OXFORD OXCB950 Datasheet

Oxford Semiconductor Ltd.

A

OXCB950

Integrated High Performance UART

FEATURE

• Single 16C950 High performance UART channel

• Cardbus/PCI compliant, single-function target

controller. Fully compliant to PC Card Standard 7.0*,

and PCI Bus Specification 2.2, Power Management

1.0.

• Function access to pre-configure UART prior to

handover to generic device drivers.

• UART fully software compatible with 16C550-type

devices.

• Baud rates up to 15Mbps in asynchronous mode and

60Mbps in external 1x clock mode

• 128-byte deep FIFO per transmitter and receiver

• Flexible clock prescaler from 1 to 31.875

• Automated in-band flow control using programmable

Xon/Xoff in both directions

• Automated out-of-band flow control using CTS#/RTS#

and/or DSR#/DTR#

* Compliance to PC Card Standard 7.1 requires small external circuitry.

Cardbus / PCI interface

• Arbitrary trigger levels for receiver and transmitter

FIFO interrupts and automatic in-band and out-ofband flow control

• Infra-red (IrDA) receiver and transmitter operation

• 9-bit data framing as well as 5,6,7 and 8

• Global Interrupt Status and readable FIFO levels to

facilitate implementation of efficient device drivers

• Detection of bad data in the receiver FIFO

• Operation via IO or memory mapping.

• 2 Multi-purpose I/O pins which can be configured as

interrupt input or ‘wake-up’ pins

• Auto-detection of optional MicrowireTM based

EEPROM, to reconfigure device.

Autodetected.

• 3.3V operation

• 100 pin TQFP package

DESCRIPTION

The OXCB950 is a single chip UART solution for either

cardbus or PCI-based serial add-in cards. It is a single

function device, offering memory or IO mapped access to

the ultra-high performance OX16C950 UART.

This UART is the fastest available PC-compatible UART,

offering data rates up to 15Mbps and 128-deep transmitter

and receiver FIFOs. The deep FIFOs reduce CPU

overhead and allow utilisation of higher data rates. The

UART is software compatible with the widely used industrystandard 16C550 devices and compatibles, as well as the

OX16C95x family of high performance UARTs. In addition

to increased performance and FIFO size, the UART also

provides the full set of OX16C95x enhanced features

including automated in-band flow control, readable FIFO

levels etc.

A set of local registers is available to enhance device driver

efficiency and reduce interrupt latency. The internal UART

has features such as shadowed FIFO fill levels, an interrupt

source register and Good-Data Status, readable in one

DWORD register visible to logical function0 in IO space

and memory space.

The efficient 32-bit, 33MHz target-only interface is

compliant with both the cardbus sections of the PC CARD

Standard, release 7.0*, and the PCI bus specifications

version 2.2 and version 1.0 of PCI Power Management

Specification.

For full flexibility, all the default register values can be

overwritten using an optional MicrowireTM serial EEPROM.

This EEPROM can also be used to provide function access

to pre-configure the UART into enhanced modes prior to

any cardbus/PCI configuration accesses and before control

is handed to generic device drivers.

25 ParkGate, Milton Park, Abingdon, Oxon, OX14 4SH, UK

Tel: +44 (0)1235 824900 Fax: +44(0)1235 821141

OXCB950 Datasheet 1.1 – November 2000

Oxford Semiconductor 2000

Part No. OXCB950-TQFP-

OXFORD SEMICONDUCTOR LTD.

OXCB950

CONTENTS

1 PERFORMANCE COMPARISON..................................................................................................4

1.1 IMPROVEMENTS OF THE OXCB950 OVER DISCRETE SOLUTIONS:...........................................................................4

2 BLOCK DIAGRAM.......................................................................................................................5

3 PIN INFORMATION .....................................................................................................................6

4 PIN DESCRIPTIONS....................................................................................................................7

5 CONFIGURATION & OPERATION............................................................................................. 11

6 PCI TARGET CONTROLLER ..................................................................................................... 12

6.1 OPERATION........................................................................................................................................................................12

6.2 CONFIGURATION SPACE.................................................................................................................................................13

6.2.1 CARDBUS / PCI CONFIGURATION SPACE REGISTER MAP.....................................................................................13

6.3 ACCESSING THE UART FUNCTION ................................................................................................................................15

6.3.1 CARDBUS/PCI ACCESS TO THE INTERNAL UART....................................................................................................15

6.4 ACCESSING LOCAL CONFIGURATION REGISTERS....................................................................................................16

6.4.1 LOCAL CONFIGURATION AND CONTROL REGISTER ‘LCC’ (OFFSET 0X00).........................................................16

6.4.2 MULTI-PURPOSE I/O CONFIGURATION REGISTER ‘MIC’ (OFFSET 0X04).............................................................17

6.4.3 UART MIRROR REGISTER ‘UMR’ (OFFSET 0X08): ....................................................................................................18

6.4.4 GLOBAL INTERRUPT STATUS AND CONTROL REGISTER ‘GIS’ (OFFSET 0X0C)................................................19

6.5 CARDBUS/ PCI INTERRUPT.............................................................................................................................................20

6.6 CARDBUS/PCI POWER MANAGEMENT..........................................................................................................................21

6.6.1 POWER MANAGEMENT VIA UART/ MIO PINS............................................................................................................21

6.6.2 POWER REPORTING.....................................................................................................................................................22

6.6.3 CARDBUS POWER MANAGEMENT.............................................................................................................................23

6.7 CARDBUS STATUS REGISTERS .....................................................................................................................................24

6.8 CARDBUS TUPLE INFORMATION ...................................................................................................................................26

7 INTERNAL OX16C950 UART..................................................................................................... 27

7.1 OPERATION – MODE SELECTION...................................................................................................................................27

7.1.1 450 MODE.......................................................................................................................................................................27

7.1.2 550 MODE.......................................................................................................................................................................27

7.1.3 750 MODE.......................................................................................................................................................................27

7.1.4 650 MODE.......................................................................................................................................................................27

7.1.5 950 MODE.......................................................................................................................................................................28

7.2 REGISTER DESCRIPTION TABLES .................................................................................................................................29

7.3 RESET CONFIGURATION .................................................................................................................................................33

7.3.1 HARDWARE RESET.......................................................................................................................................................33

7.3.2 SOFTWARE RESET .......................................................................................................................................................33

7.4 TRANSMITTER AND RECEIVER FIFOS...........................................................................................................................34

7.4.1 FIFO CONTROL REGISTER ‘FCR’................................................................................................................................34

7.5 LINE CONTROL & STATUS...............................................................................................................................................35

7.5.1 FALSE START BIT DETECTION....................................................................................................................................35

7.5.2 LINE CONTROL REGISTER ‘LCR’................................................................................................................................35

7.5.3 LINE STATUS REGISTER ‘LSR’....................................................................................................................................36

7.6 INTERRUPTS & SLEEP MODE .........................................................................................................................................37

7.6.1 INTERRUPT ENABLE REGISTER ‘IER’........................................................................................................................37

7.6.2 INTERRUPT STATUS REGISTER ‘ISR’........................................................................................................................38

7.6.3 INTERRUPT DESCRIPTION..........................................................................................................................................38

7.6.4 SLEEP MODE .................................................................................................................................................................39

7.7 MODEM INTERFACE.........................................................................................................................................................39

7.7.1 MODEM CONTROL REGISTER ‘MCR’..........................................................................................................................39

Data Sheet Revision 1.1 Page 2

OXFORD SEMICONDUCTOR LTD.

7.7.2 MODEM STATUS REGISTER ‘MSR’.............................................................................................................................40

7.8 OTHER STANDARD REGISTERS.....................................................................................................................................40

7.8.1 DIVISOR LATCH REGISTERS ‘DLL & DLM’.................................................................................................................40

7.8.2 SCRATCH PAD REGISTER ‘SPR’.................................................................................................................................40

7.9 AUTOMATIC FLOW CONTROL.........................................................................................................................................41

7.9.1 ENHANCED FEATURES REGISTER ‘EFR’...................................................................................................................41

7.9.2 SPECIAL CHARACTER DETECTION............................................................................................................................42

7.9.3 AUTOMATIC IN-BAND FLOW CONTROL.....................................................................................................................42

7.9.4 AUTOMATIC OUT-OF-BAND FLOW CONTROL...........................................................................................................42

7.10 BAUD RATE GENERATION ...............................................................................................................................................43

7.10.1 GENERAL OPERATION .................................................................................................................................................43

7.10.2 CLOCK PRESCALER REGISTER ‘CPR’.......................................................................................................................43

7.10.3 TIMES CLOCK REGISTER ‘TCR’...................................................................................................................................43

7.10.4 EXTERNAL 1X CLOCK MODE.......................................................................................................................................45

7.10.5 CRYSTAL OSCILLATOR CIRCUIT................................................................................................................................45

7.11 ADDITIONAL FEATURES ..................................................................................................................................................45

7.11.1 ADDITIONAL STATUS REGISTER ‘ASR’......................................................................................................................45

7.11.2 FIFO FILL LEVELS ‘TFL & RFL’.....................................................................................................................................46

7.11.3 ADDITIONAL CONTROL REGISTER ‘ACR’..................................................................................................................46

7.11.4 TRANSMITTER TRIGGER LEVEL ‘TTL’........................................................................................................................47

7.11.5 RECEIVER INTERRUPT. TRIGGER LEVEL ‘RTL’........................................................................................................47

7.11.6 FLOW CONTROL LEVELS ‘FCL’ & ‘FCH’......................................................................................................................47

7.11.7 DEVICE IDENTIFICATION REGISTERS .......................................................................................................................47

7.11.8 CLOCK SELECT REGISTER ‘CKS’...............................................................................................................................48

7.11.9 NINE-BIT MODE REGISTER ‘NMR’...............................................................................................................................48

7.11.10 MODEM DISABLE MASK ‘MDM’....................................................................................................................................49

7.11.11 READABLE FCR ‘RFC’...................................................................................................................................................49

7.11.12 GOOD-DATA STATUS REGISTER ‘GDS’ .....................................................................................................................49

7.11.13 DMA STATUS REGISTER ‘DMS’ ...................................................................................................................................50

7.11.14 PORT INDEX REGISTER ‘PIX’.......................................................................................................................................50

7.11.15 CLOCK ALTERATION REGISTER ‘CKA’.......................................................................................................................50

OXCB950

8 SERIAL EEPROM SPECIFICATION ........................................................................................... 51

8.1 EEPROM DATA ORGANISATION.....................................................................................................................................51

8.1.1 ZONE0: HEADER............................................................................................................................................................51

8.1.2 ZONE1 : POWER MANAGEM ENT DATA, DATA_SCALE ZONE ................................................................................. 52

8.1.3 ZONE2: LOCAL CONFIGURATION REGISTER ZONE................................................................................................53

8.1.4 ZONE 3 : CARDBUS INFORMATION STRUCTURE.....................................................................................................53

8.1.5 ZONE4: PCI CONFIGURATION REGISTERS...............................................................................................................54

8.1.6 ZONE5: FUNCTION ACCESS........................................................................................................................................55

9 COMPLIANCE TO PC CAR D STANDARDS, 7.0 AND 7.1............................................................57

10 OPERATING CONDITIONS..................................................................................................... 60

11 DC ELECTRICAL CHARACTERISTICS................................................................................... 61

11.1 NORMAL 3.3V I/O BUFFERS.............................................................................................................................................61

11.2 5.0V TOLERANT I/O BUFFERS ........................................................................................................................................ 61

11.3 DUAL MODE (CARDBUS/PCI) I/O BUFFERS.................................................................................................................62

12 POWER CONSUMPTION MEASUREMENTS........................................................................... 63

12.1 STATIC CURRENT CONSUMPTION.................................................................................................................................63

12.2 CURRENT CONSUMPTION IN APPLICATION.................................................................................................................63

13 TIMING WAVEFORMS............................................................................................................ 64

14 PHYSICAL PACKAGE DETAILS .............................................................................................66

Data Sheet Revision 1.1 Page 3

OXFORD SEMICONDUCTOR LTD.

