Overhead door 301, 303, 304, 307, 308 Installation Instructions Manual

...

Carriage House Collection

Models: 301, 302, 303,

304, 307, 308, 309

t o r s I o n s p r I n g ( s ) ,

standard lIft

InstallatIon InstructIons

T a b l e O f C o n t e n t s

Parts Breakdown 2

Parts Breakdown 2

Pre-Installation 3

Safety Information 3

Tools Required 4

Package Contents 4

Door Section Identification 4

Removing an Existing Door 5

Preparing the Opening 5

Installation 6

Optional Installation 13

Trolley Arm Hookup 13

Inside Lock 13

Pull Down Rope 13

Maintenance 14

Cleaning Your Garage Door 14

Painting Your Garage Door 14

Operation and Maintenance 14

Warranty 16

Distributor Locator Information 18

IMPORTANT NOTICES!

To avoid possible injury, carefully read and understand instructions

completely before installing and operating the garage door. Pay

close attention to all warnings and notes. After installation is

complete, fasten this manual near garage door for easy reference.

Overhead Door Corporation

2501 South State Highway 121, Suite 200, Lewisville, TX., 75067

349692 NEW 05/29/2012Part No.©COPYRIGHT 2012 OVERHEAD DOOR CORPORATION

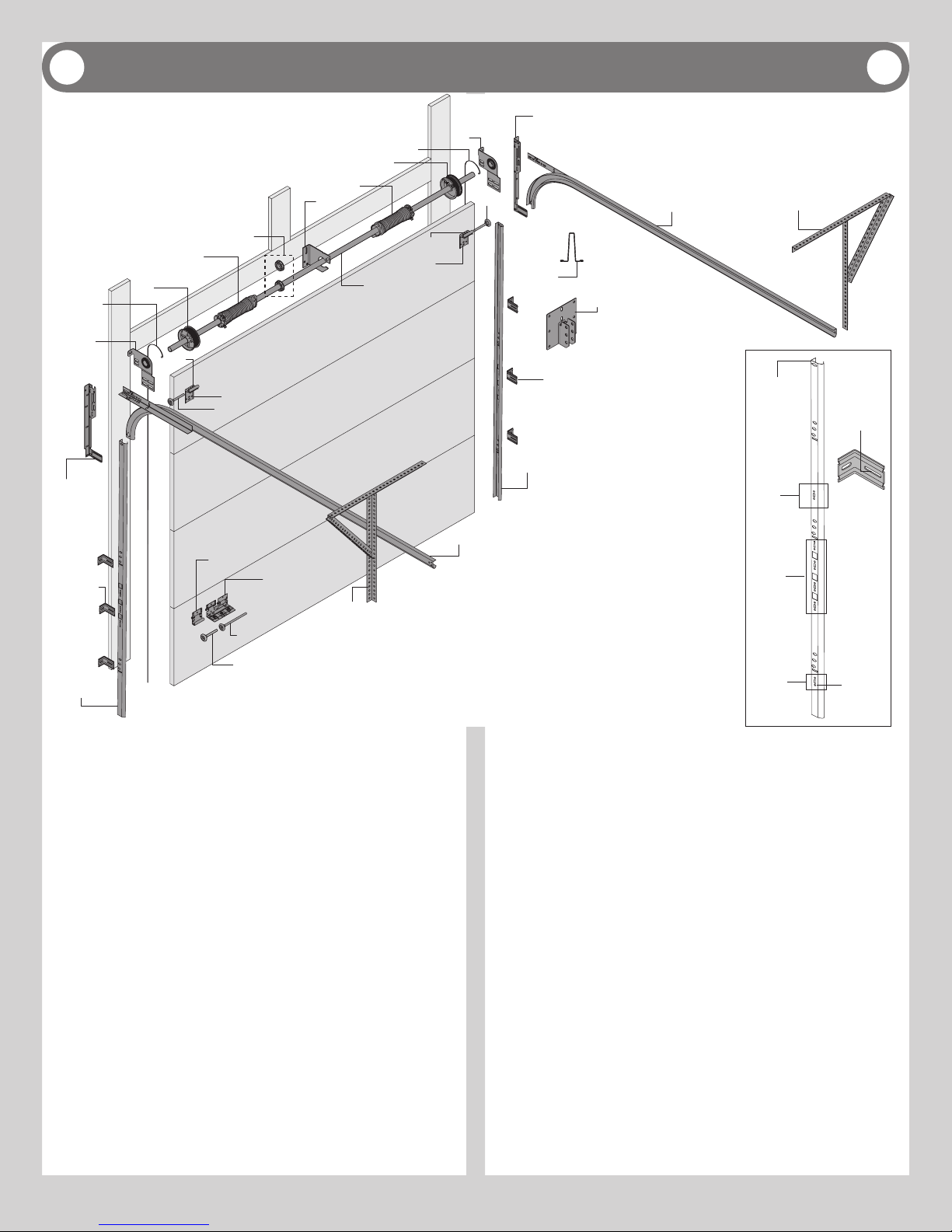

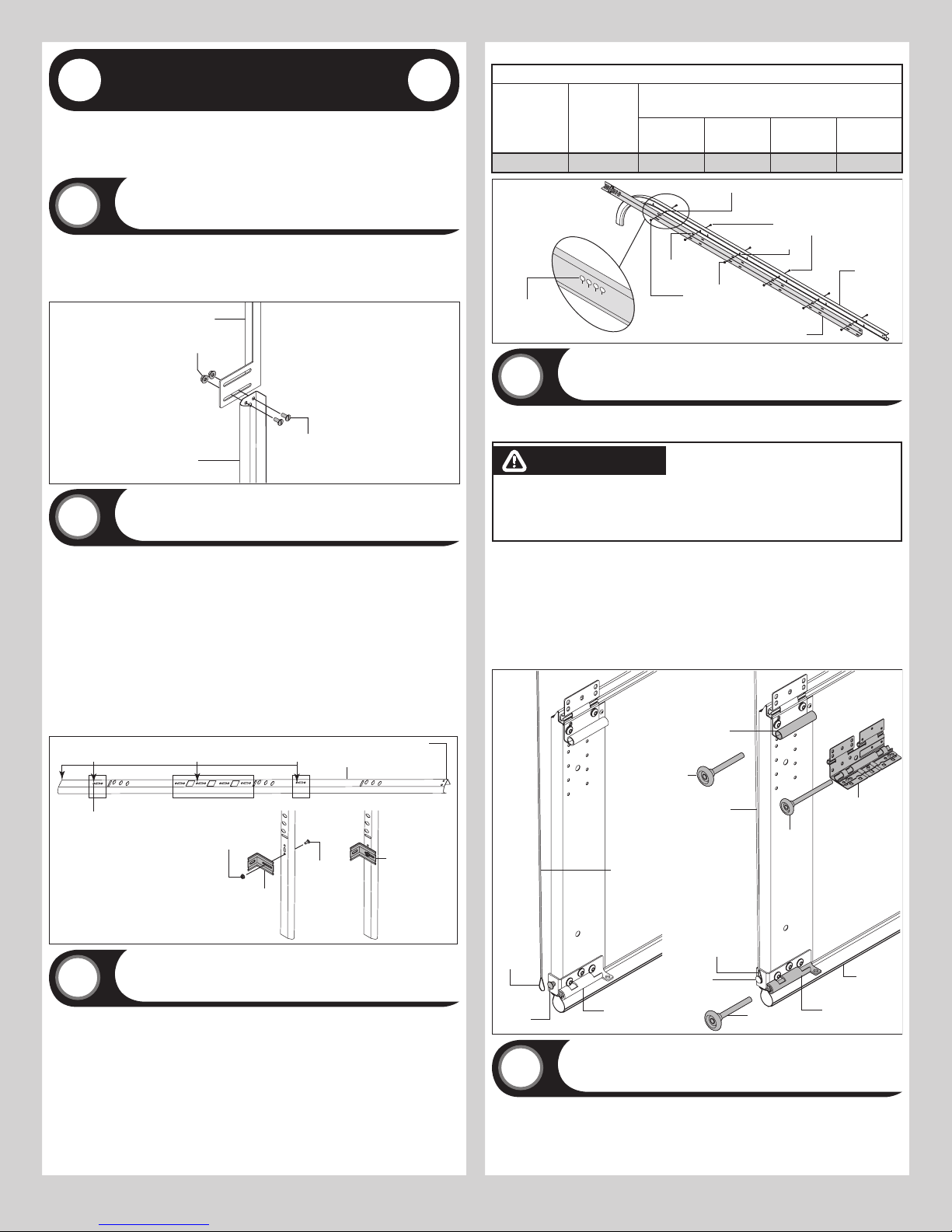

Parts Breakdown

PARTS BREAKDOWN

NOTE: The illustrations shown on this page are general

representations of the door parts. Each specific door

models may have unique variations.

J1.

J8.

J7.

J5.

J9.

J3.

F2.

F1.

C1.

A1.

D1.

B1.

D2.

K1.

J7.

J2.

E1.

E2.

E3.

J6.

J9.

E4.

F1.

F2.

A2.

J4.

C1.

G1.

H1.

B1.

I4.

I1.

I2.

K2.

Top of vertical

track

3rd

hole set

2nd

hole set

B1. (Fully

Adjustable

Feature)

C2.

C1.

I3.

