7)

The PRM-8 Page Module Control Port provides connections

for external switching of zones for Zone Paging, Zone Page

Enable, All Page Enable, and Zone Page Clear. Also provides

tally connections for all control functions. NOTE: The Zone

Page Enable and the All Page Enable tally lines are activated only

after the duck level setting is reached, as established by the front

panel control.

All Channel Select functions are operated by contact closures,

either "momentary" or "maintained" depending on SW1 (see

page 5) setting. Zone Page Enable and All Page Enable

functions are operated by "maintained" contact closures.

Pin Function

1Common

2Common

3 Bias for Back EMF

4 All Page Enable

5 Channel 1 Select

6 Channel 2 Select

7 Channel 3 Select

8 Channel 4 Select

9 Channel 5 Select

10 Channel 6 Select

11 Channel 7 Select

12 Channel 8 Select

13 Zone Page Enable

Figure 3.6: Control Port Pin-Out

Pin Function

14 Zone Page Clear

15 All Page Tally

16 Zone Page Tally

17 Channel 1 Select Tally

18 Channel 2 Select Tally

19 Channel 3 Select Tally

20 Channel 4 Select Tally

21 Channel 5 Select Tally

22 Channel 6 Select Tally

23 Channel 7 Select Tally

24 Channel 8 Select Tally

25 +15 VDC

OOR

USA BY

ORPORATION

M, ALABAMA

OL PORT

PA-422 IN

PA-422 OUT

FUSE

POWER

Figure 3.8: PA-422 Serial Control Port View

PA-422 SERIAL CONTROL PORT CONNECTIONS

(Refer to Figures 3.8, 3.9 and 3.10)

All PRM-8 functions can be controlled through the PA-422

serial control port. See Wiring detail below.

Use Belden #9681 or equivalent.

+

1

6

DSR

_

2

7

3

FEMALE

8

+

4

9

RxD

_

5

MALE

+

1

+

DSR

RxD

6

_

2

DTR

_

7

3

+

8

+

4

TxD

_

9

_

5

DRAIN (SHIELD) WIRE

+

DTR

_

+

TxD

_

Figure 3.9: PA-422 Serial Control Port Wiring

PA-422 IN

PA-422 Controller

PA-422 OUT

Function

Description

All Page Enable Initiates All Page

Use Belden #9681

or

Equivalent

PA-422 OUT of Controller

Channel X Select Assigns channel to receive the Zone

Page

Channel X Tally Provides open-collector closure to

PA-422 IN of PRM-8 Page Module

common when control function is

active

OXMOOR

Zone Page Enable Initiates Zone Page

Common Logic Common

MADE IN USA BY

OXMOOR CORPORATION

BIRMINGHAM, ALABAMA

CONTROL PORT

Zone Page Clear Clears Channel X Selections

PA-422 IN

PA-422 OUT

FUSE

CHASSIS

SERIAL #

POWER

+15 VDC DC voltage for Tally LEDs

Figure 3.10: PA-422 Typical Connection Scheme

Figure 3.7: Control Port Functions and Descriptions

Page 7

PRM-8 PROGRAMMING

1.0 PRM-8 PROGRAMMING OVERVIEW

This document is a PA-422 communications reference

for those interested in designing their own custom

software to control the OXMOOR PRM-8 system.

Intended as a supplement to the PA-422 standard

documentation (which describes in detail the operation

of PA-422), this text describes those commands which

are used with the PRM-8 . These commands are described

in a manner consistent with the PA-422 standards draft:

each command is introduced and its exact usage given in

a procedural, step-by-step fashion. Also included are

the data formats associated with each command.

2.0 DEVICE CONTROL LANGUAGE STRUCTURES

2.1 Transmit All Data - 81 hex

This command sends the data necessary to specify the

operational mode and channel configurations of the

PRM-8. The data transmitted includes the status of link

switches, device mode of operation, channel selection

for page function and enable/disable page function. To

send this command the controller must:

1. Transmit the address of the desired device.

2. Wait until DSR is set or 250 msec timeout period

has elapsed.

3. Set DTR.

4. Get DT (device-type code; 31 hex).

5. Get ID (mfg.’s identification code; 29 hex).

6. Transmit 81 hex (command code).

7. Transmit the data as shown in the data structure

description (see section 3).

8. Get COMSTAT (should be 00 hex if successfully

executed).

