Overhead door CD, CDB Owner's Manual

CD Series

¤

CDB Series

3507635556

Automatic

Chain Drive/Belt Drive

Garage Door Operator

System

Complete with Remote Control and

SERIES II Electronics

Operator MUST be installed with the included SERIES II Wall Control!

Self-diagnostic Electronic Sensory Protection System (SAFE-TBEAM SYSTEM) MUST Be Installed To Close Door!

Owner’s Manual

SAVE FOR FUTURE REFERENCE

Customer Service

CALL: 1-800-929-3667

OR VISIT WWW.OVERHEADDOOR.COM

AUTOMATIC GARAGE DOOR OPERATOR SYSTEMS

HANG MANUAL NEAR YOUR WALL CONTROL

TABLE OF CONTENTS

SECTION PAGE

SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

PARTS IDENTIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

ASSEMBLY

1 OPERATOR ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

1A Channel and Power Head Assembly . . . . . . . . . . . . . . . . . . .10

1B Rail and Power Head Assembly . . . . . . . . . . . . . . . . . . . . .10-11

INSTALLATION

2 DETERMINE DOOR TYPE AND MOUNTING METHOD . . . . . . . . . . . 11

2A Installation on Track Guided Doors . . . . . . . . . . . . . . . . 12-14

2B Installation on Trackless Doors . . . . . . . . . . . . . . . . . . . . 15-17

3 SAFE-T-BEAM®(STB) SYSTEM INSTALLATION . . . . . . . . . . . . . . . 18-19

Self-diagnostic “STB”System Troubleshooting . . . . . . . . . . . . 19

4 WALL CONTROL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5 CONNECT OPERATOR TO POWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6 MAIN LIMIT SWITCH SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

OPERATION

7 FORCE ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Contact Reverse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8 FINE LIMIT SWITCH ADJUSTMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9 REMOTE CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-25

10 BATTERY & VISOR CLIP INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 25

11 LIGHT BULB AND LENS INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . 26

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

TROUBLESHOOTING GUIDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

WARRANTY 32

PRE-INSTALLATION CHECK LIST

FOR HELP—1-800-929.3667 OR OVERHEADDOOR.COM

Things to consider if you are planning to “do-it-yourself.”

Whether you are replacing an existing garage door operator or installing an operator in your garage for

the first time, there are some pre-installation issues which need to be addressed.They are as follows:

2

mation and instructions contained herein before choosing a “Do-It-Yourself ” installation.

A

Door Dealer.

The Overhead Door Corporation recommends that you read and fully understand all infor-

ny questions should be directed to the Overhead Door Corporation or an authorized Overhead

(

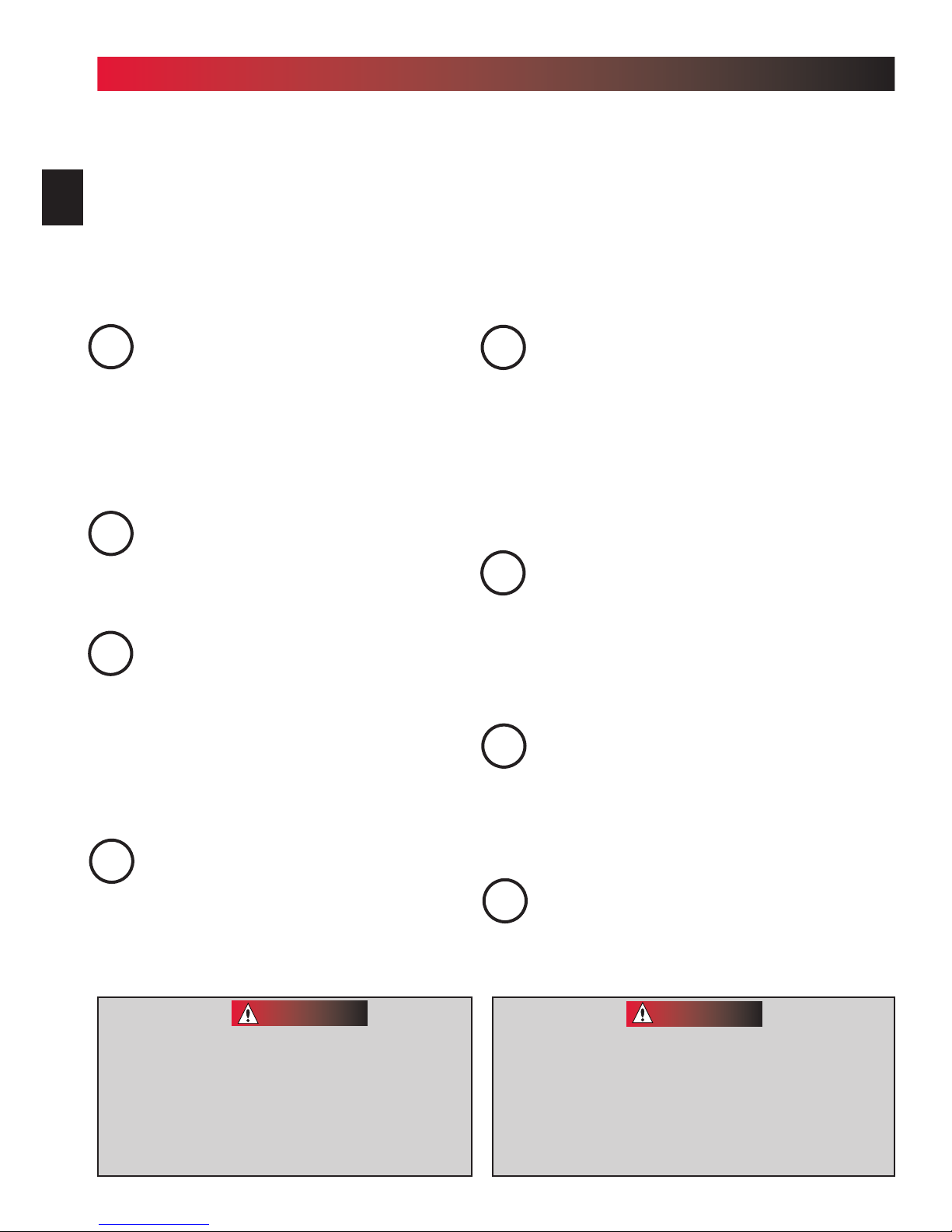

The issue numbers below refer to the circled numbers in the illustrations on page 3.

