Page 1

Ovation2

Operator’s Manual

Page 2

CG Triumvirate is a trademark of Agfa Corporation.

CG Times, based upon Times New Roman under license from The

Monotype Corporation.

Ovation, SEAQ, and PC Batch are trademarks of Datamax Bar Code

Products Corporation.

As an Energy Star Partner, Datamax Corporation has determined that

this product meets the Energy Star guidelines for energy efficiency.

Firmware (Software) Agreement: The enclosed Firmware (Software)

resident in the EPROM’s is owned by Licensor or its suppliers and is

licensed for used only on a single printer in the user’s Trade or

Business. The User agrees not to, and not to authorize or permit

any other person or party to, duplicate or copy the EPROM’s or

the information contained in the EPROM’s. The firmware

(Software) is protected by applicable copyright laws and Licensor

retains all rights not expressly granted. In no event will Licensor or its

suppliers be liable for any damages or loss, including direct, incidental,

economic, special, or consequential damages, arising out of the use or

inability to use the Firmware (Software).

Information in this document is subject to change without notice and

does not represent a commitment on the part of Datamax Bar Code

Products Corporation. No part of this manual may be reproduced or

transmitted in any form or by any means, for any purpose other than

the purchaser's personal use, without the expressed written permission

of Datamax Corporation.

© Copyright 1999 by Datamax Corporation

All rights reserved. Printed in the United States of America.

Part Number: 88-2185-01

Revision: B2

Page 3

Agency Compliance and Approvals:

FCC:This device complies with Part 15 of FCC rules.

Note: This equipment has been tested and found to comply with

the limits for a Class A digital device, pursuant to Part 15

of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when

the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio

frequency energy, and if not installed and used in

accordance with the instructions in this manual, it may

cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will

be required to correct the interference at his own

expense.

Page 4

Page 5

Important Safety Instructions

This printer has been carefully designed to give you many years of safe,

reliable performance. As with all electrical equipment, there are a few

basic precautions you should take to avoid hurting yourself or damaging

the printer:

• Carefully read the installation and operating instructions provided

with your printer.

• Read and follow all warning instruction labels on the printer.

• Place the printer on a flat, firm, solid surface.

• To protect your printer from overheating, make sure all openings

on the printer are not blocked.

• Do not place the printer on or near a heat source.

• Do not use your printer near water, or spill liquid into it.

• Be certain that your power source matches the rating listed on

your printer. If you are unsure, check with your dealer or with

your local power company.

• Do not place the power cord where it will be walked on. If the

power cord becomes damaged or frayed replace it immediately.

• Do not insert anything into the ventilation slots or openings on the

printer.

• Only qualified, trained service technicians should attempt to

repair your printer.

Page 6

Page 7

♦ Contents

♦Getting Started

1.0 Introduction ..................................................................... 1

1.1 Unpacking and Inspection................................................. 2

1.2 Additional Requirements .................................................. 2

1.3 Connecting Power ............................................................ 3

1.4 Interfacing to the Printer ................................................... 4

1.5 Interface Cables ............................................................... 4

1.6 Loading Media................................................................. 5

1.7 Loading Media for Peel Configuration.............................. 6

1.8 Loading Ribbon (Thermal Transfer Option)..................... 7

1.9 Adjustments for Various Sizes of Ribbon or Media ........... 9

1.9.1 Ribbon Width Adjustment ...................................... 9

1.9.2 Media Width Adjustment...............................................10

1.10 Power-up Configuration and Self-Test.............................. 11

1.11 Setting the Printer to the Factory Defaults......................... 12

1.12 Switches and Indicators .................................................... 13

1.13 Available Options ............................................................ 14

♦ Printing Labels

2.0 Introduction ..................................................................... 17

2.1 Programming Commands ................................................. 17

2.2 Programming Examples ................................................... 23

2.3 Configuration Command String........................................ 25

2.4 Memory Cartridges (Modules).......................................... 27

♦ Maintenance

3.0 Introduction ..................................................................... 28

3.1 Cleaning the Printhead...................................................... 29

3.2 Fine Printhead Adjustment................................................ 30

3.3 Printhead Replacement (203 DPI)..................................... 31

3.4 Printhead Replacement (300 DPI)..................................... 32

i

Page 8

♦ Troubleshooting

4.0 Introduction ..................................................................... 34

Appendix A

ASCII Control Code Chart ........................................................ 1

Appendix B

Printer Specifications................................................................. 1

Appendix C

Available Fonts and Bar Codes..................................................1

Appendix D

Error Codes............................................................................... 1

Appendix E

Warranty Information................................................................ 1

ii

Page 9

♦ Getting Started

Figure 1-1 Printer Overview

1.0 Introduction

The Ovation2 hereafter referred to as ‘the printer’, is a high

quality/low cost direct thermal and optional thermal-transfer label

printer. The printer’s unique construction combines a durable

plastic casing with a metal print mechanism to ensure reliability

and consistent print registration. The combination of powerful

capabilities, compact design, easy-to-use features, and affordable

pricing set a new standard for direct thermal and thermal-transfer

label printers.

This manual provides all the information necessary to operate

your printer. To print labels, tags, or tickets refer to the

instructions included with the software you are using to create the

labels.

Ovation2 1

Page 10

Getting Started

1.1 Unpacking and Inspection

Inspect the shipping container(s) for damage, if damage is evident

notify the shipping company to specify the nature and extent of the

damage.

Remove the printer from the packaging material and check the

contents of the package. In addition to this manual the following items

should be included:

• Label printer

• External power supply

• Special or additional items purchased.

Note: It is a good idea to save the carton and packaging materials in the

event shipping the printer is required.

1.2 Additional Requirements

The following items are necessary to generate labels with your printer.

It may be a good idea to contact your local reseller for advice on

which media and software is best suited for your needs.

• Serial or parallel cable, (see Section 1.4)

• Power cord for 230 VAC operation only, (120 VAC units

come with a power cord).

• Applicable media

• Applicable software

2 Ovation2

Page 11

Getting Started

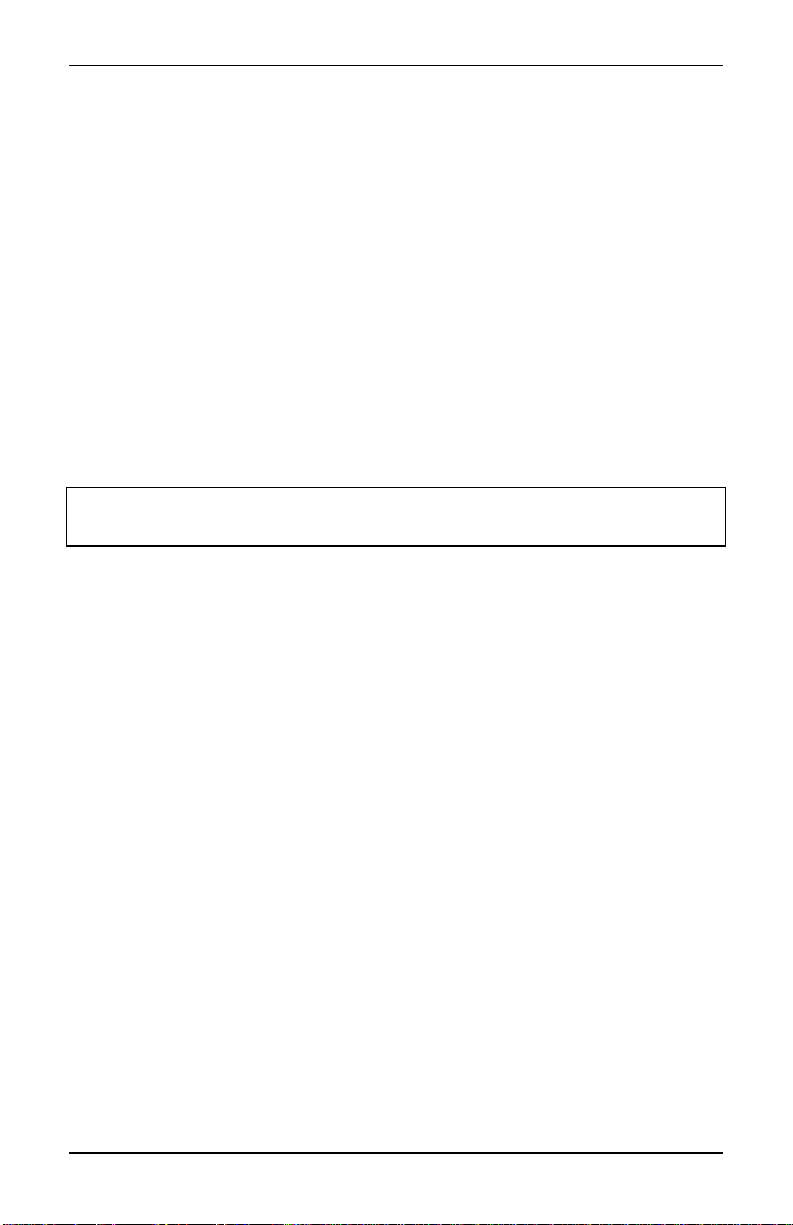

1.3 Connecting Power

The printer is powered from an external power supply that connects to

the printer as shown below. Power supplies are available in both 115

and 230 AC voltages. Ensure that the power supply shipped with your

printer matches your electrical service.

Connect power supply to printer before plugging

Caution

into AC outlet.

