Page 1

233

User Manual

P/N: 51-98-3090-00022

Oxford Instruments Coating Measurement

360 El Pueblo Rd, Scotts Valley CA 95066

Tel: (831) 439-6000 Fax: (831) 439-6050

Email: contact.support@oxinst.com

www.coatingmeasurementstore.com

Non-Warranty Customer Service:

ccc.oia@oxinst.com (978) 369-9933

© Copyright 2006 Oxford Instruments

Measurement Systems

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 2

INTRODUCTION ........................................................................................................................................ 4

PURPOSE OF EQUIPMENT ............................................................................................................................ 4

LOCATION OF INSTRUMENT ........................................................................................................................ 4

ELECTRICAL CONNECTIONS ....................................................................................................................... 4

SETUP ........................................................................................................................................................... 4

UNPACKING ................................................................................................................................................ 4

CABLE CONNECTIONS ................................................................................................................................ 4

POWER ON/OFF ......................................................................................................................................... 4

PROBE ........................................................................................................................................................ 5

UNITS ......................................................................................................................................................... 5

MEASUREMENT .......................................................................................................................................... 5

Continuous Mode .................................................................................................................................. 5

Regular Mode ....................................................................................................................................... 5

Scan Mode............................................................................................................................................. 5

MEMORY STRUCTURE ................................................................................................................................ 5

APPLICATIONS ............................................................................................................................................ 6

SAMPLE FOR MEASUREMENT ..................................................................................................................... 6

UNIT OPERATIO N ..................................................................................................................................... 6

PROBE TUNING ........................................................................................................................................... 6

CALIBRATIONS ........................................................................................................................................... 6

Universal Calibrations .......................................................................................................................... 6

How to Store Individual and Universal Calibrations ........................................................................... 6

How to Assign Universal Calibration Locations .................................................................................. 7

How to Make Calibrations .................................................................................................................... 7

One Point Calibration ........................................................................................................................... 7

Two Point Calibration .......................................................................................................................... 8

Base Calibration ................................................................................................................................... 9

Surface Roughness Calibration ............................................................................................................ 9

MEMORY MANAGEMENT ...........................................................................................................................10

Memory Structure ................................................................................................................................10

How to Select A Memory Location ......................................................................................................10

How to Clear a Memory Location .......................................................................................................10

How to Clear all Memory Locations ....................................................................................................11

HOW TO TAKE MEASUREMENTS ................................................................................................................11

Regular Mode ......................................................................................................................................11

Continuous Mode .................................................................................................................................11

Scan Mode............................................................................................................................................12

STATISTICS ................................................................................................................................................13

Viewing the Statistics ...........................................................................................................................13

Clearing the Statistics ..........................................................................................................................13

OFFSETS ....................................................................................................................................................14

How to Enter an Offset ........................................................................................................................14

How to Clear an Offset ........................................................................................................................14

LIMITS .......................................................................................................................................................14

How to Set Limits .................................................................................................................................15

How to Remove Limits .........................................................................................................................15

DATE AND TIME STAMP ............................................................................................................................15

Memory Capacity .................................................................................................................................15

Setting the Date and Time ....................................................................................................................15

Printing the Date and Time ..................................................................................................................16

OUTPUT SELECTIONS .................................................................................................................................16

Oxford Instruments Contact Measurement Page 2 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 3

Separator Character ............................................................................................................................16

Blocks ...................................................................................................................................................17

PRINTING OUTPUT .....................................................................................................................................18

SERIAL OUTPUT .........................................................................................................................................18

APPENDIX A ..............................................................................................................................................19

Troubleshooting ...................................................................................................................................19

APPENDIX B ...............................................................................................................................................21

Eddy Current ........................................................................................................................................21

Magnetic Induction ..............................................................................................................................23

Oxford Instruments Contact Measurement Page 3 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 4

INTRODUCTION

PURPOSE OF EQUIPMENT

The 233 is a dedicated non-destructive plating thickness tester. It is designed to

precisely measure nonconductive coatings on conductive substrates and/or

nonmagnetic coatings on magnetic substrates.

LOCATION OF INSTRUMENT

The 233 is a hand-held plating thickness gage designed to be used in a shop

environment. All cable connections are covered to prohibit foreign matter from

getting into the unit. The carrying case provides additional coverage of any

openings on the unit.

ELECTRICAL CONNECTIONS

Each 233 operates from a 9-volt battery or a low voltage power supply connected

to a 115-volt, 50/60 Hertz, single-phase alternating current power source. If a

battery is the source of power to the gage, when the battery voltage drops below

the level required for operation a low battery condition will occur. The unit will

show “BAT” in the lower right of the display. The battery should be replaced with

an alkaline type before the unit will function properly.

SETUP

UNPACKING

Carefully open and inspect the shipping box, and remove all items. Notify Oxford

Instruments and/or the carrier immediately in case of damage to the unit.

CABLE CONNECTIONS

There are three connectors provided at the top on the unit. Each cable

connection to the 233 is unique to prevent incorrect connection. There is a

phone type jack for connection of the printing or serial dump cable, a jack for the

connection of a low voltage power supply, and a polarized 6 pin threaded

connector for the probe. Connection of any other external device may damage

the gage.

POWER ON/OFF

The unit can be turned on at any time by pressing the ON/OFF key. The

ON/OFF key turns off the unit or it will turn off automatically after ten minutes

have passed and no entry or measurement has been made. When the unit is

turned on, the software version will show in the upper left of the display and the

model number will flash in the main display. After this, the display will show the

last reading taken in the main display and the memory location in the upper left of

the display.

Oxford Instruments Contact Measurement Page 4 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 5

PROBE

The 233 uses the ECP, SMP-1, and SMP-2 probes. It utilizes Eddy Current (with

the ECP) or Magnetic Induction technology (with the SMP-1 and SMP-2) to

perform the coating measurement. For more information on the theory of these

technologies see Appendix B.

UNITS

The measurement units can be changed from mils (1/1000 in) to um

(micrometer) by pressing the ZERO/UNITS key. Both statistics and readings will

be changed to reflect the units selected.

MEASUREMENT

The gage must be calibrated before measurements can be made.

Measurements can be taken in Continuous Mode (with an activation setting, see

How to Take Measurements —Continuous Mode), Regular Mode or Scan Mode.

Pressing the C/M key changes the mode of measurement.

Continuous Mode

When the probe is placed on a sample, instantaneous readings are displayed.

These readings cannot be saved into the statistics unless the Capture feature is

activated. Refer to the section on How to Take Measurements -- Continuous

Mode for directions on activating this feature. When the probe is placed in ai r

“InF” will show on the display until the probe is placed on a sample.

