Page 1

Jeff Jefferson, General Manager

8

Tubney Woods, TBD

X-MET8000 Series User Manual

101

Page 2

X-MET8000 Series User Manual

8

X-MET8000 Series Supervisor’s Guide

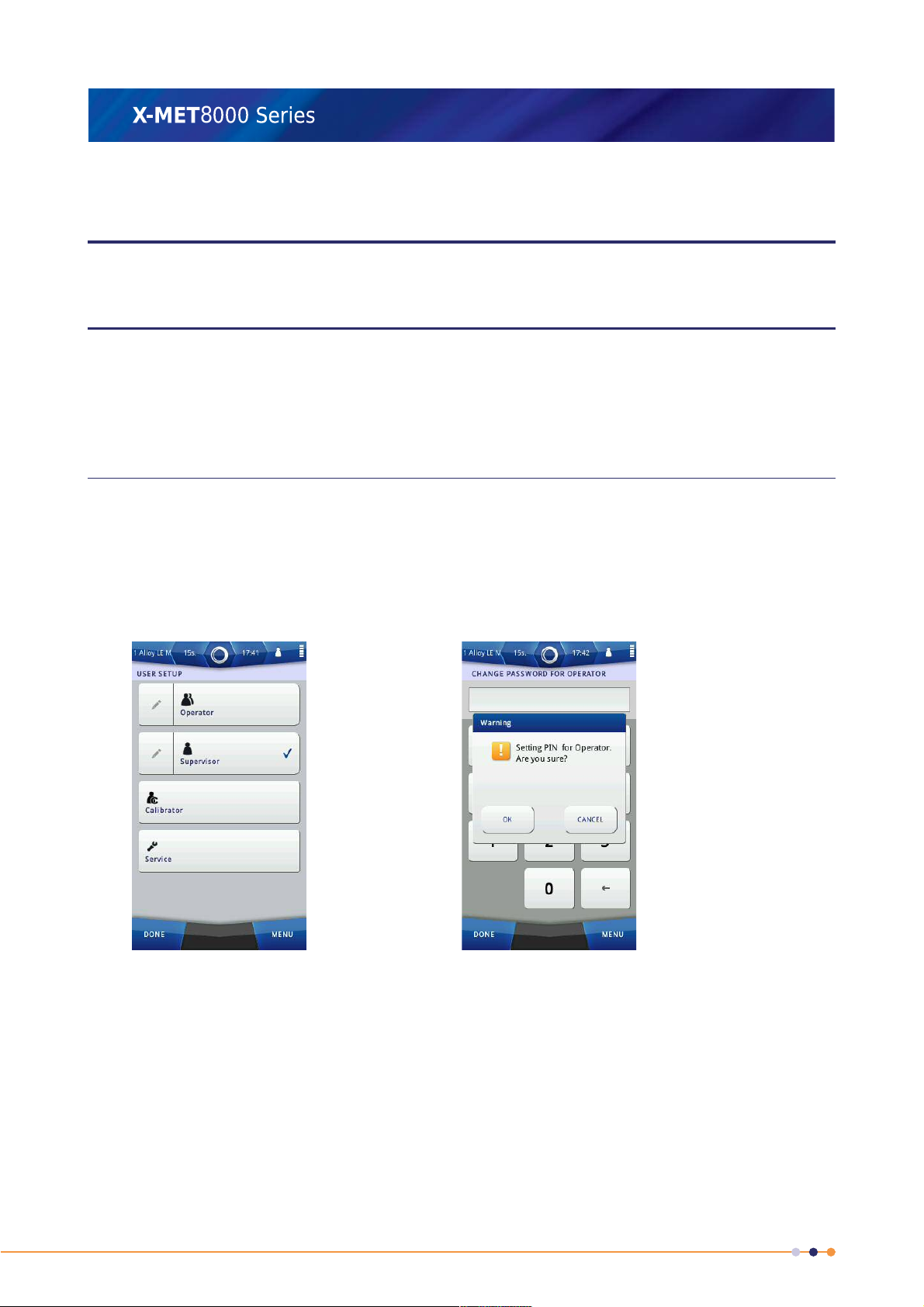

Users And Security

The supervisor can set the Operator password and the Supervisor password. The supervisor should

change both passwords to avoid the factory settings. An operator can change the Operator password.

It is possible to quickly change between users. This allows the supervisor to check which methods and

menu items the operator can access.

Set Passwords

Follow these steps to change the password.

1. Do one of the following:

• Navigate: Menu > Settings > User Setup

• Navigate: Status Bar > User

The User Setup screen appears.

2. Tap Edit (pencil) next to Operator or Supervisor, as applicable.

3. Use the numeric keypad to type the new password, and then tap Done.

A Warning dialog box appears.

4. Do one of the following:

• Tap OK to confirm the new password.

• Tap Cancel to discard the new password.

The User Setup screen appears.

5. Tap Done once or twice to return to the main screen.

102

Page 3

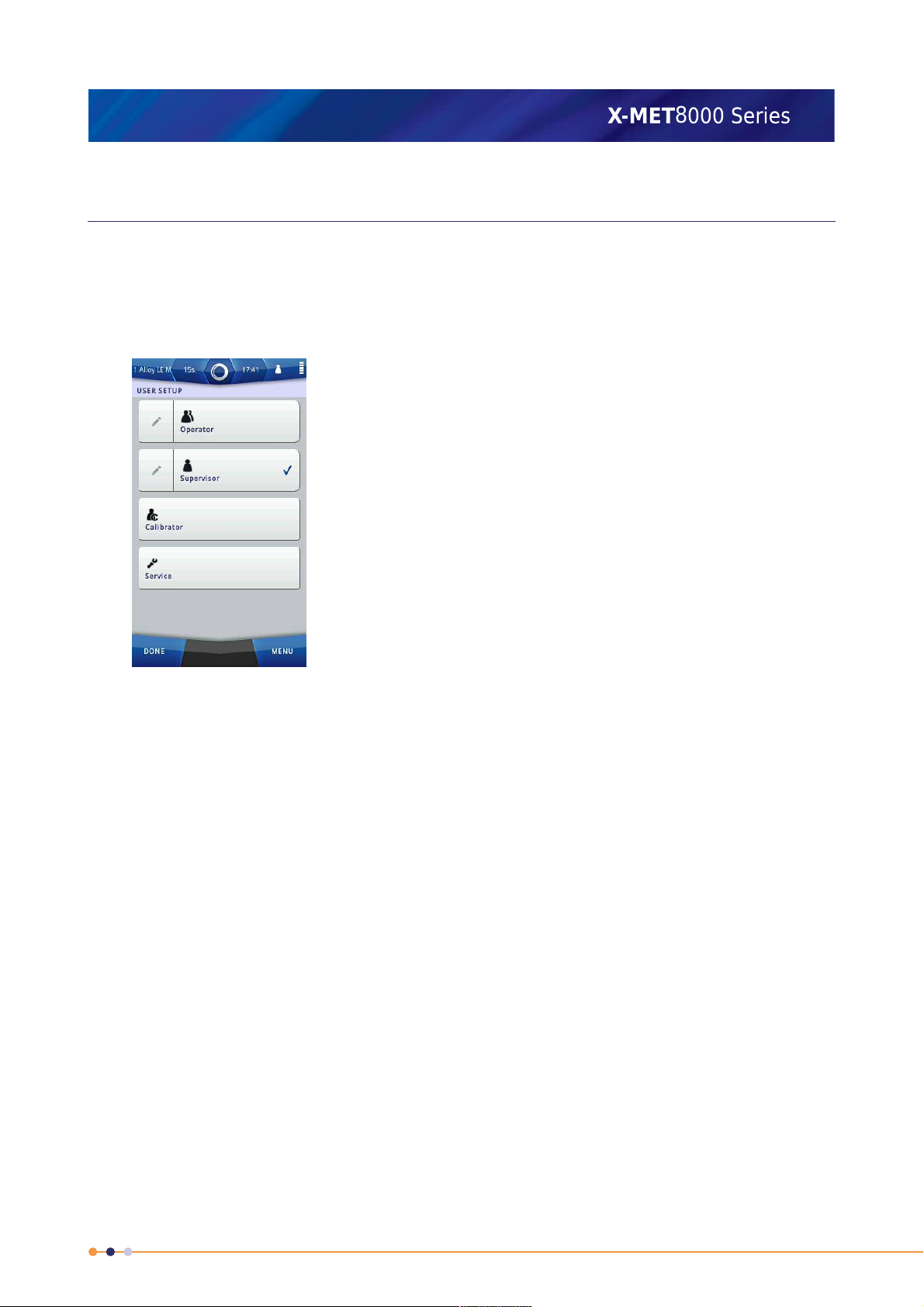

Switch User

8

Follow these steps to change the password.

1. Do one of the following:

• Navigate: Menu > Settings > User Setup

• Navigate: Status Bar > User

X-MET8000 Series User Manual

2. Tap the Operator or Supervisor tick box, as applicable.

3. Do one of the following:

• If the switch is to an Operator, tap Done once or twice to return to the main screen.

• If the switch is to a Supervisor, type the password, and then tap Done. Tap Done once or twice

again to return to the main screen.

103

Page 4

X-MET8000 Series User Manual

8

Advanced Use

The X-MET8000 series is applicable to many different types of measurement. Some applications, for

example Positive Material Identification, require more careful sample preparation and measurement

techniques. The X-MET8000 series assists these applications because it is possible to include additional

information about the sample or the measurement conditions, for example density and thickness, or

GPS information from an external receiver. It is then possible to create a report about the

measurements.

Sample Preparation

Careful sample preparation gives accurate results. Use this information to prepare the different

samples, and follow the guidelines for measurement times.

Prepare Metal Samples

Metals are usually homogeneous, and the results are an accurate representation of the metal. It is

necessary to remove any coating or paint and measure it separately, so that it does not affect the

results.

Measurement times from 2 s give good results, however light elements require between 5 s and 10 s.

Positive Material Identification requires at least a 15 s measurement time, and 30 s is preferable.

Prepare Plastic Samples

The manufacture of plastics uses many metals, for example titanium, lead, cadmium, zinc, iron,

bromine.

Use a sample with a minimum thickness of 3 mm for accurate results. Samples with a minimum

thickness of 1 mm can only give an indication of the composition. It is necessary to remove any coating

or paint and measure it separately, so that it does not affect the results.

X-rays can penetrate a plastic sample and measure whatever is behind it. For example, a measurement

of cable insulation can include the cable. Plastic samples also scatter X-rays. Use a background plate

for accurate measurements and to reduce X-ray scatter.

Measurement times from 30 s give good results.

Prepare Soil Samples

For quick results, it is possible to measure soil samples on the ground. However, more accurate results

require some preparation.

1. Remove any surface debris, for example leaves, grass and stones.

2. Use a 2 mm mesh to remove loose material if there is a lot of debris.

3. Loosen the soil to a depth of a few centimeters and stir to homogenize it.

4. Leave the loosened soil to dry for a few hours or dry it with absorbent paper.

5. Measure the sample on the ground, make sure that the X-MET8000 series is perpendicular to the

surface.

Measurement times from 30 s give good results.

104

Page 5

X-MET8000 Series User Manual

8

Prepare Powders And Pellets

Powders and pellets are usually not homogeneous, and do not give good results. Make sure that they

are dry, and then grind them. For accurate results, use a grain size less than 80 µm for Cu and Fe,

and less than 20 µm for light elements. However, coarser grain sizes do give good results.

Measurement times from 30 s up to 5 min. can be necessary for good results.

Prepare Printed Circuit Boards And Electronic Components

Printed Circuit Boards are a complex, multi-layer structure with metals, resins, fiberglass and fire

retardant chemicals. The result is an average of all the materials in the measurement area. It can be

difficult to interpret because the X-ray penetration depth depends upon the layers of material. Therefore,

the result is only an indication of the material composition.

It is better to measure individual electronic components in a sample cup. Measurement times from15 s

give good results.

Prepare Solder Samples

To comply with the Restriction of Hazardous Substances directive (RoHS), solders must have a lead

composition less than 1,000 ppm. The most common solder replacement is tin, silver, copper (Sn/Ag/Cu

or SAC). Solder can also contain flux. For accurate results, the solder sample must be homogeneous

and uniform.

If solder is measured on a printed circuit board, the board will also be in the measurement window.

The result will average the composition of the solder and the board. An accurate RoHS analysis of the

solder must measure it on its own, as an homogeneous and uniform sample.

Measurement times from 15 s are required to measure concentrations less than 1,000 ppm.

Prepare Samples For The Bench-top Stand

The bench-top stand is ideal for longer measurement times, which give more accurate results, for

example for Positive Material Identification. Use a sample bag or sample cup, and carefully place it

over the measurement window. Make sure that the lid is firmly closed, and then take the measurement.

Choose The Right Method

The method defines how the X-MET8000 series analyses the sample. The available methods depend

upon the version of the X-MET8000 series.

The X-MET8000 includes ‘LE’ in some of the method names, for example Stainless LE, Alloy LE FP or

Alloy LE Mode. The LE refers to ‘light elements’, and these methods can analyse alloys that include

magnesium, aluminum, silicon, phosphorous and sulfur.

The choice of method optimizes all the measurement parameters within the X-MET8000 series so that

it can make the most accurate measurement for that particular type of sample. It also chooses a

particular calibration to analyze the measurement.

Methods include:

• Auto select modes

• Empirical methods

• Fundamental parameter methods

Auto select modes and fundamental parameter methods are available to an operator. Empirical

methods are not available to an operator, because they can choose an auto select mode instead. All

methods are available to a supervisor.

105

Page 6

X-MET8000 Series User Manual

8

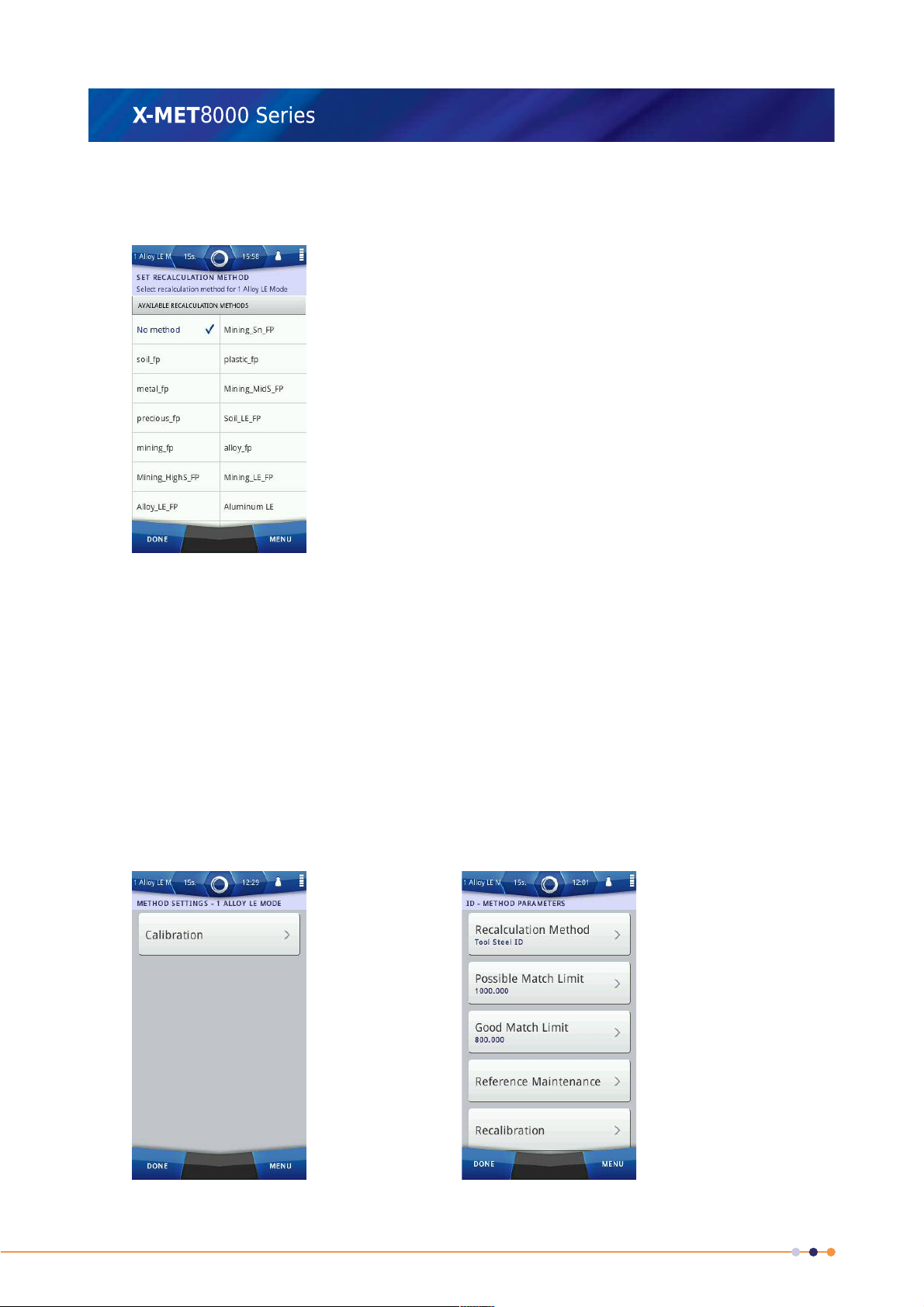

Auto Select Modes

Auto select modes have a ‘Mode’ suffix’, for example Alloy Mode, RoHS Mode. After an identification

scan, the mode chooses the most applicable method to measure the sample with. It uses this order

to choose a calibration:

1. Empirical methods

2. Fundamental parameter methods

3. A recalculation method

The supervisor can define the recalculation method. It is only used when a sample cannot be identified

by any of the empirical or fundamental parameter calibrations.

Empirical Methods

Empirical methods are available for many alloy groups, for example: aluminum, cobalt, copper, nickel,

low alloy steel, stainless steel, tool steel, solder tin and many more. They compare the unknown

sample to a set of calibration curves and other parameters, and then calculate the concentrations of

the elements. Measurements from a series of standards with known assay values create the calibration

curves for the specific analyzer. The standards have different concentrations of a set of elements that

span a range of concentrations.

Empirical methods are more accurate than fundamental parameter methods, but only when the

unknown sample is within the range of concentrations. If an element in the unknown sample is outside

the range of concentrations, a greater than, >, or less than, <, indicator appears next to the

concentration. If this occurs, review the results and decide if another method is more applicable.

Fundamental Parameter Methods

Fundamental parameter methods are abbreviated to ‘FP’ and uses a complex mathematical analysis

of X-ray fluorescence to calculate the concentrations of elements in the sample. It is less accurate

than a similar empirical method, but it is accurate over a much wider range of element concentrations.

Alloy FP

Alloy LE FP

Metal FP

Precious FP

Use Alloy FP to analyze the common elements found in alloys. The

concentration range for each element is from 0 % to 100 %.

Alloy LE FP is similar to Alloy FP, but also includes the light elements, for

example Mg, Al and Si. The concentration range for each element is from

0 % to 100 %.

Use Metal FP to analyze the elements found in alloys and in particular

hazardous elements, for example Pb, Cd, Hg and Br. The concentration

range for each element is from 0 % to 100 %.

Use Drywall FP to analyze Sr content found in drywall.Drywall FP

Use Drywall LE FP to analyze S and Sr content found in drywall.Drywall LE FP

Use Wood FP to analyze Chromated Copper Arsenate(CCA) treated wood.Wood FP

Use Precious FP to analyze the elements found in alloys and in particular

precious metals, for example Au, Ag, Pt. The concentration range for each

element is from 0 % to 100 %.

106

Aluminum FP

Plastic FP

Use Aluminum FP to analyze the heavy elements found in aluminum alloys,

for example Cr, Cu, Zn and Pb. But, do not use it to analyze light elements,

for example Al and Si.

Use Plastic FP to analyze hazardous elements in plastics, for example Pb,

Cd, Hg and Br.

Page 7

X-MET8000 Series User Manual

8

Use Soil FP to analyze heavy element concentrations in soil.Soil FP

Soil LE FP

Mining FP

Mining LE FP

Soil LE FP is similar to Soil FP, but also includes the light elements, for

example Al and Si.

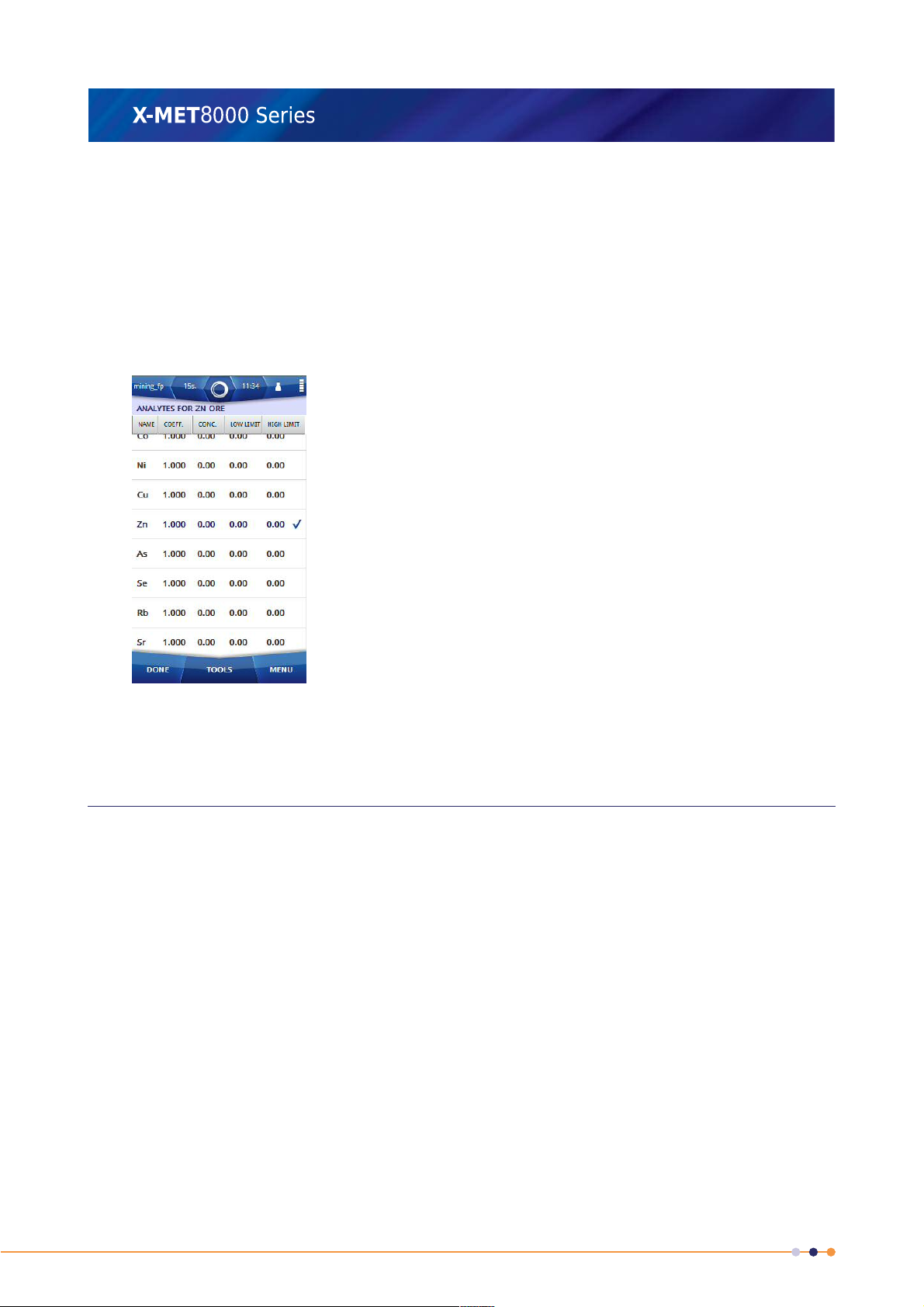

Use Mining FP to analyze the common elements found in mining, for

example Ni, Cu, Zn and Sn.

