Owens Corning EnergyComplete Instructions-parts List Manual

r_256998_313294_10b

Instructions & Parts

US Patent Number 7,036,171

Korean Patent 338185

Australian Patent Number 152610

2004230905

EP 1610904

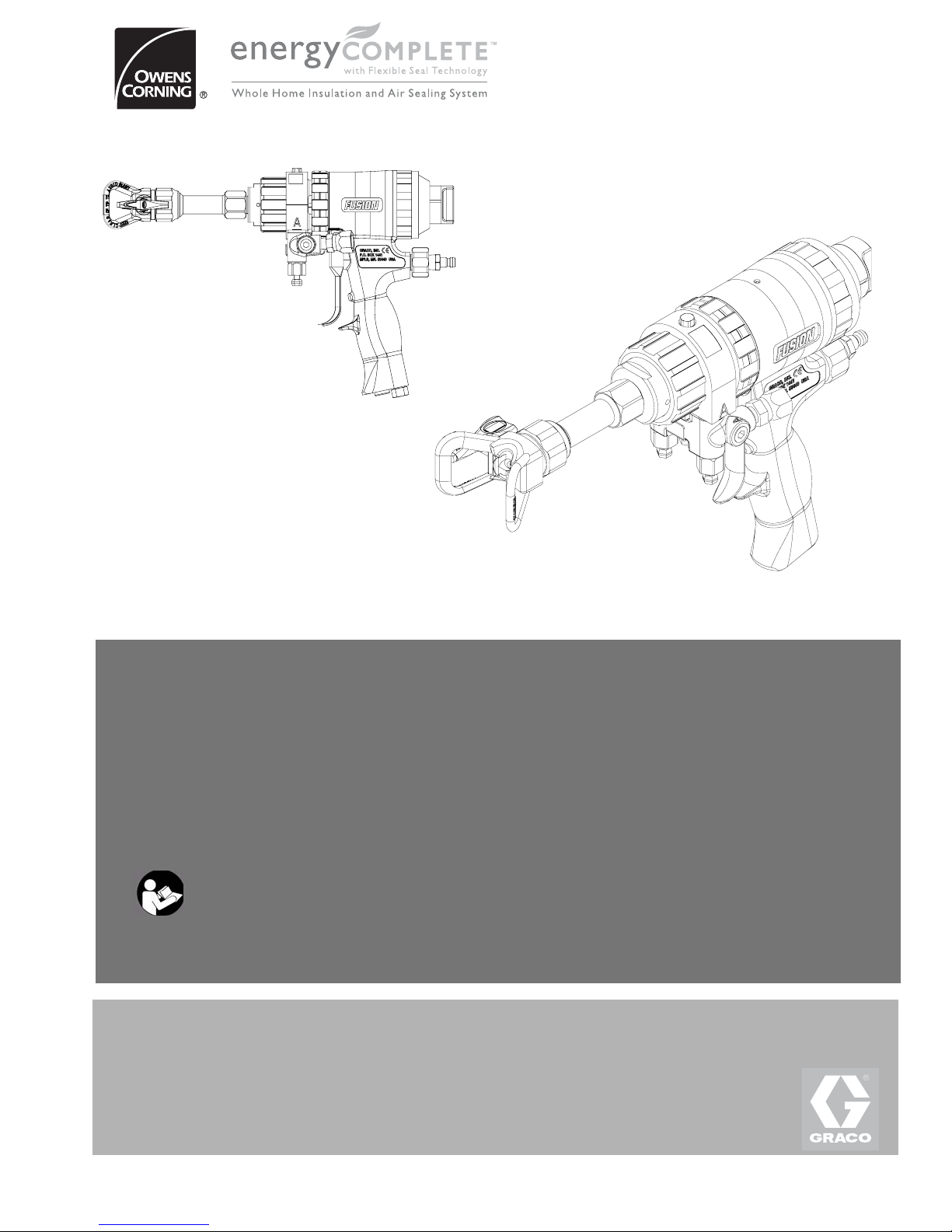

EnergyComplete™ Spray Gun

Manual No:

For use with EnergyComplete Spray Foam with Flexible Seal Technology.

