OXFORD OXFW900-TQ-A Datasheet

Oxford Semiconductor Ltd.

OXFW900

IEEE1394 to ATA/ATAPI Native Bridge

FEATURES

• S400 compliant 1394-1995 Link and Transaction

layers

• Compatible with 1394-1995 and 1394A Phys.

• Buffer Manager with max. RAM bandwidth of

800Mbps

• Microsoft Win98-Second Edition, Win2000 and Apple

MacOS 8.5 generic driver support

• SBP-2 Target Revision 4 compliant interface

• Fully ATA-4 compliant (see T13-1153D)

• Sustained IDE transfer rate of 25 Mbytes per second,

Peak transfer rate of 50Mbytes per second.

• Supports PIO modes 0 to 4, DMA modes 0 to 2 and

Ultra DMA modes 0 to 2

• Integrated 32-bit RISC processor (ARM7TDMI) with

on-chip scratch RAM

DESCRIPTION

The OXFW900 is a high-performance 1394 to

ATA/ATAPI (IDE) native bridge with an integrated target

Serial Bus Protocol (SBP-2 ) controller. By supporting

the SBP-2 protocol, the device can use generic SBP-2

drivers available in the Microsoft Windows 98SE, Microsoft

Windows 2000, Microsoft Millennium and Apple MacOS

operating systems.

The device is ideally suited for smart-cable or tailgate

interface applications for removable-media drives, compact

flash card readers, CD-ROM, CD-R, CD-RW, DVD-ROM,

DVD-RAM and hard disk drives, allowing IDE drives to be

connected to a 1394 serial bus in a plug-and-play fashion.

Both ATA and ATAPI devices are supported using the

same firmware.

This highly integrated device offers a three-chip solution to

native bridge applications using an external 1394 PHY and

Flash ROM. A slow 32Kx8 Flash ROM (up to 120ns) is

sufficient for most optical media applications. For

applications that need a sustained data rate in excess of

10Mbytes per second, for example high performance disk

drives, an 8-bit 50ns FLASH or faster is recommended.

The device is compatible with both 1394-1995 and 1394A

PHYs.

The LINK controller complies with S400 1394-1995

specification. The 1394 transaction layer and SBP-2

protocol is implemented using a combination of the

ARM7TDMI (low-power 32-bit RISC processor), an ORB

(Operational Request Block) hardware co-processor and a

high performance buffer manager.

69 Milton Park, Abingdon, Oxon, OX14 4RX, UK

Tel: +44 (0)1235 824900 Fax: +44(0)1235 821141

Data Sheet

• ORB co-processor to accelerate translation of ORBs

to ATAPI commands

• Supports ORB chaining for increased performance

• High performance ATA command translation in

firmware using Reduced Block Command (RBC) set

• Optional External Serial ROM interface for

configuration data, user serial number, etc.

• Blank Flash memory programming feature via 1394

bus

• 3.3 Volts operation

• Low Power CMOS

• Firmware and Flash Programming Utilities supplied by

Oxford Semiconductor

• ultra-thin 128-TQFP package (14mm x 14mm x 1mm )

The Buffer Manager has a RAM bandwidth of 800Mbps. It

provides storage for 1394 and ATA/ATAPI packets,

automatically storing them and passing them to the

appropriate destinations, without any intervention from the

processor. It also provides storage and manages the

sequencing of ORB fetching to reduce latency and improve

data throughput.

The configuration data including the IEEE OUI

(Organisational Unique Identifier) and device serial number

is stored in the Flash ROM which may be uploaded from

the 1394 bus, even when blank. The device also facilitates

firmware uploads from the 1394 bus.

The ORB co-processor translates ORBs as defined in the

SBP-2 protocol into ATA/ATAPI commands, and

automatically stores error/status messages at an address

specified by the host.

Concurrent operation of the ATA/ATAPI and 1394

interfaces are facilitated using the high throughput Buffer

Manager where LINK, ATAPI manager and ARM7TDMI

can perform interleaved accesses to the on-chip RAM

buffer. The high performance processor ensures that no

significant latency is incurred. The ATA command

translation is performed in firmware to meet RBC (Reduced

Block Commands) standard, T10-1228D. The ATA/ATAPI

Manager supports PIO modes 0 to 4, DMA modes 0 to 2

and Ultra DMA mode 0 to 2 and provides the interface to

the IDE bus. It is compliant with T13-1153D, ATA-4

specification.

OXFW900 Data Sheet Revision 1.0 – Nov 1999

Oxford Semiconductor 1999

Part No. OXFW900-TQ-A

OXFW900

OXFORD SEMICONDUCTOR LTD.

