■

■

■

■

MSO Series

Portable Mixed Signal Digital Storage Oscilloscope

User Manual

MSO7062TD

MSO7102TD

MSO8102T

MSO8202T

WWW.OWON.COM.HK

Headquarter:

Branch:

Nov. 2014 edition Ver1.3.7

Copy Right in this Manual © Lilliput Company. All rights Reserved.

The Lilliput's products are under the protection of the patent rights in America and other countries,

including ones which have already obtained the patent rights and those which are applying for. The

information in this manual will replace all that in the materials published originally.

The information in this manual was correct at the time of printing. However, OWON will continue to

improve products and reserves the rights to changes specification at any time without notice.

OWON is the registered trademark of the Lilliput Company.

optoelectronics, 19 Heming Road, Lantian industrial zone, Zhangzhou, Fujian, China

Tel:+86-596-2130430 Fax:+86-596-2109272

Web:

www.owon.com.hk Mail: Business Consulting: info@owon.com.hk

Park, ZhenZhuWan,

Tel:+86-592-2575666 Fax:+86-592-2575669

Xiamen Lilliput Technology Co.,Ltd.: the 5th floor, B Area, Chuangxin Mansion, Software

Fujian Lilliput Optoelectronics Technology Co.,Ltd.: The mansion of

Sale service: service@owon.com.hk

Huandao RD, Xiamen, Fujian, China

User Manual of OWON Color Mixed Signal Digital Storage Oscilloscope

General Warranty

Lilliput warrants that the product will be free from defects in materials and workmanship

for a period of 3 years from the date of purchase of the product by the original purchaser

from the Lilliput Company. And the warrant y period of accessories such as probe, battery

is 12 months. This warranty only applies to the original purchaser and is not transferable

to the third party. If the product proves defective during the warranty period, Lilliput

either will repair the defective product without charge for parts and labor, or will provide a

replacement in exchange for the defective product. Parts, modules and replacement

products used by Lilliput for warranty work may be new or reconditioned to like new

performance. All replaced parts, modules and products become the property of Lilliput.

In order to obtain service under this warranty, Customer must notify Lilliput of the defect

before the expiration of the warranty period. Customer shall be responsible for packaging

and shipping the defective product to the service c enter design ated by Lilliput, and with a

copy of customer proof of purchase.

This warranty shall not apply to any defect, failure or damage caused by improper use or

improper or inadequate maintenance and care. Lilliput shall not be obligated to furnish

service under this warranty a) to repair damage resulting from attempts by personnel other

than Lilliput representatives to install, repair or service the product; b) to repair damage

resulting from improper use or connection to incompatible equipment; c) to repair any

damage or malfunction caused by the use of non-Lilliput supplies; or d) to service a

product that has been modified or integrated with other products when the effect of such

modification or integration increases the time or difficulty of servicing the product.

Please contact the neare st Lilliput's Sales and Service Offic es for services or a complete

copy of the warranty statement.

For better after-sales service, please visit www.owon.com.hk and register the purchased

product online.

Excepting the after-sales services provided in this summary or the applicable warranty

statements, Lilliput w ill not offer any guarantee for maintenance definitely declared or hinted,

including but not limited to the implied guarantee for marketability and special-purpose

acceptability. Lilliput should not take any responsibilities for any indirect, special or consequent

damages.

i

Table of Contents

1. General Safety Requirements .......................................................................................... 1

2. Safety Terms and Symbols ............................................................................................... 2

3. General Characteristics ................................................................................................... 4

4. Junior User Guidebook ................................................................................................... 5

4.1 Introduction to the Front Panel and the User's Interface ................................................. 6

Front panel ............................................................................................................................................... 6

Control(key and knob) area ...................................................................................................................... 7

4.2 Digital Storage Oscilloscope ................................................................................................. 9

User interface introduction ....................................................................................................................... 9

How to implement the General Inspec tion ............................................................................................. 11

How to implement the Function Inspection ........................................................................................... 11

How to Implement the Probe Compensation .......................................................................................... 12

How to Set the Probe Attenuatio n Coefficient ....................................................................................... 13

How to Use the Probe Safely ................................................................................................................. 14

How to Implement Auto-calibration ...................................................................................................... 14

Introduction to the Vertical System ........................................................................................................ 14

Introduction to the Horizontal S ystem.................................................................................................... 16

Introduction to the Trigger System ......................................................................................................... 16

4.3 Logic Analyzer ..................................................................................................................... 18

LA input connection ............................................................................................................................... 18

User interface introduction ..................................................................................................................... 18

How to acquire data ................................................................................................................................ 19

How to observe and analyze the data ..................................................................................................... 19

Display systems ...................................................................................................................................... 20

Trigger s ystem ........................................................................................................................................ 21

Threshold voltage sys tem ....................................................................................................................... 22

Sampling syst e m .................................................................................................................................... 23

5. Advanced User Guidebook ............................................................................................ 25

5.1 Digital Storage Oscilloscope ............................................................................................... 26

How to Set the Vertical System.............................................................................................................. 26

Implementation of Mathemati c a l M a nipulation Function ...................................................................... 30

Using FFT function.............................................................................................................................................. 30

Application of VERTICAL POSITION and VOLTS/DIV Knobs ......................................................... 35

How to Set the Horizontal syste m .......................................................................................................... 35

How to set trigger system ....................................................................................................................... 38

How to Operate the Function Menu ....................................................................................................... 47

How to Implement Sampling Setup ....................................................................................................... 47

How to Set the Display System .............................................................................................................. 49

How to Save and Recall a Wave Form ................................................................................................... 52

How to Implement the Auxiliary System Function Setting .................................................................... 54

ii

How to Implement the Automatic M e a surement ................................................................................... 55

How to Implement the Cursor Measurement ......................................................................................... 58

How to use Autoscale ............................................................................................................................. 62

How to Use E xecutive Buttons............................................................................................................... 63

5.2 Logic analyzer ...................................................................................................................... 69

How to set sampling system ................................................................................................................... 69

How to set trigger system ....................................................................................................................... 71

How to set threshold ............................................................................................................................... 79

How to set display system ...................................................................................................................... 81

How to set BUS ...................................................................................................................................... 82

How to measure ...................................................................................................................................... 84

How to save and recall ........................................................................................................................... 84

How to use USB flash disk to storage .................................................................................................... 86

How to search ......................................................................................................................................... 86

How to review setting info ..................................................................................................................... 89

How to use cursor measurement............................................................................................................. 89

How to set Utility ................................................................................................................................... 92

6. Demonstration ............................................................................................................... 93

Example 1: Measurement of Simple Signals ........................................................................... 93

Example 2: Working out the Gain of the Amplifier in the Metering Circuit ...................... 94

Example 3: Capture the Single Signal ..................................................................................... 95

Example 4: Analyze the Details of a Signal ............................................................................. 96

Example 5: Examine the Phase shift between two related signals ........................................ 98

Example 6: Video Signal Trigger ............................................................................................. 99

7. F.A.Q ............................................................................................................................ 100

8. Technical Specifications .............................................................................................. 101

Digital Stora ge Osc il lo s cope ................................................................................................... 101

Logic analyzer .......................................................................................................................... 104

General Technical Specifications ........................................................................................... 105

9. Appendix ...................................................................................................................... 106

Appendix A: Enclosure ........................................................................................................... 106

Appendix B: Maintenance, Cleaning and Repairing ........................................................... 106

Appendix C: Battery Using Guide ......................................................................................... 107

1

1. General Safety Requirements

Before any operations, please read the following safety precautions to avoid any

possible bodily injury and prevent this product or any other products connected

from damage. In order to avoid any contingent danger, this product is only used

within the range specified.

Only the qualified technicians can implement the maintenance.

To avoid Fire or Personal Injury:

Connect the probe correctly. The grounding end of the probe corresponds to the

grounding phase. Please don't connect the grounding end to the positive phase.

Use Proper Power Cord. Use only the power cord supplied with the product and

certified to use in your country.

Connect or Disconnect Correctly. When the probe or test lead is connected to a

voltage source, please do not connect and disconnect the probe or test lead at random.

Product Grounded. This instrument is grounded through the power cord grounding

conductor. To avoid electric shock, the grounding conductor must be grounded. The

product must be grounded properly before any connection with its input or output

terminal.

When powered by AC power, it is not allowed to measure AC power source

directly, because the testing ground and power cord ground conductor are

connected together, otherwise, it will cause short circuit.

When powered by battery, the product must ground connection. To avoid electric

shock, there must be a ground wire connect between ground and the ground port

(on the back of product panel).

Check all Terminal Ratings. To avoid fire or shock hazard, check all ratings and

markers of this product. Refer to the user's manual for more information a bout ratings

before connecting to the instrument.

Do not operate without covers. Do not operate the instrument with co vers or panels

removed.

Use Proper Fuse. Use only the specified type and rating fuse for this instrument.

Avoid exposed circuit. Do not touch exposed junctions and components when the

instrument is powered.

Do not operate if in any doubt. If you suspect damage occurs to the instrument, have

it inspected by qualified service personnel before further operations.

Use your Oscilloscop e in a well-ventilated area. Make sure the instrument installed

with proper ventilation, refer to the user manual for more details.

Do not operate in wet conditions.

Do not operate in an explosive atmosphere.

Keep product surfaces clean and dry.

2

2. Safety Terms and Symbols

Safety Terms

Terms in this manual. The following terms may appear in this manual:

Warning: Warning indicates the conditions or practices that could result in

injury or loss of life.

Caution: Caution indicates the conditions or practices that could result in

damage to this product or other property.

Terms on the product. The following terms may appear on this product:

Danger: It indicates an injury or hazard may immediately happen.

Warning: It indicates an injury or hazard may be accessible potentially.

Caution: It indicates a potential damage to the instrument or other property might occur.

Safety Symbols

Symbols on the product. The following symbol may appear on the product:

Hazardous Voltage

Protective Earth Terminal

Test Ground

Refer to Manual

Chassis Ground

To avoid bod y dama ge and prevent product and connected equipment damage, carefully

read the following safety information before using the test tool. This product can only be

used in the specified applications.

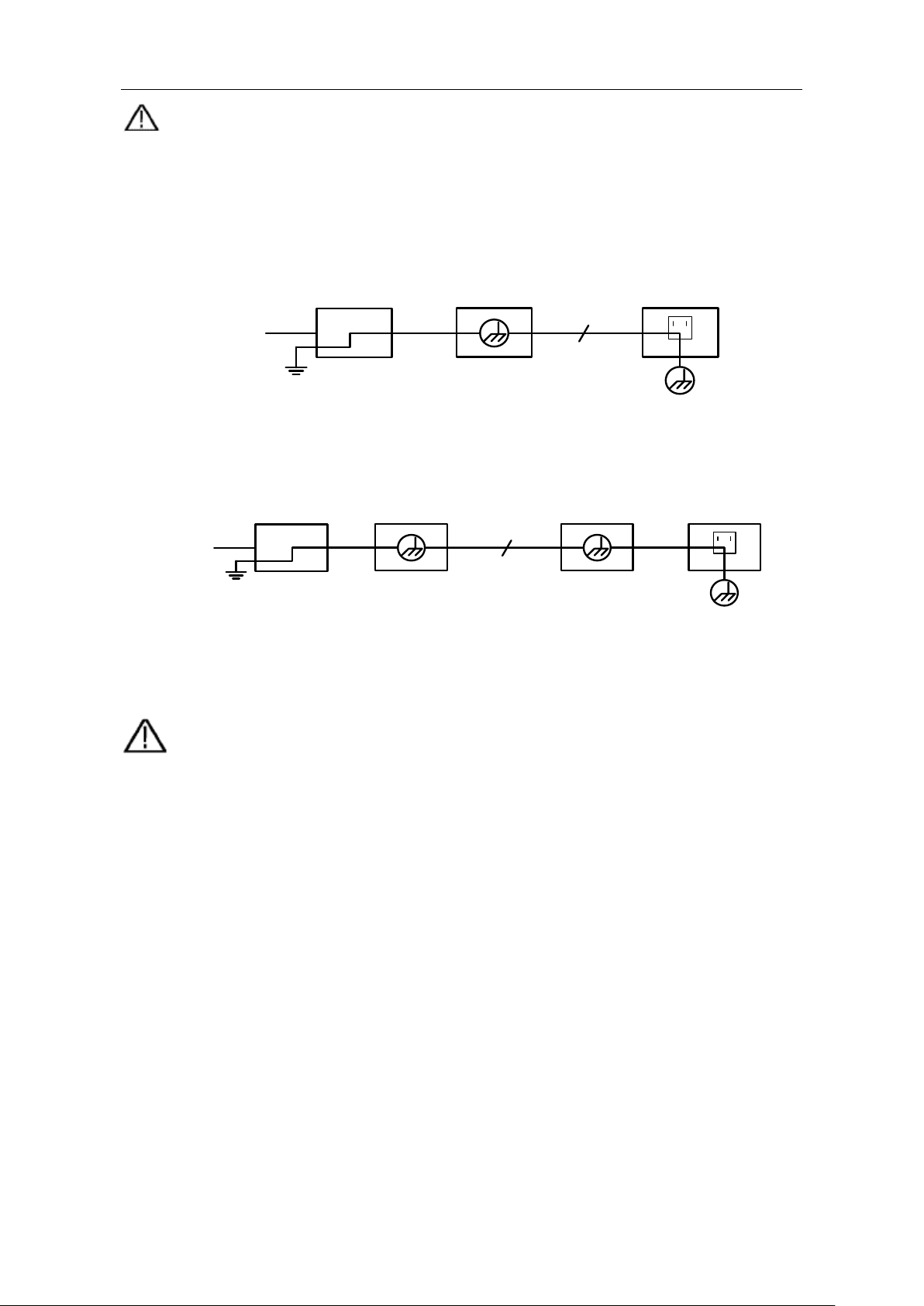

Warning:

The two channels of the oscilloscope are non-isolated electrically. The channels

should adopt common basis during measuring. To prevent short ci rcuits, the 2 probe

ground must not be connected to 2 different non-isolated DC level.

