Page 1

ARCvault

Series

Autoloader/Library

™

Service Manual

Part Number 10400025-101

October 2006

Page 2

Proprietary Notice

All information contained in or disclosed by this document is considered proprietary by Overland Storage. By

accepting this material, the recipient agrees that this material and the information contained therein are held

in confidence and in trust and will not be used, reproduced in whole or in part, nor its contents revealed to

others, except to meet the purpose for which it was delivered. It is understood that no right is conveyed to

reproduce or have reproduced any item herein disclosed without express permission from Overland Storage.

Overland Storage provides this manual as is, without warranty of any kind, either expressed or implied,

including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose.

Overland Storage may make improvements or changes in the products or programs described in this manual at

any time. These changes will be incorporated in new editions of this publication.

Overland Storage assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness of this

manual, nor for any problem that might arise from the use of the information in this manual.

Overland products are covered by one or more of the following patents registered with the USPTO: 5,870,245; 6,328,766; 6,353,581; 6,496,325.

Overland®, Overland Storage®, XchangeNOW®, VR2®, WebTLC®, PowerLoader®, LoaderXpress®, NEO SERIES®, and REO SERIES® are registered trademarks of

Overland Storage, Inc. Simply iSCSI™, Simply Protected™, Simply Protected Storage™, SnapWrite™, ULTAMUS™, ULTAMUS SERIES™, ULTAMUS PRO™,

ULTAMUS RAID™, REO™, NEO™, ARCvault™, ARCvault SERIES™, Protection OS™, Multi-SitePAC™, NDMP PAC™, CompliancePAC™, VTLPac™, and

D2D2T™ are trademarks of Overland Storage, Inc.

© 2006 Overland Storage, Inc. All rights reserved.

Worldwide Headquarters Overland Storage, Inc.

4820 Overland Avenue

San Diego, CA 92123

Toll Free: (800) 729-8725

Tel: (858) 571-5555

Fax: (858) 571-0982

Sales Tel: (858) 571-5555

Fax: (858) 571-3664

E-mail: sales@overlandstorage.com

http://www.overlandstorage.com

Technical Support Tel: (858) 571-5555

Fax: (858) 495-4202

Toll Free: (877) 654-3429

International: 001 (858) 571-5555 x5

E-mail: techsupport@overlandstorage.com

http://support.overlandstorage.com

Overland Storage, EMEA Overland House, Ashville Way

Wokingham, Berkshire

RG41 2PL, England

Tel: +44 (0) 118-9898000

Fax: +44 (0) 118-9891897

http://www.overlandstorage.com

ii Part Number 10400025-101 10/2006

Page 3

About this Manual

This service manual provides detailed information necessary for upgrading or repairing an

Overland Storage ARCvault Series™ autoloader or library. It is designed to be used only by

Overland-authorized service technicians.

Product Documentation

ARCvault product documentation and additional literature are available online at

http://www.overlandstorage.com.

Conventions

This service manual exercises several typographical conventions to help explain how to use the

ARCvault.

Convention Description & Usage

Boldface Words in boldface indicate items to select such as menu items or command

Ctrl-Alt-r This type of format details the keys you press simultaneously. In this example, hold

NOTE A Note indicates neutral or positive information that emphasizes or supplements

IMPORTANT An Important note is a type of note that provides information essential to the

CAUTION A Caution contains information that the user needs to know to avoid damaging or

WARNING A Warning contains information essential to people’s safety. It advises

buttons.

down the Ctrl and Alt keys and press the r key.

important points of the main text. A note supplies information that may apply only

in special cases—for example, memory limitations or details that apply to specific

versions of a program.

completion of a task or that can impact the product and its function.

permanently deleting data or causing physical damage to the hardware or system.

users that failure to take or avoid a specific action could result in

physical harm to the user or hardware.

Firmware Updates

The latest release of the ARCvault firmware can be obtained from the Overland Storage FTP

site.

1. Point your browser to ftp://ftp.overlandstorage.com/Firmware/ARCvault/.

2. Open the ARCvault folder.

3. Download the latest firmware file labeled ARCvault_nnnn.bin (where “nnnn” represents the

latest version number).

For additional assistance, search at http://support.overlandstorage.com/.

10400025-101 10/2006 iii

Page 4

Electrostatic Discharge Information

A discharge of static electricity can damage static-sensitive devices. Proper packaging and

grounding techniques are necessary precautions to prevent damage. To prevent electrostatic

discharge (ESD) damage, observe the following precautions:

• Transport products in static-safe containers such as conductive tubes, bags, or boxes.

• Keep electrostatic-sensitive parts in their containers until they arrive at static-free stations.

• Cover the loader or library with approved static-dissipating material.

• Use an ESD wrist strap connected to the work surface and grounded tools and equipment.

• Keep the work area free of non-conductive materials such as foam packing materials.

• Make sure you are always properly grounded when touching a static-sensitive component or

assembly.

• Avoid touching pins, leads, or circuitry.

Overland Technical Support

For assistance configuring and using your ARCvault, search for help at:

http://support.overlandstorage.com/

Our Overland Storage Technical Support staff is also available to assist you by phone at:

1 (877) 654-3429 (Toll-free and active only in US and Canada)

001 (858) 571-5555 x5 (Worldwide)

They are available on normal business days, 6 AM through 5 PM (PT), excluding Overland

holidays. At all other times we will respond to technical support calls within 4 hours.

Technical support for our European customers is available as well from our United Kingdom

office at:

+44 (0) 118-9898050

9:00 AM to 5:00 PM (GMT)

Monday through Friday

You can e-mail our technical support staff at techsupport@overlandstorage.com.

iv 10400025-101 10/2006

Page 5

Table of Contents

Section 1 - General Information

1.1 Safety ....................................................................................................................................................... 1-1

1.2 General Description ............................................................................................................................... 1-2

1.3 Version Control ....................................................................................................................................... 1-2

1.4 ARCvault Models Covered ................................................................................................................... 1-2

1.5 Specifications ......................................................................................................................................... 1-3

1.5.1 Physical Specifications ................................................................................................................. 1-3

1.5.2 Technical Information .................................................................................................................. 1-4

1.5.3 Reliability and Safety .................................................................................................................... 1-4

1.5.4 Temperature, Humidity and Altitude .......................................................................................... 1-5

1.5.5 Shock ............................................................................................................................................. 1-5

1.5.6 Vibration ........................................................................................................................................ 1-6

1.5.7 Electromagnetic Emissions .......................................................................................................... 1-7

Section 2 - System Overview

2.1 Installation ............................................................................................................................................... 2-1

2.1.1 Shipping Tie-Down Wire ............................................................................................................... 2-1

2.1.1.1 Tie-Down Removal .............................................................................................................. 2-1

2.1.1.2 Tie-Down Reinstallation for Shipment ................................................................................ 2-2

2.1.2 Rack Considerations .................................................................................................................... 2-3

2.1.2.1 Installing an ARCvault Library ............................................................................................ 2-3

2.1.2.2 Removing ARCvault Library for Service ............................................................................ 2-6

2.2 Attaching Cables ................................................................................................................................... 2-6

2.3 Power Management ............................................................................................................................. 2-7

2.3.1 Power-On Process ........................................................................................................................ 2-7

2.3.2 Power-Off Process ........................................................................................................................ 2-8

2.4 Interfaces ................................................................................................................................................ 2-8

2.4.1 Operator Control Panel ............................................................................................................... 2-8

2.4.1.1 ARCvault OCP Software Maps .......................................................................................... 2-9

2.4.2 Remote Management Utility ..................................................................................................... 2-10

2.4.2.1 ARCvault RMU Software Map .......................................................................................... 2-11

2.5 Password Protection ............................................................................................................................ 2-12

2.6 Tape Magazines ................................................................................................................................... 2-13

2.6.1 Slot Management ...................................................................................................................... 2-13

2.6.2 I/E Element .................................................................................................................................. 2-15

2.6.2.1 Single-Slot I/E Element ....................................................................................................... 2-15

2.6.2.2 Full-Magazine I/E Element ................................................................................................ 2-16

Section 3 - Troubleshooting and FSCs

3.1 Possible Problems ................................................................................................................................... 3-1

3.1.1 Sample Screens ............................................................................................................................ 3-1

3.2 Error Recovery ........................................................................................................................................ 3-1

3.2.1 FSC/ERP Cross-Reference Table ................................................................................................. 3-2

3.2.2 Error Recovery Procedures .......................................................................................................... 3-7

3.3 Tape Drive Removal ............................................................................................................................ 3-16

3.4 Touch Screen Overrides ...................................................................................................................... 3-17

3.4.1 Touch Screen Forced Recalibration .........................................................................................3-18

3.4.2 Touch Screen Contrast Reset .................................................................................................... 3-18

Section 4 - Adding or Replacing Components

4.1 Replacing a Tape Drive ........................................................................................................................ 4-1

4.1.1 Remove the Drive Assembly ....................................................................................................... 4-1

4.1.2 Replace Full-Height Drive ............................................................................................................ 4-2

Part Number 10400025-101 10/2006 v

Page 6

Table of Contents

4.2 Replacing Drive Cover Assembly ......................................................................................................... 4-4

4.3 Replacing A Media Magazine ............................................................................................................. 4-4

4.4 Exchanging a Chassis ............................................................................................................................ 4-5

4.5 Adding a Second Drive to an ARCvault 24 ........................................................................................ 4-8

4.1.3 Replace Half-Height Drive ........................................................................................................... 4-2

4.1.4 Reinstall the Drive ......................................................................................................................... 4-3

4.2.1 Remove Old Assembly ................................................................................................................. 4-4

4.2.2 Install New Assembly .................................................................................................................... 4-4

4.4.1 Removing the Old Chassis ........................................................................................................... 4-5