Not for use in explosive atmospheres or with flammable materials.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

313294D

r_256998_313294_1b

256998 EnergyComplete Spray Gun with Static Mixer Assembly

3500 psi (24.2 MPa, 242 bar) Maximum Fluid Working Pressure

80-130 psi (0.55-0.9 MPa, 5.5-9.1 bar) Air Inlet Pressure Range

200°F (94°C) Maximum Fluid Temperature

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Overall View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Keep A and B Components Separate . . . . . . . . . . 6

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Piston Safety Lock

(Trigger Lock) . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Loss of Air Pressure . . . . . . . . . . . . . . . . . . . . . . . . 7

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . 10

Optional Configurations . . . . . . . . . . . . . . . . . . . . 11

Optional Fluid Manifold Position . . . . . . . . . . . . 11

Optional Hose Position . . . . . . . . . . . . . . . . . . . 12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Supplied Tool Kit . . . . . . . . . . . . . . . . . . . . . . . . 13

Compatible Solvents . . . . . . . . . . . . . . . . . . . . . 13

Keep Gun Clean . . . . . . . . . . . . . . . . . . . . . . . . 13

As Needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Daily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Weekly to Monthly . . . . . . . . . . . . . . . . . . . . . . . 13

Flush Gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Clean Outside of Gun . . . . . . . . . . . . . . . . . . . . 14

Clean Air Cap . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Clean Spray Tip . . . . . . . . . . . . . . . . . . . . . . . . 14

Clean Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Clean Fluid Manifold . . . . . . . . . . . . . . . . . . . . . 14

Clean Mixer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Clean Slip-Fit Polycarballoy Mix Module . . . . . . 15

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Disassemble Front End . . . . . . . . . . . . . . . . . . . 18

Reassemble Front End . . . . . . . . . . . . . . . . . . . 19

Slip-Fit Polycarballoy Mix Module . . . . . . . . . . . 20

Rear Rod Seal . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Adjust Rear Rod Seal . . . . . . . . . . . . . . . . . . . . 21

Check Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Piston and Purge Rod . . . . . . . . . . . . . . . . . . . . 23

Piston Safety Lock . . . . . . . . . . . . . . . . . . . . . . . 24

Air Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Static Mixer Assembly . . . . . . . . . . . . . . . . . . . . 25

Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Gun Repair Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Check Valve Filter Screen Kits (10 per kit) . . . . . 28

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . 30

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . 30

2 313294D

Warnings

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back

to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where

applicable.

WARNING

WARNINGWARNINGWARNING

SKIN INJECTION HAZARD

High-pressure fluid from gun, hose leaks, or ruptured components will pierce skin. This may look like just

a cut, but it is a serious injury that can result in amputation. Get immediate surgical treatment.

• Do not point gun at anyone or at any part of the body.

• Do not put your hand over the spray tip.

• Do not stop or deflect leaks with your hand, body, glove, or rag.

• Do not spray without tip guard.

• Engage trigger lock when not spraying.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or

swallowed.

• Read MSDS’s to know the specific hazards of the fluids you are using.

• Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

• Always wear impervious gloves when spraying or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic

fumes, burns, and hearing loss. This equipment includes but is not limited to:

• Protective eyewear

• Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

• Hearing protection

BURN HAZARD

Equipment surfaces and fluid that’s heated can become very hot during operation. To avoid severe

burns, do not touch hot fluid or equipment. Wait until equipment/fluid has cooled completely.

313294D 3

Warnings

WARNING

WARNINGWARNINGWARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent

fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop

cloths (potential static arc).

• Keep work area free of debris, including solvent, rags and gasoline.

• Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes

are present.

• Ground all equipment in the work area. See Grounding instructions.

• Use only grounded hoses.

• Hold gun firmly to side of grounded pail when triggering into pail.

• If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment

until you identify and correct the problem.

• Keep a working fire extinguisher in the work area.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

• Do not operate the unit when fatigued or under the influence of drugs or alcohol.

• Do not exceed the maximum working pressure or temperature rating of the lowest rated system

component. See Technical Data in all equipment manuals.

• Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all

equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information

about your material, request MSDS forms from distributor or retailer.

• Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

• Do not alter or modify equipment.

• Use equipment only for its intended purpose. Call your distributor for information.

• Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

• Do not kink or over bend hoses or use hoses to pull equipment.

• Keep children and animals away from work area.

• Comply with all applicable safety regulations.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and

cause serious injury.

• Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning,

checking, or servicing equipment.

• Tighten all fluid connections before operating the equipment.

• Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

PRESSURIZED ALUMINUM PARTS HAZARD

Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids

containing such solvents in pressurized aluminum equipment. Such use can cause serious chemical

reaction and equipment rupture, and result in death, serious injury, and property damage.

4 313294D

Overall View

Overall View

L

W

K

P

T

F

C

M

D

V

R

N

U

G

B

H

A

S

r_256998_313294_7b

Key:

A A Side Fluid Valve (white)

B B Side Fluid Valve (red)

CAir Cap

D Air Line Quick Coupler

EMuffler

F Fluid Housing

G Gun Fluid Manifold

H Handle

J Optional Air Inlet

K Cleanoff Air Valve

L Piston Safety Lock

M Static Mixer Adapter

N Optional Fluid Inlets (A Side Shown)

P Lock Ring

R Fluid Inlet Swivels (A Side Shown)

S Trigger

T Gun Air Whip Hose

U Air Valve

V Static Mixer

WRAC tip

J

E

313294D 5

Keep A and B Components Separate

Keep A and B

Components Separate

NOTICE

• To prevent cross-contamination of the gun’s wetted parts, do not interchange A component

(white fluid) and B component (red fluid) parts.

The gun is shipped with the A side on the left.

The fluid manifold, fluid housing, side seal cartridge, check valve cartridge, and mix chamber

are marked on the A side.

Grounding

Check your local electrical code and proportioner manual 313221 for detailed grounding instructions.