CONTENTS

FEATURES..........................................................................................................................................................1

DESCRIPTION.....................................................................................................................................................1

CONTENTS..........................................................................................................................................................2

1 BLOCK DIAGRAM ......................................................................................................................................3

2 PIN INFORMATION.....................................................................................................................................4

3 PIN DESCRIPTIONS...................................................................................................................................5

4 OPERATING CONDITIONS........................................................................................................................7

5 DC ELECTRICAL CHARACTERISTICS....................................................................................................7

5.1 I/O BUFFERS..........................................................................................................................................................7

6 AC ELECTRICAL CHARACTERISTICS....................................................................................................8

6.1 IDE INTERFACE.....................................................................................................................................................8

6.2 1394 LINK-PHY INTERFACE................................................................................................................................11

6.3 EXTERNAL PROCESSOR INTERFACE................................................................................................................12

7 TIMING WAVEFORMS..............................................................................................................................13

8 PACKAGE INFORMATION.......................................................................................................................27

9 ORDERING INFORMATION.....................................................................................................................28

NOTES...............................................................................................................................................................29

CONTACT DETAILS.........................................................................................................................................30

DISCLAIMER.....................................................................................................................................................30

Data Sheet Revision 1.0 Page 2

OXFW900

OXFORD SEMICONDUCTOR LTD.

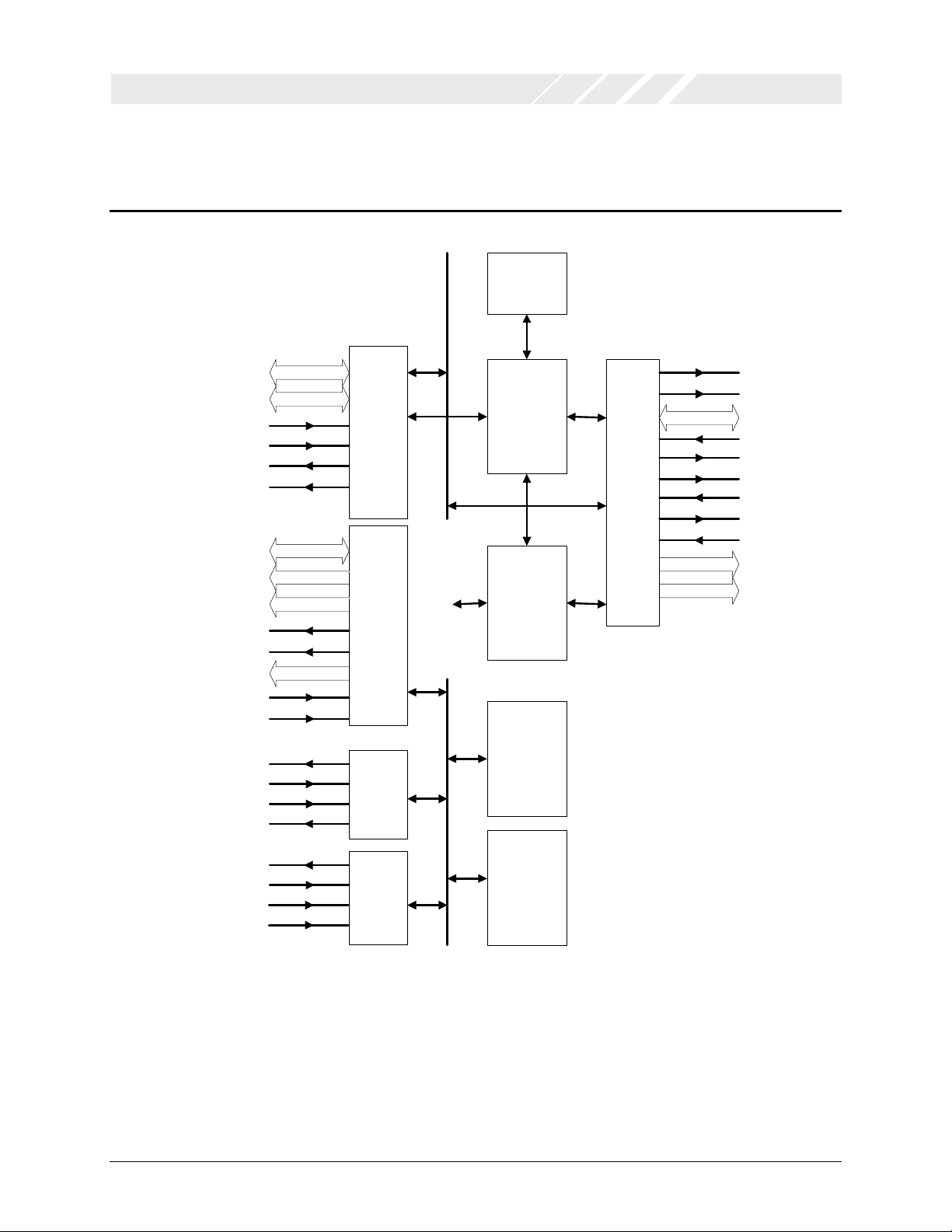

1 BLOCK DIAGRAM

Buffer RAM

PD[7:0]

CTL[1:0]

PHY_CLK

LINK_ON

LPS

LREQ

D[15:0]

A[16:0]

CS#[3:0]

OE#

WE#

BWE#[1:0]

WIDTH16

INT#

XTALO

XTALI

CKIN

CKOUT

Link-Phy

interface

External

ROM

interface

Clock

generator

RAM

Manager

ORB Co-

processor

Internal ARM7TDMI bus

ARM7TDMI

ATA/

ATAPI

manager

IDE_OE#

RTS[3:0]#

ID[15:0]

DMARQ

DIOW#

DIOR#

IORDY

DMACK#

INTRQ#

IA[2:0]

IDE_CS#[2:0]

EE_DO

Data Sheet Revision 1.0 Page 3

EE_DI

EE_CS

EEPROM

interfaceEE_CK

SCRATCH

RAM

Figure 1: OXFW900 Block Diagram

OXFW900

OXFORD SEMICONDUCTOR LTD.

