Oval TF1015-P11G-11 A, TF1050-A12G-11 A, TF1020-P11G-11 A, TF1025-A12G-11 A, TF1040-A12G-11 A Instructions Manual

MASS FLOW MONITOR

Ins. No.

S-193-11-E

MODEL:TF10□□-

P11

G- 11□A□

A12

TF1025-A12G-11□A□

TF1015-P11G-11□A□

TF1020-P11G-11□A□

Every OVAL

control.

In order to maintain its design performance throughout its life, this manual offers the operator the necessary

installation, operation and maintenance information.

Be well familiar with these instructions before you place the product in service and keep this manual at the

field location for ready reference.

Mass Flow Monitor

is fabricated and shipped from our factory under stringent quality

TF1040-A12G-11□A□

TF1050-A12G-11□A□

1

S-193-11-E

CONTENTS

1. BEFORE YOU BIGIN ............................. 3

1.1 Confirming the Nameplate ......................... 3

1.2 Transportation Considerations ................... 3

1.3 Storage Considerations .............................. 3

2. OPERATING CONDITIONS ...................4

3. GENERAL ..............................................

3.1 Features ...................................................... 4

4. COMPONENT NAMES AND

FUNCTIONS .......................................... 5

4.1 Part Names ................................................. 5

4.2 Individual Functions ................................... 5

5. INSTALLATION ...................................... 6

5.1 Installation Location .................................... 6

5.2 Physical Orientation ................................... 6

5.3 How to Change Display Orientation ........... 6

5.4 Conditions Required for Metered Fluid ...... 8

5.5 Tubing Guidelines ....................................... 8

5.6 Maximum Service Flowrate ........................ 9

7. OPERATION ........................................ 14

8. TRANSMITTER DISPLAY FUNCTIONS

AND RECONFIGURATION .................. 15

8.1 Viewing the Flow Variables ........................15

8.2 Parameter Display .....................................16

4

8.3 Default Parameter Settings .......................18

8.4 Parameter Reconfiguration .......................19

8.5 Alarm Features .........................................20

8.6 Dummy Pulse Output ................................24

8.7 Analog Output Trim ...................................25

8.7.1 Analog Trim (4mA) ....................................... 25

8.7.2 Analog Trim (20mA) ..................................... 26

8.8 Error Messages .........................................27

9. GENERAL SPECIFICATIONS ............. 28

10. APPLICABLE STANDARDS ..............28

11. PRODUCT CODE EXPLANATION .... 29

12. OUTLINE DIMENSIONS ....................30

6. WIRING CONNECTIONS ..................... 10

6.1 Wiring Specifications .................................10

6.2 Wiring Diagram ..........................................10

6.3 Cable Specifications .................................14

CONVENTIONS

Shown in this manual are the signal words NOTE, CAUTION and WARNING, as

described in the examples below:

NOTE: Notes are separated from the general text to bring the user's attention

to important information.

CAUTION: Caution statements signal the user about hazards or unsafe practices

which could result in minor personal injury or product or property

damage.

WARNING: Warning statements signal the user about hazards or unsafe practices

which could result in severe personal injury or death.

2

S-193-11-E

1. BEFORE YOU BIGIN

Every OVAL product is thoroughly inspected and tested before it leaves the factory. When received, it should

be thoroughly inspected for indication of rough handling during transit. Necessary handling precautions are

described in this section; read the instructions carefully.

As for other information, find the respective sections from "CONTENSTS" on page 2.

For any inquiries, contact your nearest OVAL designated sales office.

CAUTION:

1.1 Confirming the Nameplate

Ev e r y O VAL m o n i tor is carefull y a s s e m b l e d a n d

accurately adjusted to first-class condition. Product

code number and ratings appear on the nameplate. By

referring to the general specifications in Section 9 and

product code explanation in Section 11, make sure

that the product you received is fully in compliance

with your order.

When you make inquiries, include the product name, model number, stock

number, ratings and other pertinent information.

Nameplate

(ratings shown)

1.2 Transportation Considerations

(1) It is desirable that the monitor be transported to the installation site in the shipping container used for

transit from the factory.

(2) During transportation, exercise care to avoid impact shock and rainwater.

1.3 Storage Considerations

Storing your mass flow monitor for long periods of time upon receipt before installation can result in

un exp ecte d and undes irab le conditions . Whe n long -term storage is anti cipa ted, take th e following

precautions:

(1) The monitor can best be stored in the shipping container used for transit from the factory.