4.4.1.1 Removing Magazines ......................................................................................................... 4-6

4.4.1.2 Removing the Unit from Rack ............................................................................................ 4-6

4.4.1.3 Removing Drive Assembly .................................................................................................. 4-7

4.4.2 Incorporating the New Chassis ................................................................................................... 4-7

4.4.2.1 Install Drive Assembly .......................................................................................................... 4-7

4.4.2.2 Reattach Drive Cover ......................................................................................................... 4-7

4.4.2.3 Reinstall Unit in Rack ........................................................................................................... 4-8

4.4.3 Reconfiguring the Unit ................................................................................................................. 4-8

4.5.1 Preparing the Unit ......................................................................................................................... 4-8

4.5.1.1 Removing the Unit from Rack ............................................................................................ 4-8

4.5.1.2 Removing Drive Assembly .................................................................................................. 4-8

4.5.2 Installing the New Drive ............................................................................................................... 4-9

4.5.3 Reinstalling the Drive Assembly ................................................................................................. 4-10

Section 5 - Firmware Update

5.1 Using a Local FTP Server ........................................................................................................................ 5-1

5.2 Using a Remote FTP Server .................................................................................................................... 5-1

Index

vi Part Number 10400025-101 10/2006

Page 7

List of Figures

Section 1 - General Information

Figure 1-1: ARCvault 24 Library ..................................................................................................1-1

Section 2 - System Overview

Figure 2-1: Location of Robotics Tie-Down Wire Underneath Library .................................... 2-1

Figure 2-2: Tie-Down Removal.................................................................................................... 2-2

Figure 2-3: Tie-Down Hole Locations (Top View)...................................................................... 2-3

Figure 2-4: Tie-Down in Place ..................................................................................................... 2-3

Figure 2-5: Holes Used for Attaching Rails................................................................................. 2-4

Figure 2-6: Outside Rail Adjustment for 30" Rack ..................................................................... 2-4

Figure 2-7: Attaching Outside Rails............................................................................................ 2-5

Figure 2-8: Tighten Retaining Screws to Rack........................................................................... 2-5

Figure 2-9: ARCvault Rear Connections and Power Switch ................................................... 2-6

Figure 2-10: ARCvault Basic Cabling......................................................................................... 2-7

Figure 2-11: Power-On Points...................................................................................................... 2-7

Figure 2-12: POST Startup Logo Screen ..................................................................................... 2-8

Figure 2-13: OCP Default Screen ............................................................................................... 2-8

Figure 2-14: ARCvault 12 OCP Software Map .......................................................................... 2-9

Figure 2-15: ARCvault 24 OCP Software Map ........................................................................ 2-10

Figure 2-16: ARCvault 12 RMU Software Map ........................................................................ 2-11

Figure 2-17: ARCvault 24 RMU Software Map ........................................................................ 2-12

Figure 2-18: ARCvault 12 Normal Slot Numbering ................................................................. 2-13

Figure 2-19: ARCvault 24 Normal Slot Numbering ................................................................. 2-14

Figure 2-20: Slot Numbering with Single-Slot I/E Element ...................................................... 2-14

Figure 2-21: Slot Numbering with Full-Magazine I/E Element ................................................ 2-14

Figure 2-22: I/E Element Magazine Location.......................................................................... 2-15

Figure 2-23: Removing Single-Slot I/E Element........................................................................ 2-16

Figure 2-24: Single-Slot I/E Element With Tape........................................................................ 2-16

Section 3 - Troubleshooting and FSCs

Figure 3-1: Sample OCP Error Message Screen ....................................................................... 3-1

Figure 3-2: Sample RMU Error Message in Library Health Table.............................................. 3-1

Figure 3-3: General Troubleshooting Procedure ...................................................................... 3-2

Figure 3-4: Error Recovery Procedure 1—Defective Chassis .................................................. 3-8

Figure 3-5: Error Recovery Procedure 2—Defective Chassis or Drive .................................... 3-9

Figure 3-6: Error Recovery Procedure 3—User Configuration Error ...................................... 3-10

Figure 3-7: Error Recovery Procedure 4—User Operation Error ............................................ 3-10

Figure 3-8: Error Recovery Procedure 5—System or Application Error................................. 3-11

Figure 3-9: Error Recovery Procedure 6—Defective Media or Chassis................................ 3-12

Figure 3-10: Error Recovery Procedure 7—Defective Media, Chassis, or Drive .................. 3-13

Figure 3-11: Error Recovery Procedure 8—Defective Media or Drive ................................. 3-14

Figure 3-12: ERP Chassis vs. Tape Drive ERP ............................................................................ 3-15

Figure 3-13: Level 3 Escalation ERP .......................................................................................... 3-16

Figure 3-14: ARCvault Drive Access ........................................................................................ 3-17

Figure 3-15: Drive Cover SCSI and Fan Cables ...................................................................... 3-17

Section 4 - Adding or Replacing Components

Figure 4-1: ARCvault Rear Panel................................................................................................ 4-1

Figure 4-2: Drive Cover SCSI and Fan Cables .......................................................................... 4-2

Figure 4-3: Reattaching the Brackets to a Full-Height Drive................................................... 4-2

Figure 4-4: Removing an ARCvault Half-Height Drive ............................................................. 4-3

Figure 4-5: Drive Cover Assembly .............................................................................................. 4-4

Figure 4-6: Left and Right Media Magazines............................................................................ 4-5

Part Number 10400025-101 10/2006 vii

Page 8

List of Figures

Figure 4-7: ARCvault 24 Components to be Removed .......................................................... 4-6

Figure 4-8: Retaining Screw Location........................................................................................ 4-7

Figure 4-9: Remove Air Dam.......................................................................................................4-9

Figure 4-10: Adding a Second Half-Height Drive..................................................................... 4-9

Figure 4-11: Attaching the Serial Y-Cable............................................................................... 4-10

viii Part Number 10400025-101 10/2006

Page 9

List of Tables

Section 1 - General Information

Table 1-1: Service Manual Released Versions.......................................................................... 1-2

Section 2 - System Overview

Table 2-1: ARCvault OCP Security Levels ............................................................................... 2-13

Section 3 - Troubleshooting and FSCs

Table 3-1: FSC/ERP Cross-Reference ......................................................................................... 3-3

Table 3-2: Error Recovery Procedures ....................................................................................... 3-7

Part Number 10400025-101 10/2006 ix

Page 10

List of Tables

x Part Number 10400025-101 10/2006

Page 11

1

SECTION

General Information

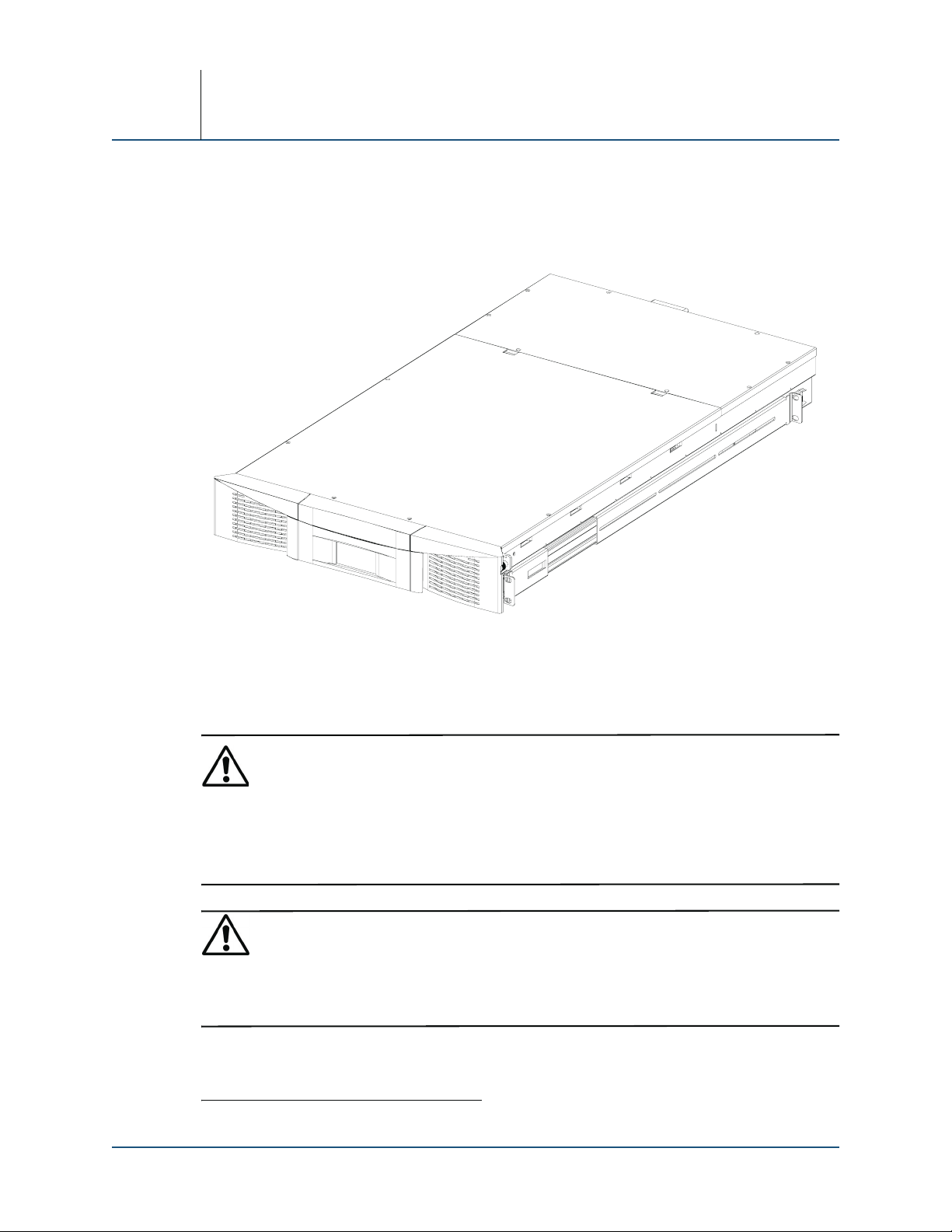

This section provides introductory information about the ARCvault Series 2U (Figure 1-1) tape

archive units—ARCvault 12 Loader1 and ARCvault 24 Library. Included are performance

specifications and characteristics, power requirements, available configurations, and list of

recommended tools and test equipment.