RESET#

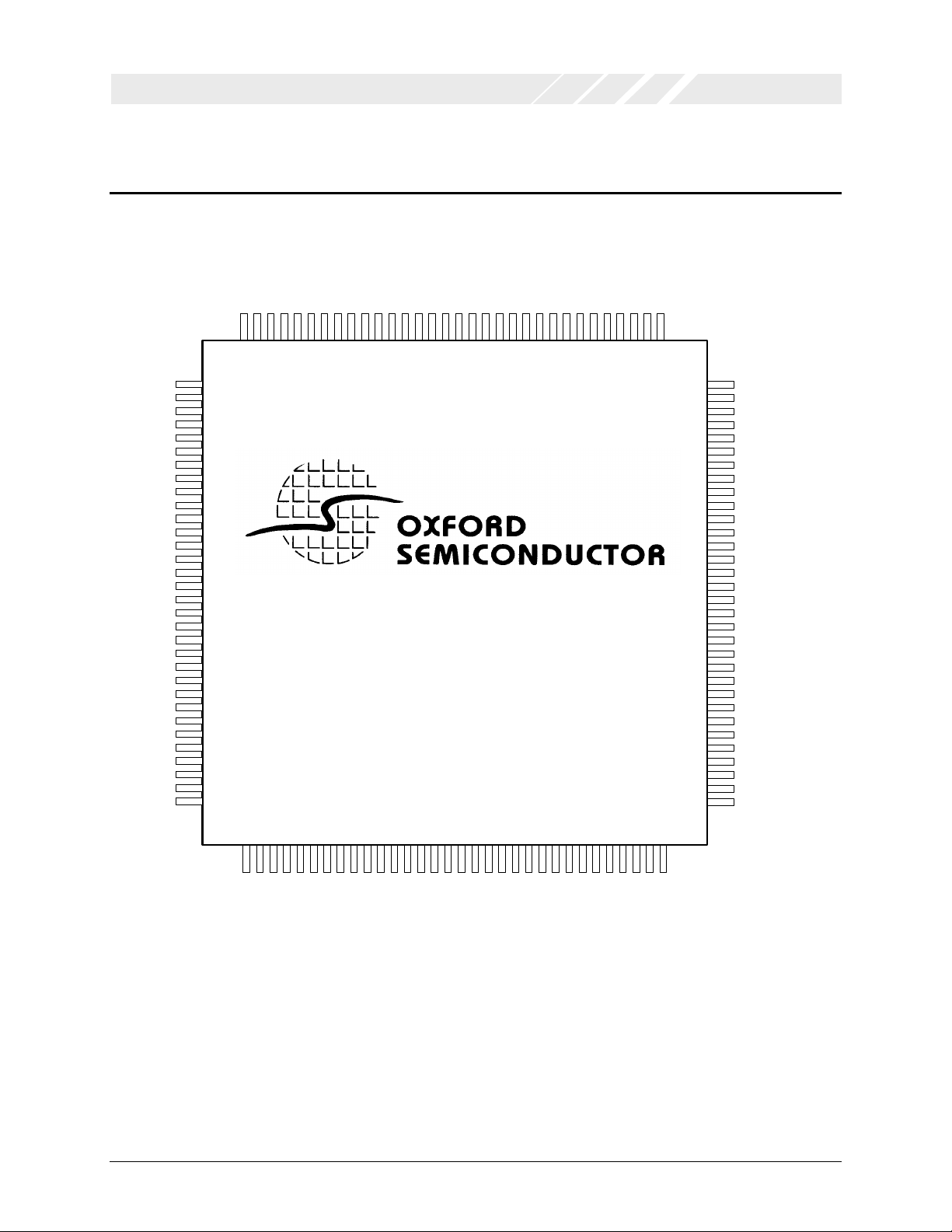

2 PIN INFORMATION

INTRQ

DMACK#

VDD

GND

IORDY

DIOR#

DIOW#

DMARQ

VDD

GND

ID15

ID0

VDD

GND

ID14

ID1

ID13

ID2

ID12

ID3

5VBIAS

GND

ID11

ID4

ID10

ID5

ID9

ID6

GND

GND

ID8

ID7

IA1

IA0

IA2

ICS0#

ICS1#

LINKON

LPS

PD7

PD6

GND

GND

PD5

PD4

PD3

PD2

5VBIAS

CKOUT

VDD

PD1

PD0

CTL1

CTL0

GND

PHYCLK

VDD

LREQ

FORCE#

TEST0

TEST1

GPO1

GPO2

GPO3

96959493929190898887868584838281807877767574737271706968676665

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

OXFW900-TQ-A

118

119

120

121

122

123

124

125

126

127

128

79

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

IRESET

IDE_OE#

WIDTH16

INT#

A0

VDD

XTLO

XTLI

CKIN

GND

A1

A2

A3

A4

A5

A6

A7

VDD

GND

A8

A9

A10

A11

A12

A13

GND

5VBIAS

A14

A15

A16

WE#

BWR0#

Data Sheet Revision 1.0 Page 4

12345678910111213141516171920212223242526272829303132

GPI

D15

D14

D13

D12

D11

D10

GND

D9D8D7D6D5

5VBIAS

D4

VDD

GND

18

D2D1D0

D3

GND

VDD

CS3#

CS2#

VDD

GND

CS1#

CS0#

OE#

Figure 2: Pinout (package = 128 TQFP)