(2) Select the storage place that meets the following requirements:

★ free from rain and water

★ free from vibration and impact shocks

★ with least temperature and humidity variation (around 25°C and 65% R.H).

(3) A monitor that has once been placed in service for any length of time should be washed clean to remove

residue of metered material completely from its main body, joint, conduit, and outer case before storage.

Especially, purge the inner wall of flow path with clean air or nitrogen gas, and then protect the flow inlet

and flow outlet against entry of dust inside.

CAUTION:

1. At cleansing, do not use solvents, such as thinner and alcohol.

2. Never attempt to cleanse the interior flow path with detergent.

3

S-193-11-E

2. OPERATING CONDITIONS

The monitor operating conditions are stated on the specification label, Section 5 "INSTALLATION" and Section

9 "GENERAL SPECIFICATIONS." Read carefully before initiating operation.

CAUTION:

This monitor is of non-explosionproof configuration; it is not serviceable in a

hazardous location.

3. GENERAL

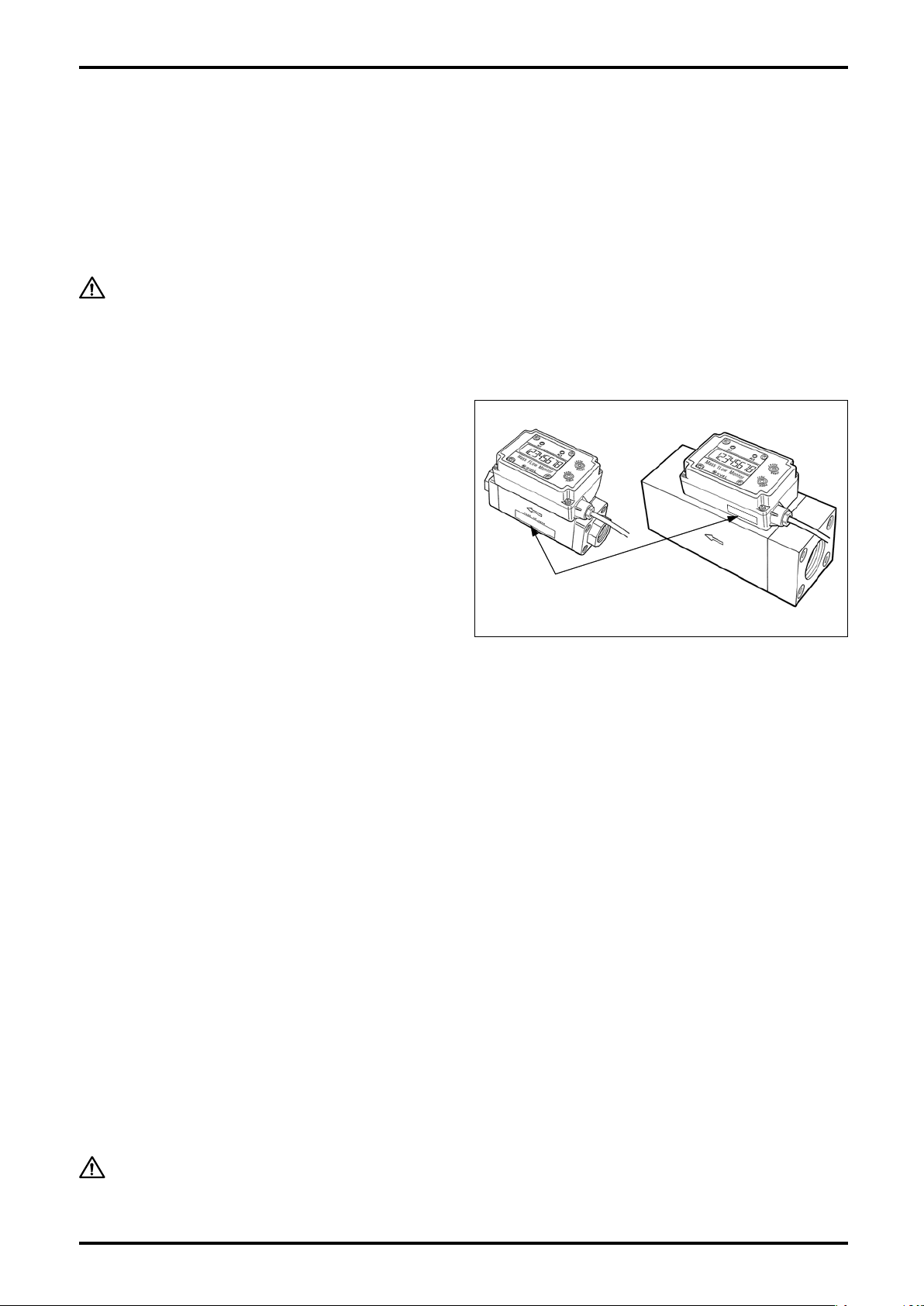

This monitor is a small, lightweight flowmeter, using a

heat-sensitive resistance element.

Of the two heat-sensitive resistance elements located

perpendicular to the fluid flow; one detects the fluid

temperature and the other, which plays the rol e of

a heater, regulates the temperature of the former to

maintain a constant temperature differential. As the

flow ing process f l uid (ma s s f low) d i s sipate s h e at

from the latter which ser ves as a heater, its supply

power increases in order to maintain the temperature

differential. This change in power consumption (voltage

and current) is used to calculate the mass flowrate.

Heat-sensitive

resistance elements

Fig. 3.1

Flow direction

3.1 Features

(1) Absence of moving parts contributes to long life.

(2) Major components are made of synthetic resin. Lightweight and compact.

(3) Sturdy metallic couplings.

(4) The display is a backlit LCD for readability in darkness.

(5) May be installed in any position. The display can be oriented in 90 deg steps to see easily.

CAUTION:

Adjusting the display orientation requires opening the upper case of transmitter.

The procedure to change orientation appears in Section 5.3 "How to Change

Display Orientation".

