Page 1

Overland

Storage

®

NEO

8000 Library

User Guide

September 2009

10400267-101

Page 2

©2005-7, 2009 Overland Storage, Inc. All rights reserved.

Overland®, Overland Data®, Overland Storage®, ARCvault®, LibraryPro®, LoaderXpress®, Multi-SitePAC®, NEO®, NEO Series®,

PowerLoader®, Protection OS®, REO®, REO 4000®, REO Series®, Snap Care®, Snap Server®, StorAssure®, ULTAMUS®, VR2®, WebTLC®,

and XchangeNOW® are registered trademarks of Overland Storage, Inc.

GuardianOS™, NEO Lite™, REO Compass™, SnapWrite™, Snap Enterprise Data Replicator™, and Snap Server Manager™ are trademarks

of Overland Storage, Inc.

All other brand names or trademarks are the property of their respective owners.

The names of companies and individuals used in examples are fictitious and intended to illustrate the use of the software. Any resemblance to

actual companies or individuals, whether past or present, is coincidental.

PROPRIETARY NOTICE

All information contained in or disclosed by this document is considered proprietary by Overland Storage. By accepting this material the

recipient agrees that this material and the information contained therein are held in confidence and in trust and will not be used, reproduced

in whole or in part, nor its contents revealed to others, except to meet the purpose for which it was delivered. It is understood that no right is

conveyed to reproduce or have reproduced any item herein disclosed without express permission from Overland Storage.

Overland Storage provides this manual as is, without warranty of any kind, either expressed or implied, including, but not limited to, the

implied warranties of merchantability and fitness for a particular purpose. Overland Storage may make improvements or changes in the

product(s) or programs described in this manual at any time. These changes will be incorporated in new editions of this publication.

Overland Storage assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness of this manual, nor for any problem that

might arise from the use of the information in this manual.

FW 5.16.

Overland Storage, Inc.

4820 Overland Avenue

San Diego, CA 92123

U.S.A.

Tel: 1.877.654.3429 (toll-free U.S.)

Tel: +1.858.571.5555 Option 5 (International)

Fax: +1.858.571.0982 (general)

Fax: +1.858.571.3664 (sales)

www.overlandstorage.com

ii X 10400267-101 09/2009

Page 3

Preface

About this Guide

This guide provides installation instructions and operational information necessary for

using the Overland Storage NEO 8000 Library. It assumes you are familiar with basic

functions of your computer and networking. It also assumes you are knowledgeable about

the SAN to which the NEO 8000 is being connected.

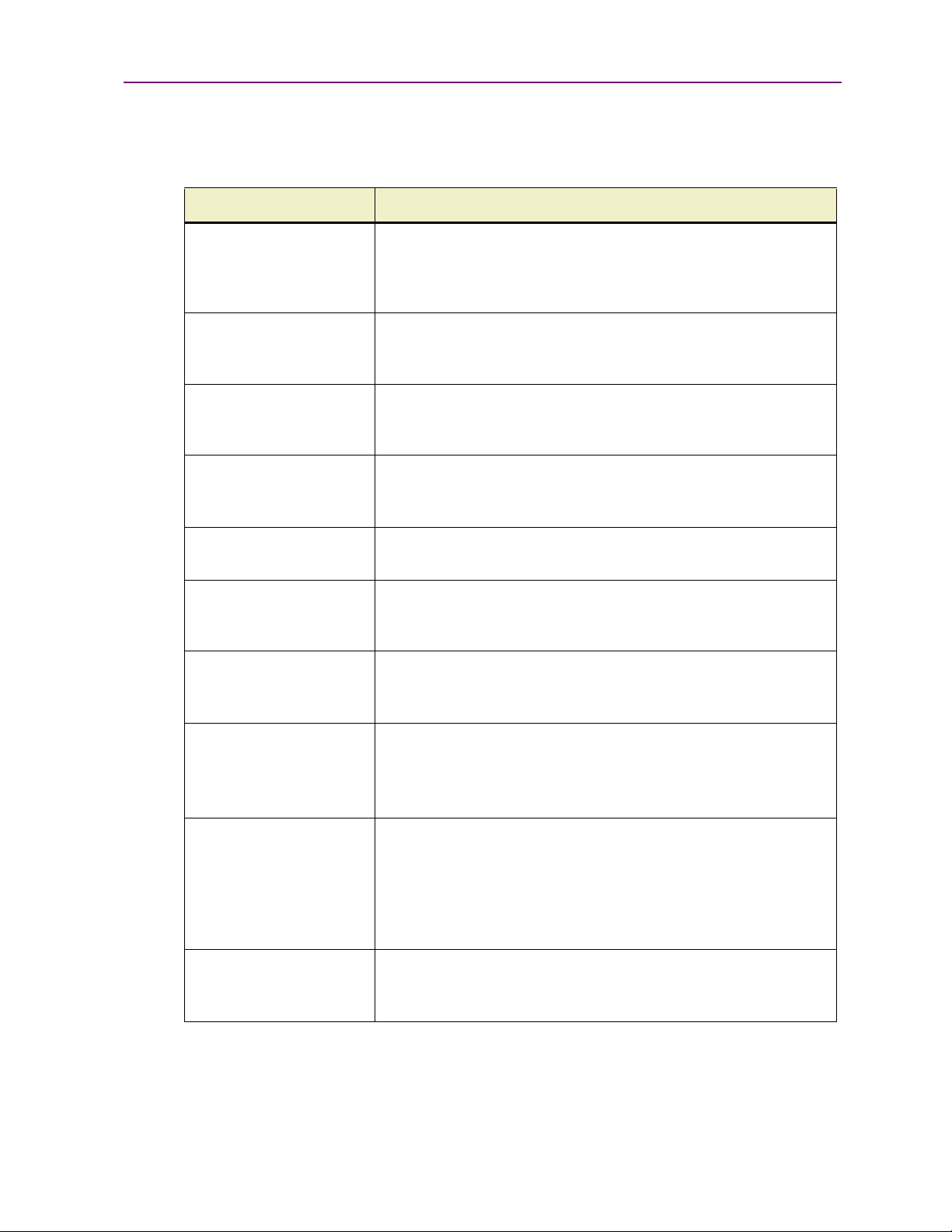

Conventions Used

This user guide exercises several typographical conventions to help explain how to use the

NEO 8000.

Convention Description & Usage

Boldface Words in boldface indicate items to select such as menu items or

command buttons.

Ctrl-Alt-r This type of format details the keys you press simultaneously. In this

example, hold down the Ctrl and Alt keys and press the r key.

NOTE A Note indicates neutral or positive information that emphasizes or

supplements important points of the main text. A note supplies

information that may apply only in special cases—for example, memory

limitations or details that apply to specific versions of a program.

IMPORTANT An Important note is a type of note that provides information essential

to the completion of a task or that can impact the product and its

function. Users can disregard information in a regular note and still

complete a task, but they should not disregard an important note.

CAUTION A Caution contains information that the user needs to know to avoid

damaging or permanently deleting data or causing physical damage to

the hardware or system.

WARNING A Warning contains information essential to people’s safety. It

Obtaining Documentation

NEO 8000 product documentation and additional literature are available online at

www.overlandstorage.com/neo8000.html

advises users that failure to take or avoid a specific action

could result in physical harm to the user or hardware.

.

10400267-101 09/2009 W iii

Page 4

Preface

Overland Technical Support

For assistance configuring and using your NEO 8000, search for help at:

http://support.overlandstorage.com/

Our Overland Storage Technical Support staff is also available to assist you by phone at:

1.877.654.3429 (Toll-free and active only in US and Canada)

1.858.571.5555 x5 (Worldwide)

On normal business days 6 AM through 5 PM (California time) excluding Overland holidays.

At all other times we will respond to technical support calls within 4 hours.

Technical support for our European customers is available as well from our United Kingdom

office at:

+44 (0) 118-9898050

9:00 am to 5:00 pm (GMT)

Monday through Friday

You can e-mail our technical support staff at techsupport@overlandstorage.com.

Electrostatic Discharge Information

A discharge of static electricity can damage static-sensitive devices. Proper packaging and

grounding techniques are necessary precautions to prevent damage. To prevent electrostatic

damage, observe the following precautions.

• Transport products in static-safe containers such as conductive tubes, bags, or boxes.

• Keep electrostatic-sensitive parts in their containers until they arrive at static-free

stations.

• Cover the library with approved static-dissipating material.

• Use a wrist strap connected to the work surface and properly-grounded tools and

equipment.

• Keep the work area free of non-conductive materials such as foam packing materials.

• Make sure you are always properly grounded when touching a static-sensitive

component or assembly.

• Avoid touching pins, leads, or circuitry.

iv X 10400267-101 09/2009

Page 5

Table of Contents

Preface

About this Guide ..................................................................................................................... iii

Conventions Used ................................................................................................................... iii

Obtaining Documentation .................................................................................................... iii

Overland Technical Support ..................................................................................................iv

Electrostatic Discharge Information ......................................................................................iv

Chapter 1 - NEO 8000 Library Overview

Benefits and Features ..........................................................................................................1-1

Accessories Included ..................................................................................................... 1-1

Library Design and Layout .................................................................................................. 1-1

Front Components ......................................................................................................... 1-2

Rear Components .......................................................................................................... 1-4

Capacity Configurations ............................................................................................. 1-13

Chapter 2 - Unpacking and Setting Up

Tools Needed ........................................................................................................................ 2-1

Removing the Outer Carton ............................................................................................... 2-1

Detaching the Pallet ............................................................................................................ 2-3

Attaching the Front Doors ................................................................................................... 2-5

Leveling the Library .............................................................................................................. 2-6

Remove the Drawer Shipping Brackets ............................................................................. 2-7

Chapter 3 - Installation and Initialization

Installation Considerations .................................................................................................. 3-1

Input Supply .................................................................................................................... 3-1

Grounding ....................................................................................................................... 3-1

Power-Up and Cabling Pre-Check .................................................................................... 3-1

Powering Up the Library ...................................................................................................... 3-2

Power-On Self Test .......................................................................................................... 3-2

Powering Down the Library ................................................................................................. 3-3

Standard Method ........................................................................................................... 3-3

Alternate Method ........................................................................................................... 3-4

Chapter 4 - Daily Operation

Common Configuration Modifications .............................................................................. 4-1

Setting a SCSI ID ..............................................................................................................4-1

Configuring a Fibre Channel Drive ............................................................................... 4-2

Creating Reserved Slots ................................................................................................. 4-4

Media Handling .................................................................................................................... 4-6

Bar Code Labels ............................................................................................................. 4-6

Using Mail Slot Magazine for Small Quantity Exchanges ........................................... 4-7

Using Media Drawers for Bulk Exchanges .................................................................. 4-10

Moving Media Inside the Library ................................................................................ 4-10

10400267-101 09/2009 W v

Page 6

Table of Contents

Chapter 5 - Graphical User Interface Usage

Tape Drive Cleaning .......................................................................................................... 4-12

Automatically Running a Cleaning Cartridge .......................................................... 4-12

Manually Running a Cleaning Cartridge .................................................................. 4-12

Replacing a Cleaning Cartridge in a Reserved Slot ................................................ 4-14

Overview ............................................................................................................................... 5-1

Default Screen ................................................................................................................ 5-2

Password Protection ....................................................................................................... 5-2

Host Lock Out ..................................................................................................................5-3

Default Screen Options ....................................................................................................... 5-3

GUI Software Map .......................................................................................................... 5-3

Menu Button ....................................................................................................................5-5

Online / Offline Button ................................................................................................... 5-6

Status Button ................................................................................................................... 5-6

Power Button ...................................................................................................................5-7

Mail Slot Access Button .................................................................................................. 5-8

Drawer Access Button ................................................................................................... 5-8

Move Media Button ....................................................................................................... 5-9

Technical Support Button ............................................................................................ 5-10

LCD Contrast Controls ................................................................................................. 5-10

Menu Screen Options ........................................................................................................ 5-10

Library Options Button (View System Data) .............................................................. 5-11

SCSI/FC Options Button (View System Data) ............................................................ 5-12

Network Options Button (View System Data) ........................................................... 5-13

Library Info Button (View System Data) ..................................................................... 5-13

Cartridge Map Button (View System Data) .............................................................. 5-14

Maintenance Button (Utilities) ..................................................................................... 5-14

Diagnostics Button (Utilities) ......................................................................................... 5-17

Factory Button (Utilities) ............................................................................................... 5-18

Security Level Button (Utilities) ..................................................................................... 5-18

Library Button (Edit Options) ........................................................................................ 5-18

SCSI/FC Button (Edit Options) ..................................................................................... 5-21

Network Button (Edit Options) ..................................................................................... 5-26

Passwords Button (Edit Options) ................................................................................. 5-28

Additional Menu Items for Partitions ................................................................................ 5-28

Chapter 6 - WebTLC Usage

Setting Up WebTLC ..............................................................................................................6-1

Accessing WebTLC .............................................................................................................. 6-2

Status Button ................................................................................................................... 6-4

Move Media Button ....................................................................................................... 6-7

Setup Button .................................................................................................................... 6-8

Functions Button ........................................................................................................... 6-15

History Button ................................................................................................................ 6-18

Logout Button ............................................................................................................... 6-18

Chapter 7 - Neo8000Center Usage

Installing Neo8000Center on a Host ................................................................................... 7-1

vi X 10400267-101 09/2009

Page 7

Table of Contents

Neo8000Center Menu Options ........................................................................................... 7-1

Configuring the Library Using Neo8000Center ..................................................................7-2

Establishing Host/Library Communications ..................................................................7-2

Launching the Configuration Dialog Box ....................................................................7-4

Exiting the Configuration Screen ................................................................................7-14

Uploading Data Files .......................................................................................................... 7-14

Downloading Data Files ..................................................................................................... 7-16

Viewing Library Information ............................................................................................... 7-17

Generating a Post-Process Report ................................................................................... 7-17

Rebooting The Library With Neo8000Center ...................................................................7-19

Chapter 8 - Cabling Options and Examples

SCSI Interface Connectors ..................................................................................................8-1

Interface Cable Specifications ........................................................................................... 8-1

SCSI Drive Cabling Examples ..............................................................................................8-2

Single Host SCSI Network with Two SCSI Drives ............................................................8-2

Fibre Channel Network with Two SCSI Drives ............................................................... 8-3

Four SCSI Drives on a Two Host SCSI Network ..............................................................8-4

Fibre Channel Cabling Examples ....................................................................................... 8-5

Multi-FCO Card System Configuration ......................................................................... 8-5

Chapter 9 - Component and Capacity Additions

Upper Power Supplies (Drives 7-12) ....................................................................................9-1

Additional Drive Assemblies ................................................................................................ 9-2

Optional Interface Cards .................................................................................................... 9-2

Adding Capacity ..................................................................................................................9-3

Scalability Option - Horizontal Robotics Assembly ............................................................9-4

Appendix A - NEO 8000 Specifications

FCC Notice ........................................................................................................................... A-7

Japanese Voluntary Control Council for Interference (VCCI) ....................................... A-7

Taiwan BSMI Class A Warning ............................................................................................ A-7

Declaration of Conformity .................................................................................................. A-8

Appendix B - Repacking for Shipment to a New Location

Tools Needed ........................................................................................................................ B-1

Prepare the Library for Transport ........................................................................................B-1

Removing the Front Doors ...................................................................................................B-2

Attaching the Drawer Shipping Brackets ..........................................................................B-3

Attaching the Pallet .............................................................................................................B-4

Attaching the Outer Carton ................................................................................................ B-6

Appendix C - Library Partitioning

Introduction ..........................................................................................................................C-1

Installing a Router Card ...................................................................................................... C-2

Installing a Partition Controller Card .................................................................................. C-3

Additional Menu Items for Partitions .................................................................................. C-4

Cabling Configuration Examples .......................................................................................C-5

2 Partitions 4 Drives 2 Hosts ............................................................................................ C-5

10400267-101 09/2009 W vii

Page 8

Table of Contents

Glossary

Index

viii X 10400267-101 09/2009

Page 9

NEO 8000 Library Overview

1

CHAPTER

The NEO 8000 Library is an enterprise library from Overland Storage that provides

unmatched performance for organizations with very large amounts of mission-critical

data.