Check your ceiling where the power

head of your new unit will be mounted. Plan

1

ho

w you will be mounting the power head.It is possible that ceiling joists may not be in the exact position needed with respect to the garage door operator.In any case, it may be necessary to add an additional bracket and

new door operator kit).

Check the wall directly above the garage

door

2

be securely fastened to this wall. Insure that the

structure will provide a strong mounting location.

3

from obstruction and has a wood surface a

brackets may also be attached to concrete if necessary but extra tools and special fasteners (not supplied) will be required.

bracket adapters are available through your local

O

verhead Door Dealer.

. The door operator’s header bracket must

Check to see if the mounting location

for the Safe-T-Beam

vailable for attaching the STB brackets

fasteners (not included with your

®

System (STB)is clear

. The

NOTE: 1-1/2" “STB”

You need a 110-120 Volt power supply

available

5

standard electrical outlet, is one available? The outlet

should be no more than about 3 feet from the power

head once it is mounted. ( The cord is 4 ft. in length.) SEE

WARNING BELOW.

To avoid damage to your door and/or

6

operator, make sure you disable any door locks

prior to installing your operator

Insure that your door is properly balanced

7

and moving freely. SEE WARNING BELOW.

. If you plan to plug the unit into a

)

.

Is your garage door made of

light-weight steel, aluminum, fiberglass or

4

glass panels

added to these type doors. If this is the case, please

contact the door distributor or manufacturer so

that they can furnish you with a “bracing kit.”

DO NOT USE EXTENSION CORD! Extension

cords can cause dangerous overheating conditions.

DO NOT USE PORTABLE GENERATOR! This

product is designed to operate on standard

house current. Do not use alternate power

supplies.

? Additional support bracing must be

WARNING

(NOT SHOWN) If your garage does not have

a separate entry door, you might want to consider

8

an emergency r

your garage door. See page 30.

If your door sticks, binds, or is out of

balance, have it adjusted by a professional. Door

springs, cables, pulleys, brackets and associated

hardware are under extreme tension and

can cause serious injury or death.

elease kit (GER-2)for installation on

WARNING

TYPICAL SECTIONAL DOOR INSTALLATION

5

36” POWER CORD

TO

120V GROUNDED

OUTLET

1

TYPICAL

SUPPORT

BRACKET

EXTENSION SPRING

OR

TORSION SPRING

3

6

2

ADDED

HEADER BRACKET

MOUNTING BOARD

3

BRACES

4

3

TYPICAL (TRACKLESS)

1-PIECE DOOR INSTALLATION

SAFE-T-BEAM

®

7

TYPICAL (TRACK GUIDED)

1-PIECE DOOR INSTALLATION

SECTIONAL DOOR

ONE-PIECE DOOR

SAFETY INFORMATION OPERATOR INSTALLATION

Garage doors are large, heavy objects that move with the help of springs under

high tension and electric motors. Since moving objects, springs under tension,and

electric motors can cause injuries, your safety and the safety of others depend on

4

you reading the information in this manual. If you have questions or do not understand the information presented,call your nearest service representative

In this section and those that follow,the words Danger

used to emphasize important safety information.

The word:

DANGER means that severe injury or death will result from failure

to f

WARNING means that severe injury or death can result from failure

t

CAUTION means that property damage or injury can result from failure

t

The word NOTE is used to indicate important steps to be followed

ortant considerations.

or imp

POTENTIAL

HAZARD

MOVING

DOOR

ELECTRICAL

SHOCK

HIGH

SPRING

TENSION

SAFETY FEATURES

OVERVIEW OF

POTENTIAL HAZARDS

, Warning, and Caution are

ollow instructions.

o follow instructions.

o follow instruction.

EFFECT PREVENTION

Keep people clear of opening while door is

WARNING:

Can Cause

Serious Injury

or Death

WARNING:

Can Cause

Serious Injur

or Death

WARNING:

Can Cause

erious Injury

S

or Death

moving.

Do Not allow children to play with the door

operator.

Do Not operate a door that jams or one that has a

broken spring.

Turn off power before removing operator cover.

When replacing cover, make sure wires are not

pinched or near moving parts.

y

Operator must be properly grounded.

Do Not try to remove, repair or adjust springs or

anything to which door spring parts are fastened,

such as, wood blocks, steel brackets,

cables or other like items.

Repairs and adjustments must be made by a

trained service person using proper tools and

instructions.

(

varies by model

)

IMPORTANT

INSTALLATION

INSTRUCTIONS

WARNING

WARNING

:

:

To reduce the risk of

severe injury or death:

1. READ AND FOLLOW ALL SAFETY, INSTALLATION AND

OPERATION INSTRUCTIONS. If you have any questions or

do not understand an instruction, call your service

representative.

2. Do Not install operator on an improperly balanced door. An

improperly balanced door could cause severe injury.

Repairs and adjustments to cables, spring

assembly,and other hardware must

be made by a trained service person using

proper tools and instructions.

3. Remove all ropes and disable all locks connected to the

door before installing operator.

4. Install door operator 7 feet or more above the floor. Mount

the emergency release knob 6 feet above the floor.

5. Do Not connect the operator to the source of power until

instructed to do so.

6. Locate the control button:

• Within sight of door.

• At a minimum height of 5 feet,so small children cannot

reach it.

• Away from all moving parts of the door.