4

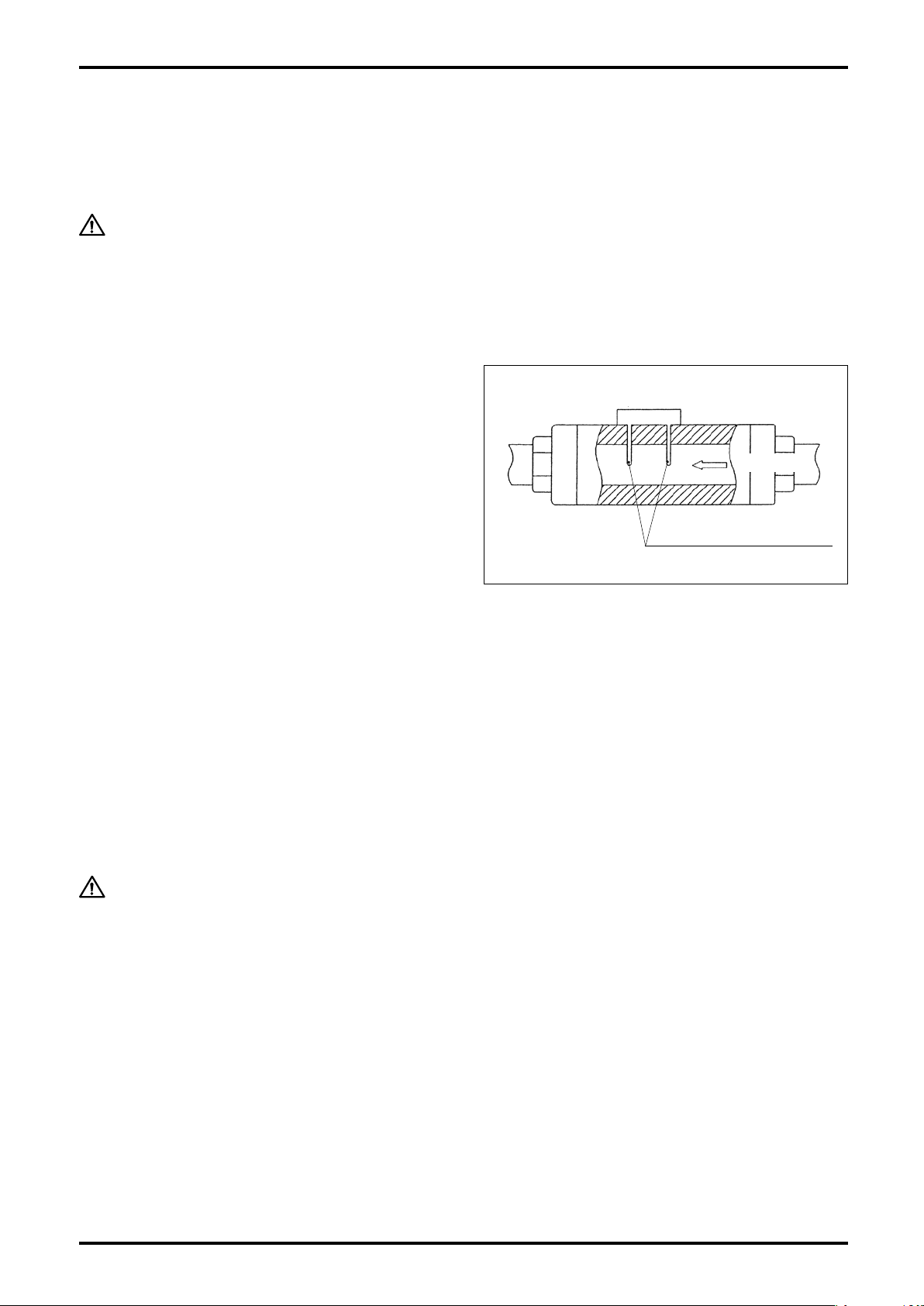

4. COMPONENT NAMES AND FUNCTIONS

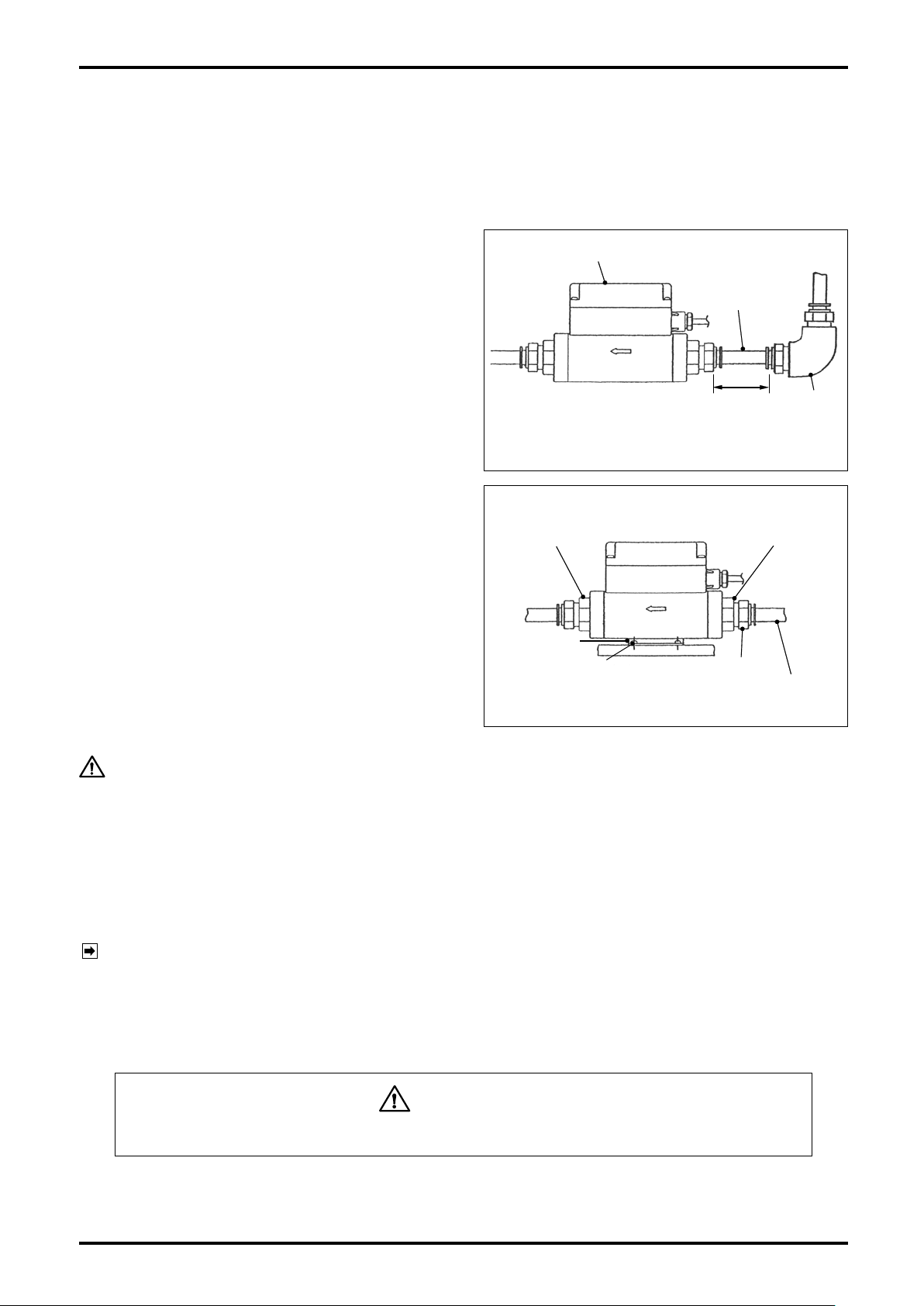

4.1 Part Names

S-193-11-E

LCD display

(Unit indicator)

③ Transmitter

② Sensor

Alarm 1 LED

Alarm 2 LED

⑤ RESET button

④ MODE button

Screw

connection

Flow direction

① Monitor body

Mounting hardware (option)

Fig. 4.1

4.2 Individual Functions

No. Part Name Description

① Body Consists of a measuring tube, straightener, and rectification mesh.

Consists of two heat-sensitive resistance elements. Power supply (voltage and current)

② Sensor

③ Transmitter

④ Mode button Changes display modes to the instant flowrate or total flow. (See Sec. 8.1 for details.)

⑤ Reset button Used to reset the "Resettable total flow" to zero.

CAUTION:

to one of the heat-resistive resistance elements changes to maintain the heat resistance at a constant level (approx. 30°C).

Changes in supply power (voltage and current) are transformed into a flowrate signal

which can be monitored on a 8-digit LCD display in terms of instant flowrate and total

flow.

Do not attempt to disassemble the meter. If the flow path is badly contaminated

or a malfunction is suspected, contact the nearest customer service network in

your area. Unauthorized disassembly will void the warranty.

5

S-193-11-E

5. INSTALLATION

5.1 Installation Location

This monitor is for indoor use.

Select an installation location that meets the requirements set forth below.

CAUTION:

(1) Free from rain and water.

(2) Least temperature variation.

(3) Free from direct exposure to the sun.

(4) Least vibration and impact shock.

(5) Easy to read the display and accessible for servicing.

(6) Process condition to keep fluid pressure not to exceed the permissible pressure of 0.7 MPa.

5.2 Physical Orientation

This monitor is NOT serviceable in a hazardous location.

There is no restriction on physical orientation of the monitor to cause loss of the accuracy.

Make sure that the actual flow direction conforms to the flow direction arrow indicated on the monitor body.

NOTE: The display orientation can be adjusted in 90 deg steps to see easily (see Section 5.3).