3

Ground Clip

Signal Input

Oscilloscope

Electrical Outlet

Probe

Power Cord

Ground Clip

Signal Input

Oscilloscope

(Battery-power)

PC Electrical OutletProbe

USB/COM Cable

Warning:

To avoid fire or electrical shock

connected

42V peak (30Vrms) or on circuits of more than

4800VA

apply input voltages above the rating of the instrument

because the probe tip voltage will directly transmit to the

Warning:

The channels should adopt common basis during measuring. To prevent short

circuits, the 2 probe ground must not be connected to 2 different non-isolated DC

level.

The diagram of the oscilloscope ground wire connection:

The diagram of the ground wire connection when the battery-powered osci llos cope is

connected to the AC-powered PC through the ports:

It is not allowed to measure AC power when the oscilloscope i s A C p o w e re d, o r when

the battery-powered oscilloscope is connected to the AC-powered PC through the

ports.

is more than

, please take note of below items:

Only use accessory insulated voltage probes and test lead.

Check the accessories such as probe before use and replace it if

there are any damages.

Remove probes, test leads and other accessories immediately after

use.

Remove USB cable which connects oscilloscope and computer.

, when the oscilloscope input signal

Do not

oscilloscope. Use with caution when the probe is set as 1:1.

Do not use exposed metal BNC or banana plug connectors.

Do not insert metal objects into connectors.

4

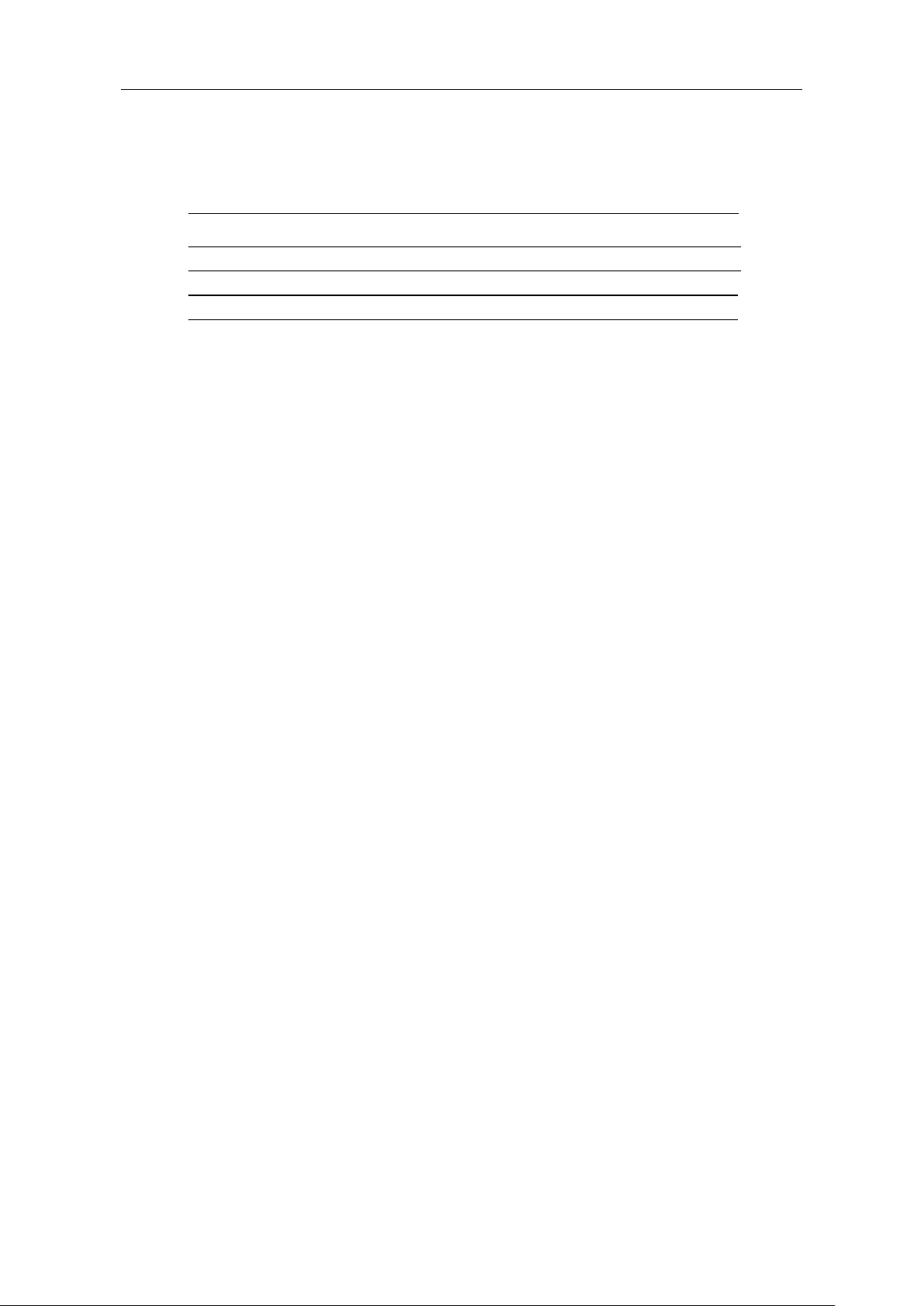

3. General Characteristics

Digital Storage Oscilloscope

Model Bandwidth Sample Rate

MSO7062TD 60MHz 1GS/s half channel*, 500MS/s each channel

MSO7102TD 100MHz 1GS/s half channel*, 500MS/s each channel

MSO8102T 100MHz 2GS/s half channel*, 1G S/s each channel

MSO8202T 200MHz 2GS/s half channel*, 1G S/s each channel

Dual channel, 2M points on each ch ann el for the Record length;

Reading-out with the cursor;

Twenty automatic measurement functions;

Autoscale function;

Color liquid crystal display of high resolution an d high contrast with adjustable

back light;

Storage and call-out of waveforms;

Automatic setting function provided capable of fast setting;

Multiple-waveform calculation function;

Built-in FFT function;

Implementation of detecting the average and peak values of the waveform;

Digital real-time oscilloscope;

Edge, video, alternate, pulse and slope triggering function;

RS232 or USB communication ports;

Different continuous displaying time;

Multiple Language User Interface.

*Half channel is when only one channel is turned on.

Logic Analyzer

16 input channel;

4M max Storage for each channel;

Plenty of trigger Mode;

Convenient data measurement & data search;

Freely setting of all kinds of threshold level.

5

4. Junior User Guidebook

This chapter deals with the following topics mainly:

Digital Storage Oscilloscope

Introduction to the front panel and the user's interface of the MSO series

oscilloscope

How to implement the general inspection

How to implement the function in s pec ti on

How to make a probe compensation

How to set t he pro be a tte nuation coefficient

How to use the probe safely

How to implement an auto-calibration

Intro d uct i on to the verti ca l sy ste m

Introduct i on to th e ho riz on ta l sy stem

Intro d uct i on to the tri gg er sy stem

Logic Analyzer

User interface introduction

How to a cquire data

How to observe and analyze the data

Displa y system

Trig ger system

Thres h old vo lta ge syste m

Sampling system

6

4.1 Introduction to the Front Panel and the User's Interface

When you get a new-type oscilloscope, you should get acquainted with its front panel at

first and the MSO series mixed digital storage oscilloscope is no exception. This chapter

makes a simple description of the operation and function of the front panel of the MSO

series mixed oscilloscope, enabling you to be familiar with the use of the MSO series

mixed oscilloscope in the shortest time. The MSO series mixed oscilloscope offers a

simple front panel with distinct functions to users for their completing some basic

operations, in which the knobs and function pushbuttons are included. The knobs have the

functions similar to other oscilloscopes. The 5 buttons in the column on the right side of

the display screen are menu selection buttons (defined as F1 to F5 from top to bottom

respectively), through which, you can set the different options for the current menu. The

other pushbuttons are function buttons, through which, you can enter different function

menus or obtain a specific function application directly.

Front panel

Fig. 4-1 Front panel overview

1、 Power on/off

2、 Display area

3、 Control (key and knob) area

4、 U slot

5、 LA signal input

6、 DSO signal input

7、 Measurement signal output

8、 Power and charging indication: Green light indicates AC supply and battery

full charged; yellow light indicate under charging.

7

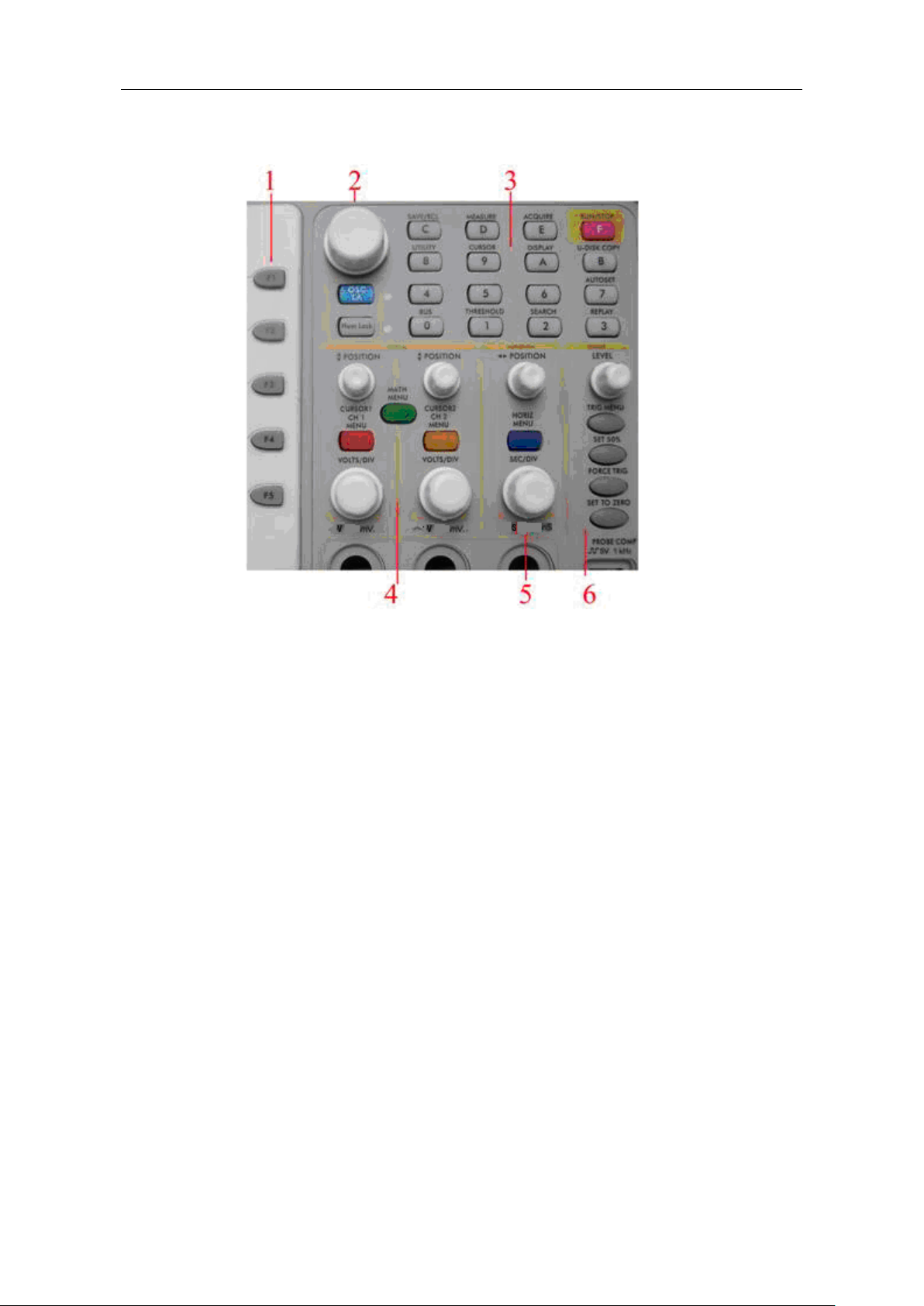

Control(key and knob) area

Fig. 4-2 Keys Overview

1、Menu option setting: F1~F5

2、Switch

Switch includes two keys and one knob. Press "OSC/LA" to switch betwe en DSO and

LA.