A. FLAG ANGLES (AS REQUIRED):

A1. Fully Adjustable (F.A.) Flag Angles

B. JAMB BRACKETS (AS REQUIRED):

B1. Fully Adjustable (F.A.) Jamb Brackets

C. TRACK ROLLERS:

C1. Short Stem Track Rollers

C2. Long Stem Track Rollers

D. GRADUATED END HINGES:

D1. Single Graduated End Hinges (S.E.H.), Anti-Pinch

D2. Single Graduated End Hinges (S.E.H.), Industry Standard

E. STACKED SECTIONS:

E1. Top Section

E2. Intermediate(s) Section

E3. Lock Section

E4. Bottom Section

F. TOP FIXTURE (AS REQUIRED):

F1. Top Fixture Bases - (L-Shaped)

F2. Top Fixture Slides - (L-Shaped)

G. STRUT(S) (AS REQUIRED):

G1. Strut (U-shaped)

H. DRAWBAR OPERATOR BRACKET (FOR TROLLEY OPERATED DOORS):

H2. Drawbar Operator Bracket

I. TRACKS:

I1. Left Hand Horizontal Track Assembly

I2. Right Hand Horizontal Track Assembly

I3. Left Hand Vertical Track

I4. Right Hand Vertical Track

J. TORSION SPRING ASSEMBLY:

J1. Center Bracket

J2. Torsion Shaft

J3. Left Hand End Bearing Bracket

J4. Right Hand End Bearing Bracket

J5. Left Hand Cable Drum

J6. Right Hand Cable Drum

J7. Right Hand and Left Hand Torsion Springs (As Required)

J8. Center Bracket Bushing

J9. Counterbalance Lift Cables

K. REAR BACK HANGS:

K1. Left Hand Rear Back Hang Assemblies

K2. Right Hand Rear Back Hang Assemblies

1st

hole set

Lower hole

of hole/

slot pattern

2

WARNING

WARNING

WARNING

Pre-Installation

Safety Information

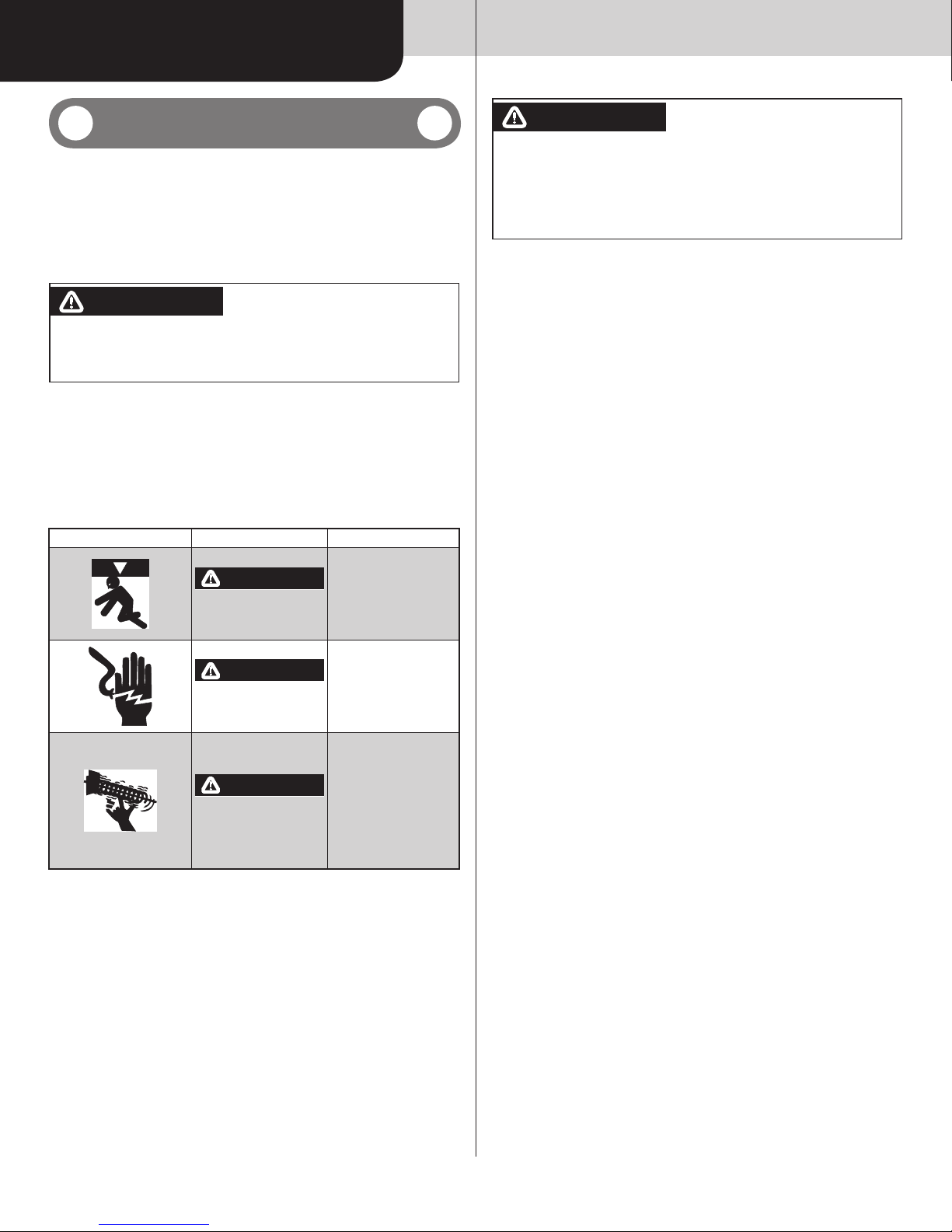

OVERVIEW OF POTENTIAL HAZARDS: READ THIS SAFETY INFORMATION CONVENTIONS

USED IN THESE INSTRUCTIONS:

Garage doors are large, heavy objects that move with the help of springs under high tension

and electric motors. Since moving objects, springs under tension, and electric motors can

cause injuries, your safety and the safety of others depend on you reading the information in

this manual. If you have questions or do not understand the information presented, call your

nearest trained door system technician or visit our website.