9. Verify DSR is reset by addressed device.

10. Reset DTR.

3.0 DEVICE CONTROL LANGUAGE (DCL) DATA

STRUCTURES

This section details the exact data streams that should be

sent with each PA-422 command to correctly

communicate with the desired device. Each data structure

is presented in the following format:

Data Transmitted:

(the data that should be sent with the command)

Byte# = Data stream position

Valid Data Range = Valid values for byte

Description = Information byte contains

Data Received:

(the data returned from the desired device).

Byte# = Data stream position

Valid Data Range = Valid values for byte

Description = Information byte contains

NOTE: All numbers in the data fields are decimal unless

noted otherwise.

2.2 Update Parameter of Device Channel - 96 hex

This command allows the controlling device to adjust

program source fade levels and fade in/out times of the

PRM-8.

1. Transmit the address of the desired device.

2. Wait until DSR is set or 250 msec timeout period

has elapsed.

3. Set DTR.

4. Get DT (device-type code; 31 hex).

5. Get ID (mfg.’s identification code; 29 hex).

6. Transmit 96 hex (command code).

7. Transmit the data as shown in the data structure

description (see section 3).

8. Get COMSTAT (should be 00 hex if successfully

executed).

9. Verify DSR is reset by addressed device.

10. Reset DTR.

Page 8

PRM-8 PROGRAMMING (CONTINUED)

3.1 Transmit All Data (81 hex)

Data Transmitted:

Byte# = 1

Valid Data Range = 0-2

Description = Page Source Input Select

0 = Mic/Line Level Input

1 = Line Level Input

2 = Both Mic/Line and

Line Level inputs

activated

Byte# = 2

Valid Data Range = 0 or 2

Description = Operational Mode Status

0 = Normal PRM-8

Application

1 = MCS Room Combining

System Application

2 = Direct Mode

Application

Byte# = 3

Valid Data Range = 0 or 1

Description = PRM-8 Paging Mode

0 = Page Function Disable

1 = Page Function Enable

Byte# = 5 through 15

Valid Data Range = 0-FF hex

Description = MCS Room Combining

System Link switch

settings

Room combinations for

each of the 11 link

switches. If a link switch is

inactive, the byte for that

switch should be zero.

Thus, if link switch one is

active and it combines

rooms 1 and 2, then byte 5

should be 00000011. Note

that byte 5 corresponds to

link switch 1, and byte 15

corresponds to link switch

11. If an MCS Room

Combining System is not

used, then byte 2

(operational mode status

byte) is zero. Bytes 5

through 15 are still

required to be transmitted,

but the data is ignored by

PRM-8.

Byte# = 4

Valid Data Range = 0-FF hex

Description = Channel Select for Page

Mode, i.e., channels 1-8.

Each bit corresponds to the

appropriate channel

desired. For example:

00010101 will route the

initiated page to channels

5, 3, and 1. Bit 8 (MSB0 is

channel 8; bit 1 (LSB) is

channel 1.

Data Received: none

Page 9

PRM-8 PROGRAMMING (CONTINUED)

3.2 Update Parameter of Device Channel (96 hex)

Data Transmitted:

Byte# = 1

Valid Data Range = 0 or 1

Description = 0 = Enable front panel trim

pots for Page function

1 = Disable trim pots and use

PA-422 data for Page

function

Byte# = 2

Valid Data Range = 0-FF hex

Description = Program source level

defined for all 8 channels.

(0 to -48dBu, -80dBu = off)

Program source attenuation

levels can be calculated as

follows:

Attenuation (dBu) = 20 Log [

(Vin / 0.7747) (decimal value /

256)]

For example:

0F hex (15 decimal) = value

transmitted 0.7747v = Vin input

-24dBu = 20 Log[ (1) (15 /256) ]

Byte# = 4

Valid Data Range = 0-FF hex

Description = Program source fade out time

for enabled page function.

(0 to 5 seconds)

FF hex = 5 sec. fade out time

0F hex = 2.5 sec. fade out time

00 hex = 0 sec. fade out time

Data Received: none

Other example values for input

voltage of 0.7747v (Vin) are:

FF hex equals 0 dBu attenuation

0F hex equals -24 dBu attenuation

01 hex equals -48 dBu attenuation

00 hex equals -80 dBu attenuation

Byte# = 3

Valid Data Range = 0-FF hex

Description = Program source fade in time

after page function isdisabled.