Regular Mode

When the probe is placed in contact with a sample a single reading is taken,

displayed, and saved into the statistics. When the probe is placed in air, the last

reading taken will remain on the display until another reading is taken.

Scan Mode

The 233 can be configured with optional Scan Mode software. Units with this

feature allow for moving the probe around the surface of a sample to obtain an

average thickness of the coating. This feature is useful when measuring large

parts, samples where the thickness of the coating varies across the surface,

sandblasted parts, and textured surfaces. The probe must be held in contact

with the sample, while being slid across its surface, for the specified scan time.

Readings are continuously being taken at a rate of approximately 2 readings per

second. After the scan time has elapsed, three beeps will sound and the word

“dOnE” will show in the main display. The mean, low, or high value of the

readings can be shown and inserted as one measurement into the statistics. The

scan time can be set from 1 to 60 seconds. The mode of printing or displaying

the statistics can be selected. See How to Take Measurements — Scan Mode.

MEMORY STRUCTURE

Memory locations 1 to 99 are available. Each location stores a calibration,

statistics and readings. Locations 1 to 50 are allocated for Magnetic applications

and locations 51 to 99 for Eddy Current applications. The memory location is

Oxford Instruments Contact Measurement Page 5 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 6

shown in the upper left of the display. “FE” shows in the lower left of the display

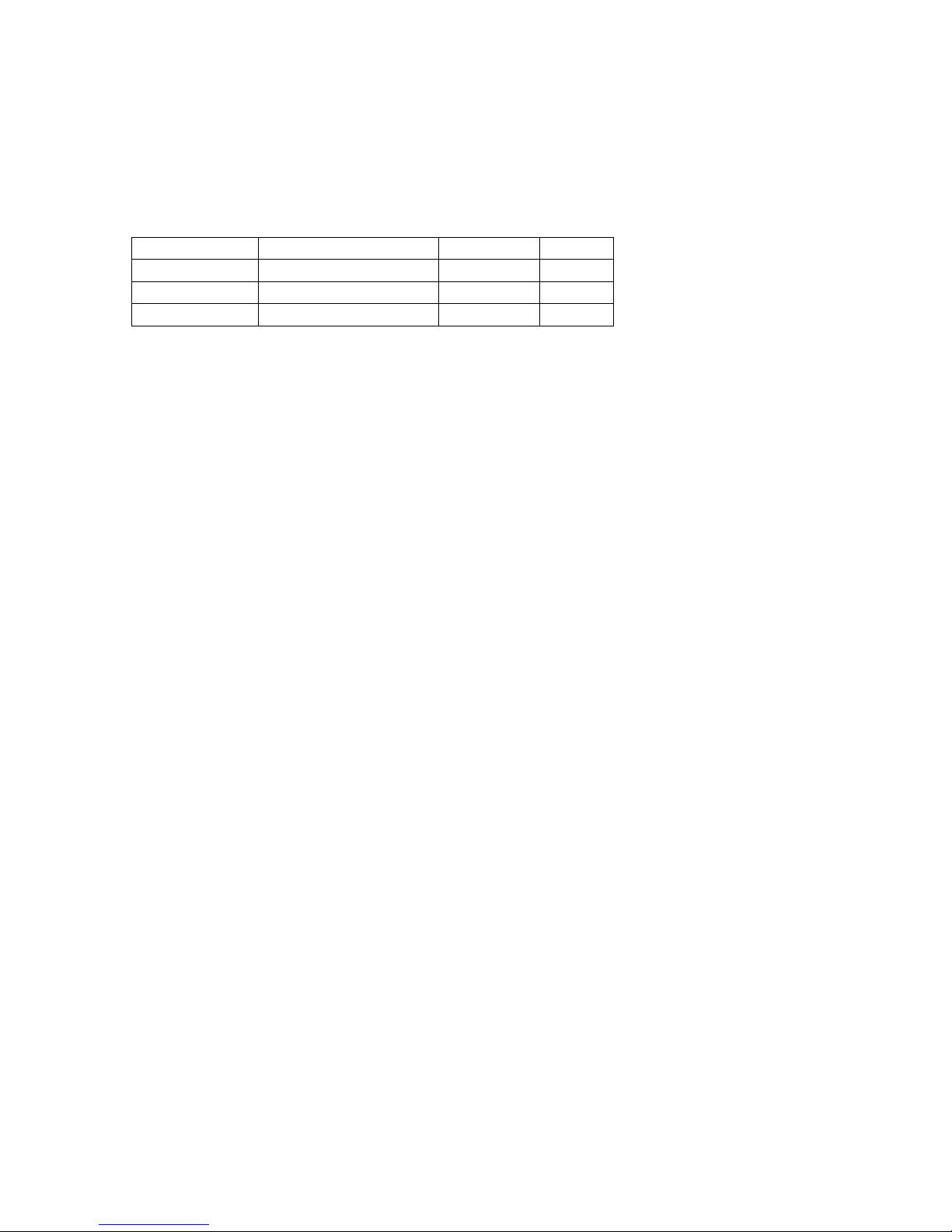

Application

Thickness Range

Display

Probe

Eddy Current

0 to 40 mil/1016 um

“NON-FE”

ECP

Magnetic

0 to 50 mil/1270 um

“FE”

SMP-1

Magnetic

0 to 120 mil/3048

“FE”

SMP-2

for Magnetic applications and “NON-FE” shows for Eddy Current applications.

APPLICATIONS

The Eddy Current and Magnetic applications thickness ra ng es for m eas urement

are given below.

SAMPLE FOR MEASUREMENT

The sample must be clean and free of surface defec ts f or pro per m eas urement.

UNIT OPERATION

PROBE TUNING

For each probe this procedure must be performed.

1. Connect the probe to the gage and turn it on.

2. Press the key sequence “٭

3. The word “tunE” will appear on the display for about 5 seconds, and the

unit will turn off.

4. The probe is now tuned and the gage can be turned on and used.

” “1” “1” “1” ENTER.

CALIBRATIONS

Universal Calibrations

The Universal Calibration feature allows the user to make one calibration that

then can be used by an assigned number of memory locations. This feature

saves time in the calibration process, and allows statistics to be stored in

separate memory locat i ons.

How to Store Individual and Universal Calibrations

Individual calibrations can be stored in any active memory location. Universal

Calibrations can only be stored in memory locations 1 and 51 for Eddy Current

and Magnetic applications, respectively. The individual calibration will apply only

to that memory location. Calibrations are automatically stored in the memory

location where they are performed.