The following Safety Alert symbol and signal words are used throughout this manual to call

attention to and identify different levels of hazard and special instructions.

WARNING WARNING

THIS IS THE SAFETY ALERT SYMBOL. THIS SYMBOL ALERTS YOU TO

POTENTIAL HAZARDS THAT CAN KILL OR HURT YOU AND OTHERS. ALL

SAFETY MESSAGES WILL FOLLOW THE SAFETY ALERT SYMBOL AND

THE WORD “DANGER”, “WARNING”, OR “CAUTION”.

DANGER: Indicates an imminently hazardous situation which, if NOT avoided, will result in

death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if NOT avoided, could result in

death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if NOT avoided, may result in

injury or property damage.

NOTE: Indicates important steps to be followed or important considerations.

IMPORTANT SAFETY INSTRUCTIONS: READ AND FOLLOW ALL INSTRUCTIONS SAVE

THESE INSTRUCTIONS

Potential Hazard Effect Prevention

Keep people clear of opening

while Door is moving.

Do NOT allow children to play

Could result in Death or Serious

Injury

Could result in Death or Serious

Injury

Could result in Death or Serious

Injury

READ THIS SAFETY INFORMATIONS:

Read this installation instruction booklet completely before starting installation of the door. If

you have questions or do not understand the information presented in these instructions, call

your nearest trained door system technician.

While not required for extension spring systems, consider having a trained door system

technician install this door for the optimum installation and performance.

You can install your new garage door yourself, if…

a) You have help (it may weigh up to 500 lbs.),

b) You have the right tools and reasonable mechanical aptitude or experience, and

c) You follow these instructions very carefully.

Garage doors use springs to balance them. There are two types of springs installed — extension or torsion. Each of these is available in either a standard or low ceiling assembly option.

Please look at the drawings to see which spring type your old door has.

with the Door Opener.

Do NOT operate a Door that jams

or one that has a broken spring.

Turn OFF power before removing

opener cover.

When replacing cover, make sure

wires are NOT pinched or near

moving parts.

Opener must be fully grounded.

Do NOT try to remove, install, repair or adjust springs or anything

to which door spring parts are

fastened, such as, wood blocks,

steel brackets, cables or other

like items.

Installations, repairs and adjust-

ments must be done by a trained

door system technician using

proper tools and instructions.

WARNING WARNING

IF YOUR OLD DOOR OR NEW DOOR USES TORSION SPRINGS, DO NOT

ATTEMPT TO REMOVE, INSTALL, REPAIR OR ADJUST THE SPRINGS

YOURSELF. HAVE A TRAINED DOOR SYSTEM TECHNICIAN REMOVE,

INSTALL, REPAIR OR ADJUST THEM. ATTEMPTING TO REMOVE, INSTALL,

REPAIR OR ADJUST A TORSION SPRING ASSEMBLY WITHOUT PROPER

TRAINING OR TOOLS MAY RESULT IN AN UNCONTROLLED RELEASE OF

SPRING FORCES WHICH CAN CAUSE SERIOUS INJURY.

• In removing a garage door that has Extension springs, follow the instructions carefully,

including the use of C-clamps or locking pliers on both sides of the door in order to keep the

door from moving once the springs are removed.

• Low Headroom doors require special instructions. Check headroom requirements located in

Preparing The Opening, before beginning.

• Be sure all hardware components for your new door are included before removing existing

door. If your door is missing any parts, call the company from whom you purchased your unit.

• Allow enough time to do the work; removing an existing door will take approximately 1-3

hours.

• A typical installation takes between 9 and 12 hours to complete.

• Keep in mind when planning the installation that the garage will be open and unsecured

when disassembling the old and assembling the new door.

• If the garage door is the only opening in the structure make sure everything you need is

inside. You will have no way of leaving the garage until the track is assembled and installed.

This will take approximately 5 hours.

• Never reuse old track or hardware. Only the track specified and supplied with the door

should be used.

• To avoid damage to the door, you must reinforce the top section of the door in order to

provide a strengthened mounting point for attachment of an automatic opener.

• Original replacement parts are recommended if repairs are ever required to your door.

• Be sure that your garage complies with all applicable state and or local ventilation requirements before you enclose any vehicles in the garage. Good ventilation avoids fire and health

hazards caused by fumes accumulating within a well-sealed garage.

• Do NOT permit children to play beneath or with any garage door or electric operating

controls.

• Keep hands and fingers clear of section joints, track, and other door parts when the door

is opening and closing to avoid injury. If lift handles are provided, ensure that the lift handles

are located for safe operation as well as easy use.