1

1

0

0

C

R

A

1.1 Safety

Observe the following warnings while servicing this system:

Figure 1-1: ARCvault 24 Library

WARNING: The power supplies in your tape archive may produce high voltages and energy

hazards, which can cause bodily harm. Only trained service technicians are authorized to

remove the covers and access any of the components inside the unit.

Die Stromversorgungen Ihres Computers oder Speichersystems erzeugen lebensgefährliche

Hochspannung. Computerabdeckungen dürfen nur von autorisierten Servicetechnikern entfernt

werden, der Zugang zu den Komponenten im Innern des Computers ist ausschließlich

autorisierten Servicetechnikern vorbehalten.

WARNING: Due to the weight of the unit, it is recommended that at least two people be used to

lift the unit out of the box to prevent injury.

Wegen des großen Gewichts der Einheit ist es empfehlenswert, dass beim Herausheben aus

dem Verpackungskarton mindestens zwei Personen beteiligt sind, um somit köperlichen

Verletzungen vorzubeugen.

1 Unless otherwise noted, the ARCvault 12 Loader is included for all generic references to an ARCvault library.

10400025-101 10/2006 1–1

Page 12

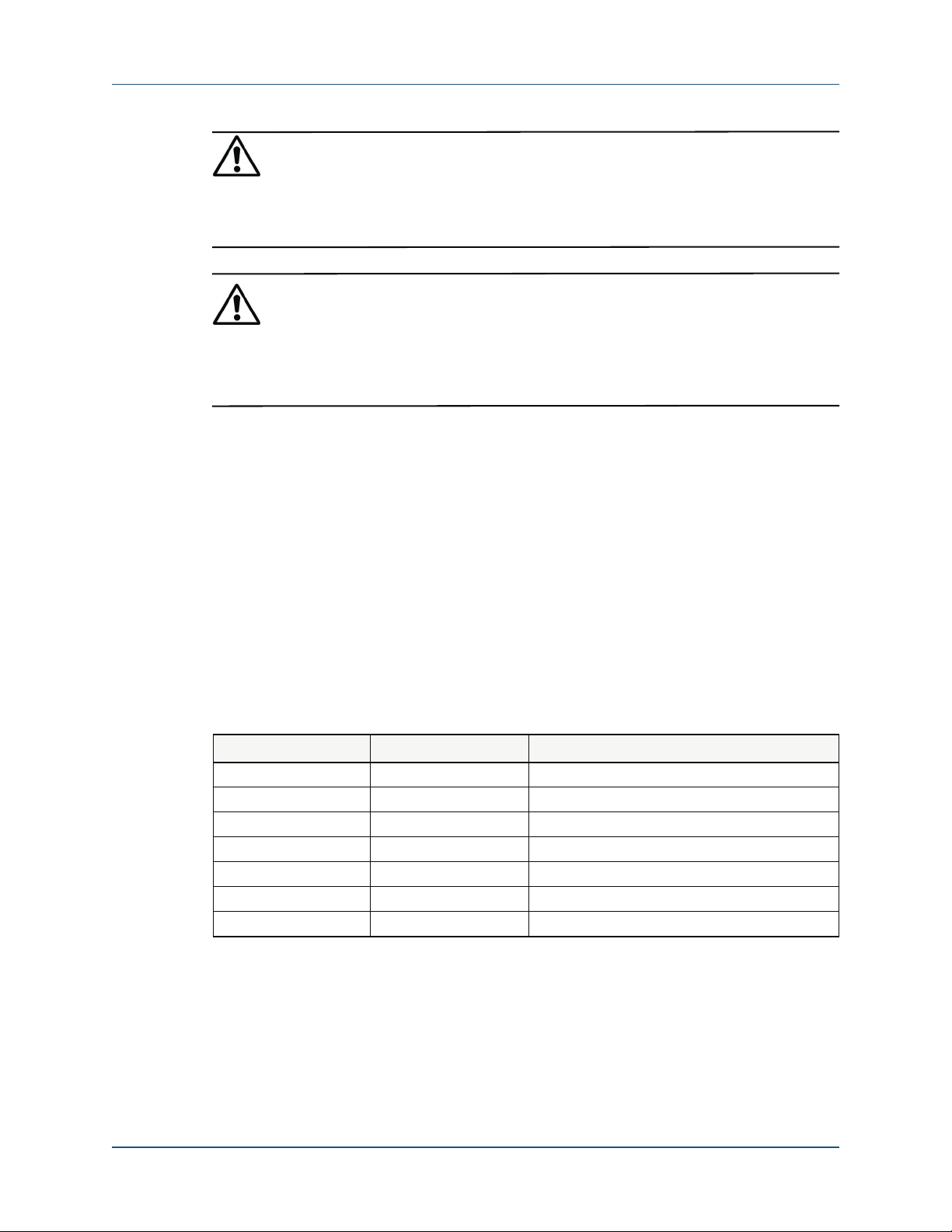

Section 1

WARNING: It is recommended that a mechanical lifter (or at least two people) be used to raise

and align the library to prevent injury during the installation into the rack.

Es wird empfohlen, dass zum Anheben und Ausrichten der Library ein mechanisches

Hebegerät (oder ein Minimum von zwei Personen) eingesetzt wird, um körperlichen

Verletzungen bei der Installation ins Rack vorzubeugen.

WARNING: Neither the touch screen nor the power switch completely shuts off power to the

library. To reduce the risk of electrical shock or damage to the equipment, unplug the power

cord.

Die Library lässt sich weder durch die Bedienung des Tastbildschirms, noch des

Betriebsschalters völlig ausschalten. Stecken Sie das Netzkabel aus, um das Risiko eines

elektrischen Schlags zu vermeiden.

Library maintenance may involve exposure to electrical shock or possible damage to the unit.

Before servicing the library, be aware of possible hazards and take necessary precautions. Refer

to the product documentation for additional notes, cautions, and other alerts.

1.2 General Description

The ARCvault loaders and libraries deliver tape backup and archive capabilities to small- and

mid-size IT environments that need to effortlessly protect large amounts of data. The combination

of high capacity and simplicity make the ARCvault family ideal for organizations looking to

implement both disk and tape for superior data protection.

1.3 Version Control

The table below shows the different versions of this service manual. This version is the last

version shown in the table:

Table 1-1: Service Manual Released Versions

Version Number Date Released Changes from Previous Version

10400025-101_A October 30, 2006 Initial Release for ARCvault firmware version 1.57.

1.4 ARCvault Models Covered

• ARCvault 12 Loader with full-height LTO3 SCSI tape drive (OV-ARC101003)

• ARCvault 12 Loader with half-height LTO2 SCSI tape drive (OV-ARC101001)

• ARCvault 24 Library with full-height LTO3 SCSI tape drive (OV-ARC101004)

• ARCvault 24 Library with half-height LTO2 SCSI tape drive (OV-ARC101002)

1–2 10400025-101 10/2006

Page 13

1.5 Specifications

1.5.1 Physical Specifications

Library Configuration

Maximum number of tape cartridges • 12 (ARCvault 12)

Number of media magazines • 1 (ARCvault 12)

Slots per magazine 12

Number of Drives 1 full-height or half-height drive (upgradable to 2

Number of I/E Element Slots

Capacity

Native capacity TB (LTO-3 / LTO-2) 4.8 / 2.4 (ARCvault 12)

Max. compressed

Performance

Native / Compressed† LTO-2 transfer rate (GB/hr) 86.4 / 172.8

Native / Compressed

Dual half-height drives

Native / Compressed

Interfaces

SCSI HD 68

Ethernet RJ-45

Serial RJ-11

LCD Touch Screen

Dimensions 2.5” x 1.25” (6.4cm x 3.2cm)

Type Pressure-sensitive blue and light-gray screen

Resolution 128 x 64 pixels @ 50 dpi

Physical Dimensions

Dimensions (H x W x D) 3.475 x 18.9 x 34.25 in. (8.6 x 48.3 x 87.0 cm)

Weight Empty 43 lbs (20kg)

Base Configuration Shipping Weight 45 lbs (21kg)

Fully Configured Weight with Maximum Number

of Magazines and Drives (No Cartridges)

*. ARCvault 24 only.

†. Assumes compression ratio of 2:1. Actual performance may vary with the application.

*

†

storage TB (LTO-3 / LTO-2)

†

LTO-2 transfer rate (GB /hr)

†

LTO-3 transfer rate (GB/hr) 216 / 432

General Information

•24 (ARCvault 24)

•2 (ARCvault 24)

half-height drives in the ARCvault 24)

0, 1, or 12, depending on configuration

9.6 /4.8 (ARCvault 24)

9.6 /4.8 (ARCvault 12)

19.2 / 9.6 (ARCvault 24)

172.8 / 345.6

• ARCvault 12: 52 lbs. (23.5kg)

• ARCvault 24: 57.5 lbs. (26kg)

10400025-101 10/2006 1–3

Page 14

Section 1

1.5.2 Technical Information

Operational Specifications

Mount time Less than 60 seconds, estimated

Dismount time (excluding rewinding) Less than 60 seconds, estimated

Inventory time (full including tape drives) Less than 3 minutes

Rewind time (maximum / average) 98 / 49 sec

Power Consumption

Idle State 80 Watts / 223 BTUs / 288 KJ

Average Running State 80 Watts / 223 BTUs / 288 KJ

Peak Power 165 Watts / 563 BTUs / 594 KJ

Voltage

Input Voltage, Low

Input Voltage, High

Input Frequency 50-60 Hz

AC Power Input One IEC320-C14 type rear-panel receptacle

BTU Heat Load

Maximum, one drive 69.0 BTU/hour

Maximum, two drives

*. The low voltage nominal will be 110 VAC and the high voltage nominal will be 220 VAC.

