Overhead door OverDrive User Manual

TABLE OF CONTENTS

The Genuine. The Original.

Complete

SECTION PAGE

PRE-INSTALLATION CHECKLIST . . . . . . . . . . . . . . . . . . . 2-3

PARTS IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

SAFETY INFORMATION & SAFETY FEATURES. . . . . . . . . . 7

OPERATOR ASSEMBLY & INSTALLATION . . . . . . . . . . . 8-16

OPERATOR ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

OPERATOR INSTALLATION . . . . . . . . . . . . . . . . . . . . . 12-16

SAFE-T-BEAM®SYSTEM INSTALLATION. . . . . . . . . . . 17-18

WALL CONTROL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . 19

CONNECTING POWER. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

SETTINGS .

WIRELESS CONTROLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-26

OPERATING SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . 26

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27-30

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

AC

CESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A

SERVICE INFORMA

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21-22

FORCE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

LIMIT SWITCH ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . 22

CONTACT REVERSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

BATTERY / VISOR CLIP INSTALLATION . . . . . . . . . . . . . 23

PROGRAMMING REMOTE CONTROLS . . . . . . . . . 23-24

WIRELESS KEYPAD INSTALLATION . . . . . . . . . . . . . . . . . 24

PROGRAMMING WIRELESS KEYPAD . . . . . . . . . . . 25-26

OPERATIONAL FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . 27

PERIODIC MAINTENANCE . . . . . . . . . . . . . . . . . . . . . 27-28

TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . 28-29

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

TION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

with

Remote Control

and

SERIES II Electronics

Included Wall Control MUST be installed prior

to Operation of this Garage Door Operator.

Safe-T-Beam

be Installed and the Force Controls Must be

Properly Set to close door.

This Equipment meets or exceeds all Federal,

State and UL325 Safety Requirements.

*

Will not operate twice as fast

on a one-piece door.

NEED HELP?

Please call us if you are having difficulty, for any reason.

We would like to help you.

Call: 1.800.929.3667

Web: www.overheaddoor.com

®

Safety Reverse System Must

3505735581

REFERENCE

SAVE FOR FUTURE

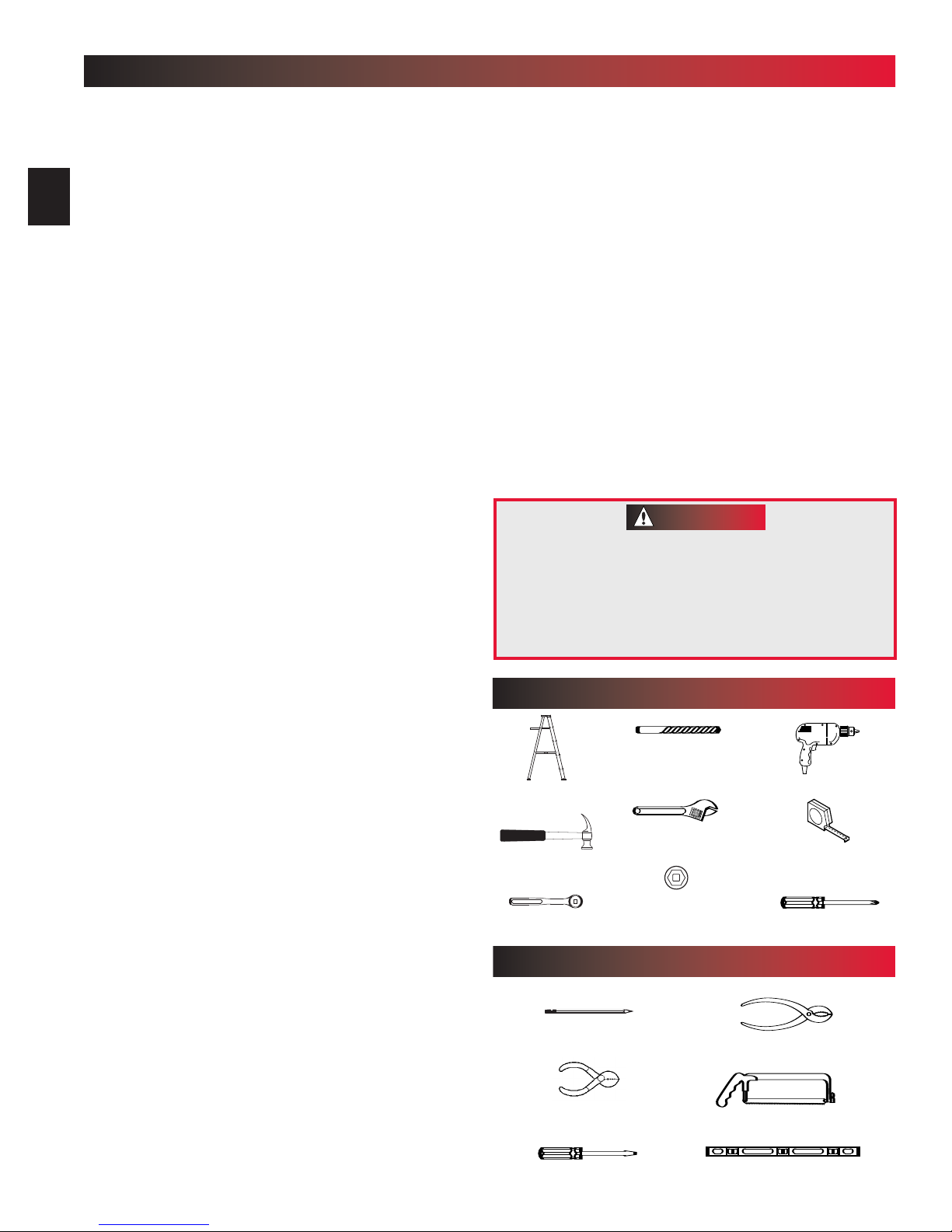

PRE-INSTALLATION CHECK LIST

FOR HELP-1.800.929.3667 OR OVERHEADDOOR.COM

Things to consider if you are planning to “do-it-yourself.”

In many cases you will be replacing an existing door operator with a new one. However, if

this will be the first operator installed there are some pre-installation issues which need to

be addressed. They are as follows:

2

(The issue numbers below refer to the circled numbers on the illustrations which appear on page 3.)