Mining LE FP is similar to Mining FP, but also includes the light elements,

for example Al, Si, S and P.

Mining HighS FP is similar to Mining FPMining MidS FP

Mining HighS FP is similar to Mining FPMining HighS FP

Analyze And Report Results

For RoHS and plastic samples, the density and thickness can affect the result. It is possible to add this

information, and improve the measurement accuracy. However, it is necessary to add both thickness

and density information to improve the results.

Occasionally, a measurement can produce a peculiar result, for example, a much higher concentration

of a particular element. When this occurs, it is possible to view the spectrum for the result. This shows

the raw sample information, with a series of peaks for each of the elements in the sample. It is then

possible to add XRF lines to the spectrum, for each element in the sample. These lines can clearly

show if a peak is associated with a particular element, or not.

An operator can make many measurements during a day. It is possible to record all necessary

information about the sample and the measurement conditions, and include this as Additional

Information. This will assist the measurement analysis when all the measurements are complete. The

supervisor can define the required information. The operator will see the same information fields, and

know that they must add this information. When all the measurements are complete, it is possible to

connect the X-MET8000 series to a PC and create a report. This can include the density and thickness

and any Additional Information. Refer to Operation With A PC on page 40 to create a report.

107

Page 8

X-MET8000 Series User Manual

8

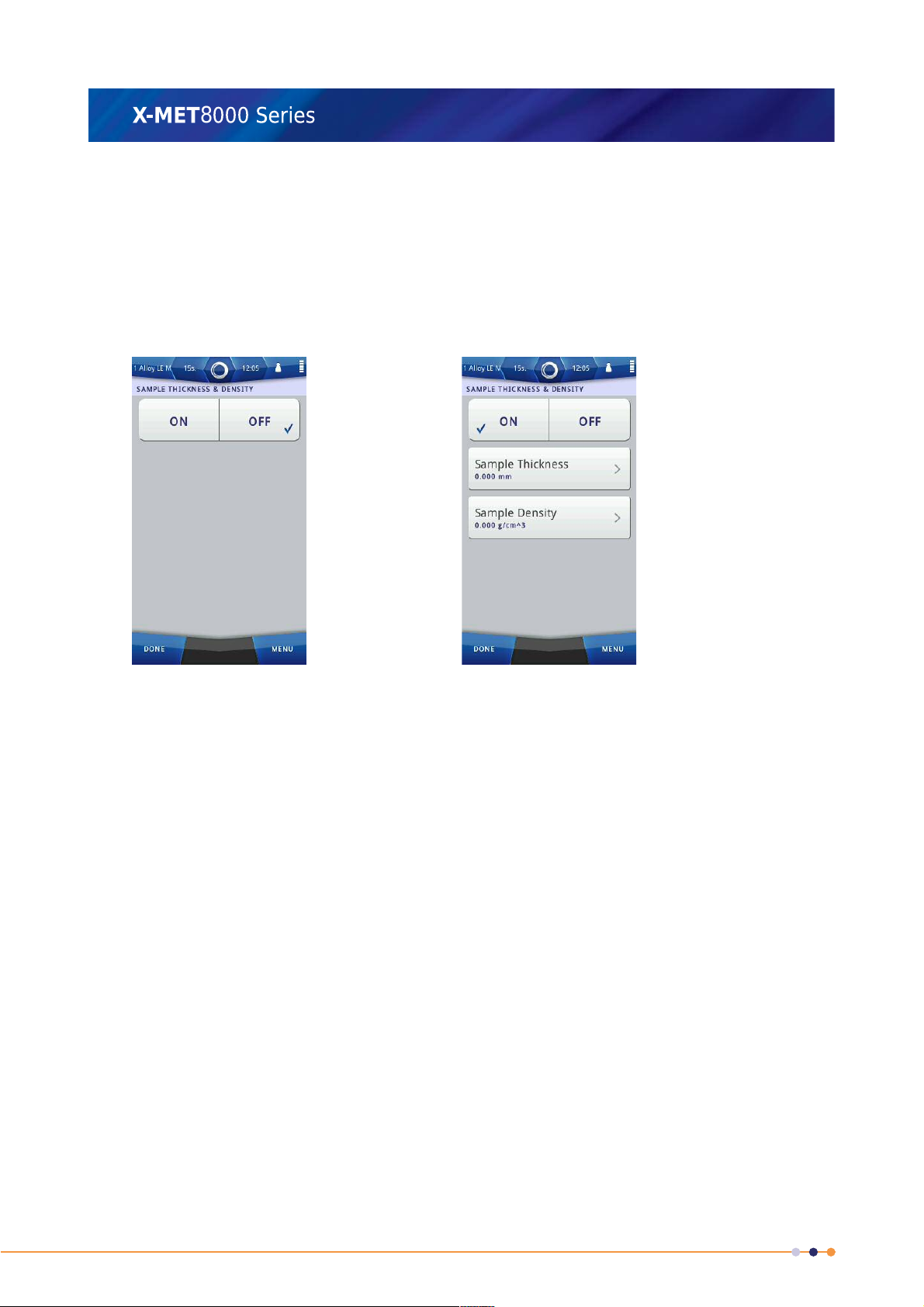

Add Density And Thickness

The density and thickness of the sample are important factors that affect the quality of a measurement.

It is possible to record these values with the sample results. Follow these steps to add density and

thickness information. It is necessary to add both to improve the measurement accuracy.

1. Navigate: Menu > Sample Name > Set Thickness &Density .

The Sample Thickness & Density screen appears.

2. Tap the ON tick box.

The Sample Thickness & Density screen changes.

3. Do one of the following:

• Tap Sample Thickness

• Tap Sample Density

4. Use the numeric keypad to type the value, and then tap Done to return to the Sample Thickness

& Density screen.

5. Tap Done twice again to return to the main screen.

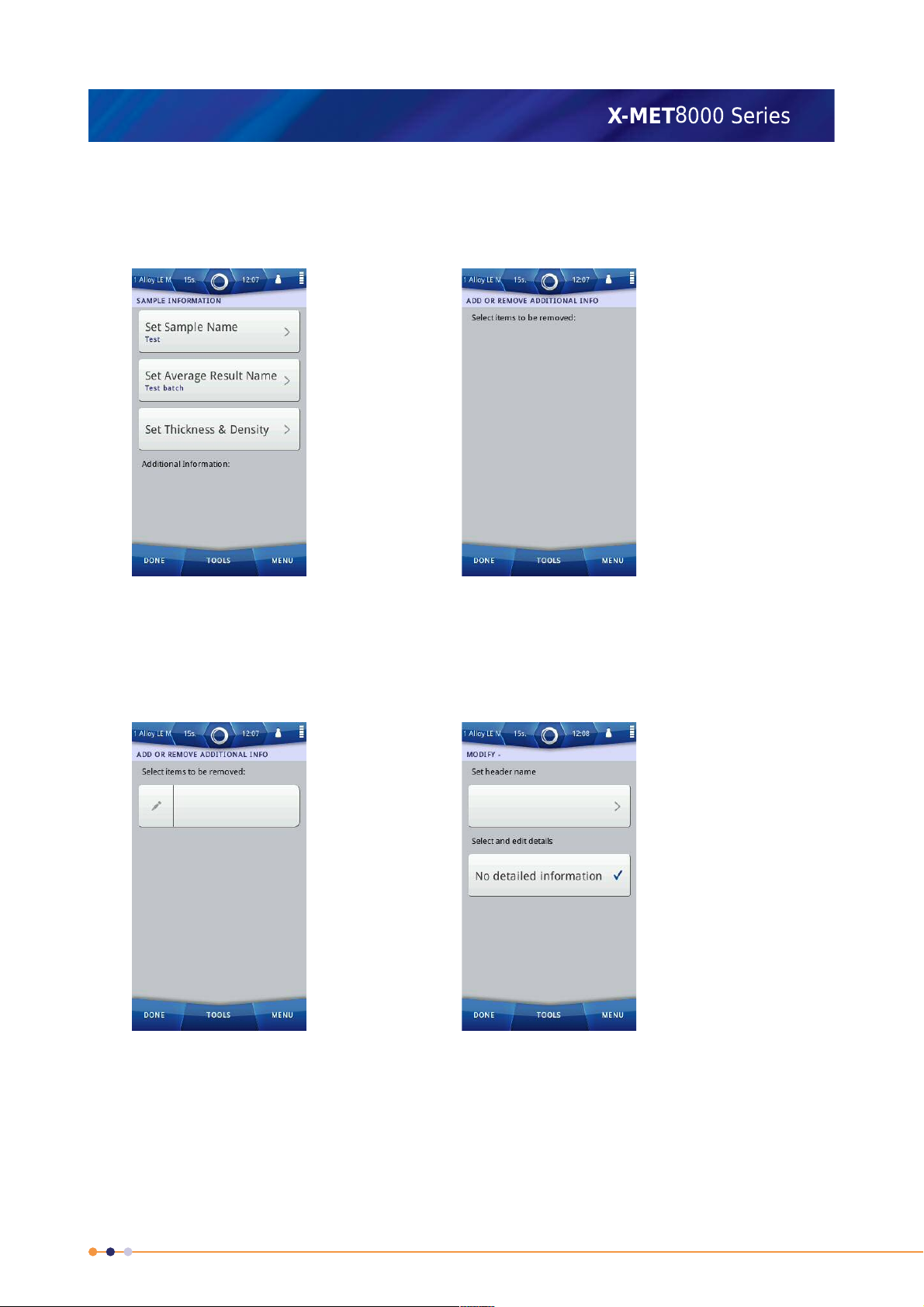

Add An Item To Additional Information

It is possible to add Additional Information about the sample. The measurement result can include

this information. The supervisor can add items for an operator to use and add details to, when they

make measurements. The detail for the item could be a prompt to assist the operator.

These are some examples of Additional Information:

• The name of the operator.

• The sample condition: wet or dry, fine or coarse.

• Notes about the sample preparation: paint or coating removal; use of a sample cup or the

background plate.

Follow these steps to add an item to Additional Information, and then add a detail to the new item.

108

Page 9

Add a new item.

8

1. Navigate: Menu > Sample Name .

The Sample Information screen appears.

X-MET8000 Series User Manual

2. Tap: Tools > Add or Remove .

The Add Or Remove Additional Info screen appears.

3. Tap: Tools > Add New Item .

The Add Or Remove Additional Info screen has a new, blank item.

4. Tap Edit (pencil) next to the new item.

The Modify - screen appears.

5. Tap the blank item box.

109

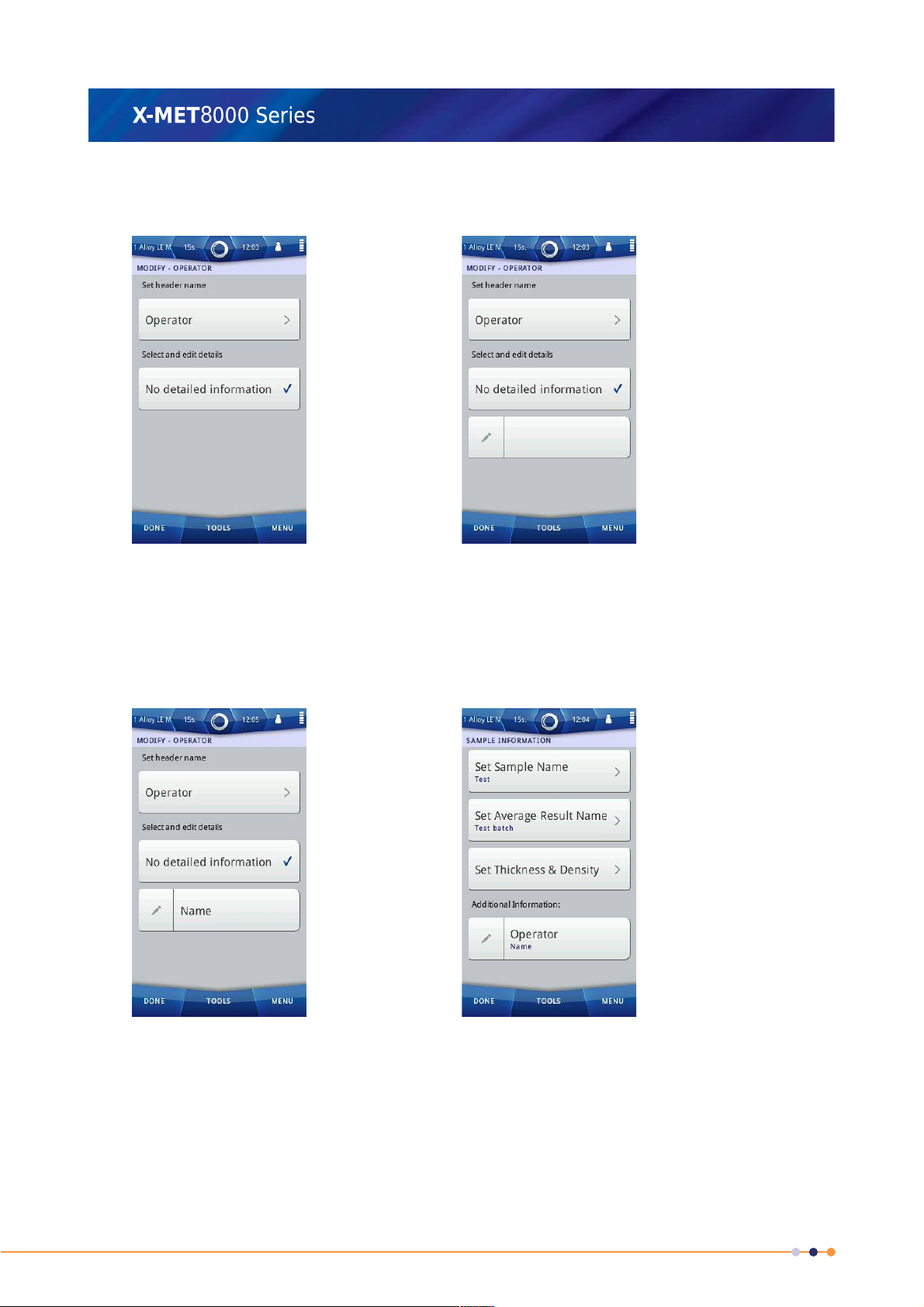

Page 10

X-MET8000 Series User Manual

8

6. Use the virtual keyboard to type the name for the new item, and then tap Done to return to the

Modify - screen.

Add a detail to the new item.

7. Tap: Tools > Add New Detail .

A new, blank detail appears on the Modify - screen.

8. Tap Edit next to the new detail.

9. Use the virtual keyboard to type the new detail, and then tap Done to return to the Modify - screen.

10. Tap the new detail box to select it, and then tap Done to return to the Add Or Remove Additional

Info screen.

11. Tap Done again to return to the Sample Information screen.

The Sample Information screen includes the new item, with its detail.

12. Tap the new item box to select it, and then tap Done to return to the main screen.

110

Page 11

X-MET8000 Series User Manual

8

Edit Detail For An Item Of Additional Information

It is possible to add Additional Information about the sample. The supervisor can add items for an

operator to use when they make measurements. The operator must edit the details, and make sure

that both the item and the detail for the item are selected.

Follow these steps to edit the details for an item of Additional Information that already exists.

1. Navigate: Menu > Sample Name .

The Sample Information screen appears, with one or more items of Additional Information.

2. Tap Edit (pencil) next to the item of Additional Information.

The Modify - screen appears.

3. Tap Edit next to the detail.

4. Use the virtual keyboard to type the new value for the detail, and then tap Done to return to the

Modify - screen.

5. Make sure that the details box is selected, and if necessary, tap it to select it. Then tap Done.

The Sample Information screen shows the changes to the item of Additional Information.

6. Make sure that the item of Additional Information is selected, and if necessary, tap it to select it.

Then tap Done to return to the main screen.

View The Spectra

It is possible to view the X-ray spectrum for a result. This can confirm if an element does have the

concentration shown in the results. It is possible to zoom into the spectrum, and also show the X-ray

fluorescence lines for selected elements.

It is possible for a single result to have more than one spectrum. This is often the case for the

X-MET7500 when it measures light elements. Different measurement conditions produce the spectra,

for example, different excitation voltages. The individual spectra are shown on the same graph in

different colours. It is possible to scroll between the measurement conditions for the spectra.

It is possible to view the spectrum for all results, from the Results screen and the History Results

screen.

111

Page 12

X-MET8000 Series User Manual

8

Follow these steps to view the spectrum, when a result is visible.

Access spectrum

1. From the Results screen, the History Results screen or the Test Measurement screen, tap: Tools

> Show Spectra .

The Spectrum screen appears.

2. If there is more than one spectrum, tap the small black arrow at the bottom of the screen on the

left or right.

The Spectrum screen changes to show the other measurement conditions, and its spectrum is put

in front.

Zoom Into The Spectrum

3. Tap Tools.

The Spectrum screen Tools menu appears.

112

Page 13

X-MET8000 Series User Manual

8

4. Tap one of the Zoom with tap options.

• Choose Both axes to be able to zoom into a small peak.

• Choose X-axis to show each peak relative to the main peak.

5. Tap one of the peaks to zoom into it. Tap it successively to zoom into it again.

A cursor line appears on the spectrum, and moves to where the tap occurred.

The energy at the cursor appears underneath the spectrum.

Press and slide the spectrum to left or right to find the peaks.

6. Tap: Tools > Fit to Window to return to the whole spectrum.

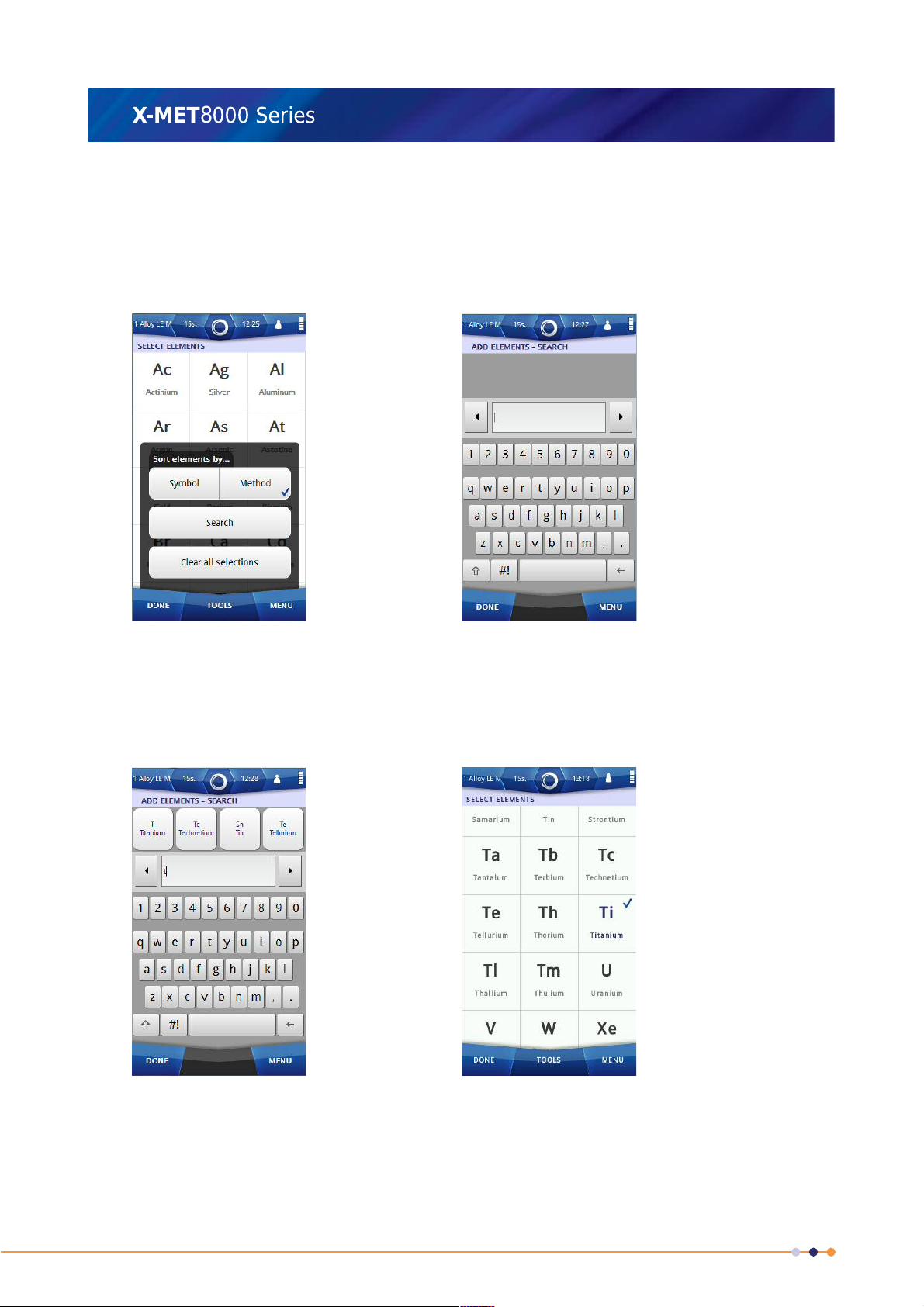

Add XRF Lines To The Spectrum

7. Tap: Tools > XRF Line Display .

The Select Elements screen appears.