For DSO "cursor" knob and "info" ke y are idle. But the "cursor" knob takes effect in

magnifying or minifying the waveform after FFT operation when the mode is FFT.

For LA, "cursor" knob to adjust current cursor position and "info" key to loading

setting info for acquired waveform and current waveform.

3、Function key area

For DSO 0~5 keys are idle and 6~F refer to different DSO function menu.

For LA, 3.4.5.6.7 refers to figure and other keys refer to digit or function menu.

4、Vertical control area

It's including 3 keys and 4 knobs.

For DSO: "CH1 menu" and "CH2 menu" correspond to setting menu in CH1 and CH2,

"Wave Math" key refer to math menu, the math menu consists of six kinds of operations,

including CH1-CH2、CH2-CH1、CH1+CH2 、CH1*CH2、CH1/CH2 and FFT .Two

"Vertical position" knobs control the vertical positi on of CH1. CH2, and two "Volts/Div"

knob control voltage scale of CH1, CH2.

For LA, "CH1 menu", "CH2 menu", "Wave math" keys and "CH2 Volts/Div" knob are

8

idle. "CH1 Vertical ", "CH2 Vertical" to adjust the M1, M2 position in Cursor menu when

cursor display is on "CH1 Volts/Div".

5、Horizontal control area with 2 knob and 1 key.

For DSO, "Horizontal position" knob control trigger position, "Volts/Div" control

time base, "Horizontal menu" key refer to horizontal system setting menu.

For LA, "Horizontal menu" key is idle. "Horizontal position" knob to adjust the

position of value displayed currently quickly. "Sec/Div" knob to adjust value resolution

displayed currently.

6、Trigger control area with 4 keys and 1 knob.

For DSO, "Trig adjust" knob is to adjust trigger voltage. Other four keys refer to

trigger system setting.

For LA, "Force trig" key is idle. "Trig menu" refer to trigger menu control. "Trig

adjust" knob to adjust trigger position in memory, "SET 50%" is to set trigger position as

50% and "SET Zero" set trigger position as 0.

9

4.2 Digital Storage Oscilloscope

User interface introduction

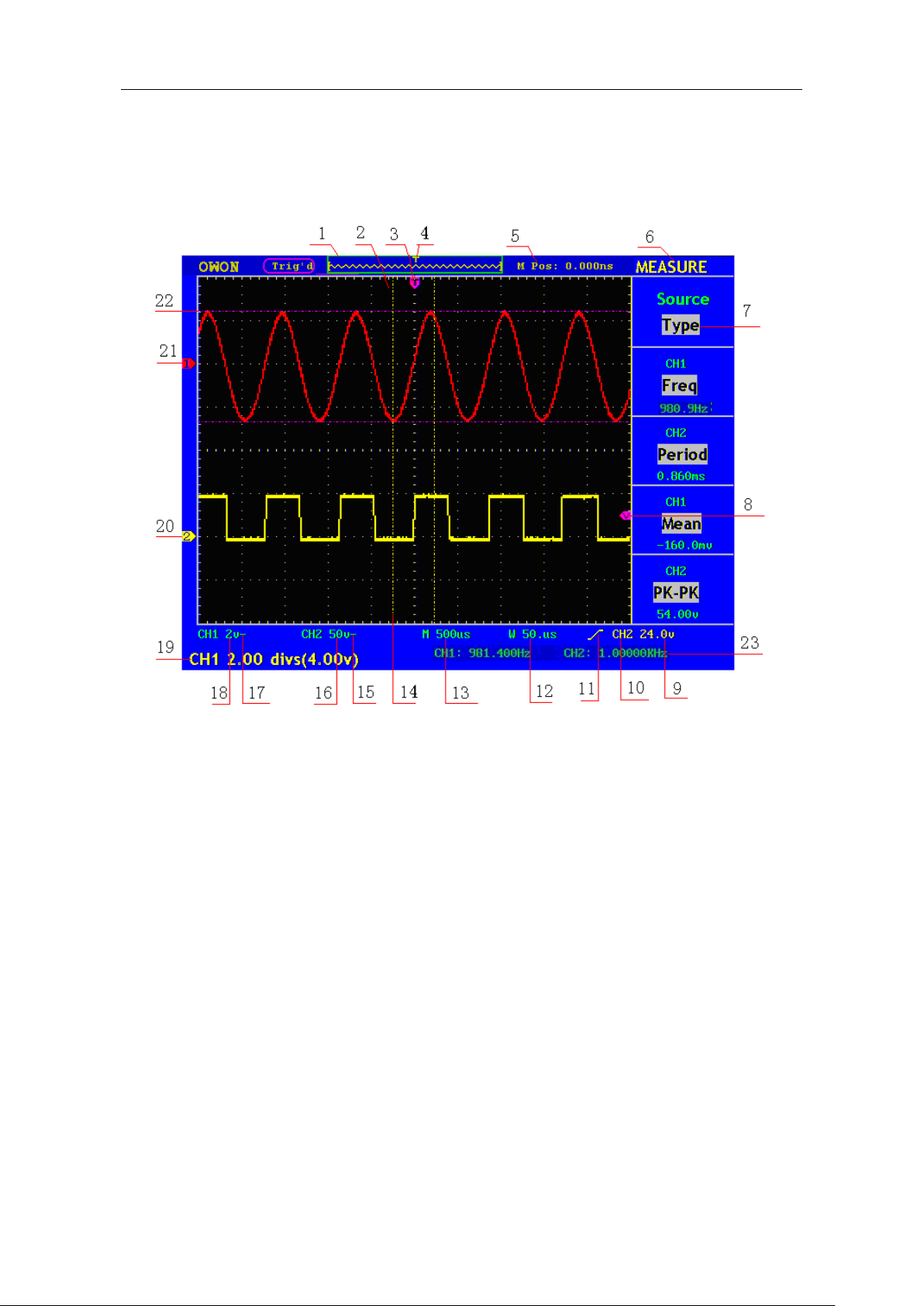

Fig. 4-3 Illustrative Drawing of Display Interfaces

1. The Trigger State indicates the following information:

Auto: The oscilloscope is under the Automatic mode and is collecting the

waveform under the non-trigger state.

Trig' d: The oscilloscope has already detected a trigger s ignal and is collectin g

the after-triggering information.

Ready: All pre-triggered data have been capt ured and the oscill oscope has been

already ready for accepting a trigger.

Scan: The oscilloscope captures and displays the waveform data continuously in

the scan mode.

Stop: The oscilloscope has already stopped the waveform data acquisition.

2. Waveform Viewing Area.

3. The purple pointer indicates the horizontal trigger position, which can be adjusted

by the horizontal position control knob.

4. The pointer indicates the trigger position in the internal memory.

10

5. This reading shows the ti me deviation between th e horizontal trigger positi on and

the window center line, which is regarded as 0 in the window center.

6. It indicates the current function menu.

7. It indicates the operation options for the current function menu, which changes

with the function menus.

8. The purple pointer shows the trigger level position.

9. The reading shows the trigger level value.

10. The reading shows the trigger source.

11. It shows the selected trigger type:

Rising edge triggering

Falling edge triggering

Video line synchronous triggering

Video field synchronous triggering

12. The reading shows the window time base set value.

13. The reading shows the main time base set value.

14. The two yellow dotted lines indicate the size of the viewing expanded window.

15. The icon shows the coupling mode of the CH2 channel.

"—" indicates the direct current coupling

" ~" indicates the AC coupling

" " indicates GND coupling.

16. The reading shows the vertical scale factor (the Voltage Division) of the CH2

channel.

17. The icon indicates the coupling mode of the CH1 channel:

The icon "–" indicates the direct current coupling

The icon "~" indicates the AC coupling

The icon " " indicates GND coupling.

18. The reading indicates the vertical scale factor (the Voltage Division) of the CH1

channel.

19. The information shows the zero point positions of CH1 or CH2 channel.

20. The yellow pointer shows the grounding datum point (zero point position) of the

waveform of the CH2 channel. If the pointer is not displayed, it shows that this

channel is not opened.

21. The red pointer indicates the grounding datum point (zero point position) of the

11

waveform of the CH1 channel. If the pointer is not displayed, it shows that the

channel is not opened.

22. The positions of two purple dotted line cursors measurements.

23. The reading shows the frequency of the two channels. It is a 6 digits cymometer.

Its measurement range of frequency is 2Hz to full bandwidth. When the

triggering mode is edge t riggering, it is a one channel cymometer and it can only

measure the frequency of the triggering channel. When the triggering mode is

alternating triggering, it is a two channel cymometer and it can measure the

frequency of two channels.

How to implement the General Inspection

After you get a new MSO series oscilloscope, it is recommended that you should

make a check on the instrument according to the following steps:

1. Check whether there is any damage caused by transportation.

If it is found that the packaging carton or the foamed plastic protection cushion has

suffered serious damage, do not throw it away first till the complete device and its

accessories succeed in the electrical and mechanical property tests.

2. Check the Accessories

The supplied access ories have been al r eady described in t he "Appendix A: Enclosure"

of this Manual. You can check wh ether ther e is any loss of accesso ries wi th referenc e

to this description. If it is found that there is any accessory lost or damaged, please get

in touch with the distributor of LILLIPUT responsible for this service or the

LILLIPUT's local offices.

3. Check the Complete Instrument

If it is found that there is damage to the appearance of the instrument, or the

instrument can not work normally, or fails in the performance test, please get in touch

with the LILLIPUT's distributor responsible for this business or the LILLIPUT's local

offices. If there i s damage t o the inst rument caus ed by the tran sportati on, pleas e keep

the package. With the transportation department or the LILLIPUT's distributor

responsible for this business informed about it, a repairing or replacement of the

instrument will be arranged by the LILLIPUT.

How to implement the Function Inspection

Make a fast function check to verify the normal operation of the instrument, according

to the following steps:

1. Connect the Instrument to the Power and Push down the Power Switch Button.

The instrument carries out all self-check items and shows the prompt "Press any Key

Enter system". Press th e "8 (UTILITY)" button to get access to the "FUNCTION"

menu and push down F2 the menu selection button to call out the function "Recall

Factory". The default attenuation coefficient set value of the probe in the menu is

12

10X,

2. Set the Switch in the Oscilloscope Probe as 10X and Connect the Oscilloscope

with CH1 Channel.

Align the slot in the probe with the plug in the CH1 connector BNC, and then tighten

the probe with rotating it to the right side.

Connect the probe tip and the ground clamp to the connector of the probe

compensator.

3. Press the "7(AUTOSET)" Button.

The square wave of 1 KHz frequency and 5V peak-peak value will be displayed in

several seconds (see Fig. 4-4).

