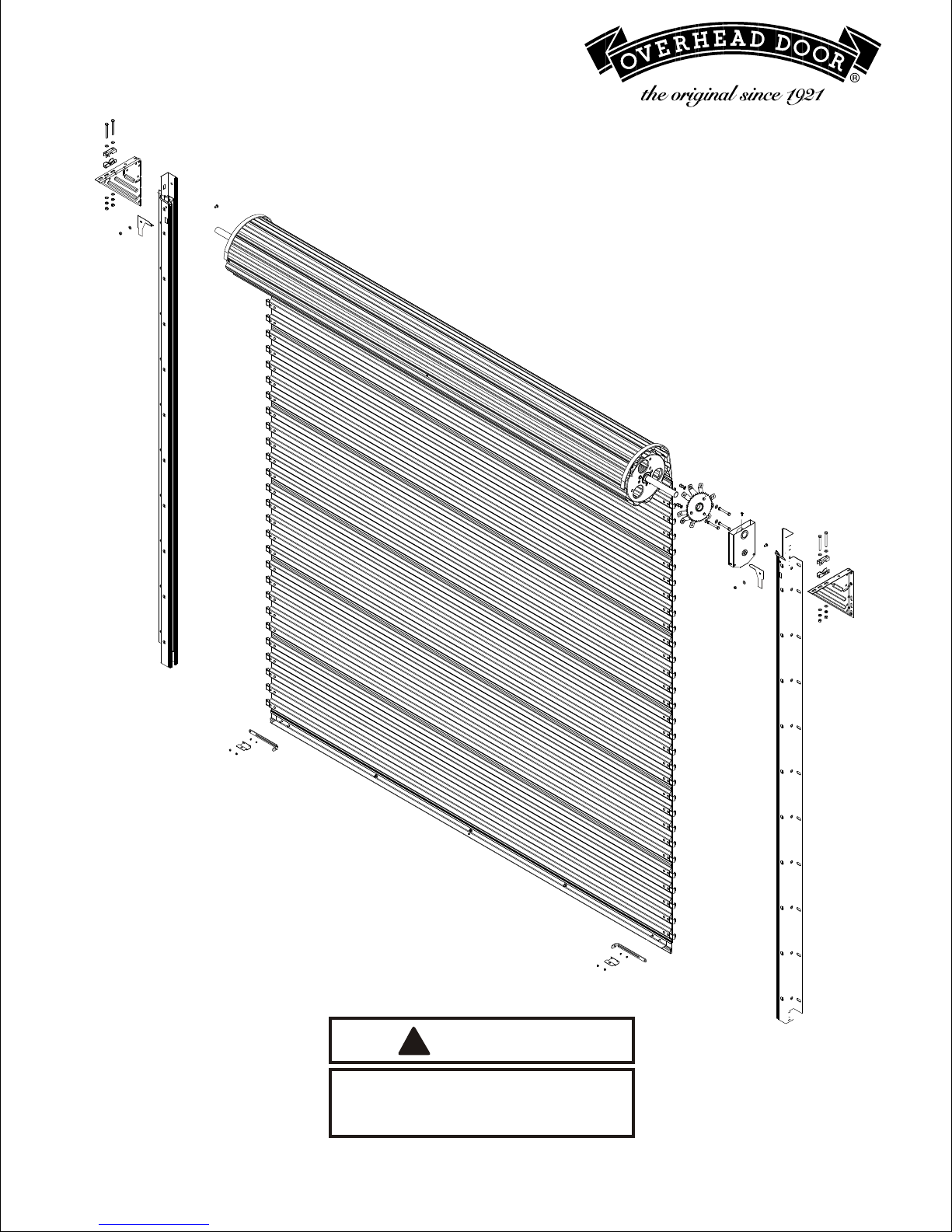

Overhead door 780 CD, 790 CW Installation Manual

INSTALLATION INSTRUCTIONS

Series 780 CD, 790 CW

220153-0001

8/14/03

CAUTION

!!

USE PROPER LIFTING EQUIPMENT AND

CORRECT LIFTING PROCEDURES TO

AVOID INJURY.

© Overhead Door Corporation

1

SAFETY INFORMATION

OVERVIEW OF POTENTIAL HAZARDS

Overhead doors are large, heavy objects that move with the help of springs under high tension

and electric motors. Since moving objects, springs under tension, and electric motors can

cause injuries, your safety and the safety of others depend on you reading the information in

this manual. If you have questions or do not understand the information presented, call your

nearest service representative.

In this section and those that follow, the words Danger, Warning and Caution are used to

emphasize important safety information. The word:

DANGER means that severe injury or death will result from failure to follow instructions.

WARNING means that severe injury or death can result from failure to follow instructions.