8. Tap an element symbol to select it.

Press and slide, or flick the list to scroll up and down to find an element.

Refer to: Select Elements on page 114 to sort and search the element list.

9. Tap Done to return to the Spectrum screen.

The spectrum now includes the XRF lines for the selected elements.

10. Tap Done to return to the Results screen.

113

Page 14

X-MET8000 Series User Manual

8

Select Elements

Follow these steps to select elements, when the Select Elements screen appears.

1. Tap Tools to sort and search the element list.

The Select Elements screen Tools menu appears.

2. Tap Search

The Add Elements - Search screen appears, with the virtual keyboard.

3. Type the first letter of the element.

Elements with that first letter in the name or symbol appear.

4. If necessary, type a second letter, or tap the required element if it is visible.

The Select Elements screen appears, with the element selected.

Repeat these steps to add all elements.

114

Page 15

X-MET8000 Series User Manual

8

5. If necessary, tap Clear all the selections to clear the element selection.

Save The Spectra

Follow these steps to save the spectra to TXT files on a USB memory device.

1. Open the connector cover underneath the display to access the external connections.

2. Plug a USB memory device into the USB A connector.

3. From the Results screen, the History Results screen or the Test Measurement screen, tap: Tools

> Show Spectra .

The Spectrum screen appears.

4. Tap: Tools > Save Spectra to USB Memory .

The spectra are each saved to its own TXT file on the USB memory device.

5. Tap Done to return to the Results screen.

Modify The Results Screen

The X-MET8000 series has powerful features to show results. As well as Normal for single measurements

and Average for batch measurements, a supervisor can create a custom Results screen format. These

can include:

• A specific set of elements.

• The information shown for each element.

• High and low limits for each element, with optional colour coding and an alarm message.

• Alarm messages for combinations of element limits.

Results screen formats do not change the XRF analysis. It is possible to switch from a custom format

with a restricted set of elements to Normal to see the full set of results. Custom formats are ideal for

repetitive analysis and production environments. These can allow an operator to quickly determine

whether a measurement meets specification (pass or fail), or whether a confirmation measurement

is necessary.

115

Page 16

X-MET8000 Series User Manual

8

When analysing metals, the results are compared to the comprehensive grade table, and all Results

screen formats include grade information. The grade table uses AISI, other available grade tables

include DIN, JIS and Au Karat grades. The supervisor can edit grades, and can add new grades. For

example, a supervisor can use a custom grade to indicate a successful match to a specific set of

criteria. In production environments, a successful match could indicate a pass, and in a RoHS

environment it could indicate a safe sample.

The grade table is selected in the result view settings and should be selected according to the method.

A supervisor would need to instruct an operator to use a specific method or choice of methods, with

a specific Results screen format. This combination of method and Results screen format would allow

an operator to quickly assess samples, and derive the necessary results.

About Results Screen Formats

A supervisor can create a custom Results screen format. This is limited to a specific set of elements,

and only those elements appear on the Results screen. The supervisor can choose the elements to

include in the screen format. This does not, however, affect the actual measurement, but only how

the results from the measurement are shown. If a chosen element is not included in a particular

method, the result for that element is not applicable, and the screen shows ‘N/A’.

The supervisor can choose what information about the elements to include on the Results screen,

such as the concentration unit and displayed columns. The units to show element concentrations and

a choice of Results screen columns.

Each element selected for the screen format can have an optional low limit or a high limit or both. If

the result is less than the low limit, or greater than the high limit, then it trips that limit. When a

measurement trips a limit, the screen shows this with a choice of colour or an alarm message or both.

The available colours are from the simple traffic light system: green, orange and red. The supervisor

can define the text of the alarm message. Limits are always a percentage value, even when the Results

screen shows the value in parts per million.

One of the parameters to set is a +/- Coefficient, for the standard deviation. It adjusts the limits to

account for the spread of measurements. The +/- Coefficient is typically an integer between 0 and 5,

and has the effect of reducing the low alarm limit, and increasing the high alarm limit.

In addition to the alarm for each individual element, the supervisor can set one or more additional

alarms that use combinations of the element limits. A combination alarm can use one or more of the

limits set for individual elements. The combination can be a logical OR, or a logical AND. A measurement

trips a logical OR alarm when it trips any of the selected limits, but only trips a logical AND alarm when

it trips all of the selected limits. The supervisor can define the text of the alarm message.

Alarms are only activated after the Minimum Test Time. This is to ensure that the alarms are not

tripped too soon during a measurement.

Pseudo-elements

Using Pseudo Elements the X-MET8000 series can show user-specified materials "Pseudo-elements".

Each new Pseudo-element will be stored and added to the list of Pseudo-elements available.

It is possible for a supervisor to add, edit and remove compounds in the Pseudo-elements settings.

A Pseudo-element can use equations to link any elements and analytes together. For example, in the

cement industry they might use the Lime Saturation Factor to control their process "LSF =

0.715*Ca/(1.784*Si+0.635*Al+0.454*Fe)".

116

Page 17

X-MET8000 Series User Manual

8

Balance

Balance function in the X-MET8000 series informs the user of how much in the sample is not reported.

Balance can be enabled in the Result Format Menu.

Balance = 100% - Sum (all displayed

Balance informs the user of how much in the sample is not “reported”. This could be non-measurable

elements (C, O, N, or lights elements) or elements that the user chose not to display.

Note: “All displayed elements” are all elements

concentrations. It uses elemental concentrations.

elements).

selected for display. This does not use the compounds

A Custom Results Screen

The X-MET8000 series provides full control of all these aspects of the Results screen.

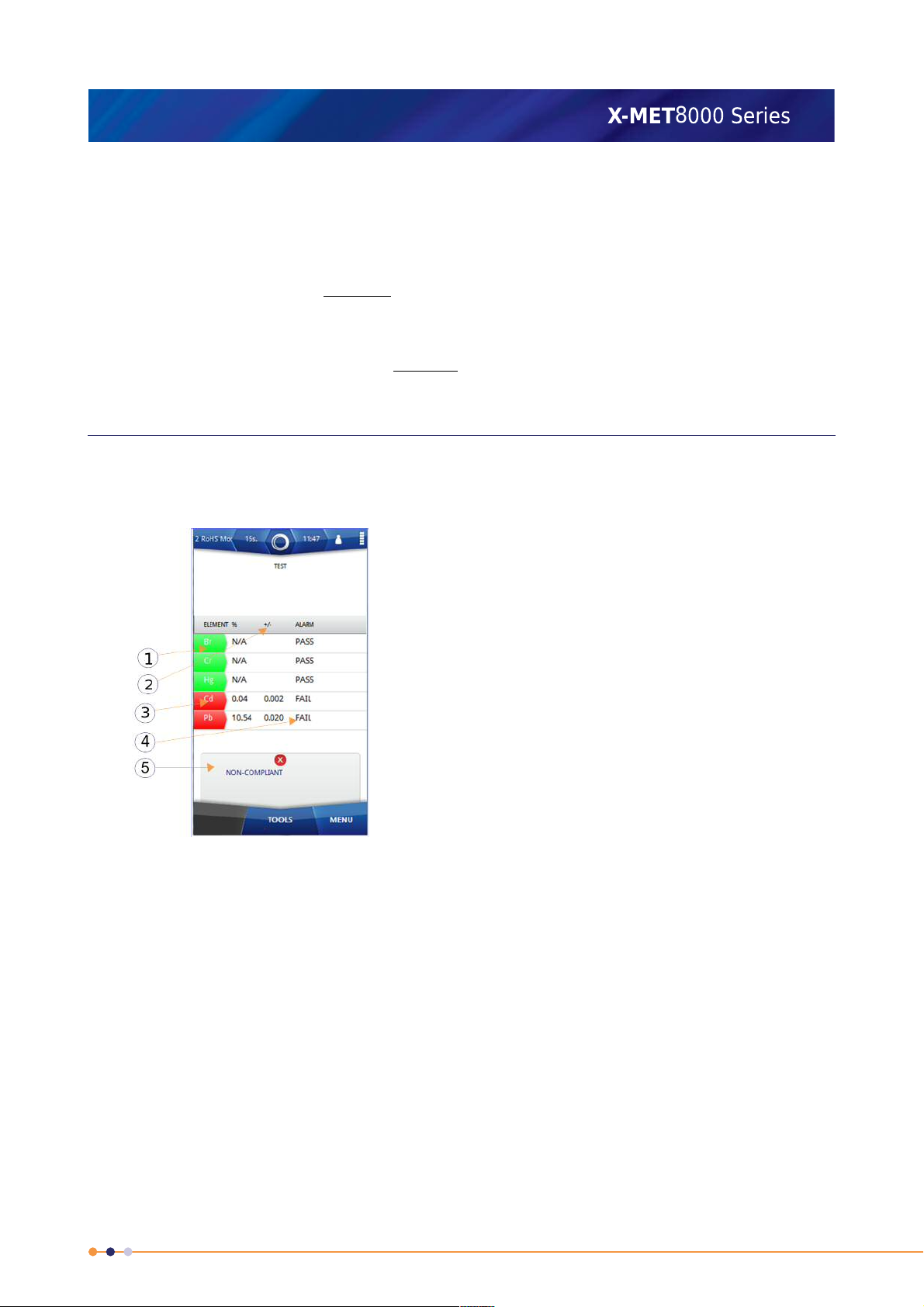

Table 2: Typical custom Results screen

1. Element list

2. +/- Coefficient

3. Coloured individual alarms

4. Individual alarm message

5. Combination alarm message

Select the elements that appear on the Results screen.Element list

Select the +/- Coefficient that appear on the Results screen.+/- Coefficient

Colour coded alarms can follow the traffic light system.Coloured individual alarms

Create messages for individual alarms.Individual alarm message

Create messages for a combination of alarms.Combination alarm message

117

Page 18

X-MET8000 Series User Manual

8

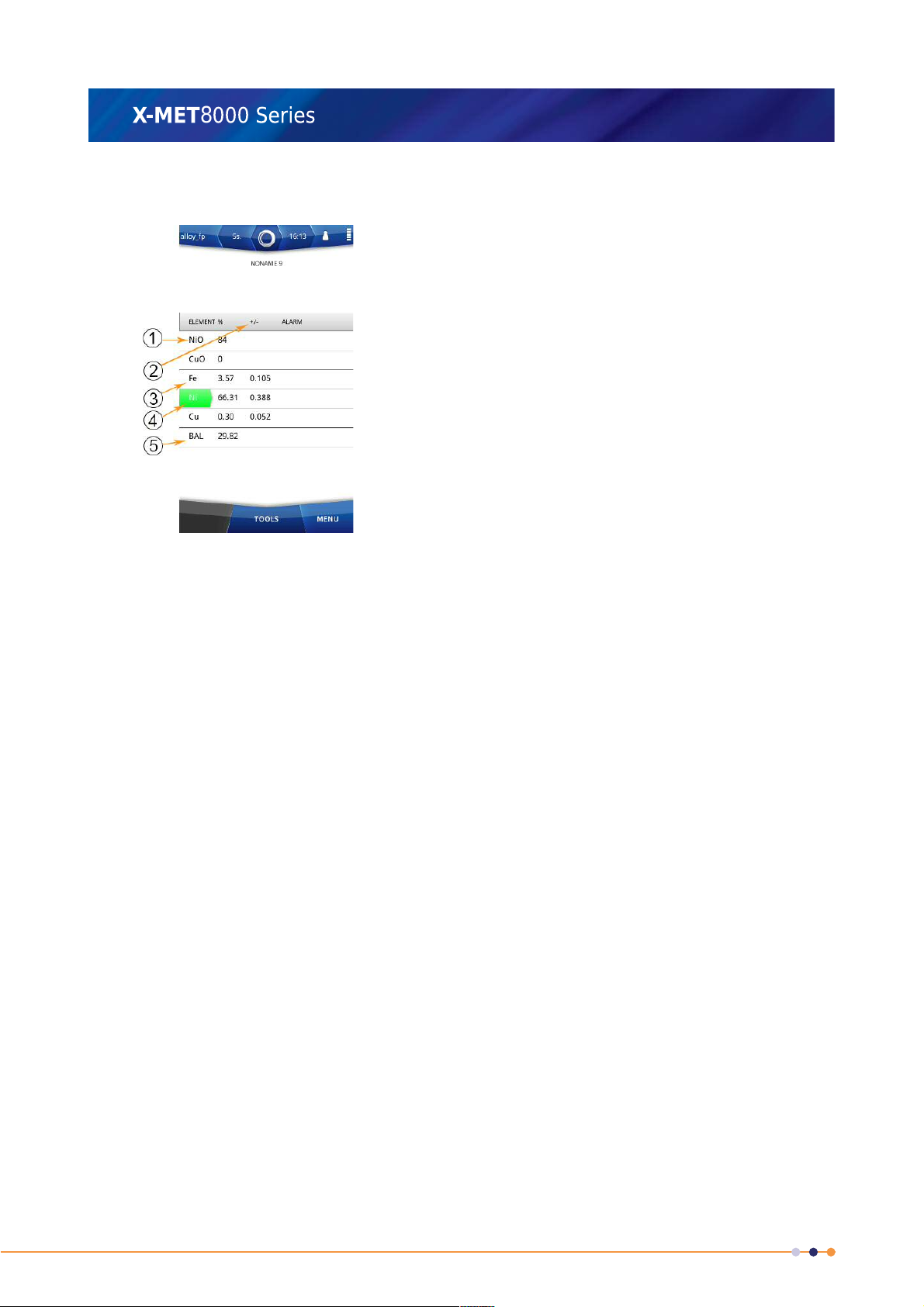

Table 3: Typical custom Results screen with Pseudo-elements and Balance

1. Pseudo-element list

2. +/- Coefficient

3. Element list

4. Coloured individual alarms

5. Balance

The selected Pseudo-elements appear first on the Results screen.Pseudo-element list

Select the elements that appear on the Results screen.Element list

Select the +/- Coefficient that appear on the Results screen.+/- Coefficient

Colour coded alarms can follow the traffic light system.Coloured individual alarms