7. Install the entrapment WARNING label next to the wall button or console. Install the emergency release tag on, or

next to, the emergency release

8. The operator must reverse when the door contacts a 1-1/2

inch high object on the floor at the center of the doorway.

This is about the size of a 2” x 4” board laid flat.

Safe-T-Beam®(STB) Non-Contact Reversing System Places an

invisible beam across door opening that reverses the door during down travel to the fully open position if anything

passes through beam.

Safe-T-Reverse

®

Contact Reversing System

Automatically stops and reverses a closing door within 2 seconds of contact with an object.

Safe-T-Stop

®

Timed Reversed System Automatically

opens a closing door,if door does not close within 30 seconds.

®

Force Guard

Control Used to set

the force required for opening and closing door. For maximum safety, set the minimum force required to fully open and

close door.

Automatic Lighting System

One or two light bulbs (depending on model) up to 100 Watts max. each are used for safer entries and exits.The light

tur

ns on when door is activated and automatically turns off 4.5 minutes later.

Manual Emergency Release

Allows the garage do

or to be opened or closed manually for emergencies or maintenance.

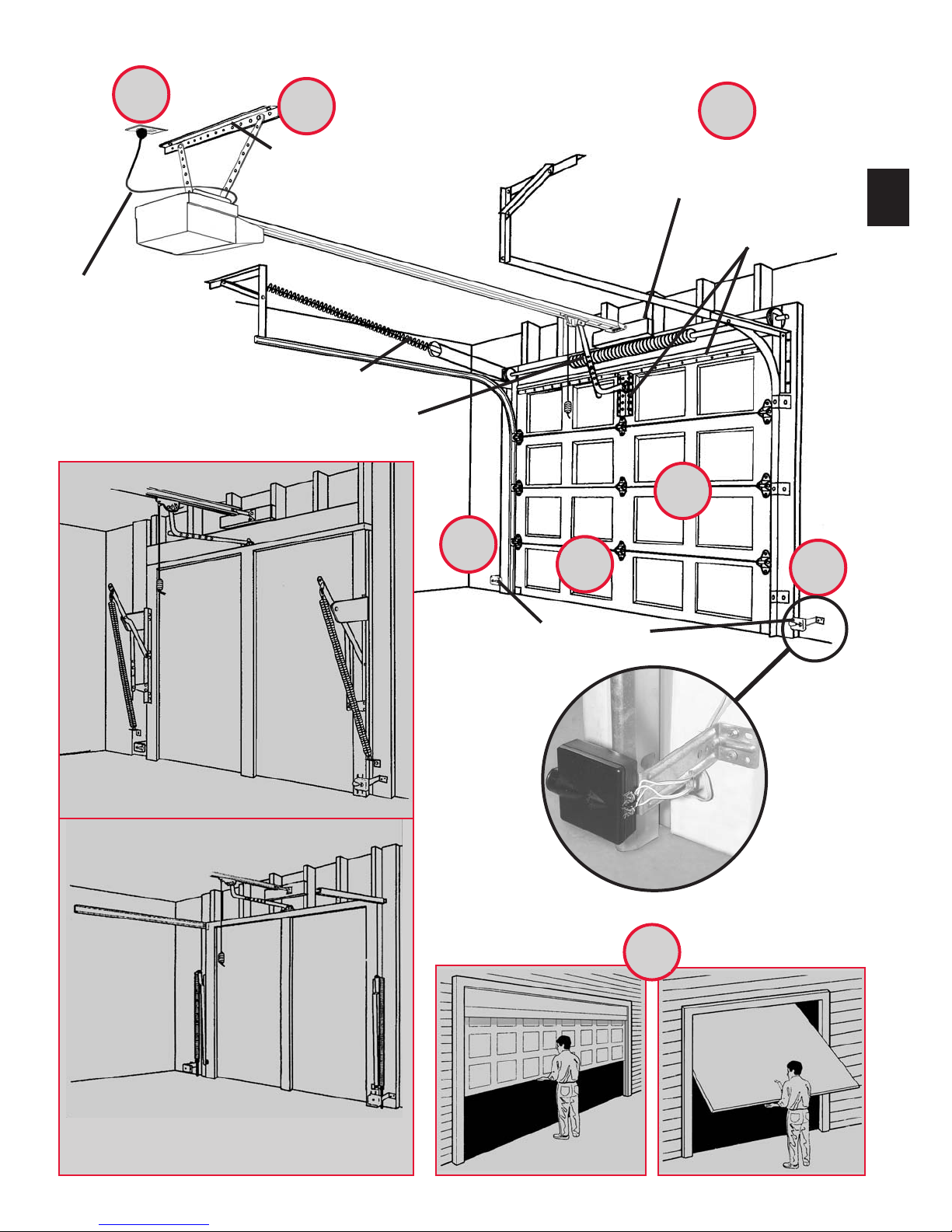

PARTS IDENTIFICATION

106

105

12 5

FOR HELP—1-800-929.3667 OR OVERHEADDOOR.COM

5

124

10 4

101

100

NOTE: Accessories vary by model.

FASTENERS -

Shown full size. See Parts List for description.

69

Bolt, #10-24 x 1/2”

112

Bolt, 5/16”-18 x 1/2”

127

Phillips Hex Head Screw,No. 10 x 1-1/4”

79

96

91

92

90

126

1/4”-20 x 3/4”

rilling Screw

Self-D

Bolt, 3/8”-16 x 7/8”

Nut, 3/8-16

remotes

vary by model

12 8

10

9

103

Insulated Staple

Wall Console Screw

Pan Head Screw #6 x 1-1/4”

Pan Head

Phillips Screw

No. 8 x 5/8”

81

82

Lag Screw,1/4” x 2”

OR

Speed Nut

Cold Head Pin

89

levis Pin

C

Cotter Pin

Hex Head Screw

No. 8 x 3/4”