BWR#

OXFW900

OXFORD SEMICONDUCTOR LTD.

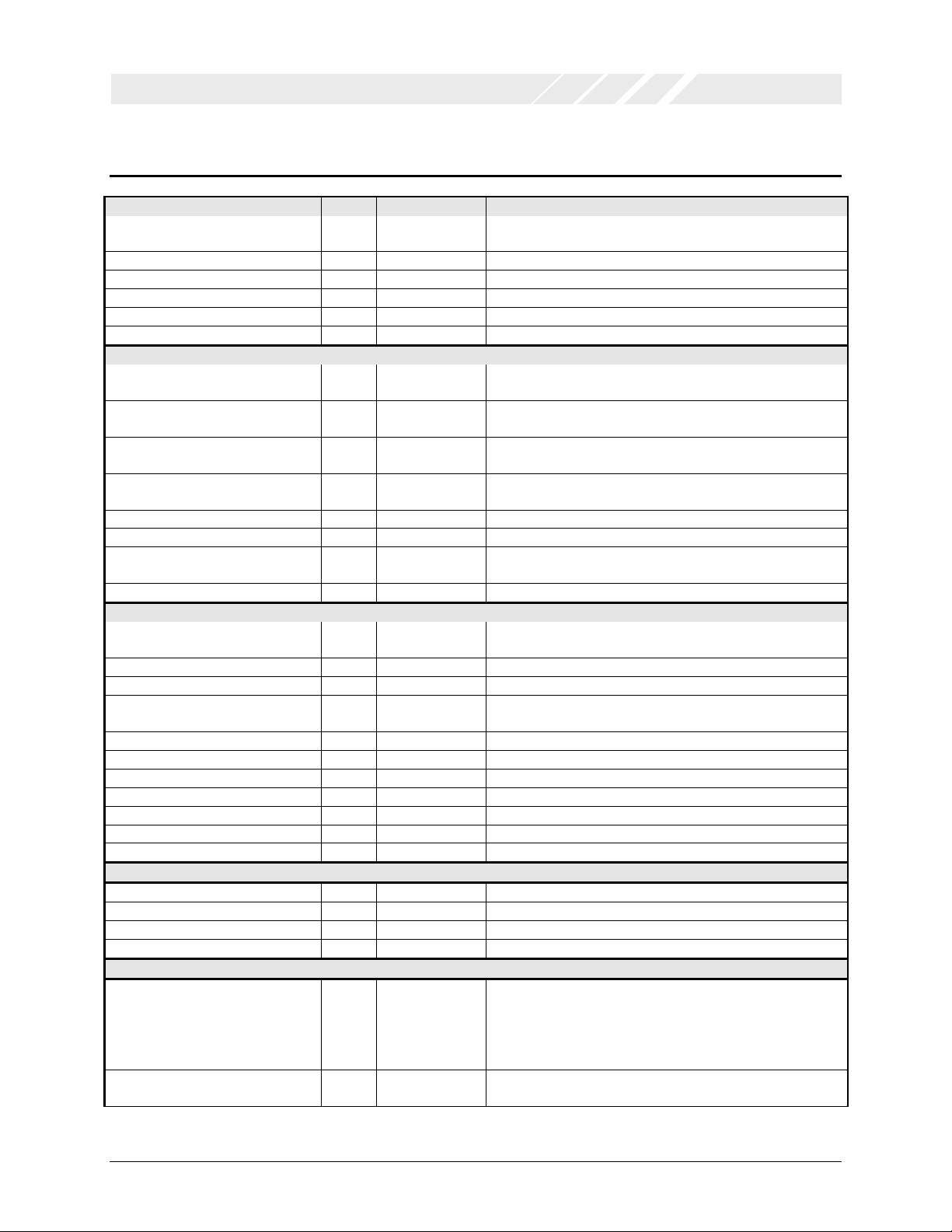

3 PIN DESCRIPTIONS

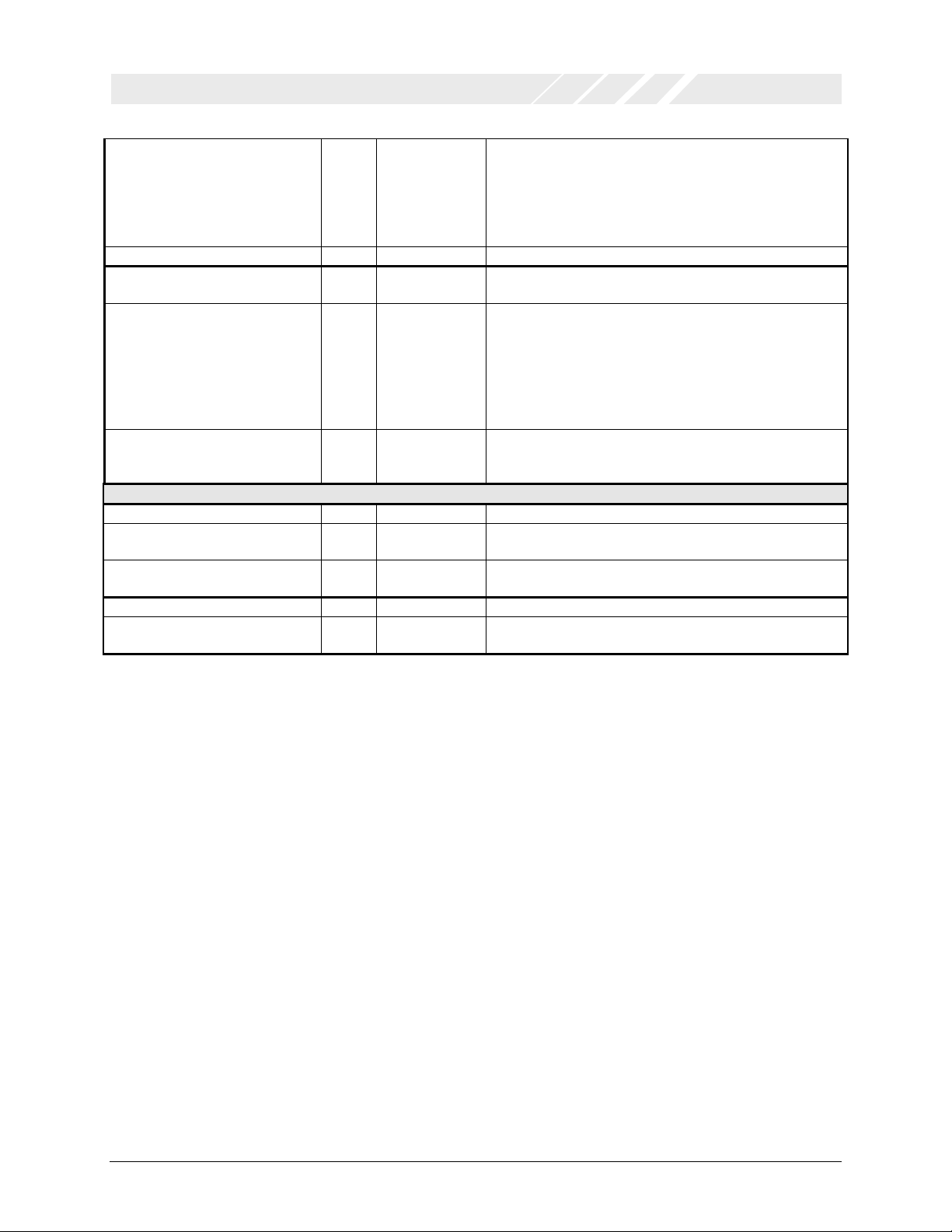

1394 PHY-LINK interface Dir1 Name Description

104, 105, 108, 109, 110, 111, 115,

116

117,118 I/O CTL[1:0] Phy-Link Control Bus

120 I PHYCLK 49.152 MHz clock sourced by PHY

122 O LREQ Link Request

102 IU LINKON Requests link to power up when in a low power mode

103 O LPS Indicates to phy that link is powered and ready

ARM external interface

2, 3, 4, 5, 6, 7, 10, 11, 12, 13, 14,

15, 18, 19, 20, 21

35, 36, 37, 40, 41, 42, 43, 44, 45,

48, 49, 50, 51, 52, 53, 54, 60

25, 26, 29, 30 T_O CS#[3:0] ARM external chip selects. CS0# is always used for program

31 T_O OE# ARM external output enable. Active when reading data from

32, 33 T_O BWR#[1:0] Byte Write enables. For future expansion

34 T_O WE# Write Enable. Active when writing to external devices

62 ID WIDTH16 ‘1’ = 16 bit external ROM ‘0’ = 8 bit external ROM

61 T_IU INT# External ARM interrupt

IDE interface

65, 66, 69, 70, 71, 72, 73, 74, 77,

78, 79, 80, 81, 82, 85, 86

97, 98, 99 T_O IA[2:0] IDE address bus