CAUTION means that property damage or injury can result from failure to follow instructions.

The word NOTE is used to indicate important steps to be followed or important considerations.

POTENTIAL HAZARD EFFECT PREVENTION

Keep people clear of opening while

Door is moving.

WARNING: Can Cause

Serious Injury or Death

MOVING DOOR

WARNING: Can Cause

Serious Injury or Death

HIGH SPRING TENSION

READ THIS MANUAL CAREFULLY AND OBSERVE ALL WARNINGS WHEN INSTALLING,

OPERATING OR MAINTAINING YOUR OVERHEAD DOOR.

IMPORTANT

CHECK for shipping damage.

CHECK door against packing list to make sure door

is the same as ordered and all parts are included.

CHECK width and height of door opening against

sizes noted with shipment to assure that door will fit.

CHECK to make sure headroom and side clearances

are adequate (Figure 1).

Do Not allow children to play with

the Door operator.

Do Not operate a Door that jams or

one that has a broken spring.

Do Not try to remove, repair or adjust

springs or anything to which Door spring

parts are fastened, such as, wood blocks,

steel brackets, cables or other like items.

Repairs and adjustments must be made

by a trained service person using proper

tools and instructions.

Read these instructions completely before

attempting to install this door.

WARRANTY VOID IF DOOR IS NOT INSTALLED

ACCORDING TO INSTRUCTIONS.

DO NOT CUT OR REMOVE RETAINING BANDS

UNTIL INSTRUCTED TO DO SO.

CHECK WARNING LABELS ON DOOR FOR PROPER

INSTALLATION PROCEDURE.