6 313294D

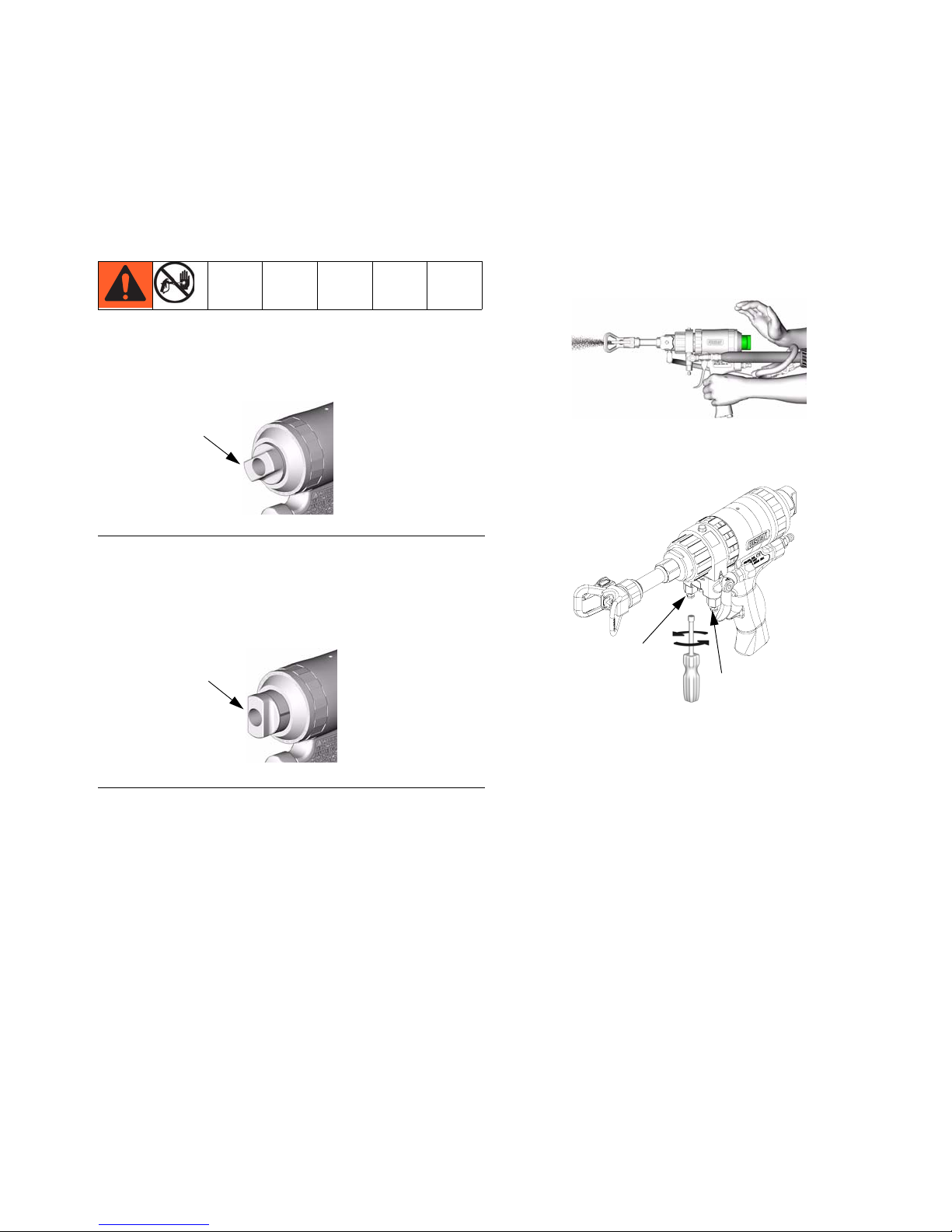

Piston Safety Lock (Trigger Lock)

Piston Safety Lock

(Trigger Lock)

Engage piston safety lock whenever you stop spraying, to avoid accidental triggering.

To engage piston safety lock: push knob in and turn

clockwise. If engaged, gun will not actuate.

Engaged

TI3850A

FIG. 1

To disengage piston safety lock: push knob in and

turn counterclockwise until it pops out. There will be a

gap between knob and gun body.

Loss of Air Pressure

In event of loss of air pressure while gun is triggered,

gun will continue to spray. To shut off gun, do one of the

following:

• Push hard or hit end of safety lock, to engage piston

safety lock.

TI5003A

• Close fluid valves A and B.