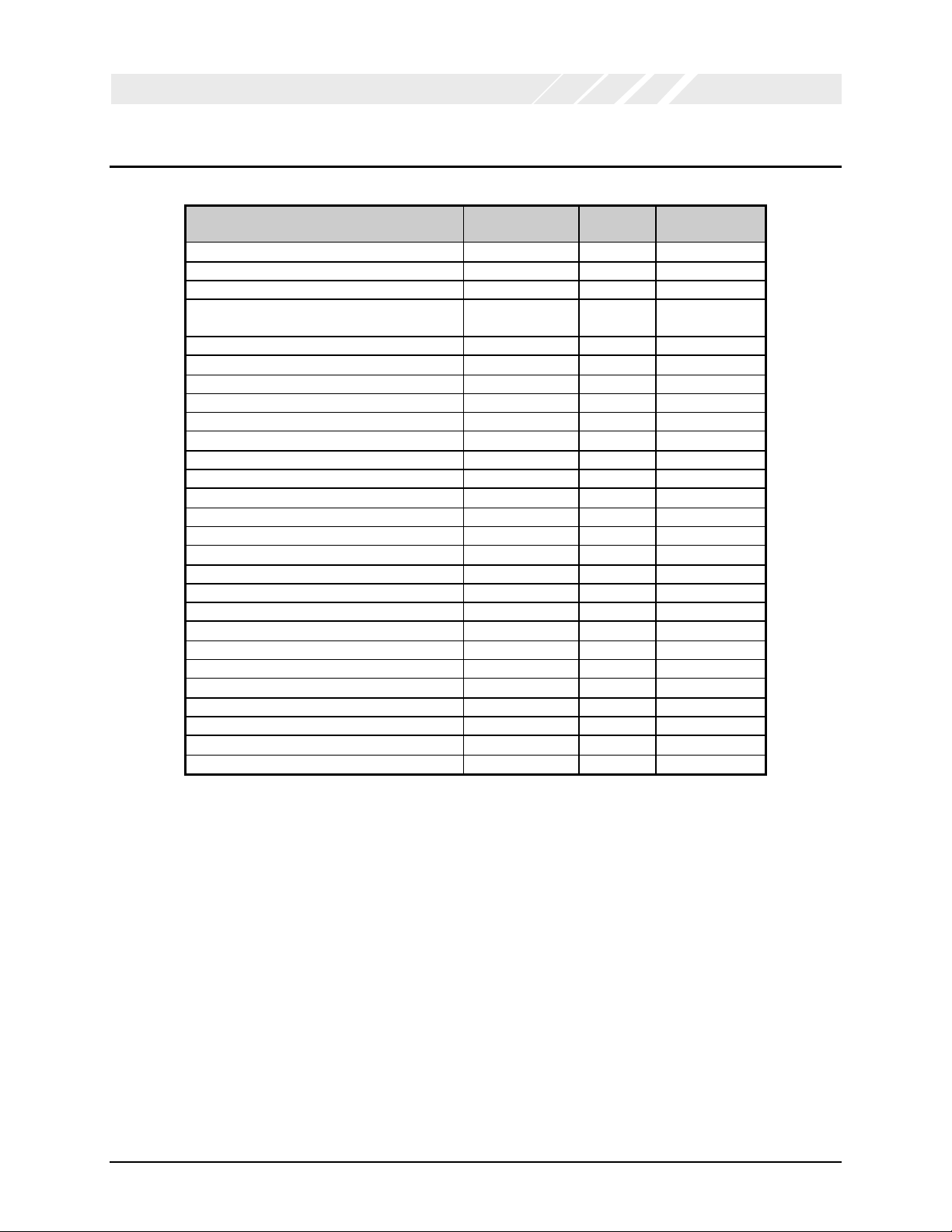

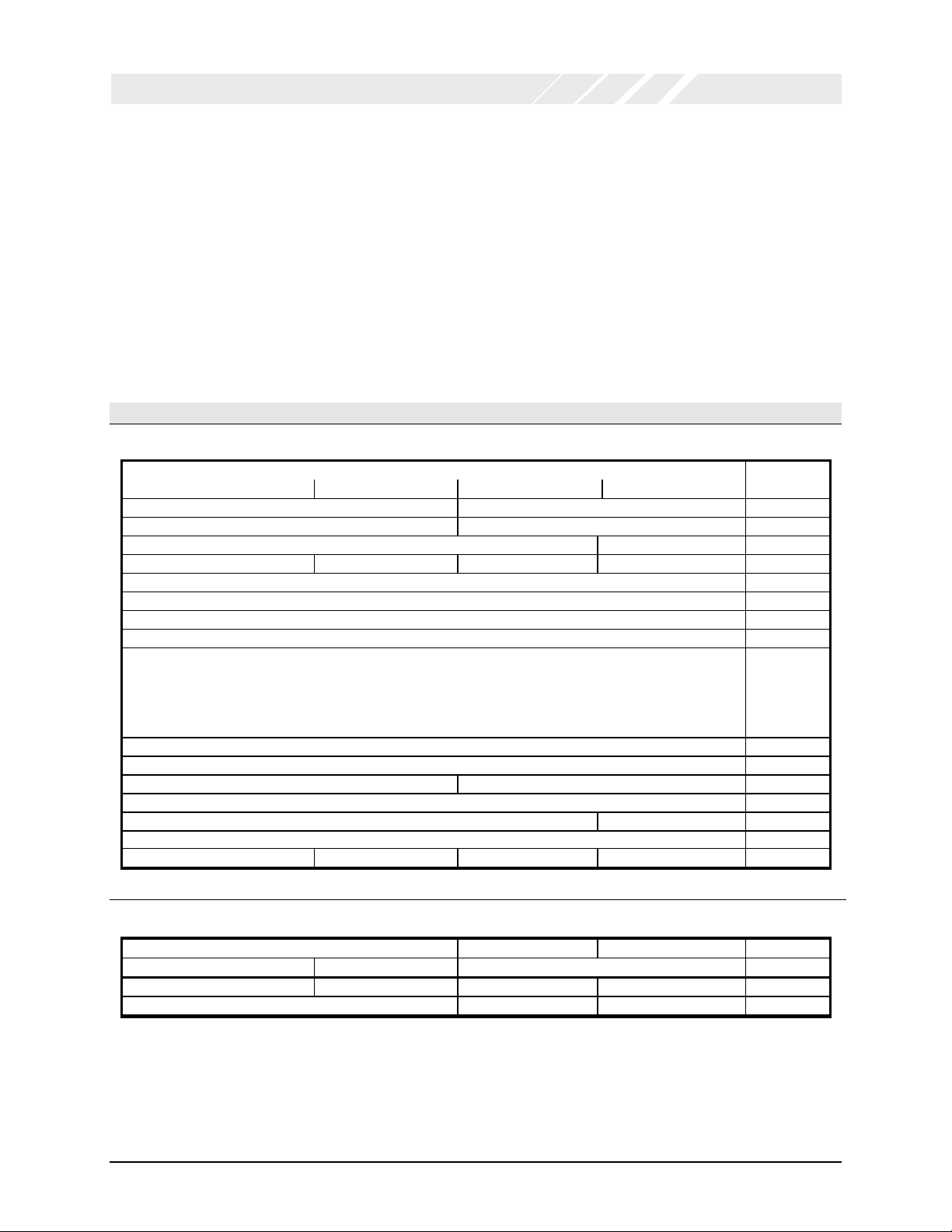

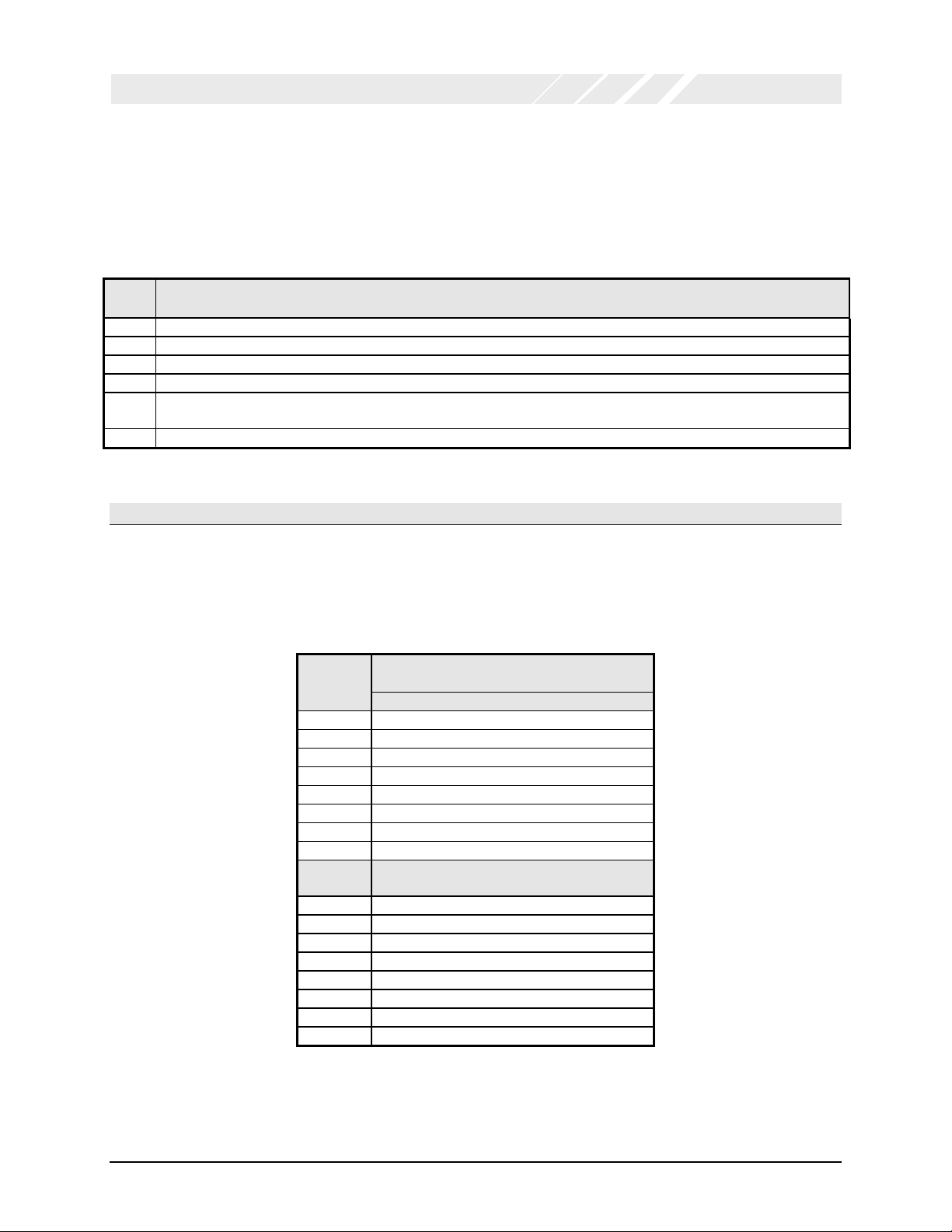

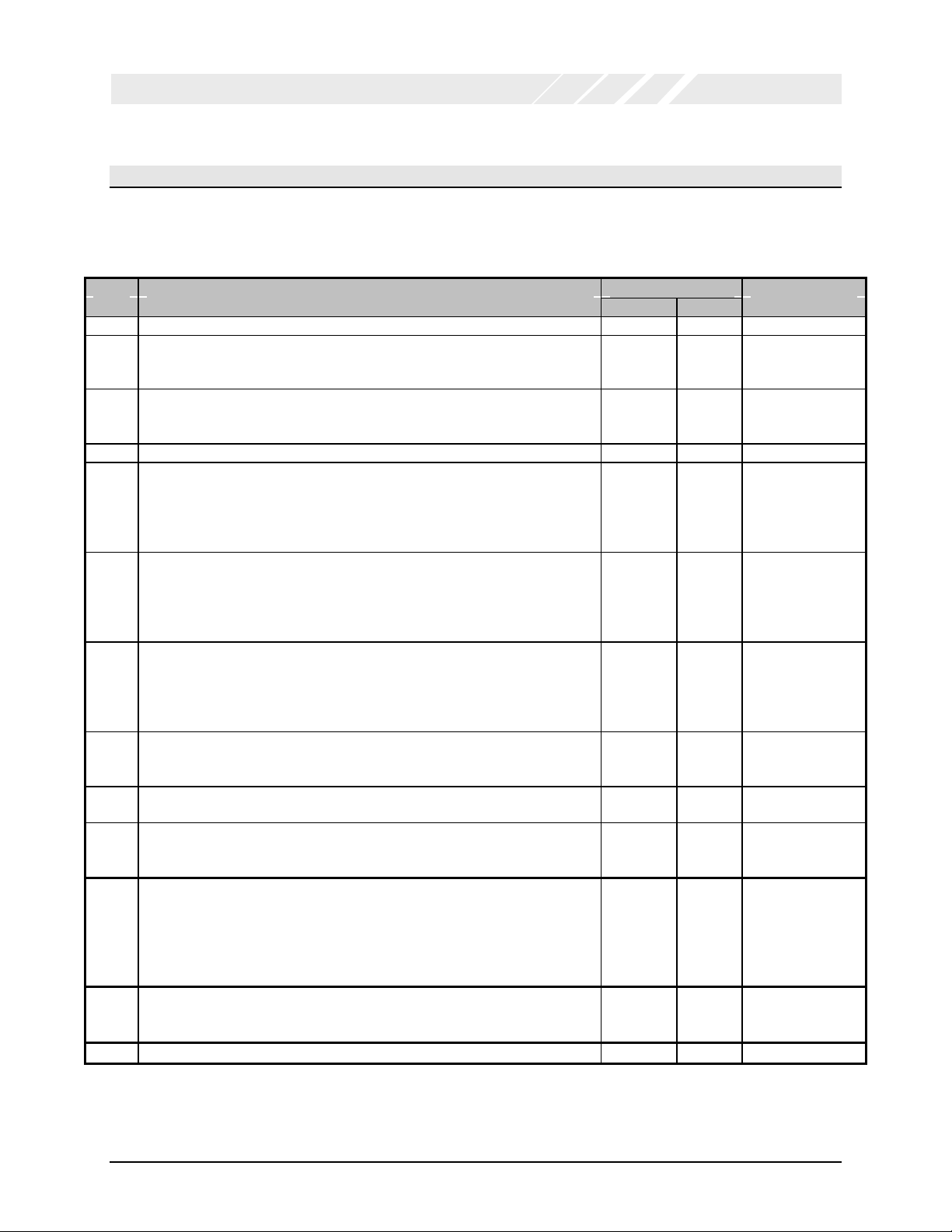

1 PERFORMANCE COMPARISON

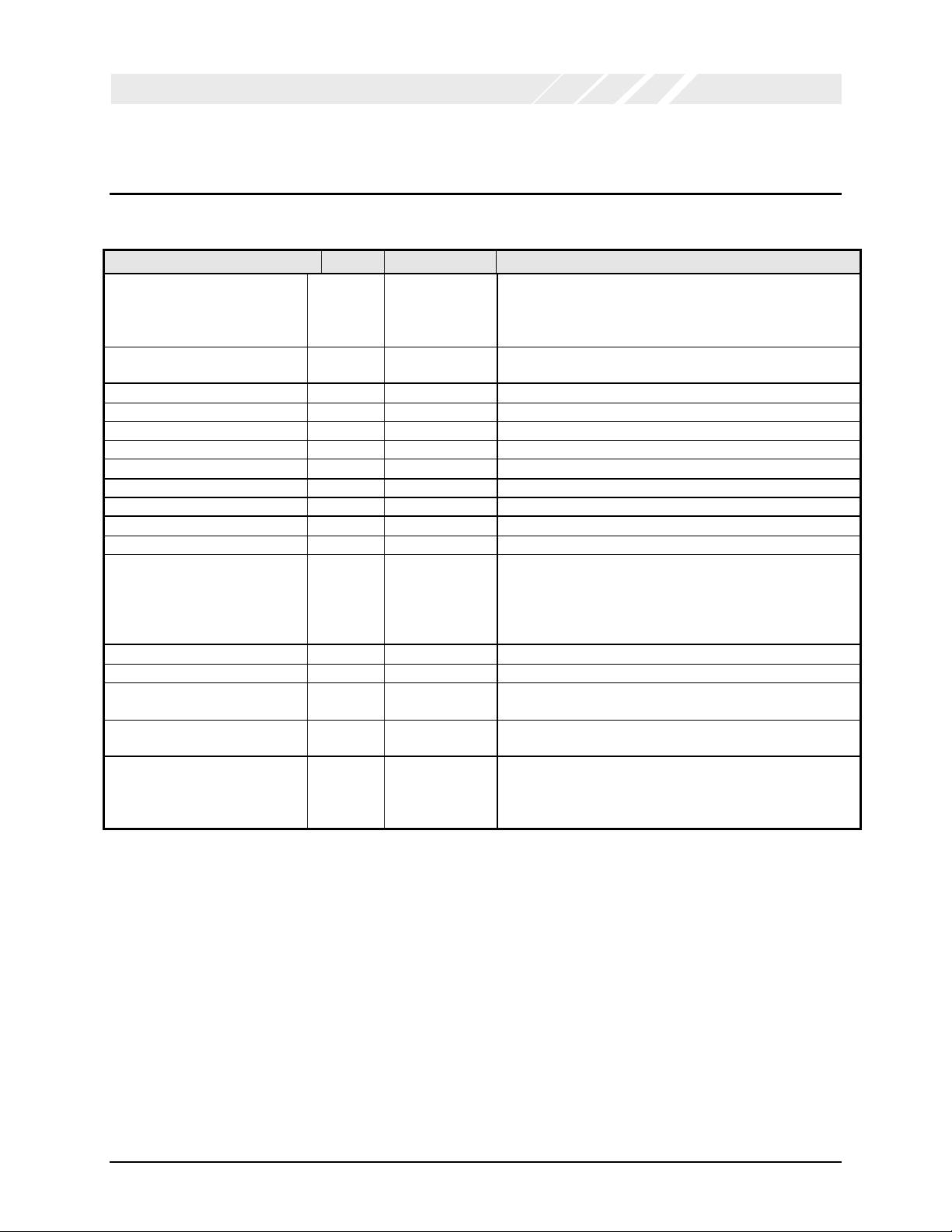

Feature OXCB950 16C550 +

Support for PCI Power Management yes no No

Zero wait-state read/write operation yes no No

No. of external interrupt source pins 2 2 2

DWORD access to UART Interrupt Source

Registers & FIFO Levels

Good-Data status yes no No

Full Plug and Play with external EEPROM yes yes Yes

External 1x baud rate clock yes no No

Max baud rate in normal mode 15 Mbps 115 Kbps 1.5 Mbps

Max baud rate in 1x clock mode 60 Mbps n/a n/a

FIFO depth 128 16 64

Sleep mode yes no Yes

Auto Xon/Xoff flow yes no Yes

Auto CTS#/RTS# flow yes no Yes

Auto DSR#/DTR# flow yes no No

No. of Rx interrupt thresholds 128 4 4

No. of Tx interrupt thresholds 128 1 4

No. of flow control thresholds 128 n/a 4

Transmitter empty interrupt yes no No

Readable status of flow control yes no No

Readable FIFO levels yes no No

Clock prescaler options 248 n/a 2

Rx/Tx disable yes no No

Software reset yes no No

Device ID yes no No

9-bit data frames yes no No

RS485 buffer enable yes no No

Infra-red (IrDA) yes no Yes

16C650 +

PLX9050

yes no No

PLX9050

OXCB950

Table 1: OXCB950 performance compared with PLX + generic UART combinations in PCI mode

1.1 Improvements of the OXCB950 over discrete solutions:

Improved access timing:

Access to the internal UART requires zero or one PCI wait states. A cardbus/PCI read transaction from the internal UART can