†. Based on 3.415179 BTU/watt.

‡. ARCvault 24 only.

*

*

†

‡

100-120 VAC ±10%

200-240 VAC ±10%

96.9 BTU/hour

1.5.3 Reliability and Safety

Reliability

Mean time between failures (MTBF) More than 250,000 hours

Maximum swaps before failure (MSBF) More than 1,000,000 cartridge swaps

Design life 7 years

Mean time to repair (MTTR) Less than 30 minutes

Safety Standards

NRTL - US IEC60950-1, Standard for Safety of Information

NRTL - Canada CAN/CSA-C22.2 No. 950, Standard for Safety of

CE Marking (European Union) Low Voltage Directive, 72/23/EEC, European Union

TÜV GS Mark (Germany) EN60950, (IEC950) Standard for Safety of

Technology Equipment

Information Technology Equipment

Information Technology Equipment, 3

rd

addition

1–4 10400025-101 10/2006

Page 15

1.5.4 Temperature, Humidity and Altitude

Operating

Dry Bulb Temperature -10°C to 40°C

Temperature Gradient 1°C / min. (across the range)

Temperature Shock 15°C (over 2 min.)

Wet Bulb Temperature 26°C

Relative Humidity 15% to 85% (noncondensing)

Humidity Gradient 10% / hr.

Power On—No Tape Loaded (Unpacked—72 hours)

Dry Bulb Temperature 0°C to 50°C

Temperature Gradient 15°C / hr. (across the range)

Temperature Shock 15°C (over 2 min.)

Wet Bulb Temperature 30°C

Relative Humidity 10% to 95% (noncondensing)

Humidity Gradient 10% / hr.

Non-Operating—Long Term (Packed or Unpacked)

Dry Bulb Temperature -40°C to 60°C

Temperature Gradient 20°C / hr. (across the range)

Temperature Shock 15°C (over 2 min.)

Wet Bulb Temperature 30°C

Relative Humidity 5% to 95% (noncondensing)

Humidity Gradient 10% / hr.

Transit—Short Term (Packed 7 Days)

Dry Bulb Temperature -40°C to 60°C

Temperature Gradient 25°C / hr. (across the range)

Temperature Shock 15°C (over 2 min.)

Wet Bulb Temperature 30°C

Relative Humidity 5% to 95% (noncondensing)

Humidity Gradient 10% / hr.

General Information

1.5.5 Shock

Operating (Within Spec—No Damage)

Peak Acceleration 31 Gs ±5%

Duration 2.6ms

Wave Shape 1/2 sine pulses

Application X,Y,Z axes

Non-Operating, with Tape Cartridges Removed (Unpacked—No Damage)

Peak Acceleration 71 Gs ±5%

Duration 2ms

Wave Shape 1/2 sine pulses

10400025-101 10/2006 1–5

Page 16

Section 1

1.5.6 Vibration

Application X,Y,Z axes

Transit/Storage (Packed—No Damage)

Peak Acceleration 30 Gs

Duration 30ms

Wave Shape 1/2 sine pulses

Application X,Y,Z axes

Physical Drop Test (Packed—No Damage)

Drop Test Distance 30 in.

Application Per TAPPI T802om-91

Operating Sine Test (Within Spec—No Damage)

Frequency Range 5–500–5Hz

Amplitude 0.1 inch, double amplitude, 0.25 G

Dwell and Duration 15 min. for a total of 1.5 hours

Wave shape Sinusoidal, 1 octave/min.

Application X,Y,Z axes, 2 sweeps per axis

Operating Random Test (Within Spec—No Damage)

Frequency Range 5–500Hz

Profile Level 0.27 GRMS

Duration 30 min. per axis

Random Tests Per ASTM D3580

Application X,Y,Z axes

Non-Operating Sine Test (Unpacked—No Damage)

Frequency Range 5–1000–5Hz

Amplitude 0.1 inch, double amplitude, 1.0 G

Dwell and Duration 15 min. for a total of 1.5 hours

Wave shape Sinusoidal, 1 octave/min.

Application X,Y,Z axes, 2 sweeps per axis

Non-Operating Random Test (Unpacked—No Damage)

Frequency Range 5–250Hz

Profile Level 1.54 GRMS

Duration 30 min. per axis

Random Tests Per ASTM D3580

Application X,Y,Z axes

Truck Transit Test (Packed—No Damage)

Frequency Range 5–200Hz

Profile Level 1.146 GRMS

Duration 30 min. per axis

Random Tests Per ASTM D4728-95

Application X,Y,Z axes

1–6 10400025-101 10/2006

Page 17

Air Transit Test (Packed—No Damage)

Frequency Range 5–300Hz

Profile Level 1.146 GRMS

Duration 30 min. per axis

Random Tests Per ASTM D4728-95

Application X,Y,Z axes

1.5.7 Electromagnetic Emissions

Agency Standards

FCC US Std. 47 CFR, Part 15 Rules, Class A. Notation on

Industry Canada (ICES) Industry Canada Rules, ICES-003, Class A. Notation

CE Marking (European Union) EMC Directive, 89/336/EEC Laws, relating to

VCCI (Japan) Class A per CISPR 22, Japan. VCCI statement on

BSMI (Taiwan) CNS: 13438, Taiwan. Class A

General Information

Product

on product

electromagnetic compatibility, European Union

EN55022, Standard, RFI limits, Information

Technology Equipment, Class A EN55024,

Information Technology Equipment, Immunity.

product

10400025-101 10/2006 1–7

Page 18

Section 1

1–8 10400025-101 10/2006

Page 19

2

SECTION

System Overview

2.1 Installation

WARNING: Due to the weight of the unit, it is recommended that at least two people be used to

lift the unit to prevent injury.

2.1.1 Shipping Tie-Down Wire

CAUTION: A tie-down wire holds the shuttle and robotics in place for shipment and MUST be removed before

operating the unit. Failure to remove this tie-down will result in damage to the internal robotics and

catastrophic failure of the unit.

2.1.1.1 Tie-Down Removal

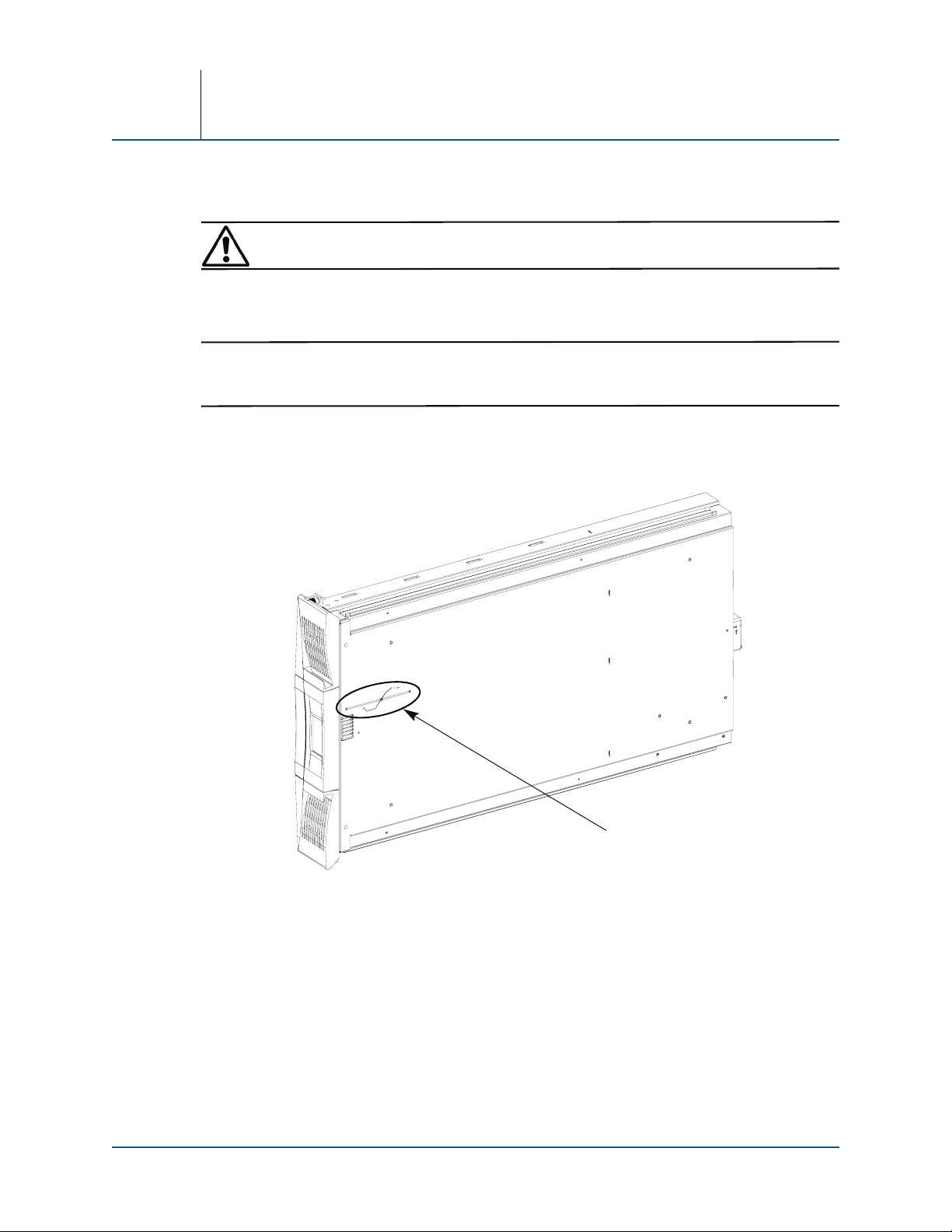

1. Turn the library on its side (Figure 2-1).

8

4

0

0

C

R

A

Robotics Tie-Down

(Must Be Removed)

