Oxford Instrucments E1000 User Manual

E1000

Dual Temperature Controller

Users Manual

Oxford Instruments Austin, Inc.

1340 Airport Commerce Blvd.

Bld. 1 Suite 175

Austin, TX 78741 USA

Sales: 800-611-8871

Support: 800-404-1055

cryo-sales@oxinst.com

support@oxinst.com

www.oxford-instruments.com

• • •

=

The Business of Science®

Oxford Instruments Austin, Inc. is a wholly-owned subsidiary of Oxford Instruments. For information about

Oxford Instruments, visit the Oxford Instruments website at:

http://www.oxford-instruments.com

How to Contact Oxford Instruments Austin, Inc. Support:

For contact information and a complete listing of Direct Sales, Distributor, and Sales Representative contacts,

visit the Oxford Instruments Austin, Inc. website at:

http://www.oxford-instruments.com/businesses/industrial-products/austin

Oxford Instruments Austin, Inc. has made its best effort to ensure that the information contained in this

document is accurate and reliable. However, the information is subject to change without notice and is

provided “AS IS” without warranty of any kind, expressed or implied. Before placing orders, customers are

advised to obtain the latest version of relevant information to verify that information being relied upon is

current and complete. All products are sold subject to the terms and conditions of sale supplied at the time of

order acknowledgment, including those pertaining to warranty, patent infringement, and limitation of

liability. No responsibility is assumed by Oxford Instruments Austin, Inc. for the use of this information,

including use of this information as the basis for manufacture or sale of any items, or for infringements of

patents or other rights of third parties.

These documents are the property of Oxford Instruments Austin, Inc. and by furnishing this information,

Oxford Instruments Austin, Inc. grants no license, expressed or implied, under any patents, copyrights,

trademarks, trade secrets, or other intellectual property rights of Oxford Instruments Austin, Inc. Oxford

Instruments Austin, Inc., the copyright owner of the information contained herein, gives consent for copies to

be made of the information only for use within the customer’s organization as related to the use of Oxford

Instruments Austin, Inc. products. The same consent is given for similar information contained on any Oxford

Instruments Austin, Inc. website or disk used to distribute information to a customer. Oxford Instruments

Austin, Inc. does give consent to the copying or reproduction by any means of the information contained

herein for general distribution, advertising or promotional purposes, or for creating any work for resale. The

names of products of Oxford Instruments Austin, Inc. or other vendors and suppliers appearing in this

document may be trademarks or service marks of their respective owners that may be registered in some

jurisdictions. A list of Oxford Instruments Austin, Inc. trademarks and service marks can be found at:

http://www.oxford-instruments.com/businesses/industrial-products/austin

Copyright (©) 2012 by Oxford Instruments, All rights reserved.

ii

• • •

The Business of Science®

Contents

Contents

ContentsContents

Overview..................................................................................................................................................................... 1

Description .................................................................................................................................................................1

E1000 Installation...................................................................................................................................................... 2

Setpoint Relay Pin-out .........................................................................................................................................3

Setpoint Relay Pin-out .........................................................................................................................................4

Analog Outputs (0 – 10 V) .................................................................................................................................. 5

E1000 Front Panel..................................................................................................................................................... 6

E1000 User Interface ............................................................................................................................................6

Manual/Auto Configuration...............................................................................................................................6

Diode Curve Selection..........................................................................................................................................7

Setpoint Configuration............................................................................................................................................8

Example................................................................................................................................................................... 9

Serial Port Interface................................................................................................................................................ 10

Serial Port Cable.................................................................................................................................................. 10

Serial Port Protocol.............................................................................................................................................10

Serial Port Commands........................................................................................................................................11

E1000 Curve Programmer .....................................................................................................................................13

Order Information ..................................................................................................................................................15