complete within five PCI clock cycles and a write transaction to the internal UART can complete within four PCI clock cycles.

Reduces interrupt latency:

The OXCB950 offers shadowed FIFO levels and Interrupt status registers of the internal UART, as well as general device

interrupt status, to reduce the device driver interrupt latency.

Power management:

The OXCB950 complies with the Cardbus Power Management Specification, given by the PC CARD standard release 7.0/7.1,

the PCI Power Management Specification 1.0 and the PC98/99 Power Management specifications, by offering the extended

capabilities for Power Management and supporting the power states D0, D2 and D3. This achieves significant power savings by

allowing device drivers to power down the cardbus/PCI function and disable the UART channel.

Data Sheet Revision 1.1 Page 4

OXFORD SEMICONDUCTOR LTD.

OXCB950

A ‘wake-up’ event (the ‘power management event’) is requested via the PME# (PCI) or CSYSCHG (cardbus) pins from either of

the power states D2 or D3, by the UART line RI (for power state D3), and any modem line and the Serial Data In (for power state

D2).

Optional EEPROM:

The OXCB950 can be reconfigured from an external Microwire

TM

based EEPROM. However, this is not required in many

applications as default values are provided for typical applications. Features available via the use of the EEPROM include

redefining device ID’s and vendor/sub-vendor ID fields in the PCI header space, cardbus-to-pci mode change, redefining Tuple

Information (relevant to cardbus applications only), and selectively enabling/disabling interrupts, powerdown and wakeup

requests.