Figure 1-2 Connecting power to the Printer

Ovation2 3

Page 12

Getting Started

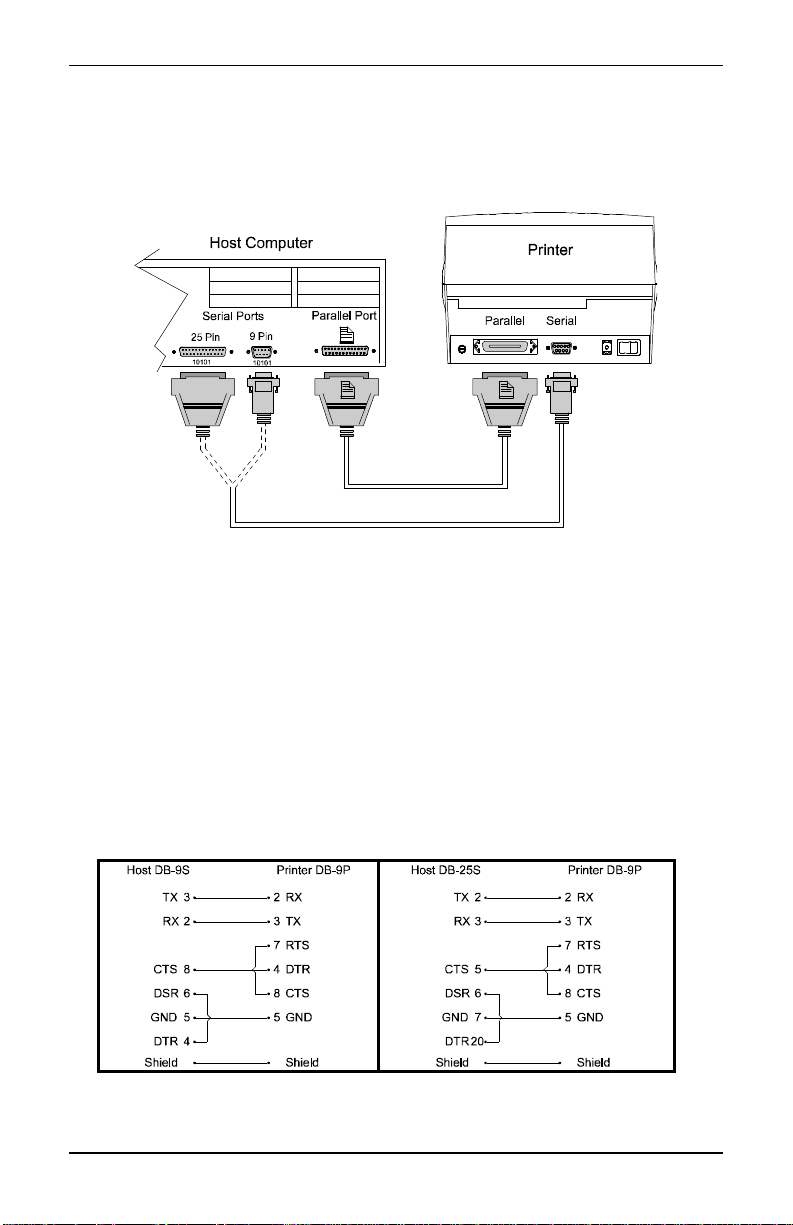

1.4 Interfacing to the Printer

The printer can be connected to the host via a serial or parallel cable.

Figure 1-3 Interfacing to the Printer

1.5 Interface Cables

An interface cable is necessary to connect the printer to the host. The

interface between the printer and the host will be either a serial RS232C or parallel cable. Cable configurations for serial (RS-232C)

interfaces are shown below, (contact your reseller for part numbers

and ordering information).

Figure 1-4 Serial Cables

4 Ovation2

Page 13

Getting Started

The printer can also be connected to the host with a parallel

connection. In addition, the printer has a unique feature where if you

connect both the serial and parallel cables to the printer at the same

time, the printer will automatically interface to the first connection,

(serial or parallel) that transmits valid data. After a connection has

been made, the printer must be turned off and then back on again to

change the interface connection.

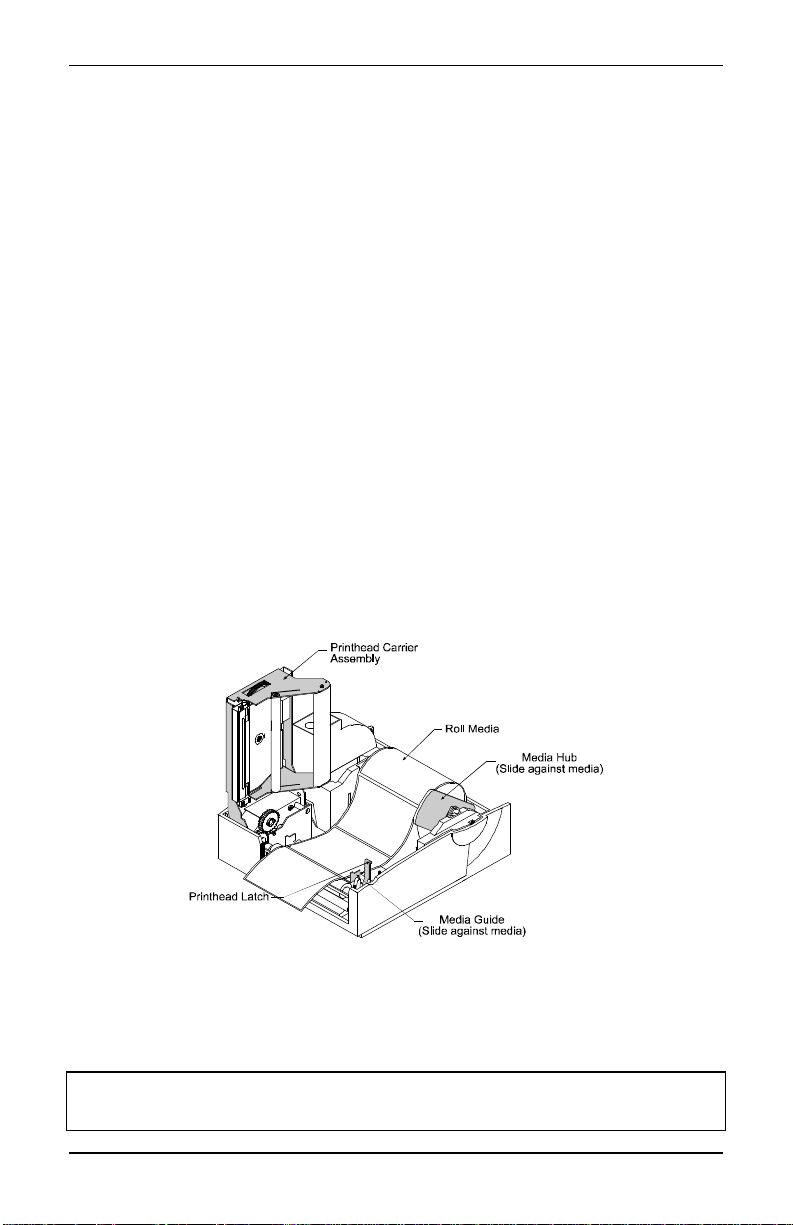

1.6 Loading Media

1. Open the cover.

2. Push the printhead latch toward the back of the printer and raise

the printhead carrier assembly.

3. Place a roll of media (labels facing up) on the media hub and

insert them into the printer. Slide the media hub against the roll of

media

4. Pull 6″ (152 mm) of media from the media roll in the printer.

5. Slide the media guide to the edge of the media.

6. Close the printhead carrier assembly and press down until it locks

into place.

Figure 1-5 Loading Media

7. Close the cover and press the ‘Feed’ Button several times to feed the

media and ensure proper tracking.

Note: The printer is factory set for 4-inch media and ribbon, when using

different width media/ribbon please refer to Section 1.9.

Ovation2 5

Page 14

Getting Started

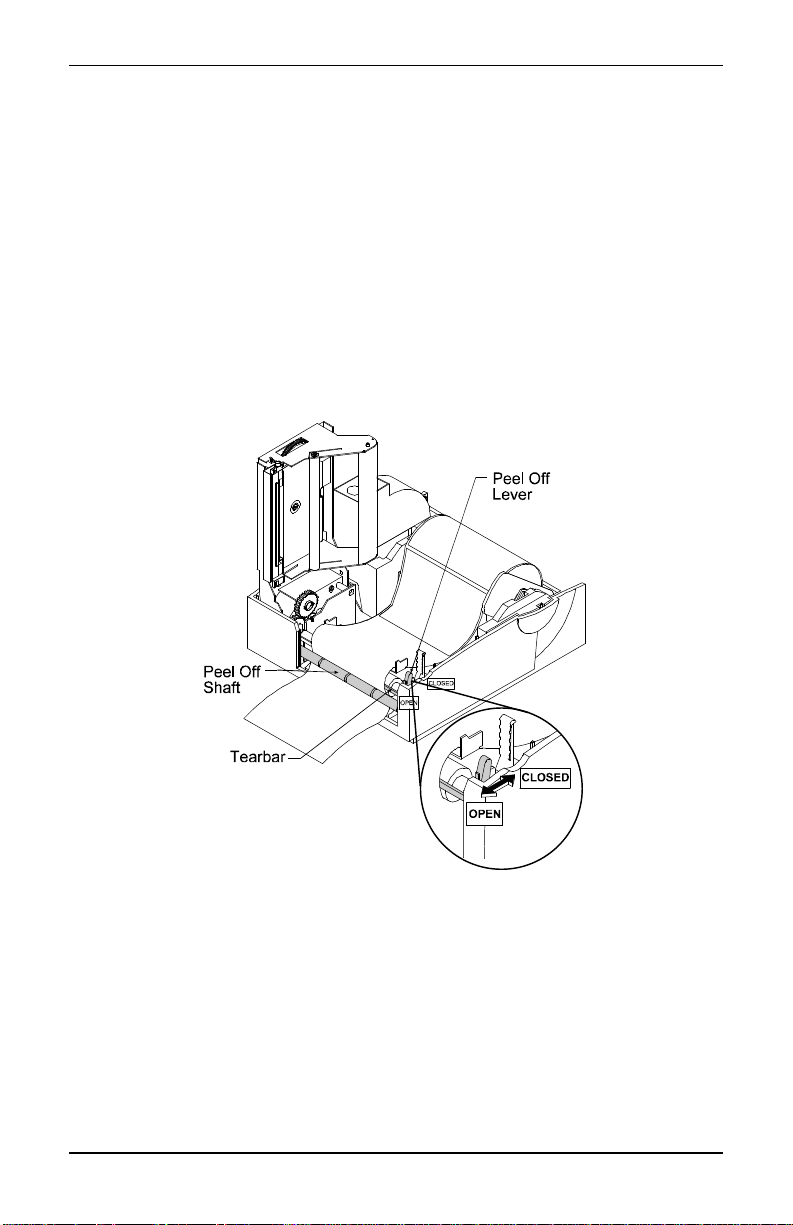

1.7 Loading Media for Peel Configuration

1. Open the cover.

2. Push the printhead latch toward the back of the printer and raise

the printhead carrier assembly.