PARTS IDENTIFICATION

FOR HELP—1-800-929.3667 OR OVERHEADDOOR.COM

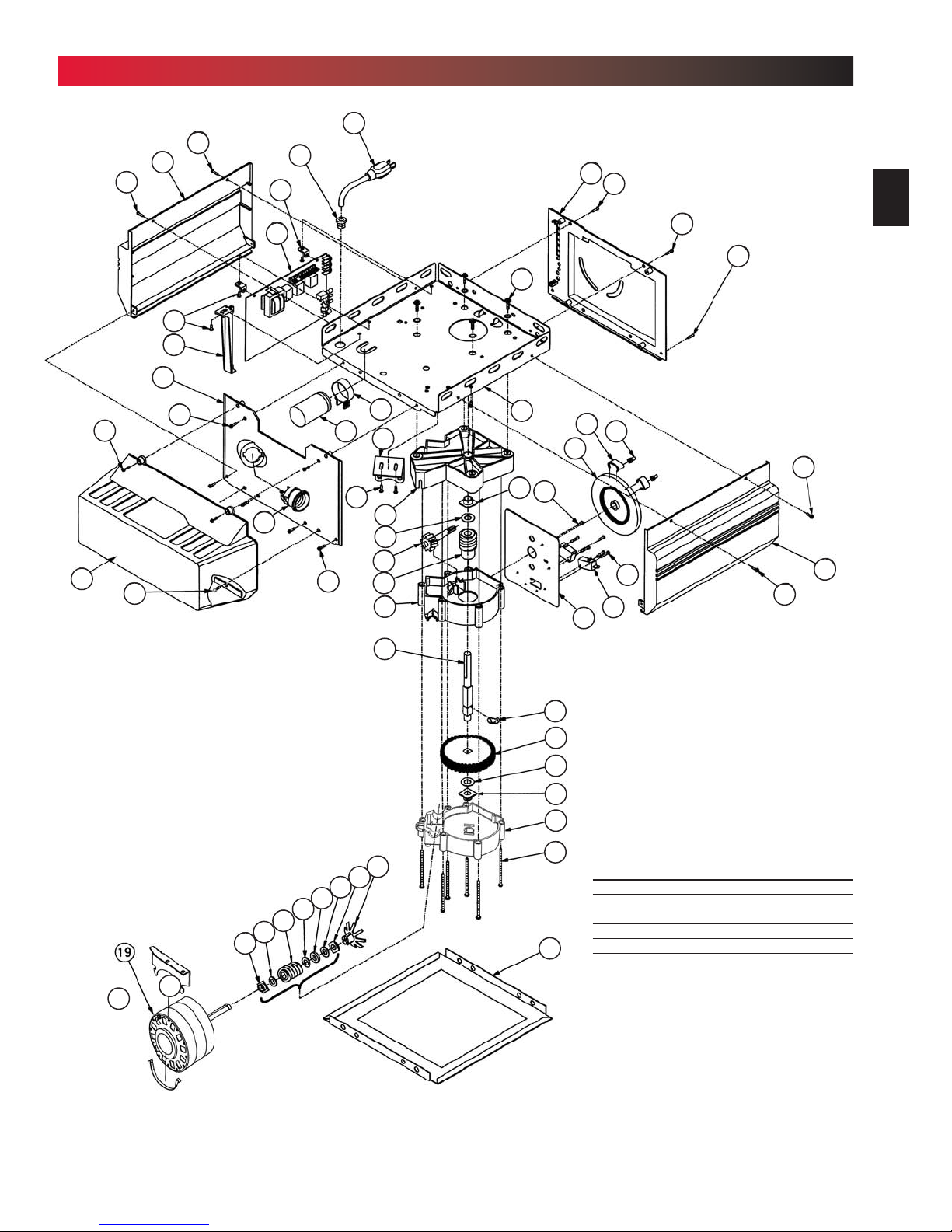

Phantom Power Head (DC)