Check your ceiling where the power head

of your new unit will be mounted. Plan how

you will be mounting the Power Head.

1

It is possible that ceiling joists simply may not

be in the exact position needed with respect to

the garage door operator

be necessary to add an additional bracket and

fasteners (not included with your new door

operator kit).

Check the wall directly above the garage

door

. The door operator’s header bracket

must be securely fastened to this wall. Insure

2

that the structure will provide a strong mounting

location. You may need to attach a board to the

wall frame in this area.

Check to see if the mounting location for

the Safe-T-Beam

obstruction and has a wood surface

3

available for attaching the STB brackets

brackets may also be attached to concrete if

necessary but extra tools and special fasteners

(not supplied) will be required.

NOTE: 1-1/2" STB Adapters are available

through your local Genie Dealer.

. In any case it may

®

System is clear from

. The

Ensure that your door is properly balanced

and moving freely. SEE WARNING BELOW.

(

This Operator is equipped with an Automatic

7

Garage Door Balance Detection System. See page

28, T

roubleshooting section.

(NOT SHOWN) If your garage does not have

a separate entry door. You might want to

consider a GER-2 Emergency Release Kit for

8

installation on your garage door

Service or visit the web site for information.

WARNING

If your door sticks, binds, or is out of

balance, have it adjusted by a professional.

Door springs, cables, pulleys, brackets and

associated hardware are under extreme

tension and can cause serious injury or

death.

TOOLS REQUIRED

Drill Bit

Stepladder

)

. Contact Customer

5/32"

Drill

Is your garage door made of light-weight

steel, aluminum, fiberglass, or glass

panels

4

added to these type doors. If this is the case,

please contact the door distributor or manufacturer

so that they can furnish you with a “bracing kit.”

You need a 110-120 Volt power supply

available

standard electrical outlet, is one available?

5

The outlet should be no more than 3 feet from

the power head once it is mounted.

To avoid damage to your door and/or

operator, make sure you disable any door

locks prior to installing your operator

6

? Additional support bracing must be

. If you plan to plug the unit into a

Wrench

Hammer

3/8", 7/16", 1/2"

Ratchet

ADDITIONAL TOOLS

Pencil

Wire Strippers

.