3. Place a roll of media (labels should be facing up) on the media

hub and insert into the printer.

4. Pull the Peel-off Lever forward to the ‘open’ position.

5. Remove 6″ (152 mm)of labels from the backing. Route the

backing over the tearbar and behind the peel-off shaft as shown

below.

Figure 1-6 Loading Media for Peel Configuration

6. Push the Peel-off Lever back to the ‘closed’ position

7. Close the printhead carrier assembly and press down until it locks

8. Close the cover and press the ‘feed’ button two or three times to

into place.

feed the media and ensure proper tracking. The labels will

separate automatically as it is feed through the printer.

6 Ovation2

Page 15

Getting Started

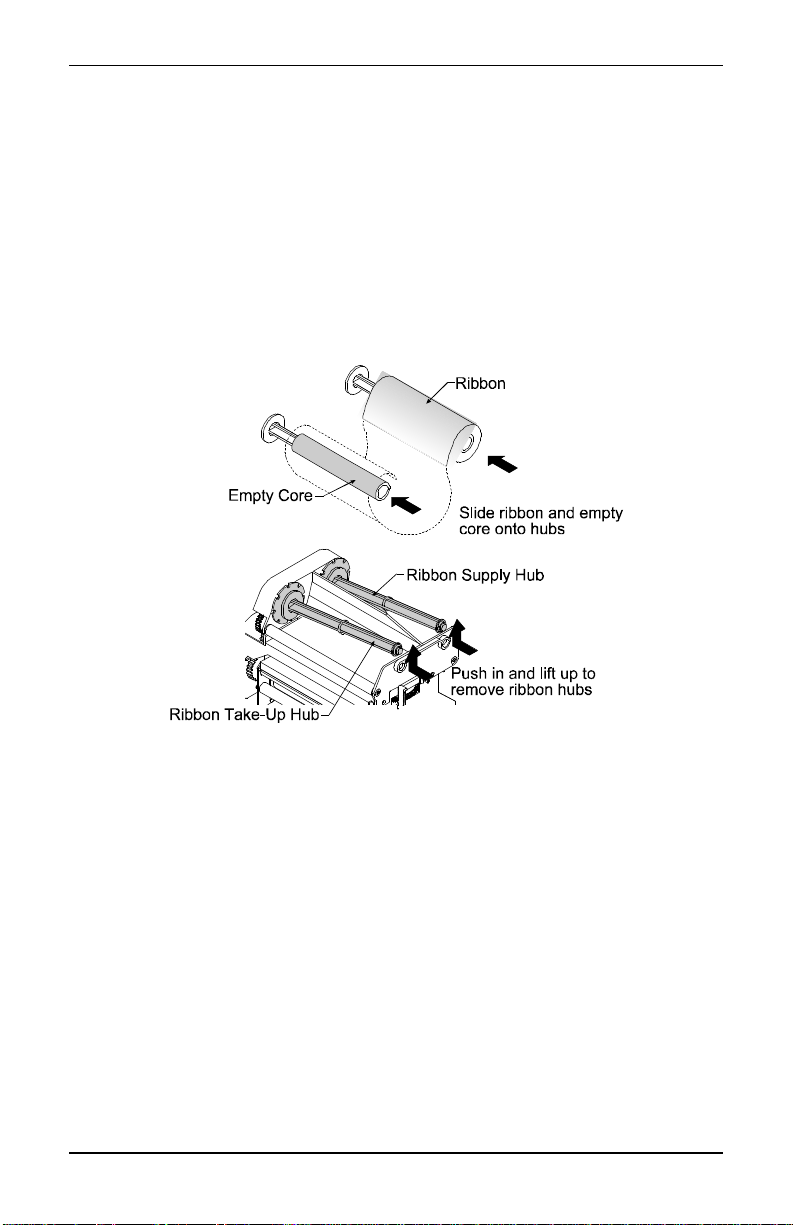

1.8 Loading Ribbon (Thermal Transfer Option)

1. Open the cover.

2. Remove the two ribbon hubs.

3. Slide the ribbon and empty core onto the hubs making sure that

the ribbon unwinds and rewinds.

Figure 1-7 Ribbon Hub Removal

4. Place the ribbon supply hub back into the thermal transfer

assembly.

5. Slide the direct/thermal transfer switch to the ‘transfer’ position.

Ovation2 7

Page 16

Getting Started

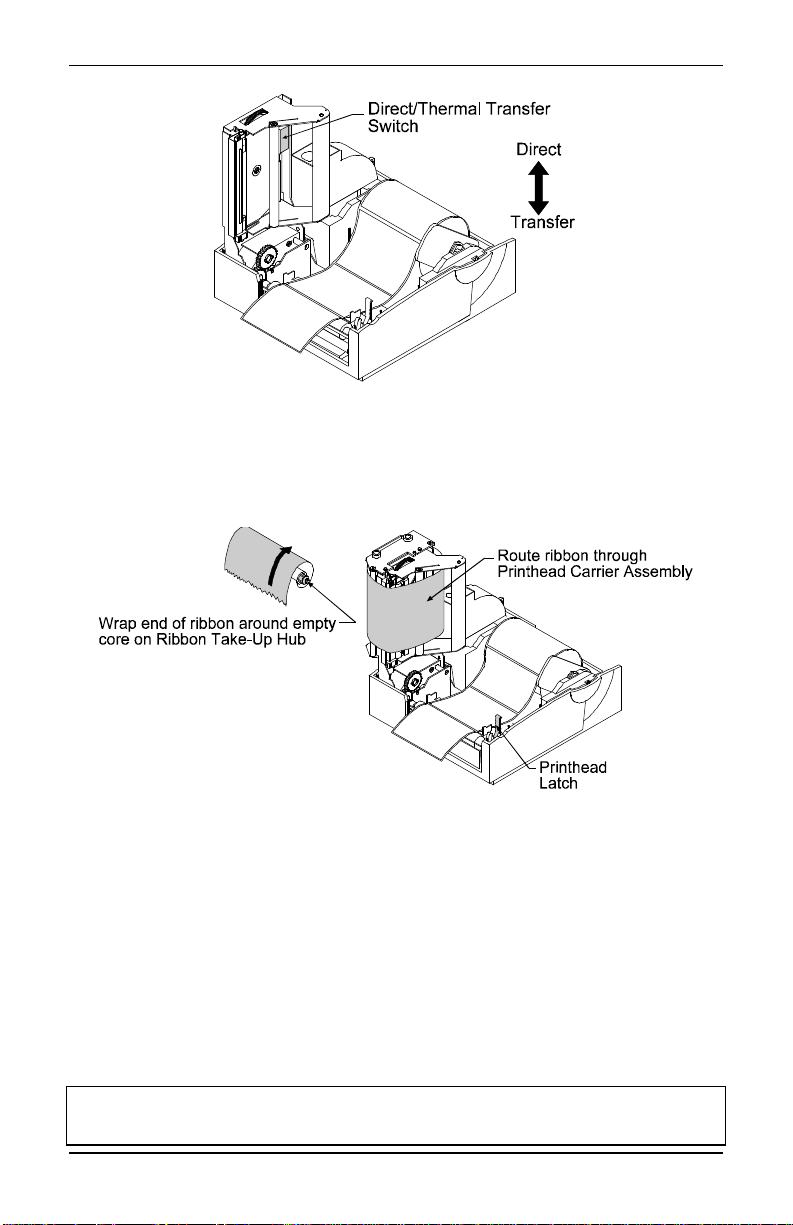

Figure 1-8 Selecting the Print Type

6. Load the printer with media (see Section 1.6) and ribbon. When

loading ribbon be sure to guide the ribbon through the printhead

carrier assembly as shown below.

Figure 1-9 Routing the Ribbon

7. Close the cover. Press and hold the feed button down while

powering on the printer. Continue to hold down the feed button

until the printer starts to move the media, then release. The printer

will now print a configuration label that confirms the thermaltransfer mode is set.

8. After printing a configuration label you must cycle power. To

cycle power simply turn the printer off for 30 seconds, and then

back on. The printer will remain set for thermal-transfer mode.

Note: The thermal-transfer mode can also be set with the configuration

command <STX KD>, see Section 2.3.