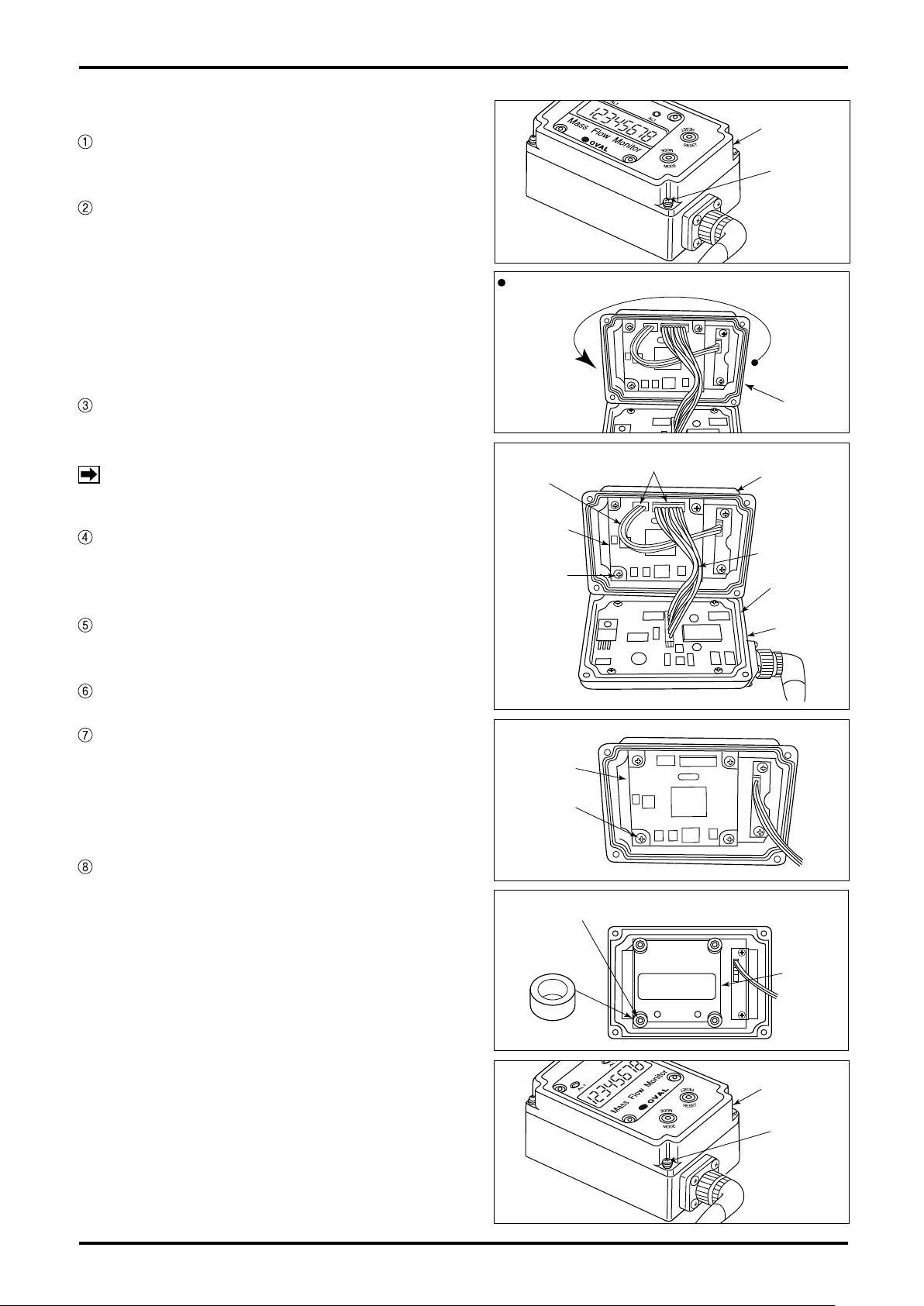

5.3 How to Change Display Orientation

This work is done with the transmitter subassembly removed. Observe the following instructions:

(1) Work in a clean environment before installing the monitor in the tubing system.

(2) Avoid working in a moist or dusty environment.

(3) Exercise care to avoid damaging the components on the electronics substrate while you work.

Required tools: Screwdrivers (for M3 and M2.6 cross recess pan head screws).

Display orientation is adjustable in 90 deg steps as shown below:

90° to the left

Standard

(at shipment from factory)

90° to the right

180°

Flow Direction

Fig. 5.1

6

S-193-11-E

How to Change Display Orientation

If power is supplied, shut it off. (Make sure

nothing appears on the LCD).

Take off four set screws (3×14) securing the

upper case to the transmitter and carefully

open the upper case (Fig. 5.2).

If a 180 deg. turn is your option, turn the upper

case the other way with lead wires intact (Fig.

5.3).

To turn 90 deg. clockwise or counterclockwise

follow the steps given below.

Take off four set screws (2.6×8) holding the

display board in place and remove the display

board (Fig. 5.5).

NOTE:

Remove four spacers (white rings) attached to

the bosses that have secured the display board

in place (Fig. 5.6).

Do not take out the screws fixing amp

board on lower case in any case.

Upper Case

Setscrew

(4 PLC'S)

Fig. 5.2

Turn the upper case 180°, with cables intact.

Upper

Fig. 5.3

Cable Connectors

3-wire

Cable

Display

Board

Setscrew

(4 PLC'S)

Case

Upper Case

10-wire Cable

O-Ring

Extract the top panel and put it onto the upper

case then in the different orientation.

Install the removed spacers over the bosses.

Place the display board in line with the top

panel and secure it with four screws (2.6×8

with tightening torque 45cN・m). (Align the

opening in the top panel with the mating LED

on the display board).

Make certain that O-ring fits in the groove

of lower case and, exercising care against

pinched cables, secure the upper case with

four screws (3×14 with tightening torque of

60cN・m). Tighten them in an alternating order

to ensure even tightening (Figs. 5.7).