Benefits and Features

The NEO 8000 provides the following major features and key benefits:

• Robust, flexible, reliable design and enterprise-class capability.

• More storage capacity per square foot than any other data center-class library.

• WebTLC, a remote library management tool embedded in the NEO, that allows you

to securely view and manage the library from any location via an internet browser.

• Redundant power feature to ensure your library is protected against power failures.

• Overland’s Virtual Interface Architecture (V.I.A.™) technology to allow your

network or SAN to easily communicate with the NEO 8000 tape library.

• Built-in diagnostic capabilities that proactively monitor and manage your backup

and archive process, and notify you with library operation status.

• An optional upgrade, the Horizontal Robotics Assembly (HRA), that allows two

libraries to function as one. (See the NEO 8000 Scalability Upgrade Installation

Instructions for more details.)

Accessories Included

The NEO 8000 comes complete with the following items installed (except for the RS-232

cable which is located in the back door pouch):

• Two (2) power cords

• VHDCI LVD/SE SCSI terminator

• RS-232 cable, 6 ft. (1.8m), 4-conductor RJ-11 to DB-9 adapter

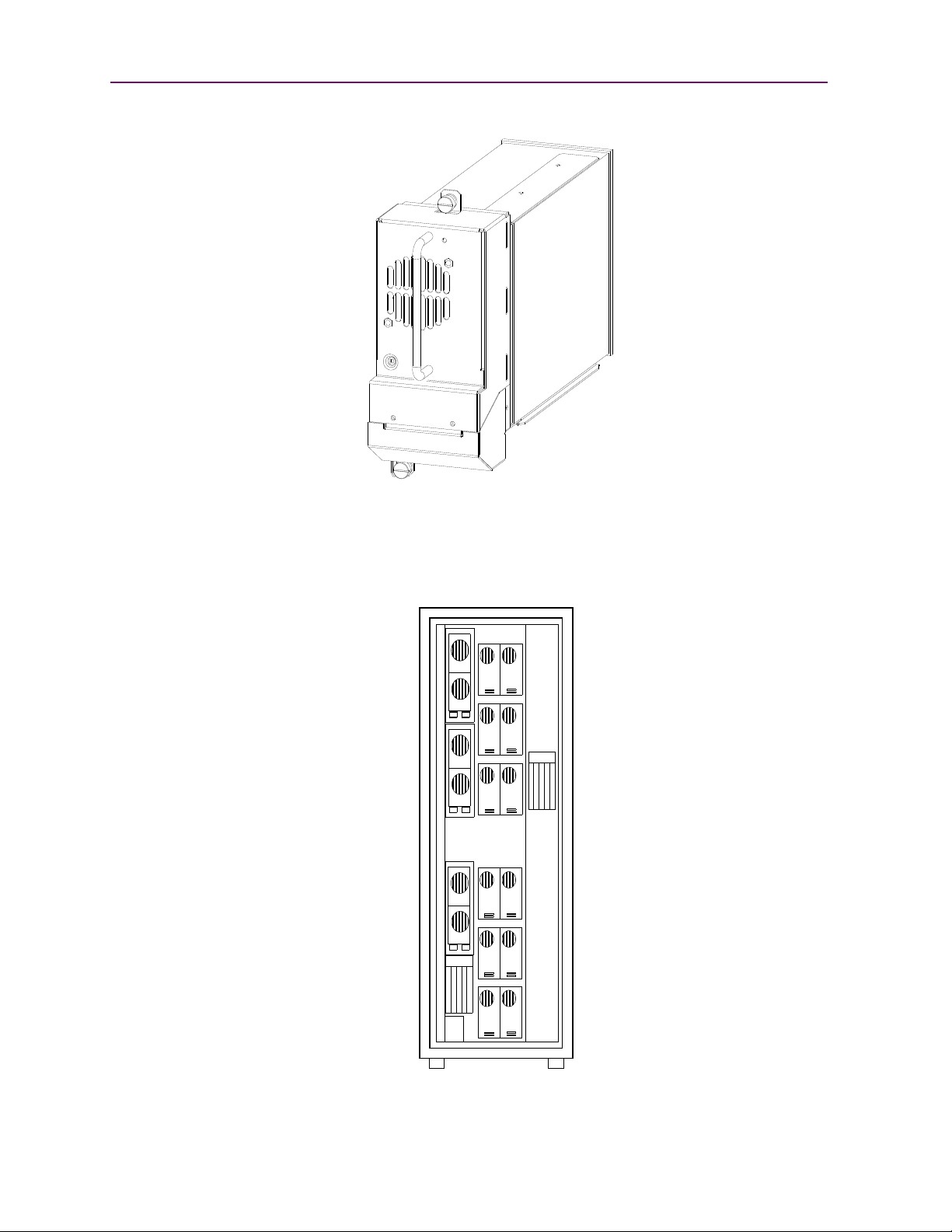

Library Design and Layout

The following sections provide a general overview of the NEO 8000 Library’s design and

layout.

10400267-101 09/2009 W 1–1

Page 10

Chapter 1: NEO 8000 Library Overview

N

E

O

-

8

0

0

1

N

E

O

-

8

0

0

1

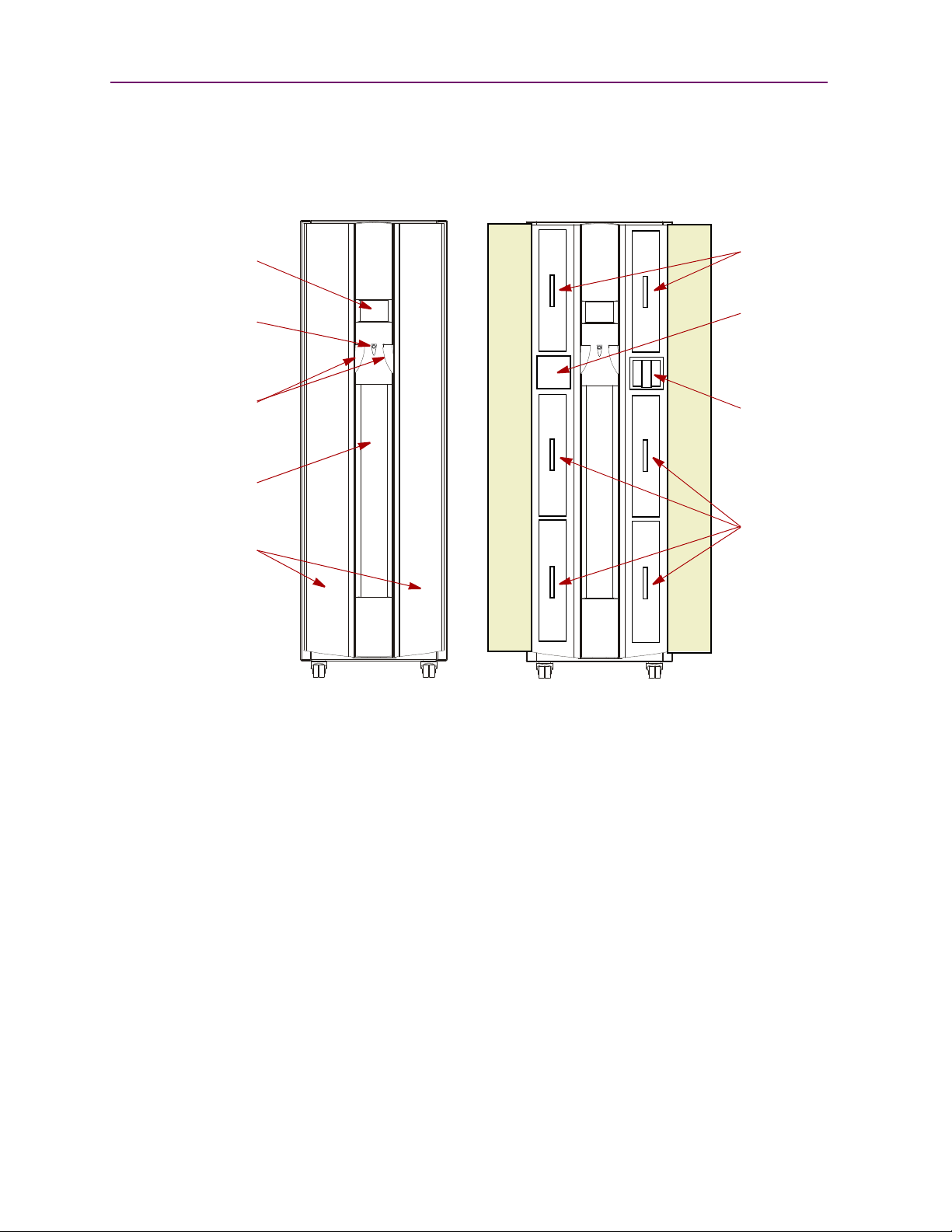

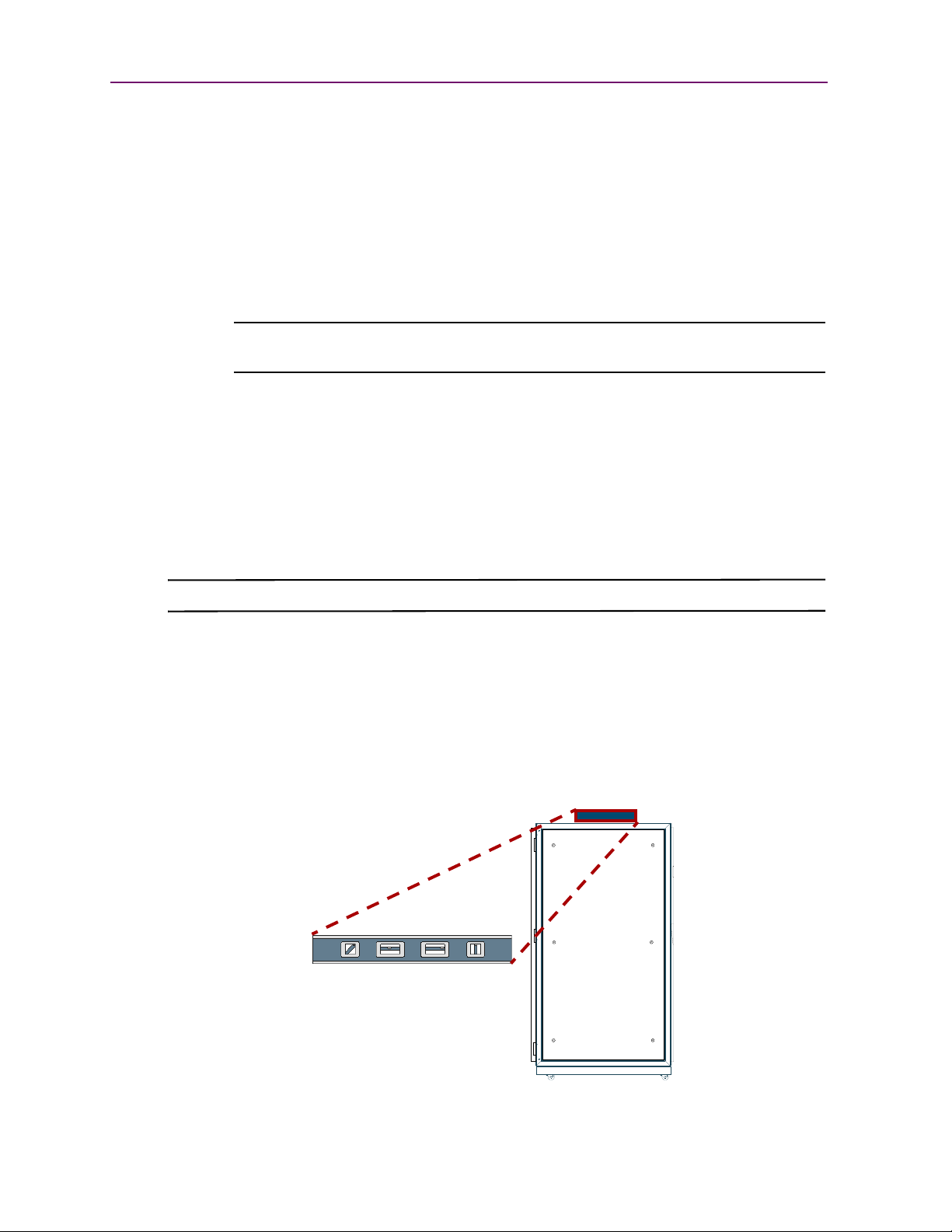

GUI Touch

Power

Door

Viewing

Media

Mail Slot

Fixed Slots

Doors Open

Drawers

Doors Closed

Media

Drawers

Media

Screen

Button

Opening

Reliefs

Window

Drawer

Access

Doors

Front Components

The library is designed to allow easy access to the control panel and tapes from the front

(Figure 1-1).

GUI Touch Screen

The Graphical User Interface (GUI) touch screen on the front of the NEO 8000 provides an

easy way to directly communicate with the library. By gently pressing the virtual buttons,

you can select menus and options to change library settings.

Mail Slot Magazine

The NEO 8000 has one removable import/export tape cartridge magazine, called a Mail Slot,

that is accessible through the right front door (Figure 1-2). The Mail Slot holds up to 15 LTO

cartridges. It provides an easy method for adding or removing cartridges without having to

stop the library to open drawers.