100, 101 T_O ICS#[1:0] IDE chip select. Selects IDE drive 0 or 1

63 T_O IDE_OE#[ IDE output enable. Only used when external buffering is

64 T_O IRESET IDE interface reset

89 T_I DMARQ

90 T_O DIOW# IDE interface write strobe

91 T_O DIOR# IDE interface read strobe

92 T_O IORDY

95 T_O DMACK#

96 T_I INTRQ

EEPROM interface

128 O GPO3 General Purpose Output 3

126 O GPO1 General Purpose Output 1

1 IU GPI General Purpose Input

127 O GPO2 General Purpose Output 2

Miscellaneous Pins

57 I XTLI Crystal Oscillator input. 24.576 MHz crystal required. If a

58 O XTLO Crystal Oscillator output. IMPORTANT – See Application

I/O PD[7:0] Phy-Link Data Bus

T_I/O D[15:0] ARM external data bus

T_O A[16:0] ARM external address bus

ROM.

external devices including program ROM

(pulldown)

T_I/O ID[15:0] IDE data bus

required to drive IDE data bus

clock module is used rather than a crystal then this input

must be tied high for the OXFW900 to operate, and the clock

module output connected to the CKIN pin. IMPORTANT See Application Notes regarding clocking

Notes regarding clocking.