2

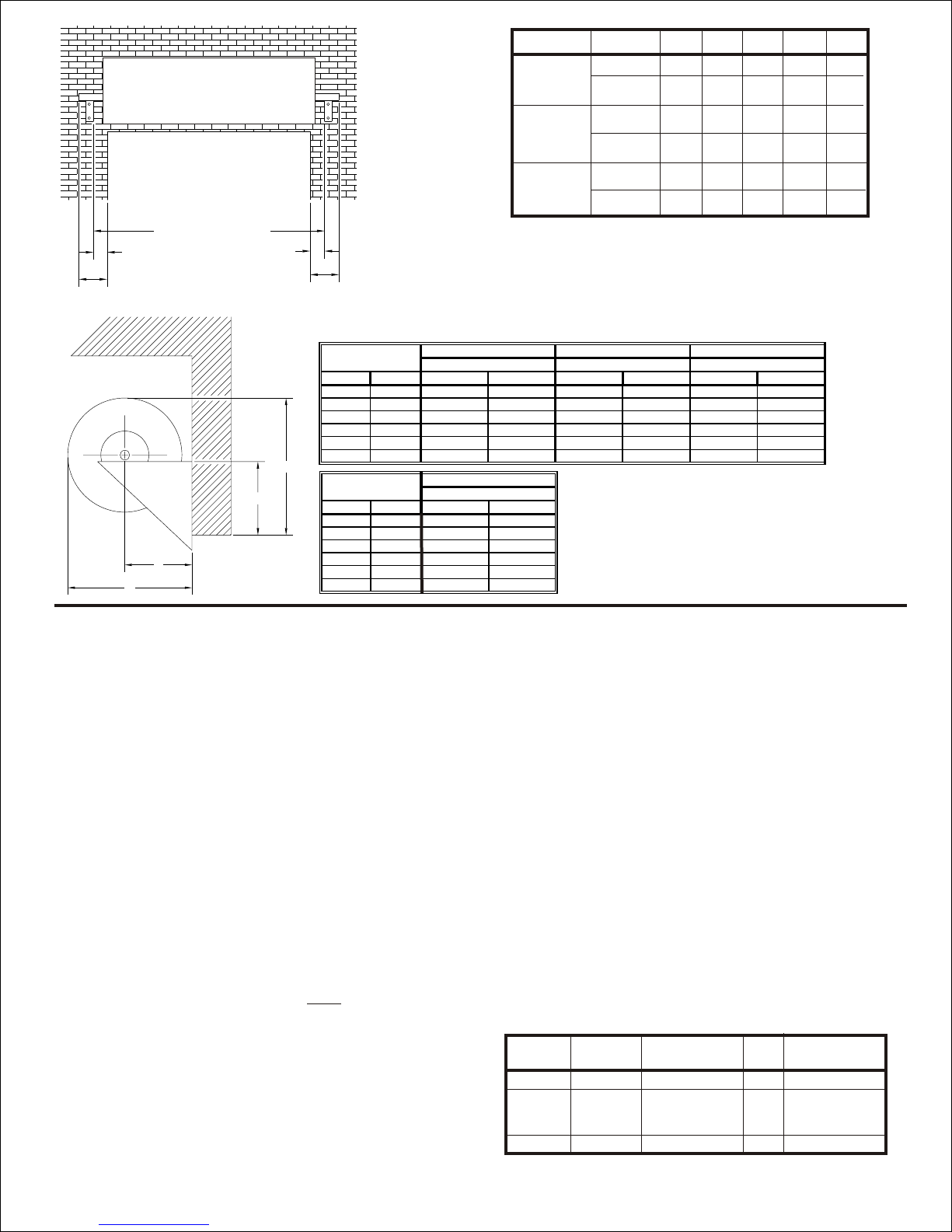

FOR REFERENCE

Over Up To

- 7' 8"

7' 9" 9' 4"

9' 5" 11' 0"

11' 1" 12' 8"

12' 9" 14' 3"

14' 4" 16' 0"

Opening Height

Recommended Minimum

20 1/4" 18 1/4"

21" 19"

21 3/4" 20 3/4"

22 3/4" 21 3/4"

23 1/4" 22 1/4"

24 3/4" 23 3/4"

B

Head Room

Over Up To Recommended Minimum Recommended Minimum Recommended Minimum

- 7' 8" 10" 8" 9 1/8" Same 18 1/8" Same

7' 9" 9' 4" 10 1/2" 8 1/2" 9 1/8" Same 18 3/8" Same

9' 5" 11' 0" 11" 10" 10 1/4" Same 19 3/4" Same

11' 1" 12' 8" 11 1/2" 10 1/2" 10 1/4" Same 20 1/4" Same

12' 9" 14' 3" 12" 11" 10 1/2" Same 20 1/2" Same

14' 4" 16' 0" 13" 12" 10 1/2" Same 21" Same

Opening Height

H J A

Head Plate Height Axle Setting Back Room

DRIVE END

Operation

Push Up

Reduced

Chain Drive

Door Type

790

780

790

780

C*

10“

10“

10“

10“

D*

10“

10“

10“

10“

F**

6“6“

4“

6“

8“

G

12“

8“

10“

12“

E

4“

4“

4“

OPENING WIDTH + G

E

C

F

D

Figure 1

B

H

J

A

NOTES

Bracing may be required to prevent

light weight building jambs from twisting.

INSTALLATION

1. Locate headplates per dimensions F, (or approximately

5” above top of guide, if headroom allows)

E, H and G (Figure 1).

2. Hold headplates in mounting position. Using a water

level, check to make sure tops of headplates are level.

Mark mounting hole locations on header. See Table 1

for supplied fasteners.Thru-bolts are recommended

for brick or stone walls or hollow concrete masonry

unit (CMU) wall. DO NOT install fastener in a void in

the wall. If this condition exists then use Thru-bolt.

Fasten headplates to wall using three fasteners. Use

top hole in headplates.