Fig. 5.4

Display

Board

Setscrew

(4 PLC'S)

Fig. 5.5

Bosses (4 PLC'S)

Spacer

(4 PLC'S)

Fig. 5.6

Lower

Case

Top Panel

Fig. 5.7

Upper Case

Setscrew

(4 PLC'S)

7

S-193-11-E

5.4 Conditions Required for Metered Fluid

Due to the fact that this monitor is a thermal flowmeter, contamination buildup can cause loss of accuracy. In

an environment where entrapment of contaminants, such as dust, oil, and water, is anticipated, it is a good

practice to provide a filter, drain, separator or similar arrangement upstream of the monitor.

5.5 Tubing Guidelines

(1) Required Tubing Conditions

Since the monitor has a built-in straightener,

tubing conditions, such as differences in tube

diameter, for example, rarely present a problem.

However, if an elbow is to be located upstream

of the monitor, provide a straight tube about the

length of a nipple (3D min.). Direct installation of

an elbow may possibly cause an error of ±1 %

F.S. or so.

There is no restriction on tubing arrangements

downstream of the monitor.

(2) Installation of mounting hardware (option for

meter sizes 15mm and 20mm).

Required tool: Torque screwdriver that fits M3

cross recess pan head screws.

Do not use any other accessories except for the

furnished dedicated screws (tap-tight screws

3 x 8). See outline dimensions in Sec. 12 for

Installation location and orientation.

Torque specification: 60±3 cN・m

Meter Fitting

Meter fitting

Monitor body

Screw

Straight tube

30 min.

D: Meter I.D.

Fig. 5.8

Mtg. Hardware

Quick-connect coupling

Synthetic resin tube

Fig. 5.9

Elbow

CAUTION:

With metal tubes, tubing stresses could damage the flowmeter at its metal

fittings. Do not use the mounting hardware with metal tubes. Instead, secure

the metal tubes with U-bolts or similar fittings.

(3) Tube Connection Procedure (for meter sizes 15mm and 20mm)

1. Connecting parts are of aluminum die casting: avoid forcibly installing them and giving an impact

shock. The monitor body is of synthetic resin: avoid applying stresses on it. Torque specification: 30 ±

1 (N・m)

NOTE: Hold the hexagonal flats of aluminum die cast connection firmly with wrench, or similar tool, when

you work (Fig. 5.9).

2. Use care to safeguard the transmitter from coming in contact with tools, such as wrench.

3. Do not hold the transmitter by force while connecting it to the tubing system.

4. Providing a union before and after the flowmeter is suggested to facilitate flowmeter removal.

WARNING

Negligence of the precautions above may result in damaged components.

(4) Flushing

If foreign solids are expected to get into the tubing system, particularly on a new installation, flushing of

the tubing assembly thoroughly is essential before installing the monitor.

8

S-193-11-E

9000

8000

7000

6000

5000

4000

3000

2400

2200

2000

1000

0

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

0.240.11

Line pressure [MPa]

Max. service flowrate [L/min (normal)]

Nominal size 40 mm

Nominal size 50 mm

Nominal size 25 mm

900

800

700

600

500

400

300

200

100

0

0 0.1 0.2 0.3 0.4 0.5 06 0.7

0.04

Line pressure [MPa]

Max. service flowrate [L/min (normal)]