Revision History

Revision History

Revision HistoryRevision History

Document Number 97-00041-002

Date

Date Revision

DateDate

December 2012 1.0.2 Update Company name and address

April 2010 1.0.1 Added statement to clarify mode change sequence

March 2010 1.0.0 New Document

Revision Description of Change

RevisionRevision

Description of Change

Description of ChangeDescription of Change

iii

• • •

The Business of Science®

E1000 Dual Channel Cryogenic Temperature

Monitor

Overview

Overview

OverviewOverview

• Continuous visual update of two temperature sensors (channels) using backlit LCD display

• Drives two temperature diodes, intended for cryogenic temperature measurement

• Diode temperature curve selection from four pre-defined curves

• Supports one user-defined, programmable diode curve

• Six programmable setpoint relays (three per sensor/channel)

• Two 0 – 10 V analog outputs for temperature monitoring (one per sensor/channel)

• Provides an RS-232 serial port for a PLC or PC digital interface

• Independent control of two outputs

Description

Description

DescriptionDescription

The E1000 Dual Channel Temperature Monitor drives two diode temperature sensors, and provides a visual

display of the temperature on a backlit LCD module. The intended applications of the E1000 include

controlling two separate cryopumps or cryocoolers simultaneously, by using one diode (channel) for each

coldhead. The E1000 also has the unique capability to control the temperature of a water pump to a user

specified temperature from90 to 130K. While in the Water pump mode, the coldhead power will be

stopped when the water pump reaches the selected off temperature and resume pumping when the upper

temperature is reached. The high resolution measurement sensors provide noise rejection to deliver precise,

accurate temperature readings. The diode curves are user selectable from four (4) pre-defined curves

providing support for common diodes. In addition, a user-programmable curve is available for nonsupported diodes. Temperature conversion is provided by a 10µA constant current source using a spline

interpolation (piecewise polynomial).