Balance = 100% - Sum (all displayed elements).Balance

118

Page 19

X-MET8000 Series User Manual

8

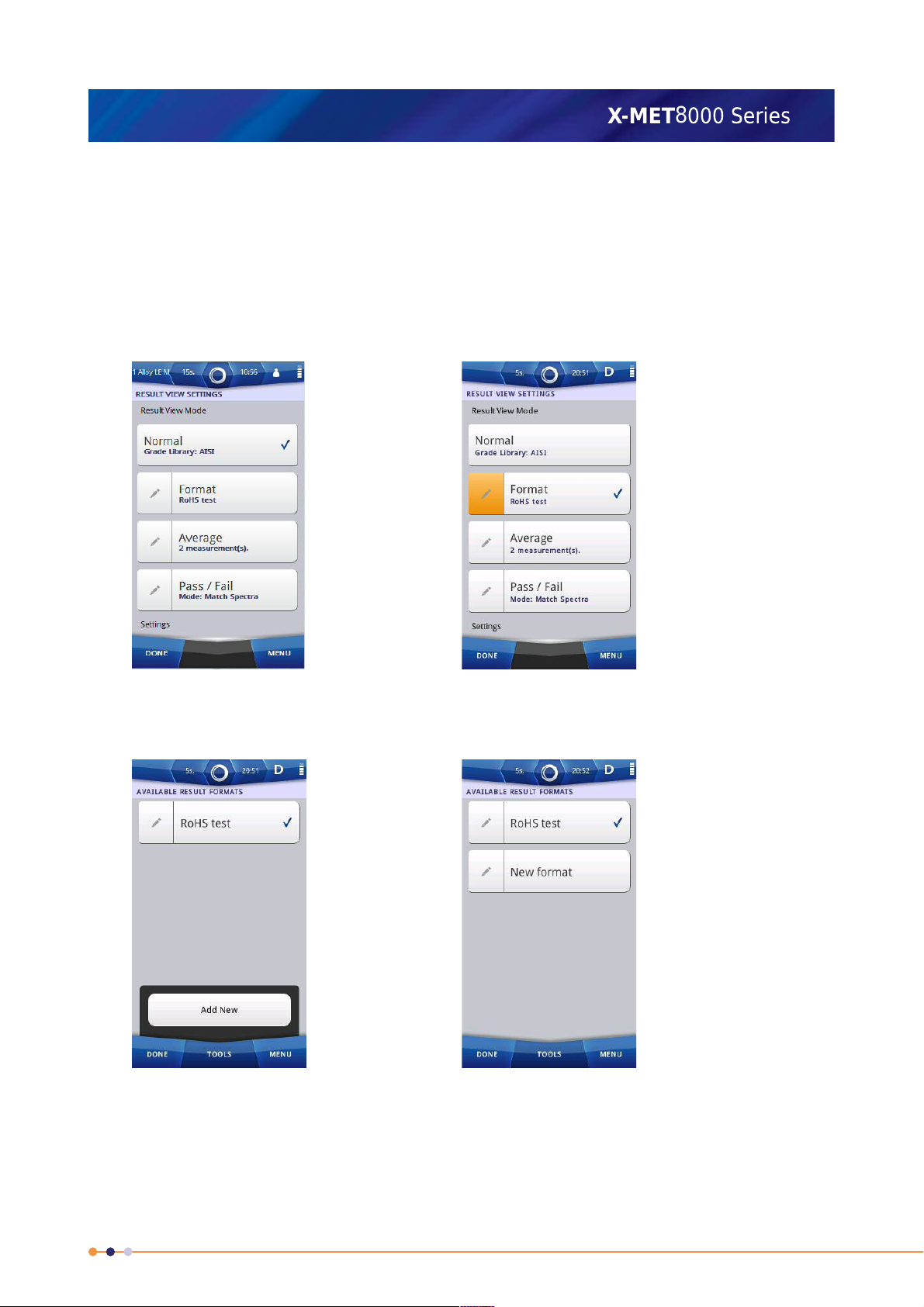

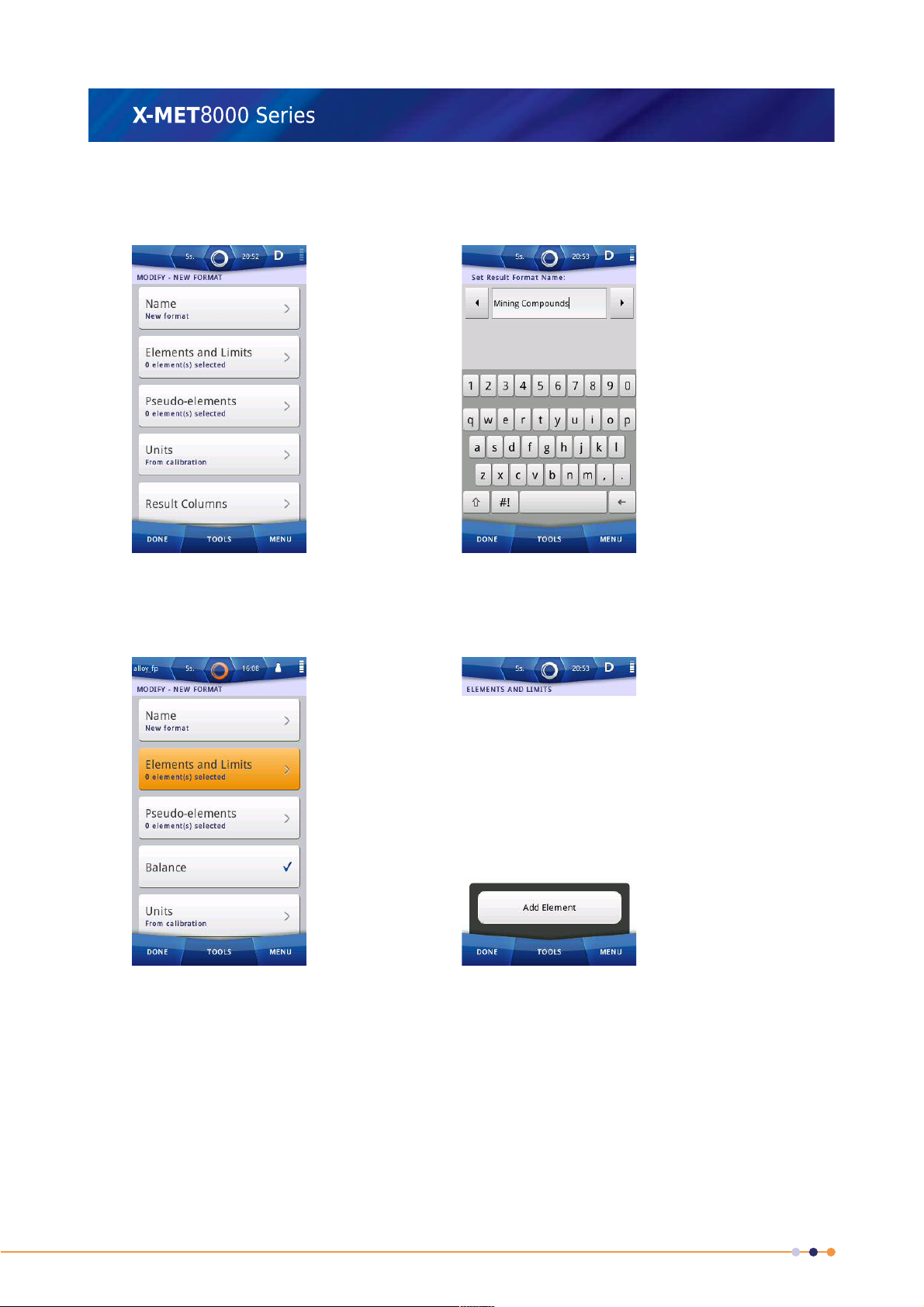

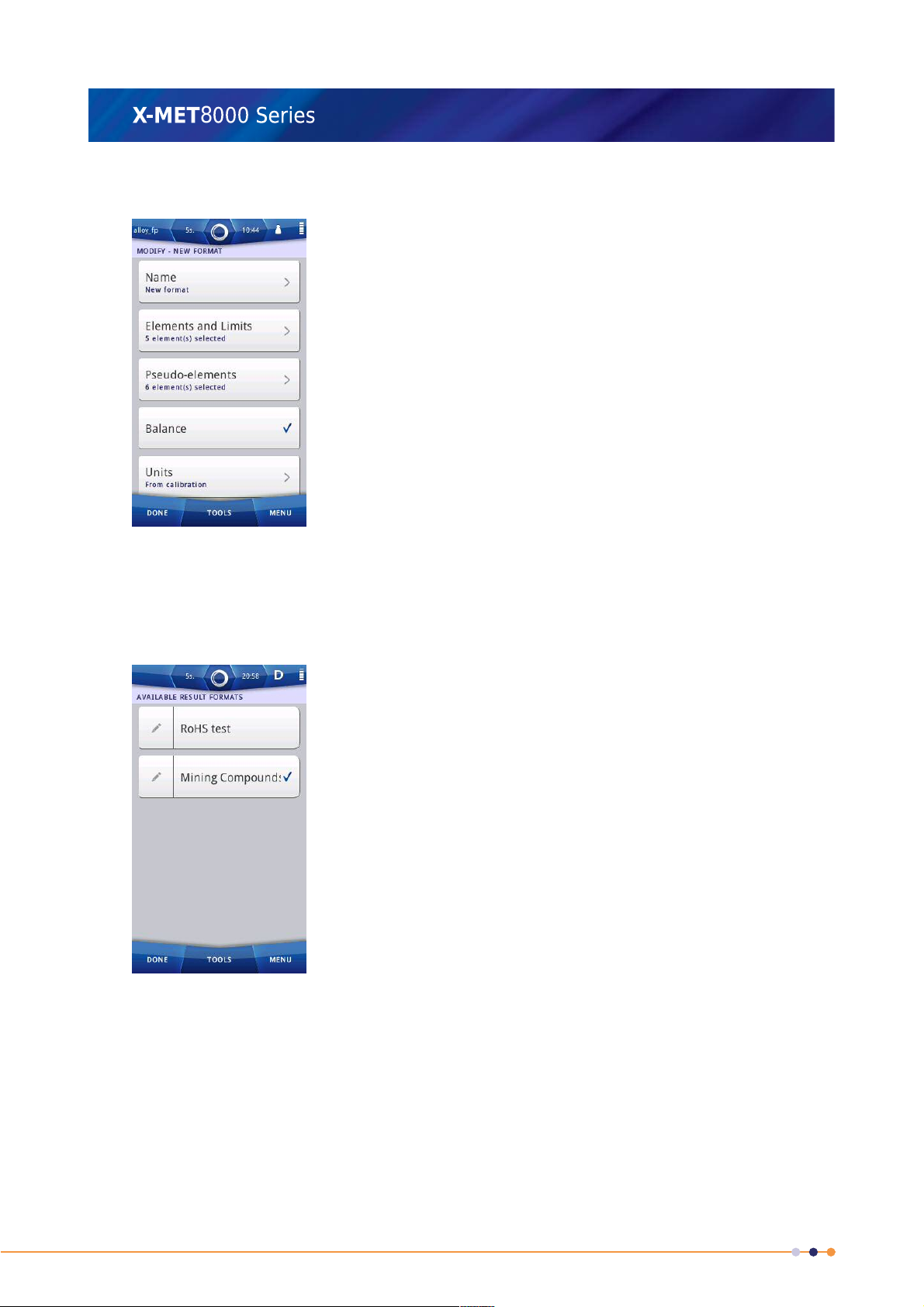

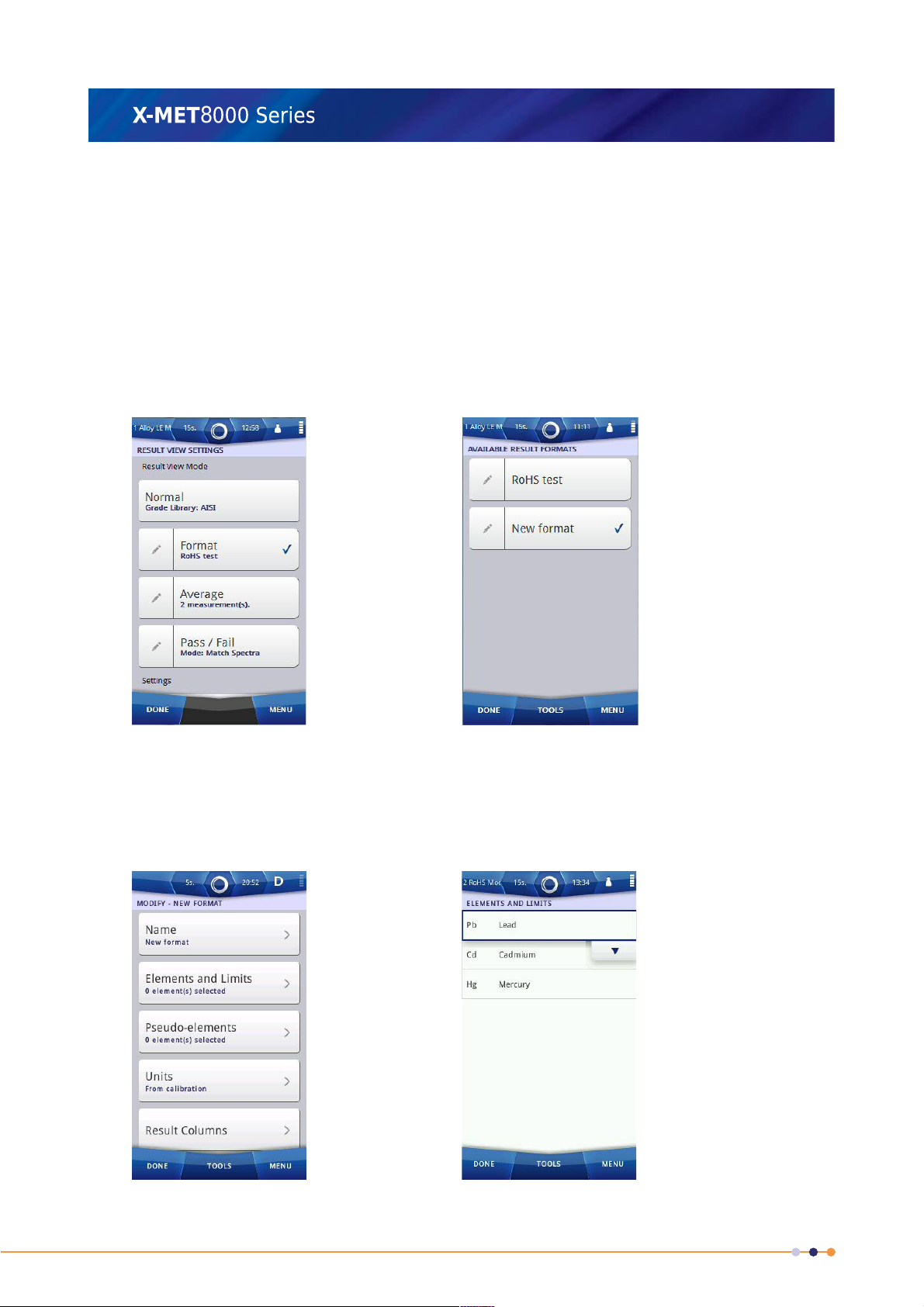

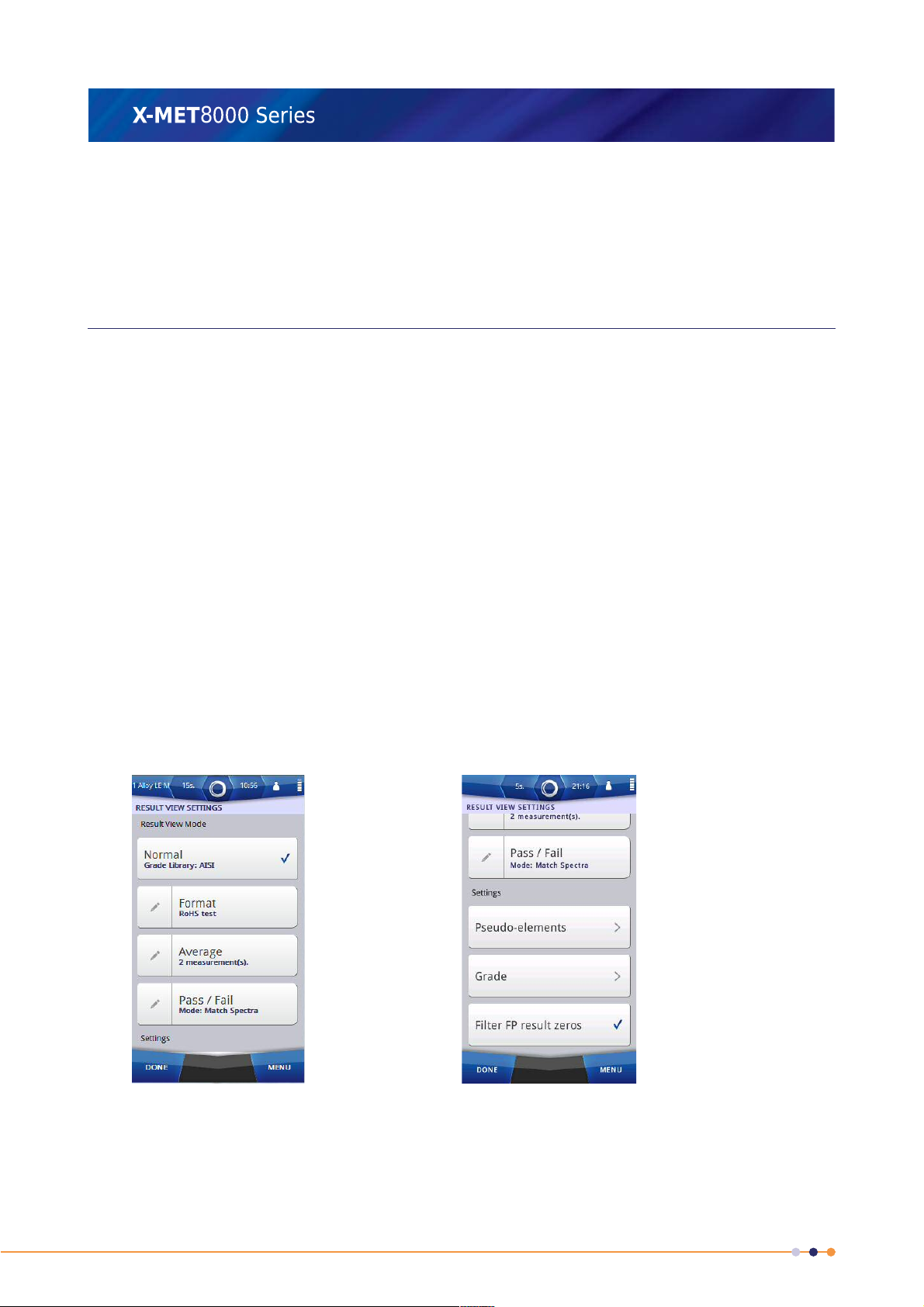

Add A New Results Screen Format

Follow these steps to add a custom results format and select the elements and Pseudo-elements to

include in the results format.

Add A Results Format

1. Navigate: Menu > Settings > Result View Settings .

The Result View Settings screen appears.

2. Tap Edit (pencil) next to Format to view the available results formats.

The Available Result Format screen appears.

3. Tap: Tools > Add New.

The Available Result Formats screen has a new results format.

119

Page 20

X-MET8000 Series User Manual

8

4. Tap Edit (pencil) next to New format.

The Modify - screen appears.

5. Tap: Name to enter a name for the result format.

6. Enter an appropriate name using the virtual keyboard and then tap Done to return to the Modify

- screen.

7. Tap: Elements And Limits.

The Elements And Limits screen appears.

8. Tap: Tools > Add Element.

The Elements selection screen appears.

120

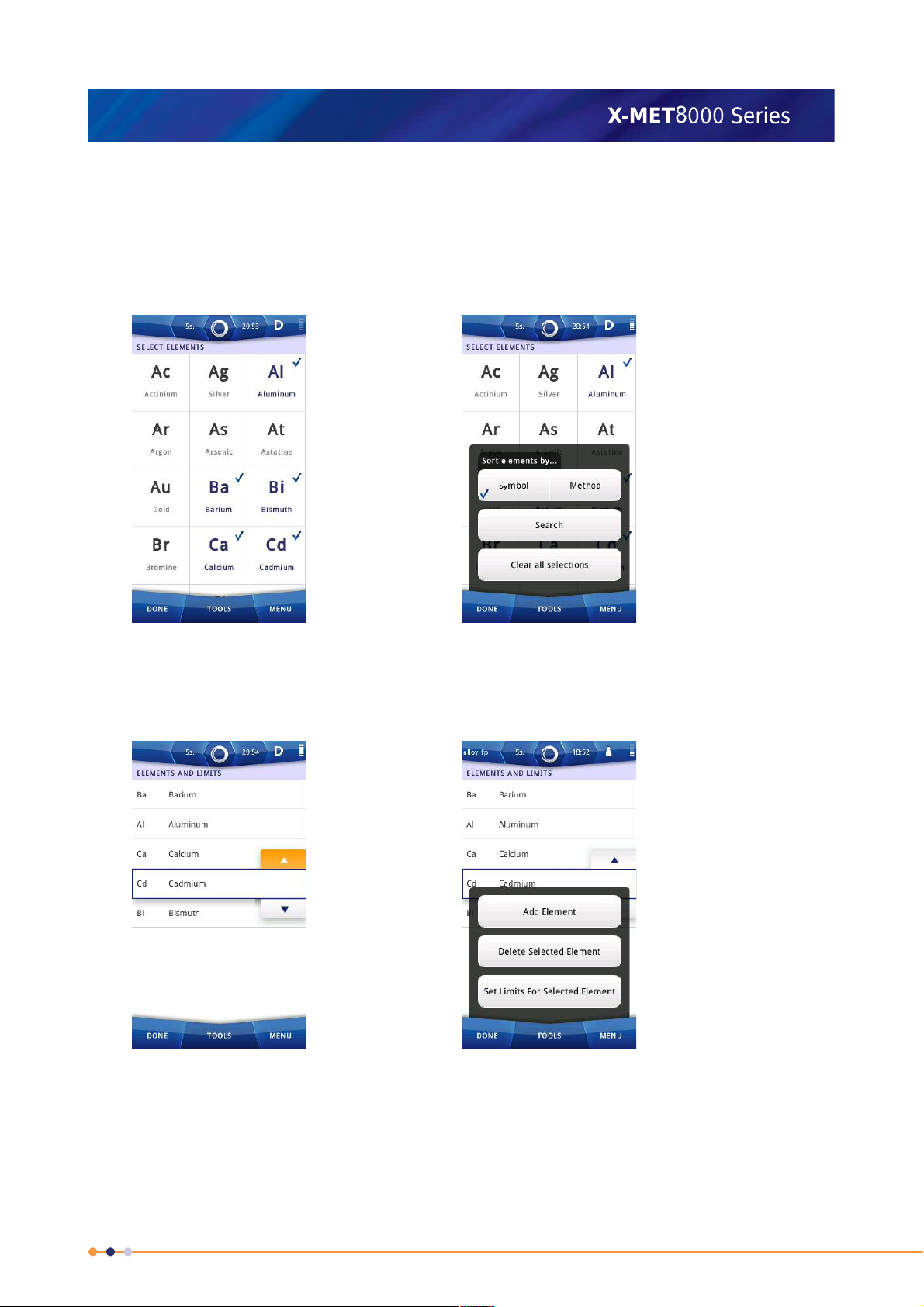

Page 21

X-MET8000 Series User Manual

8

9. Tap an element symbol to select it. Selected elements will have a checkmark.

Press and slide, or flick the list to scroll up and down to find an element.

Refer to: Select Elements on page 114 to sort and search the element list.

Note: It is possible at this stage to select elements even if they are not included in the

methods/calibrations.

10. Tap Done to return to the Elements And Limits screen.

The results format includes the selected elements.

To reorder the element list, tap the up or down arrow on the element line.

11. Tap Tools to add or delete elements from the list, and to set limits for the selected element. To

Add Combination Alarms, refer to Add Combination Alarms on page 132.

12. Tap Done to return to the Modify - screen.

121

Page 22

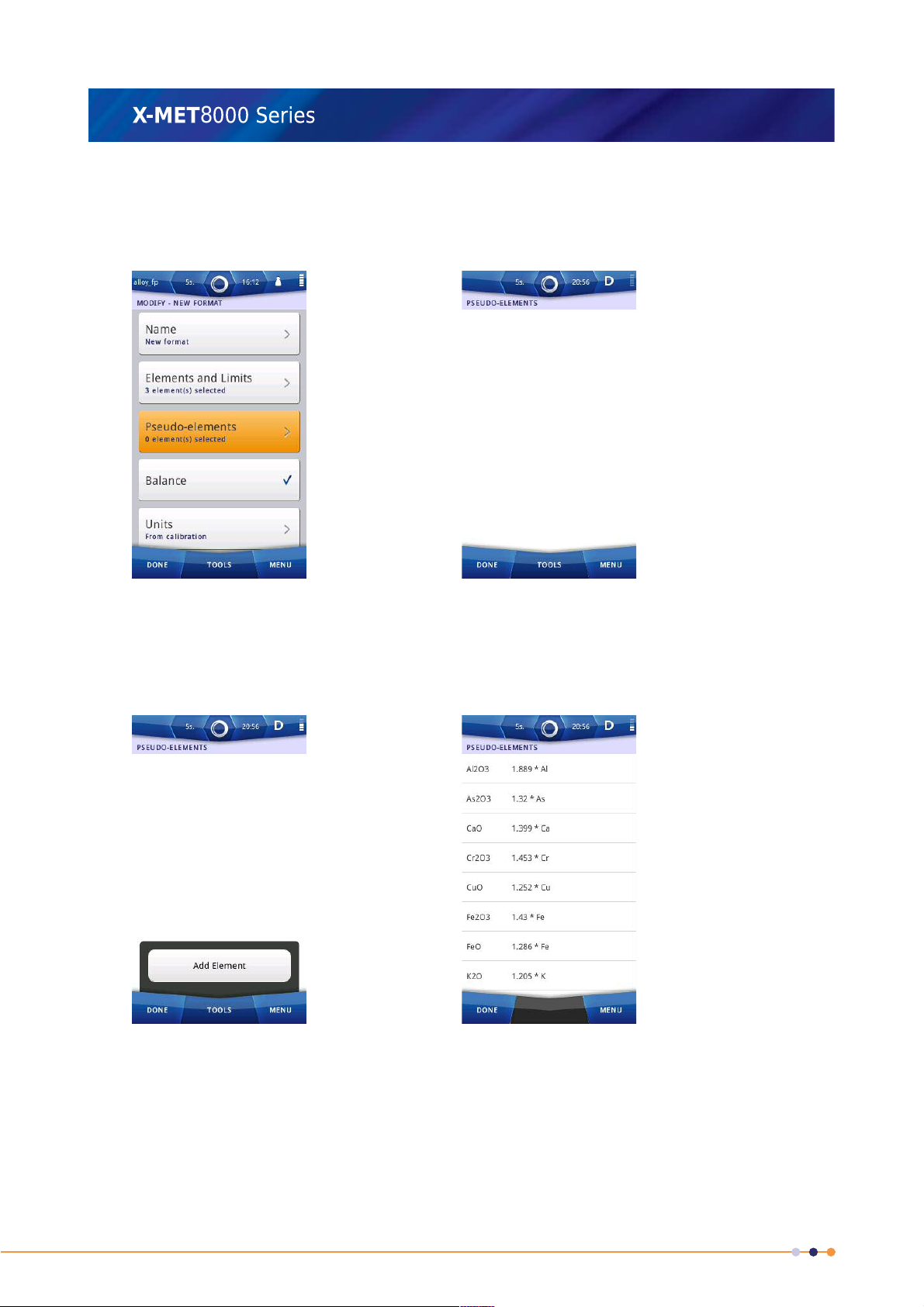

X-MET8000 Series User Manual

8

13. Do one of the following:

• Tap Pseudo-elements to add Pseudo-elements to the results format.

• To continue without adding Pseudo-elements, proceed to step 20 on page 124.

14. Tap Tools > Add Element .

The Pseudo-elements list appears.

If the desired Pseudo-element is not listed, the supervisor can create a new one in Results View

Settings.

122

Page 23

X-MET8000 Series User Manual

8

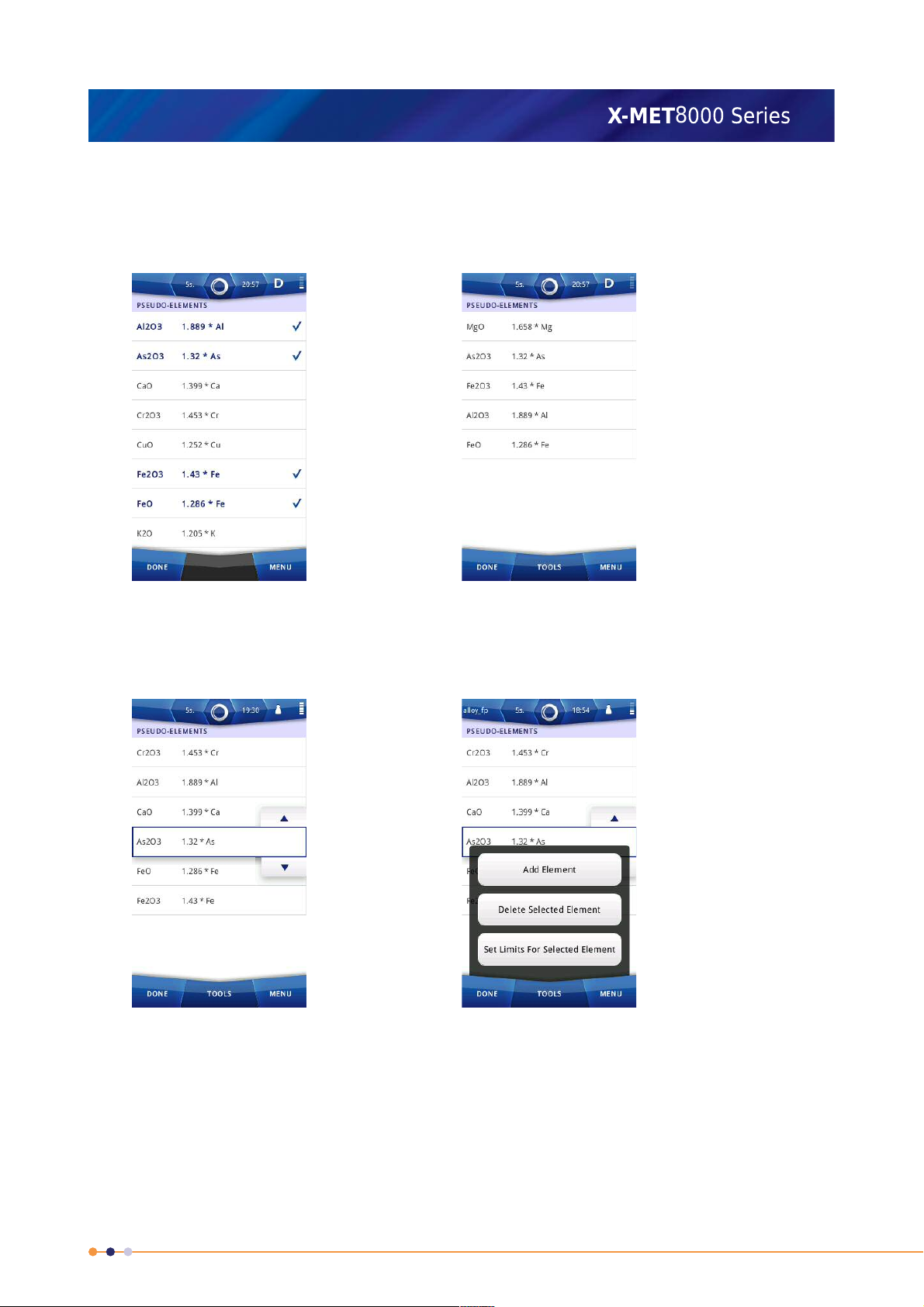

15. Tick the Pseudo-elements and compounds to include in the result format.

Press and slide, or flick the list to scroll up and down to find an element.