8 Ovation2

Page 17

Getting Started

1.9 Adjustments for Various Sizes of Ribbon or Media

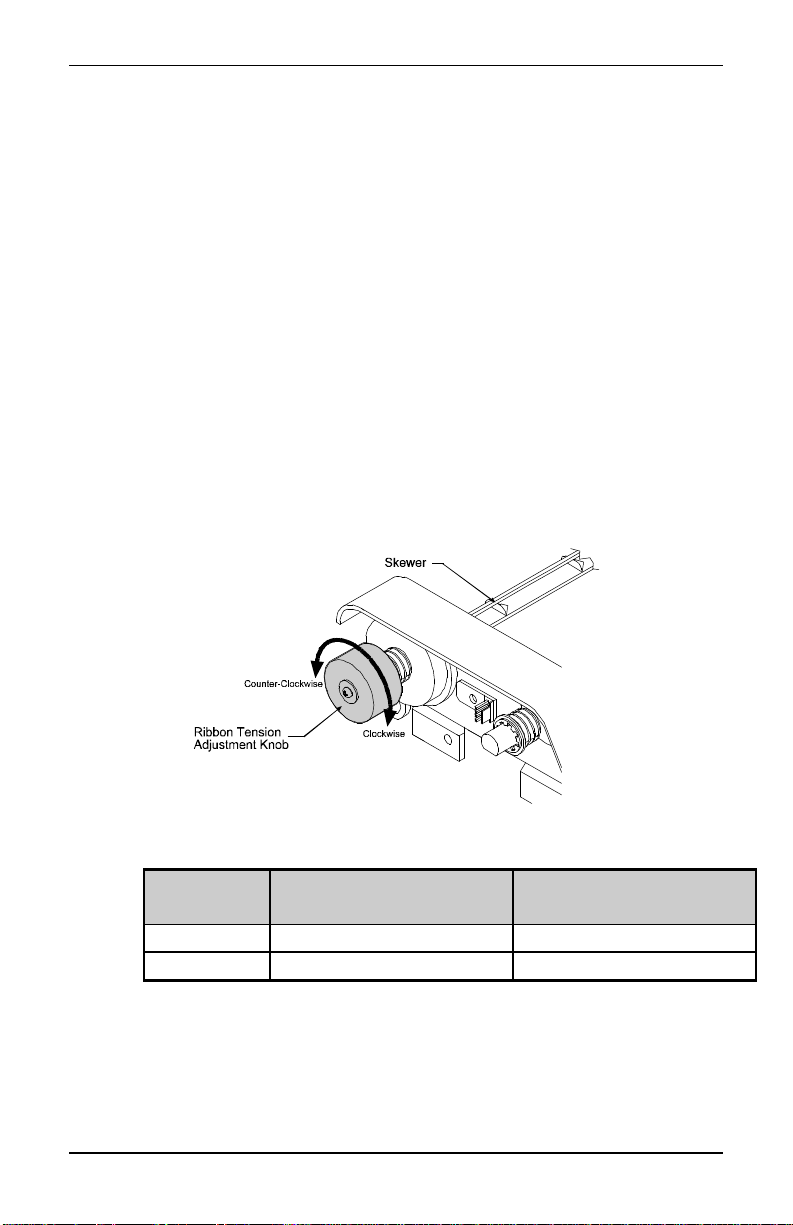

1.9.1 Ribbon Width Adjustment

The adjustable ribbon handler feature allows adjustment to the ribbon

supply hub which provides optimum tension when using different

widths of media or ribbon.

1. Turn ‘off’ the printer.

2. Hold the ribbon supply spindle and rotate the ribbon tension

adjustment knob to meet your media/ribbon widths based on the

table below. Ensure that the ribbon tension adjustment knob is

turned fully to the clockwise or counter-clockwise position, the

knob will no longer turn once it is in the proper position, do not

force or over turn.

Figure 1-10 Adjusting for Media

Ribbon

Size

Narrow 1-2 inches wide Clockwise*

Wide 2-4 inches wide Counter-Clockwise*

* Continue turning the ribbon tension adjustment knob until it

Ribbon Width Direction of Rotation

will not turn any further in either the clockwise or counterclockwise position.

Ovation2 9

Page 18

Getting Started

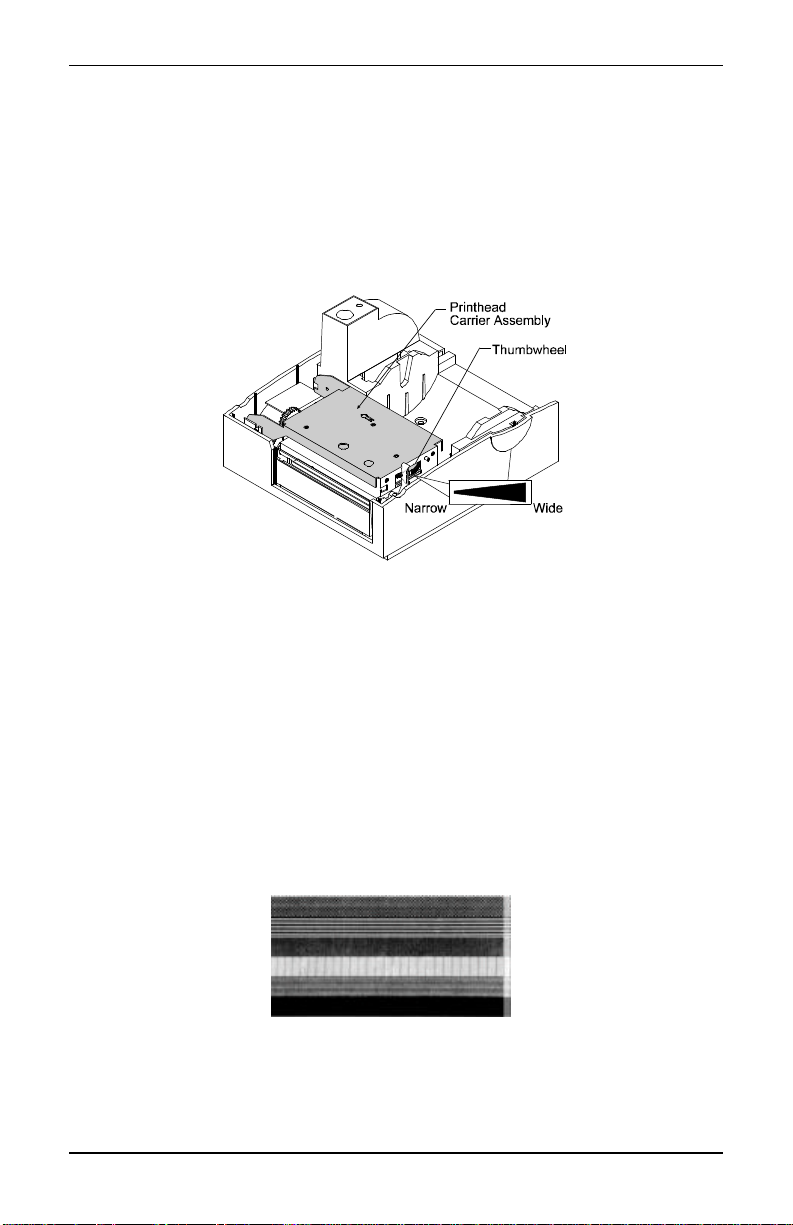

1.9.2 Media Width Adjustment

The thumbwheel on the side of the printhead carrier assembly allows

the printhead to be adjusted for various sizes of media. The numbers

on the thumbwheel serve only as a reference point and do not

correspond with a particular media width.

Figure 1-11 Thumbwheel for Media Width Adjustment

1. Load media into the printer.

2. Print a label, if it is light on the right-hand side then move the

thumbwheel to the right, (see example below).

3. An internal test label can be generated by holding the ‘feed’ button

down and turning ‘on’ the power switch until the media moves. The

first label printed is the configuration label which provides

information on the printer set-up. The second label printed is the test

pattern and shows print quality, (see Section 1.10 for additional

information).

Rotate

thumbwheel

clockwise until

print quality

along edge starts

to lighten.

(Light print on

the right side of

the test label

indicates that the

thumbwheel

should be

adjusted

clockwise.)

10 Ovation2

Page 19

Getting Started

1.10 Power-up Configuration and Self-Test

With the printer off, load the die-cut media (the media must be at least

4 inches wide), and ribbon (if printing in thermal-transfer). Press and

hold the feed button and turn the printer on, (the power LED should

be ‘on’), continue holding the feed button until the media begins to

move then release it. The printer will automatically detect if a ribbon

has been installed and will then print two test labels.

Note: After performing a power-up and self-test, the printer will be

in the 'character dump mode'. Turn the printer ‘off’ for

approximately 25 seconds, then back ‘on’ to restore normal

operation. The printer must remain ‘off’ for 25 seconds in

order for the main board to properly reboot.

The first label printed will be the configuration label, which lists the

printer's configuration and status. Note that this configuration label

shown below was printed from a printer that had the time/date option

installed.