Straight Blade Screwdriver

and 9/16" Sockets

YOU MAY NEED

Carpenter’s Level

Tape Measure

Phillips Screwdriver

Pliers

Hack Saw

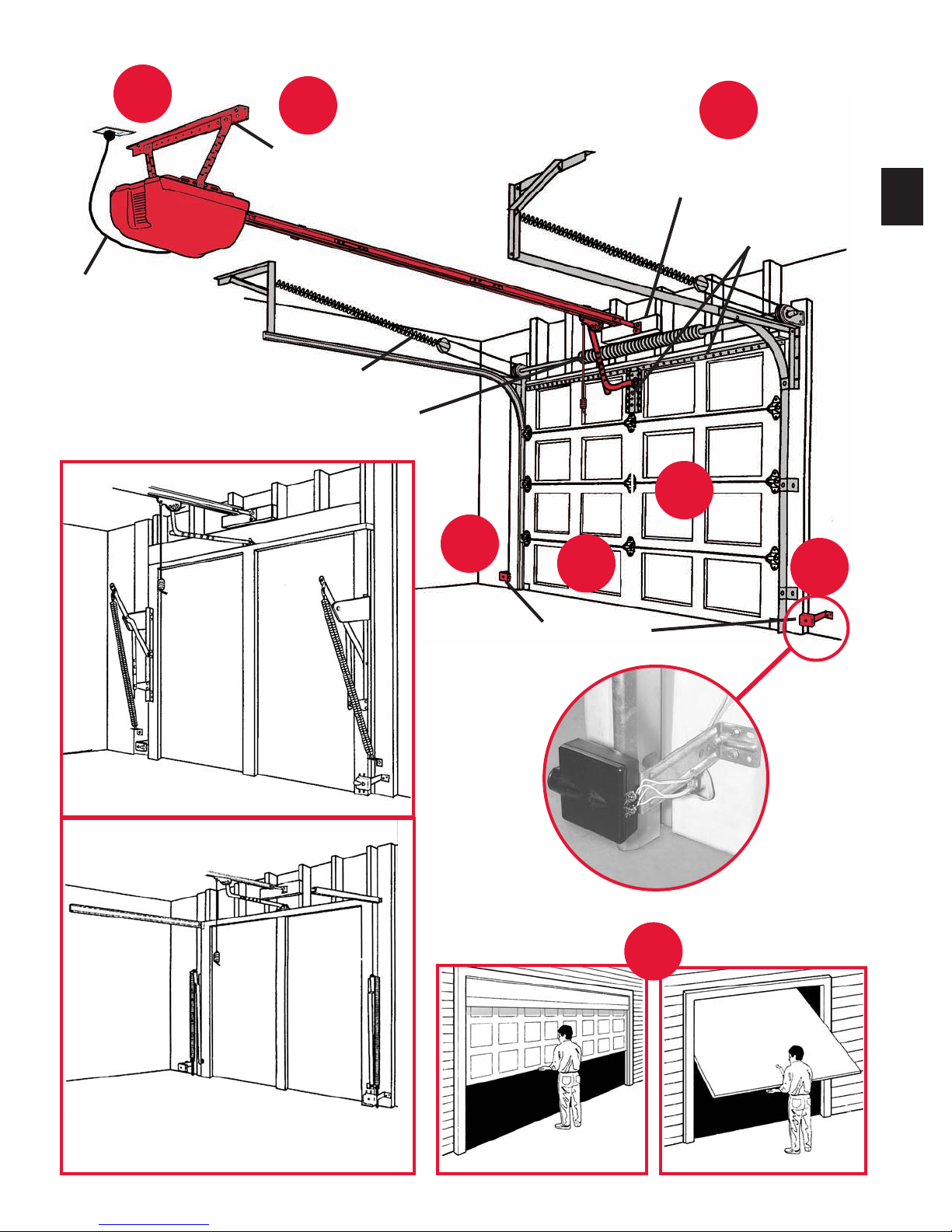

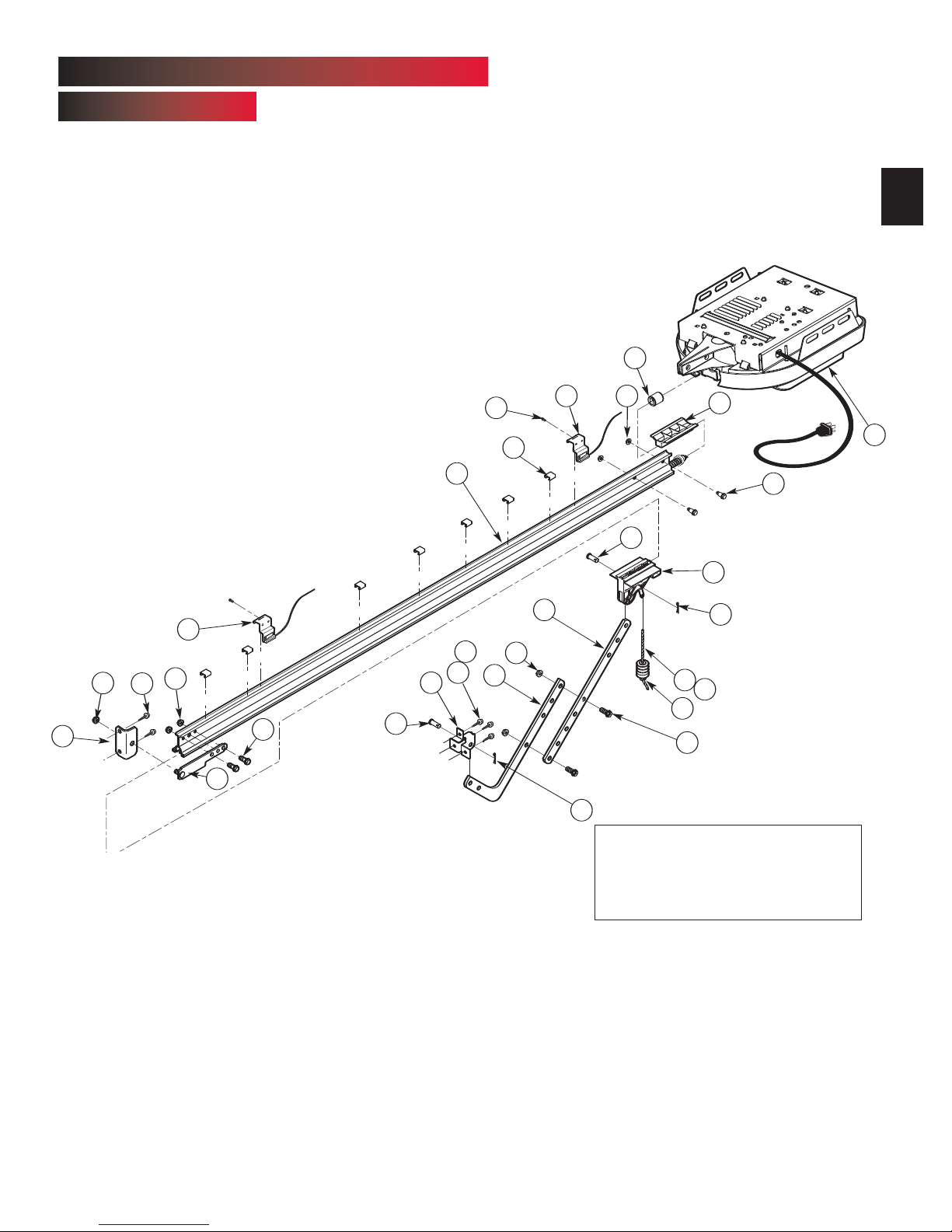

TYPICAL SECTIONAL DOOR INSTALLATION

5

36” POWER CORD

TO

120V GROUNDED

OUTLET

1

TYPICAL

SUPPORT

BRACKET

EXTENSION SPRING

OR

TORSION SPRING

3

6

2

ADDED

HEADER BRACKET

MOUNTING BOARD

3

BRACES

4

3

TYPICAL (TRACKLESS)

1-PIECE DOOR INSTALLATION

SAFE-T-BEAM

®

7

TYPICAL (TRACK GUIDED)