Figure 2-1: Location of Robotics Tie-Down Wire Underneath Library

2. Untwist the tie-down wire underneath near the front center.

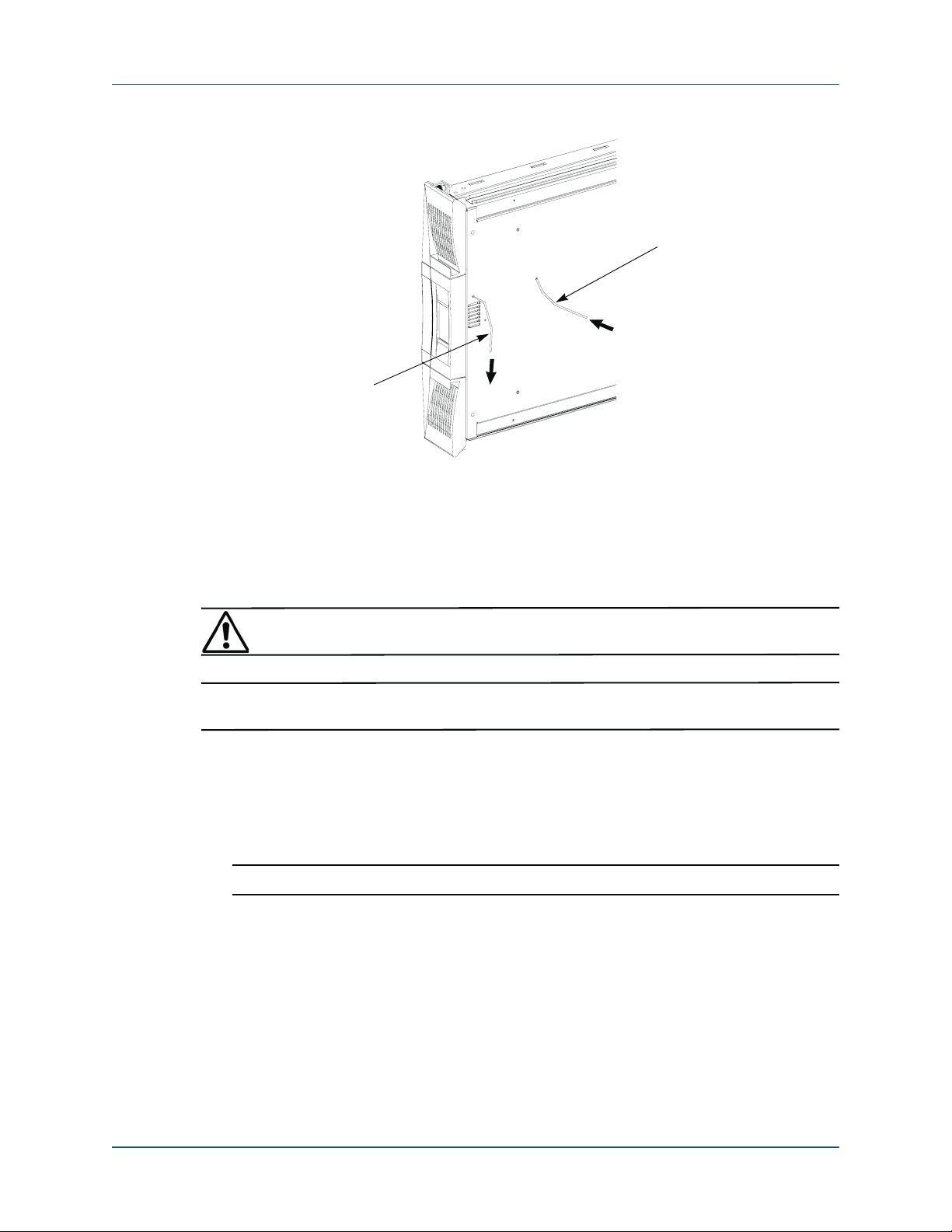

3. At the wire end closest to the center of the unit, push (Figure 2-2) part of the wire up into

the unit.

10400025-101 10/2006 2–1

Page 20

Section 2

Push In

7

5

Pull Out

0

0

C

R

A

Figure 2-2: Tie-Down Removal

4. Using the wire end closest to the front, gently pull the wire out.

If necessary, feed the other wire end up into the unit as you pull out the front end.

5. Save the tie-down wire in case you ever need to ship the unit.

2.1.1.2 Tie-Down Reinstallation for Shipment

WARNING: To reduce the risk of electric shock or damage to equipment, disconnect the power

by unplugging the power cord.

CAUTION: Do NOT turn the library upside down onto its top or allow the front bezel to contact the table if on

its side.

1. Remove and retain the six screws from the front top cover of the empty chassis.

2. Lift the front edge of the cover and pull it slightly forward to release the tabs in the rear. Set

the cover aside.

3. Verify that the shuttle is in the Home position (facing the bottom front slot of the right

magazine).

IMPORTANT: If the shuttle is not in the Home position, contact Overland Technical Support.

4. Position the library so there is space underneath the front 8 inches (20cm) of the unit.

This allows room for the tie-down to exit the chassis and be twisted together.

5. Insert one end of the saved tie-down into the front tie-down hole and the other end into the

rear tie-down hole (Figure 2-3).

Route the tie-down wire between the black motor cable and the body of the shuttle.

2–2 10400025-101 10/2006

Page 21

System Overview

Tie-Down

Holes

Shuttle

Top

Motor Cable

Figure 2-3: Tie-Down Hole Locations (Top View)

6. From the bottom, pull both ends of the tie-down wire simultaneously until tight, and then twist

them together (Figure 2-4).

8

4

0

0

C

R

A

Figure 2-4: Tie-Down in Place

7. Using the six retained screws, reattach the front top cover.

2.1.2 Rack Considerations

An ARCvault library comes with the inside slide rails attached to the unit. The provided rail kit is

used to attach the outside rails to the rack to support the unit. This rail kit is not intended to be

used on a threaded rack.

WARNING: It is recommended that a mechanical lifter (or at least two people) be used to raise,

align, and lower the unit to prevent injury during the installation into or removal from the rack.

2.1.2.1 Installing an ARCvault Library

1. Locate and mark the holes for the outside rails and retaining screws.

a. Starting with the right front flange at the bottom of the rack (or from the top of a

previously mounted component), locate the first set (Figure 2-5) of three holes with equal

gaps of 5/8 inch (1.6cm).

10400025-101 10/2006 2–3

Page 22

Section 2

Right Front Flange

Retaining Screw

Hole Mark

5/8" (1.6cm)

2U

First

Hole

Set

1/2" (1.3cm)

5/8" (1.6cm)

5/8" (1.6cm)

0

3

0

0

C

R

A

Top Rail

Hole Mark

Bottom Rail

Hole Mark

Figure 2-5: Holes Used for Attaching Rails

b. Mark the top and bottom holes of the set for the rail screws.

c. Mark the second hole above the set for the retaining screw.

d. Repeat Steps a–c for the left side.

2. Repeat Step 1 for the rear holes.

CAUTION: Be sure rear holes are horizontally in line with the front holes to assure the unit remains

level.

3. Adjust the rear mounting bracket to fit inside the rack flanges.

a. Remove and retain the two adjustment nuts and washers on the right outside rail.

b. Move the rear bracket so that the two PEM studs are in different slots (Figure 2-6).

• Use the two rear slots for a 24" deep rack.

• Use the two center slots for a 30" deep rack.

• Use the two front slots for a 36" deep rack.

Front Bracket & Rail Assembly

Adjust Rear Bracket to Fit

3

6

0

0

C

R

A

PEM Studs & Lock Nuts

Figure 2-6: Outside Rail Adjustment for 30" Rack

c. Loosely replace the retained washers and screws.

d. Repeat Steps a–c for the left rail.

4. Using the eight SEMS screws and four bar nuts provided, attach the rails inside the flanges

(Figure 2-7).

NOTE: To ensure proper alignment, the bar nut corner notches must face away from the rail.

a. Attach the right outside rail inside the marked locations (Figure 2-7) of the right front

and right rear flanges.

b. Tighten the rail adjustment nuts on the outside edge of the rail.

c. Repeat Steps a–b for the left outside rail.

2–4 10400025-101 10/2006

Page 23

Front Flanges

System Overview

Rear Flanges

Bar Nut

2

6

0

0

C

R

A

Adjustment Nuts

Clip Nut

Figure 2-7: Attaching Outside Rails

5. Attach two clip-nuts to the retaining screws holes on the front rack flanges.

6. Move the slides all the way forward to assist with the installation of the unit.

7. Lift the ARCvault unit and, aligning the inner rails into the outer rails on the rack, gently

slide it into the rack until the rail stops engage. Release the rail stops and continue sliding

the unit into the rack until the front panel touches the front flanges.

NOTE: Early models require a tool (such as a screwdriver) to release the safety catches.

8. Tighten the two retaining screws behind the doors (Figure 2-8) to secure the unit.

Retaining Screw

Figure 2-8: Tighten Retaining Screws to Rack

9. Attach all network cables and power cords (see “Attaching Cables” on page 2-6).

10400025-101 10/2006 2–5

Page 24

Section 2

2.1.2.2 Removing ARCvault Library for Service

1. Power off the unit and remove the power cord.

See “Power-Off Process” on page 2-8 for details.