6

15

14

12

2

1

10

3

13

9

12

11

20

12

27

25

6

5

4

23

24

36

35

19

34

22

26

16

21

39

7

12

17

12

11

18

19

3

28

40

29

38

37

8

12

Combined Parts List

Item Part Name

1 Lens

2 Front Cover

3 Side Cover (by series/model)

4 Top Plate Assembly

5 Strain Relief

6 Cord & Plug Assembly

7 Component Panel (by series/model)

8 Bottom Cover

9 Screw,#8 x .75 Phil Hx Hd/W Sf Tap

10 Screw,#8 x .62 Phil Pan Hd/W Sf Tap

11 Screw,#8 x .50 Slt Hx Hd/W Sf Tap

12 Screw,#8 x .38 Slt Hx Hd/W Sf Tap

13 Light Socket (by series/model)

14 Terminal Block & Lug

15 M.O.V. Assembly

16 Receiver Assembly

17 Limit Set Switch

18 Sequencer Assembly

19 Screw,#6 x .38 Slt Hx Hd/W Sf Tap

20 Transformer Assembly (by series/model)

33

26

32

31

Item Part Name

21 Rectifier Board Assembly

22 Fuse (F1), UL

23 Fuse (F2), UL

24 Limit Gear Shroud

25 Motor Bracket

26 Screw,#10 x 3/8” HH

27 Limit Plate/Pin Assembly

28 Limit Switch

29 Screw,#4-40x 5/8”Slot HH w/Wshr,SfTap

30 Motor Assembly

31 Motor Adapter Plate

32 Screw,1/4"-20 x 1/2" Slt HH w/Wshr

33 Limit Worm Gear

34 Limit Gear Bushing

35 Limit Worm Drive

36 Limit Worm Shim

37 Limit Wheel

38 Retaining Ring

39 Limit Cam

40 Limit Pinion, 8 tooth

26

30

Item Part Name

41 Capacitor

42 Capacitor Clamp

43 Screw,#10-24 x 1/2”, Slot HH Sf-Tap

44 Nut, #10-32,Hex Serrated Flange

45 Circuit Board

46 C.B. Bracket

47 Circuit Board Mount

48 Screw,#10-16 x 5/8”, HH Sf Tap

49 Top Gear Housing

50 Middle Gear Housing

51 Bottom Gear Housing

52 Drive Shaft Bushing

53 Drive Thrust Washer

54 Drive Shaft

55 1/2” Retaining Ring

56 Main Drive Worm Gear

57 Optical Interrupt Wheel

58 Motor Flanged Bushing

59 Motor Thrust Washer

60 Poly Thrust Washer

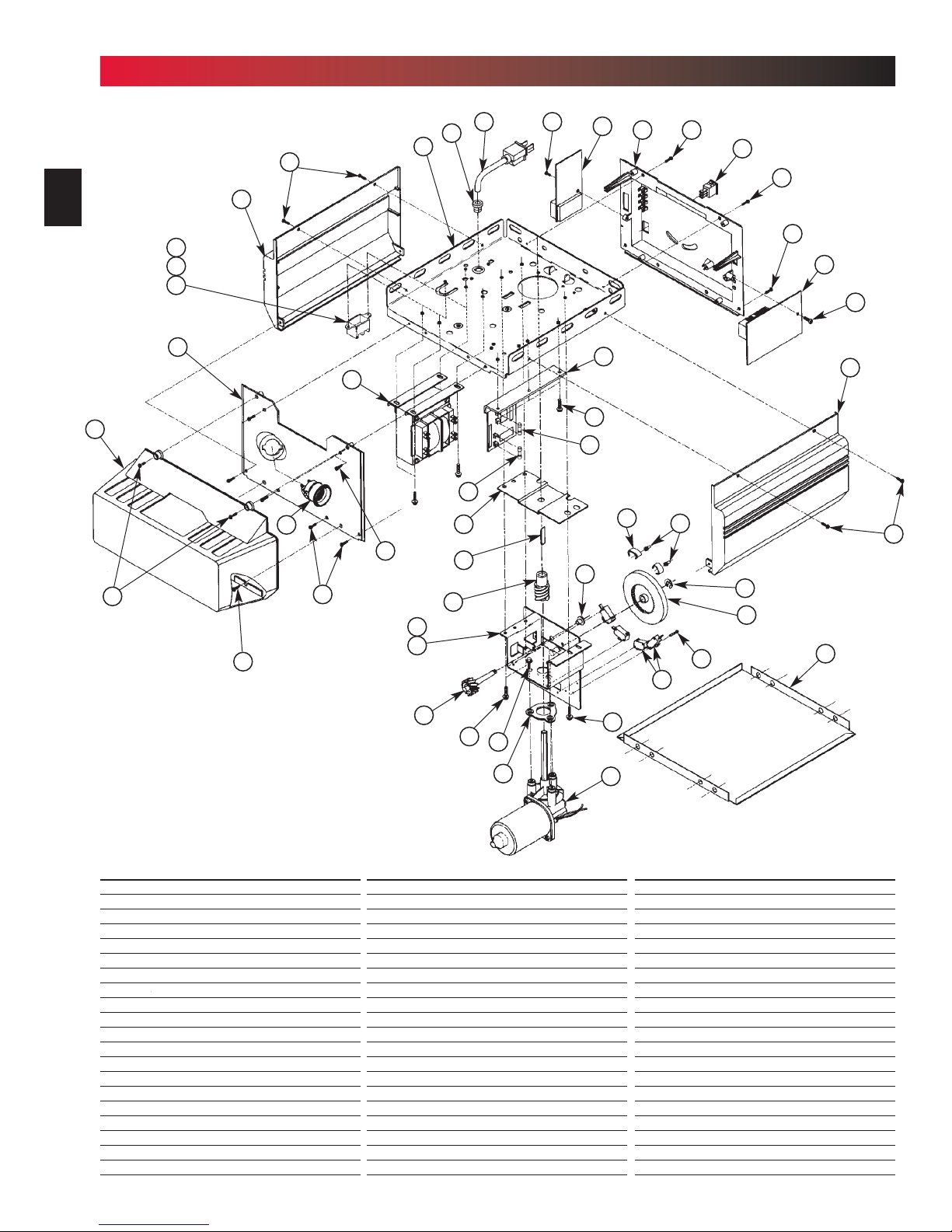

PARTS IDENTIFICATION

FOR HELP—1-800-929.3667 OR OVERHEADDOOR.COM

Legacy Power Head (AC)