Data Sheet Revision 1.0 Page 5

OXFW900

OXFORD SEMICONDUCTOR LTD.

56 I CKIN Direct clock input. Used in conjunction with an external

crystal oscillator of 24.576MHz. If a crystal is connected to

XTLI and XTLO this input must be tied low for the OXFW900

to operate. Mark space ratio of crystal oscillator must be

45:55 or better. IMPORTANT – Please refer to Application

Notes regarding clocking

23 IU RESET# Global reset for the OXFW900. Active Low.

113 T_O CKOUT Clock output. 24.576 MHz clock output. IMPORTANT –

Please refer to Application Notes regarding clocking

123 IU FORCE# This input is used to allow the OXFW900 to reprogram a

flash which has been loaded with a bad program. A bad

program is defined as one that does not have the correct

interlocking mechanism for reprogramming flash. This pin

forces the ARM watchdog timer to trigger thus allowing the

flash to be reprogrammed over the 1394 bus as if the flash

were blank.

124, 125 IU TEST[1:0] ‘11’ = NORMAL OPERATION. These pins have internal

pullup resistors and must be left unconnected. Other settings

are for foundry test purposes only.

Power and ground2

28, 47, 94, 114 3V3 3.3V AC VDD Supplies power to output buffers in switching (AC) state

17, 24, 59, 84, 88, 121 3V3 3.3V DC VDD Power supply. Supplies power to core logic, input buffers

and output buffers in steady state

9, 38, 76, 112 5V 5V BIAS VDD Supplies 5V reference bias to all 5V tolerant I/O. All four

MUST be connected to 5V rail.

8, 27, 46, 67, 75, 93, 106 G AC GND Supplies GND to output buffers in switching (AC) state

16, 22, 39, 55, 68, 83, 87, 107, 119 G DC GND Ground (0 volts). Supplies GND to core logic, input buffers

and output buffers in steady state

Table 1: Pin Descriptions

Note 1: Direction key:

I Input

IU Input with internal pull-up

ID Input with external pull-down

O Output

I/O Bi-directional

T_I 5V tolerant input

Note 2: Power & Ground

There are two GND and three VDD rails internally. One set of rails supply power and ground to output buffers while in switching

state (called AC power) and another rail supply the core logic, input buffers and output buffers in steady-state (called DC rail). A

third rail provides 5V bias voltage to 5V tolerant IO.

The rails are not connected internally. This precaution reduces the effects of simultaneous switching outputs and undesirable RF

radiation from the chip.

T_O 5V tolerant output

T_I/O 5V tolerant bi-directional

G Ground

3V3 3.3V power

5V 5V bias power

Data Sheet Revision 1.0 Page 6

OXFW900

OXFORD SEMICONDUCTOR LTD.