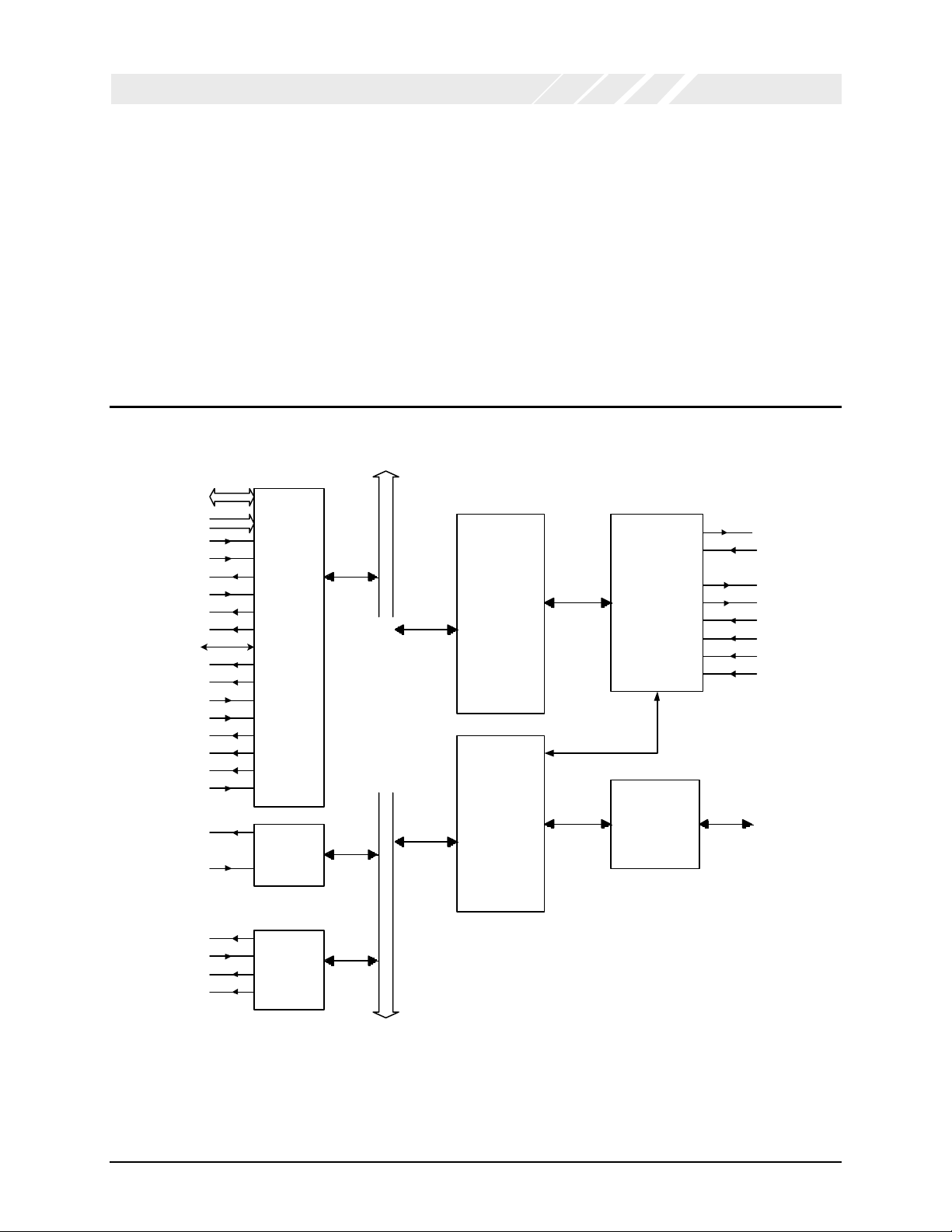

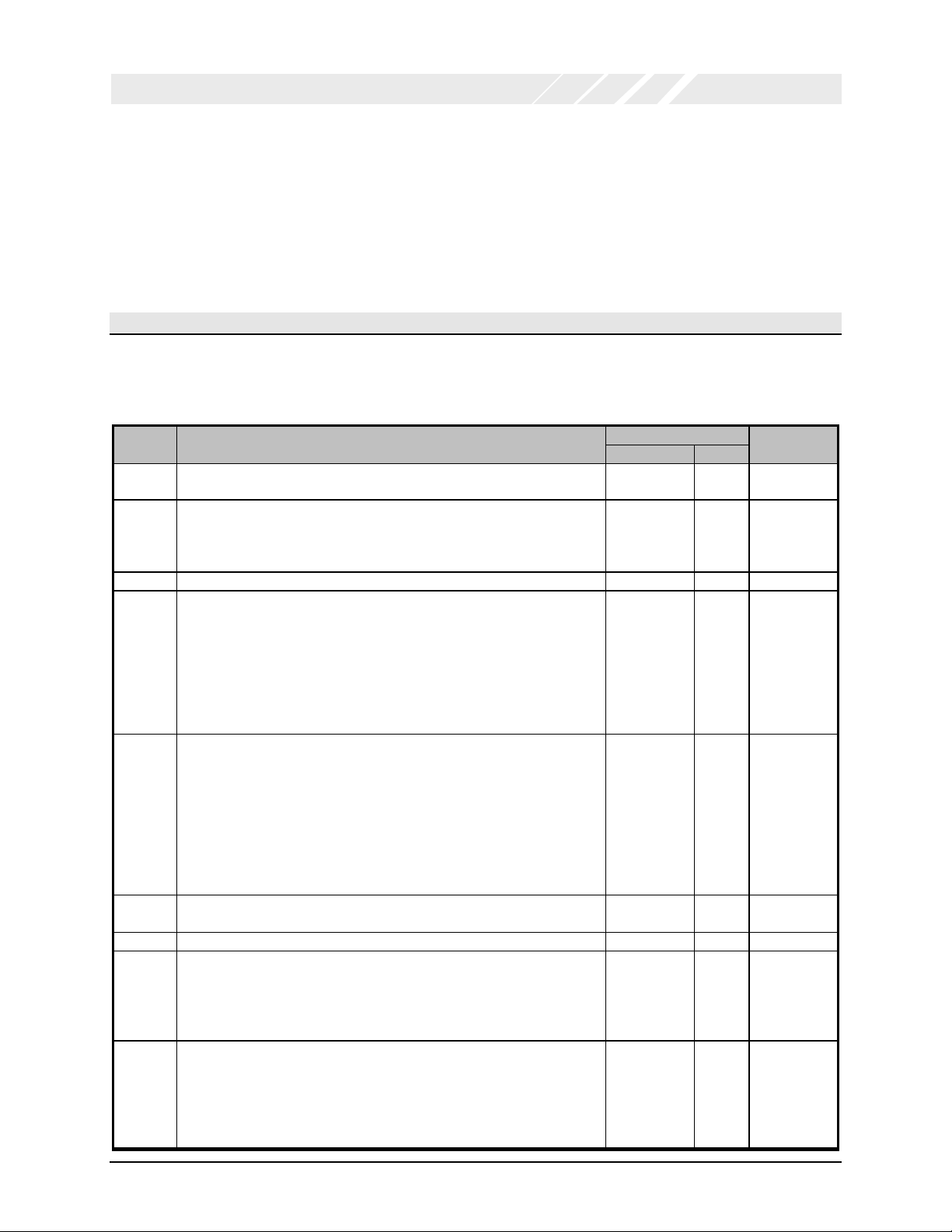

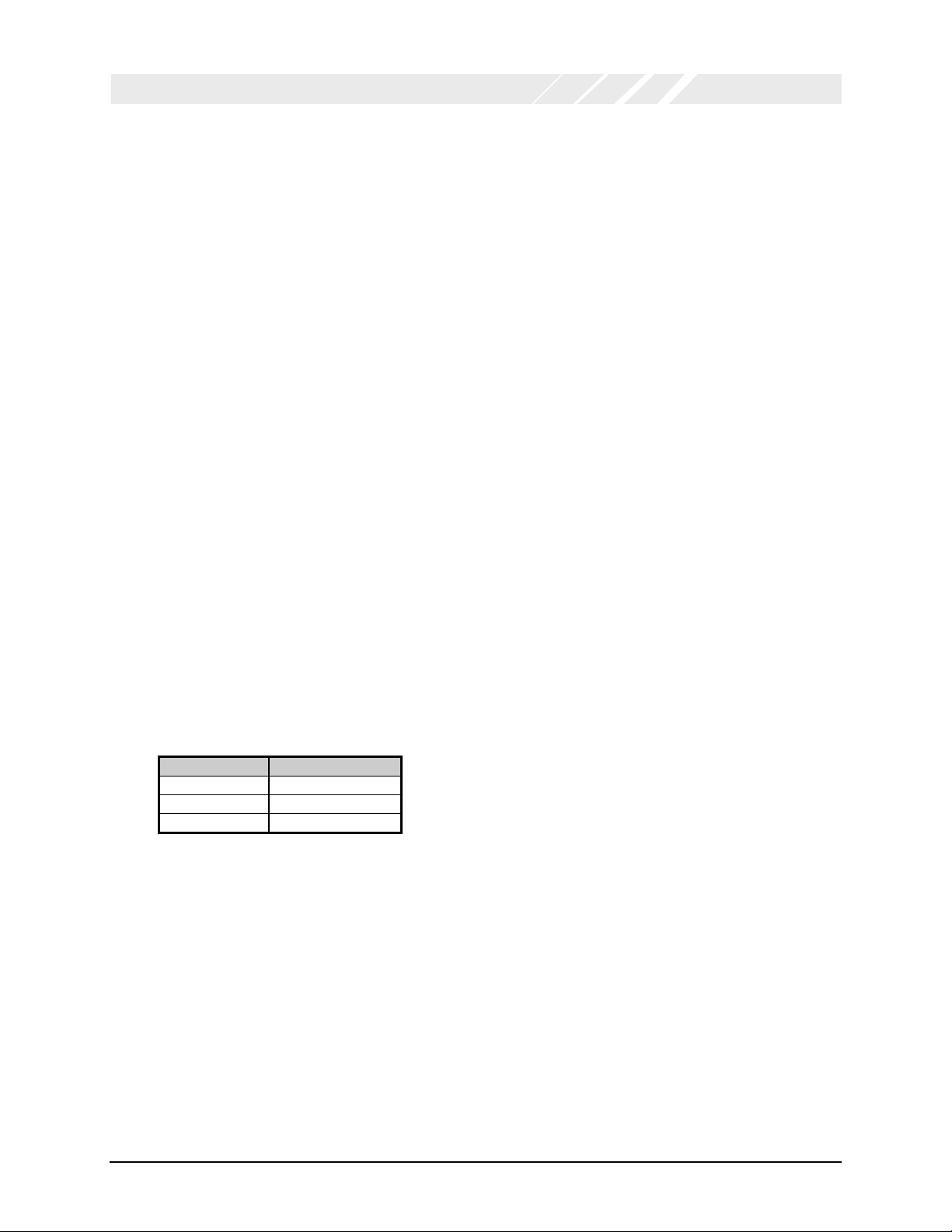

2 BLOCK DIAGRAM

AD[31:0]

C/BE[3:0]

CLK

FRAME#

DEVSEL#

IRDY#

TRDY#

STOP#

PAR

SERR#

PERR#

RST#

IDSEL

INTA#

INTB#

PME#

SLEW_RATE

PCI

3.3V or

CardBus

Interface

Function 0

Internal Data/Control Bus

UART

SOUT

SIN

RTS

DTR

CTS

DSR

DCD

RI

XTALO

Clock &

Interrupt logic

MIO pins

MIO[1:0]

Baud rate

XTALI

EE_DO

EE_DI

EE_CK

EE_CS

Generator

EEPROM

interface

Data Sheet Revision 1.1 Page 5

OXFORD SEMICONDUCTOR LTD.

OXCB950

3 PIN INFORMATION

100 pin TQFP (14mm x 14mm)

AD20

| AD21

| | AD22

| | | Z_SERR

| | | | VDD3OP_CB

| | | | | VSS0P_CB

| | | | | | AD23

| | | | | | | IDSEL

| | | | | | | | Z_CBE3

| | | | | | | | | AD24

| | | | | | | | | | VSS0P_CB

| | | | | | | | | | | VSSOP_CB

| | | | | | | | | | | | VDD3I_CB

| | | | | | | | | | | | | VSSI_CB

| | | | | | | | | | | | | | AD25

| | | | | | | | | | | | | | | AD26

| | | | | | | | | | | | | | | | CSYSCHG

| | | | | | | | | | | | | | | | | AD27

| | | | | | | | | | | | | | | | | | AD28

| | | | | | | | | | | | | | | | | | | VDD3OP_CB

| | | | | | | | | | | | | | | | | | | | VSS0P_CB

| | | | | | | | | | | | | | | | | | | | | AD29

| | | | | | | | | | | | | | | | | | | | | | AD30

| | | | | | | | | | | | | | | | | | | | | | | AD31

| | | | | | | | | | | | | | | | | | | | | | | | Z_PME

| | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | |

VSS0P_CB -- -- VSS0

AD19 -- -- EXT_DATA_OUT

AD18 -- -- Z_RTS

AD17 -- -- Z_DTR

Z_CBE2 -- -- Z_CTS

VDD3OP_CB -- -- Z_DSR

VSS0P_CB -- -- Z_DCD

Z_FRAME -- -- Z_RI

Z_IRDY -- -- EXT_DATA_IN

Z_TRDY -- -- VDD0

Z_RESET -- -- VSS0

VSSI_CB -- -- VDDIP

PCI_CLK -- -- VDDIP

VDD3I_CB -- -- XTLO

VSSOP_CB -- -- XTLI

VDD3OP_CB -- -- VSSIP

VSS0P_CB -- -- TEST0

Z_DEVSEL -- -- TEST1

Z_CINT -- . -- BUFFER_SLEW_RATE

Z_STOP -- . -- EEPROM_DI

Z_PERR -- . -- EEPROM_DO

VSS0P_CB -- 97 -- EEPROM_CS

PAR -- 98 -- EEPROM_SK

Z_CBE1 -- 99 -- MIO1

AD16 -- 1 2 3 4 5 6 7... -- MIO0

| | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | |

| | | | | | | | | | | | | | | | | | | | | | | | AD0

| | | | | | | | | | | | | | | | | | | | | | | AD1

| | | | | | | | | | | | | | | | | | | | | | AD2

| | | | | | | | | | | | | | | | | | | | | AD3

| | | | | | | | | | | | | | | | | | | | VDD30P_CB

| | | | | | | | | | | | | | | | | | | VSS0P_CB

| | | | | | | | | | | | | | | | | | AD4

| | | | | | | | | | | | | | | | | AD5

| | | | | | | | | | | | | | | | AD6

| | | | | | | | | | | | | | | AD7

| | | | | | | | | | | | | | Z_CBE0

| | | | | | | | | | | | | VDD3I_CB

| | | | | | | | | | | | VSSI_CB

| | | | | | | | | | | VSS0P_CB

| | | | | | | | | | AD8

| | | | | | | | | AD9

| | | | | | | | AD10

| | | | | | | AD11

| | | | | | VDD30P_CB

| | | | | VSS0P_CB

| | | | AD12

| | | AD13

| | AD14

| VSSOP_CB

AD15

Data Sheet Revision 1.1 Page 6

OXFORD SEMICONDUCTOR LTD.

OXCB950

4 PIN DESCRIPTIONS

Cardbus/PCI bus Pins Dir1 Name Description

52, 53, 54, 57, 58, 60, 61, 66,

69, 73, 74, 75, 77, 78, 79, 100,

1, 3, 4, 5, 8, 9, 10, 11, 16, 17,

18, 19, 22, 23, 24, 25

67, 80, 99, 15 C/P_I C/BE[3:0]# Multiplexed Command/Byte enable.

88 CP_I CLK System clock

83 CP_I FRAME# Cycle Frame1.

93 CP_O DEVSEL# Device Select

84 CP_I IRDY# Initiator ready

85 CP_O TRDY# Target ready

95 CP_O STOP# Target Stop request

98 CP_I/O PAR Parity

72 CP_O SERR# System error

96 CP_I/O PERR# Parity error

68 CP_I IDSEL Initialisation device select

86 CP_I RST# System reset

94 CP_OD INTA# /CINT# Interrupt Pin. For both cardbus and pci applications

59 CP_O CSYSCHG Power management event signal, for Cardbus applications

51 CP_OD PME# Power management event signal, for PCI applications

32 I SLEW_RATE Slew rate control for cardbus/pci outputs

1

For cardbus applications, the pin z_frame requires a pull-up (4k7) on the board. See PC Card Standard 7.0/7.1, section

5.3.3.3.3 “pull-up resistor requirements”.

C/P_I/O AD[31:0] Multiplexed Address/Data bus.

For PCI applications this pin must be connected to the IDSEL

pin on the PCI connector. For cardbus applications, there is

no IDSEL signal, so this pin must be tied to Vdd (3.3v) via a

pull-up on the board. (10K recommended).

This pin must be No-Connect (NC) for PCI applications.

This pin must be No-Connect (NC) for cardbus applications.

For cardbus applications, this must be tied to Vdd on the

board. For PCI applications, this must be tied to Gnd on the

board.

Data Sheet Revision 1.1 Page 7

OXFORD SEMICONDUCTOR LTD.

UART pins Dir1 Name Description

49 T_O EXT_DATA_OUT

42 T_I

44 T_I DCD# Active-low modem data-carrier-detect input

47 T_O

48 T_O RTS# Active-low modem request-to-send output. If automated

46 T_I CTS# Active-low modem clear-to-send input. If automated CTS#

45 T_I

43 T_I

37 O XTLO Crystal oscillator output

36 I XTLI Crystal oscillator input (10MHz – 40 MHz) or external clock

T_I

T_O

T_O

T_I

T_I

IrDA_Out

EXT_DATA_IN

IrDA_In

DTR#

485_En

Tx_Clk_Out

DSR#

Rx_Clk_In

RI#

Tx_Clk_In

OXCB950

UART serial data output

UART IrDA data output when MCR[6] of the corresponding

channel is set in enhanced mode

UART serial data input

UART IrDA data input when IrDA mode is enabled (see

above)

Active-low modem data-terminal-ready output. If automated

DTR# flow control is enabled, the DTR# pin is asserted and

deasserted if the receiver FIFO reaches or falls below the

programmed thresholds, respectively.

In RS485 half-duplex mode, the DTR# pin may be

programmed to reflect the state of the the transmitter empty

bit to automatically control the direction of the RS485

transceiver buffer (see register ACR[4:3])

Transmitter 1x clock (baud rate generator output). For

isochronous applications, the 1x (or Nx) transmitter clock

may be asserted on the DTR# pins (see register CKS[5:4])

RTS# flow control is enabled, the RTS# pin is deasserted

and reasserted whenever the receiver FIFO reaches or falls

below the programmed thresholds, respectively.

flow control is enabled, upon deassertion of the CTS# pin,

the transmitter will complete the current character and enter

the idle mode until the CTS# pin is reasserted. Note: flow

control characters are transmitted regardless of the state of

the CTS# pin.

Active-low modem data-set-ready input. If automated DSR#

flow control is enabled, upon deassertion of the DSR# pin,

the transmitter will complete the current character and enter

the idle mode until the DSR# pin is reasserted. Note: flow

control characters are transmitted regardless of the state of

the DSR# pin

External receiver clock for isochronous applications. The

Rx_Clk_In is selected when CKS[1:0] = ‘01’.

Active-low modem Ring-Indicator input

External transmitter clock. This clock can be used by the

transmitter (and indirectly by the receiver) when CKS[6]=’1’.

pin. Maximum frequency 60MHz

Data Sheet Revision 1.1 Page 8

OXFORD SEMICONDUCTOR LTD.

Multi-purpose & External

interrupt pins

26

27

EEPROM pins

28 O EE_CK EEPROM clock

29 O EE_CS EEPROM active-high Chip Select

31 IU EE_DI EEPROM data in (to be connected to the EEPROM DO

30 O EE_DO EEPROM data out. (to be connected to the EEPROM DI

Miscellaneous pins

34 ID TEST0 Test Pin 0. Should be held low at all times.

33 ID TEST1 Test Pin 1. Should be held low at all times

Power and ground2

89, 14, 63 V VDD3I_CB Supplies power to the pre-drive area of the dual mode

56, 71, 81, 91, 7, 21 V VDD3OP_CB Supplies power to the output drive of the dual mode

38, 39 V VDDIP Supplies power to the core-logic and pre-drive area of the

41, V VDDO Suppiles power to the output drive of standard IO buffers.

62, 87, 13 G VSSI_CB Supplies ground to the pre-drive area of the dual mode

55, 64,65,70, 76, 82, 90, 92, 97,

2, 6, 12, 20,

35 G VSSIP Supplies gnd to the core-logic and pre-drive area of the

40, 50 G VSSO Supplies gnd to the output drive of standard IO buffers.

Dir1 Name Description

T_I/O

T_I/O

G VSSOP_CB Supplies ground to the output drive of the dual mode

MIO[0]

MIO[1]

Multi-purpose I/O pins.