7

12

12

6

12

3

5

47

7

45

48

12

46

2

41

42

25

43

49

53

33

35

50

12

10

13

1

9

11

52

4

64

37

63

39

40

65

28

12

11

12

3

12

44

30

58

59

61

59

60

59

58

57

54

55

56

53

52

51

62

Item Part Name

61 Main Drive Worm

62 Screw,#8 x 3-1/8” Slot HH, Sf Tap

63 Limit Switch Plate

64 Screw,#6 x 3/8” Phillips w/Wshr, Sf Tap

8

65 Screw,#4 x 5/8”, Slot HH w/Wshr, Sf Tap

8

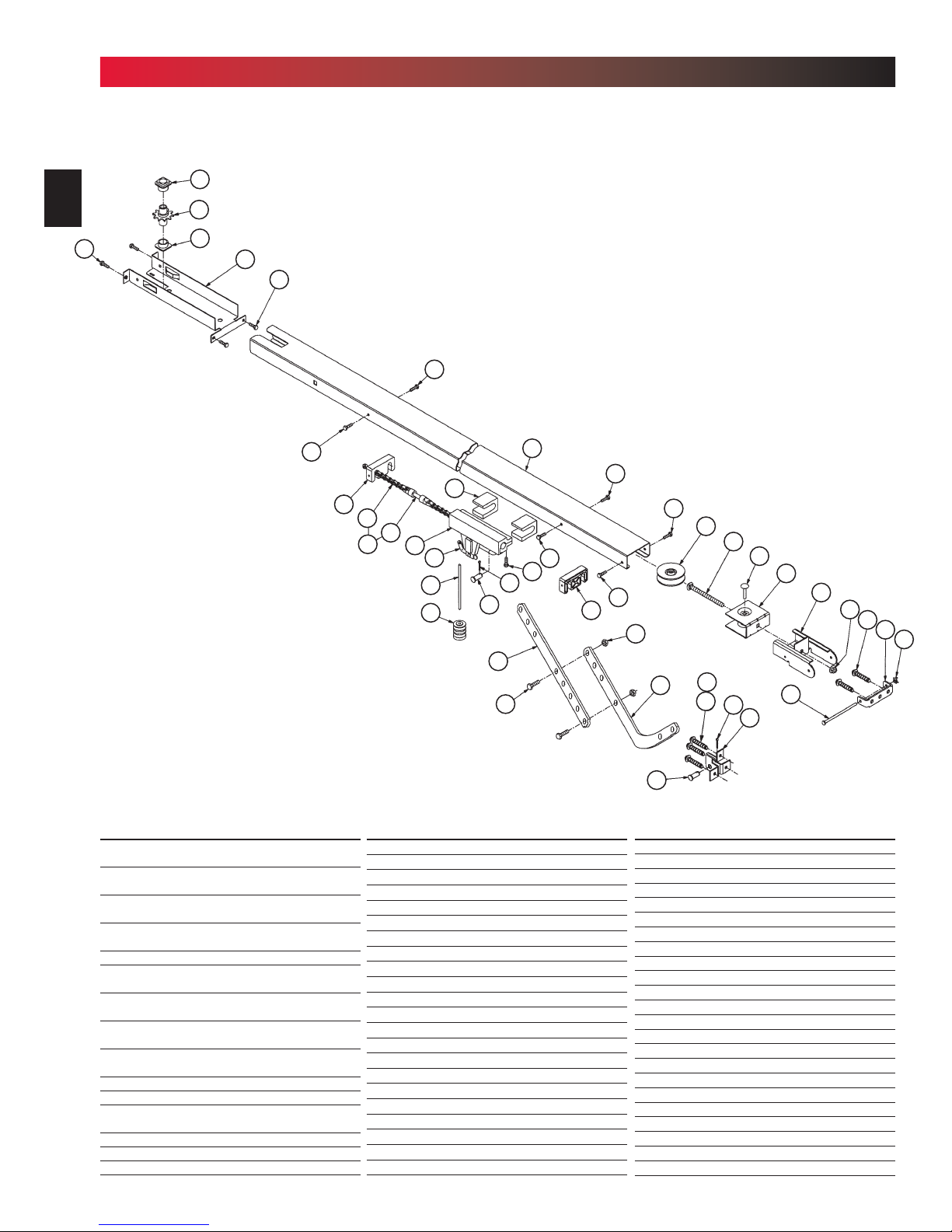

PARTS IDENTIFICATION

Channel

67

68

FOR HELP—1-800-929.3667 OR OVERHEADDOOR.COM

69

67

70

69

71

83

84

66

85

86

87

88

71

97

98

90

94

91

89

65

99

71

83

71

71

92

93

71

73

79

96

74

89

95

75

76

82

77

78

79

80

81

Combined Parts List

Item Part Name

66 Belt & Bullet Assembly - 7’6” Door

(Belt Models Only)

Belt & Bullet Assembly - 8’ Door

(Belt Models Only)

Belt & Bullet Assembly - 10’ Door

(Belt Models Only)

Belt & Bullet Assembly - 12’ Door

(Belt Models Only)

67 Sprocket Bushing

68 Sprocket, 10 Tooth - 7’6”& 8’ Doors

(Chain Models Only)

Sprocket, 12 Tooth - 10’Door

(Chain Models Only)

Drive Sprocket, 18 Tooth - 7’6” & 8’ Doors

(Belt Models Only)

Drive Sprocket - 10’ Door

(Belt Models Only)

69 Screw,#10-24 x .50 Hx Hd

70 Sprocket Bracket (Chain Models Only)

Sprocket Bracket - 7’6” & 8’ Doors

(Belt Models Only)

Sprocket Bracket - 10’ Door (Belt Only)

Sprocket Bracket - 12’ Door (Belt Only)

71 Screw,#10-24 x .38 Hx Hd/W

Item Part Name

72 Channel - 7’6” Door (128” LG )

Channel - 8’ Door (146” LG )

Channel - 10’ Door (170.75” LG )

Channel - 12’ Door (188” LG)

73 Pulley (Chain Models Only)

Pulley (Belt Models Only)

74 Carriage Bolt, 5/16”-18 x 4.0

75 Carriage Pin, 5/16”x 1.25

76 Pulley Bracket Assembly

77 End Bracket

78 Hex Flange Nut, 5/16”-18 (Chain Only)

Flat Washer (Belt Models Only)

(2) Hex Jam Nut,5/16-18 (Belt Models Only)

79 Lag Screw,1/4” x 2” Hx Hd/W

80 Header Bracket

81 Speed Nut

82 Cold Header Pin

83 Carriage Stop

84

Roller Chain-7’6”Door (Chain Only)(242.5”)

Roller Chain-8’Door (ChainOnly)(278.5”)

Roller Chain-10’Door (ChainOnly)(328.5”)

8mm Belt

90

Item Part Name

85 Chain Bullet

Belt Bullet

Belt Retainer

Screw,#6-32 x 1/2” Phil Pan Hd Slf Tap

86 Carriage Slide

87

Emerg. Release Cord-7’6”Doors (26.5”)

Emerg. Release Cord -8’-10’Doors (56.5”)

Emergency Release Cord -12’Doors(96.0”)

88 Emergency Release Knob (Red)

89 Cotter Pin

90 Clevis Pin

91 Screw,3/8”-16 x .87 Hx Hd Mach

92 Hex Nut, 3/8”-16

93 Curved Door Arm

94 Straight Door Arm

95 Door Bracket

96 Screw,1/4”-20 x 3/4” Hx Hd, Sf Tap

97 Carriage Assembly

98 Carriage Cap

99 Screw,#10-14 x 1-5/16” Hx Hd

100 Wall Console (Series II )

101 Wall Button (Series II ) (lit primary)

Wall Button (unlit secondary)