Fig.4-4 Auto set

Check CH2 by repeating Step 2 and Step 3.

How to Implement the Probe Compensation

When connect the probe with any input channel for the first time, make this

adjustment to match the probe with the input channel. The probe which is not

compensated or presents a compensation deviation will result in the measuring er ror

or mistake. For adjusting the probe compensation, please carry out the following

steps:

1. Set the attenuation coefficient of the probe in the menu as 10X and that of the

switch in the probe as 10X, and connect the oscilloscope probe with the CH1

channel. If a probe hook tip is used, ensure that it keeps in close touch with the

probe. Connect the probe tip with the signal connector of the probe compensator

and connect the reference wire clamp with the ground wire connector of the

probe connector, and then press the button "7(AUTOSET)".

2. Check the displayed wave forms and regulate the probe till a correct

compensation is achieved (see Fig.4-5 and Fig.4-6).

13

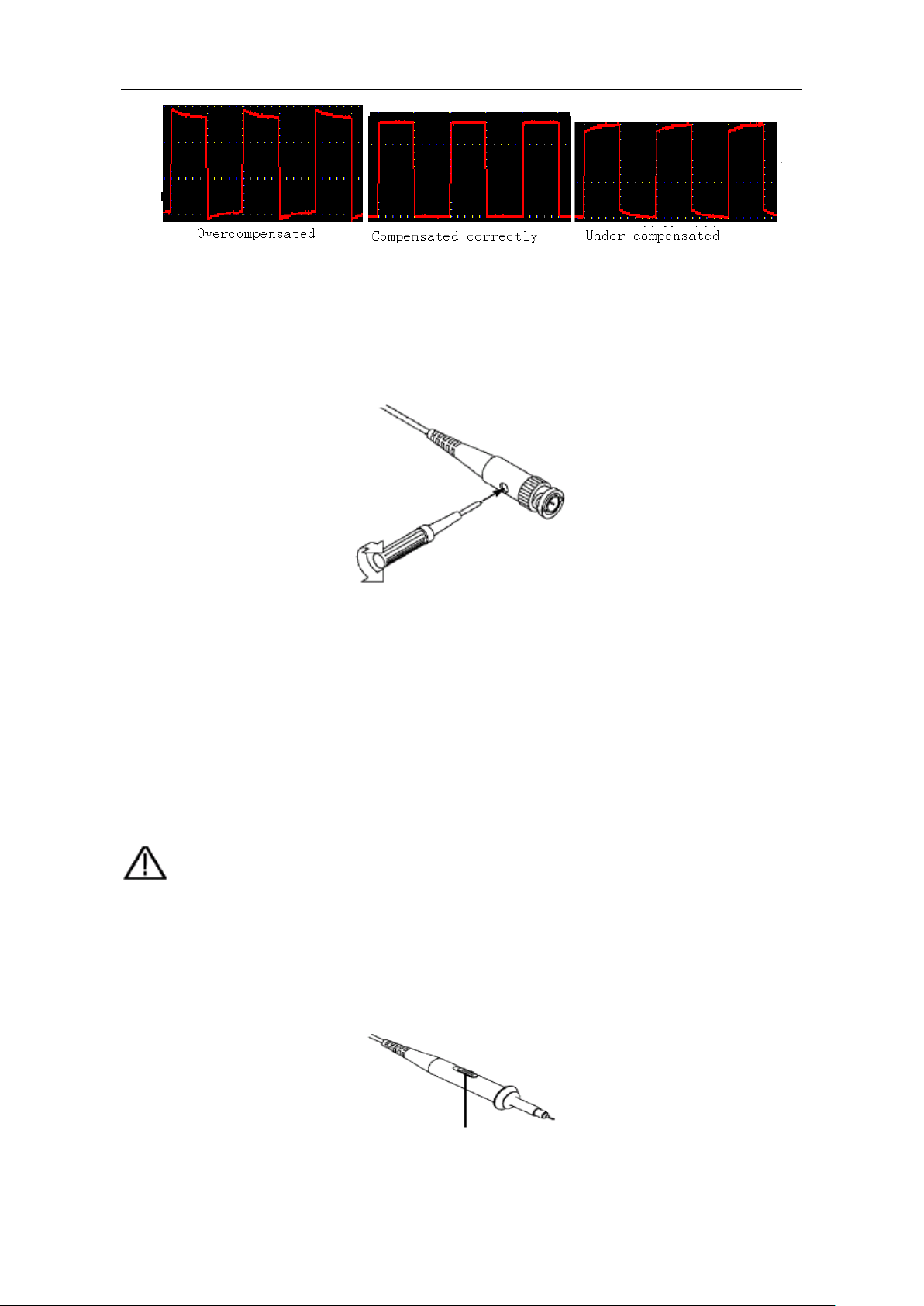

Fig. 4-5 Displayed Wave Forms of the Probe Compensation

3. Repeat the steps mentioned if necessary.

Fig. 4-6 Adjust Probe

How to Set the Probe Att enuation Coefficient

The probe has sev eral att enuation coefficien ts, which wi ll influence t he verti cal scale

factor of the oscilloscope.

If it is required to change (check) the set value of the probe attenuation coeffici ent,

press the function menu button of the channels used, then push down the selection

button corresponding to the probe till the correct set value is shown.

This setting will be valid all the time before it is changed again.

Note: The attenuation coefficient of the probe in the menu is preset to 10X when

the oscilloscope is delivered from the factory.

Make sure that the set value of the attenuation s witch in the probe is the same as the

menu selection of the probe in the oscilloscope.

The set values of the probe switch are 1X and 10X (see Fig. 4-7).

Fig.4-7 Attenuation Switch

14

Note: When the attenuation switch is set to 1X, the probe will limit the bandwidth

of the oscilloscope in 5MHz. If it is needed to use the whole bandwidth of the

oscilloscope, the switch must be set to 10X.

How to Use the Probe Safely

The safety guard ring around the probe body protects your finger against the electric

shock, shown as Fig. 4-8.

Fig. 4-8 Finger Guard

Warning: In order to avoid suffering from the electric shock, please keep your

finger behind the safety guard ring of the probe body during the operation.

In order to protect you from suffering from the electric shock during your using the

probe, do not touch the metal part of the probe tip when the probe is connected to

the power supply.

Before making any measurements, please connect the probe to the instrument and connect the

ground terminal to the earth.

How to Implement Auto-calibration

The auto-calibration application can make the oscilloscope reach the optimum

condition rapidly to obtain the most accurate measurement value. You can carry out

this application program at any time, but when the range of variation of the ambient

temperature is up to or over 5℃, this program must be executed.

For the performing of the self-calibration, all probes or wires should be disconnected

with the input connector first. Then, press the "8(UTILITY)" button to call out the

FUNCTION menu; push down the F3 menu sel ection button to choose the option "

Do Self Cal"; finally, run the program after confirming that everything is ready now.

Introduction to the Vertical System

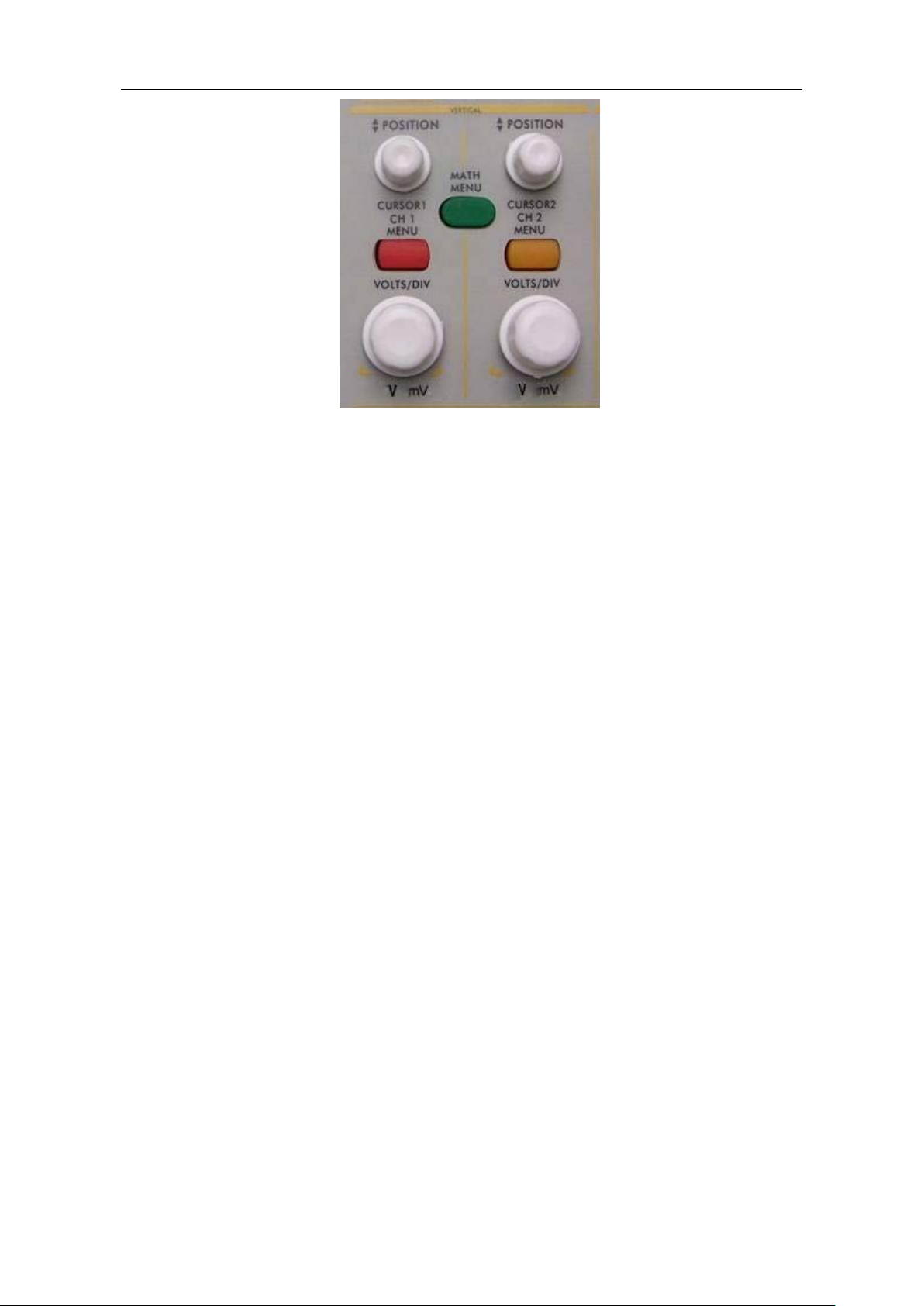

Shown as Fig.4-9, there are a series of buttons and knobs in VERTICAL

CONTROLS. The following practices will gradually direct you to be familiar with

the using of the vertical setting.

15

Fig. 4-9 Vertical Control Zone

1. Use the button "VERTICAL POSI TION" knob to show the signal in the center

of the waveform window. The "VERTICAL POSITION" knob functions the

regulating of the vertical display position of the signal. Thus, when the

"VERTICAL POSITION" knob is rotated, the pointer of the earth datum point

of the channel is directed to move up and down following the wave form.

Measuring Skill

If the channel is under the DC coupling mode, you can rapidly measure the DC

component of the signal through the observation of the difference between the wave

form and the signal ground.

If the channel is under the AC mode, the DC component will be removed by filtration.

This mode helps you display the AC component of the signal with a higher

sensitivity.

2. Change the Vertical Setting and Observe the Consequent State Information

Change.

With the information displayed in the status bar at the bottom of the waveform

window, you can determine any changes in the channel vertical scale factor.

Rotate the vertical "VOLTS/DIV" knob and change the "Vertical Scale Factor

(Voltage Division)", it can be found that the scale factor of the channel

corresponding to the status bar has been changed accordingly.

Press buttons of "CH1 MENU", "CH2 MENU" and "MATH MENU", the

operation menu, symbols, wave forms and scale factor status information of the

corresponding channel will be displayed in the screen.

16

Introduction to the Horizontal System

Shown as Fig.4-10, there are a button and two knobs in the "HORIZONTAL

CONTROLS". The following practices will gradually direct you to be familiar with

the setting of horizontal time base.