Disengaged

IG. 2

F

TI3849A

B

A

r_256998_313294_1b

313294D 7

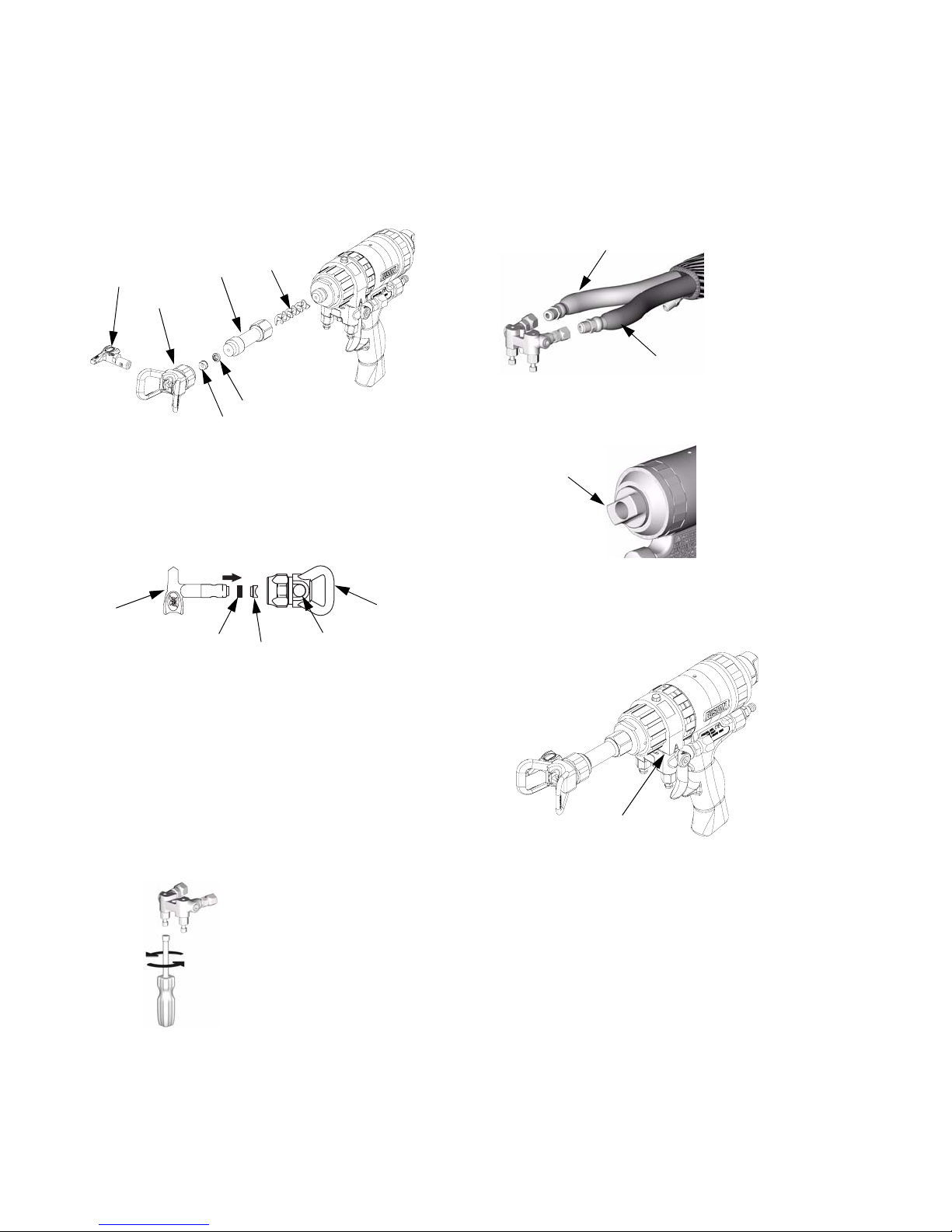

Setup

Setup

1. Assemble static mixer housing (60) and mix element

(62) on front end of gun.

62

65

60

64

gasket

r_256998_313294_2b

seat

2. Assemble RAC tip and guard (64, 65) assembly.

a. Use end of tip (65) to press gasket and seat into

guard (64), with curve matching tip bore (T).

65

seat

gasket

T

64

4. Connect A (white) and B (red) fluid hoses to fluid

manifold.

B (Red)

A (White)

TI2417A

5. Engage piston safety lock, page 7.

Engaged

TI3850A

6. Connect gun air whip hose and air valve to main air

hose. Attach fluid manifold (M) to gun.

b. Insert RAC tip (65) into tip bore (T).

c. Screw guard (64) onto static mixer housing (60)

with wrench to properly seat gasket.

d. Loosen guard (64) with wrench and tighten

hand tight.