Can be driven high or low, or be used to invoke

cardbus/PCI interrupts, and powerdown, wakeup requests.

pin).

When the optional serial EEPROM is connected, this pin

should be pulled up using an external 1-10k resistor. When

the EEPROM is not used, this external pull-up is not

required (internal pull-up is sufficient).

pin)

cardbus/pci IO buffers.

cardbus/pci IO buffers.

standard IO buffers.

cardbus/pci IO buffers.

cardbus/pci IO buffers.

standard IO buffers.

OXCB950

Table: Pin Descriptions

Note 1: Direction key:

I 3.3v Input, TTL compatible

ID 3.3v Input with pull-down, TTL compatible

IU 3.3v Input with pull-up, TTL compatible

O 3.3v Output, TTL compatible

T_O 5.0v tolerant TTL output

T_I 5.0v tolerant TTL input

T_I/O 5.0v tolerant TTL Bi-directional

Note 2: Power & Ground

There are several types of VDD and VSS in this design, providing not only power for the internal (core) and I/O pad area but also

special power lines to the dual mode cardbus/pci I/O buffers. These power rails are not connected internally.

This precaution reduces the effects of simultaneous switching outputs and undesirable RF radiation from the chip. Further

precaution is taken by segmenting the GND and VDD rails to isolate the PCI and UART pins.

Data Sheet Revision 1.1 Page 9

C/P_I Cardbus/PCI compatible input

C/P_O Cardbus/PCI compatible output

C/P_I/O Cardbus/PCI compatible bi-directional

C/P_OD Cardbus/PCI compatible open drain

G Ground

V 3.3V power

OXFORD SEMICONDUCTOR LTD.

Pinout Assignment

This device implements the “common” silicon requirements given in the PC Card Standard, release 7.x.

The pinouts for this device have been assigned specifically to align the cardbus signals to the cardbus connector without any

signal crossovers. Since the assignment of signal pins on the cardbus connector is in a different sequence than those on the PCI

connector (due to the limitations of the cardbus connector) then for the PCI environment signal crossovers do inevtiably occur.

The following signal lines are affected for the PCI environment : SERR#, AD16, INTA, CLK, and RST#.

OXCB950

Data Sheet Revision 1.1 Page 10

OXFORD SEMICONDUCTOR LTD.

5 CONFIGURATION & OPERATION

OXCB950

The OXCB950 is configured by system start-up software

during the bootstrap process that follows bus reset.

By default, the device powers-up in the cardbus mode and

for this application mode, the system examines the

Cardbus CIS pointer value contained in the predefined PCI

Header region (at Dword 0Ahex) to locate the start of the

Cardbus Information Structure (CIS). It then traverses the

tuple information contained in this CIS area

NOTE1

to identify

the device type and the necessary resources requested by

the device.

For the PCI application mode, whereby the device’s default

cardbus mode is overridden into the PCI mode though the

use of the optional EEPROM (this takes place prior to any

configuration accesses), the system scans the PCI bus and

reads the vendor and device identification codes from any

devices it finds and the resources being requested.

For both cardbus and PCI applications, the system then

loads the device-driver software according to this

information and configures the I/O, memory and interrupt

resources. Device drivers can then access the functions at

the assigned addresses in the usual fashion, with the

improved data throughput provided by cardbus/PCI buses.

A set of local configuration registers have been provided

that can be used to control the device’s characteristics

(such as interrupt handling) and report internal functional

status. This is on top of the UART registers and the

registers contained in both the PCI configuration Space

and the Cardbus Information Structure (CIS). These local

registers can be set up by device drivers or from the

optional EEPROM.

The EEPROM can also be used to redefine the reset

values of most register areas to tailor the device to the end

users requirements if the default values do not meet the

specific requirements of the manufacturer, such as the

identification registers. As an additional enhancement, the

EEPROM can be used to pre-program the UART, allowing

pre-configuration, without requiring device driver changes.

This allows the enhanced features of the integrated UART

to be in place prior to handover to any generic device

drivers.

NOTE1

Windows Support for Cardbus applications, treats the information contained in the CIS area as “supplemental” information

for devices that are not fully described using the PCI configuration Space. This means that it is possible that provided the PCI

header space implements the minimum fields as recommended by Microsoft (the cardbus “Allocated” and “Reserved” fields are

defined) then Windows will not utilise the information contained in the CIS.

Data Sheet Revision 1.1 Page 11

OXFORD SEMICONDUCTOR LTD.

6 PCI TARGET CONTROLLER

OXCB950

6.1 Operation

The OXCB950 responds to the following cardbus/PCI

transactions:-

• Configuration access: For cardbus applications, the

OXCB950 responds to type 0 configuration reads and

writes if the bus address is selecting the configuration

registers for function 0. For pci applications, the

OXCB950 will respond to the same configuration

cycles provided that the signal IDSEL is also asserted

The device will respond to these configuration

transactions by asserting DEVSEL#. Data transfer

then follows. Any other configuration transaction will

be ignored by the OXCB950.

• IO reads/writes: The address is compared with the

addresses reserved in the I/O Base Address Registers

(BARs). If the address falls within one of the assigned

ranges, the device will respond to the IO transaction

by asserting DEVSEL#. Data transfer follows this

address phase. For all modes, only byte accesses are

possible to the function BARs (excluding the local

configuration registers for which WORD, DWORD

access is supported). For IO accesses to these

regions, the controller compares AD[1:0] with the byte enable signals as defined in the PCI specification. The

access is always completed; however if the correct BE

signal is not present the transaction will have no

effect.

• Memory reads/writes: These are treated in the same

way as I/O transactions, except that the memory

ranges are used. With the exception of Memory

accesses to the local configuration registers and the

cardbus status registers, Memory access to singlebyte regions such as the UART registers is always

expanded to DWORDs in the OXCB950. In other

words, the OXCB950 reserves a DWORD per byte in

single-byte regions. The device allows the user to

define the active byte lane using LCC[4:3] so that in

Big-Endian systems the hardware can swap the byte

lane automatically. For Memory mapped access in

single-byte regions, the OXCB950 compares the

asserted byte-enable with the selected byte-lane in

LCC[4:3] and completes the operation if a match

occurs, otherwise the access will complete normally

on the PCI bus, but it will have no effect on the UART.

• All other cycles (64-bit, special cycles, reserved

encoding etc.) are ignored.

The OXCB950 will complete all transactions as disconnectwith-data, i.e. the device will assert the STOP# signal

alongside TRDY#, to ensure that the Bus Master does not

continue with a burst access. The exception to this is Retry,

which will be signalled in response to any access while the

OXCB950 is reading from the serial EEPROM.

The OXCB950 performs medium-speed address decoding

as defined by the PCI specification. It asserts the

DEVSEL# bus signal two clocks after FRAME# is first

sampled low on all bus transaction frames which address

the chip. Fast back-to-back transactions are supported by

the OXCB950 as a target, so a bus master can perform

faster sequences of write transactions to the UART

registers, the PCI configuration space and the local

configuration registers when an inter-frame turn-around

cycle is not required.

The device supports any combination of byte-enables for

accesses to the PCI Configuration Registers, the Local

Configuration registers, the Cardbus Information Structure,

and the cardbus status registers. If a byte-enable is not

asserted, that byte is unaffected by a write operation and

undefined data is returned upon a read.

The OXCB950 performs parity generation and checking on

all cardbus/PCI bus transactions as defined by the 2

standards. If a parity error occurs during the bus address

phase, the device will report the error in the standard way

by asserting the SERR# bus signal. However if that

address/command combination is decoded as a valid

access, it will still complete the transaction as though the

parity check was correct.

The OXCB950 does not support any kind of caching or

data buffering, other than those in the UART function. In

general, all registers cannot be pre-fetched because there

may be side-effects on reads.

Data Sheet Revision 1.1 Page 12

OXFORD SEMICONDUCTOR LTD.

6.2 Configuration space

The OXCB950 is a single function device, with one PCI

configuration space (and for the default cardbus mode, one

cardbus information structure).

All the required fields in the predefined PCI header region

have been implemented. This includes those fields in the

cardbus PC Card Standard that are termed “allocated” and

“reserved” for cardbus applications. This implementation is

a specific requirement for cardbus support in Windows 9x.

The device dependant region of the PCI configuration

space contains the cardbus/pci Power Management

Extended Capability register set and (for the cardbus mode

only) the Tuples making up the Cardbus Information

Structure.

The format of the PCI configuration space, for cardbus and

pci modes, is as shown in the Table below.

In general, writes to any registers that are not implemented

are ignored, and all reads from unimplemented registers

return 0.