1–2 X 10400267-101 09/2009

Figure 1-1: NEO 8000 Front View

Page 11

Library Design and Layout

N

E

O

-

8

0

0

8

N

E

O

-

8

0

1

1

N

E

O

-

8

0

3

0

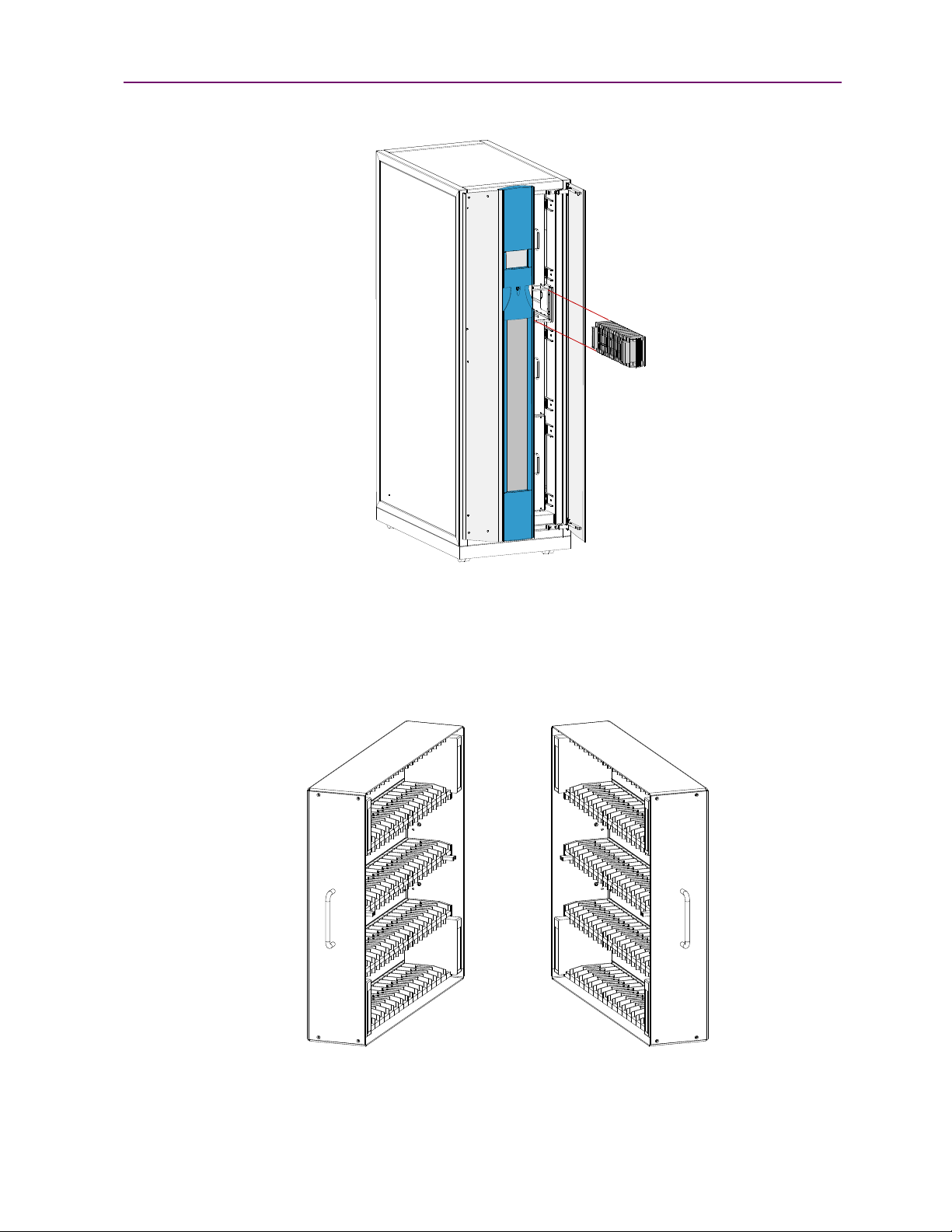

Figure 1-2: Mail Slot Location

Media Drawers and Fixed Slots

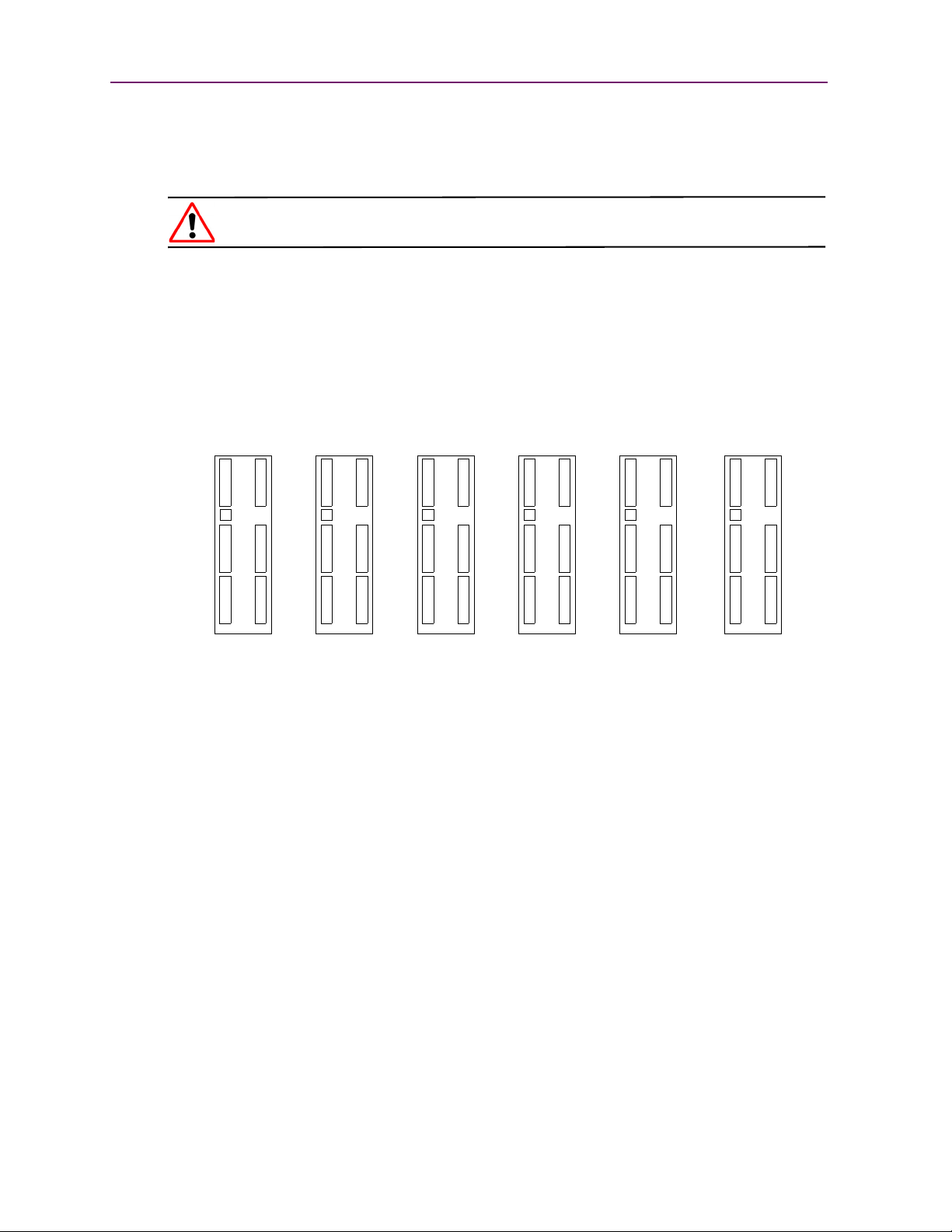

There are six media drawers (Figure 1-3) in the NEO 8000 Library. Each drawer holds up to

80 LTO cartridges.

Figure 1-3: NEO 8000 Left and Right Media Drawers

10400267-101 09/2009 W 1–3

Page 12

Chapter 1: NEO 8000 Library Overview

112

12 12 1212

34 34 343

556

1 Drawer 2 Drawers 3 Drawers 4 Drawers 5 Drawers All Enabled

For security and safety, the drawers are internally latched to prevent unauthorized access.

With the proper security credentials, they can be released from the GUI touch screen on the

front of the library.

WARNING: Removing the media drawers from the library units is not recommended

except by Authorized Overland Service Technicians.

Between the left side top and middle drawers, directly across from the Mail Slot, is a row of

fixed slots that can only be accessed by the internal robotics. These slots hold up to 20 LTO

cartridges. They can be accessed using Menu > Maintenance > Load/Unload Fixed Slots

commands. They can also be reserved for cleaning cartridges using Menu > Library > Total

Reserved Slots.

The NEO 8000 comes with 1-6 drawers enabled, depending on the purchased configuration.

Any disabled drawers can be activated by purchasing additional capacity and entering the

upgrade code (Figure 1-4).

NOTE: The fixed slots on the left side between the top and middle drawers are always enabled

and listed after any enabled drawers. For example, in an LTO library with four enabled

drawers (Slots 1–320), the fixed slots are numbered 321 to 340.

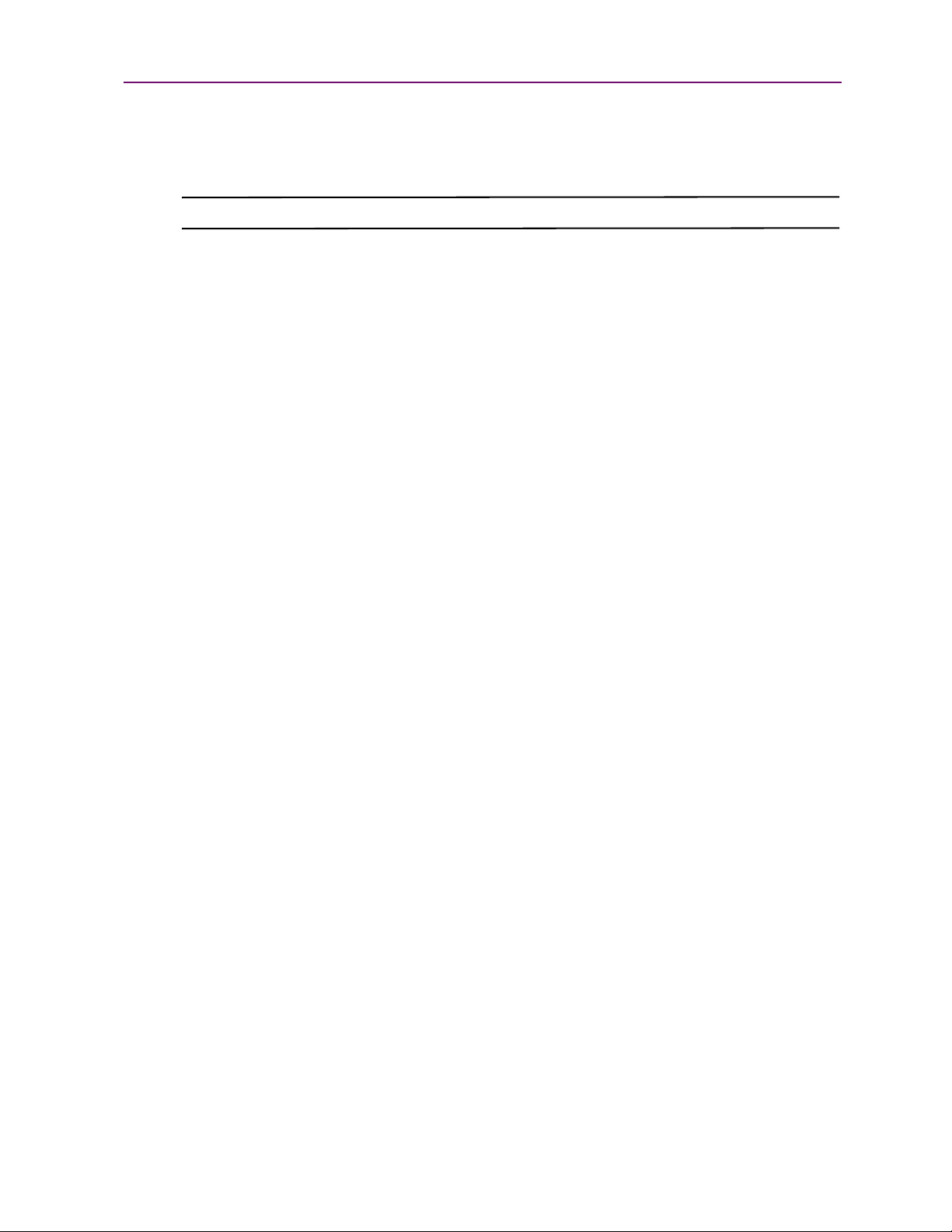

Rear Components

The rear of the library (Figure 1-5) provides easy access to the operational hardware. The

basic unit has 2 drives, 4 power supplies (for the lower drives and robotics, both primary and

redundant), and a Library Controller card. There is a power supply case for the optional

power supplies required for drives 7–12. Two V.I.A. card cages are available for the Library

Controller card and nine optional V.I.A. expansion cards.

Figure 1-4: Media Drawer Activation Order

1–4 X 10400267-101 09/2009

Page 13

Library Design and Layout

N

E

O

-

8

1

1

9

Primary

Secondary

Drives 7-12

Card Cage

Power Supplies

Library

Drives 1-6

For Robotics

Card Cage

Controller

Card (Req’d)

Power Supplies

For Drives 1-6

Power Supplies

For Drives 7-12

Figure 1-5: NEO 8000 Rear View

Power Supplies

Power is routed via power cords through the base plate of the unit into connectors on the

circuit breaker box at the base of the built-in power strip. The power strip contains

geographically placed receptacles which make AC power available to the power supply cases

without the need for routing cables.