Configuration & Operation

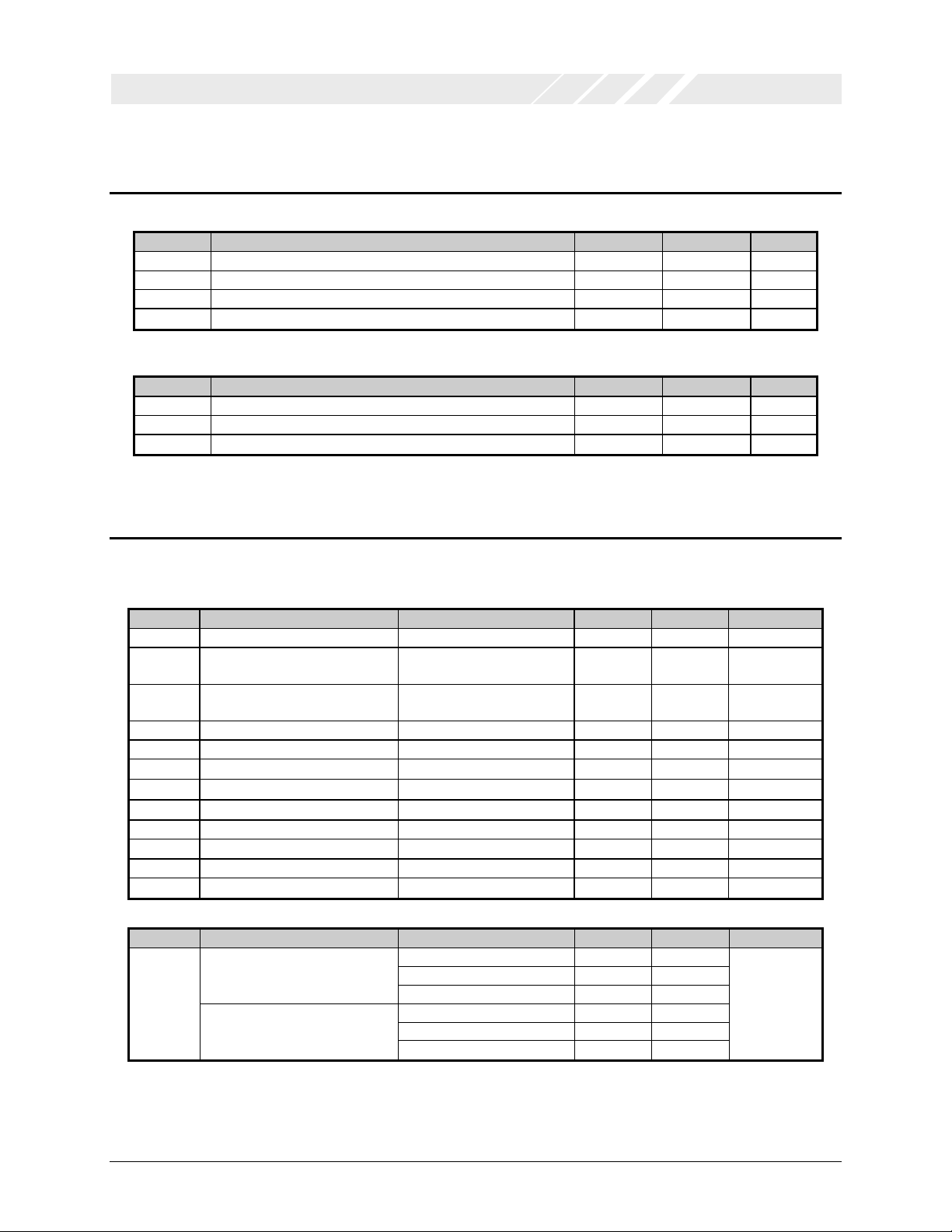

4 OPERATING CONDITIONS

Symbol Parameter Min Max Units

VDD DC supply voltage -0.3 4.6 V

VIN DC input voltage -0.3 VDD + 0.3 V

IIN DC input current +/- 10 mA

T

Storage temperature -40 125

STG

Table 2: Absolute maximum ratings

Symbol Parameter Min Max Units

VDD DC supply voltage 3.0 3.6 V

VBB 5V PMOS bulk bias 4.75 5.25 V

TC Temperature 0 70

Table 3: Recommended operating conditions

5 DC ELECTRICAL CHARACTERISTICS

°C

°C

5.1 I/O Buffers

Symbol Parameter Condition Min Max Units

VDD Supply voltage Commercial 3.0 3.6 V

V

VIL Input low voltage CMOS Interface 1

CIL Cap of input buffers 5.0 pF

COL Cap of output buffers 10.0 pF

IIH Input high leakage current Vin = VDD -10 10

IIL Input low leakage current Vin = VSS -10 10

VOH Output high voltage

VOH Output high voltage IOH = -1mA to –24mA 2.4 V

VOL Output low voltage

VOL Output low voltage IOL = 1mA to 24mA 0.4 V

IOZ 3-state output leakage current -10 10

Symbol Parameter Condition Typical Max Units

ICC

Input high voltage CMOS Interface

IH

Operating supply current in

normal mode

Operating supply current in

Power-down mode

0.7 x Vdd

CMOS Schmitt trig

2.1

0.3 x Vdd

CMOS Schmitt trig

IOH = -1 µA

IOL = 1 µA

VDD – 0.05

0.05 V

0.8

V

V

V

µA

µA

µA

mA

Data Sheet Revision 1.0 Page 7

Table 4: Characteristics of OXFW900 I/O buffers

OXFW900

OXFORD SEMICONDUCTOR LTD.