1. To make and store a Universal Calibration for a Magnetic application

select memory location 1 or for an Eddy Current application, select

memory location 51. To select a memory location, refer to Memory

Management: How to Select a Memory Location. Then calibrate the gage

as described in How to Make Calibrations.

2. To make and store an individual calibration choose any location from 1 to

51 for a Magnetic application and 51 to 99 for an Eddy Current application.

Then calibrate the gage as described in How to Make Calibrations.

Oxford Instruments Contact Measurement Page 6 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 7

3. To reset all locations to use the Universal Calibration, perform the

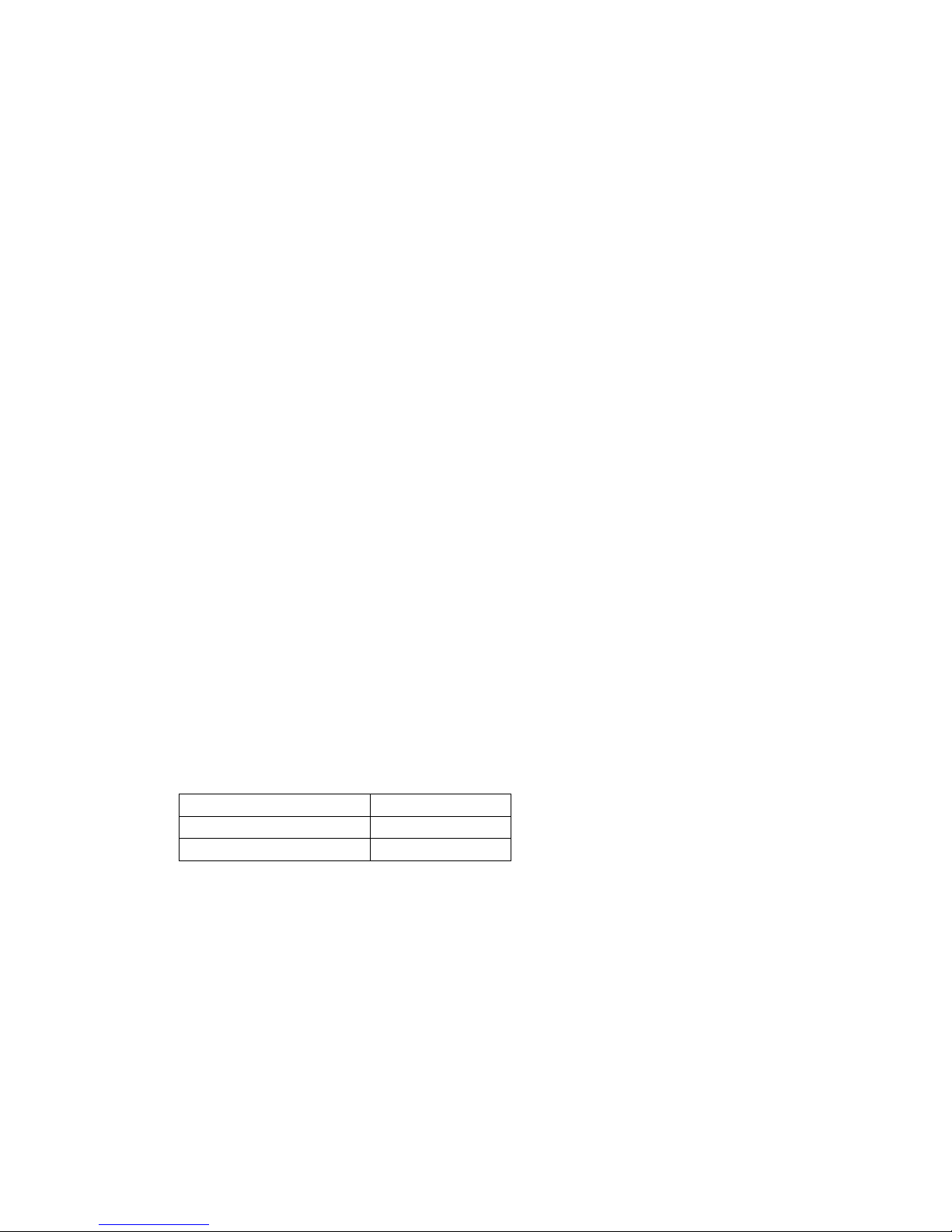

Measurement Range

Shim

Less than 1 mil

1 mil (25.4 um)

Greater than 1 mil

10 mil (254 um

procedure in step 1.

How to Assign Universal Calibration Locations

A number, N, of memory locations can be can be assigned to use the Universal

Calibration. The maximum value of N for the Magnetic application is 50 and for

the Eddy Current application is 49, which corresponds to the total memory

locations for each of these application types.

1. Press the key sequence “٭” “9” ENTER. The letters “uc” will appear in the

upper left corner of the display, and the number of locations previously

assigned will appear on the display. The default value is one.

2. Using the numerical keys, enter the number of memory locations that are

to use the universal calibration and press ENTER.

How to Make Calibrations

Four types of calibrations can be performed.

1. A two point calibration must be performed once on a gage. All gages

come with a two point factory calibration. This calibration should be

performed again if a new probe is to be used.

2. Once the two point calibration has been made, the one point calibration

can be used to quickly reset the gage.

3. After a two point calibration has been made, the base calibration can be

used to re-zero the gage and allow the use of the same calibration on

samples with a different base material.

4. The surface roughness calibration is used with parts that have varying

coating thickness, an u neven surface, and/or variations in the base alloy.

One Point Calibration

For this calibration, use the shim whose value is closest to the actual coating

thickness to be measured, or according to the expected measurement range.

See table below. For ranges greater than 10 mils (254um), consult Oxford

Instruments Technic al s upp or t for s him size information.

1. Select the memory location for the re-calibration as described in Memory

Management: How to Select a Memory Location.

2. To re-zero the unit:

a. Press the CAL key.

b. Place the probe on the bare part.

c. Press the ZERO/UNITS key.

d. Lift the probe off the bare part and wait for the beep.

3. To reset the thickness:

a. Re-zero the unit as stated in step 2.

b. Place the desired shim over the bare part.

c. Press the CAL key.

Oxford Instruments Contact Measurement Page 7 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 8

d. Place the probe on the shim over the bare part.

Measurement Range

First Shim Value

Second Shim Value

Less than 1 mil

0.2 mil (5.08 um)

1 mil (25.4 um)

Greater than 1 mil

1 mil (25.4 um)

10 mil (254 um)

e. Enter the thickness of the shim, lift the probe at least 3 inches (76

mm) away from the part, and press the ENTER key. Once a

numerical key has been pressed, the probe can be lifted from the

shim without affecting the calibration.