The selected Pseudo-elements have a checkmark next to them.

16. Tap Done to return to the Pseudo-elements screen.

The results format includes the selected Pseudo-elements.

To reorder the Pseudo-element list, tap the up or down arrow on the Pseudo-element line.

17. Tap Tools to add or delete Pseudo-elements from the selection, or to set limits for selected

Pseudo-elements. To Add Combination Alarms, refer to Add Combination Alarms on page 132.

123

Page 24

X-MET8000 Series User Manual

8

18. Tap Done to return to the Modify - screen.

19. Tap Balance to enable or disable the Balance function.

Balance has a tick against it when enabled.

20. Tap Done again to return to the Available Result Formats screen. Make sure that the applicable

result format has a tick against it.

124

Page 25

X-MET8000 Series User Manual

8

21. Tap Done again to return to the Result View Settings screen. Make sure that Format has a tick

against it.

22. Tap Done twice again to return to the main screen.

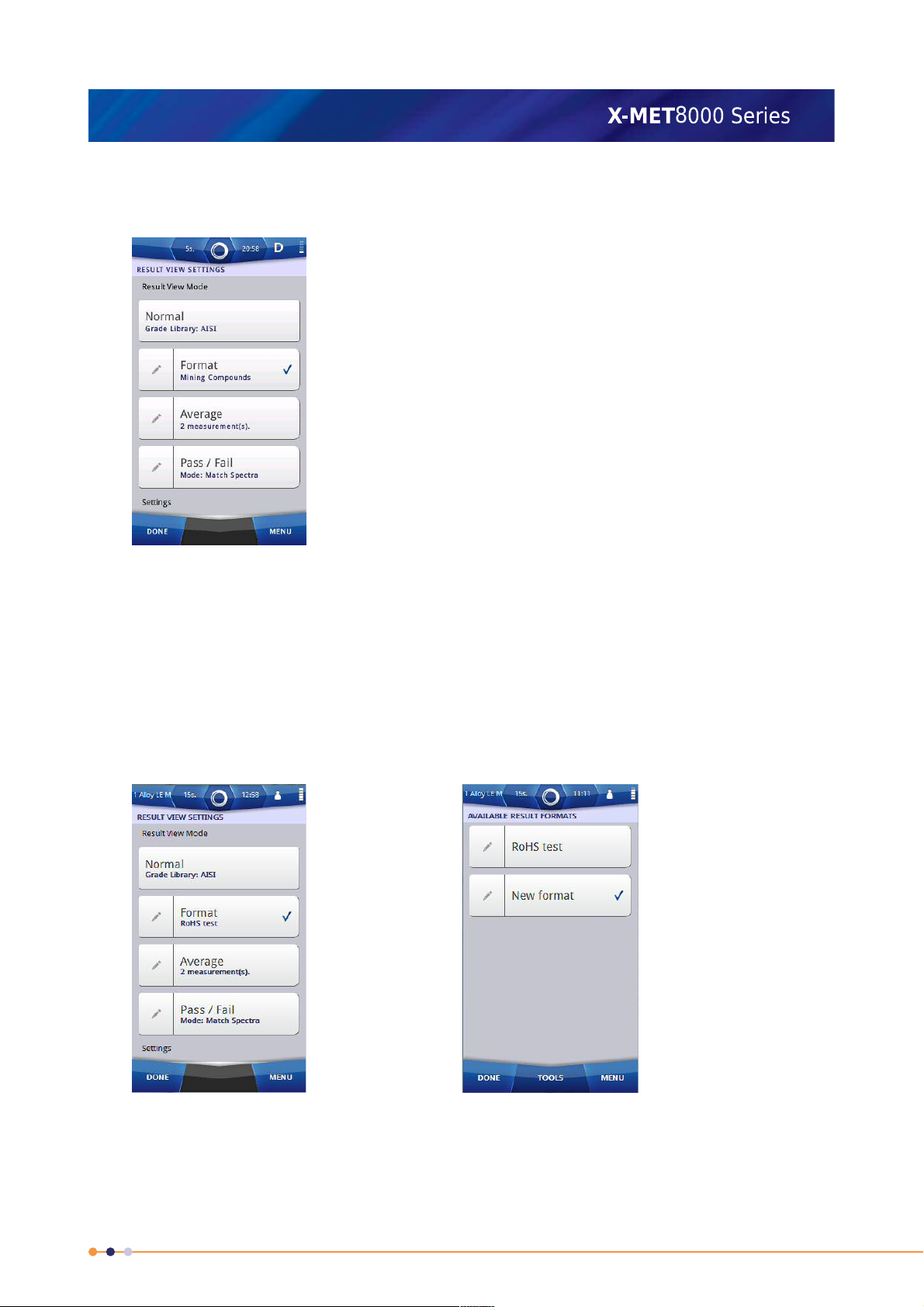

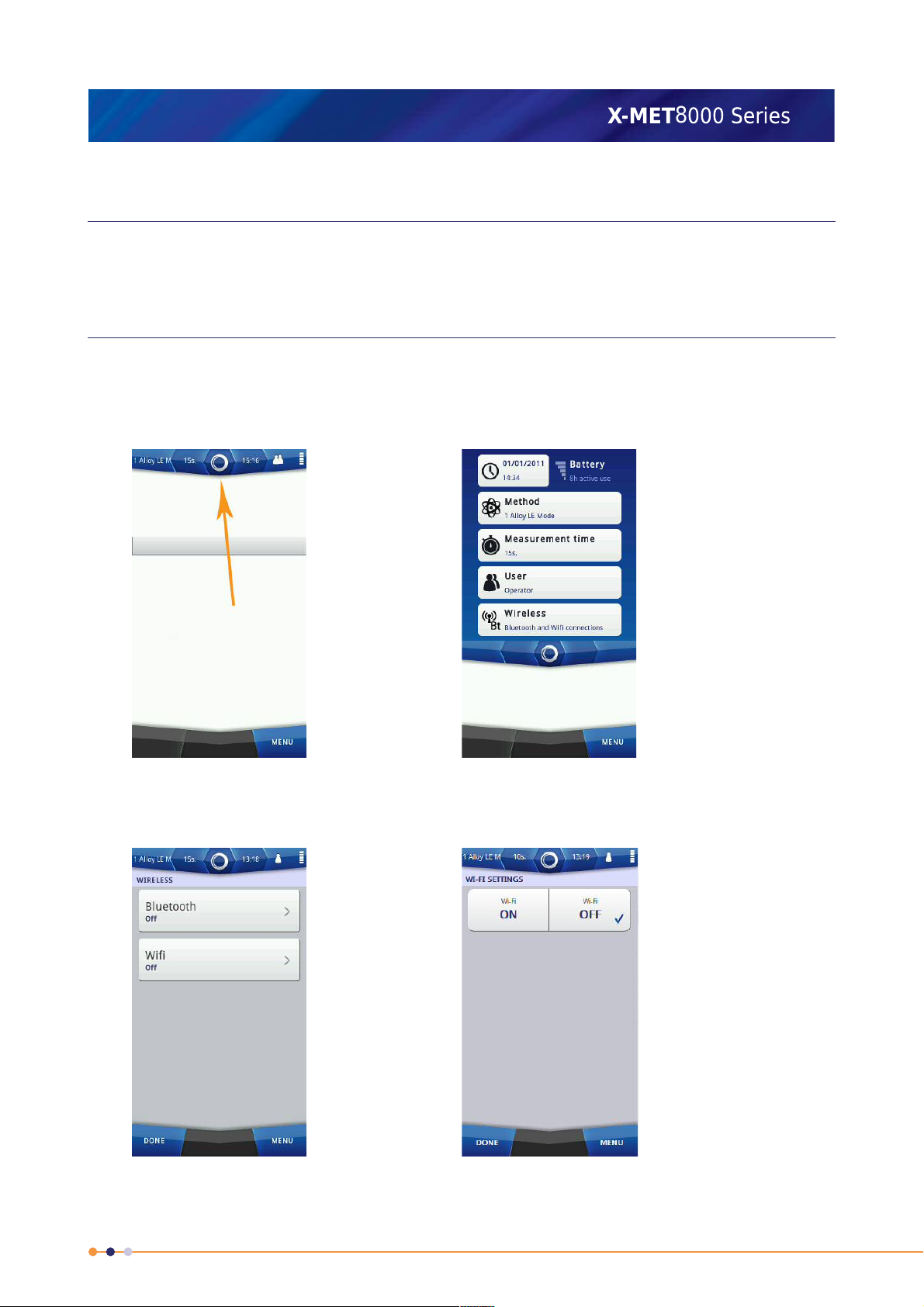

Configure A Results Screen Format

It is necessary to add a custom Results screen format before this procedure. Alarms are only activated

after the Minimum Test Time. Follow these steps to configure the Results screen format.

Select The Results Screen Format

1. Navigate: Menu > Settings > Result View Settings .

The Result View Settings screen appears.

2. Tap Edit (pencil) next to Format.

The Available Result Formats screen appears.

125

Page 26

X-MET8000 Series User Manual

8

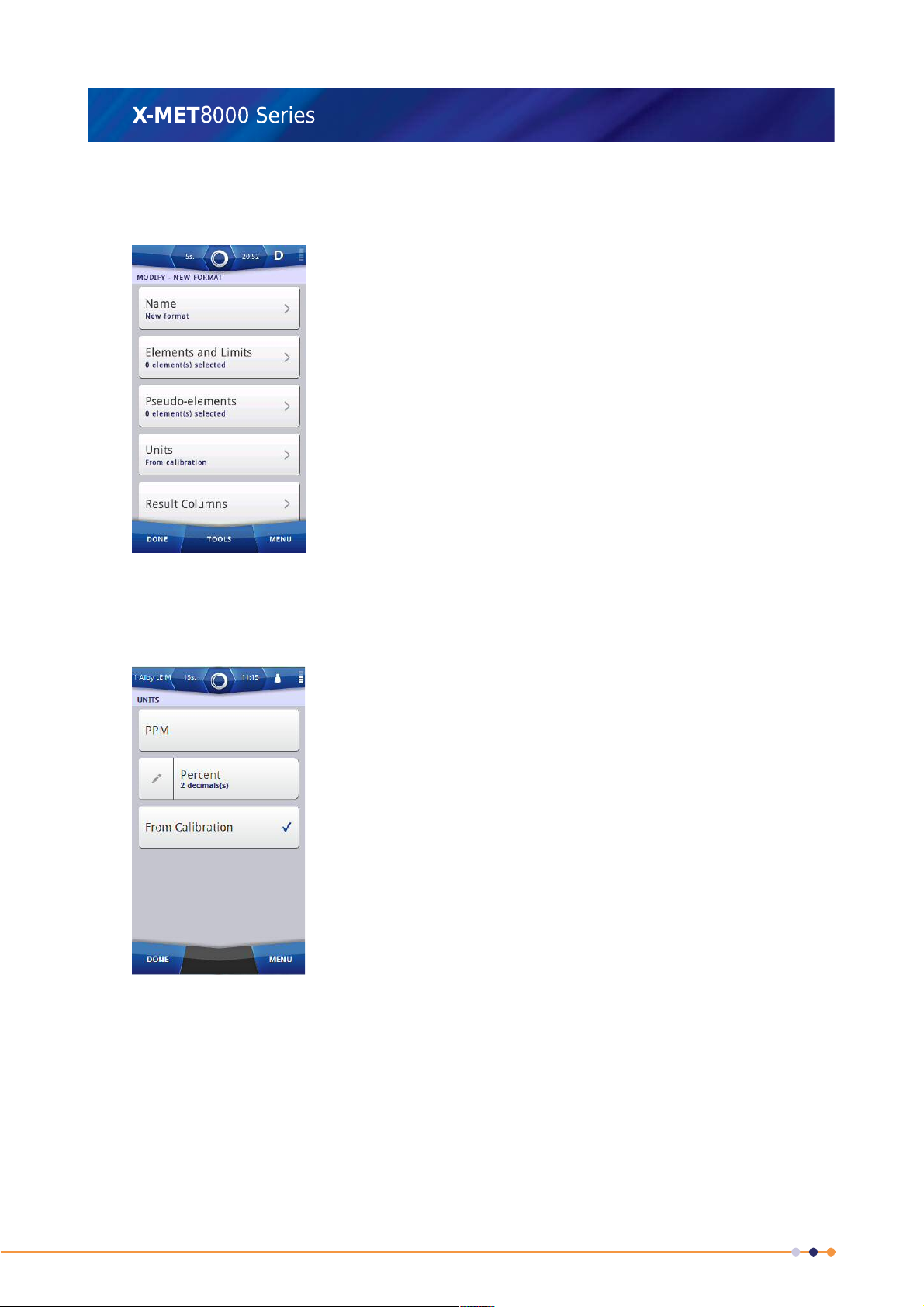

3. Tap Edit (pencil) next to the applicable format.

The Modify - screen appears.

Select The Units

4. Tap Units.

The Units screen appears.

5. Tap one of the following to choose the units for the result format:

• PPM

• Percent

• From Calibration

6. Tap Edit (pencil) next to Percent.

7. Use the numeric keypad to type the number of decimal places to show, and then tap Done to

return to the Units screen.

8. Tap Done to return to the Modify - screen.

126

Page 27

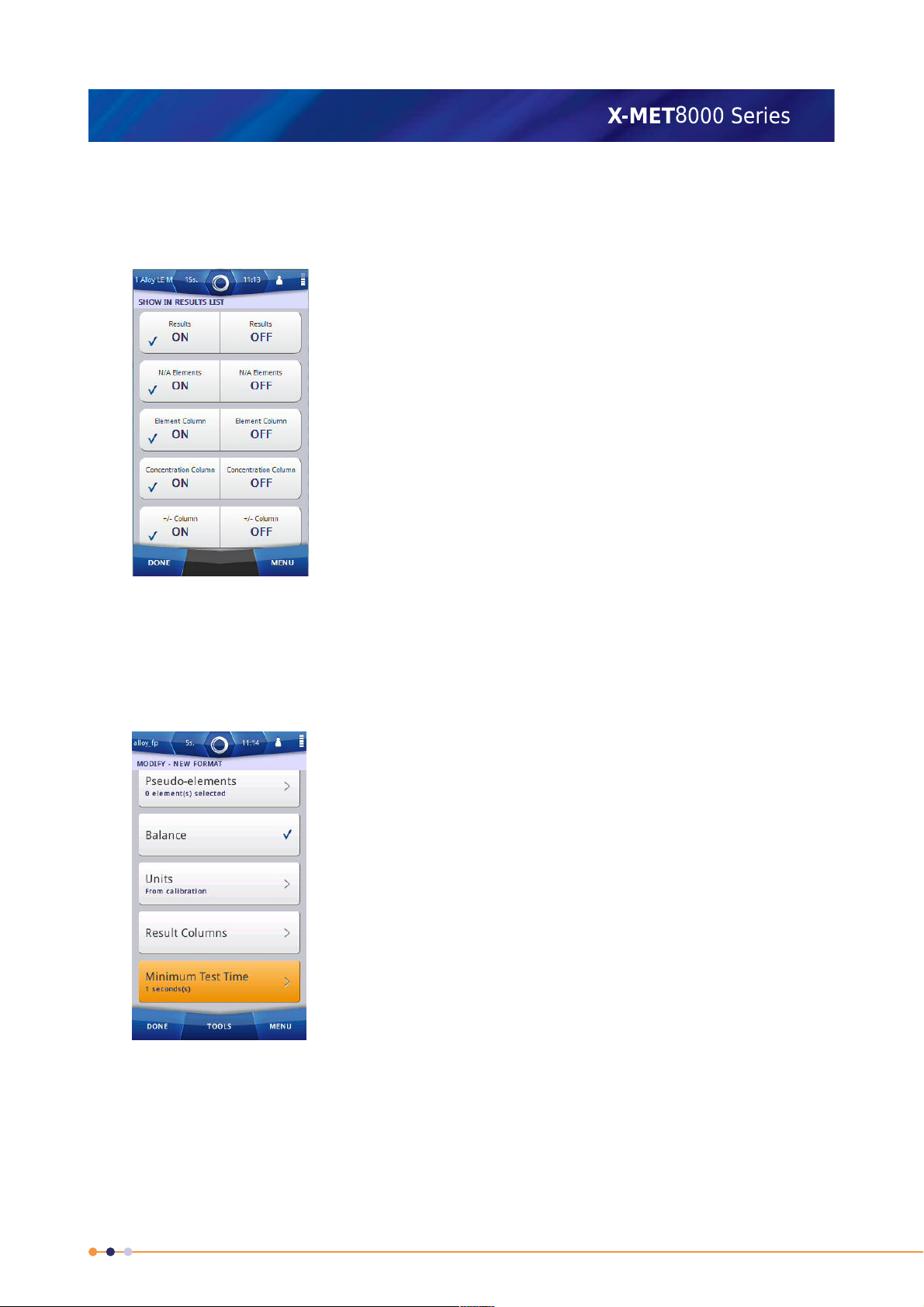

Select The Results Screen Columns

8

9. Tap Result Columns.

The Show In Results List screen appears.

X-MET8000 Series User Manual

10. Tap ON or OFF for each of the settings, as applicable, and then tap Done to return to the Modify

- screen.

Set The Minimum Test Time

11. Tap Minimum Test Time.

The Set Minimum Test Time screen appears.

12. Use the numeric keypad to type the minimum test time, and then tap Done to return to the Modify

- screen.

13. Tap Done twice to return to the Result View Settings screen.

14. Tap Done twice again to return to the main screen.

127

Page 28

X-MET8000 Series User Manual

8

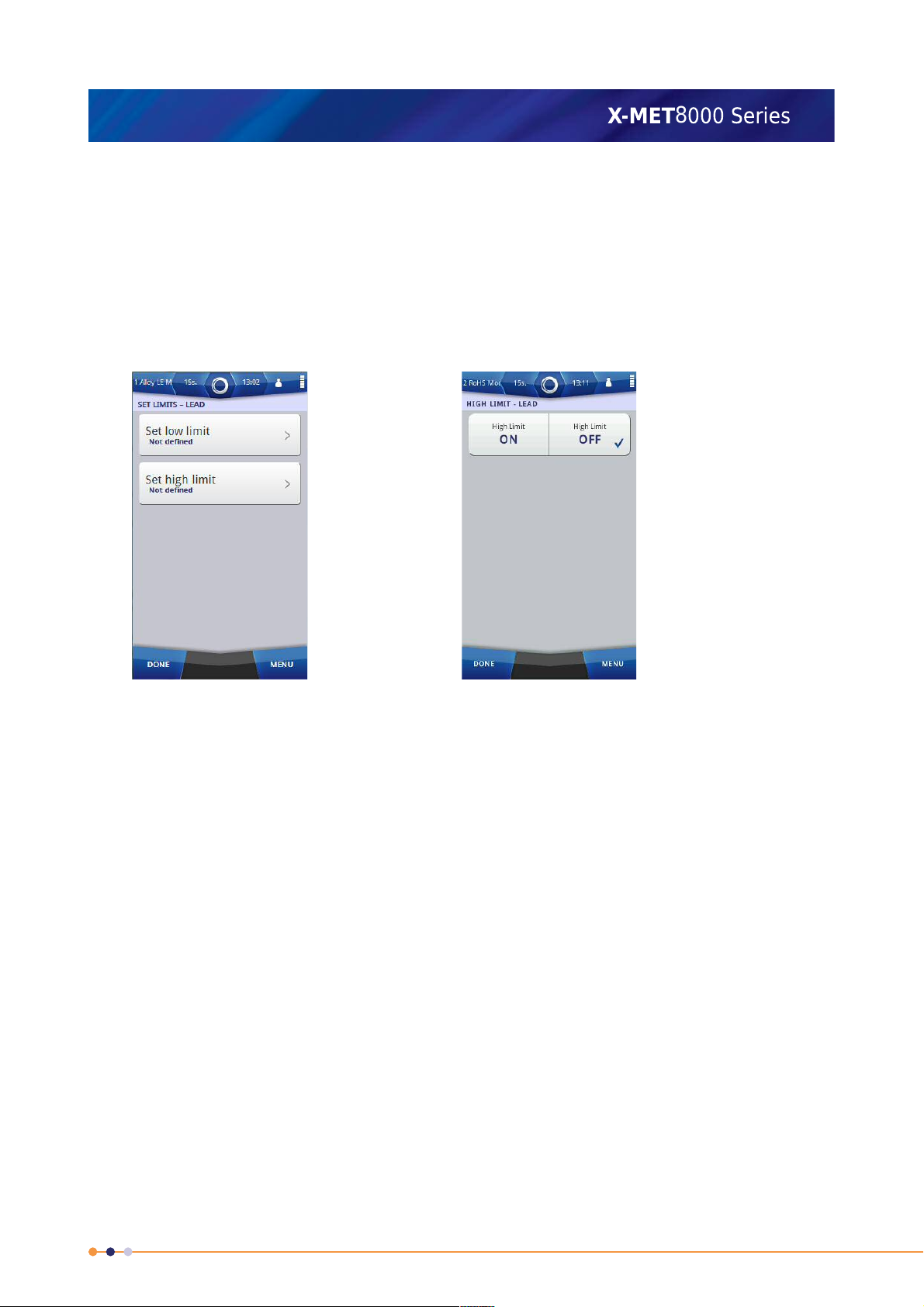

Add Limits And Individual Alarms

It is necessary to add a custom Results screen format before this procedure. Limits are always a

percentage value, even when the Results screen shows the value in parts per million. The +/- Coefficient

is typically an integer between 0 and 5, and has the effect of reducing the low alarm limit, and

increasing the high alarm limit. Follow these steps to add the limits and an alarm on an individual

element.