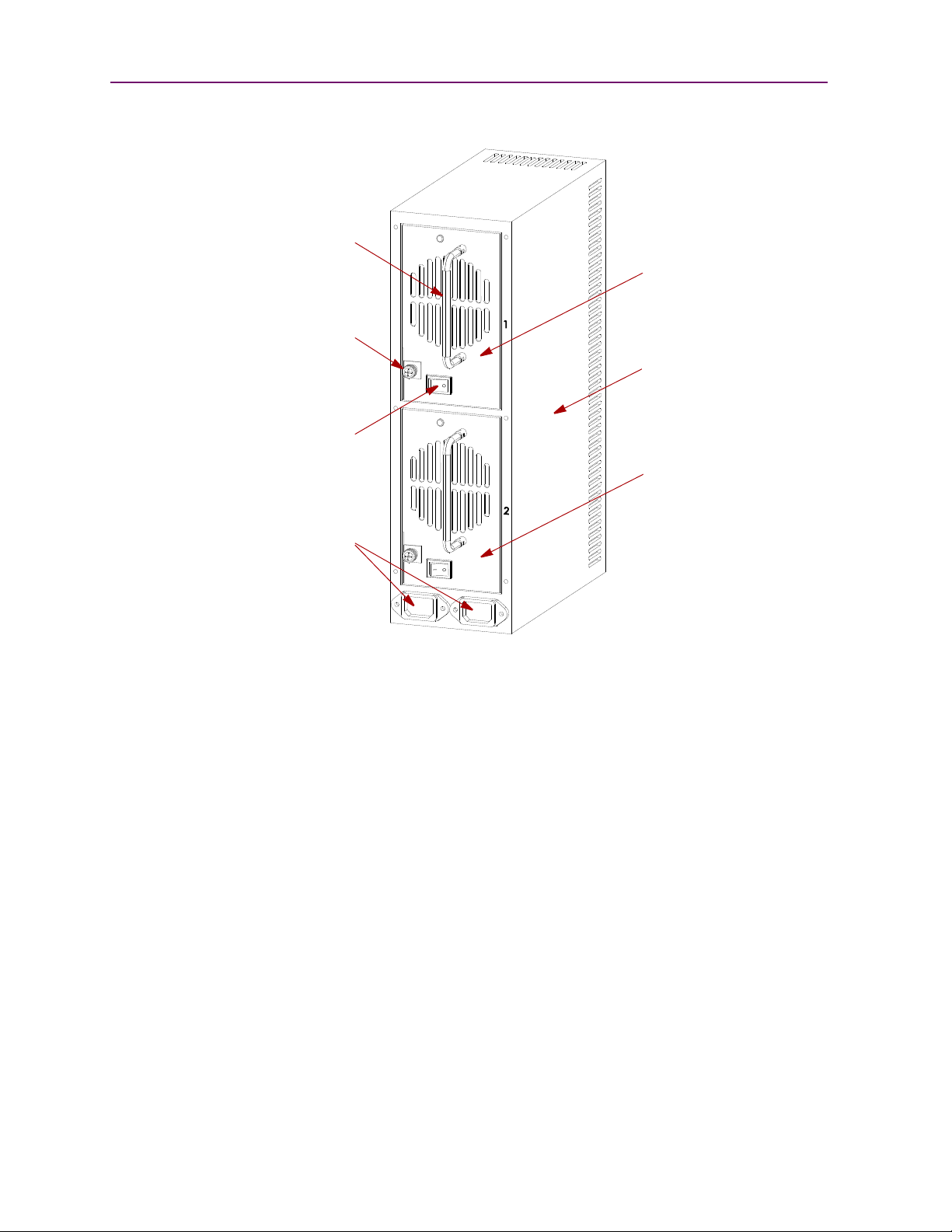

Each power supply case holds two power supplies (Figure 1-6). The upper power unit is the

primary power source while the lower unit is the redundant power source.

10400267-101 09/2009 W 1–5

Page 14

Chapter 1: NEO 8000 Library Overview

N

E

O

-

8

0

2

2

a

Primary

Redundant

Power

Supply (#1)

Power

Supply (#2)

Foldable

Handle

Thumbscrew

Release

ON/OFF

Switch

Power

Inputs

(from bus)

Power

Supply

Case

The NEO SERIES 8000 Library has three power supply cases that distribute AC power to

different portions of the library. Each power supply case holds two modular auto-ranging

power supplies: a primary power supply for daily use and a secondary power supply for

redundancy.

Each power supply is capable of using any nominal AC voltage between 100 and 240 Vac

power, at 50 Hz or 60 Hz. A thumbscrew release secures each power supply in it’s respective

power supply case.

For the library to operate, power must be available to the library controller card, robotics,

and all installed drives. Therefore, two power supplies must be installed in the middle

Robotics power supply case and two power supplies must be installed in the lower Drives 1-6

power supply case. If more than 6 drives are installed, two power supplies must also be

installed in the upper Drives 7-12 power supply case.

Power Redundancy

Power supply cases must contain two power supplies to provide redundancy for mission

critical operations and avoid power interruption to the library. Power supplies share the

load under normal operating conditions. However, if one of the power supplies fails, the

other will assume the full load.

1–6 X 10400267-101 09/2009

Figure 1-6: Power Supplies in a Power Supply Case

Page 15

Library Design and Layout

N

E

O

-

8

0

1

4

b

ONOFF

AC

Receptacles

Circuit 1

Circuit 2

(Primary)

(Secondary)

Power Circuits

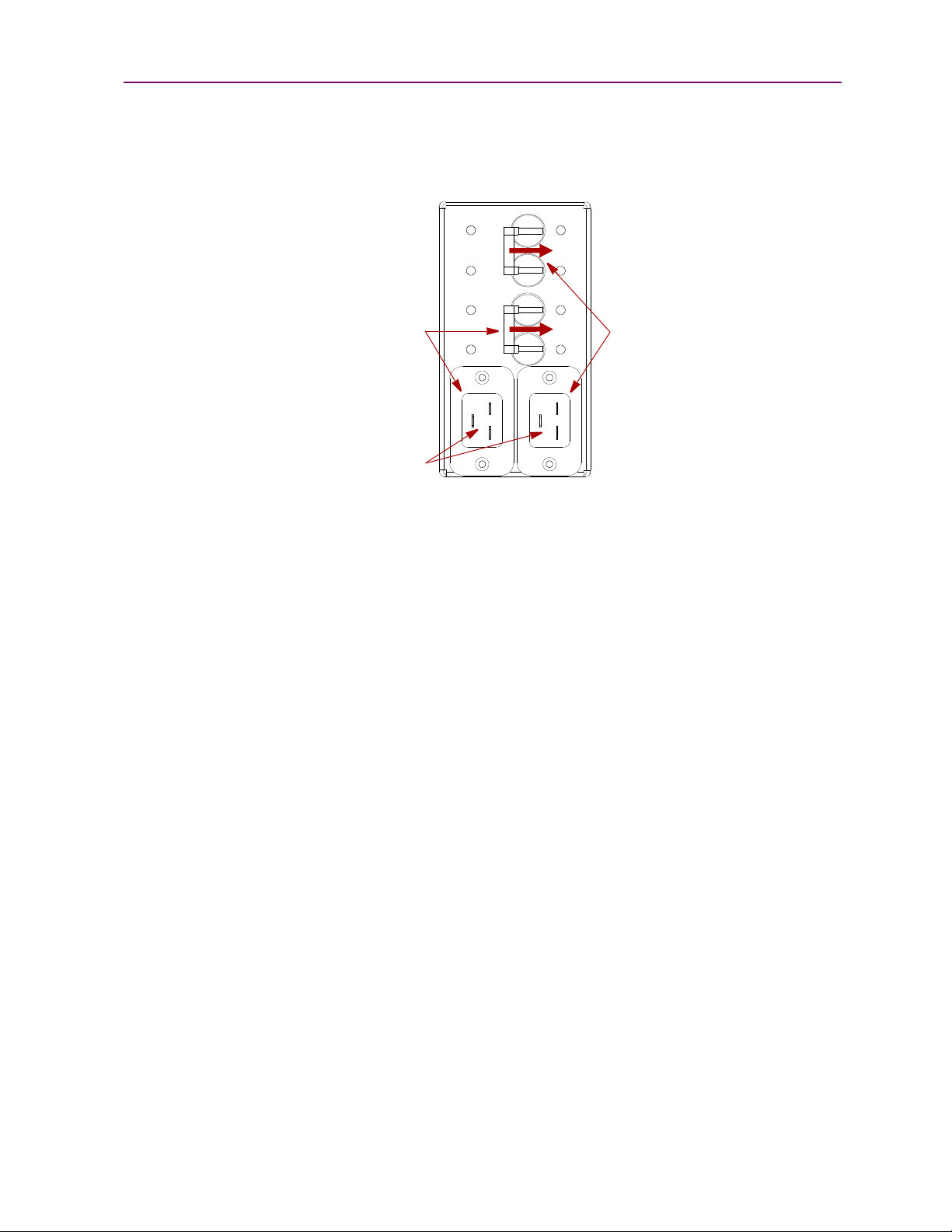

NEO 8000 has two power circuits to support the power redundancy option (Figure 1-7).

Figure 1-7: NEO 8000 Circuit Breakers Showing Primary and Secondary Circuits

The Primary circuit consists of the right-hand receptacle and top breaker on the circuit

breaker box, the upper receptacles of the power strip, and the upper installed power

supplies. The power strip receptacles and power supply cases are labeled with a “1.” The

Secondary circuit is the left-hand receptacle and lower breaker on the breaker box, the lower

receptacles of the power strip, and the lower installed power supplies. The power strip

receptacles and power supply cases are labeled with a “2.”

Drive Assemblies

The NEO 8000 library supports 2-12 tape drives (Figure 1-8). The tape drives are mounted

on special assemblies to make them hot-swap capable and provide non-disruptive

replacement.

10400267-101 09/2009 W 1–7

Page 16

Chapter 1: NEO 8000 Library Overview

N

E

O

-

8

0

6

8

12

34

56

78

910

1112

Figure 1-8: NEO 8000 Drive Assembly (SCSI)

The NEO 8000 base configurations have either zero or two drives. Additional drives can be

added one at a time, as needed, until the library is fully populated with 12 drives

(Figure 1-9).

1–8 X 10400267-101 09/2009

Figure 1-9: NEO 8000 Drive Numbering

Page 17

Library Design and Layout

The SCSI I/O for the tape drives is provided through VHDCI, 68-pin, SCSI connectors

located at the rear of the unit directly under the drives. The Fibre Channel I/O is managed

through connections located on the upper-right of Fibre Channel drives.

CAUTION: When using Fibre Channel cabling, the SCSI connectors should not be used.

Library Interfaces

The NEO 8000 features a Low Voltage Differential (LVD) SCSI interface-to-host system.

Other interfaces, such as HVD SCSI or Fibre Channel, are available with optional V.I.A.

cards. Separate SCSI connections and ID addresses are used to control the functions of the

tape drives and robotics.

Virtual Interface Architecture

The NEO 8000 contains two rear-access card cages and a Compact PCI backplane. This

backplane contains the plug-in connectors for the library’s controller board and up to nine

V.I.A. PCI cards.

The V.I.A. cards provide an easy way for the network or SAN to communicate with the

library. Simple to exchange, they offer upgrade flexibility to expand the life of the library.

Currently available cards include:

• Fibre Channel Option—provides connectivity to Fibre-based SANs.

• Gigabit Ethernet Option—provides connectivity to iSCSI Gigabit Ethernet Networks.

• High Voltage Option—provides connectivity to High Voltage Differential SCSI

systems.

• Internal Router—offers a WebTLC interface when in a Master/Slave configuration.

• Library Partition Option—provides logical soft partitioning to the drawer level

between heterogeneous servers and backup software applications.

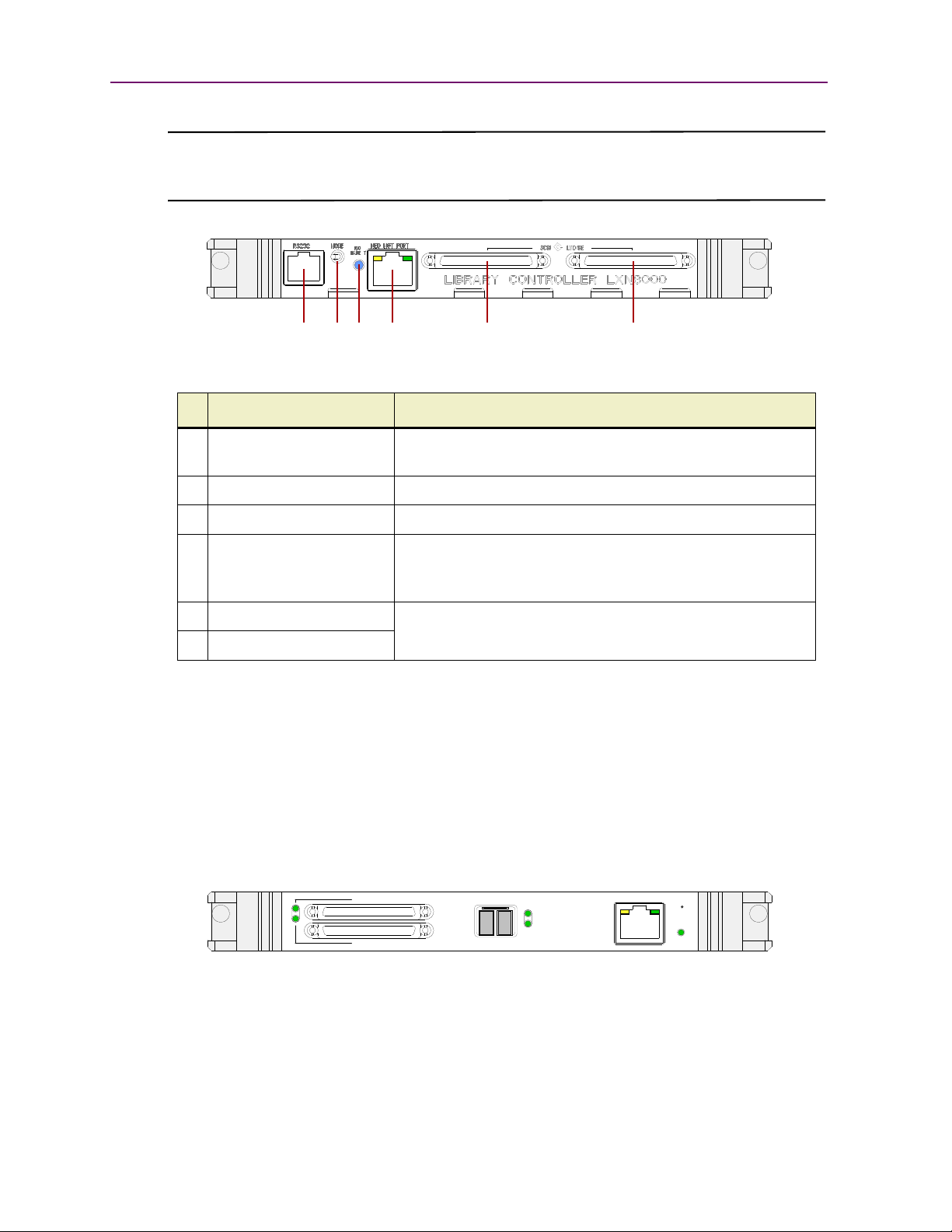

Library Controller Card

The Library Controller card (Figure 1-10) contains a single microprocessor and associated

logic devices to control all robotics operations and manage overall library functions. The

microprocessor enables the SCSI interface between the library and the host system,

including WebTLC (Web-based Total Library Control).