FRI SEPTEMBER 026, 1997 19:29 244

ROM CHECKSUMS

U09

U10

SYSTEM RAM CHECKS____ GOOD SYSTEM RAM SIZE__ 512 KBYTES

CONFIGURATION

9600,8,N

DIRECT

INPUT VALUES

PAPER: 228 EDGE: 179 REFL: 0 TEMP: 89

POT : 212 TOFA: 133 RIBN: 0

COUNTER INFORMATION

ABSOLUTE VALUES 9-18-1994 RESETTABLE VALUES 9-18-1994

LENGTH____ 773 INCHES LENGTH____ 576 INCHES

TIME______ 10 HOURS TIME______ 4 HOURS

MEMORY CONFIGURATION

INTERNAL MODULE______ 12 SCALABLE FONTS_______ 10

Figure 1-12 Configuration Test Label

Ovation2 11

Page 20

Getting Started

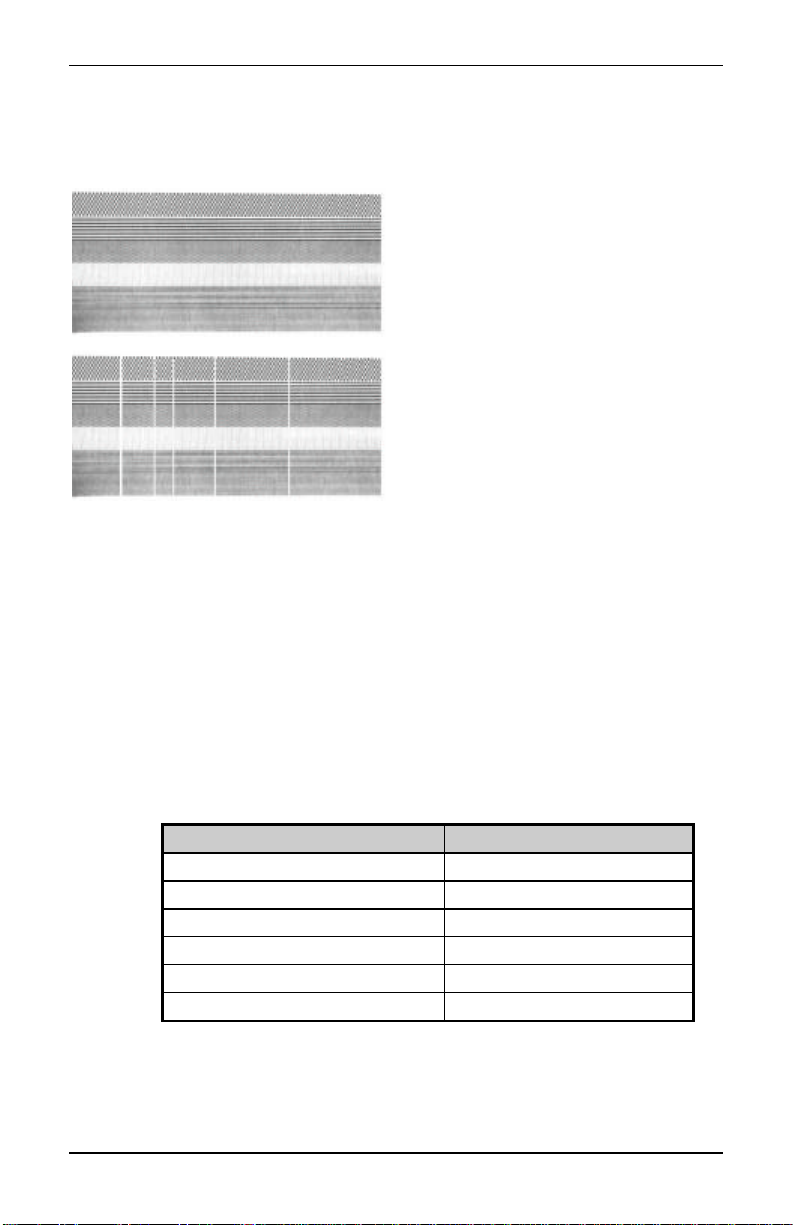

The second label printed is the test pattern label. This label is used to

determine whether the printhead is in need of replacement. 'Good' and

'Bad' Test Pattern labels are shown below:

Good Test Label: Indicates

that the printhead is operating

normally.

Bad Test Label: Streaks in

test label indicate a dirty or

faulty printhead.

(See Chapter 3 for cleaning

and replacement.)

Figure 1-13 Printhead Test Label

1.11 Setting the Printer to the Factory Defaults

With the printer off, press and hold the feed button while turning the

printer on. Continue to hold the feed button for 60 seconds and then

release. The printer will now be set to the 'Factory Defaults', which

are shown in Table 1-1.

Function Value

Baud Rate 9600

Word Length 8 bits

Print Method direct thermal

Alternate Character Set standard

Cutter disabled

Table 1-1 Factory Default Settings

Paper Type gap

12 Ovation2

Page 21

Getting Started

1.12 Switches and Indicators

Descriptions and locations of the Printer's switches and indicators are

shown below.

Figure 1-14 Switches and Indicator Locations

Switch/Indicator Function

ON/OFF switch Controls power to the Printer.

FEED Button

Printer in

ready state (LED ON)

Press twice

Press once

Printer in

alarm state (LED fast

flash)

Press once

Darkness Control Used to balance a new Printhead so that it prints at the

Power LED

Solid ON

Slow Flash

Fast Flash

Ovation2 13

Printer feeds media to first print position of next label.

Pauses Printer, press again to resume.

Clears alarm, feeds one label.

same level of darkness as the previous head.

Indicates power is supplied and the Printer is ON.

Indicates the Printer is in a 'PAUSED' condition.

Indicates the Printer is in an 'ERROR' condition such as

Media Out, Ribbon Out (if equipped), or Jam.

Page 22

Getting Started

1.13 Available Options

Thermal Transfer

Thermal transfer printing requires the use of a ribbon. The ink/wax

from the ribbon transfers to the media by the printer to create an

image. Thermal transfer printing provides exceptional clarity and

scannability.

External Cutter

The external cutter provides ease of automatic cutting for tags and

labels after a label is printed. This feature attaches to the front of the

printer.

Present Sensor

The present sensor allows the printer to be configured for "one up"

printing. With the sensor installed, the printer will not print the next

label until the previous printed label has been removed from the

printer.

DRAM Expansion

The DRAM expansion option increases the printer’s memory to 1

MB. The additional memory allows for larger label formats to be

loaded into the printer's memory, thereby making it possible to print

longer labels.

FLASH Memory Cartridges

FLASH memory cartridges are available in 256K and 512K sizes and

are used for permanent storage of custom fonts, formats and graphics.

14 Ovation2

Page 23

Getting Started

PC-Batch Software

This label-creation software package is available for IBM

PC or

compatibles.

Wall Mount Assembly

This space-saving device allows the printer to be mounted to a wall or

other vertical surface using a specially-designed mounting plate.

Time/Date

This feature allows the printer to maintain the current time and date.

This is useful when printing labels that require the current time or

date to be included within the label format.

External Media Supply Stand

The external media supply option allows the use of large media

supply rolls, up to 8-inches in diameter, on 1−3″ cores.

External Battery Pack

This option allows the printer to be operated virtually anywhere since

its power is not dependent on an AC receptacle. The battery easily

attaches to the printer and can last up to 10 hours.

Ovation2 15

Page 24

Getting Started

16 Ovation2

Page 25

♦ Printing Labels

2.0 Introduction

Labels can be generated using RS-232 or parallel communications to

a host computer or a PC with a compatible labeling software package.

This chapter explains some of the basic programming commands that

are required when writing programs to generate label formats. A

programmer's manual can be obtained by mailing or faxing the

request card located in the back of this manual.

2.1 Programming Commands

In order to be ready for a command sequence, the printer must first

receive a special character called an “attention getter” that informs the

printer that it is about to receive a command and the type of command

it will be. Immediate commands, system-level commands, and fontloading commands each have their own attention getter. The attention

getter character is followed by a command character that tells the

printer what action to take.

ASCII

Char.

SOH 1 01 Ctrl A Immediate Commands

STX 2 02 Ctrl B System-Level Commands

ESC 27 1B Ctrl [ Font-Loading Commands

Decimal

Value

HEX

Value

Table 2-1 Attention Getters

DOS

Prompt

Attention Getter For

Ovation2 17

Page 26

Printing Labels

When the printer receives an immediate command it will cease

whatever it is doing and perform that command. Commands of all

types must be in this sequence:

1. Attention Getter

2. Command Character

3. Parameters that must be entered by the user (if any).

Command

Character

# N Y Reset

A N Y Send ASCII status string

B N N Toggle pause

C N N Cancel

D N N SOH shutdown

E N Y Send batch quantity

F N Y Send status byte

Must Enter

Parameters?

Table 2-2 Immediate Commands

Printer

Responds?

Command

18 Ovation2

Page 27

Printing Labels

The system-level commands are used to create formats, load and store

graphic information, and control the printer. Table 2-3 provides a

brief description and format of each system-level command character.

Char Description Format

A Set time and date

a Enable feedback characters Returns 30 after each label and 31 after

B Get printer time and date information Print time and date to port

c Set continuous paper length

d Set Printer to double buffer mode Use to print a label while a second is

E Set quantity for stored label

e Select edge sensor for "see through" media sensing.

F Form feed Feeds one label at a time

f Set form stop position (Backfeed) Set distance to peel (tear off) position

G Print last label format

I Input graphics data block

"See Programmer's Manual for

format"

i Download scalable font

J Set pause for each label

K Extended System Commands

k Test RS-232 Port with a Y if ok Sends character "Y" to RS-232 port

L Enter Label Formatting Mode

M Set maximum label length

Table 2-3 System-Level Commands (continued)

Ovation2 19

Format: AwmmddyyyyhhMMjjj

16 digits total.

= 1 digit week, 1 is Monday

w

= 2 digits for month

mm

= 2 digits for day

dd

= 4 digits for year

yyyy

= 2 digits for hour (24 hr ft)

hh

= 2 digits for minutes

MM

= 3 digits for Julian I.D. value

jjj

each batch of labels

cnnnn = length of paper to feed per

label

formatting in memory

Ennnn = Set Quantity for stored label

fnnn = 3 digits from sensor

A bank designation, an optional word

length modifier, a format designation,

and up to a 16-character string to

identify the stored image data

Kn n =

Q - For query

D - Database Configuration

S, W, or M - Set configuration

R - Reset

fxxxx- 4 digit number, Distance

between TOF sensor and stop position

r - Resettable counters reset

Mnnnn = 4 digits (default) Maximum

12 inches

Page 28

Printing Labels

Char Description Format

m Set metric flag, enter metric mode All references set to metric until reset

n Clear metric flag, return to inch mode

O Form edge offset (start of print

position)

Onnnn = 4 digits, in/100 or mm/10

o Cycle cutter

P Enter character dump mode

p Controlled pause

Q Clear all memory modules

q Clear module

qx = Module I.D. (Uppercase)

r Select reflective sensor Used for "black-strip" media sensing,

(e.g. continuous tags, butt-cut labels.

Stripe must be printed on back side of

media)

S Slew (feed) speed

s Set up for one print buffer

Sx x = A -C (1.0 to 2.0 ips)

Set for 1 dot buffer processing. Use for

full length dot buffer processing.

T Printhead dot pattern test label

t Test RAM memory module

(Must be in Test Mode)

a bbbK module good

bbb = 256 or 512, for size of module

U Label format field replacement

V Software switch settings Vn n = 4-Label Present, 2-Internal

Batch, 1-Cutter Enable

v Firmware version information Sends version string to host

W Request memory module information Wx x = F-font, G-graphic, L-label

w Test FLASH module memory Takes about 90 seconds

x Delete module file

X Set default module bank

xMFname M=Module I.D, F=file type

Xa a - A = Memory Module A

Y Output sensor values Dumps sensor values status to RS-232

port

y Select font symbol set (optional

scalable fonts only)

y S xx

y = ASCII (0x79)

S = ASCII (0x54)

xx = symbol selection

z Pack module

Z Print internal information and dot

pattern

Zx x= Module I.D

Table 2-3 System-Level Commands (concluded)

20 Ovation2

Page 29

Printing Labels

A STX L command switches the printer from the system level to the

label-formatting mode. All command characters after STX L are

interpreted as label formatting commands until the label-formatting

mode is terminated with the command character E. All label formatting commands are terminated with hex value 0D.

CC Description Format

Set cut by amount (4 digits)

:

The cutter function will perform a cutting

action after the number of labels specified.