• Bolts must be installed at the rear end of horizontal tracks. These act to stop the rollers and

keep the door from rolling off the back of the track.

• Track installations must use sway braces on the rear track hangers to prevent sideways

movement. If the tracks are NOT firmly stabilized they might spread, allowing the door to fall

and cause severe injury and damage.

• Springs, cables, and Bottom Corner Brackets are under strong spring tension. Do NOT

attempt to remove, repair or adjust any fasteners on these components or anything to which

these parts are attached, such as wood blocks, steel brackets, or other like items. You could

suddenly release spring forces and risk severe injury.

• If the garage door and/or any of the supporting tracks are damaged, operating the door

could be hazardous. Take the door out of service and call a trained door system technician to

promptly service or repair the door.

• KEEP DOORS PROPERLY BALANCED. An improperly balanced door increases the risk of

severe injury or death. Have a trained door system technician make repairs to cables, spring

assemblies and other hardware as necessary.

• Doors equipped with automatic door operators can cause serious injury or death if NOT

properly adjusted and operated. To ensure safety of these doors:

a) Never let children operate or play with the door controls. Keep the remote control away

from children,

b) Always keep the moving door in sight and people and objects away from the door until the

door is completely closed. NO ONE SHOULD CROSS THE PATH OF THE MOVING DOOR,

c) NEVER GO UNDER A STOPPED, PARTIALLY OPEN DOOR,

d) Test operator monthly. The door MUST reverse on contact with a 1-1/2” high object (or a

2” x 4” board laid flat) at the center of the doorway on the floor. If the door does NOT reverse,

re-test the door operator after adjusting either the force or the limit of travel in accordance

with the manufacturer’s instructions. Failure to adjust the operator properly may result in

severe injury or death,

e) When possible, use the emergency release only when the door is closed. Use caution when

using this release with the door open. Weak or broken springs are capable of increasing the

rate and force of door closure and increasing the risk of severe injury or death, and

f) If your door has a pull down rope or locking mechanism, you must remove the rope and

either disable or remove any door locks.

Please Do Not Return This Product To The Store. Contact your local Overhead Door Ribbon Distributor. To find your local Overhead Door Ribbon

Distributor, refer to your local yellow pages business listings or go to the Find a Ribbon Distributor section online at www.OverheadDoor.com.

3

WARNING WARNING

PRIOR TO WINDING OR MAKING ADJUSTMENTS TO THE SPRINGS, ENSURE YOU’RE WINDING IN THE PROPER DIRECTION AS STATED IN THE

INSTALLATION INSTRUCTIONS. OTHERWISE, THE SPRING FITTINGS MAY

RELEASE FROM SPRING IF NOT WOUND IN THE PROPER DIRECTION AND

COULD RESULT IN SEVERE OR FATAL INJURY.

IMPORTANT: RIGHT AND LEFT HAND IS ALWAYS DETERMINED FROM INSIDE THE BUILDING

LOOKING OUT.