Two Point Calibration

The two point calibration is performed with two shims according to the expected

measurement range. See table below. For ranges greater than 10 mils (254

um), consult Oxford Instruments Technical Support for shim size information.

NOTE: After a Zero Calibration, 0.00 will appear on the display. After a

thickness calibration, the value entered will appear on the display. Neither of

these readings will affect the statistics.

CAUTION: When a calibration (or a re-calibration) is made while in location 1, or

location 51, the new calibration will overwrite all calibrations assigned to the

universal calibration. See Calibrations – How to Assign Universal Calibration

Locations.

1. Select the memory location for the calibration as described in Memory

Management: How to Select a Memory Location.

2. Press the CAL key. The word CAL will appear on the right of the display

and “C” will appear in the upper left.

3. Place the probe on the bare part and press the ZERO/UNITS key.

4. Lift the probe off the bare part and wait for the beep.

5. Press the “٭” key and the press the CAL key. The word CAL will appear

on the right side of the display and “C1” will appear in the upper left.

6. Place the first shim on the bare part and place the probe over the shim.

7. A thickness will be displayed on the unit. Enter the thickness of the shim

using the numerical keys, even if the displayed value is correct. Once a

numerical key has been pressed, the probe can be lifted from the shim

without affecting the calibrations.

8. Check the display. If incorrect, press the CLEAR key and re-enter the

number. When finished, lift the probe at least 3 inches (76 mm) away

from the part and press the ENTER key. The display will now show “C2”

in the upper left corner.

9. Place the second shim on the bare part and place the probe over the

shim.

10. A thickness will be displayed on the unit. Enter the thickness of the shim

using the numerical keys, even if the displayed value is correct. Once a

numerical key has been pressed, the probe can be lifted from the shim

without affecting the calibration.

Oxford Instruments Contact Measurement Page 8 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 9

11. Check the display. If incorrect, press the CLEAR key and re-enter the

number. When finished, lift the probe at least 3 inches (76 mm) away

from the part and press the ENTER key.

12. The 233 is now calibrated and ready for me a sur em ent.

Base Calibration

1. Press the CAL key.

2. Place the probe on the bare part of the different base material.

3. Press the ZERO/UNITS key.

4. Lift the probe off the bare sample and wait for the beep.

Surface Roughness Calibration

This calibration consists of taking readings on several points over the surface of

the bare part and again with shims, instead of taking a reading at just one spot.

The averages of the bare readings and the readings taken with the shims are

stored as the calibration. If a surface roughness calibration is necessary, more

than likely the individual readings taken on coated parts will vary. To lessen the

variation in the readings it is suggested that an average reading be taken. The

averages should be fair ly consi st ent.

1. Select the memory location for the calibration as described in Memory

Management: How to Select a Memory Location.

2. Press the CAL key. The word CAL will appear in the right side of the

display and “C” will appear in the upper left.

3. Place the probe on the bare part.

4. Wait for the reading to stabilize, then press the ENTER key.

5. Repeat steps 3 and 4 (up to 9 times), moving the probe around the entire

part. A “Cn” will be displayed on the upper left, with n representing the

number of readings taken so far in the calibr ation.

6. Press the ZERO/UNITS key.

7. Press the “٭” key, then press the CAL key. The word CAL will appear on

the right and “C1” will appear in the upper left.

8. Place the 1 mil (25.4 um) shim on the bare part. Place the probe over the

shim. Wait for the reading to stabilize, then press the ENTER key.

9. Repeat step 8 (up to 9 times), moving the probe and shim around the

entire part so as to take readings over the area of interest.

10. After the last measurement has been taken, enter the thickness of the

shim using the numerical keys. Once a numerical key has been pressed,

the probe can be lifted from the shim without affecting the calibration.

11. Check the display. If incorrect, press the CLEAR key and then re-enter

the number. When finished, lift the probe at least 3 inches (76 mm) away

from the part and press the ENTER key .

12. The display will now show “C2” in the upper left corner.

13. Place the 10 mil (254) shim on the bare part. Place the probe over the

shim. Wait for the reading to stabilize, then press the ENTER key.

14. Repeat step 13 up to a maximum of 9 times. Move the probe and shim

around the entire part to take readings over a large area.

Oxford Instruments Contact Measurement Page 9 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 10

15. After the last measurement has been taken, enter the thickness of the

shim using the numerical keys. Once a numerical key has been pressed,

the probe can be lifted from the shim.

16. Check the display. If incorrect, press the CLEAR key and then re-enter

the number. When finished, lift the probe at least the probe at least 3

inches (76 mm) away from the part and press the ENTER key.

17. The 233 gage is now calibrated and ready for measurement.

MEMORY MANAGEMENT

Memory Structure

The 233 has 99 memory locations. Each location stores a calibration, statistics

and readings. Locations 1 to 50 are allocated for Magnetic applications and

location’s 51 to 99 for Eddy Current applications. The memory location is shown

in the upper left of the display. “FE” shows in the lower left of the display for

Magnetic applications and “NON-FE” shows for Eddy Current applications.

When the gage is turned on (and the probe has not been changed), it selects the

last memory location that was used to take measurements and displays the last

reading for the application last used to take a measurement.

How to Select A Memory Location

A memory location must be made active before it can be used to store

information. To activate a memory location, select it by using Method 1. To

select memory locations that already are active, use either of the following

methods.

Method 1

1. Press the SEL key. The word SEL will appear on the display.

2. Enter the desired memory location (1-99) using the numerical keys. The

location number will appear in the upper left of the display.

3. Press the ENTER key.

4. The unit will beep twice if this memory location was just activated and

0.000 will show in the main display, otherwise the unit will beep once and

the last reading taken will show in the main display.

Method 2

1. Press the SEL key. The word SEL will appear on the display.

2. Press the SEL key again, causing the display to scroll through the active

memory locations. The location number will appear in the upper left of the

display.

3. When the desired memory location is displayed, press the ENTER key.

4. The last reading taken will show in the main display.

How to Clear a Memory Location

When a memory location is cleared it is deactivated and all statistics,

measurements, and parameters are deleted. If memory location 1, and /or

location 51 are cleared, all memory locations that are assigned to that universal

calibration will also be cleared. A memory location can be cleared using one of

the following methods.

Oxford Instruments Contact Measurement Page 10 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 11

Method 1

1. Press the SEL key. The word “SEL” will show on the main display.

2. Enter the desired memory location (1-99). Press the CLEAR key. If the

location was active its number will flash, otherwise the numbers will clear

and a different location number can be entered.