A Set format attribute

C Set column offset amount

c Set cut by amount (2 digits)

D Set height and width dot size h = Horiz. dot size; can be 1 or 2

E Terminate field generation and print label

G Place data in global register

H Enter heat setting

(The amount of heat applied per dot row, can

be used to help control print quality)

m Set metric mode The printer must be reset in order

M Set mirror image mode

('Mirror Images' current formatted label)

P Print speed

p Set label backup speed

Q Enter quantity of labels to print

R Set row offset amount

r Recall stored label format

S Slew (feed) speed

s Store label format in module

T Set field data line terminator

U Make previous field a string replace field

Table 2-4 Label-Formatting Commands (continued)

:nnnn

nnnn = 4 digits of labels printed

before cut. Default = 0001

An n=1-XOR, 2-Transparent, 3-

Opaque, 5-Inverse

Cnnnn nnnn= in/100 or mm/10

cnn nn = 2 cut amount

v = Vert. dot size; can be 1,2, or

3 (0.005" steps) Default is

“D22”

Hnn nn = 2 digits. 1 - 30

10 is nominal and default

to return to standard measure

'M' must be re-sent to cancel.

* Will not mirror polygons.

Px x = A -C (1.0 to 2.0 ips)

px x x = A -C (1.0 to 2.0 ips)

Qnnnn nnnn = quantity

Rnnnn nnnn = in/100 or mm/10

rnn...n nn...n Label name of up

to 16 char. terminated by CR.

Sx x = A -C (1.0 to 2.0 ips)

sann...n a - destination module

A Memory Module A

nn...n - label name (16 char.

max)

Tnn nn = 2 digit ASCII Hex

00 - FF

Ovation2 21

Page 30

Printing Labels

CC Description Format

X Terminate label formatting mode

y Select font symbol set (optional scalable

fonts only)

z or Z Zero (0) conversion to "O"

eliminates slash (/)

+ Make last field entered increment numeric

- Make last field entered decrement numeric

> Make last field entered increment

alphanumeric

< Make last field entered decrement

alphanumeric

^ Set count by amount

Table 2-4 Label-Formatting Commands (concluded)

There are two special commands used by the printer, the STX S

y S xx

y = ASCII (0x79)

S = ASCII (0x54)

xx = symbol selection

+pii Make last entered field

incrementing

p = Zero fill character

ii = Data added to field

-pii Make last entered field

decrementing

p = Zero fill character

ii = Data subtracted from field

>pii Make last entered field

incrementing 0 - Z

p = Zero fill character

ii = Data added to field

<pii Make last entered field

decrementing 0 - Z

p = Zero fill character

ii = Data subtracted from field

^nn Set count by amount

nn = 2 digits

Skip # of labels before updating

count fields and time fields

(Recall Global Data) and the STX T (Print Date and Time)

commands. Unlike the other label-format commands, which follow the

STX L command, these special commands are entered directly into

the data field.

Character Description

<STX>S Recall global data and place in field

<STX>T Print time and date

Table 2-5 Special Label-Formatting Commands

22 Ovation2

Page 31

Printing Labels

The commands used for bit mapped font loading are usually generated

by font-creation software. However, the assign font ID number

command must be sent to the printer before the font file. Font-loading

commands are listed in Table 2-6.

CC P PR Description

*c###D N N Assign Font ID Number

### = ID Number 100 to 999

)s#W Y N Font Descriptor

*c#E N N Character Code

# = ASCII Value of Character

(s#W Y N Character Download Data

# = Bytes of Bit-mapped Data

CC = Command Character

P = Must Supply Parameters? (Y/N)

PR = printer Responds? (Y/N)

2.2 Programming Examples

<STX> L <CR>

H07 <CR>

D11 <CR>

19110080100002510K OHM 1/4 WATT <CR>

1a6210000000050590PCS <CR>

E

Table 2-6 Font-Loading Commands

10K OHM 1/4 WATT

Ovation2 23

Figure 2-1 Sample Label

Page 32

Printing Labels

The example shown below prints out a Code 3 of 9 bar code with a

wide to narrow bar ratio of 3:1 and can be used to print any of the bar

codes shown in Appendix B by altering the example's fields. Refer to

Figures 2-2 and 2-3 for a brief explanation of the data fields.

<STX>L<CR>

D11<CR>

1A93040001501000123456789<CR>

121100000000100Barcode A<CR>

E

<STX>L Syntax L on line 1 is used to enter the label formatting mode.

Figure 2-2 Example line 3

Figure 2-3 Example line 4

24 Ovation2

Page 33

Printing Labels

2.3 Configuration Command String

The configuration command string sets the operating parameters of

the printer. The command strings are described below.

<STX>KDwxy <CR>

where w:

Bit # Function Value

0-2 Baud Rate

3 Word Length 0=8 bits*, 1=7bits

4&5 Unused Set to 0

6 Always 1 Set to 1

7 Always 0 Set to 0

where x:

Bit # Function Value

0 Print Method 0=direct thermal*, 1=thermal transfer

1 Present Sensor 0=not equipped, 1=equipped

2 Alternate Char.

Set

3 Cutter 0=disabled*, 1=enabled

4&5 Unused Set to 0

6 Always 1 Set to 1

7 Always 0 Set to 0

where y:

Bit # Function Value

0&1 Paper Type 0=gap*(edge), 1=reflective, 2=continuous (3")

2 Unused Set to 0

3-5 Unused Set to 0

6 Always 1 Set to 1

7 Always 0 Set to 0

* = factory defaults

Example: <STX>KD @A@ <CR>

@ Sets the printer to: 9600 baud; 8 bit word length/no parity.

A Sets the printer to: thermal transfer; no present sensor;

0=9600*, 1=600, 2=2400, 3=19200, 4=4800, 5=N/A,

6=1200, 7=9600 Test Mode

0=standard*, 1=main frame

standard character set; no cutter.

Ovation2 25

Page 34

Printing Labels

@ Sets the printer to: gap (edge) media.

26 Ovation2

Page 35

Printing Labels

2.4 Memory Cartridges (Modules)

The printer has one memory cartridge slot that can be used to store:

graphic images; smooth formed fonts; and label formats that can be

recalled by host computers.

Caution

The use of memory cartridges other than those specifically

designed for the printer can cause damage to both the

cartridge and the printer.

Figure 2-4 Inserting a Memory Cartridge

Note: When turned ‘on’ the write protect switch will not allow data to

be written to the cartridge, ensuring that important data is not

Ovation2 27

overwritten.

Page 36

♦ Maintenance

3.0 Introduction

This chapter covers the cleaning, adjusting, and some troubleshooting

tips involved with your printer. In addition, the following table

provides a recommended cleaning schedule for the various parts of

your printer.

Area Method Interval

Printhead Turn off the printer before cleaning

the printhead. Use solvent* on a

After every roll of

media.

cotton swab to clean the printhead

from end to end.

Platen Roller Turn the power off. Rotate the

platen roller and clean it thoroughly

After every roll of

media.

with solvent* and a cotton swab.

Peel-Off

Roller

Rotate the peel-off roller and clean it

thoroughly with solvent* and a

After every roll of

media.

cotton swab.

Media Path Solvent* After every roll of

media.

Peel/Tear Bar Solvent* As needed

Media Sensor Air blow Monthly

Exterior Mild detergent or desktop cleaner. As needed

Interior Brush or vacuum cleaner As needed.

* Recommend using a solvent that contains isopropyl alcohol.

Ovation2 28

Page 37

Maintenance

3.1 Cleaning the Printhead

Warning: Turn ‘off’ the printer and unplug the unit from

the outlet before cleaning the printhead.

1. Turn ‘off’ the printer and open the cover.

2. Push the printhead latch back toward the back of the printer and

raise the printhead carrier assembly.

3. Using a cotton swab dipped in isopropyl alcohol, rub the cotton

swab along the printhead.

Figure 3-1 Cleaning the Printhead

Note: The printhead should be cleaned every time a new roll of media

is installed.

Ovation2 29

Page 38

Maintenance

3.2 Fine Printhead Adjustment

A fine printhead adjustment set screw is located on top of the

printhead carrier assembly that can used for adjusting print quality.

This adjustment is set at the factory and should not need further

adjusting; however, with different types and thickness of media some

adjustment may be necessary.

To adjust the printhead, turn the set screw until optimum print quality

is obtained, (some trial and error may be necessary).

Figure 3-3 Fine Printhead Adjustment

30 Ovation2

Page 39

Maintenance

3.3 Printhead Replacement (203 DPI)

Removal:

1. Turn off the printer.

2. Unlatch the printhead

carrier assembly.

Loosen the printhead

screw until it is free

from the printhead.

Carefully remove the

printhead from the

printhead carrier

assembly.

3. Remove the printhead

cables from the back of

the printhead.

Figure 3-4 Disconnecting the Printhead Cable

Replacement:

1. Connect the printhead cables to the new printhead.

2. Position the printhead on the printhead carrier assembly and

tighten the printhead screw.

3. Ensure that the printhead cable is not pinched and that the

printhead is clean.

Ovation2 31

Page 40

Maintenance

3.4 Printhead Replacement (300 DPI)

Removal:

1. Turn off the printer.

2. Unlatch the printhead

carrier assembly,

Loosen the printhead

screw until it is free

from the printhead.

Carefully remove the

printhead from the

printhead carrier

assembly.

3. Remove the printhead

cables from the back of

the printhead.

Figure 3-5 Disconnecting the Printhead Cable

Replacement:

1. Connect the printhead cables to the new printhead.

2. Position the printhead on the printhead carrier assembly and

tighten the printhead screw.

3. Ensure that the printhead cable is not pinched and that the

Printhead is clean.

32 Ovation2

Page 41

Maintenance

Ovation2 33

Page 42

♦ Troubleshooting

4.0 Introduction

Occasionally situations occur that require some troubleshooting skills.

Possible problem situations and potential solutions are listed in this

section. While not every situation is addressed, you may find some of

these tips helpful. After the correction action is taken press the feed button

to clear the alarm. Contact a qualified service technician for problems that

persist or are not covered in this section.