2. Label and remove all wiring and cables in the rear.

3. Loosen the two retaining screws in the hinge area inside the doors.

4. Close the doors and grasp the unit by the metal bracket behind the door hinges.

CAUTION: Do not pull on the doors as this can damage or break them.

5. Gently pull the unit a few inches out of the rack to expose the case.

6. Grasp the library case and slide the ARCvault unit outward until the rail stops engage.

7. Press the safety catches on each rail to release them.

NOTE: Early models require a tool (such as a screwdriver) to release the safety catches.

8. Using two people or a mechanical lifter, carefully slide the unit the rest of the way out and set

it on a secure surface.

2.2 Attaching Cables

All the cables that connect the ARCvault unit to your host system and power source are located at

the rear of the library (Figure 2-9).

Drive Cover

SCSI Ports

Ethernet Serial

USB (not implemented)

AC ReceptaclePower Switch

Figure 2-9. ARCvault Rear Connections and Power Switch

An ARCvault library comes with a single tape drive already installed and ready to be connected to

the network (Figure 2-10).

NOTE: ARCvault 24 units that come configured with one half-height drive can accommodate a second

half-height drive (available separately). The external cabling is the same as a single drive library.

8

0

0

0

C

R

A

2–6 10400025-101 10/2006

Page 25

SCSI Cable

Power Cord

System Overview

5

7

0

0

C

R

A

1. Connect the LVD SCSI cable to one of the SCSI ports and the other end to your system.

2. Attach the SCSI terminator to the remaining open SCSI port.

3. Plug the host network connection into the Ethernet port.

4. Plug the power cord into the AC receptacle and the other end into a power source.

2.3 Power Management

WARNING: Neither the touch screen nor the power switch completely shuts off power to the unit.

To reduce the risk of electrical shock or damage to the equipment, remove the power cord.

While powering on the unit, holding the rear Power button more than 10 seconds will put the unit

into a maintenance mode. To exit the maintenance mode, recycle the power normally.

SCSI Terminator

Ethernet

Figure 2-10: ARCvault Basic Cabling

Front: Tap Here Rear: Press Here

2

2

0

0

C

R

A

8

0

0

0

C

R

A

Figure 2-11: Power-On Points

2.3.1 Power-On Process

1. Verify the power cord is plugged in.

2. Start the power-on process (Figure 2-11).

• From the front, tap the OCP.

• From the rear, press and release the Power switch.

10400025-101 10/2006 2–7

Page 26

Section 2

3. The POST process begins and displays the Startup screen (Figure 2-12).

Figure 2-12: POST Startup Logo Screen

NOTE: You can press the Continue button on the Startup screen to view the Default screen. However,

the ARCvault will not allow any changes to its settings until POST completes.

After approximately 50 seconds, the unit automatically displays the Default menu screen

(Figure 2-13).

After approximately 3 minutes, when the unit has completed its POST (including an inventory

of cartridges), it is ready for use.

2.3.2 Power-Off Process

At the OCP, press Power > Power Off to have the library perform a controlled shutdown.

Alternately, pressing and holding the Power button on the rear panel for 4 seconds shuts off power

without parking the shuttle and completing tasks.

2.4 Interfaces

There are two ways to interact with an ARCvault library: the Operator Control Panel (OCP) and

the Remote Management Utility (RMU).

2.4.1 Operator Control Panel

The OCP touch screen provides an easy way to make common configuration changes and control

access to the media. The following is a basic list of operational procedures and general instructions

for using the OCP touch screen.

• Virtual buttons are represented on the screen as rectangles with labels such as “Status.” Press

inside the rectangle to activate the button’s feature or submenu.

• A keyboard or set of option buttons is automatically displayed when numbers need to be

entered or specific selections are required.

• If more options are available than can fit on the screen, arrow buttons are displayed on the

bottom so you can scroll through the options. Only one arrow is shown when you reach the end

or beginning of the list.

Figure 2-13: OCP Default Screen

NOTE: The Status screen, Help screen, and all message screens use scroll bar arrows on the right side

in place of the Up/Down arrows.

2–8 10400025-101 10/2006

Page 27

System Overview

• A Back or Cancel button is always available on the bottom right of all secondary or lower

screens to return you to the previous screen.

• When the library is powered off but still plugged in, the OCP glows blue. Tapping the OCP

starts the power on cycle.

2.4.1.1 ARCvault OCP Software Maps

Figure 2-14: ARCvault 12 OCP Software Map

10400025-101 10/2006 2–9

Page 28

Section 2

Figure 2-15: ARCvault 24 OCP Software Map

2.4.2 Remote Management Utility

The ARCvault RMU is an interface built into the ARCvault library and provides remote access to

and configuration of the library through an Ethernet port. It hosts a dedicated, protected Internet

site that can be accessed by a web browser using the IP address assigned to the ARCvault unit. This

is accomplished either from a PC connected to your network or via the World Wide Web using the

default HTTP port 80.

NOTE: If connecting a laptop directly to the unit to access the RMU site, use a crossover Ethernet cable

plugged into the Ethernet port at the rear of the unit.

2–10 10400025-101 10/2006

Page 29

System Overview

The RMU default Login page uses Java-based encrypted HTTP authentication that encrypts the

password sent to the unit. The RMU firmware uses standard HTML-based pages that are served to

a web browser. The pages consist of two frames—a top navigational frame and a lower data frame.

2.4.2.1 ARCvault RMU Software Map

Figure 2-16: ARCvault 12 RMU Software Map

10400025-101 10/2006 2–11

Page 30

Section 2

Figure 2-17: ARCvault 24 RMU Software Map

2.5 Password Protection

For added protection, the library lets you assign different levels of security using passwords:

• The OCP touch screen has User and Service security using 4-digit numeric passwords.

• The RMU offers Operator and Administrator security using 12-digit alphanumeric characters.

The default Administrator password is “2” while the default Operator password is “1.”

• An additional level of security is built in to both interfaces for factory technicians.

2–12 10400025-101 10/2006

Page 31

System Overview

Table 2-1 shows the different OCP security levels, the access point that prompts for a password,

and the scope of access.

Table 2-1: ARCvault OCP Security Levels

Typ e Level Controls this Access Description

User 1 • Power > Power Off Library

• Power > Reboot Library

• Mag Access

•Move Media

Service 2 • Edit Opts > Library

•Edit Opts > Passwords

•Edit Opts > SCSI/FC

• Edit Opts > Network

•Utilities > Service

•Utilities > Diagnostics

Factory 4 • Utilities > Factory Factory technician use only.

NOTE: Each security type controls a specific group of OCP options. For example, adding a User password

does NOT protect Service-level options. However, a higher level of security permits access to all

lower-level functions, such as Service-level security allows access to all User-level functions.

Controls access to the power, media magazines,

and the movement of the media inside the unit.

Controls access to most of the utilities and the

editing of options.

2.6 Tape Magazines

To help manage the tape media, the cartridges are stored in 12-slot magazines that are removable.

This provides an easy way to exchange tapes and can also double as off-site storage unit.

2.6.1 Slot Management

To help manage the tape cartridge inventory, the individual slots of the magazines are numbered.

The number sequencing is from the bottom to the top, front to back. When a I/E Element is

configured, those slots are numbered separately.

The ARCvault 12 has one magazine located on the right side. Figure 2-18 shows the slot numbering

sequence for the magazine.

Right Magazine

Figure 2-18. ARCvault 12 Normal Slot Numbering

6312 9

11 8 5 2

10 7 4 1

Handle

0

2

0

0

C

R

A

10400025-101 10/2006 2–13

Page 32

Section 2

In the ARCvault 24, when no I/E Element is enabled (Figure 2-19), the slot numbering starts in the

left magazine and continues with the right magazine.

91236

25811

Left Magazine

14710

Handle

Handle

18 1524 21

Right Magazine

23 20 17 14

22 19 16 13

0

2

0

0

C

R

A

Figure 2-19: ARCvault 24 Normal Slot Numbering

When a single-slot I/E Element is enabled on an ARCvault 24, the first slot is used for it and labeled

“ie.” This causes the regular slot numbering to start from the second slot, making it slot 1 (Figure 2-

20).

81125

Left Magazine

Handle

0

2

0

0

C

R

A

Handle

Right Magazine

14710

ie 3 6 9

I/E Element

17 1423 20

22 19 16 13

21 18 15 12

Figure 2-20: Slot Numbering with Single-Slot I/E Element

With the entire left magazine configured as a I/E Element, the slots are numbered 1–12 and the

magazine name changes from “Left Mag” to “I/E Mag” (Figure 2-21). The regular slot numbering

(Slot 1) starts with the first slot of the right magazine.

91236

25811

I/E Element

(Entire Left Mag.)

14710

Handle

Handle

6312 9

Right Magazine

(Normal Slots)

11 8 5 2

10 7 4 1

Figure 2-21: Slot Numbering with Full-Magazine I/E Element

0

2

0

0

C

R

A

2–14 10400025-101 10/2006

Page 33

System Overview

2.6.2 I/E Element

The ARCvault 24 is configurable so that you can add or remove tape cartridges without stopping

the library using the I/E Element. This feature is available only on the left magazine. There are two

variations:

• Single-Slot I/E Element – in this default configuration, only the bottom front slot of the left

magazine is used as a I/E Element.

• Full-Magazine I/E Element – the entire left magazine is used as a I/E Element.

NOTE: Opening the left door immediately deactivates the robotics so that the I/E Element can be

removed. When the door is shut again, the library immediately reinventories the I/E Element

(either the single slot or all 12 slots depending on the configuration) before continuing.