Select The Results Format

1. Navigate: Menu > Settings > Result View Settings .

The Result View Settings screen appears.

2. Tap Edit (pencil) next to Format.

The Available Result Formats screen appears.

3. Tap Edit (pencil) next to the applicable format.

The Modify - screen appears.

128

Page 29

X-MET8000 Series User Manual

8

Select The Element

4. Do one of the following:

• Tap Elements And Limits

• Tap Pseudo-elements

Note: The same procedure applies for Elements and Pseudo-elements.

5. Select the element, and then tap: Tools > Set Limits For Selected Element .

The Set Limits - screen appears.

Add The Limits

6. Do one of the following:

• Tap Low Limit

• Tap High Limit

The applicable Limit - screen appears.

129

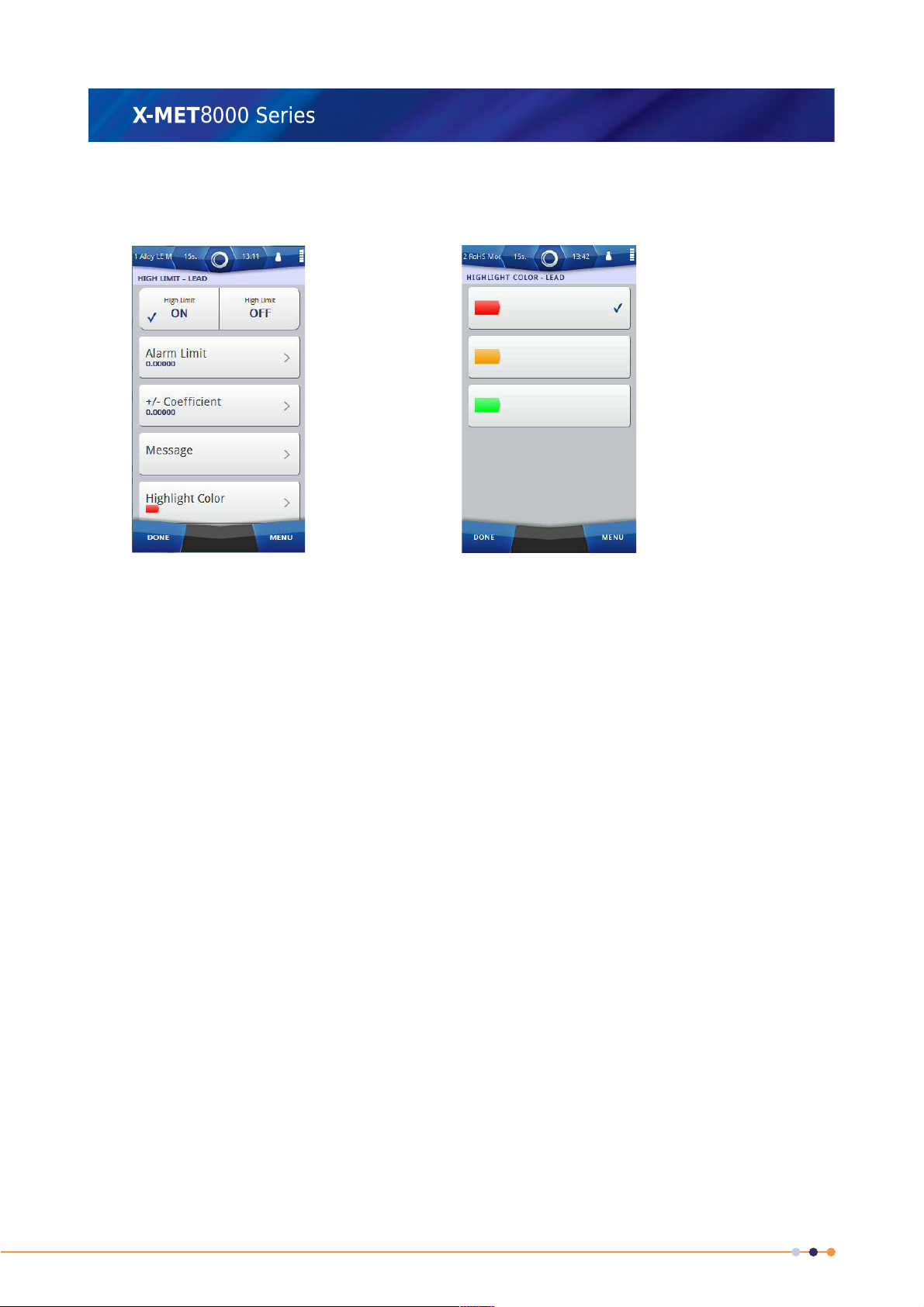

Page 30

X-MET8000 Series User Manual

8

7. Tap the ON tick box.

The Limit - screen changes.

8. Tap Alarm Limit.

9. Use the numeric keypad to type the value for the limit, and then tap Done to return to the Limit -

screen.

10. Tap +/- Coefficient.

11. Use the numeric keypad to type the value for the standard deviation coefficient, and then tap Done

to return to the Limit - screen.

12. Tap Message.

13. Use the virtual keyboard to type the message for the limit, and then tap Done to return to the

Limit - screen.

14. Tap Highlight Colour.

The Highlight Colour - screen appears.

15. Tap one of the colours, and then tap Done to return to the Limit - screen.

130

Page 31

16. Tap Done to return to the Set Limits - screen.

8

Repeat these steps for the other limit, if required.

The Set Limits - screen shows a summary of the limits.

X-MET8000 Series User Manual

17. Tap Done to return to the Elements And Limits screen.

Repeat these steps for the other elements, if required.

The Elements And Limits screen shows the elements and their limits.

18. Tap Done five times to return to the main screen.

131

Page 32

X-MET8000 Series User Manual

8

Add Combination Alarms

It is necessary to add a custom Results screen format before this procedure. It is also necessary to

add limits to individual elements. The combination can be a logical OR, or a logical AND. A measurement

trips a logical OR alarm when it trips any of the selected limits, but only trips a logical AND alarm when

it trips all of the selected limits. Follow these steps to add a combination alarm.

Select The Results Format

1. Navigate: Menu > Settings > Result View Settings .

The Result View Settings screen appears.

2. Tap Edit (pencil) next to Format.

The Available Result Formats screen appears.

3. Tap Edit (pencil) next to the applicable format.

The Modify - screen appears.

132

Page 33

Select The Element

8

4. Tap: Tools > Create Limit Alarm Tests .

The Limit Alarm Tests screen appears.

X-MET8000 Series User Manual

Add A Combination Alarm

5. Tap: Tools > Add New .

The Limit Alarm Tests screen has a new combination alarm.

6. Tap New Test.

The Modify Limit Test screen appears.

7. Tap Name.

8. Use the virtual keyboard to type a name for the combination alarm, and then tap Done to return

to the Modify Limit Test screen.

9. Tap Message.

133

Page 34

X-MET8000 Series User Manual

8

10. Use the virtual keyboard to type the message for the alarm, and then tap Done to return to the

Modify Limit Test screen.

11. Tap Test Criteria.

The Limit Test - Test Criteria screen appears.

It includes all the limits for the individual elements and Pseudo-elements included in the result

format with Pseudo-elements limits presented first.

12. Do one of the following:

• Tap AND

• Tap OR

13. Tap the individual alarms to select them for the combination, and then tap Done to return to the

Modify Limit Test screen.

14. Tap Done to return to the Limit Alarm Tests screen.

This shows the name of the new combination alarm.

15. Tap Done six times to return to the main screen.

About The Grade Table

The X-MET8000 series contains a very extensive grade library based on grades defined by AISI,DIN,JIS

and GB standards. Every user can choose the correct table for his or her own needs. When a

measurement uses a particular method, selecting an applicable grade table provides the possible

grades for the sample. For some materials there are very extensive grade tables, for example iron

and stainless steel, however grade tables are not available for all materials, for example plastics.

It is possible for a supervisor to edit existing grades in the table, and it is possible to add new grades

to a table. It is also possible to delete a grade, and to delete analytes from a grade.

There are three main steps to configure a new grade:

• Add a new grade, and define its name.

• Add analytes to the grade.

• Set the limits for each analyte.

It is also possible to define the precision and the limits that define a match to a grade, and the number

of possible matches. These settings affect all grades for every method. The grade settings are:

• The maximum number of possible grades shown.

• The coefficient for a grade match.

• The limits that define good and possible matches.

Use this table as a guide to adjust these settings.

Harder to matchEasier to matchTypical SettingValue

DecreaseIncrease1.0Grade coefficient

DecreaseIncrease1.0Good match

DecreaseIncrease5.0Possible match

If the grade coefficient is set to 0, the result must be within the grade upper and lower limit to display

the corresponding grade name. If the coefficient is set to n (n= an integer > 0), grade limits are

expanded by n*RMS error. Value 1 is a good starting point.

134

Page 35

X-MET8000 Series User Manual

8

Good match limit is the threshold limit for Good match. A difference value is calculated how close the

measurement result is compared to the grade specification. If the results of all elements match the

grade specification, the difference is 0.

If the difference is higher than the Good match limit, but lower than the Possible match limit, this is

presented as a Possible match.

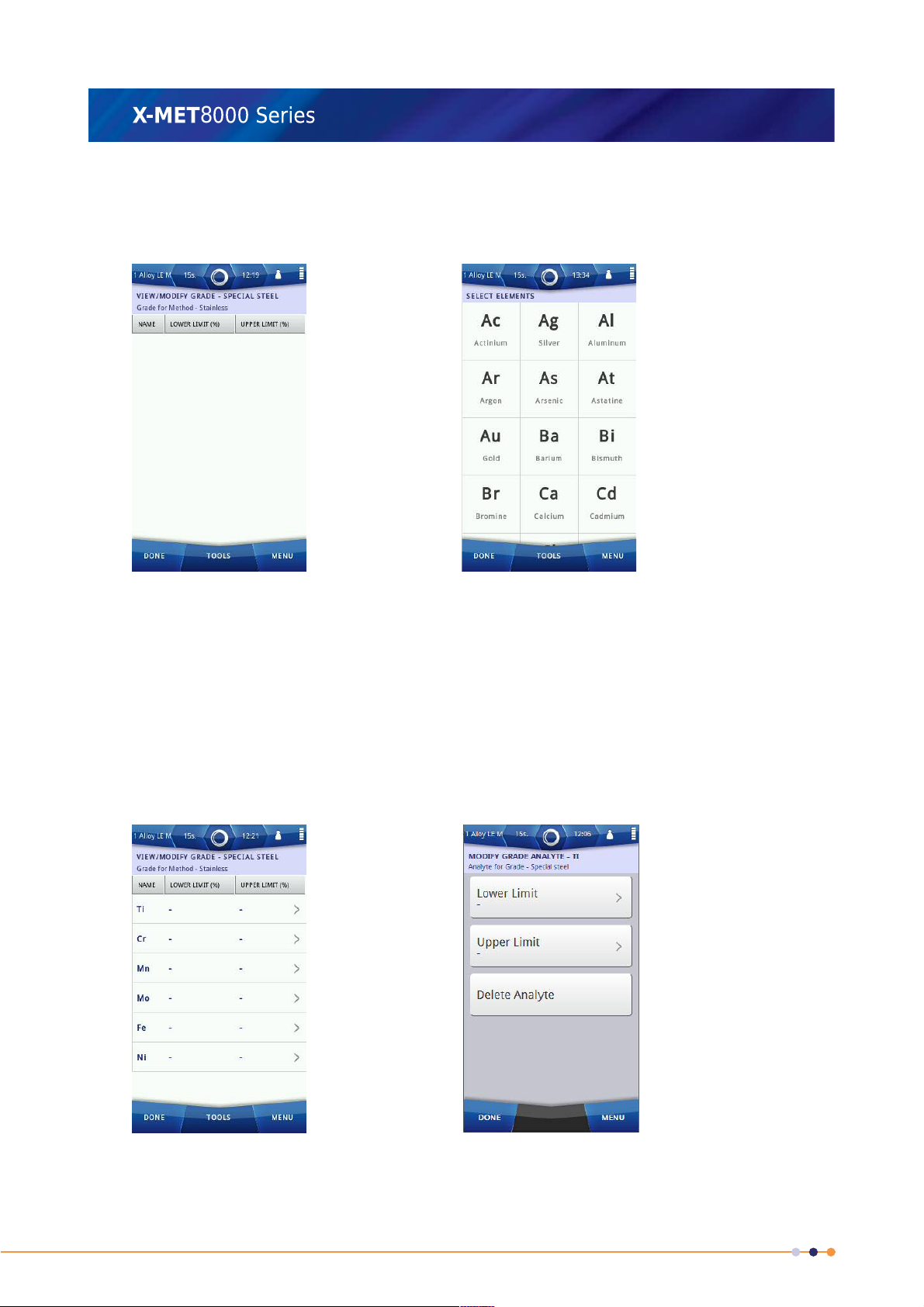

Add A Grade To A Grade Table

Follow these steps to add a grade to a grade table, add analytes to the new grade, and set limits for

an analyte.

Add A Grade

1. Navigate: Menu > Settings > Result View Settings > Grade > Grade Table Editor .

The Available Grade Libraries screen appears.

2. If the list of grade libraries is long, press and slide the list to scroll it up or down, then tap a Grade

Library to select it.

3. Tap Edit (pencil) next to the grade to show the grade library.

The Grade Library screen appears.

4. Tap: Tools > Add Grade .

135

Page 36

X-MET8000 Series User Manual

8

5. Use the virtual keyboard to type the name for the new grade, and then tap Done and scroll down

to the newly created Grade and tap on it.

The View/Modify Grade - screen appears.

Add Analytes To The Grade

6. Tap: Tools > Add Analyte(s) to Grade .

The Select Elements screen appears.

7. Tap an element symbol to select it.

Press and slide, or flick the list to scroll up and down to find an element.

Refer to: Select Elements on page 114 to sort and search the element list.

8. Tap Done to return to the View/Modify Grade - screen.

The grade includes the selected elements.

136

Page 37

X-MET8000 Series User Manual

8

Set Limits For The Analytes

9. Tap one of the analytes.

The Modify Grade Analyte - screen appears.

10. Do one of the following:

• Tap Lower Limit

• Tap Upper Limit

11. Use the numeric keypad to type the value, and then tap Done.

Repeat these steps for the other limit, if required.

12. Tap Delete Analyte, if required.

Warning dialog box appears. Select OK.This removes the analyte from the grade, and returns to

the View/Modify Grade - screen.

13. Tap Done to return to the View/Modify Grade - screen, and tap Done again to return to the Grade

Library for the Method.

14. Tap Done five times to return to the main screen.

Configure Grade Settings

The grade settings are all numeric values. Follow these steps to configure them.

1. Navigate: Menu > Settings > Result View Settings > Grade .

The Grade Settings screen appears.

2. For Grade Calculation, tap the ON tick box.

When ON is selected, the result screen will show a grade.

3. Do one of the following:

• Tap Number of Grades

• Tap Grade Coefficient

• Tap Good Match Limit

• Tap Possible Match Limit

137

Page 38

X-MET8000 Series User Manual

8

4. Use the numeric keypad to type the new value, and then tap Done to return to the Grade Settings

screen.

Repeat these steps for other grade settings, if required.

5. Tap Done three times to return to the main screen.

About Pseudo Elements

If the desired Pseudo-element is not listed, the supervisor can create a new one in the global list of

Pseudo-elements.

It is possible for a supervisor to add, edit and remove compounds in the Pseudo-elements settings. A

Pseudo-element can use equations to link any elements and analytes together. For example, in the

cement industry they might use the Lime Saturation Factor to control their process "LSF =

0.715*Ca/(1.784*Si+0.635*Al+0.454*Fe)".

How to calculate an element-to-compound concentration conversion factor:

Element A is displayed as compound AxByCz.

MAis the atomic mass of element A, MBthe atomic mass of element B, etc.

The atomic mass of the compound is: xMA+yMB+zMC.

The conversion factor from A to AxByCzis (xMA+yMB+zMC)/xMA.

Create A New Pseudo Element

Follow these steps to create a new Pseudo-element.

Note: The supervisor will also be able to delete compounds.

1. Navigate: Menu > Settings > Result View Settings .

The Result View Settings screen appears.

138

Page 39

2. Scroll down to Settings and Tap Pseudo-elements.

8

The Available Pseudo-elements screen appears.

X-MET8000 Series User Manual

3. Tap: Tools > Create New Element .

The Add/Edit Pseudo-element screen appears.

4. Tap Name.

5. Enter an appropriate name using the virtual keyboard and then tap Done to return to the Add/Edit

- screen.

6. Tap Formula to enter a formula for the new Pseudo-element.

139

Page 40

X-MET8000 Series User Manual

8

7. Enter an appropriate name using the virtual keyboard and then tap Done to return to the Add/Edit

- screen.

The formula can include any elements and analytes and supports basic math functions + - * / ^

and ( ).

The formula does not check for elements and analytes so ensure that the correct element or analyte

chemical symbols are used. Errors or division by zero in the formula results in N/A results.

8. Tap Done to return to the Pseudo-elements - screen.

9. Tap Done to return to the Result View Settings - screen.

The new Pseudo-element can now be included in custom result formats.

10. Tap Done twice again to return to the main screen.

140

Page 41

X-MET8000 Series User Manual

8

Wireless Network Use Cases

The X-MET8000 series can connect to Wi-Fi networks in Managed and Ad hoc mode. A typical use for

Wi-Fi is to connect to a PC. This can allow more than one PC to connect to the X-MET8000 series.

The Wi-Fi connection can be used to transfer reports directly to a shared network resource and for

operation of the X-MET8000 series trough a PC or tablet device using the WEB-interface or VNC. The

Wi-Fi connection can also be used to control the X-MET8000 series remotely using the XAPI protocol.

In a managed network the X-MET8000 series can write reports to shared network folders and print

reports to network printers. In addition the X-MET8000 series can be controlled from any computer

on the local network providing that the IP address for the X-MET8000 series is known.

This manual will in detail explain how to connect the X-MET8000 series to a Wi-Fi network, enable

shared folders for file transfer and connect to the X-MET8000 series using a Wi-Fi enabled computer

or tablet.

Trough an ad hoc network connection it is possible to remotely access and control the X-MET8000

series using an WEB-browser or VNC and from the X-MET8000 series use shared folders and printers

physically connected to the computer providing the ad hoc network.

Note that shared network resources may not work in ad hoc mode unless the resources are located

on the device providing the ad hoc network.

The X-MET8000 series can be remotely controlled trough a VNC connection and using most common

WEB browsers. This manual includes instructions on how to setup and control the X-MET8000 series

using a WEB browser running on a PC and trough a VNC-connection from a PC and an iPad.

WEB browsers on mobile devices may not be fully compatible with the X-MET8000 series web interface,

some features might not work properly if used with a mobile device web browser.

Multiple Wi-Fi connected X-MET8000 series devices can be controlled from a single computer using

tabs in the WEB browser, one tab for each X-MET8000 series device.

Using the XAPI interface and a Wi-Fi connection multiple X-MET8000 series devices can be used for

automated operation with a minimum of additional equipment and infrastructure.

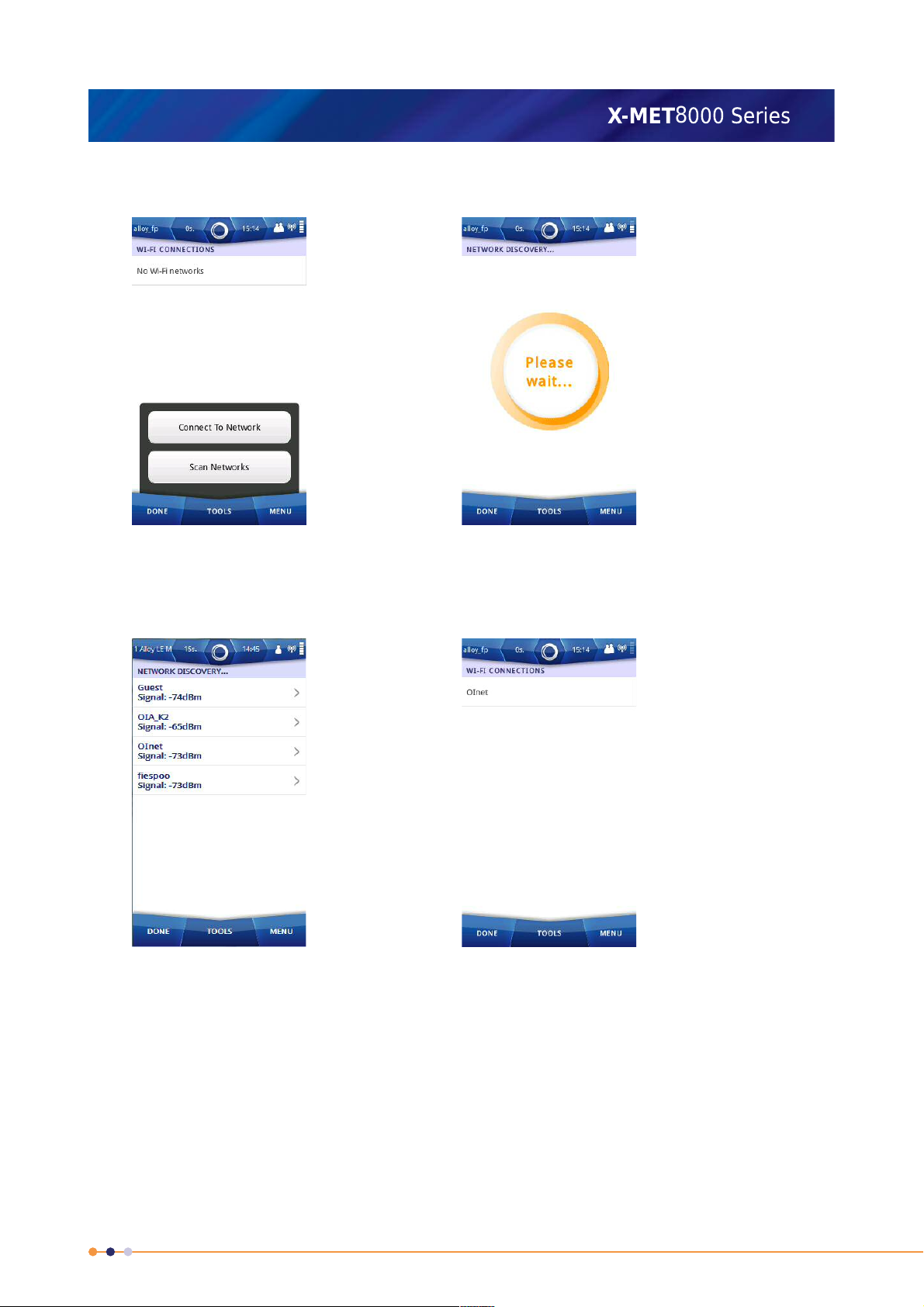

Wireless Connections

The X-MET8000 series can connect to Bluetooth and Wi-Fi networks. Both networks are switched off

by default. A typical use for Bluetooth would be to connect to a precision GPS receiver for mining

applications, and it is possible to check the GPS information from the X-MET8000 series. A typical use

for Wi-Fi is to connect to a PC. This can allow more than one PC to connect to the X-MET8000 series.