3. Close fluid valves A and B.

TI2411A

M

r_256998_313294_1b

8 313294D

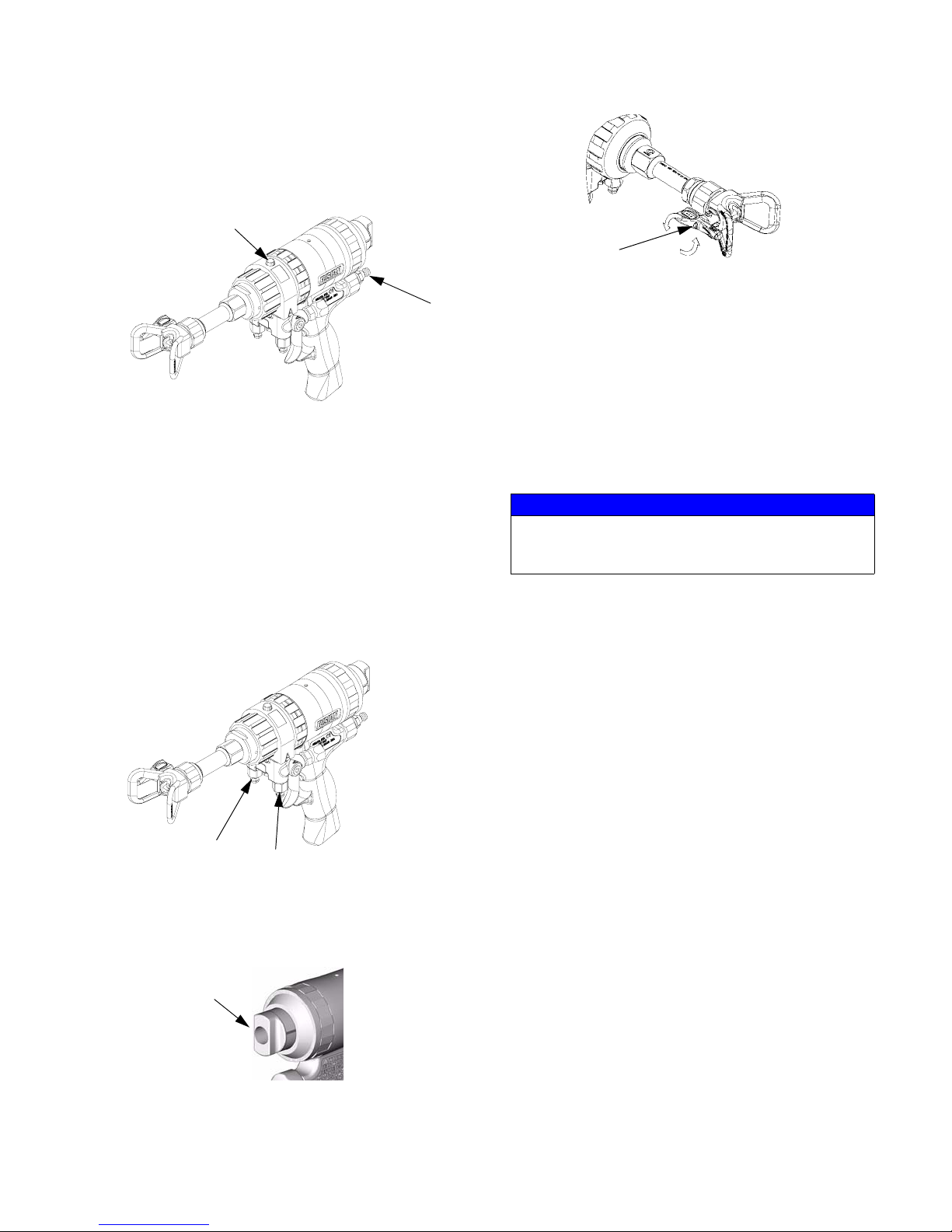

7. Connect quick coupler (D). Turn on air. Open air

valve connected to whip hose. Air valve (K) should

be screwed tight. There is no clean off air to adjust

on the mechanical purge gun.

K

65

Shutdown

exp1008A

D

r_256998_313294_1b

NOTE:

To use optional air inlet, see Optional Hose Position

on page 12.

8. Adjust Purge Rod Position, see page 23.

9. Turn on proportioner.

10. Open B (red fluid) fluid valve (about three half

turns). Then open A (white fluid) fluid valve.

13. Test spray onto cardboard. Adjust pressure and

temperature to get desired results.

14. Apply layer of lubricant over front of gun and lock

ring, or use gun cover to prevent overspray buildup

and ease disassembly. See Accessories on page

28 to order lubricant and gun cover.

15. Gun is ready to spray.

NOTICE

Air supply is required for gun actuation. Do not disconnect gun air supply until fluid pressure is relieved,

page 10.

Shutdown

1. Follow Pressure Relief Procedure, page 10.

2. Flush Gun, page 14.

B fluid valve

A fluid valve

11. Disengage piston safety lock, page 7.

Disengaged

12. Turn RAC tip (65) to spray position.

313294D 9

r_256998_313294_1b

TI3849A

Loading...

Loading...