1

• • •

The Business of Science®

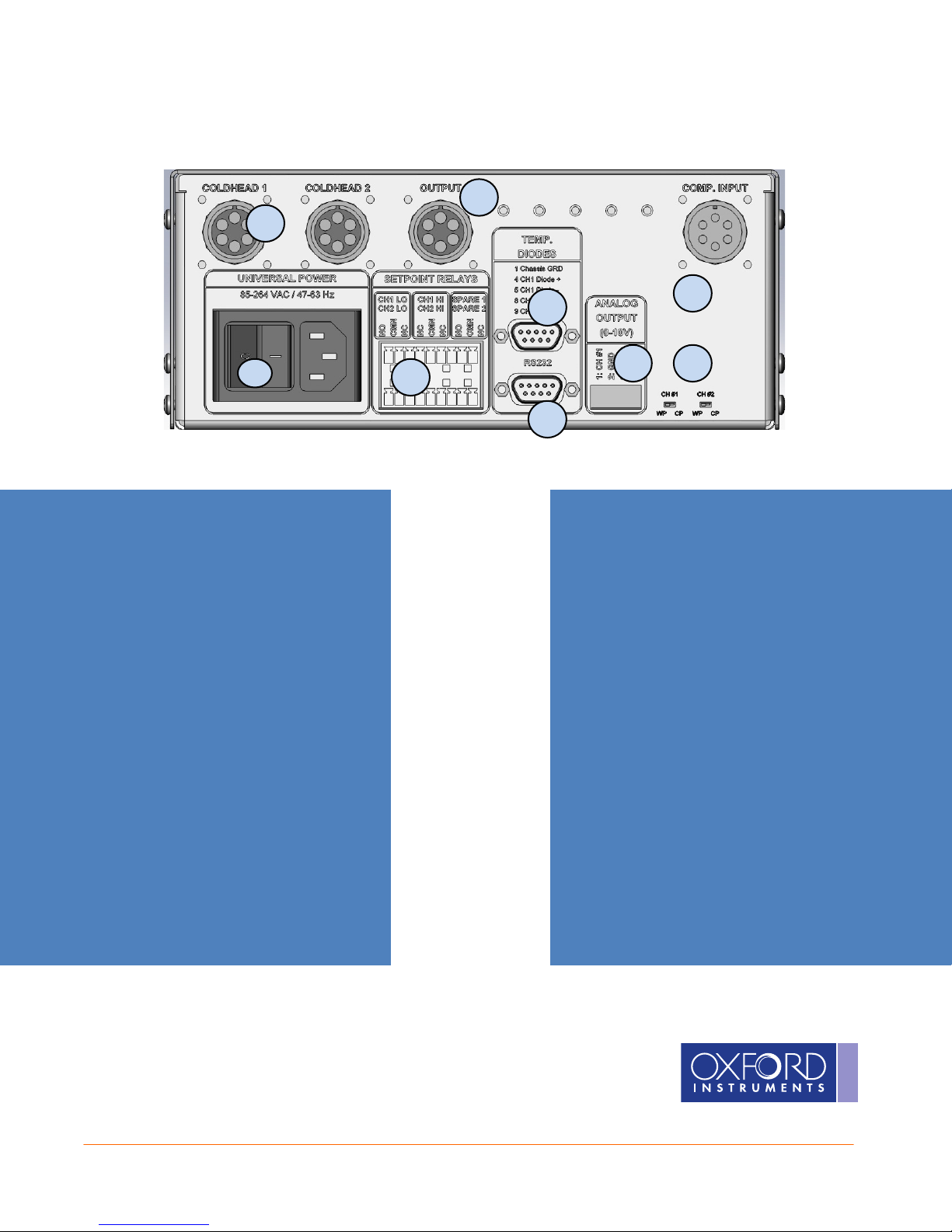

1 – IE

C Power Entry

1

4 – D-sub 9 Male: RS

-

232 Serial Port.

E1000 Installation

E1000 Installation

E1000 InstallationE1000 Installation

8

9

. Universal Power

input accepts 110 or 220 VAC at 50 or 60

Hz

2 – Setpoint Relays. Dry contacts are

provided to trigger external equipment, or

to provide status to control electronics,

such as a PLC. Three relays are provided

for each temperature channel. The top

row connector is controlled by Channel #1

sensor, and the bottom is controlled by

Channel #2. See the setpoint table for a

detailed pin-out.

3 – D-sub 9 Female: Temperature

Sensors. Connect temperature sensor

according to the following pin out:

Pin 1: Shield (GND)

Pin 2: No Connect (NC)

Pin 3: NC

Pin 4: Diode Sensor #1 Positive

Pin 5: Diode Sensor #1 Negative

Pin 6 – 7: NC

Pin 8: Diode Sensor #2 Positive

Pin 9: Diode Sensor #2 Negative

2

3

7

5 6

4

Provides serial interface to a remote serial

device. The serial port is intended to be

used with a standard “straight through”

serial cable (not NULL Modem).

Pin 1: No Connect (NC)

Pin 2: RS-232 Transmit Out

Pin 3: RS-232 Receive In

Pin 4: NC

Pin 5: GND

Pin 6 – 9: NC

5 – Analog Outputs. Analog outputs are

provided for recorder logging, or as status

to a PLC. The outputs provide 0 – 10 V for

each channel.

Pin 1: Channel #1 Voltage Output

Pin 2: GND

Pin 3: Channel #2 Voltage Output

Pin 4: GND

2

• • •

The Business of Science®

6 – Mode Selection

7 – Compressor Power in.

E1000 Rear Panel cont.

E1000 Rear Panel cont.

E1000 Rear Panel cont.E1000 Rear Panel cont.

. 2 miniature slide

switches allow the user to select either

Coldhead or Waterpump mode. In the

coldhead mode, the channel will provide

power to the output at all times and will

operate the relays according to the user

set temperatures. In the Cryopump mode,

power will be supplied at all times to the

coldhead, unless, the manual mode is

selected. To change the Mode of the

E1000, the power switch must be turned

off and back on after changing the

positioni of the switch.

Input drive

power from the compressor. Requires

special drive cable.

8 – Compressor Power Out. Power out to

drive and additional E1000. The power is

fused at 3 amps.

9 – Coldhead out - Output power to the

coldhead or water pump. Uses standard

cryopump drive cable.

3

• • •

The Business of Science®

Loading...

Loading...