Unacceptable print quality:

• Dirty printhead. Clean the printhead, (see Section 3.1).

• The printhead temperature is too high. Use the software

control to adjust the burn time or heat setting or adjust the

darkness POT located on the back of the printer.

• The incorrect ribbon/paper combination is being used, check

the ribbon type being used.

The Printer does not print or prints several labels at once:

• The labels are incorrectly loaded, see the loading instructions

on the inside cover of the printer, or Section 1.6.

• The media sensor or media sensor circuitry may be defective,

call for service.

Ovation2 34

Page 43

Troubleshooting

The ribbon does not advance

(The printer advances paper but ribbon does not advance).

• The ribbon is installed incorrectly. Make sure that the dull

side (side with ink) is facing the paper.

• A bad ribbon/paper combination is resulting in an insufficient

amount of friction between paper and ribbon. Ensure that the

correct type of ribbon is being used.

Skips every other label

(Print quality is good but skips every other label).

• The label is formatted too close to the top edge of the form.

Leave white space equal to 8-dot rows at the top of the label,

approximately .02" (.5mm).

• The media sensor or media sensor circuitry may be defective,

call for service.

Unable to print in rotation 4

• The characters are formatted outside the dimensions of the

label. Check that the row/column values provide enough room

for the height of the characters or bar code to be printed.

Prints light on the right side of the label

• The media width adjustment thumbwheel is set for a narrower

media width than the actual media being used, (see Section

1.9).

• The printhead is adjusted for thick media or cardstock.

• The printhead is not properly aligned, call for service.

• The printhead is not locked down.

Ovation2 35

Page 44

Troubleshooting

Printer fails to turn on

• A fuse may be blown, call for service.

• Faulty AC cord.

• A bad power switch may exist on the printer, call for service.

• A faulty AC wall outlet.

Label advances 1-2 inches before a fault indication

• The ribbon is installed incorrectly. Make sure that the dull

side (side with ink) is facing the paper.

• A bad ribbon/paper combination is resulting in an insufficient

amount of friction between paper and ribbon. Ensure that the

correct type of ribbon is being used.

Label advances 12 inches before a fault indication

• The media sensor or media sensor circuitry may be defective,

call for service.

The labels start to print on an angle and the top-of-form is not

able to be sensed, (improper tracking of media) commonly

seen when switching between various widths of stock.

• The media is not loaded properly, see Section 1.6. When

loading media be certain that the media hub and media guide

are against the media.

36 Ovation2

Page 45

Troubleshooting

Ovation2 37

Page 46

Page 47

Appendix A

ASCII Control Code Chart

Char Dec Hex Char Dec Hex Char Dec Hex Char Dec Hex

NUL 0 00 32 20 @ 64 40 ` 96 60

SOH 1 01 ! 33 21 A 65 41 a 97 61

STX 2 02 Ò 34 22 B 66 42 b 98 62

EXT 3 03 # 35 23 C 67 43 c 99 63

EOT 4 04 $ 36 24 D 68 44 d 100 64

ENQ 5 05 % 37 25 E 69 45 e 101 65

ACK 6 06 & 38 26 F 70 46 f 102 66

BEL 7 07 Ô 39 27 G 71 47 g 103 67

BS 8 08 ( 40 28 H 72 48 h 104 68

HT 9 09 ) 41 29 I 73 49 i 105 69

LF 10 0A * 42 2A J 74 4A j 106 6A

VT 11 0B + 43 2B K 75 4B k 107 6B

FF 12 0C , 44 2C L 76 4C l 108 6C

CR 13 0D - 45 2D M 77 4D m 109 6D

SO 14 0E . 46 2E N 78 4E n 110 6E

SI 15 0F / 47 2F O 79 4F o 111 6F

DLE 16 10 0 48 30 P 80 50 p 112 70

DC1 17 11 1 49 31 Q 81 51 q 113 71

DC2 18 12 2 50 32 R 82 52 r 114 72

DC3 19 13 3 51 33 S 83 53 s 115 73

DC4 20 14 4 52 34 T 84 54 t 116 74

NAK 21 15 5 53 35 U 85 55 u 117 75

SYN 22 16 6 54 36 V 86 56 v 118 76

ETB 23 17 7 55 37 W 87 57 w 119 77

CAN 24 18 8 56 38 X 88 58 x 120 78

EM 25 19 9 57 39 Y 89 59 y 121 79

SUB 26 1A : 58 3A Z 90 5A z 122 7A

ESC 27 1B ; 59 3B [ 91 5B { 123 7B

FS 28 1C < 60 3C \ 92 5C | 124 7C

GS 29 1D = 61 3D ] 93 5D } 125 7D

RS 30 1E > 62 3E ^ 94 5E ~ 126 7E

US 31 1F ? 63 3F _ 95 5F 127 7F

Note: For the software handshake XON/XOFF commands:

XON=(DC1) XOFF =(DC3)

Ovation2 A-1

Page 48

ASCII Control Code Chart

Char Dec Hex Char Dec Hex Char Dec Hex Char Dec Hex

Ç 128 80 á 160 A0 192 C0 Ó 224 E0

ü 129 81 í 161 A1 193 C1 ß 225 E1

é 130 82 ó 162 A2 194 C2 Ô 226 E2

â 131 83 ú 163 A3 195 C3 Ò 227 E3

ä 132 84 ñ 164 A4 196 C4 õ 228 E4

à 133 85 Ñ 165 A5 197 C5 Õ 229 E5

å 134 86 ª 166 A6 ã 198 C6 µ 230 E6

ç 135 87 ° 167 A7 Ã 199 C7 þ 231 E7

ê 136 88 ¿ 168 A8 200 C8 Þ 232 E8

ë 137 89 ® 169 A9 201 C9 Ú 233 E9

è 138 8A 170 AA 202 CA Û 234 EA

ï 139 8B 1/2 171 AB 203 CB Ù 235 EB

î 140 8C 1/4 172 AC 204 CC ý 236 EC

ì 141 8D ¡ 173 AD 205 CD Ý 237 ED

Ä 142 8E 174 AE 206 CE 238 EE

Å 143 8F ¯ 175 AF 207 CF 239 EF

É 144 90 176 B0 ð 208 D0 240 F0

æ 145 91 177 B1 Ð 209 D1 ± 241 F1

Æ 146 92 ² 178 B2 Ê 210 D2 242 F2

ô 147 93 ³ 179 B3 Ë 211 D3 3/4 243 F3

ö 148 94 ´ 180 B4 È 212 D4 244 F4

ò 149 95 Á 181 B5 213 D5 245 F5

û 150 96 Â 182 B6 Í 214 D6 ÷ 246 F6

ù 151 97 À 183 B7 Î 215 D7 ¸ 247 F7

ÿ 152 98 © 184 B8 Ï 216 D8 º 248 F8

Ö 153 99 ¹ 185 B9 217 D9 ¨ 249 F9

Ü 154 9A 186 BA 218 DA · 250 FA

ø 155 9B » 187 BB 219 DB 251 FB

£ 156 9C 188 BC 220 DC 252 FC

Ø 157 9D ¢ 189 BD 221 DD 253 FD

x 158 9E ¥ 190 BE Ì 222 DE 254 FE

ƒ 159 9F 191 BF 223 DF 255 FF

A-2 Ovation2

Page 49

Appendix B

Printer Specifications

Mechanical

Width 8.8" (22.35 cm)

Depth 10.1" (25.65 cm)

Height 6.2" (15.75 cm)

Weight 7 lbs. (3.2 kg)

Operating Temperature

40° F to 100° F (4° C to 38° C)

Printer Specifications

Print Type Direct Thermal

Print Speed 1, 1.5, and 2" per second

Resolution 203 dpi (8 dots/mm)

300 dpi (11.8 dots/mm)

Tear Bar Tear up

DRAM Memory 512 kb

EPROM Memory 512 kb

Ovation2 B-1

Page 50

Printer Specifications

Media/Ribbon

Media Types Roll-Fed, Die-Cut, Continuous, Fan-Fold

Max. Media Width 4.65" (118 mm)

Max. Print Width 4.1" (104 mm)

Min. Print Width 1" (25 mm)

Max. Print Length 12" (305 mm) with standard RAM

Min. Print Length .375" (.95 cm)

.5" (1.27 cm) w/ Present Sensor

Media Thickness .0025" - .01" (.0635 mm - .254 mm)

Supply Roll Capacity 4" O.D. on 1" core

Max. Ribbon Width

4.3" (109mm)

Optional Ribbon Matched to media; approx. 361’ (110m)

long 1.5" O.D. on .5" core

Communications

Interface RS-232 (DB-9), and Centronics Parallel

Baud Speed 1200 to 19200 bps

Handshaking Xon/Off, CTS, DTR

Parity Even, Odd, or None

Stop Bits 1 or 2

Data Bits 7 or 8

Electrical

External Power Supply Nominal 115 or 230 VAC IN/ 19 VAC

OUT

B-2 Ovation2

Page 51

Printer Specifications

Fonts

10 Resident Styles

Resident Fonts Expandable to 8x

Reverse Image

Rotated 0, 90, 180, 270 degrees

Available Bar Codes

Code 39, Ext Code 39, Code 93, Ext Code 93, Code 128 UCC, Code

128

A, B & C, Codabar, Interleaved 2 of 5, UPC-A, UPC-E, UPC Ship C

Code, EAN-13, EAN-8, EAN 128, POSTNET, MaxiCode, PDF417

Options

Present Sensor

FLASH Memory Cartridges

External Cutter

Thermal Transfer

DRAM Memory, (Expandable to 1MB)

Wall Mount

External Battery Pack

Time/Date

External Media Supply Stand

PC Batch Software

Ovation2 B-3

Page 52

Printer Specifications

B-4 Ovation2

Page 53

Appendix C

Available Fonts and Bar Codes

All character fonts and bar codes available with the printer are

described in this section. Each font and bar code has a name

associated with it for use in programming. Human-readable fonts

have numeric names while bar code fonts have alpha names.