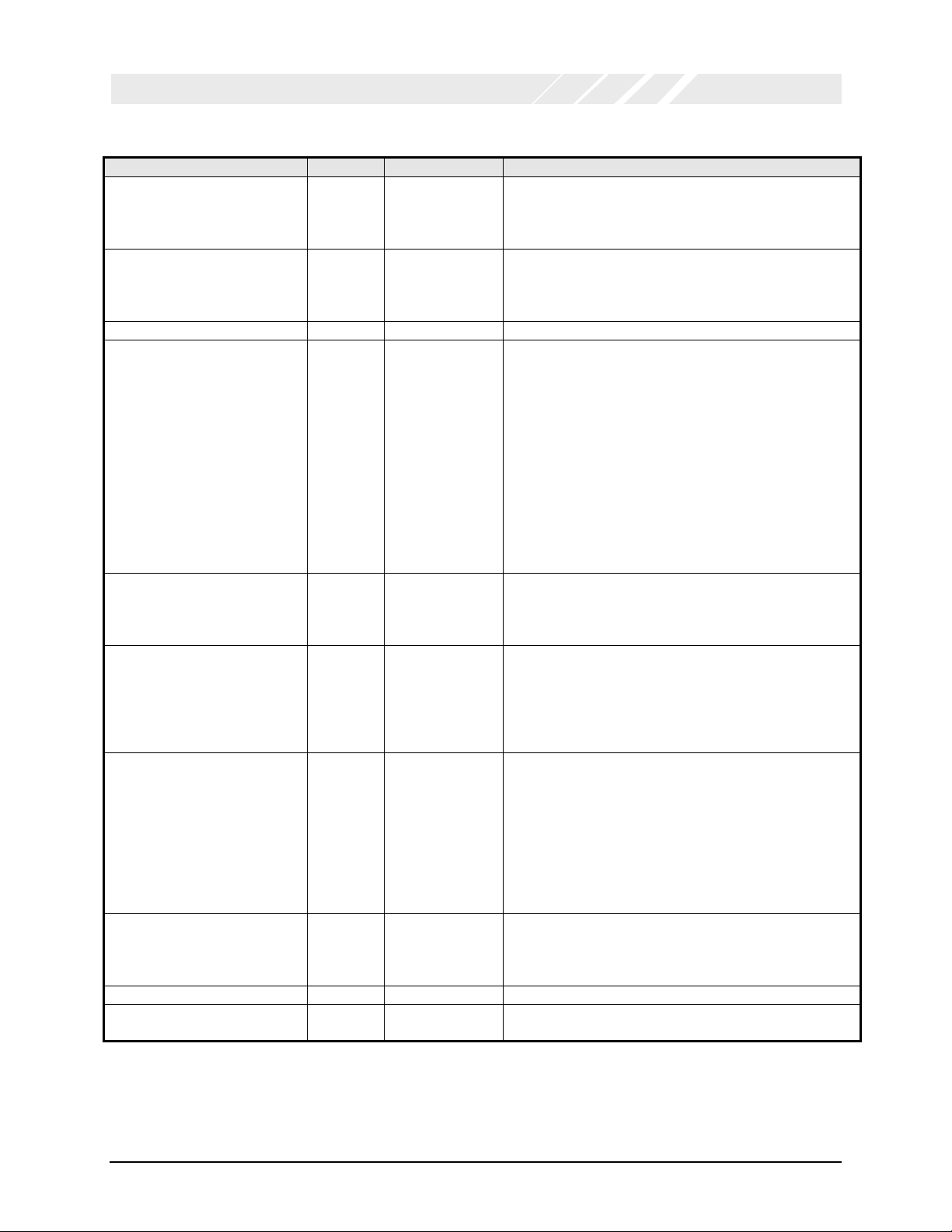

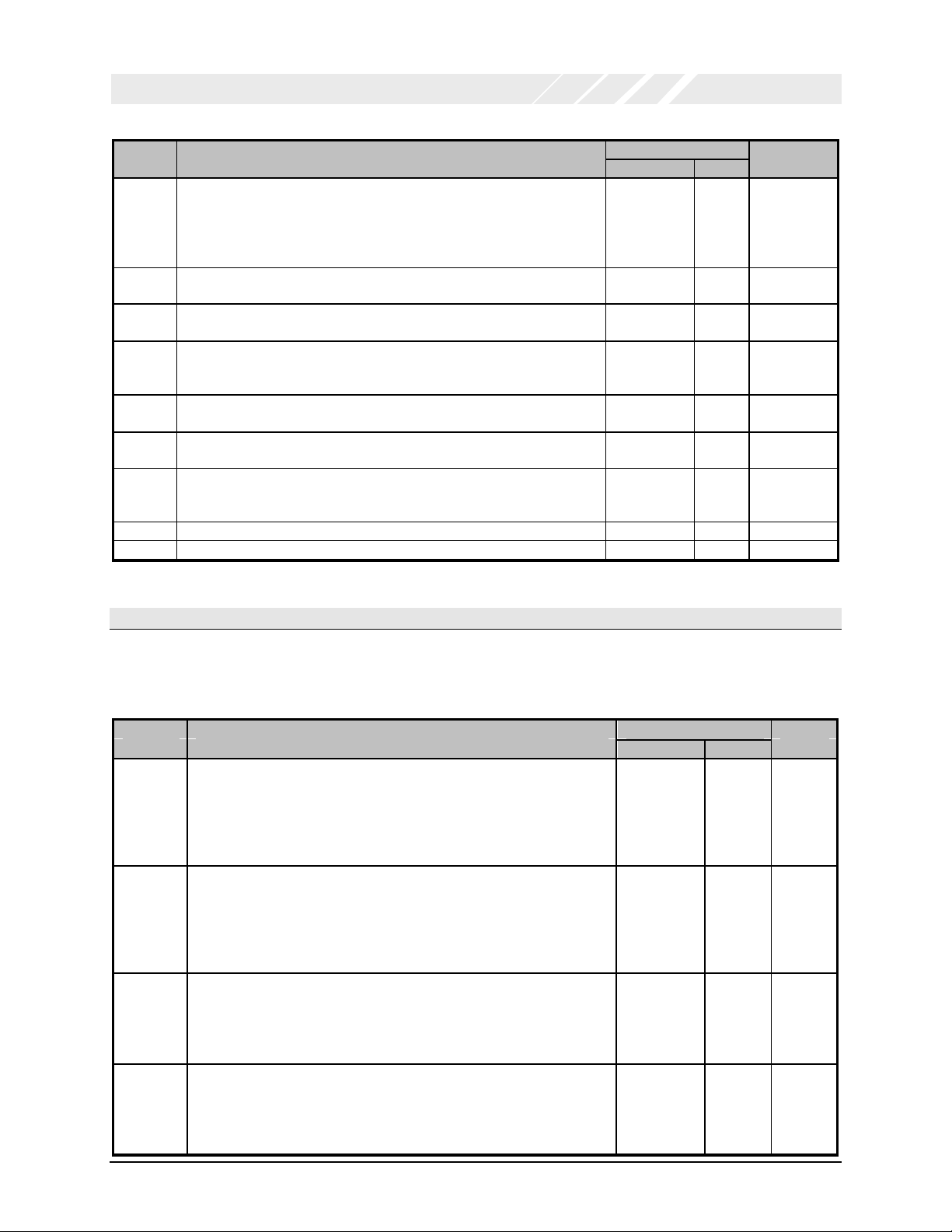

6.2.1 Cardbus / PCI Configuration Space Register map

31 16 15 0

Device ID Vendor ID 00h

Status Command 04h

BIST1 Header Type Reserved Reserved 0Ch

Base Address Register 0 (BAR0) – UART Function in I/O space 10h

Base Address Register 1 (BAR 1) - UART Function in Memory space 14h

Base Address Register 2 (BAR 2) – Local Configuration Registers in IO space 18h

Base Address Register 3 (BAR3) – Local Configuration Registers in Memory space 1Ch

Base Address Register 4 (BAR4) – Cardbus Status Registers in Memory Space

Subsystem ID Subsystem Vendor ID 2Ch

Reserved Reserved Interrupt Pin Interrupt Line 3Ch

Configuration Register Description Offset

Class Code Revision ID 08h

Function Event : Offset +0

Function Event Mask : Offset +4

Function Present State : Offset +8

Function Force Event : Offset +12

Reserved (Bar 5) 24h

Cardbus CIS Pointer 28h

Reserved 30h

Reserved Cap_Ptr 34h

Reserved 38h

OXCB950

Address

20h

Predefined PCI Header Region

Device Dependant PCI Region

Power Management Capabilities (PMC) Next Ptr Cap_ID 40h

Reserved Reserved PMC Control/Status Register (PMCSR) 44h

Tuple Byte3* Tuple Byte 2* Tuple Byte1* Tuple Byte 0* 48h

… Tuple Byte (n+1)* Tuple Byte n* 4Ch

* Tuples are available for the Cardbus mode only. These fields return all 0’s for the PCI mode of the device.

Table 2: Cardbus/PCI Configuration space

Data Sheet Revision 1.1 Page 13

OXFORD SEMICONDUCTOR LTD.

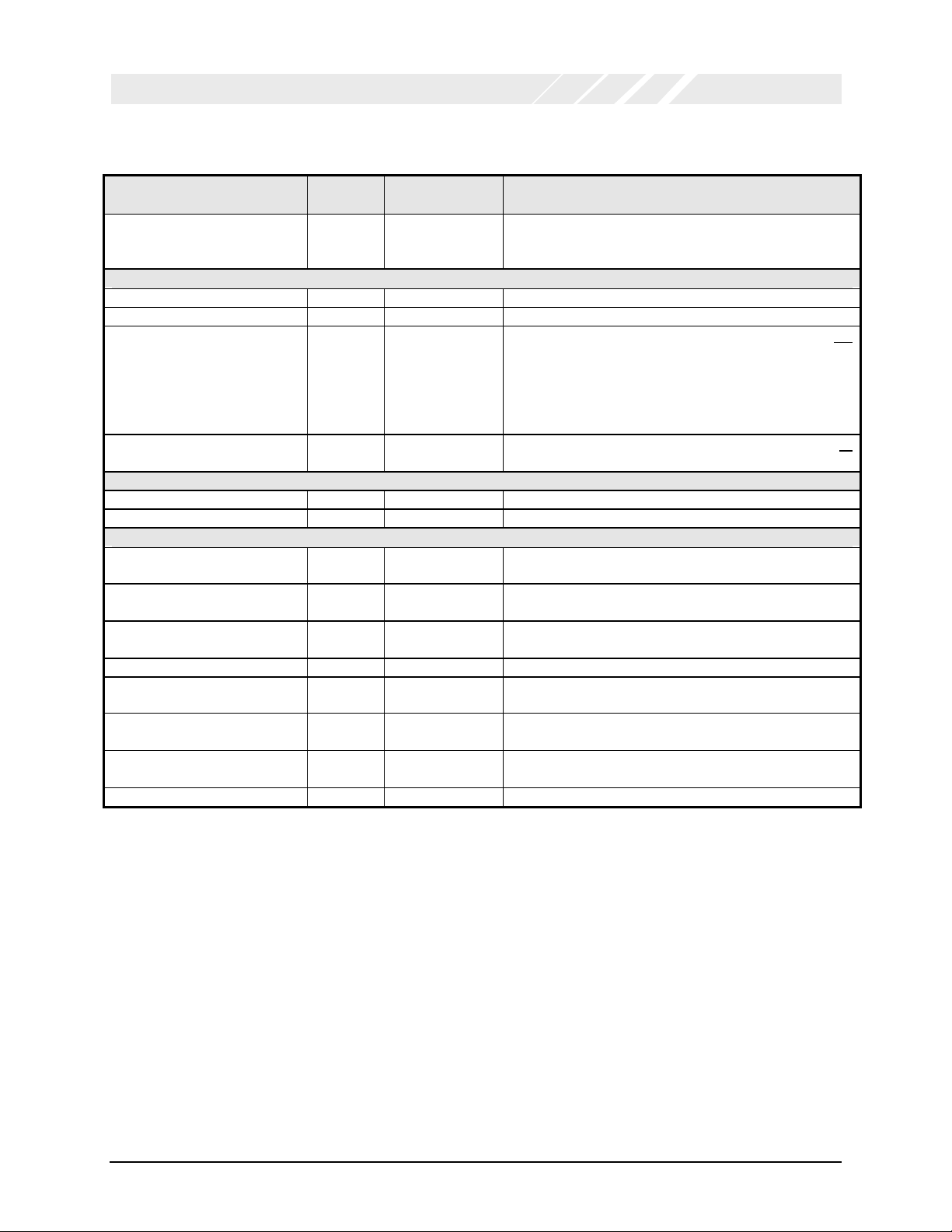

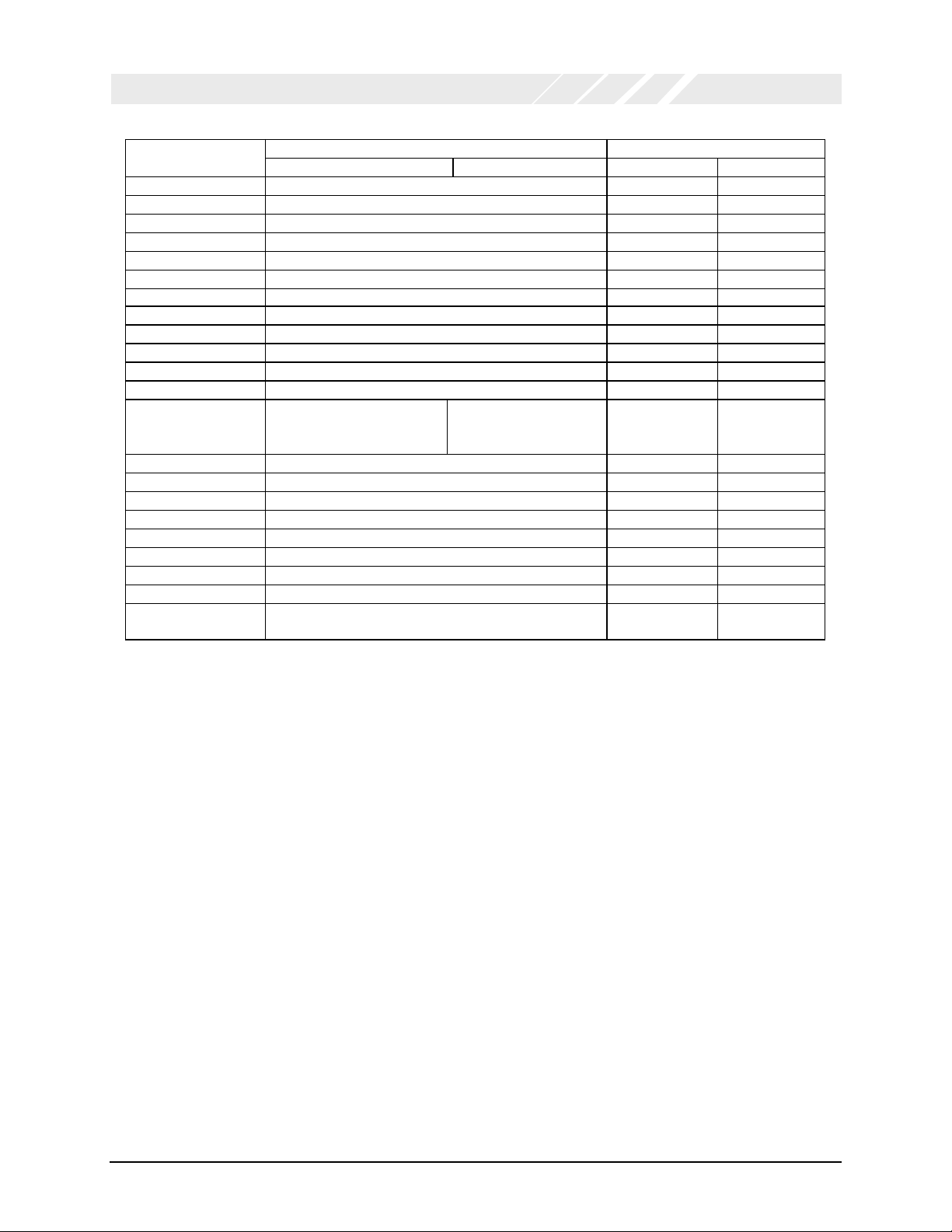

Reset value Program read/write Register name

Cardbus Mode PCI Mode EEPROM PCI

Vendor ID 0x1415 1 W R

Device ID 0x950B 1 W R

Command 0x0000 - R/W

Status 0x0290 W(bit 4) R/W

Revision ID 0x00 1 - R

Class code 0x070006 1 W R

Header type 0x00 - R

BAR 0 0x00000001 - R/W

BAR 1 0x00000000 - R/W

BAR 2 0x00000001 - R/W

BAR 3 0x00000000 - R/W

BAR 4 0x00000000 - R/W

Cardbus CIS Pointer 0x00000048 (relocate3 = 0)

or

0x00000000

(no CIS)

W R

0x00000080 (relocate3 = 1)

Subsystem VID 0x1415 2 W R

Subsystem ID 0x0001 2 W R

Cap ptr. 0x40 - R

Interrupt line 0x00 1 - R/W

Interrupt pin 0x01 W R

Cap ID 0x01 - R

Next ptr. 0x00 - R

PM capabilities 0x6C01 W R

PMC control/ status

0x0000 - R/W

register

OXCB950

Table 3: Cardbus/PCI configuration space default values

1

For cardbus applications, the PC Card Standard 7.x defines these fields as “Allocated”. However, for cardbus support in

Windows, these fields need to be defined to fully support the PCI configuration Space.

2

For cardbus applications, the PC Card Standard 7.x defines these fields as “Reserved”. However, for cardbus support in

Windows, these fields need to be defined to fully support the PCI configuration Space.

3

Relocate is a bit in the local configuration registers that can locate the start of the cardbus information structure at DWORD18

or DWORD 32 in the PCI configuration region. This bit is writable only via the optional EEPROM. The default state is 0, so the

CIS is available at DWORD18 in the PCI configuration region.

Data Sheet Revision 1.1 Page 14

OXFORD SEMICONDUCTOR LTD.

OXCB950

6.3 Accessing the UART function

Access to the internal UART is achieved via standard I/O and memory mapping, at addresses defined by the Base Address

Registers (BARs) in the PCI configuration space. These BARs are configured by the system to allocate blocks of I/O and

memory space to this logical function, according to the size required by the function. The base addresses that have been

allocated can then be used to access this uart function. The mapping of these BARs is shown in the table below.