Fig. 4-10 Horizontal Control Zone

1. Use the horizontal "SEC/DIV" knob to change the horizontal time base setting

and observe the consequent status information change. Rotate the horizontal

"SEC/DIV" knob to change the horizontal time base, and it can be found that the

"Horizontal Time Base" display in the status bar changes accordingly. The

horizontal scanning speed steps from

2 ns up to 100s in the sequence of 1-2-5 ----- MSO7062TD,7102TD,8102T;

1 ns up to 100s in the sequence of 1-2-5 ----- MSO8202T.

2. Use t he "HORIZONTAL POSITION" knob to adjust the horizontal position of

the signal in the waveform window. The "HORIZONTAL POSITION" knob is

used to control the triggering displacement of the signal or for other special

applications. If it is applied to triggering the displacement, it can be observed that

the wave form moves horizontally with the knob when you rotate the

"Horizontal Position" knob.

3. With the "HORIZONTAL MENU" button pushed down, you can set and initiate

the Window Expansion.

Introduction to the Trigger System

Shown as Fig.4-11, there are a knob and four buttons in the "TRIGGER

CONTROLS". The following practices will dire ct you to be familiar with the setting

of the trigger system gradually.

17

Fig.4-11 Trigger Control Zone

1. Press the "TRIG MENU" button and call out the trigger menu. With the

operations of the 5 menu selection buttons, the trigger setting can be changed.

2. Use the "LEVEL" knob to change the trigger level setting.

With the rotation of the "LEVEL" knob, it can found that the trigger indicator in

the screen will move up and down with the rotation of the knob. With the

movement of the trigger indicator, it can be observed that the trigger level value

displayed in the screen changes.

3. Press the button "SET TO 50%" to set the trigger level as the vertical midpoint

values of the amplitude of the trigger signal.

4. Press the "FORCE TRIG" button to force a trigger signal, which is mainly

applied to the "Normal" and "Single" trigger modes.

5. The "SET TO ZERO" button is used to reset the trigger horizontal position.

18

4.3 Logic Analyzer

LA input connection

Insert the plug of OL-16 LA module 50P into the LA signal input on front panel and fix

two screw. Then 16 channel clamp of OL-16 LA connect to target signal and ready for

measurement

User interface introduction

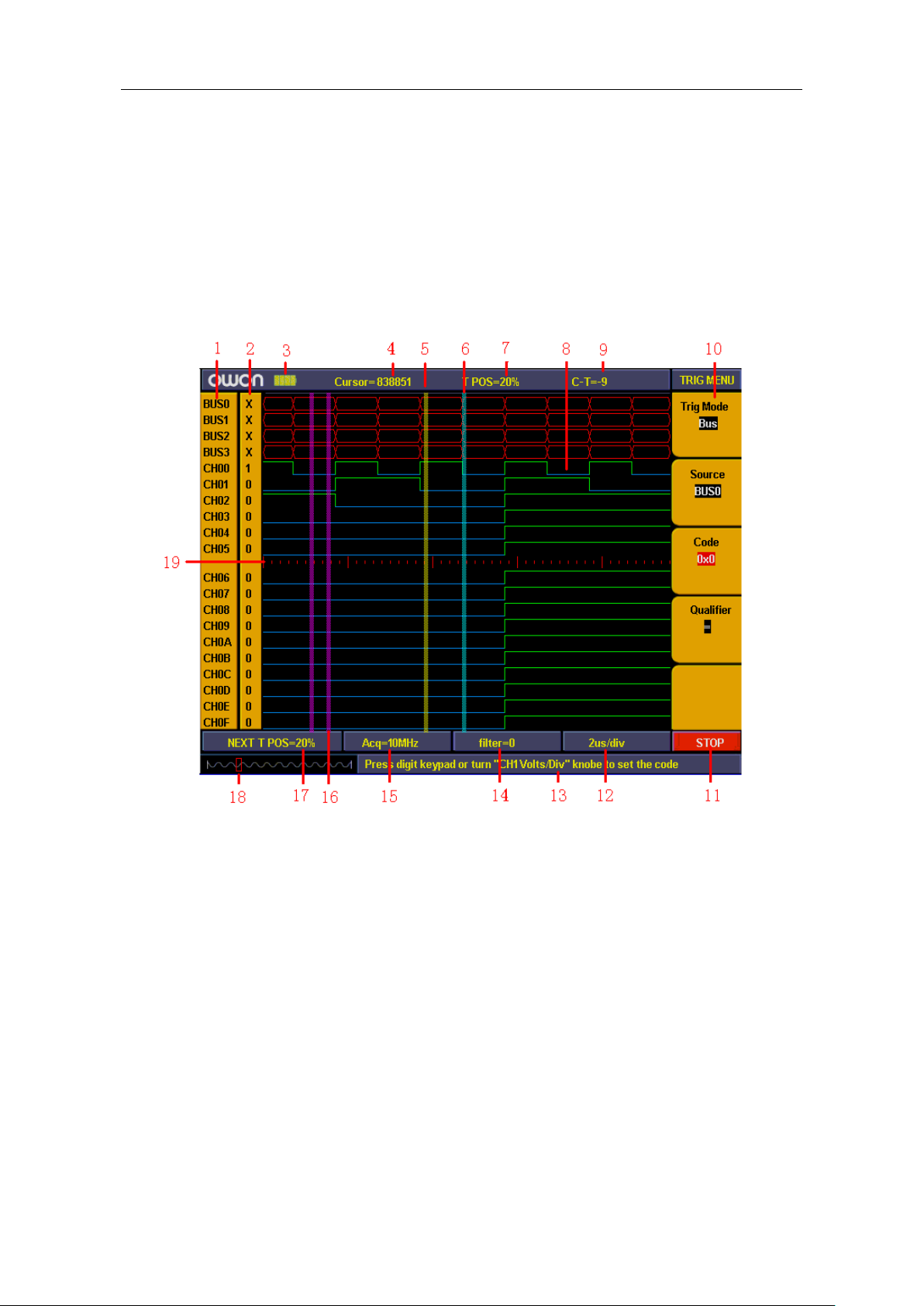

Fig.4-12:User interface of logic analyzer

1、Channel and Bus indicate: display current working channel and bus 。

2、Channel binary value display: display binary system value for the channel position in

current cursor 。

3、Battery powers indicate: indicate battery power when battery inside。

4、Decimal system value indicate the position of current cursor in storage area。

5、Yellow dashed line indicates current cursor。

6、Blue dashed line indicates current trigger position。

7、Percentage value indicate current trigger position in storage area。

8、Sample data area indication: red for bus, blue and green for "0", "1" i n each channel

data。

9、Decimal system value indicate the position of current cursor relate to current trigger。

10、Operation options indicate current function menu and different function menu have

different display。

11、Sample status indicate: "RUN" for sampling and wait for trigger, "TRIG" fo r trigger

19

detected and wait for sample finished. "STOP" for sampling finished。

12、Value indicate current time base。

13、Info windows: different operation display different info。

14、Value display current filter modulus setting。

15、Value display current sample rate setting。

16、Two purple lines for cursor 1 and cursor 2 in cursor measurement

17、Percentage value indicate trigger position for next sampling in storage area。

18、Red square indicate the current sampling data position in storage area。

19、Red scale line indicates the time base width in sampling data display area and totally

4.8 divisions. The width between two long scale lines is 1 division and between short

scale lines are 0.1 divisions。

How to acquire data

When you start to acquire LA begins sampling data from the probes. Then each time

clock occurs the data will be sampled.

Then sampled data is sent to trigger function block and store in main memory. The

trigger program checks specific events with the sampled data and take specific action. The

trigger program can check events as rising edge, data values, and data ranges etc. LA

module enables a post trigger delay counter when trigger reach specified value and to

allow post trigger portion of the acquisition memory to fill before data acquisition stops.

Press "F" to get into data acquisition mode after finish setting for trigger and

sampling. Then running status display as "RUN" and running status display "TRIG" when

detected trigger signal and display "STOP" when data acquisition finished. Then you can

start to analyze data. Data acquisition can be stopped by press "F" again during the

process.

Note:

When running status display as "RUN"、"TRIG" during data acquiring

process ,only "F" key fo r operat e and oth er keys or knob s are idl e. Only til l status

display as "STOP" then others operations are working.

How to observe and analyze the data

Follow up below steps to observe and analyze the current data acquired:

1. Turn "Sec/Div" knob to adjust the time length for data display in each division (to

adjust the data resolution displayed).

2. Turn "Cursor" knob to observe more details for the data of current cursor

position. The data of binary value for current cursor position display in binary

system area and power on measure menu then bus value for current cursor

position will display in measurement window.

3. Turn "horizontal positio n" knob can move the current displayed data to left/right

position in storage area quickly.

We will use a simple measurement example to explain the primary setting for LA

measurement.

We need to measure a three lines SPI signal, three signals are enable, clock and data.

Clock is in effect when enable is low clock data, and clock frequency is 1M, data width is

32 digits, every clock corresponds to one data. Signal voltage is 3.3V.

20

Display systems

We need only three channels as what we measure is 3 signals. And other channel and

bus can be off. In this way the display resolution in using channel will be increased.

Display system mainly to set on/off for measure channel. We use CH00、CH01、

CH02 as measure channel correspond to signal enable, clock, data accordingly. Other

channel and bus is off.

1、 Press "A(DISPLAY)" and display menu appears.

2、 Press "F1" till signal sources display as "Channel".

3、 Press "F2" or turn "CH1 Volts/Div" knob till channel No. display as "CH00".

4、 Press "F3" and set the signal sources as "ON". Repeat operation of steps 3.4 and

set CH01, CH02 as "ON" and CH03-CHOF as "OFF". Refer to Fig.4-13.

5、 Press "F1" till sources display as" BUS".

6、 Press "F2" till Bus No. display as"BUS0".

7、 Press "F3" and set signal sources as "OFF". Repeat operation of steps 6.7 and set

BUS1、BUS2、BUS3 all as "OFF". Ref to Fig.4-14.

Now the screen only show CH00、CH01、CH02 and others channel and bus are all off. Ref

to Fig.4-15

Fig.4-13

21

Fig.4-14

Fig. 4-15

Trigger system

LA is same as DSO and need to make trigger to synchronize data. The trigger system

mainly to set trigger sources, trigger mode and trigger position.

We make CH00 as trigger source and trigger mode as falling edge, trigger position in

50%. Trigger system setting steps as below:

1. Press "Trig menu" and menu appears.

2. Press "F1" till trigger mode display as "Edge".

3. Press "F2" or turn "CH1 Volts/Div" till trigger sources display as "CH00".

4. Press "F3" till trigger type display as "Falling".

5. Turn "Trigger adjust" knob or press "SET 50%"till "NEXT T POS" window

display as "50%"

Then trigger system setting finished (ref to Fig.4-16).

22

Threshold voltage system

Fig. 4-16

Threshold voltage system is to set high/low of the trigger voltage. The system already

fixed the setting for normal logic voltage as CMOS, LVMOS etc. And you can set any

trigger voltage using custom setting.

The signal voltage is 3.3V and we set threshold voltage as "LVCMO3.3/1.7V" as

below steps:

1. Press "1 (Threshold)" key and the menu appears.

2. Press "F1" key till Channel display as "CH00~CH03"

3. Press "F2" key till threshold display as "LVCMOS 3.3/1.7V".

Then the threshold setting is finished (ref to Fig.4-17).