3. To continue the clearing process, press the CLEAR key again then press

the ENTER key. Otherwise, to abort the clearing process, press the

ENTER key only.

Method 2

1. Press the SEL key. The word “SEL” will show on the main display.

2. Press the SEL key again, which causes the display to scroll through the

active memory locations. The memory location number will show in the

upper left corner of the display.

3. When the desired memory location shows, press the CLEAR key. The

location number will flash.

4. To continue the clearing process, press the CLEAR key again then press

the ENTER key. Otherwise, to abort the clearing process, press the

ENTER key only.

How to Clear all Memory Locations

To clear and deactivate (except memory location 1 which can be cleared but not

deactivated) all memory locations and their storage of readings and statistics,

press in sequence “٭” “9” “1” “9” “1” ENTER.

HOW TO TAKE MEASUREMENTS

Press the C/M key to change the mode of measurement between Continuous,

Regular and Scan.

Regular Mode

Select a memory location to store readings. Place the probe in contact with the

sample to be measured. The gage will beep, the measurement will be displayed,

and the reading will be saved into the statistics. If an unwanted measurement is

taken while in the Regular Mode, it can be cleared from the statistics by pressing

the CLEAR key. After the CLEAR key is pressed, the reading will be deleted and

the previous reading will be displayed.

Continuous Mode

To take measurements in Continuous Mode, place the probe on the part.

Instantaneous readings will be displayed until the probe is lifted off the part.

They will not be saved into the statistics unless the Capture Readings feature is

activated as described below.

How to Activate the Capture Readings feature

1. Place the gage in Continuous Mode.

2. Press the key sequence “٭” “4” “0” ENTER. The feature is now active and

readings will be saved into the statistics.

3. Place the probe on the sample to be measured. Press the ENTER key to

capture the reading.

Oxford Instruments Contact Measurement Page 11 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 12

4. Continue taking readings, and press the ENTER key for each reading to

Print Display Option

Key Code Sequence

Print Nothing

“٭” “2” “1” ENTER

Low – High

“٭” “2” “2” ENTER

Mean

“٭” “2” “3” ENTER

Low – High – Mean

“٭” “2” “4” ENTER

All Readings Output During Scan

“٭” “2” “5” ENTER

be captured.

5. The statistics can be viewed in the normal manner. See Statistics –

Viewing the Statistics.

How to Deactivate the Capture Readings Feature

1. Place the gage in Continuous Mode.

2. Press the key sequence “٭” “4” “1” ENTER.

3. The capture feature is not active and readings taken will not be saved into

statistics.

Scan Mode

The 233 can be configured with the optional Scan Mode feature. Units with this

feature allow for sliding the probe around the surface of a sample to obtain an

average thickness of the coating on the sample. This feature is convenient for

measuring large samples or for samples where the thickness of the coating

varies across the surface. Review the scan time and the print options before

using the Scan Mode to take measurements. Make any desired changes to the

default settings as described below.

How to Set the Scan Time

The default scan time is 5 seconds. To enter a different time, press in sequence

the “٭” “1” “1” keys and then press the ENTER key. “Sc” will show in the upper

left of the display and the present scan time will show in the main display. Using

the numerical keys enter a new value from 1 to 60 and then press the ENTER

key. The new value will be accepted, if it is from 1 through 60, and the gage will

go back to the measure mode. If an out of range value is entered, a long beep

will sound. The gage will revert back to the previous value and remain in the set

time mode until either an accept able value is entered, or the ENTER key is

pressed.

How to Set the Output Options

When in Scan Mode, information about the measurement can be printed out from

a serial printer, or sent to a PC serial port to be displayed. The print option is

selected by pressing a key sequence that begins with the “٭” key, then the two

digits that determine the option, and then the ENTER key. The table below lists

the available options and the corresponding keystrokes. The default option

setting is Low – High – Mean.

How to Set Display Options

When in Scan Mode, the mean, low or high values of the measurement can be

shown on the display. The display option is selected by pressing a key sequence

Oxford Instruments Contact Measurement Page 12 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 13

that begins with the “*” key, then the two digits that determine the option, and

Display Option

Key Code Sequence

Mean

“٭” “2” “6” ENTER

Low

“٭” “2” “7” ENTER

High

“٭” “2” “8” ENTER

then the ENTER key. The table below lists the available options and the

corresponding keystrokes. The default option setting is Mean.

STATISTICS

After readings have been taken, the statistics saved in each memory location can

be displayed. If a statistic is displayed while the gage is in the Regular Mode, the

statistic will remain on the display until the ENTER key is pressed or the probe is

placed on another sample. With the gage in Continuous Mode and with the

Capture Feature on, a statistic will remain on the display for three seconds after

which time the gage reverts to the Continuous Mode.

Viewing the Statistics

Measurements taken in each memory location are stored separately as individual

sets of statistics. Select the memory location from which you wish to display the

statistics. The statistic keys are located in the top two rows of the keypad. The

information associated with each key is listed below. When a statistics key is

pressed, a letter shown in parenthesis below, and the word STAT will show in the

lower left of the display.

Number (N) Number of Readings

MEAN (M) Mean or Average

S.D. (S) Standard Deviation

High (H) Highest Reading

Low (L) Lowest Reading

To leave the statistics mode and continue taking readings press the ENTER key

or place probe on the part. Upon leaving the statistics mode, the last reading

taken will be displayed. Any subsequent readings will be added to the statistics

in the memory location selected.

Clearing the Statistics

If the word “FULL” appears on the display and the unit error (long duration)

beeps while taking measurements, the statistics’ memory is full. To clear the

statistics, follow the procedure below. This can be done in Regular or

Continuous Modes.

1. To clear statistics from a memory location, select the desired memory

location.

2. Press any of the statistics keys so that the gage is displaying a statistic.

3. Press the CLEAR key. The word “STAT” will flash in the lower left of the

display.

4. To abort the clearing of the statistics, press the C/M key while the unit is

flashing “STAT”.

5. To continue the clearing process, press the CLEAR key again to confirm

that the statistics are to be cleared.

Oxford Instruments Contact Measurement Page 13 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 14

OFFSETS

An offset is applied to measurements taken in any memory location. Its purpose

is to be subtracted from any reading taken there. If a non-zero offset is stored, it

will flash in the main display and “OF” will show in the upper left of the display

when entering any memory location. In this case see both of the Method 2’s

below to accept or clear this offset otherwise, see both Method 1’s below.