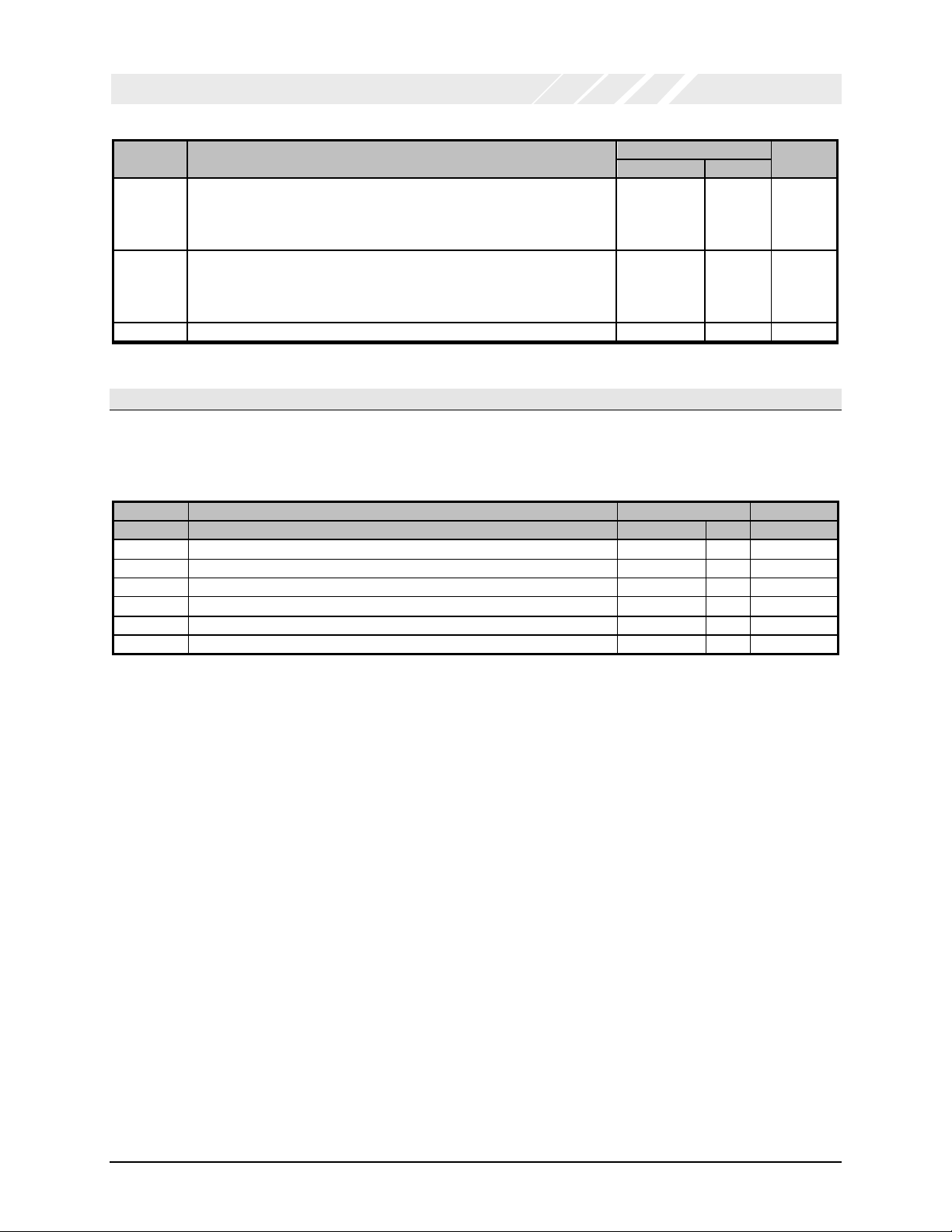

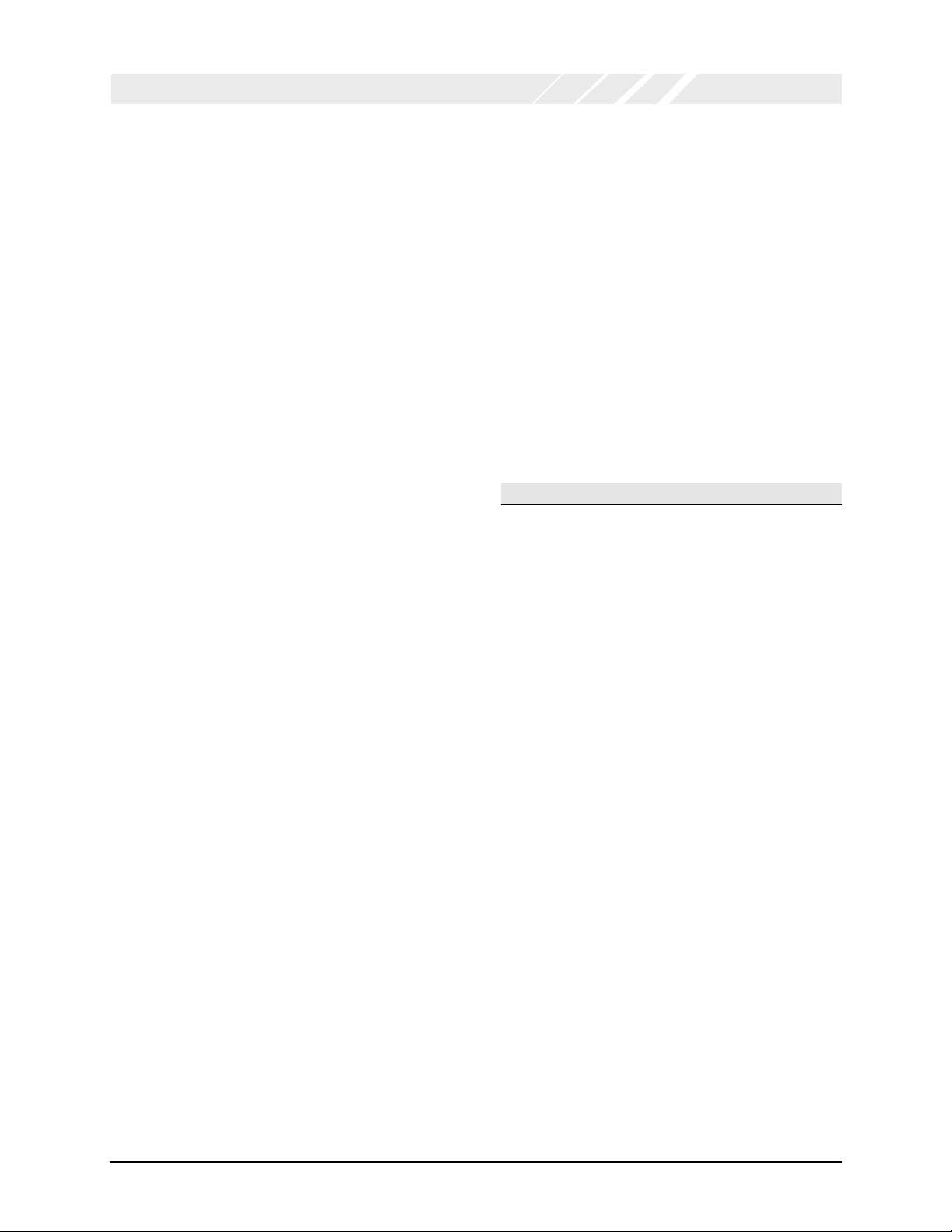

BAR UART Function

0 Internal UART (I/O Mapped)

1 Internal UART(Memory Mapped)

2 Local configuration registers (I/O Mapped)

3 Local configuration registers (Memory Mapped)

4 Cardbus Status Registers (Memory Mapped)

– relevant to cardbus mode only

5 Unused

Table 4: Base Address Register definition

6.3.1 Cardbus/PCI access to the internal UART

IO and memory space

BAR 0 and BAR 1 of function 0 are used to access the internal UART. The function reserves an 8-byte block of I/O space and a

4K byte block of memory space. Once the I/O and/or the Memory access enable bits in the Command register (of the PCI

configuration space) are set, the UART can be accessed following the mapping shown in Table 5.

UART

Address

(hex)

0 0

1 1

2 2

3 3

4 4

5 5

6 6

7 7

UART

Address

000 00

001 04

002 08

003 0C

004 10

005 14

006 18

007 1C

Cardbus/PCI Offset from Base Address 0

for Function0 in IO space (hex)

Cardbus/PCI Offset from Base Address 1

for Function0 in Memory space (hex)

Note 1: Since 4K of memory space is reserved and the full bus address is not used for decoding, there are a number of aliases of the UART in the allocated

memory region

Data Sheet Revision 1.1 Page 15

Table 5: Cardbus/PCI address map for the internal UART (I/O and memory)

OXFORD SEMICONDUCTOR LTD.

OXCB950

6.4 Accessing Local configuration registers

The local configuration registers are a set of device specific registers which can always be accessed, irrespective of the cardbus

or pci modes of the device. They are mapped to the I/O and memory addresses set up in BAR2 and BAR3, with the offsets

defined for each register. I/O or memory accesses can be byte, word or dword accesses, however on little-endian systems such

as Intel 80x86 the byte order will be reversed.

6.4.1 Local Configuration and Control register ‘LCC’ (Offset 0x00)

This register defines control of ancillary functions such as Power Management, endian selection and the serial EEPROM. The

individual bits are described below.

Bits Description Read/Write Reset

0 Cardbus Mode. This bit returns the state of the device.

1=> Cardbus Mode. 0 => PCI Mode.

1 Relocate Cardbus Information Structure.

0 => Make available CIS at DWORD18 in PCI configuration Space

1 => Make available CIS at DWORD32 in the PCI configuration Space

This bit has meaning only for cardbus applications.

2 Reserved - R 0

4:3 Endian Byte-Lane Select for memory access to UART function.

00 = Select Data[7:0] 10 = Select Data[23:16]

01 = Select Data[15:8] 11 = Select Data[31:24]

Memory access to UART registers is always DWORD aligned. When

accessing 8-bit regions this option selects the active byte lane. As both

cardbus/PCI and PC architectures are little endian, the default value will

be used by systems, however, some non-PC architectures may need to

select the byte lane.

7:5 Power-down filter time. These bits define a time value for an internal

filter that filters the device’s powerdown requests before the request is

recognised. Once Function0 is ready to go into the power down mode,

the OXCB950 will wait for the specified filter time and if Function0 is still

in the power-down request mode, it can assert a cardbus/PCI interrupt

000 = Power-down request disabled

001 = 4 seconds

10:8 Reserved: Power management test bits. The device driver must write

zero to these bits

20:11 Reserved. - R 000h

21 Source of Cardbus Information Structure. This bit returns which area

the tuple information had been provided.

0 => CIS from hardcoded Values

1 => CIS from RAM (Set when a download into the CIS zone was made)

This bit has meaning only for cardbus applications.

22 Enable Writes to Cardbus InformationStructure.

Provided that the CIS is contained in RAM (LCC[21]= ‘1’), then setting

this bit allows the tuple information contained in RAM to be written by

cardbus/pci configuration transactions. This does not update the CIS

information in the EEPROM.

This bit has meaning only for cardbus applications

010 = 129 seconds

011 = 518 seconds

1XX = Powerdown Immediate

EEPROM

W R 1

W R 0

W RW 00

W RW 000

- R 000

W R 0

W R/W 0

PCI

Data Sheet Revision 1.1 Page 16

OXFORD SEMICONDUCTOR LTD.

Bits Description Read/Write Reset

23 Enable Cardbus Status Registers

When set (1), all interrupt sources and power management events are

controlled by the INTR, GWAKE/WKUP fields of the cardbus status

registers.

This bit has meaning only for cardbus applications

24 EEPROM Clock. For reads or writes to the external EEPROM , toggle

this bit to generate an EEPROM clock (EE_CK pin).

25 EEPROM Chip Select. When 1 the EEPROM chip-select pin EE_CS is

activated (high). When 0 EE_CS is de-active (low).

26 EEPROM Data Out. For writes to the EEPROM, this output bit feeds the

input-data of the external EEPROM. This bit is output on the devices

EE_DO and clocked into the EEPROM by EE_CK.

27 EEPROM Data In. For reads from the EEPROM, this input bit is the

output-data (D0) of the external EEPROM connected to EE_DI pin.

28 EEPROM Valid.

A 1 indicates that a valid EEPROM program header is present

29 Reload configuration from EEPROM.

Writing a 1 to this bit re-loads the configuration from EEPROM. This bit is

self -clearing after an EEPROM read

30 Reserved - R 0

31 Reserved - R 0

EEPROM

W R/W 0

- RW 0

- RW 0

- RW 0

- R 1

- R X

- RW 0

OXCB950

PCI

6.4.2 Multi-purpose I/O Configuration register ‘MIC’ (Offset 0x04)

This register configures the operation of the multi-purpose I/O pins ‘MIO[1:0]’ as follows.

Bits Description Read/Write Reset

1:0 MIO0 Configuration Register

00 -> MIO0 is a non-inverting input pin

01 -> MIO0 is an inverting input pin

10 -> MIO0 is an output pin driving ‘0’

11 -> MIO0 is an output pin driving ‘1’

3:2 MIO1 Configuration Register

00 -> MIO1 is a non-inverting input pin

01 -> MIO1 is an inverting input pin

10 -> MIO1 is an output pin driving ‘0’

11 -> MIO1 is an output pin driving ‘1’

4 MIO0 Power Management Event Enable.

A value of ‘1’ enables the MIO0 pin to set the PME_Status bit in the PCI

PMCSR register, and hence assert the PME# (pci) or CSYSCHG

(cardbus) pin if this option has been enabled.

A value of ‘0’ prevents MIO0 from setting the PCI PME_Status bit.