1-PIECE DOOR INSTALLATION

SECTIONAL DOOR

ONE-PIECE DOOR

3

DEF

1

2

456

7

8

9

0

GHI

JKL

MNO

P

QRS

TUV

WXYZ

9

V

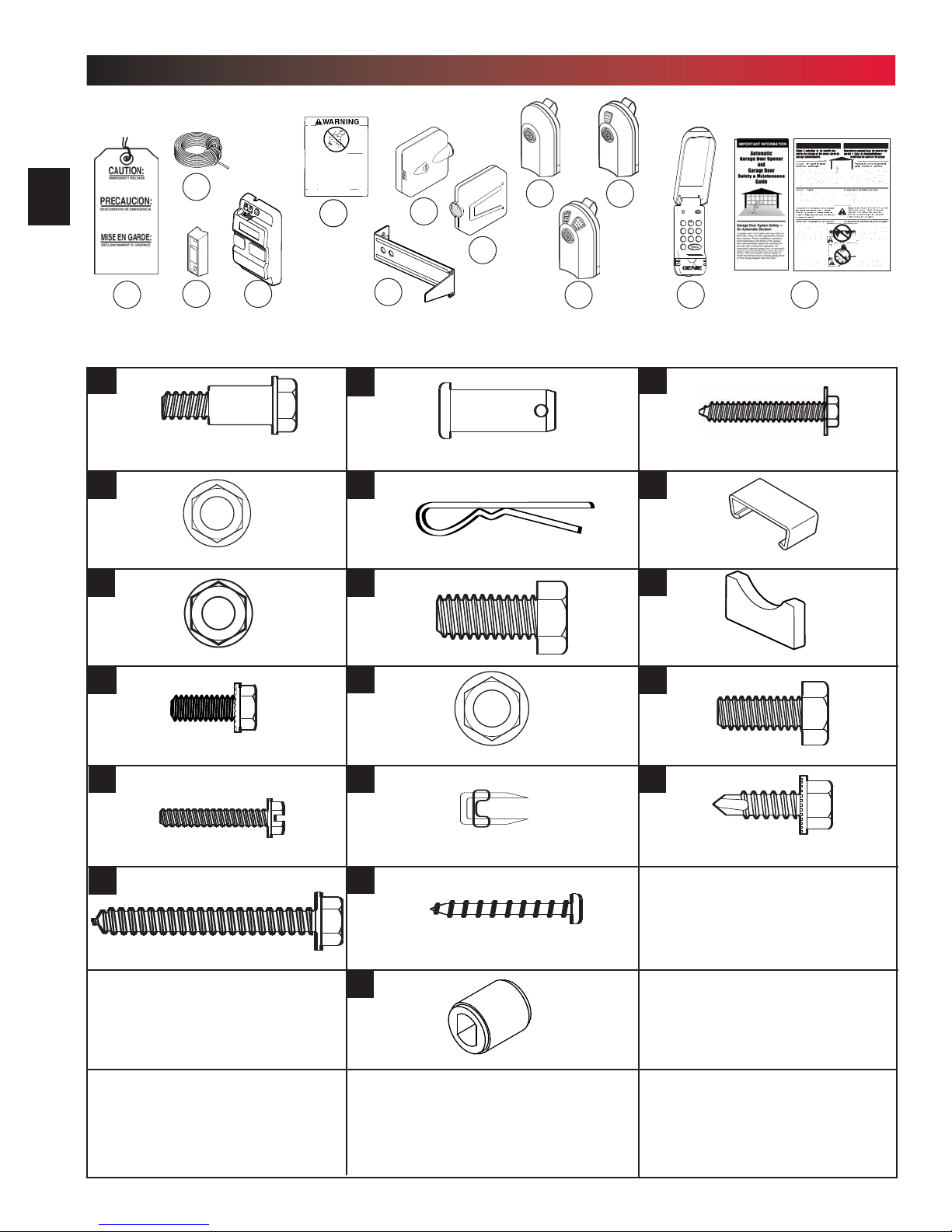

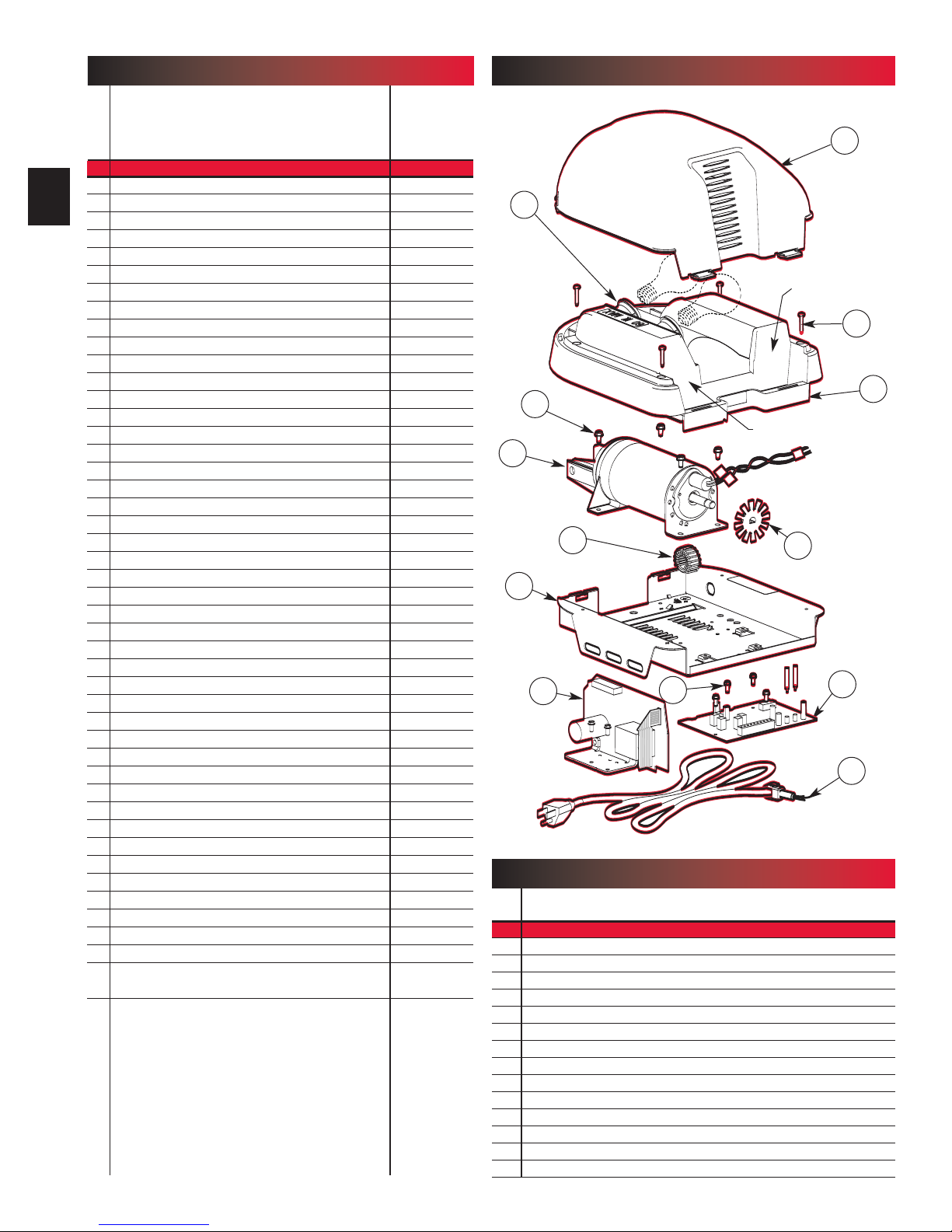

PARTS IDENTIFICATION

FOR HELP-1.800.929.3667 OR OVERHEADDOOR.COM

4

25

39

40

NOTE: Accessories vary by Model

42

45

.

FASTENERS - Shown Full Size. See Parts List for description.