WebTLC is one of the functions built in to the Library Controller card. WebTLC enables you

to remotely monitor and control the tape library from any terminal in a local network or the

internet.

The SCSI I/O for the robotics is provided through VHDCI, 68-pin, SCSI connectors located

on the Library Controller card. The card also contains a sensor for control of the backplane

fans to prevent overheating.

The Library Controller card is installed in the lower card cage at the rear of the library, and

can be serviced without requiring special tools.

10400267-101 09/2009 W 1–9

Page 18

Chapter 1: NEO 8000 Library Overview

N

E

O

-

8

0

7

6

b

1234 5 6

V

I

A

-

0

0

7

8

Fibre ChannelSCSI Port 1

SCSI Port 2

Link

Activity

Ethernet

Ready

Fault

Reset

CAUTION: The Library Controller card must be installed in the right slot of the lower card cage. The

upper card cage does not support the required connections for proper operation of the Library

Controller board.

Figure 1-10: NEO 8000 Library Controller Card

# Port Description Function

1 RS-232 Serial Port RJ-11 based RS-232 serial port for firmware updates and

2 Mode Momentary Switch For service use only.

local configuration and management.

3 Power LED Glows blue when power is available.

4 Ethernet Port RJ-45 GigE Ethernet Port for connecting to your management

LAN for either local or out-of-band remote configuration and

management (such as WebTLC).

5 SCSI Port 0 VHDCI-based LVD SCSI Ports for connecting to the NEO

6SCSI Port 1

SERIES library and tape drives.

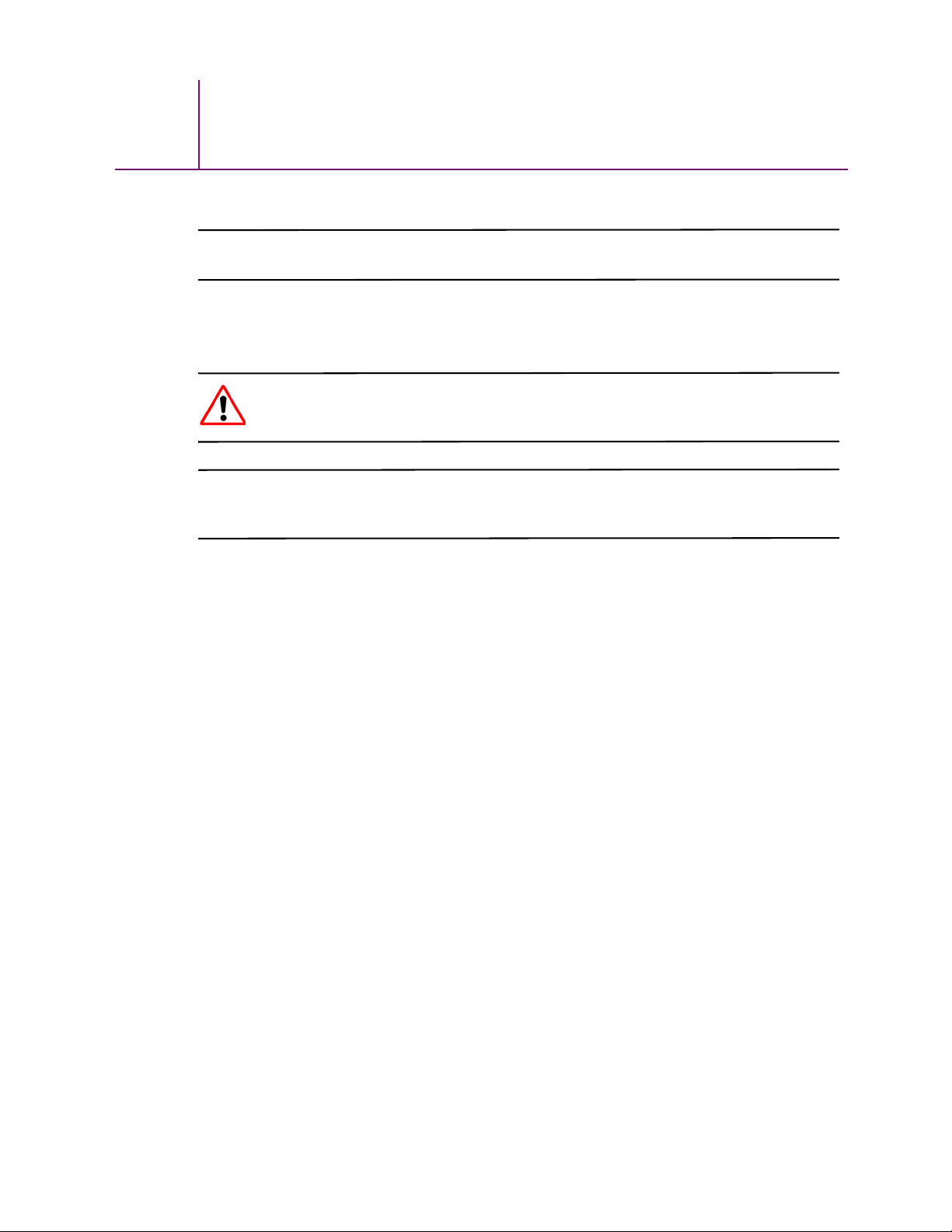

Fibre Channel Option Card

The V.I.A. Fibre Channel Option (FCO3) card (Figure 1-11) is a 4/2/1-Gigabit Fibre

Channel-to-SCSI bridge configured with one Fibre Channel port and two independent SCSI

buses (1x2) providing an interface between SCSI and Fibre Channel resources in a Storage

Area Network (SAN). It includes battery backed-up memory, verbose trace log capabilities,

and date/time stamp.

The FCO card is designed to fit into either one of the V.I.A. bays built into the NEO 8000.

Refer to the documentation that accompanies the card for more details.

Figure 1-11: FCO3 Card

1–10 X 10400267-101 09/2009

Page 19

Library Design and Layout

V

I

A

-

0

0

4

9

b

SCSI Port 0

SCSI Port 1

Data Port 0

RS-232

Fault

G

b

E

O

p

t

i

o

n

C

a

r

d

Data Port 1 Management Port

N

E

O

-

8

0

7

6

b

Gigabit Ethernet Option Cards

The V.I.A. Gigabit Ethernet Option (GEO) card (Figure 1-12) is a Gigabit Ethernet-to-SCSI

bridge for the NEO SERIES libraries. The GEOi card supports both the copper version of the

Gigabit Ethernet (GigE) standard of 1000 Base-T, and Revision 2.0 of the Internet

Engineering Task Force (IETF) iSCSI protocols

.

The GEO card allows NEO SERIES libraries to communicate seamlessly with GigE

networks providing protocol conversion for iSCSI commands, routing commands, data, and

status information between SCSI devices and an iSCSI SAN.

The GEO card is designed to fit into either one of the V.I.A. bays built into the NEO 8000.

Refer to the documentation that accompanies the card for more details.

Figure 1-12: GEOi Card

High Voltage Option Card

The V.I.A. High Voltage Option (HVO) card (Figure 1-13) provides a bridge for the NEO

8000 to work seamlessly with existing High Voltage Differential SCSI-based servers and

systems. With an 80 MB/sec maximum transfer rate, the HVO card meets the performance

demands of even the fastest HVD SCSI systems. The card supports all major operating

systems including HP-UX, IBM AIX, Linux, Mac OS, Novell NetWare, SCO UNIX, Sun

Solaris, Tru64 UNIX, and Windows NT/2000.

The HVO card is designed to fit into either one of the V.I.A. bays built into the NEO 8000.

Refer to the documentation that accompanies the card for more details.

Figure 1-13: HVO Card

10400267-101 09/2009 W 1–11

Page 20

Chapter 1: NEO 8000 Library Overview

V

I

A

-

0

0

7

3

b

12345678

V

I

A

-

0

0

5

3

b

Internal Router Card

The V.I.A. Router card (Figure 1-14) is a special purpose device designed with one specific

function—to provide a WebTLC interface for the NEO 8000 when in a Master/Slave

configuration (i.e., partitioned or multi-module). To the external network, it functions as an

endpoint device, not a network router or switch.

The Router card must be installed in one of the lower option card slots of the NEO 8000.

Refer to the documentation that accompanies the card for more details.

Library Partitioning Controller Card

The V.I.A. Partition Controller card (Figure 1-15) allows multiple servers to use the same

physical library while maintaining control of their allocated resources. Each controller card

can be connected directly to the SCSI bus of a server or daisy-chained to another SCSI bus.

Figure 1-14: Router Card

LPO cards can be installed in either the upper or lower card slots based on which slots are

most convenient for cabling the SCSI bus. Refer to the documentation that accompanies the

card for more details.

Figure 1-15: LPO Card

1–12 X 10400267-101 09/2009

Page 21

Capacity Configurations

N

E

O

-

8

1

1

9

N

E

O

-

8

1

0

5

Basic Configuration Fully Populated Configuration

Upper

Power

Case

Drives 7-12

Drives 1-6 are powered by the lower power supplies that come standard on the NEO 8000.

When expanding to drives 7-12, additional optional power supplies need to be installed in

the upper power case (Figure 1-16).

Library Design and Layout

Figure 1-16: NEO 8000 Rear Views: Basic and Fully Populated

10400267-101 09/2009 W 1–13

Page 22

Chapter 1: NEO 8000 Library Overview

1–14 X 10400267-101 09/2009

Page 23

2

CHAPTER

Unpacking and Setting Up

IMPORTANT: Overland Storage recommends that all NEO 8000 Libraries be installed by an

Overland Storage authorized service provider.

This chapter describes how to unpack and set up a new NEO 8000 Library. This same

information is also available in the NEO 8000 Library Important Unpacking Instructions

located on the outside of the shipping container.

WARNING: Exercise care when unpacking and moving the NEO 8000 Library. Due to

its size and weight, it is recommended that at least two people be involved with the

unpacking process.

CAUTION: You should read and familiarize yourself with this entire chapter before starting the

unpacking procedure. Steps performed out of sequence may cause damage to the library which

voids existing warranties.

NOTE: Retain all packaging materials in a protected place in case the library needs to be

shipped to a different location.

Tools Needed

These tools that are needed to unpack the library:

• 9/16” wrench

• 10” adjustable wrench

• Large flat-blade offset screwdriver

• Box knife

Removing the Outer Carton

To ensure safe delivery, each NEO 8000 comes packed with tie-down hardware securing it

to the pallet. The proper steps must be taken to remove the packaging.

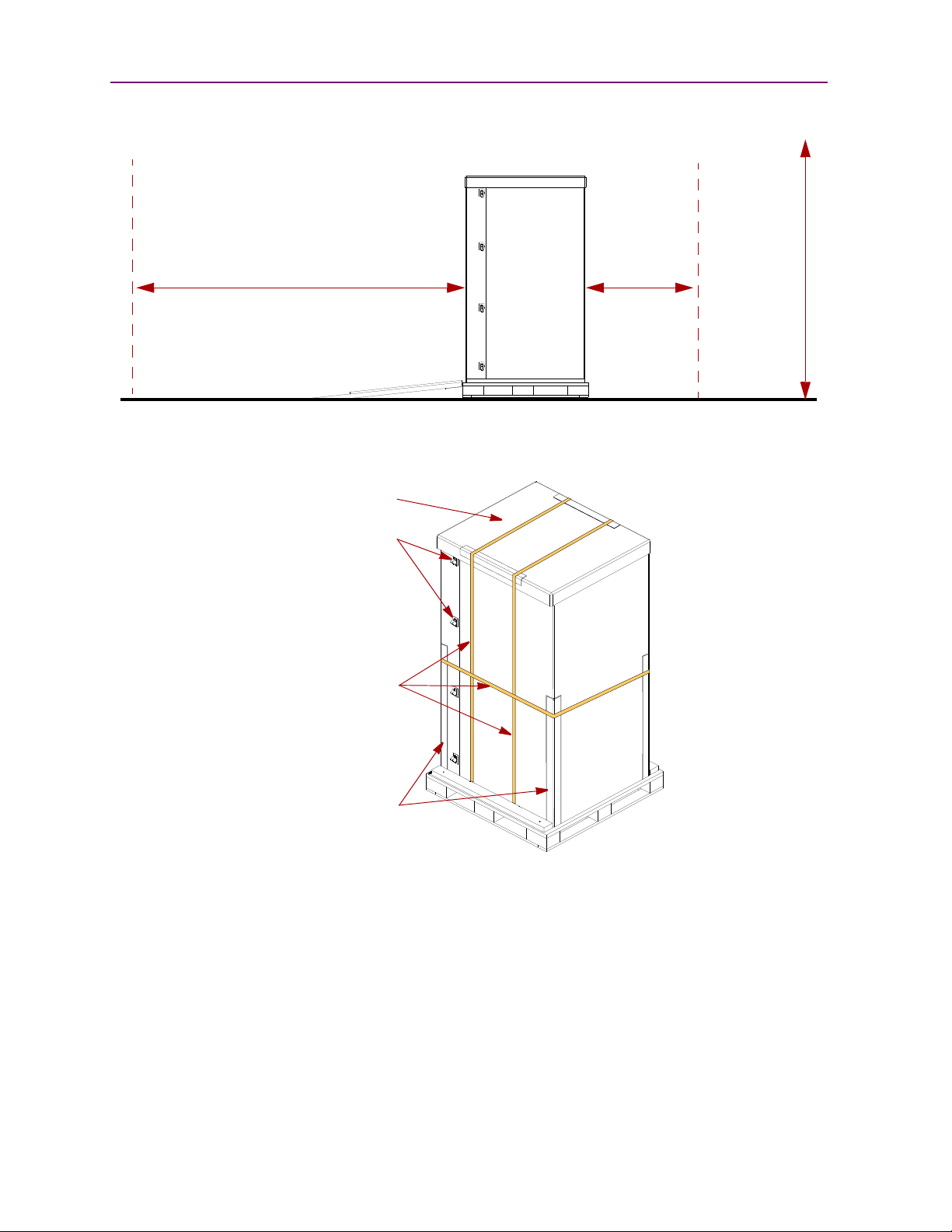

1. Position the shipping container on a level surface so there is enough clearance to

work around it (Figure 2-1).

• Allow at least 10 feet of clear space on the removal side of the container.

• Allow about 3 feet of clearance around the other three sides of the container.

• At least 8 feet of vertical clearance is needed.