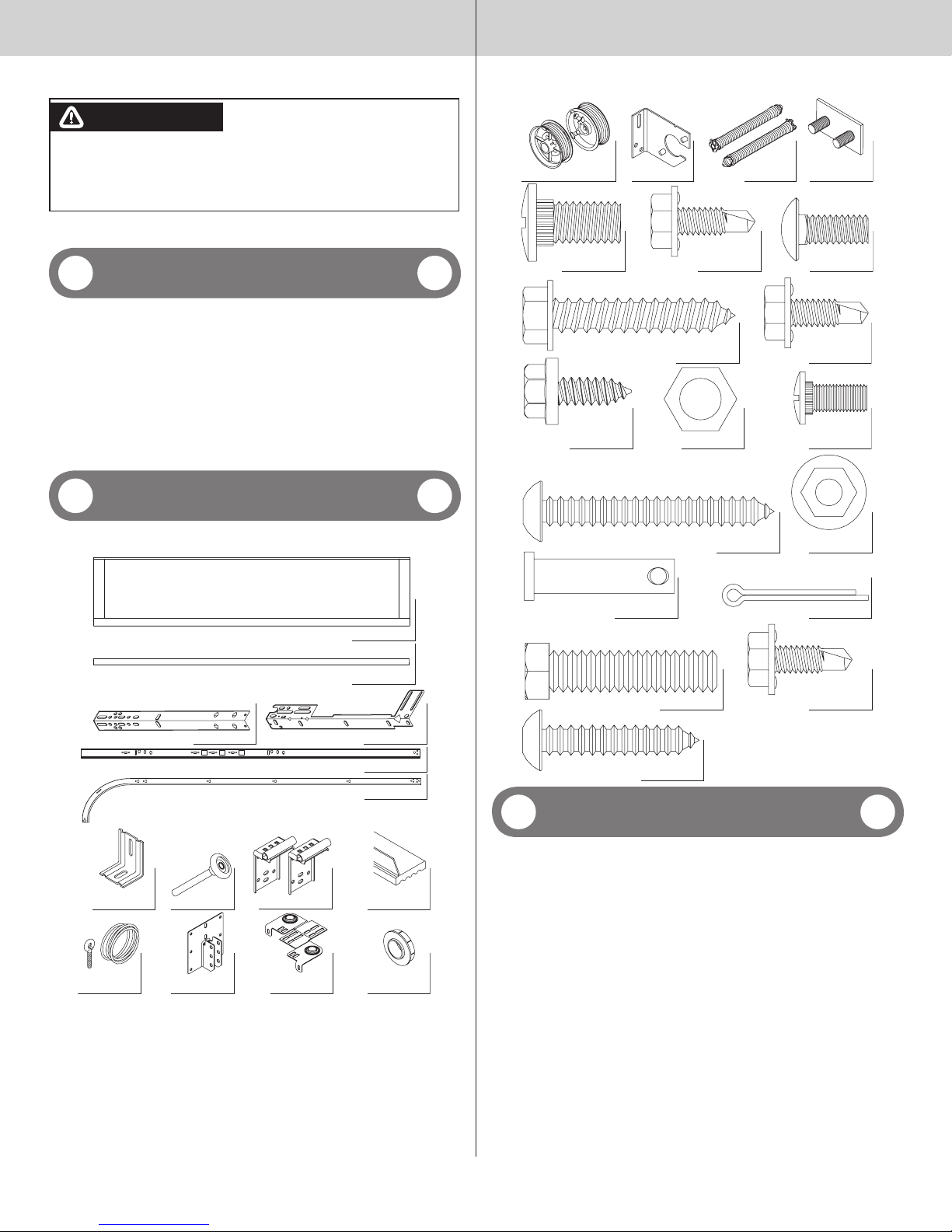

Tools Required

Cable drums RH/LH Torsion springs RH/LH

(2) 3/8”-16 x 3/4”

Truss head bolts

Center bracket

1/4”-20 x 7/8” Self

drilling screws (as required)

Stud Plate

(as required)

(4) 1/4”-20 x 5/8”

Carriage bolts

• Power drill

• Drill bits: 1/8”,

3/16”, 9/32”, 7/16”,

1/2”

• Ratchet wrench

• Socket driver: 7/16”

• Sockets: 7/16”,

1/2”, 9/16”, 5/8”

• Phillips head

screwdriver

• Locking Pliers

• (2) Vice clamps

• Wrenches: 3/8”,

7/16”, 1/2”, 9/16”,

5/8”

• 1/4” Torx bit

• Hammer

• Tape measure

• Step Ladder

• Level

• Pencil

• Leather gloves

• Safety glasses

• Approved winding

rods

Package Contents

NOTE: Depending on the door model, some parts listed will not be supplied if not required.

Rear Back Hangs may not be included with your door.

Door sections (as required)

Torsion shaft

(2) Horizontal track angles (as required)

F.A. flag angles RH/LH (as required)

Vertical tracks RH/LH

Horizontal tracks RH/LH

5/16” x 1 5/8” Hex head lag screws

1/4”-14 x 5/8” Self tapping

screws (as required)

5/16” x 1-1/4”

(2) 3/8”-16 x 1-1/2” Hex bolts

5/16” x 1-5/8” Tamper-resistant

hex head lag screws (as required)

5/16” x 2” Tamper-resistant hex head

Clevis pin

(as required)

(2) 3/8”- 16 Hex nuts

lag screw (as required)

Door Section Identification

1/4”-20 x 5/8” Self

drilling screws (as required)

1/4”-20 x 9/16”

Track bolts (as required)

1/4”- 20 Flanged

hex nuts (as required)

Cotter pin

1/4”-20 x 11/16” Self

drilling screws (as required)

F.A. jamb brackets

(as required)

Pull down rope

(if included)

Track rollers

Drawbar operator

bracket (if included)

Please Do Not Return This Product To The Store. Contact your local Overhead Door Ribbon Distributor. To find your local Overhead Door Ribbon

Distributor, refer to your local yellow pages business listings or go to the Find a Ribbon Distributor section online at www.OverheadDoor.com.

(2) Top fixtures

(2) End bearing

brackets

Weather seals & nails

(If included)

Center bracket

bushing

Graduated end and center hinges are always pre-attached at the top of each section (except

top section) and the graduated end hinges are stamped for identification, #1, #2, #3, and #4

(#4 only on five section doors). The stamp identifies the stacking sequence of the section.

The sequence is always determined by #1 being the bottom section to #3 or #4 being the

highest intermediate section. If the stamp on the graduated end hinge is illegible, refer to

the section side view illustration. The section side view illustration shows the graduated end

hinge profile of all sections, and can also be used to identify each section.

The BOTTOM SECTION can be identified by #1 graduated end hinges, the factory attached

bottom astragal and by the factory attached bottom corner brackets.

The LOCK SECTION can be identified by #2 graduated end hinges on a 4 section high door

and by #3 graduated end hinges on a 3 section high door.

The INTERMEDIATE SECTION can be identified by #3 graduated end hinges (Only on a 4

section high door).