37

2

1/4"-20 Shoulder Bolt

8

1/4"-20 Nut

11

32

33

35

43

44

Clevis Pin

Cotter Pin

48

49

51

50

47

#10-16 x 1-1/4" Phillips Hex Head Screw

53

Wire Clip

54

52

16

21

30

5/16"-18 Nut

1/4"-20 x 5/8" Bolt

#8-32 x 1" Screw

1/4" x 2" Lag Screw

36

38

41

46

3/8"-16 x 7/8" Bolt

3/8"-16 Nut

Insulated Staple

#6 x 1-1/4” Pan Head Screw

Coupler

Rubber Bumper

55

5/16"-18 x 3/4" Bolt

56

1/4"-20 x 3/4" Self-Drilling Screw

D

OOR

DOOR

D

OOR

DOOR

12

22

24

31

35

33

36

34

32

32

28

11

26

30

15

16

53

2

19

18

1

30

2

1

54

46

56

3

8

23

8

33

1-PIECE BOOM HARDWARE EXPLODED VIEW

“PRO” ONLY

[3]

NOTE: The Operator will not

function unless the Safe-T-Beam

System is installed and the

Force Controls are properly set.

®

5

Assembly for 10' or 12' door includes:

1. Special “Close” Limit Switch with longer

wires.

2. 96" Emergency Release Cord (yellow)

3. Rail Support Kit

PARTS LIST

POWER HEAD EXPLODED VIEW

[1]

Item Part Name Parts Required

1 Power Head Assembly (main carton) 1

6

2 1/4"-20 Hex Head Shoulder Bolt (blue bag) 2

3 Boom Assembly (1 piece)(packaged separately) 1

8 1/4"-20 Hex Serrated Flange Nut (blue bag) 4

11 5/16"-18 Hex Serrated Flange Nut (blue & orange bag)

12 Carriage Assembly (main carton) 1

15 Boom Strap (blue bag) 1

16 1/4"-20 Hex Head Bolt (blue bag) 2

18 Open Limit Switch Assembly (White)(green bag) 1

19 Close Limit Switch Assembly (Brown) (green bag) 1

21 No.8-32 x 1" Hex Head Screw (green bag) 2

22 Emergency Release Cord (green bag) 1

23 Emergency Release Cord (long)(yellow)

24 Emergency Release Knob (green bag) 1

25 Emergency Release Tag (green bag) 1

26 Header Bracket (orange bag) 1

28 Door Bracket (orange bag) 1

30 1/4" x 2" Lag Screw (orange bag)

31 Straight Door Arm (main carton) 1

32 Clevis Pin (yellow bag) 2

33 Cotter Pin (yellow bag) 2

34 Curved Door Arm (main carton) 1

35 3/8" x 7/8" Hex Head Bolt (yellow bag) 2

36 3/8" Hex Serrated Flange Nut (yellow bag) 2

37 Wire (main carton)

38 Insulated Staple (red bag)

39 Wall Button (red bag)

40 Wall Console (main carton)

41 #6 x 1-1/4" Pan Head Screw (red bag) 4

42 Entrapment WARNING Label (manual) 1

43 Safe-T-Beam (STB) Sensor (Green LED)(main carton) 1

44 Safe-T-Beam (STB) Source (Red LED)(main carton) 1

45 Safe-T-Beam (STB) Bracket (yellow bag) 2

46 Coupler (blue bag) 1

47 No.10-16x1 1/4" Phillips Hex Head Screw (yellow bag) 4

48 Single Button Remote Control (main carton)

49 Multi-Button Remote Control (main carton)

50 Wireless Keypad (main carton)

51 2-Button Remote Control (main carton)

52 Safety & Maintenance Guide (manual) 1

53 Wire Clip (green bag)

54 Carriage Stop (blue bag) 1

55 5/16"-18x 3/4" HexHead Bolt (orange bag)

56 1/4-20 x 3/4" Self-drilling Screw (orange bag) 3

57 Mounting Straps (main carton)

varies/model

10' & 12' only

varies/model

≈

95ft

≈

30

varies/model

varies/model

varies/model

varies/model

varies/model

varies/model

varies/model

varies/model

varies/model

1C

1K

1D

1N

1B

1G

1M

POWER HEAD PARTS LIST

Item Part Name

1 Power Head Assembly

1A Lens (By Series/Model)

1B Top Plate Assembly

1C Light Socket (2)

1D Motor Assembly

1E Cover

1F Opto Wheel

1G Motor Drive Board

1H Controller Board

1K No. 10-24 x 3/8”Hex Head

1L No. 8-32 x 1” Phillips Screw

1M No. 8-32 x 3/8”Slotted Hex Head Screw

1N Toroid

1P Power Cord

1A

MODEL

NUMBER

1L

1E

SERIAL NUMBER

1F

1H

1P

SAFETY INFORMATION OPERATOR INSTALLATION

OVERVIEW OF

POTENTIAL HAZARDS

Garage Doors are large, heavy objects that move with the help of springs

under high tension and electric motors. Since moving objects, springs under

tension, and electric motors can cause injuries, your safety and the safety of

others depend on you reading the information in this manual. If you have

questions or do not understand the information presented, call your nearest

service representative.

In this Section and those that follow, the words Danger, Warning, and

Caution are used to emphasize important safety information. The word:

DANGER means that severe injury or death will result from failure to

follow instructions.

WARNING means that severe injury or death can result from failure to

follow instructions.

CAUTION means that property damage or injury can result from failure to

follow instructions.

The word NOTE is used to indicate important steps to be followed or

important considerations.

POTENTIAL

HAZARD

MOVING

DOOR

ELECTRICAL

SHOCK

HIGH

SPRING

TENSION

EFFECT PREVENTION

Keep people clear of opening while door is

WARNING:

Can Cause

Serious Injury

or Death

WARNING:

Can Cause

Serious Injury

or Death

WARNING:

Can Cause

Serious Injury

or Death

moving.

Do Not allow children to play with the door

operator.

Do Not operate a door that jams o r one t hat

has a broken spring.

Turn off power before removing operator

cover.

When replacing cover, make sure wires are

not pinched or near moving parts.

Operator must be properly grounded.

Do Not try to remove, repair or adjust

springs or anything to which door spring

parts are fastened, such as, wood blocks,

steel brackets, cables or other like items.

Repairs and adjustments must be made by

a trained service person using proper tools

and instructions.