The Wi-Fi connection can be to a broadcast network or to a hidden network. For a broadcast network,

it can be necessary to know the passkey. For a hidden network, it is necessary to know the SSID.

Hidden networks can be either managed or ad-hoc. Managed networks can use either WPA or WPA2

Personal encryption, and ad hoc networks can use WPA None encryption. If a hidden network uses

encryption, it is necessary to know the passkey. The network administrator will know the type of

network in use, and can provide the SSID and passkey, as applicable.

An ad hoc Wi-Fi network is a decentralized type of wireless network. The network is ad hoc because

it does not rely on a pre existing infrastructure, such as access points in managed wireless networks.

Network shared folders and printer will most likely not work trough an ad hoc network

141

Page 42

X-MET8000 Series User Manual

8

A managed Wi-Fi network utilizes access points providing wireless access to the network infrastructure

including shared folders and printers

Most common full featured web browsers i.e. IE, Mozilla and Chrome will work with the X-MET8000

series web user interface and are platform and X-MET8000 series software version independent.

Many mobile devices use web browsers optimized for mobile web browsing, these might not include

all features required by the X-MET8000 series web GUI. Multiple X-MET8000 series devices running

different software versions can be operated simultaneously using tabs in the web browser.

Wi-Fi ad hoc network topology

The laptop provides the Wi-Fi network in ad hoc mode and the X-MET8000 series connects directly to

the laptop. Network resources might not be accessible from the X-MET8000 series.

142

Page 43

X-MET8000 Series User Manual

8

Wi-Fi managed network topology

In managed networks existing infrastructure like routers and switches connects the clients to the

network, shared resources are accessible from all network connected clients.

Add A Bluetooth Connection

Follow these steps to connect to a Bluetooth device.

1. Navigate: Status Bar > Wireless .

The Wireless screen appears.

143

Page 44

X-MET8000 Series User Manual

8

2. Tap Bluetooth.

The Bluetooth Settings screen appears.

3. Tap the ON tick box.

The Bluetooth Settings screen changes.

4. Tap Set Device Name.

5. Use the virtual keyboard to type an applicable name, and then tap Done to return to the Bluetooth

Settings screen.

6. Tap View Connections.

The Bluetooth Connections screen appears.

7. Tap: Tools > Discover New Devices .

The Bluetooth Device Discovery screen appears, and a search for the Bluetooth devices begins.

When the search is complete, the screen shows the available Bluetooth devices.

144

Page 45

X-MET8000 Series User Manual

8

8. If necessary, tap: Tools > Discover Again .

Another search for the Bluetooth devices begins, and the Bluetooth Device Discovery screen

updates.

9. Tap on one of the discovered bluetooth devices.

The Set Pin Code for Bluetooth Device screen appears.

10. Enter the correct Pin Code.

11. Tap Done twice to return to the Bluetooth Connections screen.

The Bluetooth device is added to the Bluetooth Connections screen.

12. Tap on the newly added bluetooth device and select Tools and choose one of the applicable options.

The Bluetooth Connections screen updates.

13. Tap Done to return to the Bluetooth Settings screen.

14. Tap Done twice again to return to the main screen.

Add A Bluetooth Keyboard

Follow these steps to add a Bluetooth keyboard directly to the X-MET8000 series.

1. Navigate: Status Bar > Wireless .

The Wireless screen appears.

2. Tap Bluetooth.

The Bluetooth Settings screen appears.

145

Page 46

X-MET8000 Series User Manual

8

3. Tap the ON tick box.

The Bluetooth Settings screen changes.

4. Tap Set Device Name.

5. Use the virtual keyboard to type an applicable name, and then tap Done to return to the Bluetooth

Settings screen.

6. Tap View Connections.

The Bluetooth Connections screen appears.

7. Tap: Tools > Discover New Devices .

The Bluetooth Device Discovery screen appears, and a search for the Bluetooth devices begins.

When the search is complete, the screen shows the available Bluetooth devices.

8. If necessary, tap: Tools > Discover Again .

Another search for the Bluetooth devices begins, and the Bluetooth Device Discovery screen

updates.

146

Page 47

X-MET8000 Series User Manual

8

9. Tap on the discovered Bluetooth keyboard.

The Set Pin Code for Bluetooth Device screen appears.

10. Enter the correct Pin Code, verify the correct code from the keyboard manual if necessary.

Tip: If the password does not work, try typing the passkey on the touch screen, then type the same

passkey and press <ENTER> on the Bluetooth keyboard.

Please refer to the keyboard manual for additional information on pairing the keyboard.

11. Tap Done twice to return to the Bluetooth Connections screen.

The Bluetooth keyboard is added to the Bluetooth Connections screen.

12. Tap on the newly added bluetooth keyboard and select Tools > Connect To Input .

The Bluetooth Connections screen updates. An information message is displayed informing that

the keyboard is connected.

13. Tap Done to return to the Bluetooth Settings screen.

14. Tap Done twice again to return to the main screen.

The Bluetooth keyboard can no be used as input device in all fields where text or numeric input is

applicable.

Check GPS Information

Once a Bluetooth connection is made to the GPS receiver, it is possible to check the GPS position data

and satellite information. Follow these steps to check the GPS information.

1. Navigate: Status Bar > Wireless

The Wireless screen appears.

2. Tap Bluetooth.

The Bluetooth Settings screen appears.

147

Page 48

X-MET8000 Series User Manual

8

3. Tap View GPS Information.

The GPS Position Data screen appears.

4. Tap: Tools > Refresh Now to refresh the GPS Position Data.

5. Tap: Tools > View Satellites

The GPS Satellite Information screen appears.

6. Tap Done to return to the GPS Position Data screen.

7. Tap Done to return to the Bluetooth Settings screen.

8. Tap Done twice again to return to the main screen.

148

Page 49

X-MET8000 Series User Manual

8

Connect the X-MET8000 series to a company network

The procedure may differ depending on the network security level and server versions used. If the

network utilizes device based authentication or you are unable to connect to the network using the

following steps, please contact your local network administrator for support.

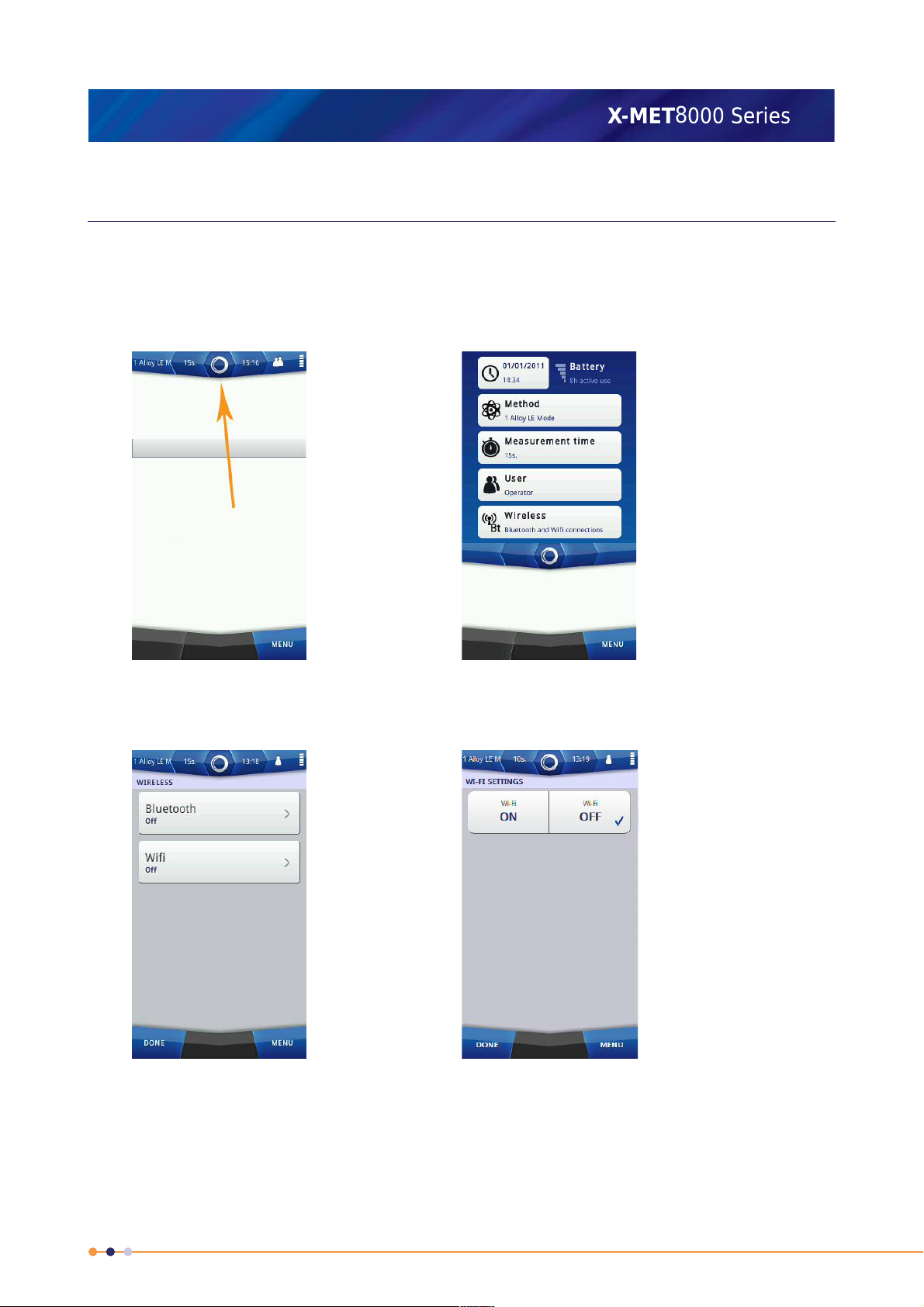

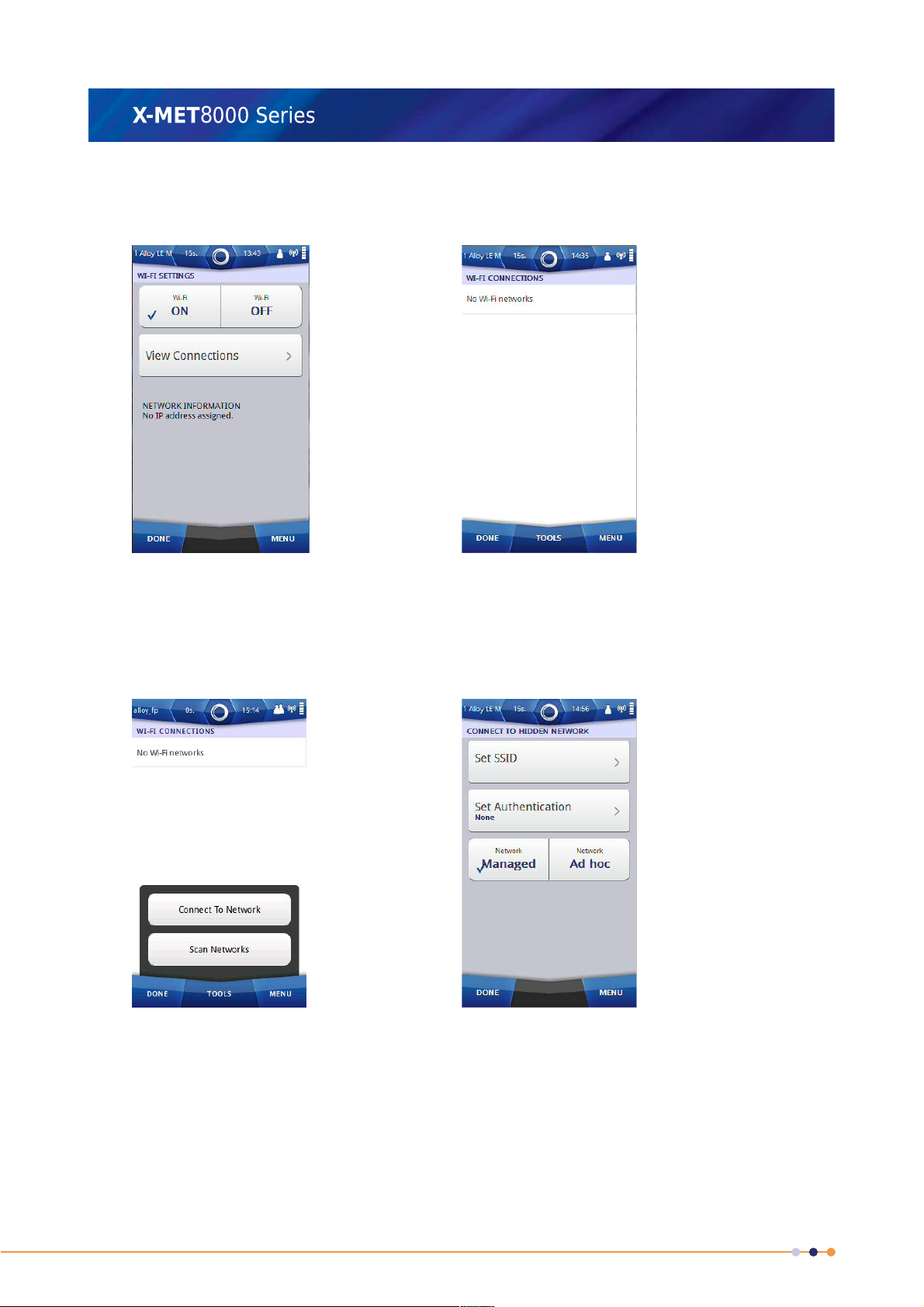

Add A Broadcast Wi-Fi Connection

Follow these steps to connect to a broadcast Wi-Fi network.

1. Navigate: Status Bar > Wireless .

The Wireless screen appears.

2. Tap Wi-Fi.

The Wi-Fi Settings screen appears.

149

Page 50

X-MET8000 Series User Manual

8

3. Tap the ON tick box.

The Wi-Fi Settings screen changes.

4. Tap View Connections.

The Wi-Fi Connections screen appears.

150

Page 51

5. Tap: Tools > Scan Networks .

8

X-MET8000 Series User Manual

The Network Discovery screen appears, and a search for Wi-Fi networks begins.

When the search is complete, the screen shows the available Wi-Fi networks.

The list is ordered with the strongest signals at the top.

6. If necessary, tap: Tools > Scan Again .

Another search for Wi-Fi networks begins, and the Network Discovery screen is refreshed.

7. Tap one of the Wi-Fi networks.

151

Page 52

X-MET8000 Series User Manual

8

8. If the selected Wi-Fi network requires a passkey, use the virtual keyboard to type the passkey for

the network, then tap Done to return to the Network Discovery screen.

9. Tap Done to return to the Wi-Fi Connections screen.

This shows the active Wi-Fi connection.

10. Tap Done to return to the Wi-Fi Settings screen.

Wait until the Network Information IP address and Mask update in the Wi-Fi Settings screen. The

updated IP address can be used to access the X-MET8000 series from the other computers that

are in the same network.

11. Tap Done twice to exit the Wi-Fi Settings screen.

152

Page 53

X-MET8000 Series User Manual

8

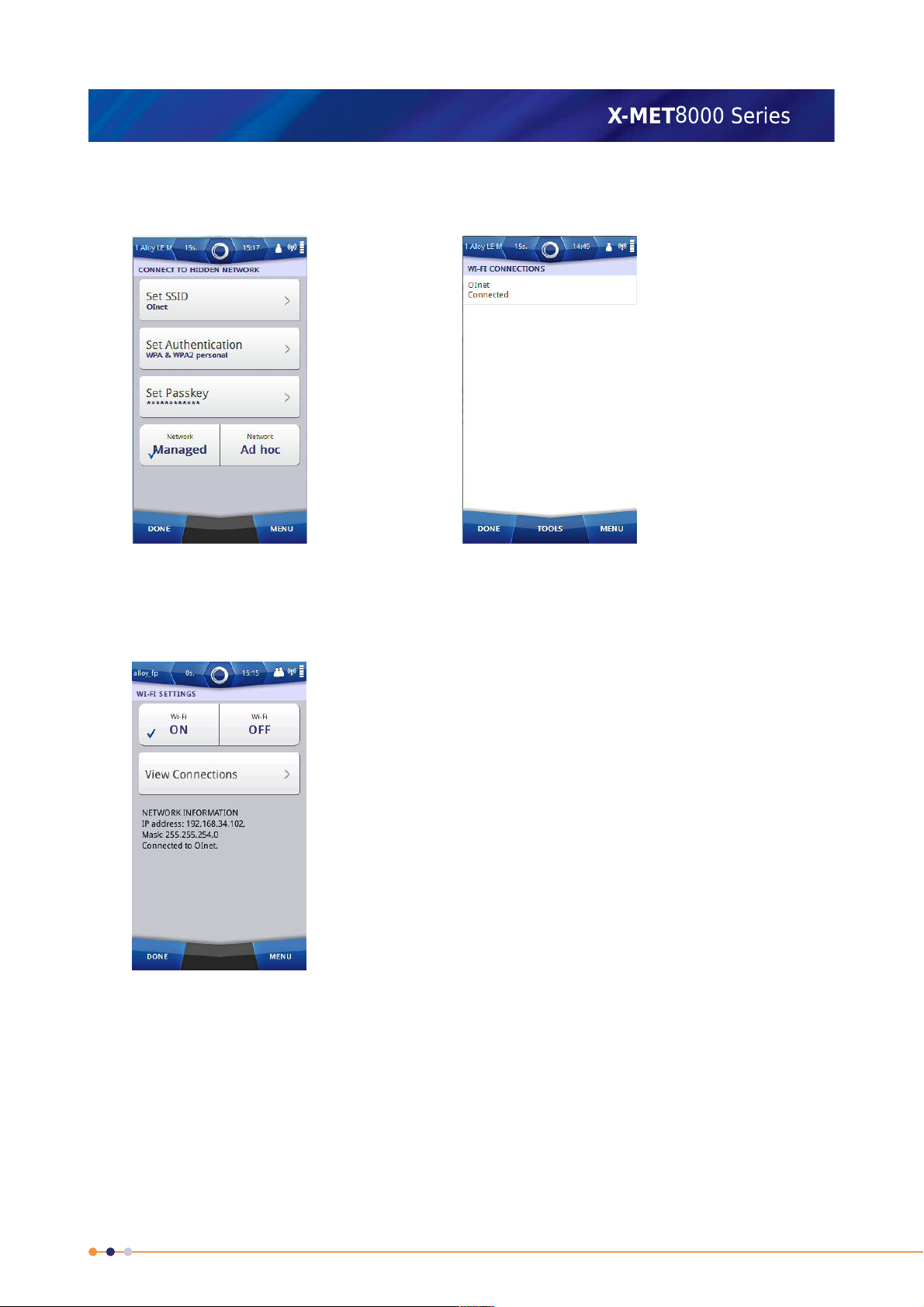

Add A Hidden Wi-Fi Connection

Follow these steps to connect to a hidden Wi-Fi network. Managed networks can use either WPA or

WPA2 Personal encryption, and ad hoc networks can use WPA None encryption.

1. Navigate: Status Bar > Wireless .

The Wireless screen appears.

2. Tap Wi-Fi.

The Wi-Fi Settings screen appears.

153

Page 54

X-MET8000 Series User Manual

8

3. Tap the ON tick box.

The Wi-Fi Settings screen changes.

4. Tap View Connections.

The Wi-Fi Connections screen appears.

5. Tap: Tools > Connect To Network .

The Connect To Hidden Network screen appears.

6. Tap Set SSID.

154

Page 55

X-MET8000 Series User Manual

8

7. Use the virtual keyboard to type the SSID, and then tap Done to return to the Connect To Hidden

Network screen.

8. Do one of the following:

• Tap Managed

• Tap Ad Hoc

9. Tap Set Authentication.

The Set Authentication Method screen appears.

155

Page 56

X-MET8000 Series User Manual

8

10. Do one of the following:

• Tap None

• Tap WPA & WPA2 Personal

For an ad hoc network, the second choice is WPA None.

11. Tap Done to return to the Connect To Hidden Network screen.

The Connect To Hidden Network screen changes.

12. Tap Set Passkey.

156

Page 57

X-MET8000 Series User Manual

8

13. Use the virtual keyboard to type the passkey for the network, and then tap Done to return to the

Connect To Hidden Network screen.

14. Tap Done to return to the Wi-Fi Settings screen.

Wait until the Network Information IP address and Mask update in the Wi-Fi Settings screen. The

updated IP address can be used to access the X-MET8000 series from the other computers that

are in the same network.