NOTE: #4 graduated end hinges are used on the fourth section of five section doors.

The TOP SECTION can be identified with no pre-installed graduated end or center hinges.

4

operated, 2-1/2” (64 mm) of additional headroom is required.

Backroom requirement: Backroom is defined as the distance needed from the opening

back into the garage to allow the door to open fully.

Top section

#3

Intermediate section

#2

Lock section

#1

1-3/8”

#3 Graduated

end hinge

1-1/8”

#2 Graduated

end hinge

7/8”

#1 Graduated

end hinge

BACKROOM REQUIREMENTS

DOOR HEIGHT TRACK MANUAL LIFT MOTOR OPERATED

6’0” - 7’0” 15” Radius 98” (2489 mm) 125” (3175 mm)

7’1” - 8’0” 15” Radius 110” (2794 mm) 137” (3480 mm)

HEADROOM REQUIREMENTS

TRACK TYPE SPACE NEEDED

15” Radius Track 14 1/2” (368 mm)

Min. Side

Suitable mounting surface

2”x 6” lumber minimum

Header board 2”x 6”

lumber preferred

Headroom

room

Clearance

is 3 1/2”

Backroom

Bottom weather

seal

Typical graduated

end hinge

stamping location

Bottom section

Bottom corner

bracket

Bottom weather seal

Section side view illustration

Removing an Existing Door

IMPORTANT: COUNTERBALANCE SPRING TENSION MUST ALWAYS BE RELEASED BEFORE

ANY ATTEMPT IS MADE TO START REMOVING AN EXISTING DOOR.

WARNING WARNING

A POWERFUL SPRING RELEASING ITS ENERGY SUDDENLY CAN CAUSE

SEVERE OR FATAL INJURY. TO AVOID INJURY, HAVE A TRAINED DOOR

SYSTEM TECHNICIAN, USING PROPER TOOLS AND INSTRUCTIONS,

RELEASE THE SPRING TENSION.

Preparing the Opening

IMPORTANT: IF YOU JUST REMOVED YOUR EXISTING DOOR OR YOU ARE INSTALLING A

NEW DOOR, COMPLETE ALL STEPS IN PREPARING THE OPENING.

To ensure secure mounting of track brackets, side and center brackets, or steel angles to

new or retro-fit construction, it is recommended to follow the procedures outlined in DASMA

technical data sheets #156, #161 and #164 at www.dasma.com.

The inside perimeter of your garage door opening should be framed with wood jamb

and header material. The jambs and header must be securely fastened to sound framing

members. It is recommended that 2” x 6” lumber be used. The jambs must be plumb and the

header level. For low headroom applications, the jambs should extend to the ceiling height.

Minimum side clearance required, from the opening to the wall, is 3-1/2” (89 mm).

IMPORTANT: CLOSELY INSPECT JAMBS, HEADER AND MOUNTING SURFACE. ANY WOOD

FOUND NOT TO BE SOUND, MUST BE REPLACED.

For Torsion counterbalance systems, a suitable mounting surface (2” x 6”) must be firmly

attached to the wall, above the header at the center of the opening.

NOTE: Drill a 3/16” pilot hole in the mounting surface to avoid splitting the lumber. Do not

attach the mounting surface with nails.

Weather seal (may not be included):

Cut or trim the weather seal (if necessary) to the header and jambs.

NOTE: If nailing product at 40°F or below, pre-drilling is required.

Align the header seal 1/8” to 1/4” inside the header, and temporarily secure it to the header

with equally spaced nails. Next, fit the jamb seals up tight against the header seal and 1/8”

to 1/4” inside the jamb. Temporarily secure the jamb seals with equally spaced nails. This

will keep the bottom section from falling out of the opening during installation. Equally space

nails approximately 12” to 18” apart.

NOTE: Do not permanently attach weather seal to the jamb at this time.

Headroom requirement: Headroom is defined as the space needed above the top of the

door for tracks, springs, etc. to allow the door to open properly. If the door is to be motor

Min. Side

room

Clearance

is 3 1/2”

Weather seal

Plumb

jambs

Finished

Jambs

Level header

Finished

Height

Door width

Door

Jamb

Jamb

Nail

1/8” to 1/4”

1/8” to 1/4”

Weather

Seal

Weather

Seal

Door Section

Please Do Not Return This Product To The Store. Contact your local Overhead Door Ribbon Distributor. To find your local Overhead Door Ribbon

Distributor, refer to your local yellow pages business listings or go to the Find a Ribbon Distributor section online at www.OverheadDoor.com.

5

INSTALLATION

Before installing your door, be certain that you have read and followed all of the instructions covered in the pre-installation section of this manual. Failure to do so may result in an

improperly installed door.

NOTE: Reference TDS 160 for general garage door terminology at www.dasma.com.

Attaching Flag Angles to Vertical Tracks

1

NOTE: Flag angles are right and left handed.

Hand tighten the left hand flag angle to the left hand vertical track using (2) 1/4”-20 x

9/16” track bolts and (2) 1/4”-20 flange hex nuts. Repeat for other side. Flange nuts will be

secured after flag angle spacing is completed in step, Top Section.