Uppercase alpha names will print bar codes with human readable

interpretations. Lowercase alpha names will print bar codes only.

Fonts

Fonts 0 through 8 use the slash zero (Ø) conventions for

distinguishing between the zero and the alphabetic O. These fonts are

non-proportional (monospaced) fonts; all of the characters take up the

same amount of space when printed. The sizes of these fonts are

shown in Table B-2.

The Triumvirate font number 9 is a proportional font; each character

will take up a different amount of space when printed.

Font Valid ASCII Characters

0 32-127

1 32-168, 171, 172, 225

2 32-168, 171, 172, 225

3 32, 35-38, 40-58, 65-90, 128, 142-144, 146, 153, 154,

156, 157, 165, 168, 225

4 32, 35-38, 40-58, 65-90, 128, 142-144, 146, 153, 154,

156, 157, 165, 168, 225

5 32, 35-38, 40-58, 65-90, 128, 142-144, 146, 153, 154,

156, 157, 165, 168, 225

6 32, 35-38, 40-58, 65-90, 128, 142-144, 146, 153, 154,

156, 157, 165, 168, 225

7 32-126

8 32, 48-57, 60, 62, 67, 69, 78, 83, 84, 88, 90

9 32-126, 128-169, 171-173, 181-184, 189, 190, 198, 199, 208-216,

222, 224-237, 241, 243, 246-250

Table B-1 Valid Human-Readable Font ASCII Characters

Ovation2 C-1

Page 54

Available Fonts and Bar Codes

Table B-2 lists the font sizes. The numbers indicate the number of dots.

FONT HEIGHT WIDTH SPACING

Font 0 7 5 1

Font 1 13 7 2

Font 2 18 10 2

Font 3 27 14 2

Font 4 36 18 3

Font 5 52 18 3

Font 6 64 32 4

Font 7 32 15 5

Font 8 28 15 5

Table B-2 Font Sizes

Font 0 96-character

alphanumeric, upper

and lower case.

Font 2 138-character

alphanumeric, upper and

lower case.

Font 1 145-character upper and

lower case alphanumeric

w/ descenders and

ascenders.

Font 3 62-character

alphanumeric, uppercase.

C-2 Ovation2

Page 55

Available Fonts and Bar Codes

Font 4 62-character

alphanumeric, uppercase.

Font 5 62-character

alphanumeric, uppercase.

Font 6 62-character alphanumeric, uppercase.

Ovation2 C-3

Page 56

Available Fonts and Bar Codes

Font 7 OCR-A, size I. Font 8 OCR-B, size III.

Font 9 Internal Triumvirate font.

Point sizes are selected by the number in the bar code height.

Larger point sizes can be obtained by increasing the height and

width multipliers (see the Programmer's Manual for more

information).

C-4 Ovation2

Page 57

Available Fonts and Bar Codes

Bar Codes

Font Length Cksum Valid ASCII Characters Bar widths

A Varies No 32, 36, 37, 42, 43, 45-57, 65-90 2:1 - 3:1

B 11 Yes 48-57 Numeric only

Option V used in the

6th & 7th position

C 6 Yes 48-57 Numeric only 2:1 - 4:1

D Varies No 48-57 Numeric only 2:1 - 3:1

E Varies M-103 32-127 2:1 - 4:1

F 12 Yes 48-57 Numeric only

Option V used in the

7th & 8th position

G 7 Yes 48-57 Numeric only 2:1 - 4:1

H Varies M-43 32, 36-39, 42, 43, 45-57, 65-90 2:1 - 3:1

I Varies No 36, 43, 45-58, 65-68 2:1 - 3:1

J Varies M-10 48-57 Numeric only 2:1 - 3:1

K Up to14M-10 48-57 Numeric only

Option + is Last Character

for Second M-11 Checksum

L 13 M-10 48-57 Numeric only 2:1 - 3:1

M 2 Yes 48-57 Numeric only 2:1 - 4:1

N 5 Yes 48-57 Numeric only 2:1 - 4:1

O Varies No 0 - 127 ASCII characters 2:1 - 4:1

p Varies Yes 48-57 Numeric only Same as fonts

Q 19 Yes 48-57 Numeric only 2:1 - 4:1

R 18 Yes 48-57 Numeric only 2:1 - 4:1

S 34 + Yes 48-57 Numeric only 2:1 - 4:1

T Varies Yes 0 - 127 ASCII characters 2:1 - 4:1

u 84 Yes Alpha numeric N/A

v 1 No A, B, C, D Same as fonts

z Varies Yes All Any Ratio

2:1 - 4:1

2:1 - 4:1

2:1 - 3:1

Table B-3 Bar Code Characteristics

Uppercase bar code identifiers (I.D's) have corresponding lowercase

I.D's that when selected suppress printing of associated humanreadable text.

Ovation2 C-5

Page 58

Available Fonts and Bar Codes

Bar Code A Code 3 of 9 Bar Code B UPC-A

Bar Code C UPC-E Bar Code D Interleaved 2 of 5

Bar Code E Code 128 Bar Code F EAN-13

Bar Code G EAN-8 Bar Code H Health Industry Bar

Code (HBIC)

C-6 Ovation2

Page 59

Available Fonts and Bar Codes

Bar Code I Codeabar Bar Code J Interleaved 2 of 5

w/modulo 10

checksum

Bar Code K Plessey Bar Code L Interleaved 2 of 5

w/modulo 10

checksum and

shipping bearer bars

Bar Code M 2 Digit UPC

addendum

Bar Code N 5 Digit UPC

addendum

Bar Code O Code 93 Bar Code p Postnet

Ovation2 C-7

Page 60

Available Fonts and Bar Codes

Bar Code Q UCC/EAN Code

128

Bar Code S UCC/EAN Code

128 Random

Weight

Bar Code R UCC/EAN Code

128 KMART NON

EDI

Bar Code T Telepen

Bar Code u UPS MaxiCode Bar Code v FIM

Bar Code z PDF-417

C-8 Ovation2

Page 61

Appendix D

Error Codes

The error codes that may be transmitted by the printer are described here.

Lowercase "v"

There is an input buffer overflow situation.

Uppercase "R"

This code is sent every time the printer is turned on. It signals that

there was a hardware reset.

Uppercase "T"

This code signals that there was a software reset. A software reset

results from sending the <SOH># command sequence to the printer or

by doing a front panel reset.

Ovation2 D-1

Page 62

Error Codes

D-2 Ovation2

Page 63

Appendix E

Warranty Information

Datamax

Limited Warranty Statement

Ovation2 Label Printer

Printer

Datamax Corporation warrants to Purchaser that under normal use

and service, the Ovation2 Label Printer purchased hereunder shall

be free from defects in material and workmanship for a period of one

year, (365 days), from the date of shipment by Datamax Corporation.

Expendable and/or consumable items or parts such as lamps, fuses,

labels and ribbons are not covered under this warranty. This warranty

does not cover equipment or parts which have been misused, altered,

neglected, handled carelessly, or used for purposes other than those

for which they were manufactured. This warranty also does not cover

loss, damages resulting from accident, or damages resulting from

unauthorized service.

Ovation2 E-1

Page 64

Warranty Information

Thermal Printhead

This warranty is limited to a period of one year, (365 days), or

1,000,000 linear inches of use, whichever comes first, for the

Ovation2 Label Printer thermal printhead. This one year, (365 day),

warranty is valid only if a Datamax-approved thermal or thermal

transfer label media is used, as defined in the then current Datamax

list of approved thermal/thermal transfer media, a copy of which is

available from Datamax. Failure to use Datamax-approved media is

justification for invalidation of this thermal printhead warranty. This

warranty does not cover printheads which have been misused, altered,

neglected, handled carelessly, or damaged due to improper cleaning or

unauthorized repairs.

Warranty Service Procedures

If a defect should occur during the warranty period, the defective unit

shall be returned, freight and insurance prepaid, in the original

shipping containers, to Datamax at: 4724 Parkway Commerce Blvd.,

Orlando, Florida 32808. A Return Material Authorization (RMA)

number must be issued before the product can be returned. To open

an RMA please call Datamax Customer Service Support Department

at (407) 523-5540. Please include your RMA number on the outside

of the box and on the shipping document. Include a contact name,

action desired, a detailed description of the problem(s), and examples

when possible with the defective unit. Datamax shall not be

responsible for any loss or damages incurred in shipping. Any

warranty work to be performed by Datamax shall be subject to

Datamax’s confirmation that such product meets Datamax's warranty.

In the event of a defect covered by its warranty, Datamax will return

the repaired or replaced product to the Purchaser at Datamax's cost.

With respect to a defect in Hardware covered by the warranty, the

warranty shall continue in effect until the end of the original warranty

period, or for sixty (60 days) after the repair or replacement,

whichever is later.

E-2 Ovation2

Page 65

Warranty Information

General Warranty Provisions

Datamax makes no warranty as to the design, capability, capacity or

suitability of any of its hardware, supplies, or software.

Software is licensed on an 'as is' basis without warranty.

Except and to the extent expressly provided herein, and in lieu of all

other warranties, there are no warranties, expressed or implied,

including, but not limited to any warranties of merchantability or

fitness for a particular purpose.

Purchaser shall be solely responsible for the selection, use, efficiency

and suitability of Datamax's products.

Limitation of Liability

In no event shall Datamax be liable for any indirect, special, or

consequential damages or lost profits arising out of or relating to

Datamax's products, or the performance or nonperformance thereof,

even if Datamax has been advised of the possibility thereof.

Datamax's liability, if any, to its purchaser or to any customer(s) of

its purchaser shall in no event exceed the total amount paid to

Datamax by the initial purchaser of the defective product.

In the event any implied warranties (including, but not limited to, the

implied warranties of merchantability and fitness for a particular

purpose) are found to exist, such warranties are limited in duration to

the period of the warranties set forth above.

Some States do not permit the exclusion of incidental or consequential

damages, and in those States the foregoing limitations may not apply.

The warranties here give you specific legal rights, and you may have

other legal rights which vary from State to State.

Ovation2 E-3

Page 66

Warranty Information

E-4 Ovation2

Loading...

Loading...