(0 to 5 seconds)

FF hex = 5 seconds fade in time

0F hex = 2.5 sec. fade in time

00 hex = 0 seconds fade in time

Page 10

TYPICAL PAGING CONTROL PANEL

Illustrated below is a typical control panel that could be used with Oxmoor’s PRM-8 Page Routing Module. While

there are many other ways of controlling Oxmoor's page module, the illustration includes the functions most often

desired.

Two types of paging are possible with this panel. Zone Page distributes a page to zones selected with the Zone Select

switches. All Page sends the page to all zones. LED tally indicators, incorporated into each push-button, provide a

visual confirmation of the status of each function.

ZONE 1 ZONE 2 ZONE 3 ZONE 4 ZONE 5 ZONE 6 ZONE 7 ZONE 8

Zone Select

Switches

ZONE PAGE ALL PAGE

Page

Switch

Zone Select Switches

A page can be sent to any one or any combination of

zones. Use the Zone Select switches to determine which

zones will receive a page. These buttons function in a

“push-on/push-off” fashion.

Select zones to receive a page by pushing each

appropriate Zone Select switch once. The LED will turn

on, indicating that the zone has been selected. To remove

a zone that has been selected, simply push the appropriate

zone’s button once.

Once a zone or zones have been selected, a Zone Page

may be initiated.

Note: An Illuminated LED indicates only that the zone is

programmed to receive a page, not that the PRM-8's page

input is on.

Page Switch

To page, press and hold the Page switch. The Page

Switch’s LED will turn on, indicating that a page is in

progress. As long as the Page switch is held down, the

page input will be on and the page message will be

directed to all selected zones.

All Page

Switch

When the page is complete, release the Page switch.

The LED on the Page switch will be turned off,

indicating the page input is off.

Note: As long as the Page Switch's LED is on, no

additional zones can be added or deleted from the

setup.

All Page Switch

To send a page to all zones simultaneously, push and

hold the All Page switch. The All Page switch’s LED

will illuminate, indicating that a page is in process. The

All Page function overrides whatever selections have

been made at the Zone Select switches. As long as the

All Page switch remains depressed, the page input will

be on and the page message will be directed to all

zones, whether they have been selected or not.

When the All Page is complete, release the All Page

switch. The LED on the All Page switch will be turned

off, indicating the all page input is off.

Page 11

PRM-8 SET-UP NOTES

Page 12

PRM-8 SPECIFICATIONS

FREQUENCY RESPONSE 20 Hz to 20 kHz ....................................... +0, -0.3 dB

HUM AND NOISE Ref. +4 dBm Output @ Unity Gain -85 dB (20 Hz to 20 kHz, Unweighted)

DISTORTION THD + Noise and IMD* ........................ -80 dB/0.01%

CROSSTALK Channel to Channel ............................... -80 dB (20 Hz to 20 kHz)

PROGRAM INPUTS Type ............................................................ Electronically Balanced (RF Suppressed)

Connectors .................................................. Screw Terminal Blocks with Mating Connector

Input Impedance ........................................ 80 K Ohms

Input Sensitivity ......................................... Nominal +4 dBu, Maximum +24 dBu

PROGRAM OUTPUTS Type ............................................................ Electronically Balanced (RF Suppressed)

Connectors .................................................. Screw Terminal Blocks with Mating Connector

Source Impedance ...................................... 150 Ohms (75 Ohms/Side)

Recommended Load Impedance .............. 600 Ohms or Greater

Maximum Output Level ............................ Ref. 1 kHz @ Rated THD

Terminated w/600 Ohms ........................ +24 dBm (All Outputs Driven Simultaneously)

Unterminated ............................................ +26 dBu

PAGE MIC/LINE INPUT Type ............................................................ Electronically Balanced (RF Suppressed)

Connectors .................................................. Female XLR, Pin 1 Shield (Chassis), Pin 2 +, Pin 3 –

Input Impedance ........................................ 1.5 K Ohms

Mic. Input Sensitivity ................................. Nominal -50 dBu

Mic. Gain Control Range ........................... -50 dB to 0 dB (Ref. 0 dBu Output)

Line Input Sensitivity ................................. Nominal +4 dBu, Maximum +24 dBu

Mic/Line Switch ......................................... Sets Input for Microphone or Line-Level Source

PAGE LINE INPUT Type ............................................................ Electronically Balanced (RF Suppressed)