Fig. 4-17

23

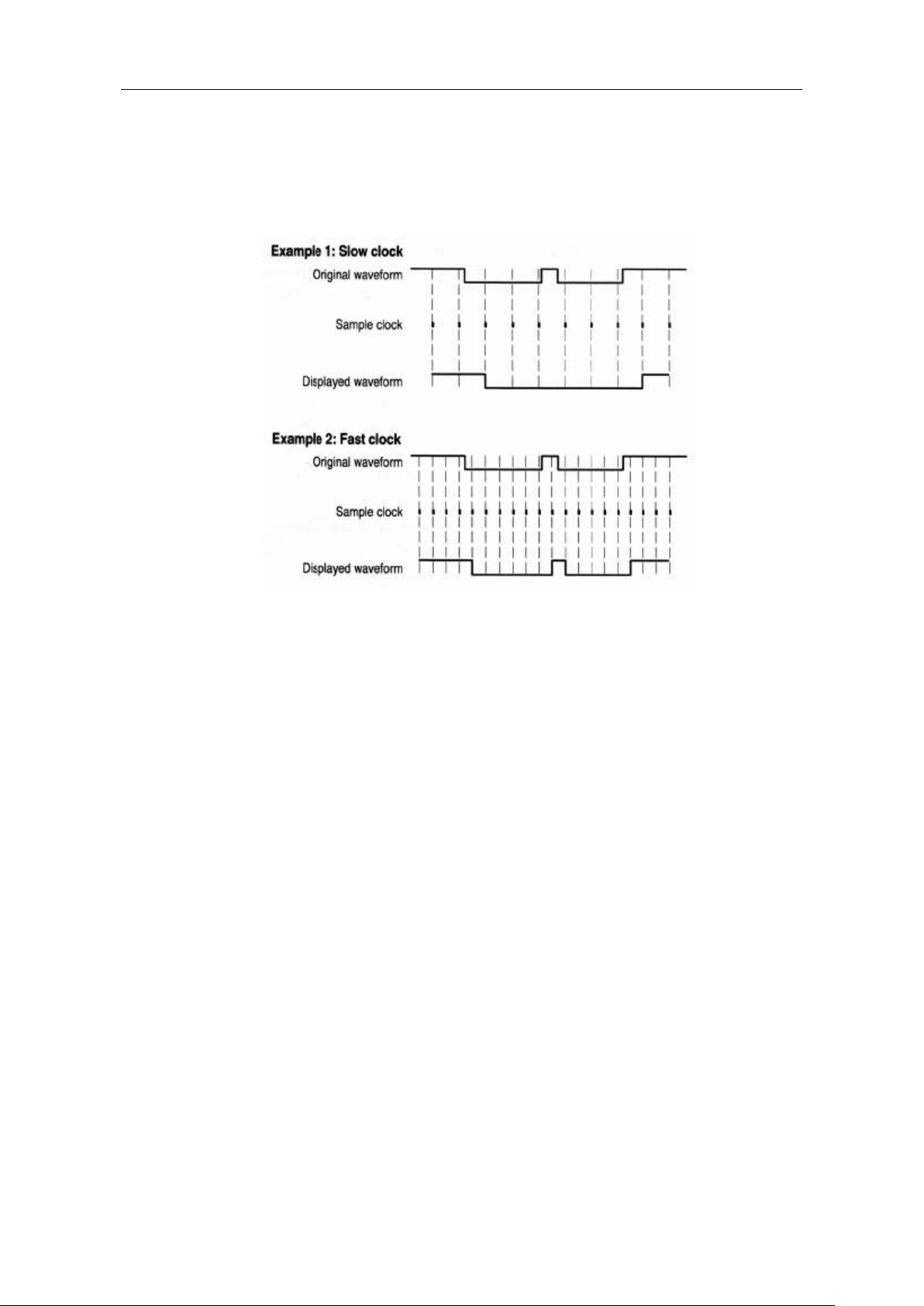

Sampling system

The waveform accuracy reverts from sample data depend on sample rate for

measured signals. The waveform reverted in LA is referring to the sample signals storage

in the memory. The recorded data will display in error if the sample rate is too lower.

Below figures explains how sample rate influence the waveform recorded in LA.

Fig.4-18

There is an importance compromise between recorded signal resolution and its

continuance (relate to time). The sample memory depth of LA is fix ed and once adding

sample rate then resolution will get better accordingly. But it will decrease the

continuance for acquire signal. In a word, if the sample rate is quicker, the continuance for

recorded signal will get smaller but with better resolution.

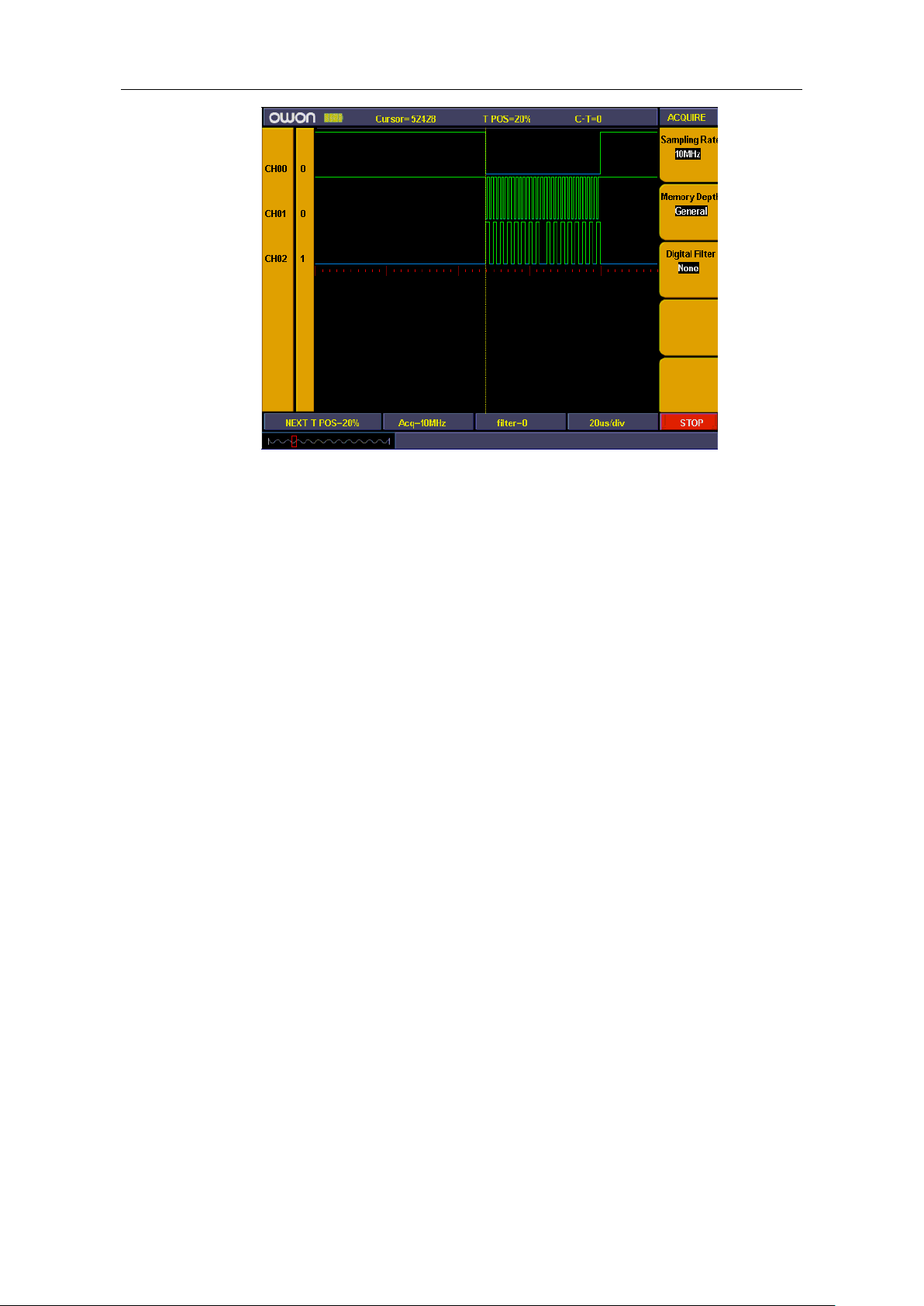

Sampling system can set difference sample rate and storage depth.

We use 10 times sampling rate to measure the signal clock frequency of 1M, and

storage depth set as "Normal". Sampling system setting steps as below:

1. Press "E(ACQUIRE)" and menu appears.

2. Press "F1" or turn "CH1 Volts/div" knob till sample rate setting display as"10M".

3. Press "F2" till storage depth display as "General".

Sampling system setting finished (ref to the fig.)

Then press "F" and start to sampling data. Display show as fig. 4-19 when sampling

finished.

24

Fig. 4-19

25

5. Advanced User Guidebook

Up till now, you have already been familiar with the initial operations of the

functions of the function areas, buttons and knobs in the front panel of the MSO series

oscilloscope. Based the introduction of the previous Chapter, the user should have an

intimate knowledge of the determination of the change of the oscilloscope setting through

observing the status bar. If you have not been familiar with the above-mentioned

operations and methods yet, we advise you to read the section of "Chapter One Junior

Users' Guidebook".

This chapter will deal with the following topics mainly:

Digital Storage Oscilloscope

How to Set the Vertical System

How to Set the Horizontal System

How to Set the Trigger System

How to Implement the Sampling Setup

How to Set the Display System

How to Save and Recall Wave Form

How to Implement the Auxiliary System Function Setting

How to Implement the Automatic Measurement

How to Implement the Cursor Measurement

How to Use Autoscale function

How to Use Executive Buttons

Logic analyze r

How to set sampling system

How to set trigger system

How to set threshold

How to set display system

How to set BUS

How to measure

How to save and recall

How to use USB Mass storage device to storage

How to search

How to review setting info

How to use cursor measurement

26

Function Menu

Setting

Description

AC

GROUND

Block the DC component from input signal.

Pass both AC and DC components from

OFF 100MHz

Get full bandwidth.

Limits the channel bandwidth to 20MHz to

reduce display noise.

OFF

ON

Close the measurement channel.

Open the measuring channel.

1X

1000X

Choose one according to the probe

OFF

ON

Display original waveform.

Display inverted waveform.

How to set Utility

It is recommended that you read this chapt er carefully to get acquainted the various

measurement functions and other operation methods of the MSO series oscilloscope.

5.1 Digital Storage Oscilloscope

How to Set the Vertical System

The VERTICAL CONTROLS includes three menu buttons such as CH1 MENU,

CH2 MENU and MATH MENU, and four knobs such as VERTICA POSITION,

VOLTS/DIV (one group for each of the two channels).

Setting of CH1 and CH2

Every channel has an independent vertical menu and each item is set respectively

based on the channel.

With the "CH1 MENU" or "CH2 MENU" menu button pushed down, the system

shows the operation menu of the corresponding channel (see Fig. 5-1). By pressing

F1,F2,F3,F4 etc., you can change and select the settings. The following table explains

more details of these function and settings.

Fig.5-1

Channel

Setting

Menu

Band Limit

Coupling

Channel

Probe

Inverted

DC

ON 20MHz

10X

100X

input signal.

Input signal is interrupted.

attenuation factor to make the vertical scale

reading accurate.

1. Setting Coupling for selected Channel

A square waveform is used as an input in this example.

Press the CH1 MENU button to show submenu CH1 SETUP.

Press F1 next to Coupling and select "AC", now DC component is blocked

27

from input signal. See Fig.5-2.

Press F1 again to set "DC" mode, both AC and DC components get passed.

See Fig.5-3.

The wave forms are shown as Fig.5-2 and Fig.5-3.

Fig. 5-2 AC Coupling Oscillogram

Fig. 5-3 DC Coupling Oscillogram

2. Setting the "Band Limit"

Taking the Channel 1 for example, the operation steps are shown as below:

(1). Press the CH1 MENU button and call out the CH1 SETUP menu.

(2). Press the F2 menu selection button and select the Band Limit as OFF

100MHz, with Channel 1 Band Limit switched off.

(3). Press F2 menu selection button again, select the Band Limit as ON 20MHz,

with Channel 1 Band Limit is switched on.

3. Setting the Channel "ON/OFF"

28

Taking the Channel 1 for example, the operation steps are shown as below:

(1). Press the CH1 MENU button and call out the CH1 SETUP menu.

(2). Press the F3 menu selection button and select the Channel as OFF, with

Channel 1 switched off.

(3). Press F3 menu selection button again, select the channel as ON, with

Channel 1 is switched on.

Note: In FFT mode, both CH1 and CH2 are not allowed to be ON when F3 is

pressed. See Fig.5-4.

Fig. 5-4 Channel CH1 is disable under FFT mode

4. Regulate the Attenuation Ratio of the Probe

In order to match the attenuation coefficient of the probe, it is required to adjust

the attenuation ration coefficient of the probe through the operating menu of the

Channel accordingly. If the attenuation coefficient of the probe is 1:1, that of the

oscilloscope input channel should also be set to 1X to avoid an y errors presented

in the displayed scale factor information and the measured data.