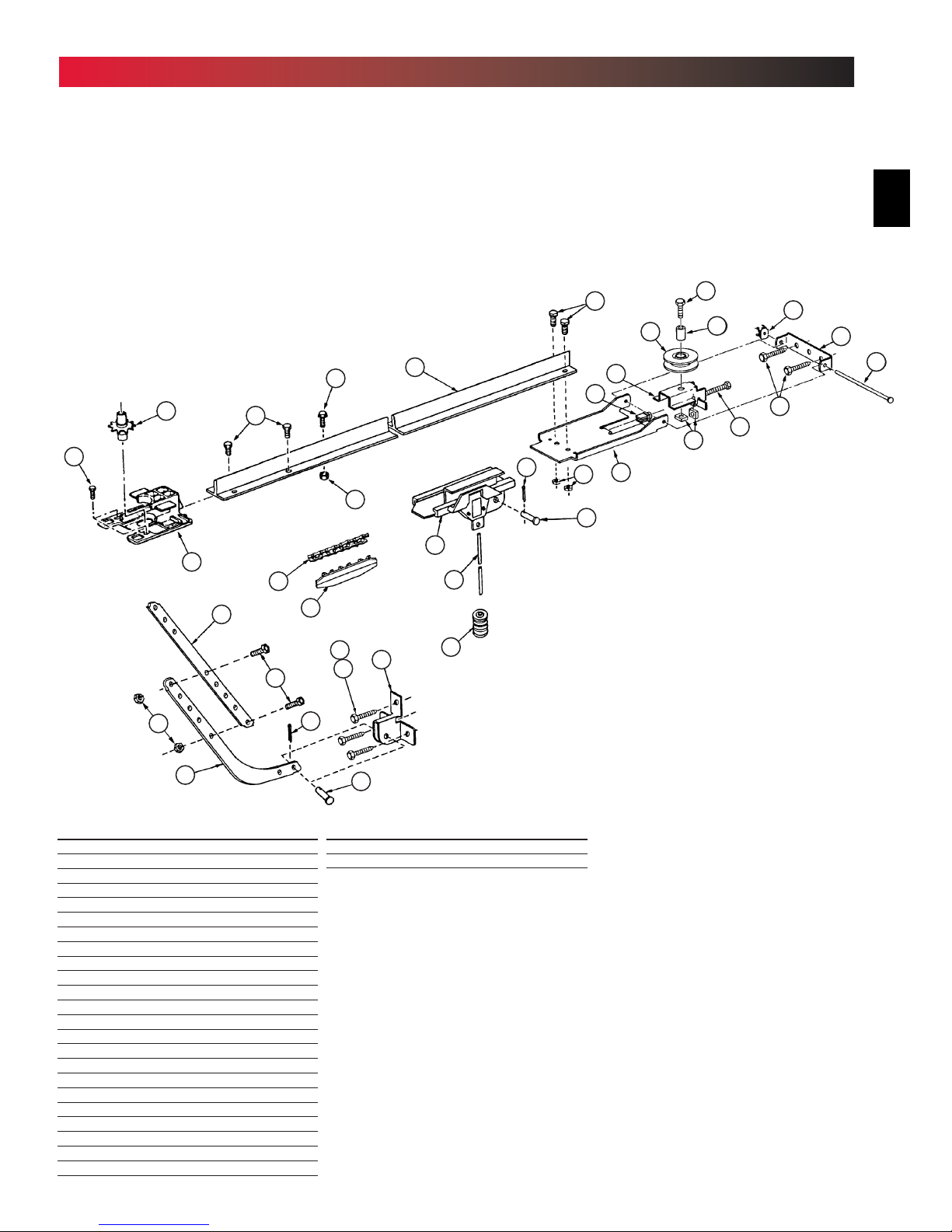

PARTS IDENTIFICATION

FOR HELP—1-800-929.3667 OR OVERHEADDOOR.COM

Rail

9

69

92

68

115

94

112

114

91

86

89

121

79

96

122

95

110

97

88

87

89

123

90

111

117

76

118

81

12 0

119

80

82

79

116

73

11

93

Item Part Name

102 Boom Support Kit (not shown)

103 Safety & Maintenance Guide

104 Emergency Release Tag (Tri-L)

105 Entrapment WARNING Label

106 Wire

110 Rail (L=112.475”)

111 Screw, 5/16”-18 x 3/4”

112 Screw, 5/16”x 1/2” HH w/Wshr

113 Pulley Support

114 Chain

115 Sprocket Saddle

116 Screw, 5/16”-18 x 2-1/4”HH

117 Bolt Retainer

118 Screw, 5/16”-18 x 1-1/8”HH

119 Large Pulley Bushing

120 Square Nut, 5/16”-18

121 Screw, 1/4”-20 1”HH

122 Hex Nut/Lockwasher, 1/4”-20

123 5/16"-18 Lock Nut

124 STB System Sensor (Green LED)

125 STB System Source (Red LED)

126 STB Mounting Brackets (2)

90

Item Part Name

127 Screw, 1-1/4”Phillips HH

128 Insulated Staples

...