2

NOTE: The bottom jamb bracket is always the shortest bracket, while the center jamb

bracket is the next tallest. If three jamb brackets per side are included with your door, you will

have received a top jamb bracket, which is the tallest.

To attach the bottom jamb bracket, locate lower hole of the hole/ slot pattern of the 1st hole

set on the vertical track. Align the slot in the jamb bracket with the lower hole of the hole/ slot

pattern. Secure jamb bracket using (1) 1/4”-20 x 9/16” track bolt and (1) 1/4”-20 flange hex

nut. Repeat for other side.

Place the center jamb bracket over the lower hole of the hole/ slot pattern that is centered

between the bottom jamb bracket and flag angle of the 2nd hole set. Secure jamb bracket

using (1) 1/4”-20 x 9/16” track bolt and (1) 1/4”-20 flange hex nut. Repeat for other side.

If a top jamb bracket was included, secure it to vertical track using the lower hole of the hole/

slot pattern in the 3rd hole set and (1) 1/4”-20 x 9/16” track bolt and (1) 1/4”-20 flange hex

nut. Repeat for other side.

1st hole set

(10”)

Lower hole of

hole/ slot pattern

Tools: None

Flag angle

1/4”-20

Flange hex nuts

Vertical

track

1/4”- 20 x 9/16”

Track bolts

Attaching F.A. Jamb Brackets

Tools: None

2nd hole set

(34”)

1/4”- 20

Flange hex nut

Jamb

bracket

3rd hole set

(58”)

1/4”- 20 x

9/16”

Track bolt

Vertical track

Top of track

Jamb bracket

in place

Repeat same process for the right hand side. Set tracks aside.

Horizontal Track Angle Schedule

Door Height

7’0” - 8’0” 3 Or 4 X - - -

Fixed

position

offset holes

How Many

Sections High

Slots

12 34

Fixed Position Offset Holes

1 2 3 4

Hole

1/4”- 20 x 9/16”

Track bolts

Slots

1/4”- 20

Flange hex nuts

Left hand horizontal track angle

Left hand

horizontal

track

Cable Drum Assemblies and Track Rollers

4

NOTE: The bottom section can be identified by the smallest graduated edge hinge of the

factory installed graduated edge hinges, see Parts Breakdown on page 2.

Tools: None

WARNING WARNING

FAILURE TO ENSURE TIGHT FIT OF CABLE LOOP OVER MILFORD PIN

COULD RESULT IN COUNTERBALANCE LIFT CABLE COMING OFF THE PIN,

ALLOWING THE DOOR TO FALL, POSSIBLY RESULTING IN SEVERE OR

FATAL INJURY.

Uncoil the counterbalance lift cables. Starting on the left hand side, place the cable loop on

the milford pin of the bottom corner bracket. Insert a short stem track roller into the factory

attached bottom corner bracket and another into the #1 graduated end hinge at the top of

the bottom section. Repeat for other side.

NOTE: Check to ensure cable loops fits tightly over the milford pins.

NOTE: Larger doors will use long stem track rollers with double graduated end hinges.

NOTE: Verify bottom weather seal is aligned with bottom section. If there is more than 1/2”

excess weather seal on either side, trim weather seal even with bottom section.

#1 Single

graduated

end hinge

(Hinge tube)

Short stem

track roller

Long

stem

track

roller

Double graduated

end hinge

(Hinge tube)

Bottom

section

Bottom

section

Counterbalance

Counterbalance

lift cable

lift cable

Horizontal Track Angles

3

NOTE: For larger doors, a full length horizontal track angle may not already be spot welded to

the horizontal track. If the horizontal track angle is not welded, the horizontal track angle will

be installed, as shown.

Position the left hand horizontal track angle up against the left hand horizontal track, as

shown.

Referring to the horizontal track angle schedule, align one of the fixed position offset holes

(1, 2, 3, 4) in the horizontal track angle with the hole in the horizontal track. Fasten using (1)

1/4”-20 x 9/16” track bolt and (1) 1/4”-20 flange hex nut. Align the rest of the slots in the

horizontal track angle with the slots in the horizontal track. Secure the horizontal track angle

to the horizontal track using 1/4”-20 x 9/16” track bolts and 1/4”-20 flange hex nuts, as

shown.

Tools: Hammer, 9/16” Wrench

Please Do Not Return This Product To The Store. Contact your local Overhead Door Ribbon Distributor. To find your local Overhead Door Ribbon

Distributor, refer to your local yellow pages business listings or go to the Find a Ribbon Distributor section online at www.OverheadDoor.com.

Cable

loop

Milford

pin

Bottom

corner

bracket

Cable loop

Milford

pin

Short stem

track roller

Bottom

corner

bracket

Bottom Section

5

Center the bottom section in the door opening. Level the section using wooden shims (if

necessary) under the bottom section.

6

Tools: Level, Wooden shims (if necessary)

Bottom

weather

seal

Loading...

Loading...