Take the Channel 1 as an exam pl e, t he at ten u at io n coefficient of th e prob e is 10:1,

the operation steps is shown as follows:

(1). Press the CH1 MENU button, access CH1 SETUP menu.

(2). Press the F4 menu selection button and select 10X for the probe.

The Fig.24 illustrates the setting and the vertical scale factor when the probe of

the attenuation coefficient of 10:1.is used.

29

Attenuation Coefficient of the Probe

Corresponding Menu Setting

1:1

1X

10:1

10X

100:1

100X

1000:1

1000X

Fig. 5-5 Regulation of the Attenuation Ratio of the Probe

A List of the Attenuation Coefficient of Probes and the Corresponding Menu Settings:

5. Setting of Wave Form Inverted

Wave form inverted: the displayed signal is turned 180 degrees against the phase

of the earth potential.

Taking the Channel 1 for example, the operation steps are shown as follows:

(1). Press the CH1 MENU button and get access to the CH1 SETUP menu.

(2). Press the F5 menu selection button and select ON in the Inverted. The wave

form inverted function is initiated.

(3). Press the F5 menu selection button again and select OFF for Inverted item.

The function of wave form inverted is closed off.

For the screen display, see Fig. 5-6 and Fig. 5-7

Fig. 5-6 Wave Form not inverted Fig. 5-7 Wave Form I nvert ed

30

Setting

Description

CH1-CH2

Subtract the Channel 2 wave form from the Channel 1 wave form.

CH2-CH1

Subtract the Channel 1 wave form from the Channel 2 wave form.

CH1+CH2

Add the Channel 1 wave form to the Channel 2.

CH1*CH2

Multiply Channel 1 wave form by Channel 2 wave form.

CH1/CH2

Channel 1 wave form is divided by the Channel 2 wave form.

FFT

Waveform of Corresponding FFT operation.

Implementation of Mathematical Manipulation Function

The Mathematical Manipulation function is used to show the results of the

additive,multiplication, division and subtraction operations between Cha nnel 1 and

Channel 2, and the FFT operation of CH1 or CH2 .

The corresponding FCL (Functional Capabilities List) of the Wave Form

Calculation

Taking the additive operation between Channel 1 and Channels 2 for example, the

operation steps are as follows:

1. Press the MATH MENU button and call out the WAVE MATH menu.

2. Press the F3 menu selection button and choose CH1+CH2. The green calculated

wave form M is displayed in the screen; press the F3 menu selection butt on again,

the wave form M is closed off (see Fig.5-8).

Fig. 5-8 Wave Form resulted from CH1 +CH2 Mathematical Manipulation

Using FFT function

An FFT breaks down signals into component frequencies, which the oscilloscope uses

to display a graph of the frequency domain of a signal, as opposed to the osci lloscope's

standard time domain graph. You can match these frequencies with known system

frequencies, such as system clocks, oscillators, or power supplies.

FFT in this oscilloscope can transform 2048 points of the time-domain signal into its

frequency components and the final frequency contains 1024 points ranging from 0Hz to

Nyquist frequency .

The following table describes the FFT menu:

31

Function Menu Setting Instruction

FFT

Source

Window

Format

Zoom

ON

OFF

CH1

CH2

Rectangle

Blackman

Hanning

Hamming

dB

Vrms

*1

*2

*5

Turn on FFT function.

Turn off FFT function.

DO FFT on Channel l

DO FFT on Channel 2

Type of window for FFT.

Display in dB

Display in Vrms

multiple *1

multiple *2

multiple *5

*10

multiple *10

Taking the FFT operation for example, the operation steps are as follows:

1. Press F1 once to turn on FFT, Press again to turn it off. Be aware that only to use FFT

when Horizontal Menu is set for main Timebase Not on Window setting mode. Again,

the green waveform is displayed as a result of FFT.

2. Press F2 to switch the FFT between CH1 and CH2.

3. Press F3 to choose WINDOW for FFT, there are four options here, including

Rectangle、Hamming、Hanning and Blackman. We will give details of these options

later.

4. Press F4 to switch between dB and Vrms.

5. Press F5 to zoom in/out, options including multiplied *1, *2, *5, *10.

6. Adjust the "Horizontal" knob in horizontal control zone to move the waveform and

the shown frequency of M Pos is the exact frequency of the cursor point i n the middle

of spectrum.

7. Press F1 to turn off FFT and then press math menu to go back to WAVE MATH

menu.

Selecting an FFT Window

■ The FFT feature provides four windows. Each one is a trade-off between frequenc y

resolution and magnitude accuracy. What you want to measure and your source signal

characteristics hel p you to determine which window to use. Use the following guidelines

32

to select the best window.

Type

Description

Window

This is the best type of window for resolving

repetitive signals

ectangle for measuring transients or bursts

nearly equal. Also, use this window for

This is a very good window for resolving

Use Hamming for measuring sine, periodic and

This is a very good window for measuring

amplitude accuracy but less so for resolving

Use Hanning for measuring sine, periodic, and

This is the best window for measuring the

amplitude of frequencies but worst at resolving

requency waveforms to look for higher

frequencies that are very close to the same value

but worst for accurately measuring the amplitude of

those frequencies. It is the best type for measu ring

the frequency spectrum of nonand measuring frequency components near DC.

Rectangle

Use r

where the signal level be fore and after t he ev ent a re

equal-amplitude sine waves with frequencies that

are very close and for broadband random noise with

a relatively slow varying spectrum.

frequencies that are very close to the same value

with somewhat improved amplitude accuracy over

the rectangle window. It has a slightly better

Hamming

frequency resolution than the Hanning.

narrow band random noise. This window works on

transients or bursts where the signal levels before

and after the event are significantly different.

frequencies.

Hanning

narrow band random noise. This window works on

transients or bursts where the signal levels before

and after the event are significantly different.

frequencies.

Blackman

Use Blackman-Harris for measuring predominantl y

single f

Fig.5-9, 5-10, 5-11, 5-12 show four kinds of window function refer ring to sine wave of

1KHz.

order harmonics.

33

Fig.5-9. Blackman window

Fig.5-10 Hamming window

Fig.5-11. Rectangle window

34

Fig.5-12 Hanning window

Quick Tips

If desired, use the zoom feature to magnify the FFT waveform.

Us e the defau lt dBV RM S scale t o see a det ailed view of mul tiple freq uencies , even if

they have very different amplitudes. Use the linear RMS scale to see an overall view

of how all frequencies compare to each other.

Signals that have a DC component or offset can cause incorrect FFT waveform

component magnitude values. To minimize the DC component, choose AC Coupling

on the source signal.

To reduce random noise and aliased components in repetitive or single-shot events, set

the oscilloscope acquisition mode to average.

Term interpretation

Nyquist frequency: The highest frequenc y that any Real Time Digital Oscilloscope can

measure is exactl y half of the sampling rate und er the condition of no mistakes, wh ich is

called Nyquist frequency. If under-sampling occurs when the frequency sampled is higher

than Nyquist frequency, "False Wave" phenomenon wil l appear. So pay more attention to

the relation between the frequency being sampled and measured.

NOTE:

While FFT mode is turned on, DO NOT USE THESE SETTINGS:

1) Horizontal window setting.

2) Change source channel in CH1/CH2 Setup menu

3) Turn on XY Format

4) Trigger control "SET 50%"

5) Auto-scale function

.

35

Application of VERTICAL POSITION and VOLTS/DIV Knobs

1. The . VERTIVAL POSITION knob is used to adjust the vertical positions of the

wave forms of all Channels (including those resulted from the mathematical

operation).

The analytic resolution of this control knob changes with the vertical division.

2. The VOLTS/DIV knob is used to regulate the vertical resolution of the wave

forms of all channels (including those obtained from the mathematical

manipulation), which can determine the sensitivity of the vertical division with

the sequence of 1-2-5. The vertical sensitivity goes up when the knob is rotated

clockwise and goes down when the knob is rotated anticlockwise.

3. When the vertical position of the channel wave form is adjusted, the screen shows

the information concerning the vertical position at the lower left corner (see

Fig.5-13).

Fig. 5-13 Information about Vertical Position

How to Set the Horizontal system

The HORIZONTAL CONT ROLS includes the HORIZONTAL MENU button and

such knobs as HORIZONTAL POSITION and SEC/DIV.

1. HORIZONTAL POSITION knob: this knob is used to adjust the horizontal

positions of all channels (include those obtained from the mathematical

manipulation), the analytic resolution of which changes with the time base.

2. SEC/DIV knob: it is used to set the horizontal scale factor for settin g the main

time base or the window.

3. HORIZONTAL MENU button: Press this button to active TIME MODE shown

as below with description of each function (see Fig. 5-14).

36

Function Menu

Setting

Description

The setting of the horizontal main time

base is used to display the wave form.

A window area is defined by two

cursors.

The defined window area for display is

expanded to the full screen.

Main Time Base

Set Window

Zone Window

Fig. 5-14 Time Mode

Main Tim e Base

Press the F1 menu selection button and choose the Ma in Time Ba se. In this case, the

HORIZONTAL POSITION and SEC/DIV knobs are used to adjust the main

window. The display in the screen is shown as Fig.5-15

Set Window

Press the F2 menu selection button and choose Set Window. The screen will show a

window area defined by two cursors. In this case, the HORIZONTAL POSITION

and SEC/DIV knobs can be used to adjust the horizontal position and size of this

window area. Press F2 menu button under the FFT mode ,it will notice "FFT mode

disable". See Fig.5-16.

Fig. 5-15 Main Time Base

37

Fig. 5-16 Window Setting

Fig..5-17 Set Window disable under FFT mode

Zone Window

Press the F3 menu selection button and choose Zone Window. As a result, the

window area defined by two cursors will be expanded to the full screen size (see Fig.

5-18).

38

Fig. 5-18 Zone Window

How to set trigger system

When the oscilloscope begins to collect the data and display the wave form depends

on a trigger. Once it is set correctly, the trigger can transfer the unstable display into a

meaningful wave form.

When beginning to collect data, the oscilloscope will collect adequate data to draw the

wave form at the left side of the trigger point at first. It will continuously perform the

data acquisition while waiting for the trigger condition. After a trigger is detected, the

oscilloscope will continuously collect data enough to draw the wave form at the right

side of the trigger point.

One knob and four function menu buttons are included in the trigger control zone.

TRIG LEVEL: Trigger the level control knob and set the signal voltage

corresponding to the trigger point.

SET TO 50%: Set the trigger level as t he vertical midpoint value of the amplitude of

the trigger signal.

FORCE TRIG: It is a force trigger button for the generation of a trigger signal,

which is mainly used in the "Normal" and "Single" triggering modes.

SET TO ZERO: Trigger the resetting of the horizontal position.

TRIG MENU: It is a trigger menu button. When it is pressed, an operation menu

will be presented in the screen.

Trigger Control

The oscilloscope provides two trigger types: single trigger and alternate trigger. Press

F1 to choose.

Single trigger: Use a trigger level to capture stable waveforms in two channels

simultaneously

Alternate trigger: Trigger on non-synchronized signals.

39

MENU

SETTING

INSTRUCTION

CH1

AC LINE

Channel 1 as the trigger source.

AC Line as resource trigger signal.

Mode

Edge

Set vertical channel trigger type for edge trigger.

Rising

Falling

Trigger on the rising edge.

Trigger on the falling edge.

Auto

Acquire data and display waveform with or without a trigger.

and stop sampling.

The Single Trigger and Alternate Trigger menus are described respectively as follows:

Single trigger

Single trigger has four modes: edge trigger, video trigger, pulse trigger and slope trigger .

Edge Trigger: It happens when the trigger input passes through a given level along the set

direction.

Video Trigger: Carry out field or line video trigger on the standard video signal.

Pulse Trigger : Use this trigger type to catch pulses with certain pulse width..

Slope Trigger : The oscilloscope begins to trigger according to the signal rising or falling

speed.