5 MIO1 Power Management Event Enable.

A value of ‘1’ enables the MIO1 pin to set the PME_Status bit in the PCI

PMCSR register, and hence assert the PME# (pci) or CSYSCHG

(cardbus) pin if this option has been enabled.

A value of ‘0’ prevents MIO1 from setting the PCI PME_Status bit.

EEPROM

W RW 00

W RW 00

W RW 0

W RW 0

PCI

Data Sheet Revision 1.1 Page 17

OXFORD SEMICONDUCTOR LTD.

Bits Description Read/Write Reset

6 MIO0 Power Down Filter Control:

A ‘1’ enables the MIO0 pin to invoke a powerdown request via the power

down filter (if the filter is enabled). State of MIO0 that causes the

powerdown request is governed by the controls MIC[1:0).

7 MIO1 Power Down Filter Control:

A ‘1’ enables the MIO1 pin to invoke a powerdown request via the power

down filter (if the filter is enabled). State of MIO1 that causes the

powerdown request is governed by the controls MIC[3:2).

31:8 Reserved - R 00

EEPROM

W RW 0

W RW 0

OXCB950

PCI

6.4.3 UART Mirror Register ‘UMR’ (Offset 0x08):

The internal UART’s FIFO levels (both on the transmitter and receiver) and general interrupt source register, is mirrored

(shadowed) in the local configuration registers as follows

Bits Description Read/Write Reset

7:0 UART Receiver FIFO Level (RFL[7:0]) - R 00h

15:8 UART Transmitter FIFO Level (TFL[7:0]) - R 00h

21:16 UART Interrupt Source Register (ISR[5:0]) - R 01h

26:22 Reserved - R 00h

27 UART Good-Data Status - R 1h

31:28 Reserved - R 0h

Good-Data status for the internal UART is set when all of the following conditions are met:

• ISR reads a level0 (no-interrupt pending), a level 2a (receiver data available, a level 2b (receiver time-out) or a level 3

(transmitter THR empty) interrupt

• LSR[7] is clear so there is no parity error, framing error or break in the FIFO

• LSR[1] is clear so no over-run error has occurred

If the device driver software reads the receiver FIFO levels from this register, then if Good-Data status is set, the driver can

remove the number of bytes indicated by the FIFO level without the need to read the line status register. This feature enhances

the driver efficiency.

If the Good-Data status bit is not set, then the software driver should examine the ISR bits. If the ISR indicates a level 4 or higher

interrupt, the interrupt is due to a change in the state of modem lines or detection of flow control characters. The device driversoftware should then take appropriate measures as would in any other 550/950 driver. When ISR indicates a level 1 (receiver

status) interrupt then the driver can examine the Line Status Register (LSR) of the relevant channel. Since reading the LSR

clears LSR[7], the device driver-software should either flush or empty the contents of the receiver FIFO, otherwise the GoodData status will no longer be valid.

EEPROM

PCI

Data Sheet Revision 1.1 Page 18

OXFORD SEMICONDUCTOR LTD.

OXCB950

6.4.4 Global Interrupt Status and Control Register ‘GIS’ (Offset 0x0C)

This register controls the assertion of interrupts and power management events, as well as returning the internal status of all

interrupt sources and power management events.

Bits Description Read/Write Reset

1:0 Reserved - R 0x0h

2 MIO0 Internal State.

This bit reflects the state of the internal MIO[0] signal. The internal MIO[0]

signal reflects the non-inverted or inverted state of MIO0 pin. 2

3 MIO1 Internal State

This bit reflects the state of the internal MIO[1] signal. The internal MIO[1]

reflects the non-inverted or inverted state of MIO1 pin. 2

17-4 Reserved - R 0

18 MIO0 Interrupt Enable

When set (1) allows the pin MIO0 to assert an interrupt on the device’s INTA#

(CINT#) pin. The state of the MIO0 signal that causes an interrupt is

dependant upon the polarity set by the register fields MIC(1:0)

19 MIO1 Interrupt Enable

When set (1) allows the pin MIO1 to assert an interrupt on the device’s INTA#

(CINT#) pin. The state of the MIO1 signal that causes an interrupt is

dependant upon the polarity set by the register fields MIC(3:2)

20 Power-down Internal Interrupt Status.

This is a sticky bit. When set, it indicates that a power-down request has been

recognised (validated), which would normally have asserted a powerdown

interrupt on the INTA# (CINT#) pin if GIS bit 21 was set.

Reading this bit clears the Internal Powerdown Interrupt Status.

21 Power-down interrupt enable.

When set to ‘1’, a powerdown request is allowed to generate an interrupt on

the INTA#/ (CINT# ) pin.

22 UART interrupt status

. 1

This bit reflects the interrupt status of the internal UART.

23 UART Interrupt Enable.

When set (1) allows the UART to assert an interrupt on the device’s INTA#

(CINT# ) pin

3

24 UART Power Management Event Enable

A value of ‘1’ enables the UART ‘wakeup’ events to set the PME_Status bit in

the PCI PMCSR register, and hence assert the PME# (pci) or CSYSCHG

(cardbus) pin if this option has been enabled.

A value of ‘0’ prevents any wakeup events from the UART from setting the

PCI PME_Status bit.

25 UART Powerdown Filter Control

A ‘1’ enables the UART to invoke a powerdown request via the power down

filter (if the filter is enabled).

31:24 Reserved - R 00h

EEPROM

-

-

PCI

R

R

W RW 1

W RW 1

- R X

W RW 0

- R 0

W R/W 1

W R/W 0

W R/W 0

X

X

Data Sheet Revision 1.1 Page 19

OXFORD SEMICONDUCTOR LTD.

OXCB950

Note1 GIS(22) is the inverse of UMR(16).

Note 2: The returned value is either the direct state of the corresponding MIO pin or its inverse as configured by the Multi -purpose I/O Configuration register

Note 3: The UART Interrupt Enable register bit is set after a hardware reset to enable the interrupt from the internal UART. This will cater for generic device-

‘MIC’ (offset 0x04). As the internal MIO can assert a cardbus/PCI interrupt, the inversion feature can define each external interrupt to be defined as

active-low or active-high, as controlled by the MIC register.

driver software that does not access the Local Configuration Registers. The default setting for the UART Interrupt Enable bit can be changed using

the serial EEPROM. Note that even though by default the UART interrupt is enabled in this register, since after a reset the IER register of the UART

is disabled then a cardbus/PCI interrupt will not be asserted by the UART after a hardware reset.

6.5 Cardbus/ PCI Interrupt

Interrupts in cardbus/PCI systems are level-sensitive and

can be shared. In the OXCB950, there are three sources of

interrupts - two from the Multi-Purpose I/O pins (MIO0,

MIO1), and one from the internal UART.

Since the OXCB950 has only one interrupt pin (INTA# /

CINT#), the default routing information contained in the

device (the interrupt pin value) results in all interrupts being

made available on this single interrupt pin.

This default routing may be modified (to disable all

interrupts, for example) by writing to the Interrupt Pin field

in the cardbus/PCI configuration registers using the serial

EEPROM facility. The Interrupt Pin field is normally

considered a hard-wired read-only value in cardbus/PCI. It

indicates to system software which interrupt pin (if any) is

used by a function. The interrupt pin may only be modified

using the serial EEPROM facility, and card developers

must not set any value which violates the cardbus/PCI

specification on this issue. If in doubt, the default routings

should be used. Table 6 relates the Interrupt Pin field to the

device pin used.

Interrupt Pin Device Pin used

0 None

1 INTA# (CINT#)

2 to 255 Reserved

Table 6: ‘Interrupt pin’ definition

During the system initialisation process and cardbus/PCI

device configuration, system-specific software reads the

interrupt pin field to determine which (if any) interrupt pin is

used by the function. It programmes the system interrupt

router to logically connect this interrupt pin to a systemspecific interrupt vector (IRQ). It then writes this routing

information to the Interrupt Line field in the function’s

cardbus/PCI configuration space. Device driver software

must then hook the interrupt using the information in the

Interrupt Line field.

The Interrupt status for all sources of interrupts are

available using the GIS register in the Local Configuration

Register set, which can be accessed using I/O or Memory

accesses.

The 3 sources of interrupts on the OXCB950, can be

enabled/disabled individually using the options in the local

configuration register “GIS”.

By default, these options are enabled so that irrespective of

the device’s application mode (cardbus or pci) the

assertion of the 2 Multi_Purpose I/O pins (MIO0, MIO1)

will, following the initial cardbus/PCI configuration process,

assert the interrupt pin of the device. By the same token,

any UART based interrupts that are generated as a result

of enabling interrupts in the UART’s interrupt register (the

ISR register) will result in the assertion of the UART

interrupt on the interrupt pin of the device.

Once an interrupt has been asserted, this interrupt can only

be removed by the device driver either by disabling the

relevant controls in the GIS register or by removing the

conditions on the 3 interrupt sources. For the UART, this

will require reads of the relevant register to clear any UART

based interrupts.

Cardbus applications, normally expect a set of four 32-bit

registers: Function Event, Function Event Mask, Function

Present State, and Function Force Event Registers to

control the assertion/deassertion of interrupts (and power

management events). These are the cardbus status

registers located in memory space at the location given by

the CISTPL_CONFIG_CB tuple. For the OXCB950, these

registers reside at the memory base address register BAR4

that is dedicated to provide access to these additional

registers. By default, in cardbus mode, these status

registers are disabled (bypassed) so cardbus applications

exhibit the same interrupt behaviour as per the pci mode.

This default setting is particularly suitable for those

applications, such as Windows 9x, that treat cardbus

functions as PCI functions and continue to utilise (modified)

versions of PCI device drivers for cardbus functionality.

These PCI based device drivers do not expect the

presence of these cardbus status registers to further

control the interrupt generation / deassertion logic.

For those cardbus applications that do require use of these

cardbus status registers, these registers can be enabled by

setting LCC, bit 23 located in the device’s local

configuration registers. This can be achieved by performing

Data Sheet Revision 1.1 Page 20

OXFORD SEMICONDUCTOR LTD.

an I/O or Memory write to this bit in the local configuration

register or by using the optional EEPROM to download into

this area.

Once these cardbus status registers are enabled, interrupts

will only be asserted on the device’s interrupt pin provided

that the INTR field is enabled in the Function Event Mask

Register (disabled by default) and the corresponding INTR

field in the Function Event Register has detected (latched)

a valid internal interrupt request. Once asserted, the

interrupt on the device’s interrupt pin can only be disabled

by either disabling the INTR field in the Function Event

Mask register or by writing a “1” to the INTR field of the

6.6 Cardbus/PCI Power Management

OXCB950

Function Event Register. The INTR field in the Function

Present State register will reflect the current (non-latched)

state of any internal interrupt requests and the INTR field in

the Function Force register is available to generate

software based interrupts for debug purposes.

NOTE : Enabling of the cardbus status registers provides

additional controls to the interrupt generation/deassertion

logic. The interrupt controls in the local configuration

registers must nevertheless be enabled to detect the

interrupts from the device’s 3 interrupt sources in the first

place.

The OXCB950 is compliant with the Power Management

Requirements for cardbus PC cards as detailed in the

Electrical Specification of the PC Card Standard, release

7.x. It is also compliant to the PCI Power Management

Specification Revision 1.0. The device (function0)

implements a set of Power Management registers and

supports the power states D0, D2 and D3.

Power management is accomplished by handling the

power-down and power-up (“power management event”)

requests, that are asserted on the device’s interrupt pin

and the pins PME#/CSYSCHG respectively. Note, PME# is

the power management event for PCI applications and

CSYSCHG is the power management event for cardbus

applications. The logic behind these signals is identical.

Power-down requests are not defined by any of the Power

Management specifications. It is a device-specific feature

and requires a bespoke device driver implementation. The

device driver can either implement the power-down itself or

use a special interrupt and power-down features offered by

the device to determine when the device is ready for

power-down.

For PCI applications, it worth noting that the PME# pin can,

in certain cases, activate the PME# signal when power is

removed from the device, which will cause the PC to wake

up from Low-power state D3(cold). To ensure full crosscompatibility with system board implementations, use of an

isolator FET is recommended. If Power Management

capabilities are not required, the PME# pin can be treated

as no-connect. There are no such problems for cardbus

applications. The CSYSCHG line is not capable of being

asserted on removal of device power.

6.6.1 Power Management via UART/ MIO pins

Provided that the necessary controls have been set in the

device’s local configuration registers (LCC, MIC, and GIS),

the internal UART and the 2 multi_purpose (MIO) pins can

be programmed to issue powerdown requests and/or

‘wakeup’ requests (power management events).

For the case of the internal UART, the device can be

configured to monitor the activity of the serial channel, and

issue a power-down interrupt when the UART is inactive

(no interrupts pending and both transmitter and receiver

are idle).

For the case of the MIO pins, the MIO state that governs

powerdown is the inverse of the MIO state that asserts the

device’s interrupt pin (the INTA# / CINT# line, if that option

were to be enabled). This means that when any external

device is not interrupting it will automatically begin the

powerdown cycle.

When either a powerdown request from the internal UART

or a powerdown request from the MIO pins has been

detected, the internal power management circuitry waits for

a period of time as programmed into the Power-Down Filter

Time (defined by the local configuration register LCC[7:5])

and if the powerdown requests are still valid i.e. for the

UART, this means that the channel is still inactive, then the

OXCB950 can issue a powerdown interrupt on the device’s

interrupt pin if this option is enabled. Alternatively, the

device driver can poll the powerdown status field in the

local configuration register GIS[20] to determine a

powerdown request. This powerdown filter stops the

UART and the MIO pins from issuing too many powerdown

interrupts whenever the UART and MIO pin activity is

intermittent.

Data Sheet Revision 1.1 Page 21

Loading...

Loading...