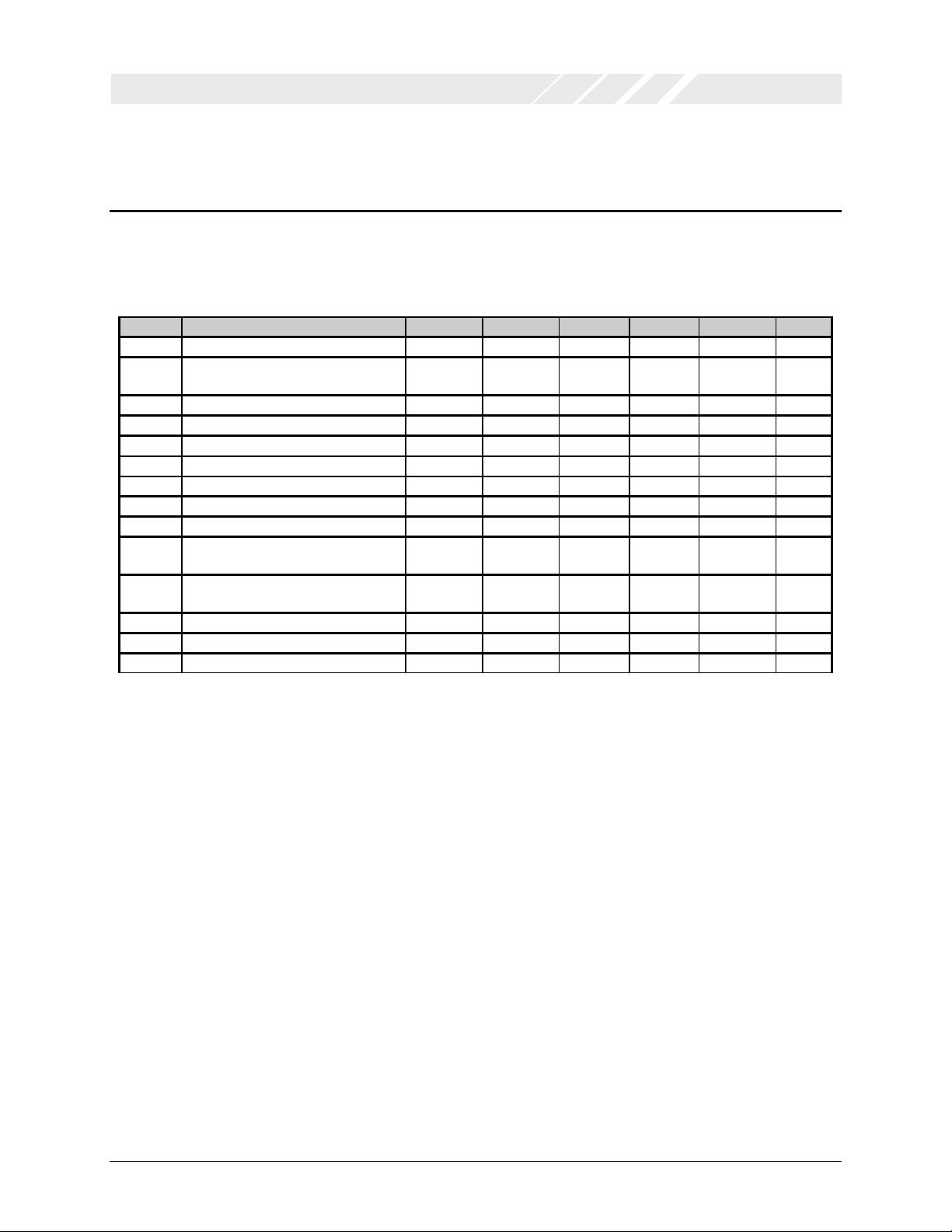

6 AC ELECTRICAL CHARACTERISTICS

6.1 IDE interface

Symbol Parameter Mode 0 Mode 1 Mode 2 Mode 3 Mode 4 Units

t0 Cycle Time 600 400 360 200 120 ns

t1 Address Valid to DIOR# / DIOW#

setup

t2 DIOR# / DIOW# pulse width 320 320 320 80 80 ns

t2i DIOR# / DIOW# recovery time - - - 80 40 ns

t3 DIOW# data setup (min ) 60 45 30 30 20 ns

t4 DIOW# data hold 40 40 40 40 40 ns

t5 DIOR# data setup ( min ) 50 35 20 20 20 ns

t6 DIOR# data hold ( min ) 5 5 5 5 5 ns

t6z DIOR# data tristate (max ) 30 30 30 30 30 ns

t9 DIOR# / DIOW# to address valid

hold

tRD Read Data Valid to IORDY active if

IORDY initially low after tA

tA IORDY Setup time 35 35 35 35 35 ns

tB IORDY Pulse Width ( max ) 1250 1250 1250 1250 1250 ns

tA IORDY assertion to release 5 5 5 5 5 ns

80 80 40 40 40 ns

40 40 40 40 40 ns

0 0 0 0 0 ns

Table 5: OXFW900 IDE PIO / Register Transfers

Data Sheet Revision 1.0 Page 8

OXFW900

OXFORD SEMICONDUCTOR LTD.

Symbol Parameter Mode 0 Mode 1 Mode 2 Units

t0 Cycle time 480 160 120 ns

tD DIOR# / DIOW# 240 80 80 ns

tE DIOR# data access ( max ) 150 60 50 ns

tF DIOR# data hold ( min ) 5 5 5 ns

tG DIOR# / DIOW# data setup 100 30 20 ns

tH DIOW# data hold 20 15 10 ns

tI DMACK to DIOR# / DIOW# setup ( min ) 0 0 0 ns

tJ DIOR# / DIOW# to DMACK hold ( min ) 20 5 5 ns

tKr DIOR# negated pulse width 80 80 40 ns

tKw DIOW# negated pulse width 240 80 40 ns

tLr DIOR# to DMARQ delay ( max ) 120 40 35 ns

tLw DIOW# to DMARQ delay ( max ) 40 40 35 ns

tM IDCS[1:0] valid to DIOR# / DIOW# 80 40 40 ns

tN IDCS[1:0] hold 40 40 40 ns

tZ DMACK to tristate ( max ) 20 25 25 ns

Table 6: OXFW900 Multiword DMA timings

Data Sheet Revision 1.0 Page 9

Loading...

Loading...