NOTE: The container pallet is labeled “RAMP SIDE” on each corner of the removal side.

10400267-101 09/2009 W 2–1

Page 24

Chapter 2: Unpacking and Setting Up

N

E

O

-

8

1

1

7

`

Allow at least 10 ft. in

the rear to remove the

library from the pallet

Ramp

Floor

Allow 3 ft.

around

the library

Allow 8 ft.

vertical

clearance

N

E

O

-

8

1

1

3

Plastic

Strap

Corners

Reinforcing

Shipping

Retainers

Straps

Top Cap

Figure 2-1. Unpacking Space Requirements

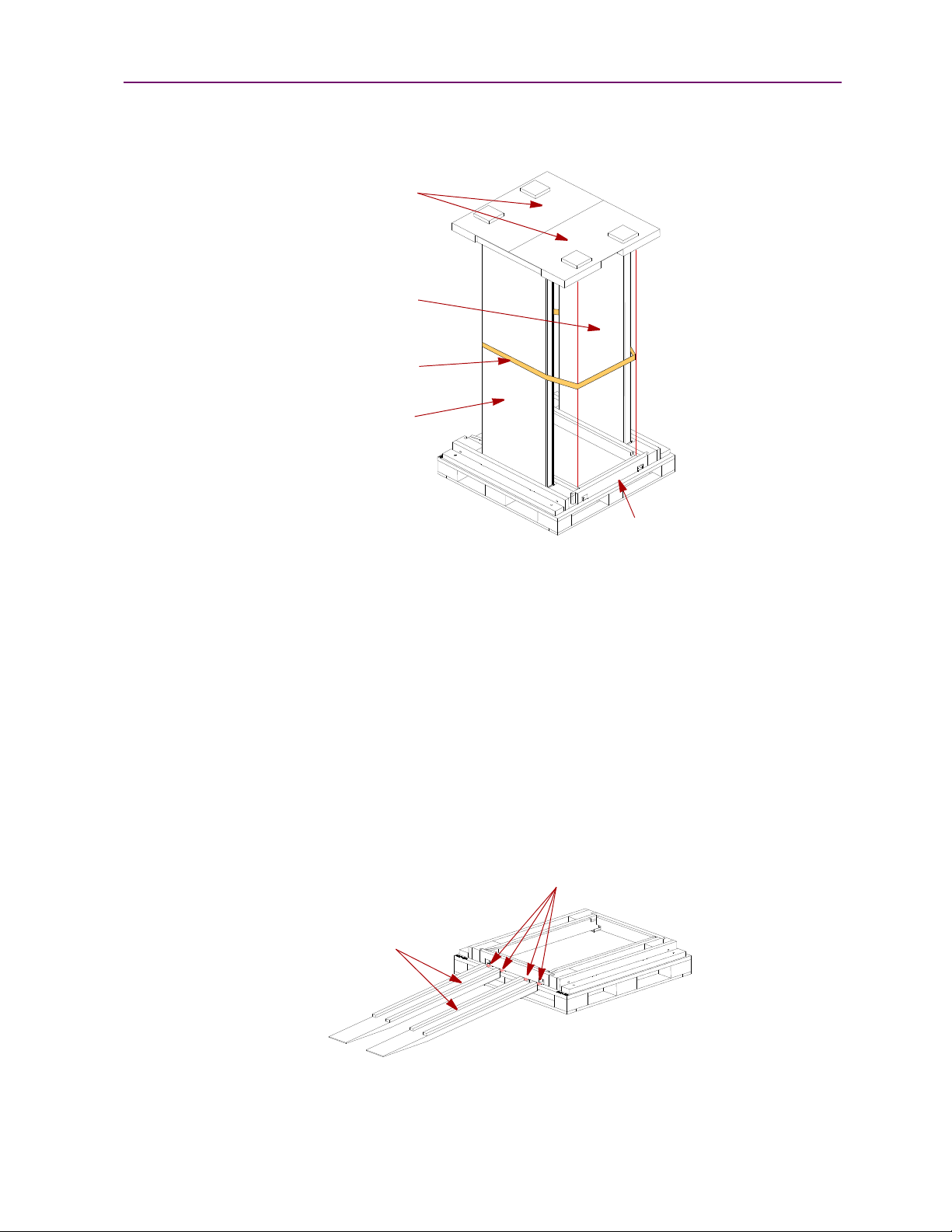

2. Remove the outside packaging (Figure 2-2).

a. Cut the three (3) shipping straps and remove.

b. Remove the six (6) shipping strap reinforcing corners from around the box.

c. Remove the top cap.

d. Release and remove each of the eight (8) plastic retainers (four each on opposite

corners).

e. Remove the two (2) large pieces of cardboard surrounding the library.

2–2 X 10400267-101 09/2009

Figure 2-2: Library Packaging Components

Page 25

3. Remove the inner packaging (Figure 2-3).

N

E

O

-

8

1

1

4

RAMP Box

Strap

(Library hidden for clarity)

Front

Top Pads

DOOR Box

N

E

O

-

8

1

1

5

(Library hidden for clarity)

Slots

Ramps

Detaching the Pallet

Figure 2-3: RAMP and DOOR Box Locations

a. Remove the two (2) pads on top of the library.

b. While holding the RAMP and DOOR boxes (one on each side of the library), cut and

remove the strap that secures the boxes to the library.

c. Remove the RAMP and DOOR boxes and set them aside for now.

d. Remove the plastic sheet that covers the library.

Detaching the Pallet

Once the cardboard pieces are removed, you can remove the hold-down hardware.

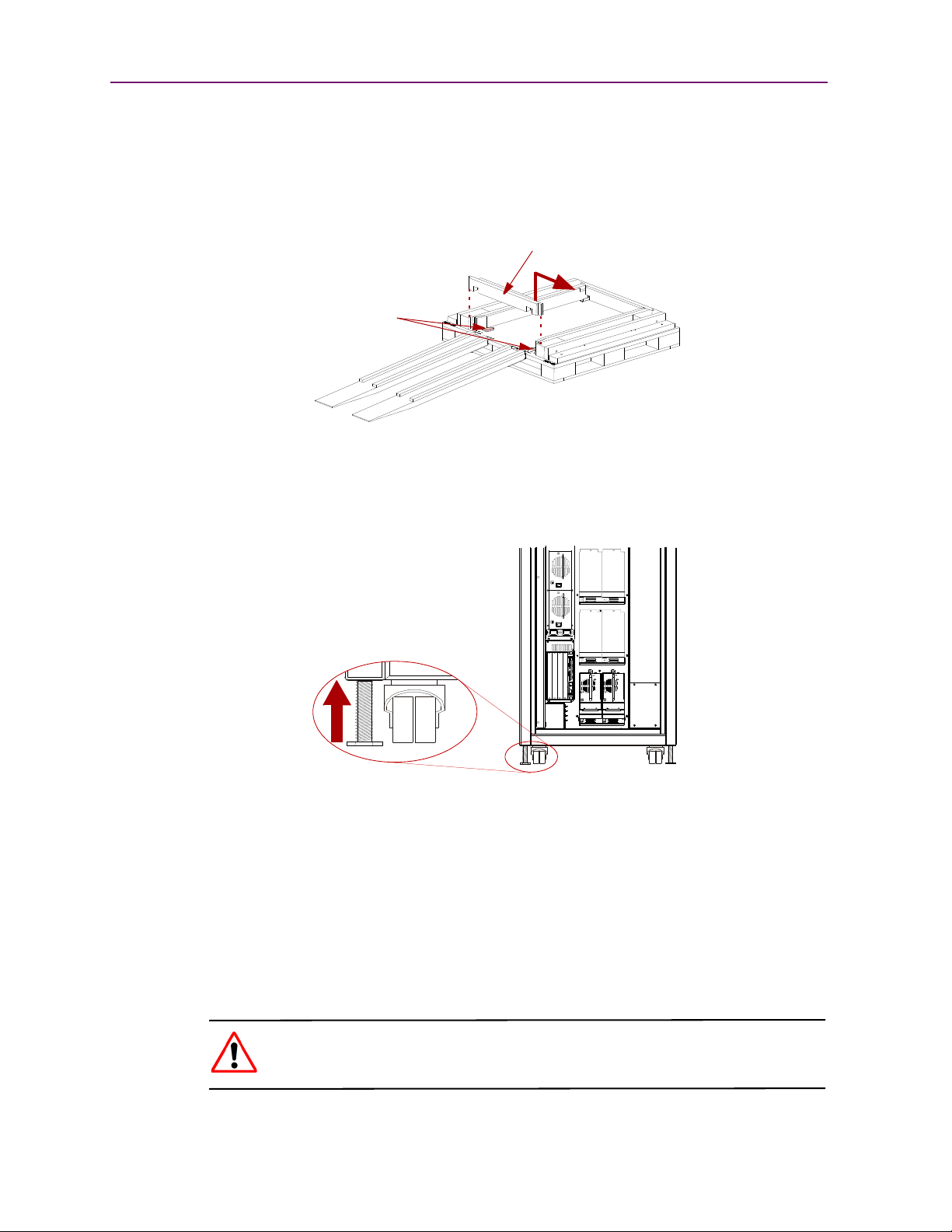

1. Remove the ramps from the RAMP box and lay them down, placing the brackets into

the corresponding slots in the pallet (Figure 2-4).

Figure 2-4: Placing the Ramps in Position

10400267-101 09/2009 W 2–3

Page 26

Chapter 2: Unpacking and Setting Up

N

E

O

-

8

1

1

6

Crossbar

Bolts

(Library hidden for clarity)

N

E

O

-

8

1

0

6

2. Remove the rear hardware holding the library on the pallet.

a. To provide access to the hold-down bolts and leveling legs, remove the rear

crosspiece (Figure 2-5). This is done by opening the rear door, lifting the right

end of the crosspiece, and sliding the left end of the crosspiece out of its recess.

Figure 2-5: Removing the Rear Crosspiece

b. Use a 9/16” wrench to remove the two bolts and hold-down brackets.

c. Use the adjustable wrench to loosen and raise the two leveling legs (Figure 2-6).

3. Remove the front hardware holding the library on the pallet.

NOTE: Lift the front crosspiece ends for access to the bolts, brackets, and leveling legs.

a. Use a 9/16” wrench to remove the bolts and hold-down brackets.

b. Use the adjustable wrench to loosen and raise the two leveling legs

(Figure 2-6).

4. Verify that all four leveling legs can clear the floor at the bottom of the ramp and that

the library is only supported by the four caster wheels.

2–4 X 10400267-101 09/2009

Figure 2-6: NEO 8000 Casters and Leveling Legs

WARNING: Most of the weight of a library is in the rear of the unit. If the leveling

legs are not raised high enough, they can catch at the bottom of the ramps, tipping

over the library unit.

Page 27

5. Carefully move the library down the ramps and onto the floor.

N

E

O

-

8

0

9

1

Nylon Washers

Door

Left Door

Hinge

Block

Library Hinge Block

(between hinges)

Hinge Pin

Door Check

CAUTION: Do not pull on the media drawer handles when moving the library.

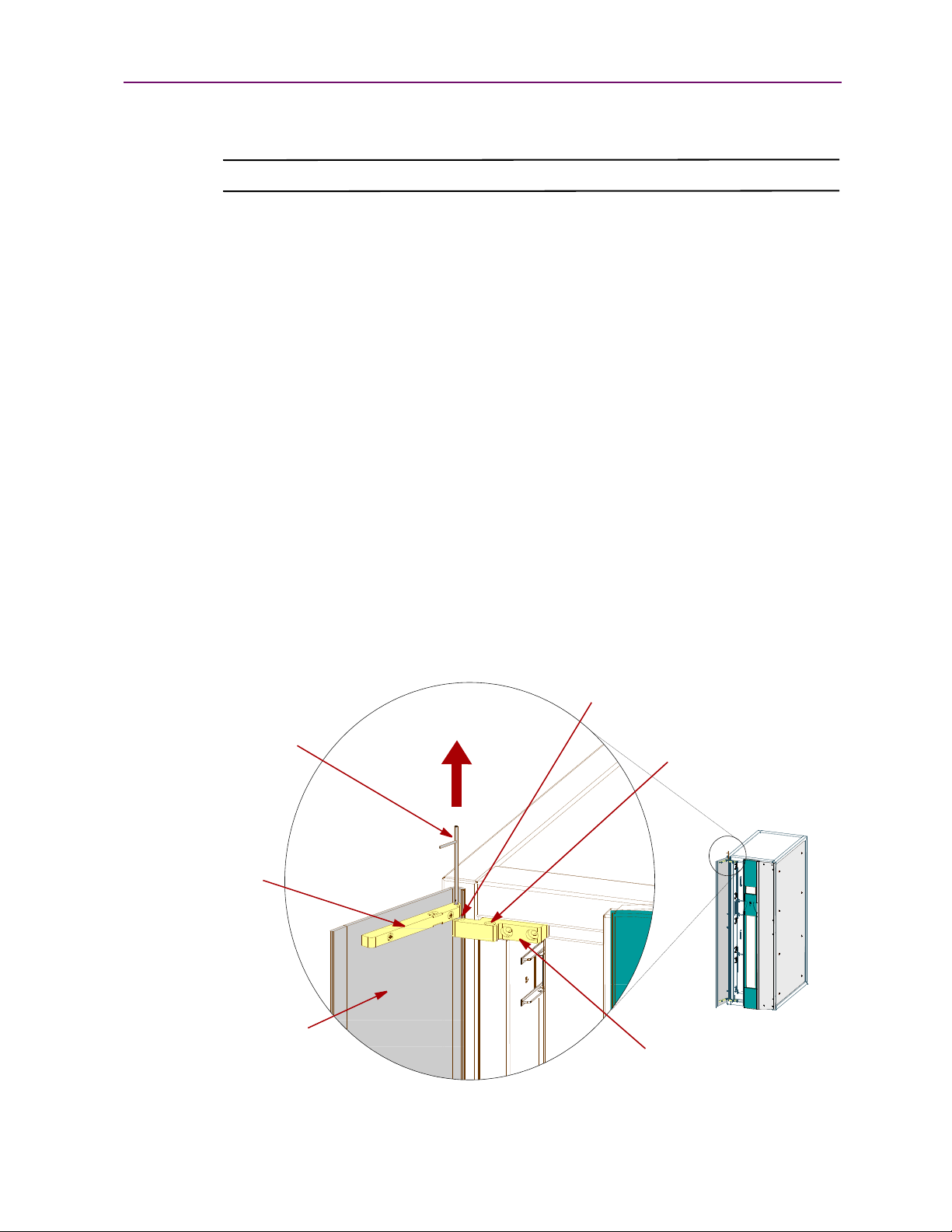

Attaching the Front Doors

Before moving the library to its final operating position, attach the front doors.