The four trigger modes in Single Trigger are described respectively as follows:

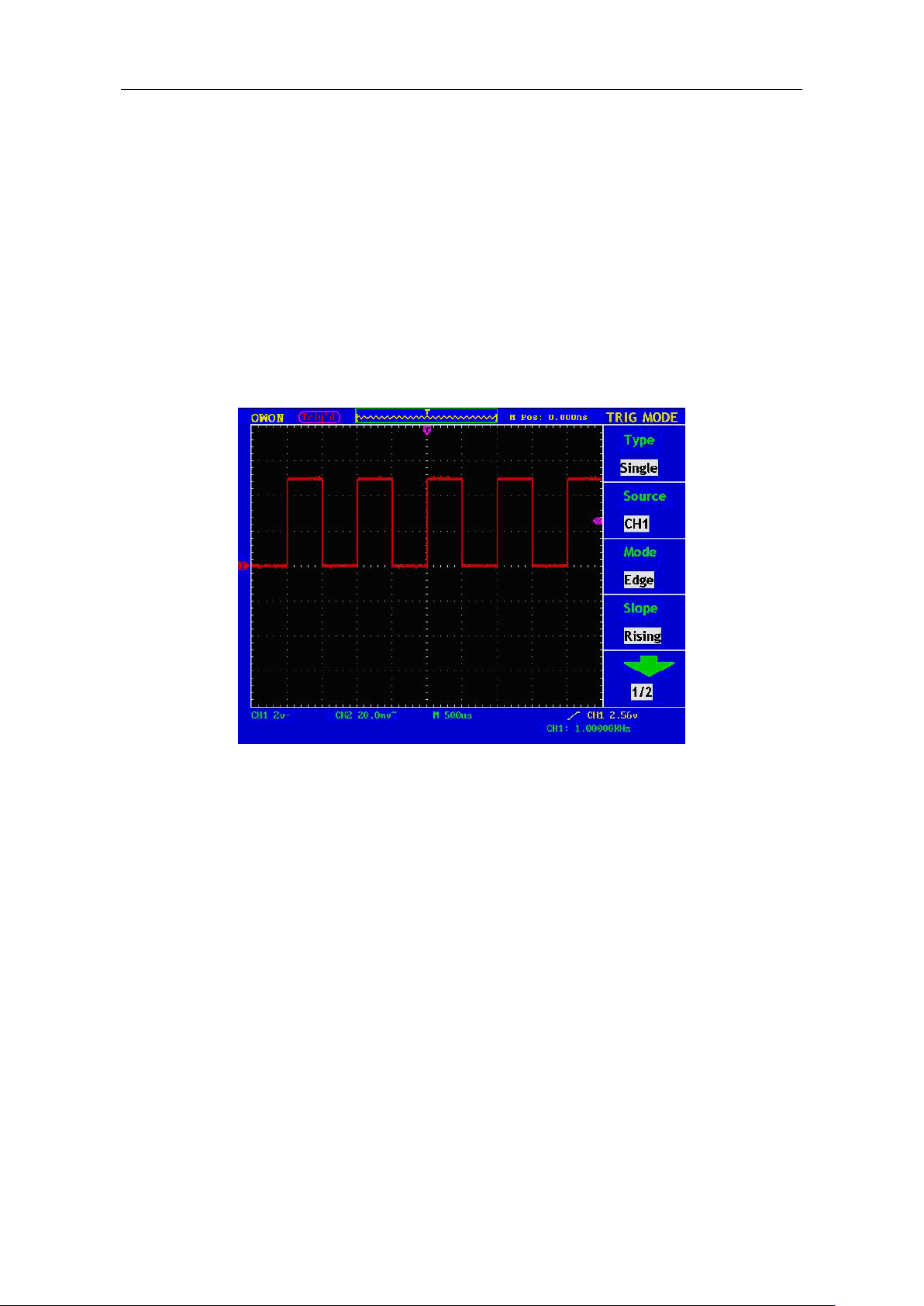

Edge Trigger

Under the Edge Trigger mode, a trigger happens in the trigger threshold value of the

input signal edge. When the Edge Trigger is selected, a trigger will occur in the

rising or falling edge of the input signal.

The Edge Trigger Menu is shown as Fig.5-19

Fig. 5-19 Edge trigger menu

Edge menu list:

Source

CH2

EXT

EXT/5

Channel 2 as the trigger source.

Use external source.

1/5 of the External Trigger Source for increasing range of level.

Slope

Trigger

mode

Normal

Single

Acquire data and display waveform when trigger.

Acquire data and display waveform when detecting a trigger

40

AC

Block the direct current component.

frequency signal and only unblock the

y unblock the high

-frequency component.

100ns

10s

Set interval by using TRIG LEVEL control, value range from

100ns~10s.

Holdoff

Reset

MENU

SETTING

INSTRUCTION

CH1

EXT/5

Channel 1 as the trigger source.

1/5 of the External Trigger Source for increasing range of level.

Mode

Video

Designed Line

Trigger the time base on the line of input video signal.

Trigger the time base on chosen line of input video signal.

NTSC

PAL/SECAM

Set interval by using TRIG LEVEL control, value range from

100ns~10s.

Holdoff

Reset

Coupling

Holdoff

DC

HF

LF

Unblock all components.

Block the highlow-frequency component.

Block the low-frequency signal and onl

~

Reset hold time to 100ns

Video Trigger

Choose video trigger to trigger on fields or lines of NTSC, PAL, or SECAM standard

video signals. Trig menu refer to Fig.5-20

Video menu list

Source

Sync

CH2

EXT

Line

Field

Odd Field

Even Field

Modulation

Holdoff 100ns~10s

Fig. 5-20 Video trigger menu

Channel 2 as the trigger source.

Use external source.

Trigger the time base on the field of input video signal..

Trigger the odd fields of input video signal.

Trigger the even fields of input video signal.

Format of video signal.

Reset hold time to 100ns

41

MENU

SETTING

INSTRUCTION

CH1

CH2

Channel 1 as the trigger source.

Channel 2 as the trigger source.

Mode

Pulse

(+pulse width less than )

Time setting

24ns~10s

Turn "TRIG LEVEL" knob to set time

Auto

Acquire waveform whatever detect

when detect trigger condition then stop

AC

Block the direct current component.

unblock the high -frequency component.

Set interval by using TRIG LEVEL

control, value range from 100ns~10s.

Holdoff

Reset

Pulse Width Trigger

Pulse trigger occurs according to the width of pulse. The abnormal signals can be detected

through setting up the pulse width condition.

The Pulse Width Trigger Menu is shown as Fig. 5-21.

Fig. 5-21 Pulse Width Trigger menu

Pulse Width T rigg er menu list

Source

when

Trigger

mode

Coupling

(+pulse width more than )

(+Pulse width equal to)

(-Pulse width less than)

(-Pulse width more than)

(-Pulse width equal to)

Normal

Single

DC

HF

LF

To select pulse width condition

trigger condition or not

Only acquire waveform when match

trigger condition

Only acquire waveform for single time

Unblock all components.

Block the high-frequency signal and only

unblock the low-frequency component.

Block the low-frequency signal and only

Holdoff 100ns~10s

Reset hold time to 100ns

42

MENU

SETTING

INSTRUCTION

CH1

CH2

Channel 1 as the trigger source.

Channel 2 as the trigger source.

Mode

Turn "TRIG LEVEL" knob to set slope time

High level

Turn "TRIG LEVEL" knob to set the High level

Turn "TRIG LEVEL" knob to set Low level

Slew rate

Slew rate=( High level- Low level)/ Settings

Auto

Acquire waveform whatever detect trigger condition or not

condition then stop.

100ns

10s

Set interval by using TRIG LEVEL control, value range from

100ns~10s.

Holdoff

Reset

Slope Trigger

Slope trigger sets the oscilloscope as the positive/negative slope trigger within the

specified time.

The Slope Trigger Menu is shown as Fig. 5-22.

Slope Trigger menu list

Source

Slope

When

Settings

Low level

Trigger

mode

24ns~10s

Normal

Single

Fig. 5-22 Slope Trigger menu

Set slope condition

Only acquire waveform when match trigger condition

Only acquire waveform for single time when detect trigger

Holdoff

~

Reset hold time to 100ns

Alternate trigger

Trigger signal comes from two vertical channels when alternate trigger is on. This

43

MENU

SETTING

INSTRUCTION

CH1

CH2

Channel 1 as the trigger source.

Channel 2 as the trigger source.

Mode

Edge

Set vertical channel trigger type for edge trigger.

Rising

Falling

Trigger on the rising edge.

Trigger on the falling edge.

AC

Block the direct current component.

frequency signal and only unblock the

frequency signal and only unblock the high

-frequency component.

Set interval by using TRIG LEVEL control, value range

from 100ns~10s.

Holdoff

Reset

mode is used to observe two unrelated signals. You can choose different trigger modes

for different channels. The options are as follows: edge, video, pulse or slope.

Alternate trigger(Trigger mode: Edge)

Alternate trigger(Trigger Type: Edge) Menu is shown as Fig.5-23.

Fig.5-23 Alternate trigger(Trigger Type: Edge) Menu

Alternate trigger(Trigger Type: Edge) Menu list:

Source

Slope

Coupling

DC

HF

LF

Unblock all components.

Block the highlow-frequency component.

Block the low-

Holdoff 100ns~10s

Reset hold time to 100ns

Alternate trigger(Trigger Mode: video)

Alternate trigger(Trigger Type: video) Menu is shown as Fig.5-24.

44

MENU

SETTING

INSTRUCTION

CH1

EXT/5

Channel 1 as the trigger source.

1/5 of the External Trigger Source for increasing range of level.

Mode

Video

Trigger the time base on the line of input video signal.

Trigger the time base on chosen line of input video signal.

NTSC

PAL/SECAM

Set interval by using TRIG LEVEL control, value range from

100ns~10s.

Holdoff

Reset

Fig.5-24 Alternate trigger(Trigger Type: video) Menu

Alternate trigger(Trigger Type: video) Menu list:

Source

Sync

Modulation

CH2

EXT

Line

Field

Odd Field

Even Field

Designed Line

Channel 2 as the trigger source.

Use external source.

Trigger the time base on the field of input video signal..

Trigger the odd fields of input video signal.

Trigger the even fields of input video signal.

Format of video signal.

Holdoff 100ns~10s

Reset hold time to default value (100ns).

Alternate trigger(Trigger Mode: Pulse)

Alternate trigger(Trigger Type: Pulse) Menu is shown as Fig.5-25.

Fig.5-25 Alternate trigger(Trigger Type: Pulse) Menu

45

MENU

SETTING

INSTRUCTION

CH1

CH2

Channel 1 as the trigger source.

Channel 2 as the trigger source.

Mode

Pulse

(+pulse width less than )

(-Pulse width equal to)

Turn "TRIG LEVEL" knob to set time

AC

Block the direct current component.

frequency signal and only

unblock the high -frequency component.

Set interval by using TRIG LEVEL

control, value range from 100ns~10s.

Holdoff

Reset

MENU

SETTING

INSTRUCTION

CH1

CH2

elect CH1 as the trigger source.

Select CH2 as the trigger source.

Mode

Slope

Slope

Rising Edge and more than.

Alternate trigger(Trigger Type: Pulse) menu list

Source

(+pulse width more than )

when

(+Pulse width equal to)

(-Pulse width less than)

(-Pulse width more than)

To select pulse width condition

settings

Coupling

24ns~10s

DC

HF

LF

Unblock all components.

Block the high-frequency signal and only

unblock the low-frequency component.

Block the low-

Holdoff 100ns~10s

Reset hold time to default value (100ns).

Alternate trigger(Trigger Mode: Slope )

Alternate trigger(Trigger Type: Slope )Menu is shown as Fig.5-26.

Fig.5-26 Alternate trigger(Trigger Type: Slope )Menu

Alternate trigger(Trigger Type: Slope) menu list:

Source

S

46

Condition

Rising Edge and less than.

Negative pulse and equal to

Turn "TRIG LEVEL" knob to set slope time

Turn "TRIG LEVEL" knob to set the

Turn "TRIG LEVEL" knob to set

Slew rate=(

AC

Block the direct current component.

unblock the

-frequency component.

100ns

10s

Set interval by using TRIG LEVEL control, value range

from 100ns~10s.

Holdoff

Reset

Rising Edge and equal to .

Falling Edge and more than

Negative pulse and less than

settings

High level

Low level

Slew rate

24ns~10s

DC

Coupling

HF

Holdoff

Term interpretation

1. Source: Trigger can occur from several sources: Input channels (CH1, CH2), AC Line,

Ext, Ext/5.

Input :It is the most commonly used trigger source. The channel will work when