2.6.2.1 Single-Slot I/E Element

Configuring your ARCvault to have a single-slot I/E Element provides a maximum benefit with a

minimum impact on operations since only one slot is dedicated to that purpose. The single-slot

I/E Element can be removed by pressing both release tabs together and pulling the handle

(Figure 2-22).

I/E Element Magazine Release Tabs Standard Magazine

Figure 2-22: I/E Element Magazine Location

CAUTION: When removing a single-slot I/E Element with a tape cartridge in it, be careful to keep the slot tray

level. Tilting the I/E Element can result in the tape falling out and possibly being damaged.

4

2

0

0

C

R

A

10400025-101 10/2006 2–15

Page 34

Section 2

The bottom front slot and handle that form the single-slot I/E Element assembly is removed

(Figure 2-23). The remainder of the magazine (11 slots) stays in the library.

4

0

0

0

C

R

A

3

0

0

0

C

R

A

Figure 2-23: Removing Single-Slot I/E Element

Once the I/E Element is out of the unit, media can be removed or inserted (Figure 2-24).

Tape Ca r t ridg e

Front

Handle

2

0

0

0

C

R

A

I/E Element

Figure 2-24: Single-Slot I/E Element With Tape

2.6.2.2 Full-Magazine I/E Element

In this configuration, the entire left magazine is dedicated as an I/E Element, allowing 12

cartridges to be exchanged without stopping the library. This is useful when backing up large

amounts of data requiring numerous tapes to be exchanged before job completion.

CAUTION: Keep a loaded magazine level. Tilting the magazine can result in the tapes falling out and possibly

being damaged. Also, don’t hold a magazine by just the handle; use both hands to support it.

Once unlocked, a full-magazine I/E Element is removed by just pulling the magazine handle. The

release tabs are not used.

2–16 10400025-101 10/2006

Page 35

3

SECTION

Troubleshooting and FSCs

This section provides some troubleshooting information and a list of Fault Symptom Codes (FSCs)

for the ARCvault library that may be displayed when there is a possible malfunction. A descriptive

message and instructions for clearing the fault accompany each FSC.

3.1 Possible Problems

An incorrect installation or configuration can cause platform problems. In such a case, the library

appears to be operating normally, but data can not be interchanged. An error code may be displayed

on the OCP touch screen. To resolve an error caused by this type of problem, check your installation

and configuration setup. Refer to your user guide for information on how to correctly install and

configure the library.

General drive errors usually result from a miscommunication between the library and tape drive, or

a mechanical malfunction within the library.

Both platform problems and general drive errors display an FSC and an error message on the OCP

touch screen and the RMU Library Health Status table. Use the FSC to determine a recovery

procedure or report errors to your service provider.

3.1.1 Sample Screens

When a malfunction occurs, an error message is displayed on the OCP touch screen:

Use the arrow buttons on the right to scroll down to see all the message.

The same information is available in the RMU. Click the Status tab and choose the Library Health

option to view the following table:

3.2 Error Recovery

To simplify the error recovery process, follow this General Troubleshooting procedure (Figure 3-3)

using the table and Error Recovery Procedure (ERP) flowcharts to troubleshoot the problem.

Figure 3-1: Sample OCP Error Message Screen

Figure 3-2: Sample RMU Error Message in Library Health Table

10400025-101 10/2006 3–1

Page 36

Section 3

Using the Fault Code Table, note

number of the Err or Recovery

Procedure (ERP).

ERP = 1?

Yes

No

ERP = 2?

Yes

No

ERP = 3?

Yes

No

ERP = 4?

Yes

Customer repor ts either a backup application failed or a

Fault Symptom Code (FSC) is being displayed .

ERP = 1

Yes

FSC listed in

Fault Code Table?

No

Yes

START

FSC listed in

ERP=2

Fault Code Table?

No

ERP=3

New FSC

Found

Note fault code and error

message. Retrieve library trace.

Attempt to run standalone

cartridge-cycle and dr ive -cycle

diagnostics on library.

No

Passed?

Yes

Attempt to run read/write tests to

tape drive with known good

media.

No

ERP = 5?

No

ERP = 6?

No

ERP = 7?

No

ERP=8

ERP=4

Yes

ERP=5

Yes

ERP=6

Yes

ERP=7

Figure 3-3: General Troubleshooting Procedure

3.2.1 FSC/ERP Cross-Reference Table

Table 3-1 lists the possible FSCs and accompanying messages and descriptions. Use the listed

ERP number to determine the correct procedure to use for resolving the problem:

Drive

R&R

Level 3

Escalation

No

Passed?

Yes

Verify system and application is at

appropriate r evision levels and

has no defective hardware or

No

cabling .

Problem

Resolved?

Yes

(Resume normal operation)

END

3–2 10400025-101 10/2006

Page 37

Troubleshooting and FSCs

Table 3-1: FSC/ERP Cross-Reference

FSC Message ERP Description

101 “Serial Port Initialization Error” 1 The serial port controller on the library controller

card failed to initialize during POST.

306 “NVRAM Update Error” 1 The Non-Volatile RAM did not update during POST.

402 “Non-Volatile Configuration Save

Error”

404 “Drive Configuration Error Full-

height drive Is incorrectly cabled.”

405 “Drive Initialization Error” 2 The tape drive did not initialize correctly during

501 “Bar Code Reader Not Detected” 1 The bar code reader was not detected during POST.

901 “OS Critical Error” 1 The library firmware encountered a critical internal

902 “Network Catastrophic Error” 1 The RMU firmware encountered a critical internal

0A01 “Invalid Ethernet (MAC) Address” 1 An invalid MAC address was encountered when the

0A02 “Invalid IP Subnet Mask

(255.255.255.255)”

0C01 “Exception Error” or

“Firmware Exception”

1001 “SCSI Firmware Error” 1 The library SCSI firmware encountered a critical

1011 “SCSI Initialization Error.

None of the attached drives have

ADI Bridging Enabled.”

2001 “Invalid Control Command” 1 The library control firmware detected an invalid

2004 “Loader Not Ready” 1 The library control firmware detected that the

2008 “Illegal Move” 1 The library control firmware detected an illegal

2009 “Door Open” 4 The library door/switch is open and all robotics

200F “Drive Media Removal Prevented” 5 A host move medium command was attempted but

2010 “Control Firmware Error” 1 The library control firmware detected a critical

20b0 “Unknown exchange for the async

message”

3000 “Motor Fault Condition, see trace

for details”

1 The Non-Volatile RAM configuration did not save

correctly during POST.

2 The library detected that the wrong serial cable is

connected to the full height drive.

POST.

error.

error during network initialization.

library was initializing the RMU ethernet port.

3 An invalid IP subnet was detected when initializing

the RMU ethernet configuration.

1 The library firmware encountered a critical internal

error.

internal error.

2 The library SCSI firmware was not able to initialize

because an ADI-enabled drive was not detected.

internal command.

loader hardware was not ready.

move attempted by an internal process.

operations are suspended until this condition is

cleared.

the library detected that the drive is in a prevent

medium removal state from the host.

internal error.

1 The library interprocess communications firmware

detected a critical internal error.

1 A motor fault condition was detected and the

library trace file is required for additional error

detail.

10400025-101 10/2006 3–3

Page 38

Section 3

Table 3-1: FSC/ERP Cross-Reference

FSC Message ERP Description

3002 “Picker Tach Errors” 1 The library picker motor has reported excessive

tach errors.

3011 “Bin Fetch Failure” 6 The library failed to fetch a cartridge from a slot

and all retries were exhausted.

3012 “Bin Stow Failure” 6 The library failed to stow a cartridge to a slot and all

retries were exhausted.

3013 “Drive Fetch Failure” 7 The library failed to fetch a cartridge from a drive

and all retries were exhausted.

3014 “Drive Stow Failure” 7 The library failed to stow a cartridge to a drive and

all retries were exhausted.

3016 “Drive Status Failure” 2 The library was not able to get status from the drive

serial (ADI) interface during the normal status

check.

301B “Drive Communication Error” 2 The library was not able to communicate with the

drive ADI.

301C “Drive Get General Status Fail” 2 The drive did not return the general status packet

over the ADI.

301E “Drive Unload Fail” 8 The drive did not successfully unload a cartridge

when the library issued the eject command over

the ADI.

3020 “Undefined Config” 2 The library firmware detected an invalid

configuration during a diagnostic operation. This

error usually indicates an internal hardware

problem.

3035 “Drive Unload Prevented” 5 The library was unable to eject the cartridge from

the drive to scan its barcode during an inventory

because the drive is in a prevent media removal

state. The prevent media removal state is set by a

host SCSI command to the drive.

3041 “Loader Received Invalid Cmd” 1 The library loader firmware process detected an

invalid internal command.

3045 “Loader Invalid Drive Number in

Cmd”

3051 “No Cartridges In Library” 4 A cartridge cycle diagnostic was attempted with no

3052 “Too Many Cartridges” 4 A cartridge cycle diagnostic was attempted with no

3053 “Need 3 Cartridges Minimum” 4 A drive cycle diagnostic was attempted with too few

3054 “Need 1 Drive Minimum” 4 A drive cycle diagnostic was attempted but no

3055 “Memory Allocation Error” 1 The library firmware detected an internal memory

305b “Diag Fetch, Drive not loaded” 6 The drive cycle diagnostic attempted to fetch a

1 The library loader firmware process detected an

invalid drive number in an internal command.

media in the library.

empty slots in the library.

cartridges in the library.

drives were detected.

allocation error.

cartridge from the drive and detected the drive in

an unexpected not loaded state.

3–4 10400025-101 10/2006

Page 39

Troubleshooting and FSCs

Table 3-1: FSC/ERP Cross-Reference

FSC Message ERP Description

305f “Invalid bin number” 1 During cartridge cycle or drive cycle diagnostics,

the library firmware detected an invalid slot

selection. This condition indicates a diagnostic

firmware error.