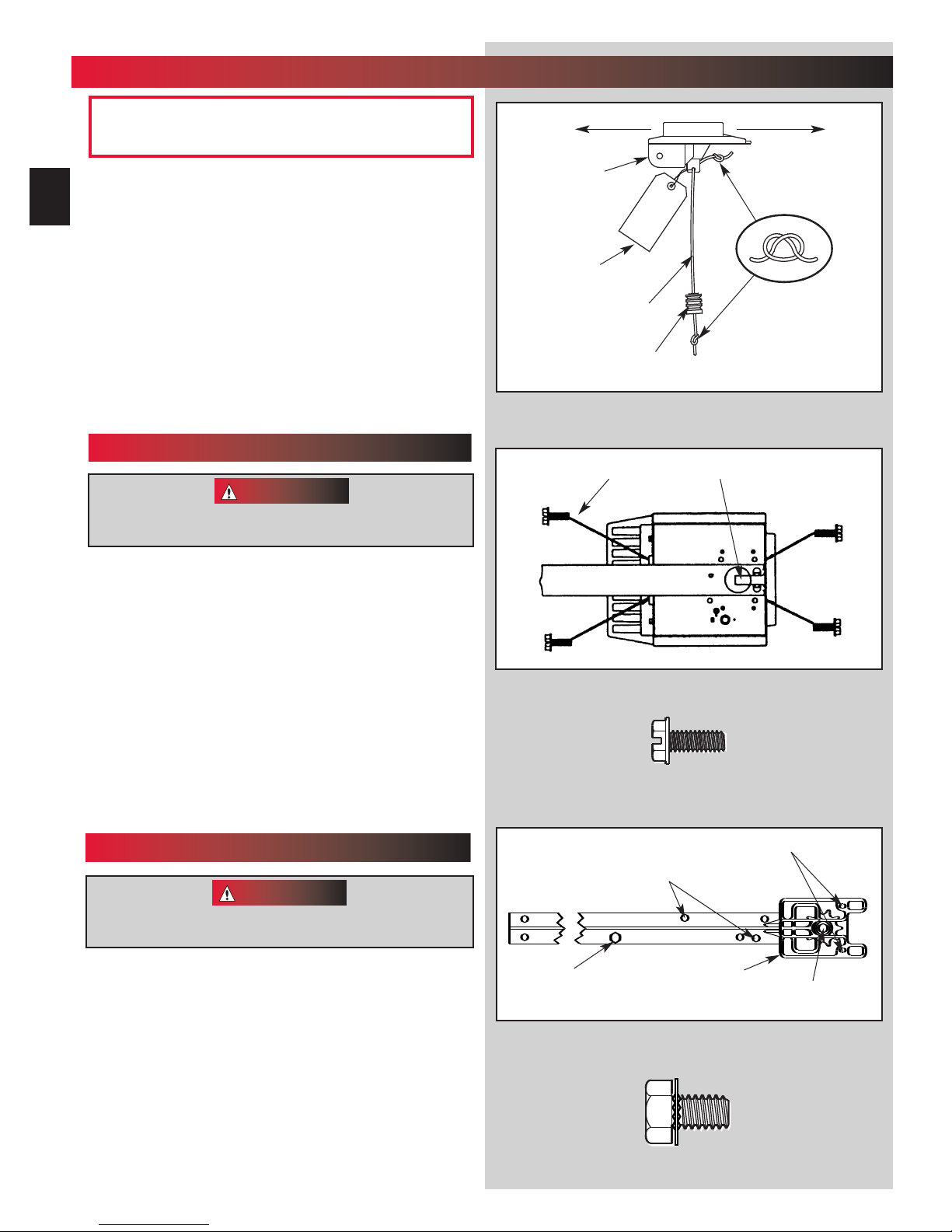

OPERATOR ASSEMBLY

1

FOR HELP—1-800-929.3667 OR OVERHEADDOOR.COM

10

OPEN BLUE PARTS BAG

Screws for attaching light cover are included in this bag.

Attach emergency release knob cord (Fig. 1-1).

1.

• Tie overhand knot in end of cord.

• Thread cord through knob so knot is inside knob.

• Thread cord through hole in carriage lever.

• Tie overhand knot in other end of cord.

Do Not cut cord until after power head is mounted.

2. Attach emergency release tag (Fig. 1-1).

• Thread wire through hole in carriage lever.

• Wrap wire around itself, tie securely.

PLEASE NOTE THE ASSEMBLY PROCEDURES ARE

DIFFERENT FOR RAIL AND CHANNEL. BE SURE TO

FOLLOW THE APPLICABLE STEPS.

CHANNEL & POWER HEAD ASSEMBLY

Do Not attempt to run power head or to set limits until

operator is fully assembled and attached to the door.

Please set aside for use later.

CAUTION

Emergency

Release

Tag

Hex Head Screws

[69]

Toward Door Toward Power Head

Carriage

Emergency

Release

Cord

Emergency

Release

Knob

Fig.1-1

“D” -Shaft and Hole

3. Place power head and channel on clean, flat surface.

4. Slide drive end of channel down over “D”-shaft on top of

p

ower head (Fig. 1-2).

• Support header end of channel level with power head.

• Slide carr

• Slide channel down “D”-shaft flush with power head.

5. Fasten channel to power head .

• Align mounting holes in front and r

• Insert and securely tighten the four (4) No.10 x 1/2”hex

head screw

NOTE: Chain inner-slide or belt bullet should remain at midtra

vel when assembling to power head to provide proper travel

when setting limits.

iage to align “D”-shaft with “D”-hole in sprocket.

ear of power head frame.

s [69].

RAIL & POWER HEAD ASSEMBLY

CAUTION

Do Not attempt to run power head or to set limits until

operator is fully assembled and attached to the door.

3. Place power head and rail on clean, flat surface.

4. Slide drive end of rail down over “D”-shaft on top

of power head (F

• Support header end of r

• Slide car

in sprocket.

• Slide rail down “D”-shaft flush with power head.

dr

ags on the rail

ig. 1-3).

ail level with power head.

riage enough to align “D”-shaft with “D”-hole

5/16” x 1/2” Hex Head Screws

[

]

112

Carriage Stop

Fig.1-2

[69]

No. 10 x 1/2” Hex Head Screw

[69]

Sprocket Saddle

Fig.1-3

[

]

112

No. 10-24 x 1/2” Hex Head Screws

“D” -Shaft and Hole

5/16” x 1/2” Hex Head Washer Screw

Loading...

Loading...