IMPORTANT

INSTALLATION

INSTRUCTIONS

WARNING

WARNING

:

:

To reduce the risk of

severe injury or death:

1. READ AND FOLLOW ALL SAFETY, INSTALLATION AND

OPERATION INSTRUCTIONS. If you have any questions or

do not understand an instruction, call your service

representative.

2. Do Not install operator on an improperly balanced door. An

improperly balanced door could cause severe injury.Repairs

and adjustments to cables, spring assembly, and other

hardware must be made by a trained service person using

proper tools and instructions.

3. Remove all ropes,and disable all locks connected to the

door before installing operator.

4. Install door operator 7 feet or more above the floor. Mount

the emergency release knob 6 feet above the floor.

5. Do Not connect the operator to the source of power until

instructed to do so.

6. Locate the control button:

• Within sight of door.

• At a minimum height of 5 feet,so small children cannot

reach it.

• Away from all moving parts of the door.

7. Install the entrapment WARNING label next to the wall

button or console. Install the emergency release tag on, or

next to, the emergency release

8. The operator must reverse when the door contacts a 1-1/2

inch high object on the floor at the center of the doorway.

This is about the size of a 2" x 4" board laid flat.

7

SAFETY FEATURES

(

varies by model

Safe-T-Beam®(STB) Non-Contact Reversing System

Places an invisible beam across door opening, that reverses the door during down travel to the fully open

position if anything passes through beam.

Safe-T-Reverse

®

Contact Reversing System

Automatically stops and reverses a closing door within 2 seconds of contact with an object.

Safe-T-Stop

®

Timed Reversed System

Automatically opens a closing door, if door does not close within 30 seconds.

Force Guard

®

Control

Used to set the force required for opening and closing door. For maximum safety, set the minimum force

required to fully open and close door.

Automatic Lighting System

T

wo light bulbs up to 60 Watts max. each, are used for safer entries and exits. The light turns on when door is

activated and automatically turns of

f 4.5 minutes later

Manual Emergency Release

Allows the garage door to be opened or closed manually for emergencies or maintenance.

)

.

...

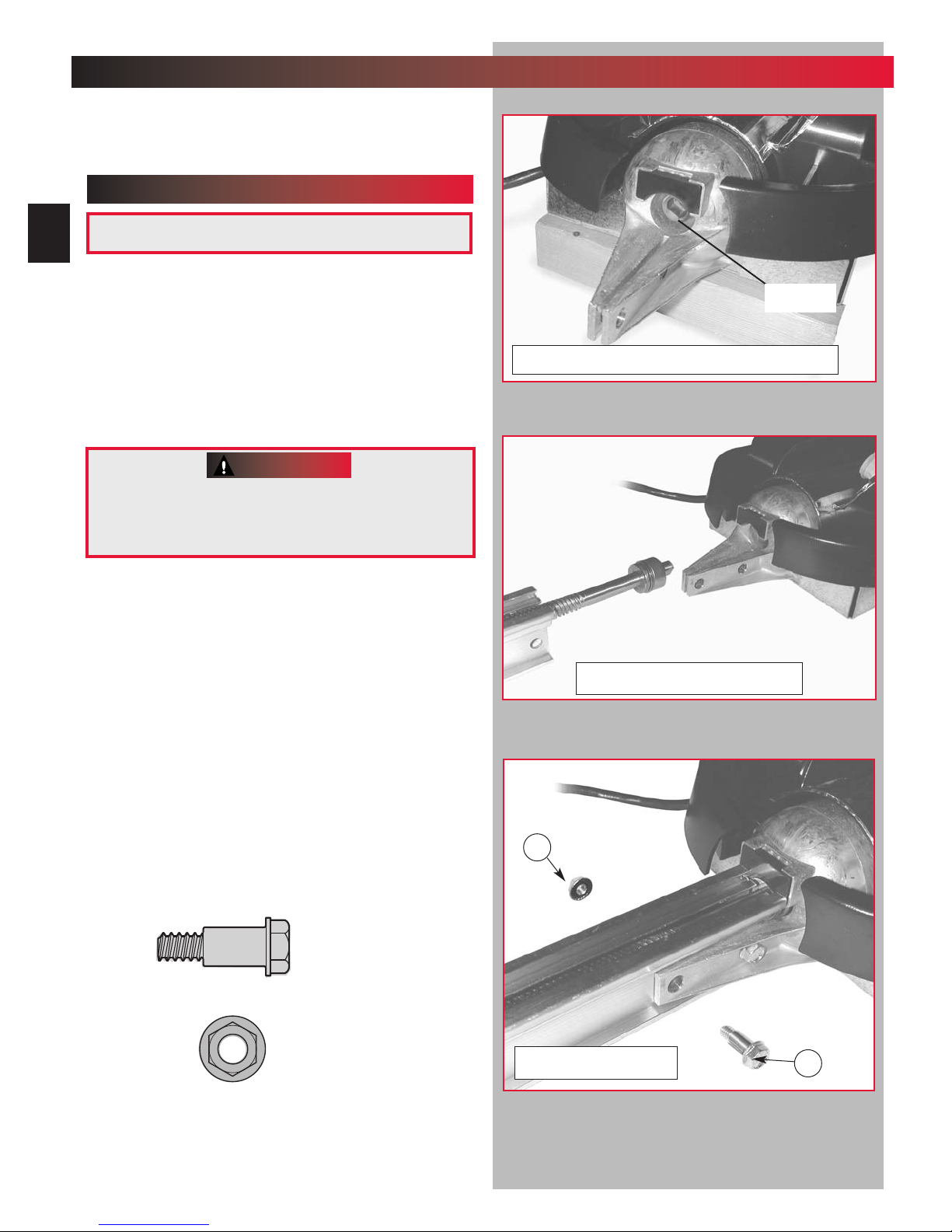

OPERATOR ASSEMBL Y & INSTALLATION

1

Record your Model Number and Serial

Number now on page 11 in the center of

this manual.