Connectors .................................................. Cage-Clamp Connector with Mating Connector

Input Impedance ........................................ 80 K Ohms

Input Sensitivity ......................................... Nominal +4 dBu, Maximum +24 dBu

Gain Control Range .................................... ± 15 dB

PAGE LEVEL CONTROLS Ref. +4 dBm Output @ Unity Gain 0 to -80 dB (Accessed Through Front Panel)

DUCK ADJUSTMENTS Attenuation............................................... 0 dB to -80 dB (Variable)

Fade In........................................................ 0 to 5 Seconds (Variable)

Fade Out .................................................... 0 to 5 Seconds (Variable)

CONTROL PORT Connector .................................................. 25-pin D-sub, Female

Input Type ................................................... Active Low, Internally Pulled Up

Logic Action

Channel Select "Selectable" ...................... Momentary or Maintained Closure to Common

All Page & Zone Page .............................. Maintained Closure to Common

Logic Levels ................................................ Low < .8 Volts, High > 2.4 Volts

Maximum Sink Current ............................. 1 mA

Maximum Cable Length ............................ 600 m (2000 ft.), #22 AWG

Switching Time ........................................... 50 ms

Power Output ............................................. +15 VDC ±0.1 V, 50 mA

COMMUNICATION Protocol ...................................................... PA-422

Input Connector .......................................... 9-pin D-sub, Male

Output Connector ...................................... 9-pin D-sub, Female

MAINS POWER Power Requirements.............................. 100 to 125 VAC or 200 to 230 VAC, 50/60 Hz

MECHANICAL Overall Dimensions ............................... 44 H x 482 W x 254 D mm

(1.72 H x 19 W x 10 D in)

Finish ........................................................... Textured Black Paint

Weight ......................................................... Shipping: 6.3 Kg (14 lb) Net: 5.9 Kg (13 lb)

*SMPTE Method; 60 Hz + 7 kHz mixed 4:1. ** Input terminated w/600 ohms, unity gain, adjacent channel driven to +4 dBm output.

Specifications subject to change without notice.

Page 13

OXMOOR FACTORY SERVICE

For service information contact:

Oxmoor Product Service Department

309 Cahaba Valley Parkway

Birmingham, Alabama 35124

E-mail: info@oxmoor.com

Additional Installation & Operation Manuals are available from Oxmoor. Contact the

Oxmoor Sales Department for pricing and other ordering information. Consult

warranty statement for cautions concerning unauthorized service.

Telephone: (205) 982-8200

Toll Free: 1 (800) 262-6898

Fax: (205) 982-8250

Internet: www.oxmoor.com

OXMOOR TWO YEAR LIMITED WARRANTY

Oxmoor warrants that each Oxmoor electronic product shall be free from defects in workmanship

and materials and will, at its option, repair or replace any part of the product without charge

provided the product is delivered to Oxmoor within two years of date of original purchase from

or delivery by an authorized Oxmoor dealer. Excluded from this warranty are finish and

appearance items and malfunction resulting from abuse, from use that is not in accordance with

instructions, or operation under other than specified conditions. Also excluded are incidental or

consequential damages except where precluded by applicable law. This warranty provides the

customer with specific legal rights; there may also be other rights which vary from state to state.

Repair by other than Oxmoor Factory Service Department or its authorized service agency,

unauthorized modification, or the removal or defacing of the serial number will void this

warranty.

Products returned for factory warranty service must be prepaid and packaged in such a way as to

insure safe transit and must be accompanied by a sales slip or other valid proof of purchase date.

PRIOR AUTHORIZATION FROM OXMOOR IS REQUIRED FOR RETURN. Contact Oxmoor for

a Return Authorization (R.A.) Number and shipping information before returning product for

service.

CONTACT

OXMOOR

Oxmoor Corporation, LLC, 309 Cahaba Valley Parkway, Birmingham, AL 35124 USA

Toll Free 1 (800) 262-6898 Telephone (205) 982-8200 Fax (205) 982-8250 E-mail info@oxmoor.com

For 24-hour access to product specs and information visit Oxmoor's complete product line on the internet at www.oxmoor.com.

Oxmoor is a registered trademark of Oxmoor Corporation, LLC.

Specifications and design are subject to change without notice.

Oxmoor PRM-8 Page Routing Module

Rev. 3.1/073101 Part Number:1700015

Loading...

Loading...