How to Enter an Offset

Method 1

1. Press the “٭” key. The main display will be cleared and “OP” will show in

the upper left of the display .

2. Press the ZERO/UNITS key. The “OP” will change to “OF”. The current

offset or 0.000 will be displayed.

3. Enter the value of the offset using the numerical keys or advance to the

next step.

4. Press the ENTER key to save the value and activate the offset. The unit

reverts to the measurement mode.

Method 2

1. If a non-zero offset is stored, it will flash in the main display and “OF” will

show in the upper left of the display when entering any memory location.

2. To take readings with this offset, press the ENTER key. The unit will

revert to the measurement mode.

How to Clear an Offset

Method 1

1. Press the “٭” key. The main display will be cleared and “OP” will show in

the upper left of the display .

2. Press the ZERO/UNITS key. The “OP” will change to “OF”. The current

offset or 0.000 will be displayed.

3. Press “0”.

4. Press the ENTER key. The offset will be removed (i.e. it is zero). The unit

will revert to the measurement mode.

Method 2

1. If a non-zero offset is stored, it will flash in the main display and “OF” will

show in the upper left of the display when entering any memory location.

2. To clear this offset, press the CLEAR key. 0.000 will momentarily display.

The offset will be removed. The unit will revert to the measurement mode.

LIMITS

Limits can be entered into the 233 gage to provide an indication that a reading

exceeds a high or low thickness specification. When a reading is taken in the

Regular Mode that falls outside of the limits, there will be a long beep and the

word “HI” or “LO”, as appropriate, will show in the upper left of the display. The

limits apply only to the memory location that is in use when the limits are entered.

Each memory location can have its own set of limits.

Oxford Instruments Contact Measurement Page 14 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 15

How to Set Limits

1. Press the LIMIT key. H-L will show in the main display.

2. To enter the high limit, press the HIGH key. Or to enter the low limit,

press the LOW key.

3. The default (See Setup – Applications for the range for eac h appl i ca ti on)

or any previously entered limit will be displayed.

4. To accept press ENTER key, otherwise enter the desired limit using the

numerical keys and press the ENTER key.

How to Remove Limits

1. Press the LIMIT key. H-L will show in the main display.

2. To remove the high limit, press the HIGH key. Or to remove the low limit,

press the LOW key.

3. For high limit enter default high limit shown in the table above for Setup Applications, for low limit enter 0.000 mil/ 0.000 um and press the ENTER

key.

DATE AND TIME STAMP

The 233 has a Date and Time Stamp feature. This feature is supplied in one of

the two options described in Memory Capacity. The date and time information

will be included when statistics and readings are printed, or uploaded to a PC.

Memory Capacity

The 233 can be ordered with the Date and Time Stamp Every Reading feature

installed. The user can then turn it on or off. See Printing the Date and Time

below. With this feature installed the date and time is stored with each reading.

The maximum number of readings saved is 8900.

The default installation is Date and Time Stamp First and Last Reading. With

this option the date and time is stored only for the first and last reading taken at a

memory location. With this option, 26000 readings can be saved.

Setting the Date and Time

Before taking measurements with the gage, the correct time and date should be

entered. This information will be stored with the readings and appear on the

printouts or uploads.

1. Press in sequence the “٭” “1” “0” keys, and then press the ENTER key.

2. The word “cL” will show in the upper left of the display and a time in the

main display. The time displays and prints in a 24-hour for m at. Ex ample:

1:18 P.M. will display as 1318.

3. Enter the correct time in a 24-hour format. Press the ENTER key if

entering three digits and the display will advance to the next setting.

4. The word “dA” will now show in the upper left of the display and a date in

the main display. Key in the value for the month and day in the format of

MMDD and press the ENTER key.

Oxford Instruments Contact Measurement Page 15 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 16

5. The word “yr” will appear in the upper left of the display and a year in the

1

“٭” “1” ENTER

End each line with a carriage return

2

“٭” “2” ENTER

End each line with a carriage return and a line feed

3

“٭” “3” ENTER

Disregard the printer BUSY line when outputting data

4

“٭” “4” ENTER

Output data only when the printer BUSY line is not active

5

“٭” “5” ENTER

Set output baud rate to 300

6

“٭” “6” ENTER

Set output baud rate to 1200

7

“٭” “7” ENTER

Set output baud rate to 4800

8

“٭” “8” ENTER

Set output baud rate to 9600

main display. Enter the last two digits of the year and press the ENTER

key.

Printing the Date and Time

When the time and date has been stored with each reading with the Date and

Time Stamp Every Reading feature installed, the default is to print them

alongside each reading when using the printing selection P-A or P-d (see Printing

Output). Without this feature, the default is to print the date and time of the first

and last reading of the memory location with any printing selection.

OUTPUT SELECTIONS

Review the default settings for the output selections before printing or performing

a serial output. To change the baud rate and /or formatting enter the appropriate

keystrokes described in the following table. Select and make one entry for lines

5 through 8 of the table. The factory default settings in the gage are “٭” “2”

“ENTER”; “٭” “3” “ENTER”; “٭” “7” “ENTER”. This is a setting of “Carriage return

and line feed”; “Disregard BUSY line”; and “4800 baud”.

Separator Character

The Separator Character is ASCII 29. When the Separator Character feature is

enabled, this character is inserted with stored readings each time the MEAN key

is pressed. The printing functions P-A and P-d (See Printing Output) will

recognize the Separator Character and insert “start of block n” in the printout.

When uploading to a PC (See Serial Output), the ASCII 29 character will be

transmitted. These printing and uploading functions will ignore the Separator

Character when the feature is disabled even though the character remains with

the readings until the readings are deleted.

How to Enable the Separator Character Feature

1. Press the “٭” key. The display will be cleared and “OP” will appear in the

upper left of the display .

2. Press the “5” “0” keys. The Separator Character Feature is now activated

and the unit returns to the measure me nt mod e.

How to Add a Separator Character

1. With the Separator Character Feature enabled, press the MEAN key in the

measurement mode.

Oxford Instruments Contact Measurement Page 16 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 17

2. The gage will beep twice. The first beep is for pressing the MEAN key

which displays the mean and the second beep indicates the insertion of

the Separator Character. The Separator character is now inserted with

the stored readings.

How to Remove a Separator Character

Separator Characters can only be removed by deleting the statistics. See

Statistics - Clearing the Statistics. Note, that if the Separator Character feature is

disabled, these special characters will be ignored when printing or uploading to a

PC.

How to Disable the Separator Character Feature

1. Press the “٭” key. The display will be cleared and “OP” will appear in the

upper left of the display .