NOTE: The square, straight end of the door is the top and the curved end is the bottom.

1. Remove the two doors from the DOOR shipping box and extract them from their

plastic shipping bags.

2. Locate the bag of nylon washers inside the bag on the back door.

The washers are used as bearings between the hinges.

3. Attach the left door and adjust it for alignment and operation (Figure 2-7).

a. Lift the top hinge pin just enough to retract the tip into the left door’s hinge

block.

Attaching the Front Doors

b. Place one nylon washer onto the bottom hinge pin that protrudes below the door

hinge block.

It is held in place by the hinge pin’s ball retainer.

c. Position the door vertically with the bottom hinge pin above the library hinge

block hole and seat it.

d. Raise the door slightly, push down the top hinge, and place a washer on it.

Figure 2-7: Attaching the Doors

10400267-101 09/2009 W 2–5

Page 28

Chapter 2: Unpacking and Setting Up

N

E

O

-

8

1

1

2

e. Lower the door so that the top hinge pin is above the library hinge block hole and

seat it.

f. Using the flat-blade offset screwdriver, unscrew the door checks in both the

upper and lower library hinge blocks until the door closes freely.

g. Close the door and check that the top edge of the door meets the front panel

façade evenly.

• If the door is low, add washers to raise the door.

• If the door is high, remove the top washer.

CAUTION: The weight of the door should be carried by at least one hinge with a nylon

washer.

h. When the door height is correct, screw in the door checks until the door closes

smoothly yet is held firmly.

4. Repeat Steps a–h for the right door.

Leveling the Library

You are now ready to move the unit into its final position and level it.

CAUTION: Do not pull on the media drawer handles when moving the library.

1. Position the library at its operating location.

2. Run down all four leveling legs by hand until they contact the floor.

3. Using a wrench, turn each leg, one after the other in equal increments, until you have

turned them at least one full turn.

NOTE: Be sure the library has been raised high enough so none of the casters touch the floor.

4. Place a level, front to rear, on the top side edge of the library (Figure 2-8).

2–6 X 10400267-101 09/2009

Figure 2-8: Positioning the Level

Page 29

5. Note the position of the bubble. Raise both of the front legs or both of the rear legs the

N

E

O

-

8

0

0

6

Right-side

Brackets

same amount to achieve a level front-to-rear reading.

6. Place the level across the top front edge of the library.

7. Note the position of the bubble. Raise both of the left feet or both of the right feet the

same amount to achieve a level side-to-side reading.

8. Recheck the level from front-to-rear and from side-to-side. Adjust as needed until the

library is level.

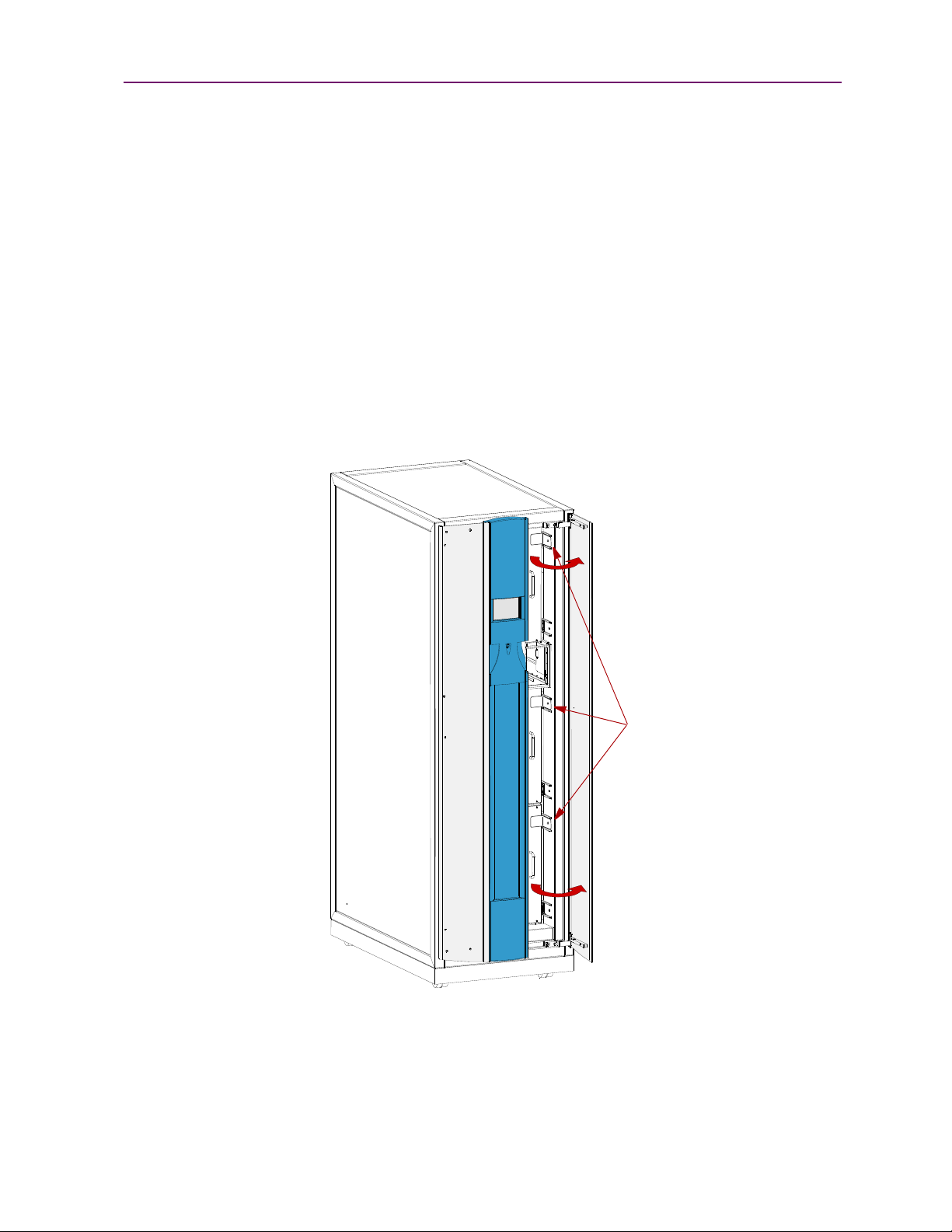

Remove the Drawer Shipping Brackets

Once the library is in position, use a phillips screwdriver to remove the six drawer shipping

brackets located inside the doors on the side trim pieces (Figure 2-9). Replace the screws

back into the trim pieces and retain the brackets.

Remove the Drawer Shipping Brackets

Figure 2-9: Drawer Shipping Brackets

10400267-101 09/2009 W 2–7

Page 30

Chapter 2: Unpacking and Setting Up

2–8 X 10400267-101 09/2009

Page 31

Installation and Initialization

3

CHAPTER

Once the NEO 8000 Library is secure and level, you need verify the basic cable

connections are in place before powering on the library for the first time.

Installation Considerations

If the unit is installed in a closed environment it may require further evaluation by

Certification Agencies. The following items must be considered:

• The ambient temperature within the unit may be greater than room ambient.

Installation should be such that the amount of air flow required for safe operation is

not compromised. The maximum temperature for equipment environment is 50°C.

Consideration should be given to maximum rated ambient.

• Installation should be such that a hazardous stability condition is not achieved due

to uneven loading.

Input Supply

Check nameplate ratings to assure there is no overloading of supply circuits that could

have an effect on over-current protection and supply wiring.

Grounding

Reliable earthing of this equipment must be maintained. Particular attention should be

given to supply connections when connecting power strips, rather than direct connections

to the branch circuit.

Power-Up and Cabling Pre-Check

The NEO 8000 comes from the factory with any installed components connected and

ready to use. Before powering up the library, it is recommended that you verify these

connections have not come loose in shipment.

NEO 8000 Libraries come with zero factory-installed drives. All drives are shipped as

“add-on” drives and must be installed on site. Refer to the instructions that come with

every add-on drive assembly for the preferred installation procedure and cabling

recommendations.

For more information about cabling options, refer to Chapter 8, “Cabling Options and

Examples.”

10400267-101 09/2009 W 3–1

Page 32

Chapter 3: Installation and Initialization

N

E

O

-

8

0

1

4

b

ONOFF

AC

Receptacles

Circuit 1

Circuit 2

(Primary)

(Secondary)

Powering Up the Library

Use the following instructions to apply power to your library:

1. Route the two supplied power cords through the slot opening in the base plate at the

bottom transom of the library.

2. Connect the power cords to the two AC receptacles at the bottom of the circuit breaker

box (Figure 3-1).

3. Connect the other ends of the power cords to your AC source.

4. Set both circuit breakers to the ON position.

5. Set the power switches on the power supplies to the ON (|) position.

At this point, the library automatically turns on. You do not need to touch the GUI or power

button on the front panel.

Power-On Self Test

When power is first applied to the library, a series of Power-On Self Test (POST) diagnostics

are performed. The POST consists of these items occurring in this order:

• Validates firmware CRC.

• Activates the power supplies in this order:

• Robotics

• Drives 1-6

• Drives 7-12 (if installed)

• Tests SCSI protocol chip.

• Checks the status of the drives installed.

• Initializes the internal robotics.

• Inventories the media drawers and drives.

• Activates full library functionality.

Figure 3-1: NEO 8000 Circuit Breakers (OFF Position)

3–2 X 10400267-101 09/2009

Page 33

Powering Down the Library

As the POST starts, the Initialization screen appears (Figure 3-2).

Figure 3-2: Initialization Screen

After about 50 seconds (or if the Continue button is pressed), the Default screen appears

(Figure 3-3).

Figure 3-3: Library Default Screen

NOTE: Though visible, this screen is not fully functional until POST completes. During POST, you

can only access two Menu functions—Network Options and Library Info.

Once POST completes, the library is online and ready for use.

Powering Down the Library

WARNING: The GUI touch screen does not completely shut off library system power. To

reduce the risk of electric shock or damage to equipment, disconnect power by

unplugging the power cords.

Standard Method

This is the recommended method for powering down the library. It initiates a controlled

power-down sequence that provides enough time to park the robotics assembly and shuttle.

1. Press the GUI Power button located on the Default screen.

2. Choose one of the following options from the dialog box:

• Press OK to confirm power down.

• Press Cancel to return to default display.

10400267-101 09/2009 W 3–3

Page 34

Chapter 3: Installation and Initialization

Alternate Method

This method can be used to bypass the controlled power-down sequence for quickly shutting

down the library.

1. Press and hold the power button on the front panel for about 3 seconds.

2. Choose one of the following options from the dialog box:

• Press OK to confirm power down.

• Press Cancel to return to default display.

3–4 X 10400267-101 09/2009

Page 35

Daily Operation

4

CHAPTER

This chapter covers some of the configuration changes to the NEO 8000 Library that occur

during everyday use.

Common Configuration Modifications

The library provides several configuration options to support a variety of applications and

platforms. The settings for each of the available options are stored in non-volatile memory

in the library.

For most applications, you do not have to change the factory default settings; however, if

you do need to change the configuration, use the instructions provided in the following

sections. If you are uncertain whether you need to change a setting, contact your

authorized service provider.

For detailed information about the GUI touch screen and its options, refer to Chapter 5,

“Graphical User Interface Usage.”

Setting a SCSI ID

Each SCSI tape drive installed in the library requires a unique SCSI ID. The information

provided in this section instructs you on how to change a default SCSI ID.

1. From the Default screen of the GUI, press Menu.

2. In the Edit Options area, press SCSI/FC.

NOTE: If a Service password is enabled, the validate password screen is displayed. Enter

The initial SCSI screen is shown (Figure 4-1).

the correct password and press Validate.

Figure 4-1: SCSI Initial Screen (Edit Options)

3. If necessary, use the arrow buttons to scroll down to locate the drive being changed.

10400267-101 09/2009 W 4–1

Page 36

Chapter 4: Daily Operation

4. Press the virtual button to the right of the tape drive you are changing.

The Bus ID edit screen is displayed (Figure 4-2).

5. Press one of the SCSI ID number buttons for the new ID and press Save.

6. At the Confirm dialog box, press either OK to accept or Cancel to discard the change.

Figure 4-2: Bus ID Edit Screen

NOTE: If you enter a ID number that is already assigned, you are prompted to accept the

duplication (Figure 4-3).

Figure 4-3: Bus ID Confirmation Dialog Box

The newly selected SCSI ID flashes for a few seconds while the drive is being updated,

then stops indicating that the operation is complete.

7. Press Back twice to return to the Default screen.

Configuring a Fibre Channel Drive

In most cases, you can use the default configuration values for Fibre Channel drives.

However, if it becomes necessary to change the default values, these values are editable:

• Port n Control

• Port n Loop ID

4–2 X 10400267-101 09/2009

Page 37

Common Configuration Modifications

• World Wide Port n Name

• World Wide Node Name

• Topology

• Speed

• Directory Registration

Table 5-6 in Chapter 5, “Graphical User Interface Usage,” details all the different settings

available. The information in this section shows you how to make those changes.

CAUTION: To support different LTO FC drives, the library firmware must be at least at these levels:

• LTO-3 Fibre Channel Drive – Version 4.03 or higher

• LTO-4 Fibre Channel Drive – Version 6.04 or higher

Verify the firmware level of your library by selecting Menu > Library Info from the Default screen. If it

needs to be upgraded, visit the Overland Storage Technical Support web site for the latest versions

of the firmware. For information about downloading firmware, see “Downloading and Flashing

Library/Tape Drive Firmware” on page 6-17.

1. From the Default screen of the GUI, press Menu.

2. In the Edit Options area, press SCSI/FC.

NOTE: If a Service password is enabled, the validate password screen is displayed. Enter the

correct password and press Validate.

The initial FC screen is shown (Figure 4-4).

Figure 4-4: FC Initial Screen (Edit Options)

3. If necessary, use the arrow buttons to scroll down to locate the drive being changed.

4. Press the Set Values button to the right of the tape drive you are changing.

The Set Values edit screen (Edit Drive Configuration) is displayed (Figure 4-5).

10400267-101 09/2009 W 4–3

Page 38

Chapter 4: Daily Operation

Reserved Slots

5. Make all the necessary changes by pressing the appropriate buttons and entering the

new data.

6. Press Save.

A dialog box appears stating the configuration is being updated, and then you are

automatically returned to the FC edit screen.

Figure 4-5: Edit FC Drive Configuration (Set Values) Screen

7. Press Back twice to return to the Default screen.

Creating Reserved Slots

This process deactivates some of the media slots in the library from use as storage slots. This

is usually done to meet licensing requirements or to dedicate media slots as cleaning tape

slots.