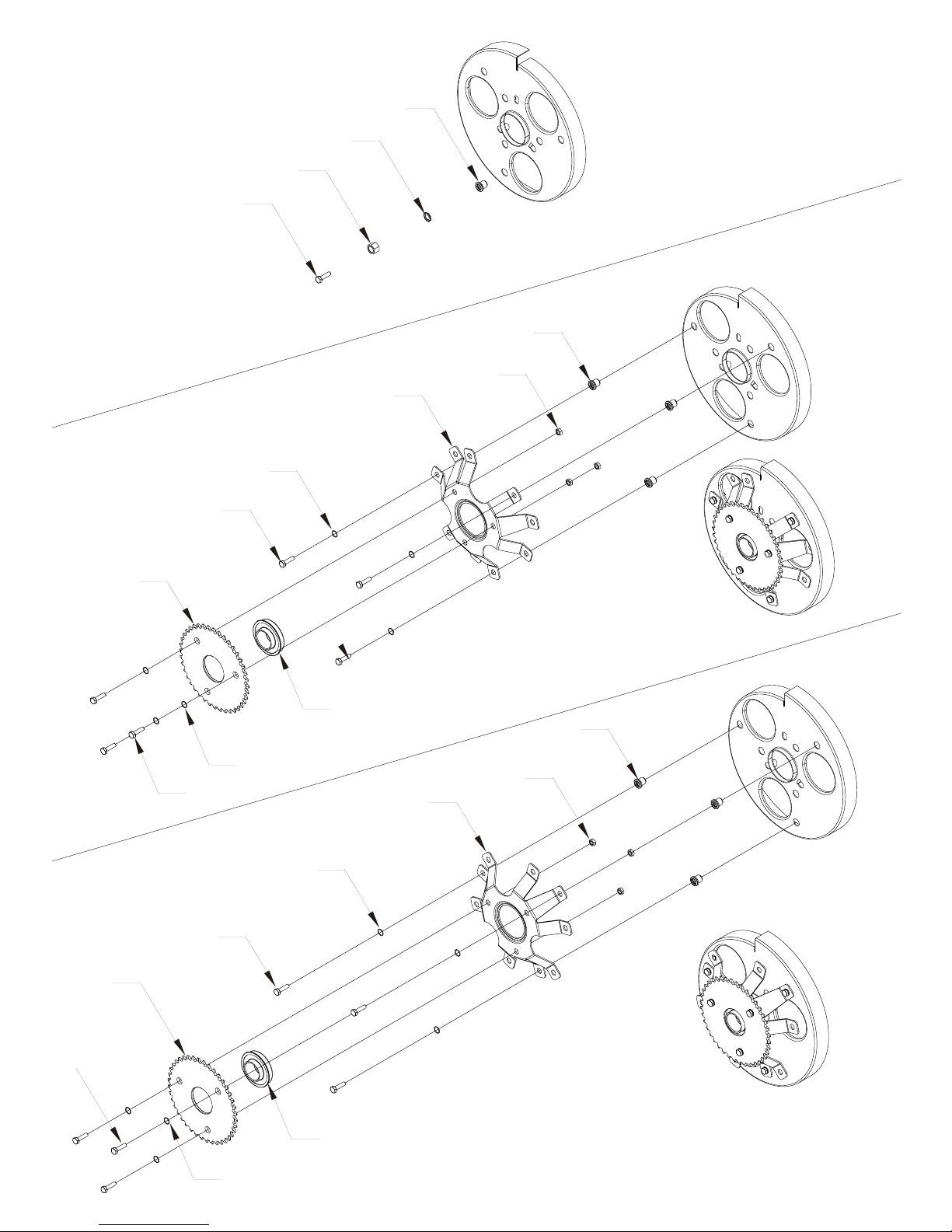

3. IF DOOR IS CHAIN DRIVEN:

a. Remove hardware from package.

b. Slide 1/2“-13 nut and 3/8” external tooth locking

washer over bolt as shown in Figure 2. (Note:

Sharp edges of locking washer must be in contact

with flange of self clinching nut).

c. Thread self clinching nut onto threads of bolt and

snug until finger tight.

d. Insert assembly into one of the 3 outer mounting

holes on end ring.

f. While maintaining pressure to keep assembly

e. Use a backup wrench(channel lock, vise grips or

equivalent) to prevent 1/2“ nut from spinning while

torquing bolt to seat self clinching nut.

seated against ring, use a 9/16“ ratchet, wrench

Operator

790

780

10“

10“

10“

10“

4“

4“

8“

4“

6“

10“

*Excess shaft may be cut off of non-drive sides of

doors for additional clearance. It is recommended that

at least 1” of shaft be retained past the headplate to

facilitate spring tension adjustment.

**Dimension “F” applies to Drive End only.

RH shown, LH opposite.

or power driver to turn the bolt and secure the self

clinching nut.

g. Tighten bolt until self clinching nut is fully seated.

(Resistance against the back up wrench will be felt

as clinching nut begins to seat).

h. With backup wrench still applied to 1/2“ nut,

reverse torque on bolt to remove.

I. Repeat for 2 remaining holes.

j. Place bearing into recess of bracket. (Figure 2)

k. Bolt sprocket to bracket to capture bearing.

l. Slide bracket assembly over shaft, and align

appropriate legs to self clinching nuts in ring.

m. Bolt to ring as shown.

n. Thread hand chain thru chain guide slots, over

chain wheel and connect ends. NOTE: Make sure

chain is not twisted.

o. Slide chain hoist assembly onto door shaft.

p. Install drive chain to sprocket and hoist assembly.

Align both sprockets and tighten set screw on

hoist.

q. Install chain keeper to wall.

Table 1 - Headplate Fasteners

Fastener

Jamb

Steel

Concrete/

Masonry

Wood

*Drill size for supplied fasteners. For others, refer to

manufacturer’s specified installation method.

Doors

All

All

All

See Page 4 For Ilustration

Fastener

3/8“ bolt

3/8“ exp. anchor

3/8“ Lag

Drill

Specifications

Size

7/16“

Use ANSI B95.12

3/8“*

carbide tipped

drill bit

5/16“

3

Self Clinching

Nut Installation

780 Installation

No Windlocks

1919

1616

2525

2626

1919

2929

1313

88

1515

2727

1515

790 Installation

With Windlocks

1515

2727

2828

1919

88

2929

1313

88

1515

88

2828

Figure 2a-4:1 Hoist

See Page 9 For

Bill Of Materials

4

Loading...

Loading...