2. Press the “5” “1” keys. The Separator Character Feature is now disabled

and the unit returns to the measure me nt mod e.

Blocks

The 233 can be ordered with the Block feature installed. This allows the labeling

of specific blocks of readings within a memory location. The purpose of the

Block feature is to separate groups of readings to be transmitted as Serial

Output. See Serial Output. With the Block feature installed (it cannot be

disabled), all printing functions are disabled. The Block feature does not affect

the calculation of statistics for the total readings at a memory location. For

multiple blocks at a memory location, statistics are not available for each block.

How to Label Blocks

1. Press the PRINT key. “bL” will show in the upper left of the display.

2. Enter a number between 1 and 255, then press the ENTER key. This

activates the selected block.

3. All subsequent measurements will store readings in the currently active

block. If a block that already contains readings is selected, all subsequent

readings will be appended to the currently stored readings in that block.

How to Transmit Blocks

See Serial Output for outpu t co nnec t ions . Th en fol low this procedure.

1. Press DUMP key. “bL” will show in the upper left of the display.

2. Enter the block number using the numerical keys and press the ENTER

key to begin data transfer from the selected block. To transfer all blocks

enter “0” and press the ENTER key.

How to Remove Blocks

1. Press the “٭” key. The display will be cleared and “OP” will appear in the

upper left of the display .

2. Press the CLEAR key. “bL” will appear in the upper left of the display.

3. Enter the block number to be cleared by using the numerical keys and

then press the ENTER key. All readings stored in that block will be

cleared.

Oxford Instruments Contact Measurement Page 17 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 18

4. After clearing any block number, the active block will be block number 1.

P-A

=

Print Stats, Data, and Hi st og r am

P-S

=

Print Stats only

P-d

=

Print Data only

P-H

=

Print Histogram only

P- = No Printing

PRINTING OUTPUT

Readings taken in Regular Mode, Continuous Mode or Scan Mode can be

printed. To print readings and/or statistics, connect the serial printer to the gage

with the cable supplied from Oxford Instruments. Select the memory location

and the type of information to be printed as described below. If the printer is

connected to the gage while the readings are being taken, the reading will be

transferred directly to the printer and printed out. If the printer is not connected to

the gage while readings are being taken, the readings are stored in the statistics’

memory and can be printed out later. To print the statistics and/or reading s

perform the following steps.

1. Select the memory locati on to pr i nt fro m.

2. Press the PRINT key.

3. The main display will show “P-A”. Repeatedly pressing the PRINT key

causes the display to scroll through the available printing options.

4. To start the printing, press the ENTER key when the required option is

displayed or wait for 3 seconds when the required option is displayed.

SERIAL OUTPUT

The stored readings can be uploaded to a PC with the Oxford Instruments upload

cable.

1. Connect the cable to the serial output port of the gage and connect the

other end of the cable to a PC that has software suitable for receiving

serial data.

2. Select the memory location from which to upload readings.

3. Press the DUMP key to begin the data transfer.

Oxford Instruments Contact Measurement Page 18 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 19

APPENDIX A

Switch

Position

Setting

DSW1

1

OFF

2 ON

3 ON

4 ON

5 OFF

6 OFF

7 ON

8 ON

DSW2

1

ON

2 ON

3 ON

4 OFF

5 OFF

6 ON

Troubleshooting

Problem 1: While in the automatic measurement mode, the unit beeps and takes

a reading while the probe is in air.

Solution 1: Retune probe.

Problem 2: While in the continuous measurement mode, a large reading (over

40 mils) will intermittently display.

Solution 2: Retune probe.

Problem 3: Printer prints out incoherent symbols every time a reading is taken.

Solution 3: Factory settings in the gage have changed. Press “٭” “2” ENTER “٭”

“3” ENTER and “٭” “7” ENTER. Or the Seiko printer has changed. Set the dip

switches as follows:

Or make sure all of the connections to and from the printer are secure.

Problem 4: Unit shows “BAT” in lower right of the display, beeps three times and

then shuts off.

Solution 4: The battery is low or dead. Replace battery.

Problem 5: The word FULL is displayed after taking a reading.

Solution 5: The statistics’ memory is full. Clear the statistics following the

instructions in the manual.

Problem 6: The unit will not calibrate.

Solution 6: Recalibrate the unit following the instructions in the manual. Or

return the probe and recalibrate the unit following the instructions in the manual.

Or make sure the correct units of measurement are being used, i.e. do not enter

.86 um instead of .86 mils.

Oxford Instruments Contact Measurement Page 19 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 20

Problem 7: The gage locks up and no other troubleshooting techniques correct

the problem.

Solutions 7: Use this p ro cedu re as a la st reso rt . Try all other solutions first.

Clear all of the gage settings by pressing in sequence the “٭” “9” “1” “9” “1” keys.

This clears all calibrations, statistics, and probe tuning information from every

memory location. After this procedure is used, retune all probes and re-calibrate

the gage.

Oxford Instruments Contact Measurement Page 20 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 21

APPENDIX B

Eddy Current

Theory

The eddy current technique is utilized for measuring nonconductive coatings on

nonmagnetic metal substrates, metallic coatings on ferrous substrates and

conductive coatings on nonconductive substrates. The eddy current measuring

probe contains a coil that produces an oscillating electromagnetic field. When

the probe is applied to the surface of the coating being tested, a flow of eddy

currents is induced in both the coating and the substrate of the sample. Eddy

currents flow in closed circular paths and the depth of penetration is i nversely

proportional to the square root of the probe frequency and also to the square root

of the electrical conductivity of the material in which the eddy currents flow. The

eddy currents create a counter-magne ti c field that re acts upo n the pr obe by

reactance and alters its output voltage. The change in output voltage created is

used to calculate a thickness. In the case of nonconductive films over

nonmagnetic metals (lift-off), increasing the thickness of the coating increases

the separation from the conductive substrate. This increased separation causes

a decrease in the magnitude of the eddy currents induced in the base, and

therefore a decrease in output voltage of the probe. In the measurement of

metallic coatings on ferrous substrates, the eddy currents flow in both the coating

and the base. The intensity of the eddy current reaction depends on the

conductivity of both metals involved. As the coating thickness increases, more of

the eddy currents flow in the coating than in the base metal, and the reaction on

the probe corresponds more closely to that of the pure coating metal.

Base Variations

Calibrating an eddy current probe for a nonconductive over conductive

application, commonly referred to as lift-off, consists of placing nonconductive

shims of known thicknesses directly over the bare conductive substrate. Since

all of the eddy currents are flowing through the base, this application is very

susceptible to changes in the base. Because of this, calibrations must be made

on a bare sample of th e part being measured.