3060 “Cart blocking vertical” 6 The library detected an unexpected cartridge

ejected from the drive when the shuttle is not in

front of the drive. This condition prevents the

vertical robotics movement and requires manual

intervention.

3061 “Unable to Complete Homing

Algorithm”

3074 “Drive Eject Failed” 7 The library issued an eject command over the ADI

3075 “Drive Eject Failed” 7 The library issued an eject command over the ADI

3078 “Diag get drive status failed” 2 The library diagnostic firmware failed to get ADI

3079 “Diag get drive status failed” 2 The library diagnostic firmware failed to get ADI

3082 “Drive Stow Fail, Media Returned to

Source”

3083 “Drive Stow Fail, Media Remains in

Drive”

3084 “Unsupported Drive for Requested

Operation”

308F “No Retry Fault on Fetch/Stow” 1 A robotics fetch stow operation failed and no retry

30b0 “Mail Slot Load/Unload Error” 6 The library was unable to fetch/stow the import/

3100 “Picker Jammed” 7 The library detected a jam condition with the picker

3101 “Picker Overtraveled Stall” 7 The library detected an unexpected overtravel

3102 “Flex cable failure” 1 The library was unable to extend the picker due to a

3115 “Picker Retraction Jam” 7 The library was unable to retract the picker motor

3200 “Shuttle Jammed” 7 The library shuttle motor was stalled/jammed

3305 “Cart sense switch failed” 6 The library did not detect the cartridge sense

6 The library could not complete the vertical homing

algorithm. This usually indicates an obstruction

(such as, a cartridge in the bottom of the chassis or

other impediment).

and drive 1 did not successfully eject.

and drive 2 did not successfully eject.

status from drive 1.

status from drive 2.

7 The library was unable to successfully stow a

cartridge to the drive so the cartridge was returned

to the originating slot.

7 The library was unable to successfully stow a

cartridge to the drive but the cartridge was left in

the drive.

2 The library detected an unsupported drive (usually

a hardware error).

was possible.

export slot.

motor.

condition when moving the picker motor to a

position (stall was expected).

possible flex cable fracture.

and a jam condition was detected.

during a shuttle move operation.

switch in the shuttle assembly.

10400025-101 10/2006 3–5

Page 40

Section 3

Table 3-1: FSC/ERP Cross-Reference

FSC Message ERP Description

3306 “Cart stuck halfway in shuttle” 6 The library firmware detected a cartridge stuck

halfway in the shuttle - an unrecoverable hardware

condition.

3500 “Vertical Elevator Jammed” 6 The library vertical motor was stalled/jammed

during a vertical move operation.

5015 “Expired Cleaning Cart” 9 The library detected an expired cleaning cartridge

as reported by a drive.

5016 “Not a Cleaning Cart” 9 A clean operation was attempted through the

library menu but the drive reported that it was not a

cleaning cartridge.

503B “Move Command Fail” 9 A library (menu mode) cartridge move operation

failed.

503C “Clean Operation Timeout” 9 A library (menu mode) clean operation failed.

70nn “OCP Control errors” 1 All of these fault codes (7001-70ff) should be

considered library internal firmware errors related

to OCP firmware errors.

8001 “Cartridge load recovery failed.” 8 The drive failed to successfully load the cartridge at

the completion of a library stow-to-drive operation.

8003 “Drive Load did not Complete.” 8 The library stowed a cartridge to the drive but the

drive did not successfully complete the load

operation in the timeout period.

8009 “Drive Load Error” 8 The drive reported a cartridge load error through

the ADI.

800A “Expired Cleaning Cartridge” 9 The drive reported an expired cleaning cartridge

error through the ADI.

800B NEED INFO????

800C “Invalid Cleaning Cartridge” 9 The drive reported an invalid cleaning cartridge

error through the ADI.

800D “Defective Media” 6 The media in the tape drive cannot be used.

8020 “Firmware update failed” 5 Drive firmware update using RMU failed. Retry

update procedure.

A00n “SMX error” 1 All of these fault codes (A001-A0nn) should be

considered library internal firmware problems

related to interprocess task communication errors.

C0nn “RMU Firmware errors” 1 All of these fault codes (C001-C0nn) should be

considered library internal firmware problems

related to RMU firmware failures.

3–6 10400025-101 10/2006

Page 41

3.2.2 Error Recovery Procedures

Use the following 10 troubleshooting ERP flowcharts to diagnose the problem that caused the

FSC. Table 3-2 lists ERP codes and the possible problem area. This list includes only those

procedures that can be safely performed by an end user.

Table 3-2: Error Recovery Procedures

ERP # Possible Problem Area

1 Defective chassis

2 Defective chassis or drive

3 User configuration error

4 User operation error

5 System or application error

6 Defective media or chassis

7 Defective media, chassis, or drive

8 Defective media or drive

Troubleshooting and FSCs

10400025-101 10/2006 3–7

Page 42

Section 3

ERP = 1

Reboot the library and retry the

operation that produced the FSC.

New FSC

Found

New FSC

displayed ?

1. Turn off power to the library.

2. Wait 5 seconds .

3. Power up the library.

4. Retry the operation that

produced the fault code.

New FSC

displayed ?

Chassis

FSC

Same FSC

FSC

Same FSC

R&R

No FSC

No FSC

END

(Resume normal operation)

Figure 3-4: Error Recovery Procedure 1—Defective Chassis

3–8 10400025-101 10/2006

Page 43

ERP=2

Reboot the library and retry the

operation that produced the FSC.

Troubleshooting and FSCs

New FSC

Found

New FSC

displayed ?

1. Turn off power to the library.

2. Wait 5 seconds .

3. Power up the library.

4. Retry the operation that

produced the fault code.

New FSC

displayed ?

Chassis/

Drive R&R

FSC

Same FSC

FSC

Same FSC

No FSC

No FSC

END

(Resume normal operation)

Figure 3-5: Error Recovery Procedure 2—Defective Chassis or Drive

10400025-101 10/2006 3–9

Page 44

Section 3

ERP=3

Instruct the customer on the

correct value to enter for their

librar y configuration.

FSC

displayed ?

Yes

No

Chassis

(Resume normal operation)

END

Figure 3-6: Error Recovery Procedure 3—User Configuration Error

ERP=4

Correct the condition indicated by

the fault code and retry the

operation.

R&R

FSC

displayed ?

Yes

No

Chassis

(Resume normal operation)

END

Figure 3-7: Error Recovery Procedure 4—User Operation Error

3–10 10400025-101 10/2006

R&R

Page 45

ERP=5

Verify that the system, drivers,

and backup application are

supported configurations running

at the current version, then retry

the operation.

Troubleshooting and FSCs

FSC

displayed ?

Yes

No

Level 3

(Resume normal operation)

END

Figure 3-8: Error Recovery Procedure 5—System or Application Error

Escalation

10400025-101 10/2006 3–11

Page 46

Section 3

ERP= 6

Reboot the library to attempt to

clear the fault condition.

New FSC

New FSC

FSC

displayed ?

Same FSC

No FSC

Select a different piece of media

and retry the move operation.

FSC

displayed ?

Same FSC

No FSC

Remove the defective

media from the library.

New FSC

Found

(Resume normal operation)

END

Chassis

R&R

Figure 3-9: Error Recovery Procedure 6—Defective Media or Chassis

3–12 10400025-101 10/2006

Page 47

ERP=7

Reboot the library to attempt to

clear the fault condition.

Troubleshooting and FSCs

New FSC

New FSC

FSC

displayed?

Same FSC

No FSC

Select a different piece of media

and retry the fetch/stow

operation.

FSC

displayed?

Same FSC

No FSC

Remove the defective

media from the library.

Chassis /

Drive R&R

Try the move operation to/

from a different drive or slot.

Was the operation

successful ?

New FSC

Found

(Resume normal operation)

END

Chassis

R&R

Drive

R&R

Figure 3-10: Error Recovery Procedure 7—Defective Media, Chassis, or Drive

10400025-101 10/2006 3–13

Page 48

Section 3

ERP=8

Reboot the library to attempt to

clear the fault condition.

New FSC

New FSC

FSC

displayed ?

No FSC

Retry the drive fetch/stow

operation with a different

piece of media.

FSC

displayed ?

No FSC

Remove the defective

media from the library.

Same FSC

Same FSC

New FSC

Found

(Resume normal operation)

END

Drive R&R

Figure 3-11: Error Recovery Procedure 8—Defective Media or Drive

3–14 10400025-101 10/2006

Page 49

Chassis/

Drive R&R

Remove the suspected tape drive

assembly from the library and

inspect for visible damage.

Troubleshooting and FSCs

Damaged?

No

Dual Drives?

No

Inspect the chassis assembly

interconnect cabling for visible

damage.

Damaged?

No

Yes

Yes

Yes

Swap drives to check

drive vs. position.

Retry the operation.

Replace tape drive

assembly .

Yes

Problem

with same physical

drive?

No

Replace chassis

assembly .

Replace both chassis assembly

and tape drive assembly.

(Resume normal operation)

END

Figure 3-12: ERP Chassis vs. Tape Drive ERP

10400025-101 10/2006 3–15

Page 50

Section 3

Level 3

Escalat ion

Save a Library Trace at

the point of failure. Save all

system informat ion, version

information, system logs , and

application logs .

Notify technical support

and wait for patch.

3.3 Tape Drive Removal

While troubleshooting the library, it may become necessary to remove the tape drive assembly for

examination. Follow this procedure to correctly and safely remove the assembly:

1. At the OCP, press Power > Power Off Library to power down the unit.

2. After the unit has shut down, remove the power cord.

3. At the rear, remove the LVD SCSI cable and terminator from the drive cover SCSI ports

(Figure 3-14).

Apply librar y or system patch .

No

Problem