15. Tap Done twice to exit the Wi-Fi Settings screen.

157

Page 58

X-MET8000 Series User Manual

8

Wireless Printing

The X-MET8000 series supports printing Reports directly to a network connected printer over a Wi-Fi

connection. Setup wireless printing using the following instructions.

Configure A Printer

It is necessary to connect the X-MET8000 series device to a Wi-Fi network before configuring a printer.

Follow the steps below to configure a printer.

The supervisor must configure network printers.

1. Navigate: Menu > Settings > Instrument Configuration > Printers .

158

The Printers screen appears.

Page 59

X-MET8000 Series User Manual

8

2. Tap Tools > Add Printer .

The Select Printer screen appears and a search begins for the network printers. When the search

is complete, the screen shows the available Network Printers and Add Other Printer.

3. If necessary, scan again by selecting Tools > Scan Again .

4. Tap either on the found Network Printers or Add Other Printer to input the printer information

manually.

The Add/Edit Printer screen appears.

5. Do the following:

• Tap Name

The Printer name can be any text, it is used to identity a printer when multiple printers are

configured in the device.

• Tap URI

The system administrator will need to provide the IPP address for the printer.

159

Page 60

X-MET8000 Series User Manual

8

6. Use the virtual keyboard to type the new value, and tap Done to return to the Add/Edit Printer

screen.

7. It is not necessary to change Model as most of the printers work with a default generic postscript

driver which is available in the device. If the user wants to install a different PPD driver from a USB

memory device, then tap Model .

The Printer Model screen appears.

8. Tap Maker to select the applicable maker. Tap Done to return to the Printer model screen.

The Printer Model screen updates with the new values.

9. Tap User PPD to install the PPD file for the printer from the memory stick.

10. Tap Done.

The Information dialog box appears.

11. Tap OK to return to the Select Printer screen.

12. Tap Done 4 times to return to the main screen.

160

Page 61

X-MET8000 Series User Manual

8

Print A Test Page

It is necessary to configure a printer before printing a test page. Follow the steps below to print a test

page.

1. Navigate: Menu > Settings > Instrument Configuration > Printers .

The Printers screen appears.

2. Select a printer and tap Tools > Maintenance Selected .

The Printer Maintenance screen appears.

3. Tap Print Test Page.

The Information dialog box appears.

4. Tap OK to return to the Printer Maintenance screen.

5. If the printing of the test page is successful, set the printer as the default printer by selecting Set

As Default Printer in the Printer Maintenance screen.

6. Tap Done 4 times to return to the main screen.

161

Page 62

X-MET8000 Series User Manual

8

Generate Report to Printer

The Supervisor must configure a network printer in the device in order to generate reports directly

on a printer, and must connect the device to the same WiFi network as the one to which the network

printer is connected. Please refer to the Supervisor manual to set this up. Follow the below steps to

generate report to printer.

1. Tap Menu, and then tap History.

The History screen appears.

2. Tap: Tools > Generate Report

The Report Generator screen appears.

3. Tap: Tools > Select Template

The Select Report Template screen appears with the default report template list and also user

defined templates which were created in the Web GUI.

162

Page 63

X-MET8000 Series User Manual

8

4. Tap on the applicable template and then tap Done to return to Report Generator screen.

5. Select the measurement results for the report by tapping on each result row in Report Generator

screen or tap Tools and select results using following options

• Filter by

• Sort by

• Mark All

• Mark between selected rows

6. Tap: Tools > Printer after selecting results.

Device starts generating report to the printer. Once the report is generated to the printer, an

Information dialog box appears .

7. Tap OK.

The Report Generator screen appears.

8. Tap Done twice to return to the main screen.

163

Page 64

X-MET8000 Series User Manual

8

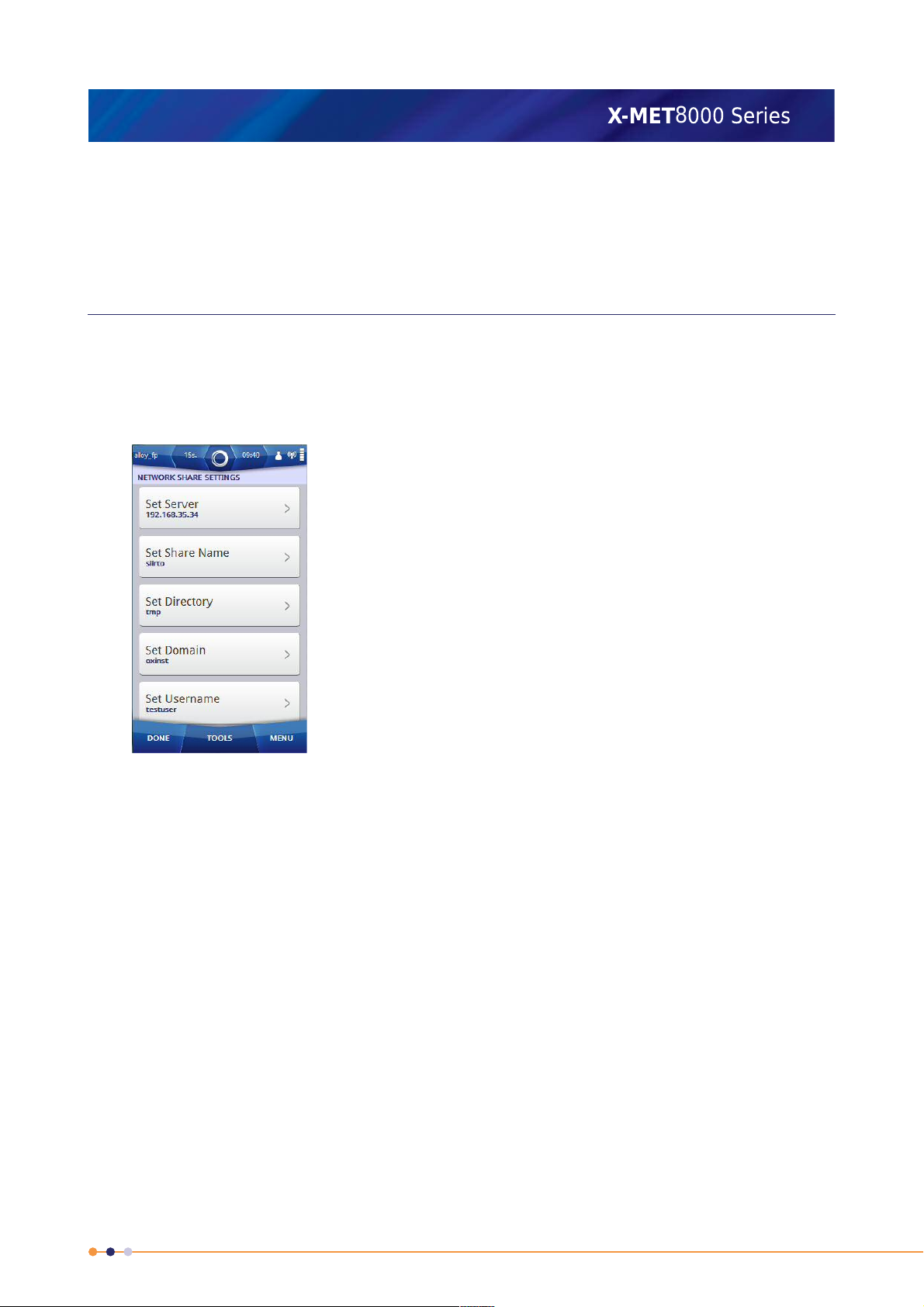

Wireless File Transfers

The X-MET8000 series can store reports directly to a network share over a Wi-Fi connection. Setup

shared folders using the following instructions.

Configure Network Share Settings

Follow the steps below to configure the Network Share Settings.

1. Navigate: Menu > Settings > Instrument Configuration > Network Share .

The Network Share Settings screen appears.

2. Do all of the following:

• Set Server

Set Server is the IP address of the server hosting the network share.

• Set Share Name

Set Share name is the name of the network share.

• Set Directory

Set Directory is the directory path inside the network share.

• Set Domain

Set Domain is the domain or workgroup where the user account is created.

• Set Username

Set Username is the username of the user to access the network share.

• Set Password

Set Password is the password of the user to access the network share.

164

Page 65

X-MET8000 Series User Manual

8

3. The sytem administrator will know the settings of the available shares in the network, and can

provide the necessary information for the Network Share Settings. Use the virtual keyboard to type

the new value, and tap Done to return to the Network Share settings.

4. Tap Done three times to return to the main screen.

Write Test File To Network

It is necessary to configure the Network Share Settings before writing a test file to the network. Follow

these steps to write a test file.

1. Navigate: Menu > Settings > Instrument Configuration > Network Share .

The Network Share Settings screen appears.

2. Tap Tools > Write Test File .

The Information dialog box appears.

3. Tap OK and then tap Done three times to return to the main screen.

165

Page 66

X-MET8000 Series User Manual

8

Generate Report to Network Share

The Supervisor must configure the network share in order to save reports on the selected network,

and must connect the device to the same WiFi network as the one to which the server hosting the

network share is connected. Please refer to the Supervisor manual to set this up. Follow the below

steps to generate report to Network Share.

1. Tap Menu, and then tap History.

The History screen appears.

2. Tap: Tools > Generate Report

The Report Generator screen appears.

3. Tap: Tools > Select Template

The Select Report Template screen appears with the list of the default report templates and user

defined templates which were created in the Web GUI.

166

Page 67

X-MET8000 Series User Manual

8

4. Tap on applicable template and then tap Done to return to Report Generator screen.

5. Select the measurement results for the report by tapping on each result row in the Report Generator

screen or tap Tools and select the results using following options.

• Filter by

• Sort by

• Mark All

• Mark between selected rows

6. Tap: Tools > Network Share after selecting the results.

Device starts generating report to the printer. Once the report is generated to the network share

Report Generator screen appears.

7. Tap Done twice to return to the main screen.

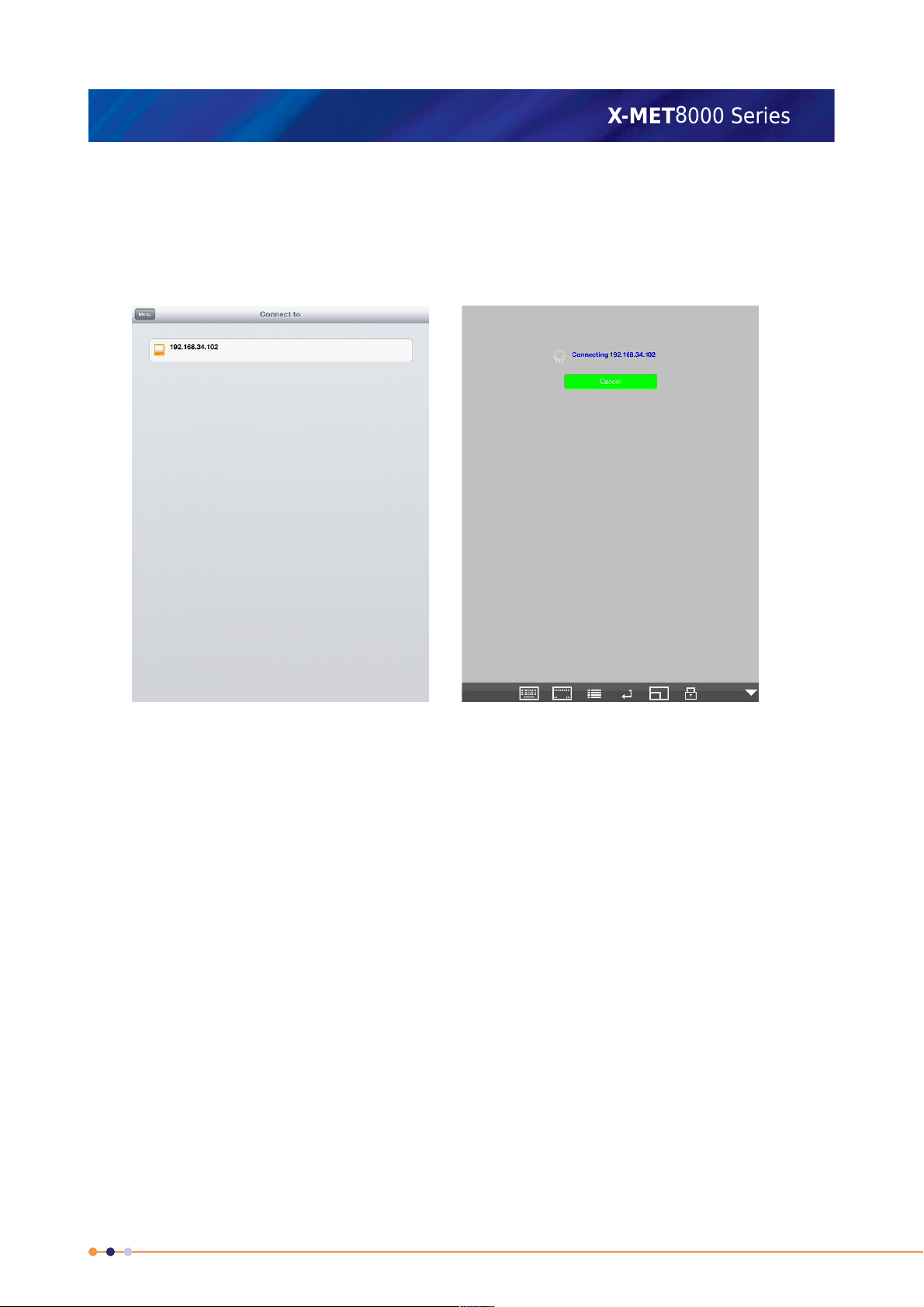

VNC connection to the X-MET8000 series

The X-MET8000 series can be used trough VNC over a Wi-Fi connection. Setup a VNC connection using

the following instructions.

Using a VNC connection all the operations that are available locally on the X-MET8000 series are

accessible trough remote screen.

167

Page 68

X-MET8000 Series User Manual

8

Configure VNC Server Settings

It is necessary to have a VNC client on computer to connect to the X-MET device's VNC server. Contact

your IT service administrator to setup a VNC client on your computer. A VNC connection can be

established by connecting a VNC client with a VNC server using either the X-MET device's Wi-Fi IP

address, or the IP address 10.0.0.1 when using a direct USB connection. Follow the steps below to

configure the VNC server settings in the device.

1. Navigate: Menu > Settings > Instrument Configuration > VNC Server .

The VNC Server Settings screen appears.

2. Tap VNC Server ON.

The Information dialog box appears.

3. Tap OK to return to the VNC Server Settings.

4. If necessary, do the following to change the VNC screen width and height before setting VNC

Server ON.

• Set VNC Screen Width

• Set VNC Screen Height

5. Use the virtual keyboard to type the new value, and tap Done to return to the VNC Server Settings.

6. To reset the VNC screen width and height to the default values, tap Reset VNC Screen Size.

7. Tap Done three times to return to the main screen.

Setup a VNC connection on a PC

Follow these steps to set up a VNC connection on a PC and connect to the X-MET8000 series.

It is necessary to have a VNC client on computer to connect to the X-MET8000 series device's VNC

server. Contact your IT service administrator to setup a VNC client on your computer. A VNC connection

can be established by connecting a VNC client with a VNC server using either the X-MET8000 series

device's Wi-Fi IP address, or the IP address 10.0.0.1 when using a direct USB connection. The VNC

Server must be set up on the X-MET8000 series before a connection can be established.

168

Page 69

X-MET8000 Series User Manual

8

1. On the PC, Download and install a VNC client, i.e. RealVNC Viewer from http://www.realvnc.com.

Follow the instructions for the selected software to install the VNC client.

2. Start the VNC Client on the PC and enter the X-MET8000 series IP address found under Network

settings Status Bar > Wireless > Wi-Fi .

3. On the VNC client, tap Connect to open the remote connection.

If the VNC client is unable to connect to the X-MET8000 series it might be necessary to disable and

restart the Wi-Fi on the X-MET8000 series, from the Wi-Fi settings, tap OFF and then ON again to

restart the adapter.

4. If prompted for a passcode in the VNC client, leave this blank.

The X-MET8000 series screen appears on the PC. The X-MET8000 series can now be controlled

from the PC.

5. To end the VNC connection, tap Close Connection from the tools menu.

The VNC window on the PC closes.

169

Page 70

X-MET8000 Series User Manual

8

Control the X-MET8000 series using an iPad

An iPad or similar tablet can be used to control the X-MET8000 series trough VNC over a Wi-Fi

connection. Setup a iPad VNC connection using the following instructions.

Setup an iPad to control the X-MET8000 series

Follow these steps to install and set up a VNC client on a iPad to connect to the X-MET8000 series.

The same basics can be applied to other tablets.

The Wi-Fi and VNC Server must be set up and started on the X-MET8000 series before a VNC connection

can be established.

1. On the iPad, purchase and install a VNC client of choice, these instructions are for Mocha VNC client

and can also be used as a guide for other VNC clients.

Follow the instructions for the selected software to install the VNC client.

2. Start the VNC Client on the iPad. When started for the first time, add a New connection by tapping

on New.

If a connection already exists, use Menu/Add another Server to add new servers.

Once a connection is stored, use the Menu in the upper left corner to switch between Connect

and Configure.

170

Page 71

X-MET8000 Series User Manual

8

3. In the VNC client, enter the X-MET8000 series IP address found under Network settings (Navigate:

Status Bar > Wireless > Wi-Fi ) and verify that that the settings in the VNC client are according

to the following table:

Note, 32-bit color mode will not work with the X-MET8000 series, other default settings in Mocha

VNC should be adequate.

Table 4: Configuration table

ValueVNC Server

X-MET8000 series IP addressVNC server address

5900VNC server port

OFFMac OS X Lion sign on

<optional>VNC password

<not used>Mac OS X User ID

<not used>Mac OS X Password

<optional>Hardware address

(optional)

9WOL port

OFFWOL broadcast

OFFWOL send ping

<optional>Name (optional)

ValueMore

OFFMac OS X server

171

Page 72

X-MET8000 Series User Manual

8

ValueMore

US or according to keyboard preferencesMac keyboard

OFF32bit color mode

ONMouse at finger

OFFShow warnings

ONShow circle at click

OFFView only mode

OFFMotions

OFFWireless keyboard

ONKey click

OFFToggle black toolbar

OFFClose session on exit

ONLocal mouse

OFFAuto lock

OFFStylus pen

ONZoom to screen height

4. Follow the steps in the next chapter to connect and control the X-MET8000 series using the iPad.

Control the X-MET8000 series using an iPad

Follow these steps to connect to the X-MET8000 series using an iPad. The same basics apply also to

other tablets.

Wi-Fi and the VNC Server must be set up and started on the X-MET8000 series and the IP address of

the X-MET8000 series must be known before a connection can be established.

172

Page 73

X-MET8000 Series User Manual

8

1. Tap on the connection with the IP address for the X-MET8000 series to connect to. If necessary,

tap Menu in the upper left corner to switch between Connect and Configure.

If no connection exist for the correct IP address, add a new server or modify an existing connection

to match the X-MET8000 series current IP address.

The VNC connection to the X-MET8000 series is started.

173

Page 74

X-MET8000 Series User Manual

8

2. If prompted for a passcode, this can be left blank.

The X-MET8000 series screen appears on the iPad. Log in to the X-MET8000 series as usual, the

X-MET8000 series can now be controlled using the iPad.

3. To end the VNC connection, tap Menu Symbol at the bottom of the iPad screen.

4. Tap Disconnect to end the VNC session.

The VNC session ends.

174

Page 75

X-MET8000 Series User Manual

8

Manage Backups

It is possible to back up the configuration of the X-MET8000 series. This includes calibration data and

application data. The calibration data includes the main calibration data as well as test calibration

data. Application data includes Results screen formats, report templates and Additional Information

about the sample.

The X-MET8000 series creates an internal backup and a backup on a USB memory device at the same

time. It is necessary to have a USB memory device to create a backup, with at least 10 MB of free

disk space. It is possible to restore or to delete a backup from the internal memory or from a USB

memory device.

Create A Backup

Follow these steps to back up the configuration of the X-MET8000 series.

1. Open the connector cover underneath the display to access the external connections.

2. Plug a USB memory device into the USB A connector.

3. Navigate: Menu > Settings > Instrument Configuration > Configuration Backup .

The Backup Menu screen appears.

175

Page 76

X-MET8000 Series User Manual

8

4. Tap Create A New Backup.

An Information dialog box appears.

5. Tap OK to start the backup.

The Information dialog box changes to show the progress of the backup. It can take several minutes.

When the backup is complete, the Information dialog box shows the name of the backup file.

6. Tap Done three times to return to the main screen.

7. Remove the USB memory device.

176

Page 77

X-MET8000 Series User Manual

8

Restore A Backup

To restore a backup from the internal memory or from a USB memory device, follow these steps.

1. To restore a backup from a USB memory device, follow these two steps.

a) Open the connector cover underneath the display to access the external connections.

b) Plug a USB memory device into the USB A connector.

2. Navigate: Menu > Settings > Instrument Configuration > Configuration Backup .

The Backup Menu screen appears.

3. Tap Restore From A Backup.

The Choose Storage Location screen appears.

177

Page 78

X-MET8000 Series User Manual

8

4. Do one of the following:

• Tap Internal Memory

• Tap USB Memory Stick

The Select Backup screen appears.

5. Tap the applicable backup.

The Choose Items To Restore screen appears.

6. Tap any or all of the following:

• Normal Calibrations

• Test Calibrations

• Application Data

A tick appears in the applicable box.

7. Make sure that all the necessary items are selected, and then tap: Tools > Restore Selected

Items .

A Warning dialog box appears.

8. Tap OK to restore the chosen backup.

When the process is complete, the Safety screen appears.

9. Remove the USB memory device.

178

Page 79

X-MET8000 Series User Manual

8

Delete A Backup

To delete a backup from the internal memory or from a USB memory device, follow these steps.

1. To delete a backup from a USB memory device, follow these two steps.

a) Open the connector cover underneath the display to access the external connections.

b) Plug a USB memory device into the USB A connector.

2. Navigate: Menu > Settings > Instrument Configuration > Configuration Backup .

The Backup Menu screen appears.

3. Tap Delete A Backup.

The Choose Storage Location screen appears.

179

Page 80

X-MET8000 Series User Manual

8

4. Do one of the following:

• Tap Internal Memory

• Tap USB Memory Stick

The Select Backup screen appears.