Base Metal Thickness

If the base metal thickness is less than infinite, any variations in the thickness of

the base will affect the coating measurements. The magnitude of this effect

decreases with increasing coating thickness. Limit the effect of the base

variations as follows. Take numerous readings on the bare sample during the

calibration to average out the base variations. When taking measurement on the

coated samples, several measurements must be also taken over the entire

surface of the sample to determine the average coating thickness.

Inherent Base Variation

Base variation can also be due to inherent variations in electrical conductivity or

magnetic permeabili ty due to the manufacturing process es. To determine the

Oxford Instruments Contact Measurement Page 21 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 22

effect of these variations on the sample measurements, calibrate the unit and

then take several measurements across the bare sample. If the range of

readings is found to be large, then calibrate in the same method as described in

Base Metal Thickness.

Surface Roughness

Since the lift-off method (used to measure nonconductive coatings over

conductive bases) measures coating thickness as the probe distance from the

surface of the base material, surface roughness will cause variations in surface

to probe contact and affect both the repeatability and the accuracy of

measurements. It is recommended that numerous measurements be taken on

rough samples to average out the effects of the surface roughness. Any foreign

particles on the surface will also affect the accuracy of the measurements, since

the contact between the probe and the surface will be obstructed.

Sample Shape

The size and shape of the part is also an important consideration when using the

lift-off method.

Edge Effects

Since the field may extend past the edges of the sample, the eddy current

technique is sensitive to abrupt changes in the surface contour of the sample

area. Measurements should not be made near an edge unless that is the

specific area to be measured.

Curvature

Sample curvature has a large affect on the measurements. It is recommended

that the base sample used to calibrate the eddy current probe have the same

radius as the samples to be measured. If there is more than one type of sample

curvature, a separate calibration will be necessary on each radius of curvature

being measured.

Probe Orientation

The correct orientation of the probe is perpendicular to the surface or tangent to

the curved surface. It is necessary to have proper probe orientation and

consistent probe pressure to ensure accurate and repeatable results. There are

several probe guides and stands available to help with the proper orientation and

pressure of the probe.

Chrome over Copper

The Cr/Cu application can be done using the nonconductive/conductive method,

but the calibration must be done on a Cr/Cu plated standard. There are two

reasons for this. First Cr is slightly conductive, therefore, the application will not

work as a straightforward nonconductive over conductive calibration. Secondly,

Cr plating generally has many cracks in the surface that would cause inaccurate

readings. The Cu base must be at least 0.030” thick. When calibrating with the

0.5 mil standard the recommended tracking range is 0 to 1.0 mil, but the

Oxford Instruments Contact Measurement Page 22 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 23

application is capable of tracking from 0 to 40 mil if thicker standards are used in

the calibration.

Magnetic Induction

Theory

The magnetic induction method is used for measuring the thickness of any

nonmagnetic coating such as zinc, cadmium, paint, etc. on a steel substrate.

This measurement method is also called the “lift-off” method. Magnetic principles

are also used to measure magnetic nickel on a nonmagnetic substrate. In this

technique, the probe system is essentially a transformer. The primary winding

for the probe is driven with an alternating current. The secondary winding (the

output of the probe) reacts to the presence of a magnetic material. As the probe

is brought closer to the magnetic material, the efficiency steadily increases and

progressively more voltage is output. Thickness readings are based on the

output voltage of the probe. As the coating gets thicker, the distance between

the probe and the magnetic substrate increases, decreasing the output voltage.

Base Variations

Calibrating a magnetic probe consists of placing nonmagnetic shims of known

thicknesses directly over the bare conductive substrate. The magnetic probes

are very susceptible to changes in the base including different grades of steel,

hardening processes, or shapes of the sample. Because of this, calibrations

must be made on a bare sample of the same part to be measured. If the

company has several parts of different types of steel or configurations, they will

need a calibration for each type of part.

Base Metal Thickness

If the base metal thickness is less than infinite, any variations in the thickness of

the base will affect the coating measurements. The magnitude of this effect

decreases with increasing coating thickness. Limit the effect of the base

variations as follows. Take numerous readings on the bare sample during the

calibration to average out the base variations. When taking measurement on the

coated samples, several measurements must be also taken over the entire

surface of the sample to determine the average coating thickness.

Inherent Base Variation

Base variation can also be due to inherent variations in electrical conductivity or

magnetic permeabili ty due to the manufacturing process es. To determine the

effect of these variations on the sample measurements, calibrate the unit and

then take several measurements across the bare sample. If the range of

readings is found to be large, then calibrate in the same method as described in

Base Metal Thickness.

Surface Roughness

Since the magnetic method measures coating thickness as the probe distance

from the surface of the base material, surface roughness will cause variations in

surface to probe contact and affect both the repeatability and the accuracy of

Oxford Instruments Contact Measurement Page 23 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Page 24

measurements. It is recommended that numerous measurements be taken on

rough samples to average out the effects of the surface roughness. Any foreign

particles on the surface will also affect the accuracy of the measurements, since

the contact between the probe and the surface will be obstructed.

Sample Shape

The size and shape of the part is also an important consideration when using the

lift-off method.

Edge Effects

Since the magnetic field may extend past the edges of the sample, the magnetic

induction technique is sensitive to abrupt changes in the surface contour of the

sample area. Measurements should not be made near an edge unless that is the

specific area on the sample to be measured.

Curvature

Sample curvature has a large affect on the measurements. It is recommended

that the base sample used to calibrate the magnetic probe have the same radius

as the samples to be measured. If there is more than one type of sample

curvature, a separate calibration will be necessary on each radius of curvature

being measured.

Probe Orientation

The correct orientation of the probe is perpendicular to surface or tangent to the

curved surface. It is necessary to have proper probe orientation and consistent

probe pressure to ensure accurate and repeatable results. There are several

probe guides and stands available to help with the proper orientation and

pressure of the probe.

Magnetized Steel

The magnetic induction method should not be used to measure coating thickness

on highly magnetized steel. Measurements on slightly magnetized steel are

correct if the user calibrates with a bare sample magnetized to the same extent

as the samples to be measured.

Stainless Steel Base

If a stainless steel substrate is magnetic (400 Series), then the magnetic

induction method can be used in measurements. If the stainless steel in nonmagnetic (300 Series), no measurements can be made.

Oxford Instruments Contact Measurement Page 24 of 24

233 USER GUIDE

The information in this document is private and confidential and must not be copied.

Oxford Instruments plc

Loading...

Loading...