All of the Fixed Slots (20 LTO) can be converted to reserved slots. The reserved slots are

labeled “Clng n” on the Cartridge Map and Status screens (Figure 4-6).

1. From the Default screen of the GUI, press Menu.

4–4 X 10400267-101 09/2009

Figure 4-6: Labeling of Reserved Slots on GUI Screens

Page 39

Common Configuration Modifications

2. In the Edit Options area, press Library.

NOTE: If a Service password is enabled, the validate password screen is displayed. Enter the

correct password and press Validate.

The initial Library screen is shown (Figure 4-7).

Figure 4-7: Library Initial Screen (Edit Options)

3. Press the button to the right of Total Reserved Slots.

The Total Reserved Slots option screen is displayed (Figure 4-8).

Figure 4-8: Total Reserved Slots Option Screen

4. Using the Decimal Keypad, enter the number of slots you want to reserve.

The number must be within the range shown on the screen.

5. Press Save.

6. At the Confirm dialog box (Figure 4-9), press either OK to accept or Cancel to discard

the change.

10400267-101 09/2009 W 4–5

Page 40

Chapter 4: Daily Operation

Bar Code Label

7. Press Back twice to return to the Default screen.

Media Handling

Figure 4-9: Total Reserved Slots Confirm Dialog Box

The tape cartridge media is the focus for most of the daily operations of a NEO 8000 Library.

A library manages up to 500 cartridges including any cleaning cartridges.

Bar Code Labels

The graphic below (Figure 4-10) shows you how to install a bar code label on an LTO tape

cartridge.

NOTE: Only Overland Storage bar code labels are supported with the library. To order additional

labels, contact your authorized Overland Storage reseller.

4–6 X 10400267-101 09/2009

Figure 4-10: Bar Code Label Installation

Page 41

The following are tips to ensure maximum LTO cartridge media performance and life:

N

E

O

-

8

0

0

8

• For best results use Overland Storage media and bar code labels.

• Place labels only in the recessed area, just below the write protection switch.

Never place labels on the top, bottom sides or rear of the cartridge—they can cause

loader faults and interfere with normal operations. Labels placed in such locations can

come off inside the equipment causing damage.

• Always inspect cartridges for incorrect or improperly attached labels.

• Never erase information on a cartridge label—always replace the label.

Using Mail Slot Magazine for Small Quantity Exchanges

The NEO 8000 features a Mail Slot that allows you to import or export multiple cartridges

without interrupting library operation. The Mail Slot magazine (Figure 4-11) holds 15 LTO

cartridges.

Media Handling

Figure 4-11: Mail Slot Location

The first slot is the one closest to the front of the magazine while the last slot is at the rear.

10400267-101 09/2009 W 4–7

Page 42

Chapter 4: Daily Operation

N

E

O

-

8

0

5

6

LTO Mail Slot Magazine

Last Slot (15)

First Slot

Insert tape cartridges so that the bar code labels are facing outward and the tape hub is

toward the left (Figure 5-12). Handle and store tape cartridges in a clean, dust-free

environment.

Adding Media

Follow these steps to add tape cartridges:

Figure 4-12: Inserting Cartridges Into the Mail Slot

NOTE: You can also add 10 cartridges at a time using the Load/Unload Fixed Slots button. See

“Load/Unload Fixed Slots Button” on page 5-16 for more details.

1. At the GUI screen, press Mail Slot Access.

2. When you hear the latch release, remove the Mail Slot magazine.

3. Insert the tape cartridges being added to the library into the magazine, and reinsert

the magazine into the library.

4. Press the Mail 1-nn button to relatch it, and then press Back.

5. At the Default screen, press Move Media.

The Move Media screen is displayed (Figure 4-13).

NOTE: When selecting the Source or Destination locations, you can repeatedly press the

Element Type button to cycle through all the available choices. You can also use the

Decimal Keypad to enter the choice number directly into the field.

4–8 X 10400267-101 09/2009

Page 43

Media Handling

Figure 4-13: Move Media Screen

6. Press in the Source field, select Mail Slot as the Source Element Type, and select the

slot number where it is located.

7. Press in the Destination field, select a location for the tape being added as the

Destination Element Type, and select the destination slot number.

8. Press Execute Move.

Wait for the tape to be moved. You are automatically returned to the Default menu

when done.

9. Repeat Steps 5–8 until all tapes are moved from the Mail Slot.

Removing Media

Follow these steps to remove tape cartridges:

NOTE: You can also remove 10 cartridges at a time using the Load/Unload Fixed Slots button. See

“Load/Unload Fixed Slots Button” on page 5-16 for more details.

1. At the GUI screen, press Move Media.

2. Press in the Source field, select the location of the tape being removed as the Source

Element Type, and select the slot number where it is located.

3. Press in the Destination field, select Mail Slot as the Destination Element Type, and

select the destination slot number.

4. Press Execute Move.

Wait for the tape to be moved. You are automatically returned to the Default menu

when done.

5. Repeat Steps 1–4 until all tapes are in the Mail Slot or it is full.

6. Press Mail Slot Access.

7. When you hear the latch release, take out the Mail Slot magazine and remove the

applicable tapes from the magazine.

8. Reinsert the Mail Slot magazine into the library.

9. Press the Mail 1-nn button to relatch it, and then press Back.

10400267-101 09/2009 W 4–9

Page 44

Chapter 4: Daily Operation

N

E

O

-

8

0

1

1

N

E

O

-

8

0

3

0

First Slot

Last Slot

Using Media Drawers for Bulk Exchanges

There are six media drawers in the NEO 8000 Library. Each drawer holds up to 80 LTO

cartridges. The first slot is located at the bottom front of the drawer and the last slot is at the

top back (Figure 4-14).

NOTE: Depending on the library’s configuration, some drawers may not be enabled.

Figure 4-14: NEO 8000 Left and Right Media Drawers

If you need to add or remove a large number of tape cartridges, it is usually easier to stop the

library and open the media drawers.

1. Press Drawer Access.

This takes the library offline. Wait for the robotics to come to a complete stop.

2. Press either a specific drawer button or Unlock All.

3. Open the Media Access Doors.

4. Load or unload a drawer.

a. Pull an unlatched drawer outward until it stops.

b. Add or remove the media.

c. Slide the drawer all the way back into the library.

5. Repeat Step 4 for any remaining drawers.

6. Close the Media Access Doors.

7. Press either the same specific drawer button or Lock All.

The library comes back online.

8. Press Back to update the library and return to the Default screen.

Moving Media Inside the Library

The Move Media command provides the means to move cartridges around the library

without physically touching them.

Standalone

1. At the GUI screen, press Move Media.

4–10 X 10400267-101 09/2009

Page 45

Media Handling

Slave

Library

Selection

Library

Status

Info

2. Press the Source field, select the location of the tape being moved as the Source

Element Type, and enter its slot number.

3. Press the Destination field, select a destination for the tape as the Destination

Element Type, and enter the destination slot number.

4. Press Execute Move.

Wait for the tape to be moved. You are automatically returned to the Default menu

when done.

Master/Slave with HRA

IMPORTANT: See the NEO 8000 Scalability Upgrade Installation Instructions for more details.

Moving media back and forth between Master and Slave units using the HRA is the same as

with a Standalone library. The move is executed at the Master GUI screen. The libraries are

differentiated by the slot and drive numbering.

NOTE: Because all Master drawers must be enabled before any Slave drawers can be activated,

the Slave unit slot numbering always starts with 501 for LTO. However, drives are

numbered sequentially with Master first and Slave next.

Element numbering can be checked using the Status button. With a Master/Slave system, a

new drop-down option is visible in the upper right corner (Figure 4-15). Choose either

Master or Slave to view the appropriate information.

Figure 4-15: Master/Slave Status (Library Information) Screen

10400267-101 09/2009 W 4–11

Page 46

Chapter 4: Daily Operation

Tape Drive Cleaning

CAUTION: Only perform a Clean Drive option when the library displays a message informing you that

a drive needs cleaning. Because a cleaning cartridge is abrasive, excessive cleaning can shorten the

life of a drive.

The NEO 8000 has options to either automatically or manually clean a tape drive. Most

backup software also can manages the cleaning of library tape drives as a normal part of

operations but it is usually based on a time limit rather than a drive need.

There are two ways to manage the cleaning of the installed tape drives:

• Automatically, by enabling Auto Clean Mode available under Menu > Library Options.

• Manually, by selecting the Clean Drive option located under Menu > Maintenance.

NOTE: With the exception of Clean Drive, Load/Unload Fixed Slots, and Configure Capacity, the

Maintenance option is designed for use by Overland Authorized Service Technicians and is

not recommended for access by end users.

Automatically Running a Cleaning Cartridge

You can configure the library to automatically run the cleaning cartridge mode. If a tape

drive needs cleaning, after it completes an unload operation, it sends a cleaning needed

message to the library. This activates the automatic cleaning cycle provided a cleaning

cartridge slot has been reserved with a cleaning tape in it.

To automatically run a cleaning cartridge using Auto Clean Mode:

1. Reserve one or more cleaning cartridge slots using Menu > Library > Total

Reserved Slots.

2. Install a cleaning cartridge into a reserved slot.

3. Enable automatic cleaning using Menu > Library > Auto Clean Mode > Enabled.

Manually Running a Cleaning Cartridge

A cleaning cartridge can be installed and run from one of three locations:

• Mail Slot - This location has the advantage of not needing to use a data cartridge slot

or to reserve a cleaning cartridge slot.

• Data Cartridge Slot - This location requires inserting a cleaning cartridge into a data

cartridge slot and then removing it after cleaning.

• Cleaning Slot - This location requires reserving some of the Fixed Slots for exclusive

use as cleaning cartridge slots. The advantage with this method is that the cleaning

cartridge is stored in the library and is always available for use. It only needs to be

handled when the cartridge needs to be replaced. See Total Reserved Slots under

“Library Options Button (View System Data)” on page 5-11 for more information.

NOTE: When selecting the Source or Cleaning locations, you can repeatedly press the Element

Type button to cycle through all the available choices. You can also use the Decimal

Keypad to enter the choice number directly into the field.

4–12 X 10400267-101 09/2009

Page 47

Tape Drive Cleaning

Running a Cleaning Cartridge from the Mail Slot

1. Install a cleaning cartridge into the Mail Slot magazine.

2. From the GUI screen, select Menu > Maintenance > Clean Drive.

3. Press the Source field and select Mail Slot as the Source Element Type.

4. Select the Cleaning field and press Drive in the Destination Element Type box.

5. Press Execute Clean.

When the cleaning cycle completes, the library returns the cleaning cartridge back to

the Mail Slot magazine and the display returns to the Maintenance options screen.

6. Press Back twice to return to the Default screen.

7. Use the Mail Slot Access option to remove the cleaning cartridge.

Running a Cleaning Cartridge from a Data Cartridge Slot

1. Install a cleaning cartridge into a data cartridge slot (Slot 1, for example) using the

Drawer Access option.

2. From the GUI screen, select Menu > Maintenance > Clean Drive.

3. Press the Source field and select Slot as the Source Element Type.

4. Select the Cleaning field and press Drive in the Destination Element Type box.

5. Press Execute Clean.

When the cleaning cycle completes, the library returns the cleaning cartridge back to

the designated slot and the display returns to the Maintenance options screen.

6. Press Back twice to return to the Default screen.

7. Use the Drawer Access option to remove the cleaning cartridge.

Running a Cleaning Cartridge from the Cleaning Slot

1. Reserve one or more cleaning cartridge slots using Menu > Library > Total

Reserved Slots.

2. Install a cleaning cartridge into a reserved slot.

3. From the GUI screen, select Menu > Maintenance > Clean Drive.

4. Press the Source field and select Cleaning Slot as the Source Element Type.

5.

Select the Cleaning field and press Drive in the Destination Element Type box.

6. Press Execute Clean.

When the cleaning cycle completes, the library returns the cleaning cartridge back to

the designated cleaning slot and the display returns to the Maintenance options

screen.

7. Press Back twice to return to the Default screen.

10400267-101 09/2009 W 4–13

Page 48

Chapter 4: Daily Operation

Replacing a Cleaning Cartridge in a Reserved Slot

When a tape drive detects an expired cleaning cartridge, a message appears on the front

panel display. It is then necessary to replace the cleaning cartridge.

1. Use the Status screen to verify that the cleaning cartridge has been unloaded from

the tape drive.

If necessary, unload it using the Move Media menu option.

2. Move the expired cartridge to the Mail Slot.

3. Select Mail Slot Access.

4. Remove the Mail Slot magazine from the library.

5. Remove the expired cartridge, mark it “EXPIRED,” and then properly dispose of it.

6. Place a new cleaning cartridge in the Mail Slot magazine.

7. Insert the Mail Slot magazine back into the library.

8. If the cleaning cartridge did not reside in the Mail Slot magazine, use Move Media to

move it to its proper place.

4–14 X 10400267-101 09/2009

Page 49

5

N

E

O

-

8

0

0

1

a

GUI Touch Screen

CHAPTER

Graphical User Interface Usage

The Graphical User Interface (GUI) touch screen on the front of the NEO 8000 provides

an easy way to directly communicate with the library.

By gently pressing the virtual buttons, you can select menus and options to view or

change library settings.

NOTE: Refer to “WebTLC Usage” or “Neo8000Center Usage” for other ways to communicate

Overview

The GUI is a 4.5” x 3.5” (11.4 x 8.9 cm) pressure-sensitive color screen. It provides text and

graphic messages and, through the use of virtual buttons and sliders, allows users to

make changes to current library settings.

Some features are comprised of multiple screens. To move between these screens, use the

or arrows. The Back button returns you to the previous screen.

For most applications, you do not have to change the factory default settings. If changes

are needed, use the instructions provided in the following sections. If you are uncertain

whether you need to change a setting, contact your authorized service provider.

Figure 5-1: GUI Touch Screen Location

and configure the library.

10400267-101 09/2009 W 5–1

Page 50

Chapter 5: Graphical User Interface Usage

Technical

Contrast

Controls

Support

Default Screen

The Default screen appears 50 seconds after POST diagnostics begins or when the Continue

button is pressed (Figure 5-2).

Figure 5-2: Library Default Screen

NOTE: Though visible, this screen is not fully functional until POST completes. During POST, you

can only access the Menu functions Network Options and Library Info in the View System

Data area.

From this screen you can access all options, functions, informational screens, and screen

contrast adjustments of the NEO 8000. You can also initiate a controlled shutdown of the

library. Tapping the logo area turns on the internal light for 30 seconds.

Password Protection

To avoid accidental interruption of library operation, the NEO 8000 lets you assign up to