OPERATOR ASSEMBLY

FOR HELP-1.800.929.3667 OR OVERHEADDOOR.COM

8

8

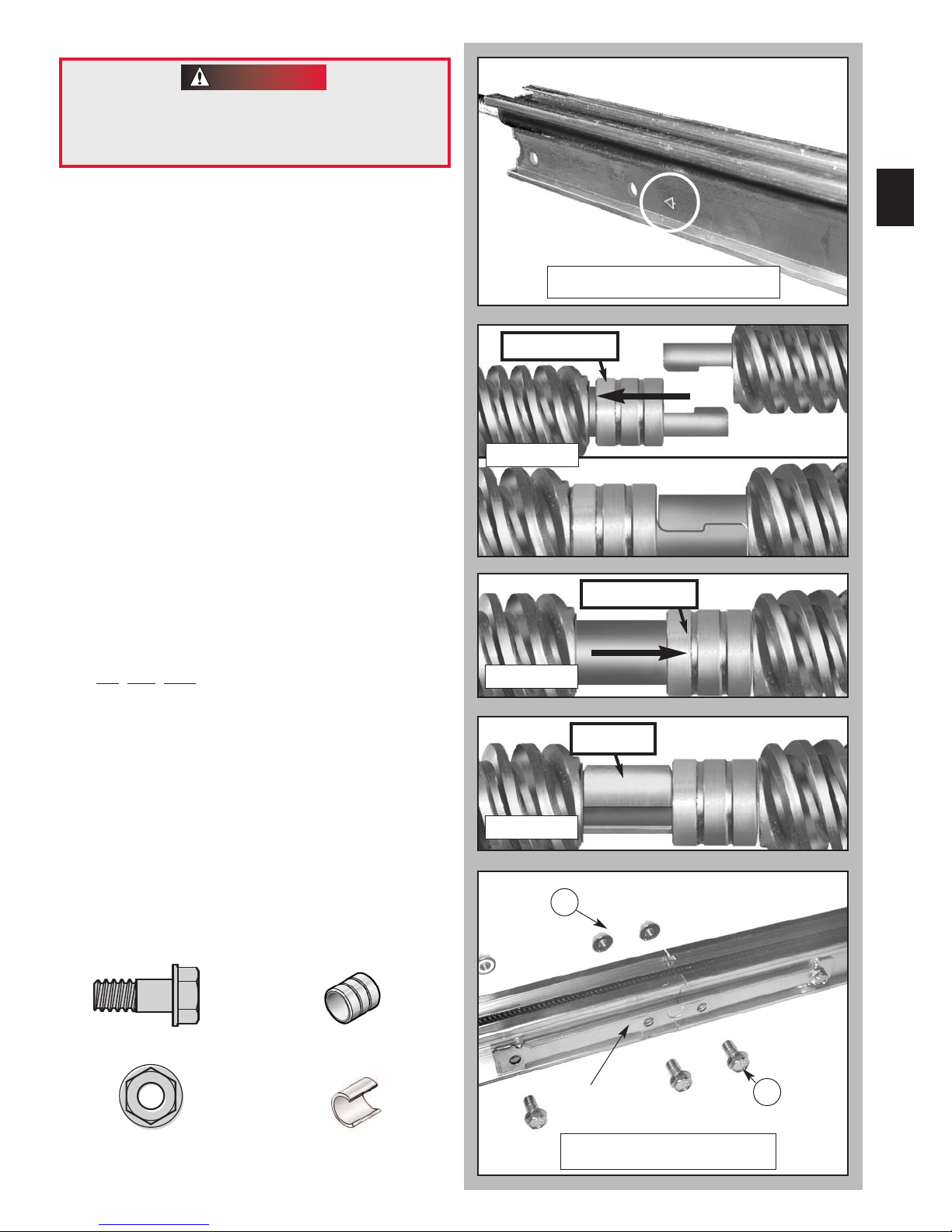

OPEN BLUE PARTS BAG

NOTE: 3 piece operator assembly is for doors up

to 7 feet 6 inches high. An extension kit for an 8 feet

high door is available.

Assemble on a clean, flat surface.

1. Install coupler [46] (Fig. 1-1).

• Line up and slide on motor shaft.

CAUTION

Drive screw and boom liner can slide out

of boom sections. Keep boom sections

level until operator is fully assembled.

.

2. Connect boom to power head. Either 1-piece

boom or first section of 3-piece boom

(

Fig. 1-2).

•

Insure arrow on boom points away from power

head. (Fig 1-4 on page 9.)

•

Push drive screw out about 5 inches.

• Line up and slide drive screw into coupler.

Slide boom into bracket and line up holes with

•

those on power head (Fig. 1-3).

– Connect with bolts [2] and nuts [8].

Coupler

Fig. 1-1 Install rubber bumper and coupler

Fig. 1-2 Push drive screw out

[2]

1/4"-20 Hex Head Bolt

[8]

1/4"-20 Hex Flange Nut

8

Fig. 1-3 Attach boom

2

CAUTION

Drive screw section and boom liner can slide

out of boom sections. Keep boom sections

level until operator is fully assembled

3. On 1 piece boom assembly go to step 11.

4. Arrange arrows on boom sections (Fig. 1-4).

• Point arrows in same direction

power head.

5. Attach middle boom section to first

boom section.

•

Push middle drive screw out about 2 inches

toward the power head.

•

Slide collar [13] over the middle boom hook

(Fig.1-5).

• Turn screw by hand to align coupler hooks

between first and middle boom sections.

• Latch the two hooks together and

slide the collar over them (Fig. 1-6).

•

Snap clip [14] next to collar (Fig. 1-7).

6.

Attach boom clamps at the middle boom to

first boom joint (Fig. 1-8).

•

Slide the middle boom section against the first

boom section.

Place a boom clamp on each side of the boom

•

at the joint and line up the holes with those in

the boom.

• Fin

ger tighten boom clamps with bolts [10] and

nuts [11].

away

from

9

Fig. 1-4 Arrange arrows

slide collar

Fig. 1-5

slide collar

Fig. 1-6

7. Attach end boom section to middle boom

section to first boom section (Step 6).

8. Attach boom clamps at the end boom to

middle boom joint (Fig. 1-8).

•

Repeat procedure used to attach middle boom

section to first boom section (Step 7).

NOTE: If installing a 3-piece boom assembly on

an eight foot high door refer to the instruction

sheet included with the optional boom extension

at this point.

[

]

[

]

10

5/16"-18 Hex Head Shoulder Bolt

[11]

5/16"-18 Hex Head Flange Nut

Collar

Retaining Clip

13

[

14

]

Fig. 1-7

clip

11

Clamp

het

Fig. 1-8 Attach rail clamps

10

10

10

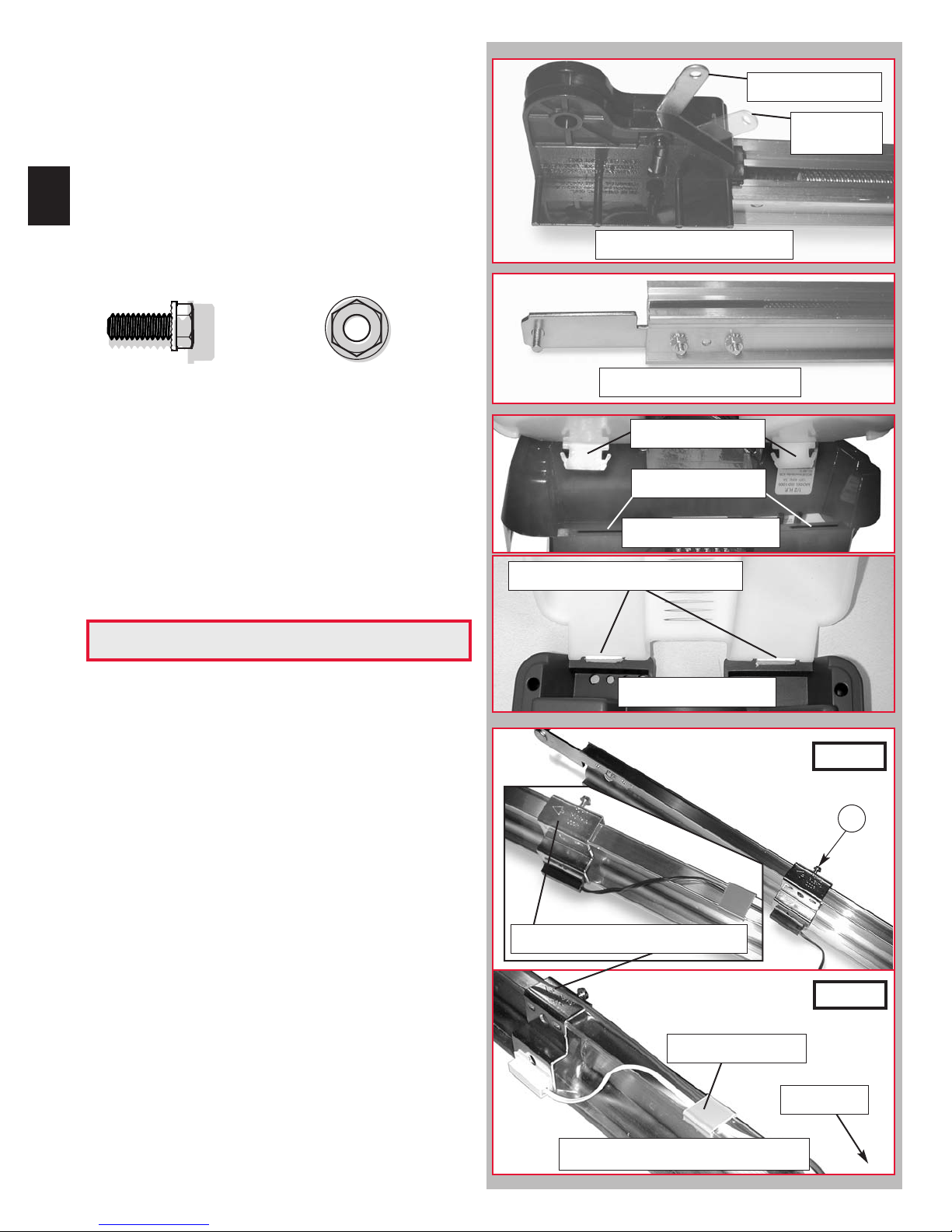

9. Install carriage and carriage stop (Fig. 1-9).

• Slide carriage stop into railand along the length

of the rail to the power head.

• Point arrow on side of carriage toward door.

• Place carriage lever in release position.

• Slide into carriage slot of boom assembly.

NOTE: Carriage release lever will be facing

power head.

10. Attach boom strap (Fig. 1-10).

• Connect to end boom section with bolts

[16] and nuts [8].

Release position

Engaged

position

Fig. 1-9 Install carriage

[

]

16

1/4"-20 Hex Head Bolt

11. Tighten all nuts and bolts.

NOTE: Tighten nuts and bolts on boom so that

they grip metal snuggly. Do Not Over-Tighten.

12. Install lens cover (Fig. 1-11).

• Align hinge tabs with slots on motor cover

(Fig. 11A).

•

Move antenna outside lens and out of way

• Push hinges into slots on cover until

they snap into place (Fig. 11B).

•

Swing lens cover closed and snap into place.

1/4"-20 Serrated Hex Nut

[8]

.

OPEN GREEN PARTS BAG

13. Place limit switches (

•

urn unit right side up.

T

• Uncoil limit switch wires.

• Place switches on boom with arrows pointing

toward boom strap.

– Place CLOSE limit switch (brown wire) 12

from boom strap.

– Finger tighten the hold-down screw [21].

– Lay out the wire in the channel on top of the

boom, using wire clips [53] to hold it in place

as you go toward the power head.

– Save one clip for the OPEN switch.

– Place OPEN limit switch (white wire) 12

from power head. (Place over brown wire.)

– Finger tighten the hold-down screw.

– Lay out the wire in the channel on top of the

boom, using the last wire clip to hold both

limit switch wires in place.

Fig. 1-12).

"

"

Fig. 1-10 Attach boom strap

Hinge tabs

Slots

Fig. 1-11A Install lens

Push in until they catch

Fig. 1-11B Install lens

CLOSE

21

Arrow points toward boom strap

OPEN

NOTE:Do not over-tighten screw [21] on limit

switch brackets.

• Limit switch adjustments will be made later.

Last wire clip [53]

power head

Fig. 1-12 Limit switch placement

Loading...

Loading...