Nominal size 20 mm

Nominal size 15 mm

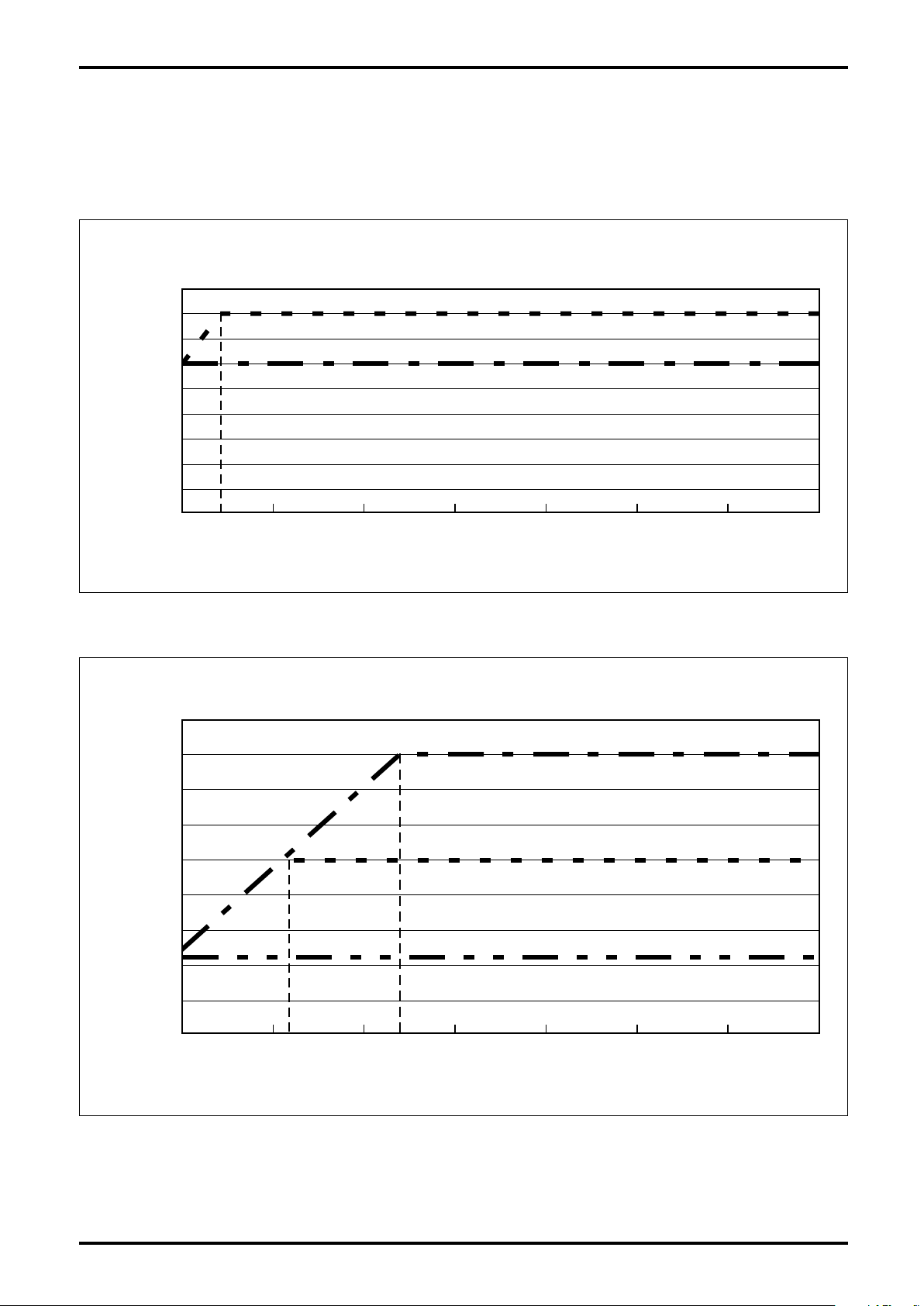

5.6 Maximum Service Flowrate

The maximum service flowrate varies with line pressure. Measurement continuation at larger service flowrates

may possibly damage the sensor. Therefore, determine the maximum service flowrate from the following

graphs and place the sensor in service within the rate so obtained.

■ Line pressure vs. maximum service flowrate (nominal sizes 15mm and 20mm)

■ Line pressure vs. maximum service flowrate (nominal sizes 25mm, 40 and 50mm)

9

S-193-11-E

1: SUP (power +)

4: Flow pulse output

3: COM (power-)

GND

Shieldedwire

ConnecttheshieldedwiretoGND.

BRN:SUP(power+)

WHT:Alarm1output

YEL:Flowpulseoutput

GRN:COM(power-)

max.

30VDC,

20mADC

max.

30VDC,

20mADC

24VDC±10%

BRN:SUP(power+)

2: Alarm 1 output

Connector terminal

1

3

4

2

WHT:Alarm1output

BLK:Flowpulseoutput

BLU:COM(power-)

max.

30VDC,

20mADC

max.

30VDC,

20mADC

24VDC±10%

●Cable (OMRON)

●Cable (OVAL)

Model: XS2F-D42□-□80-F

Note: For cables, refer to the following figures.

• When product code "Output terminal" is [2] or [4], OVAL cable is supplied.

• When product code "Output terminal" is [3] or [5], cable must be prepared by the customer.

In this case, OMRON cable is recommended.

25 cm

3m

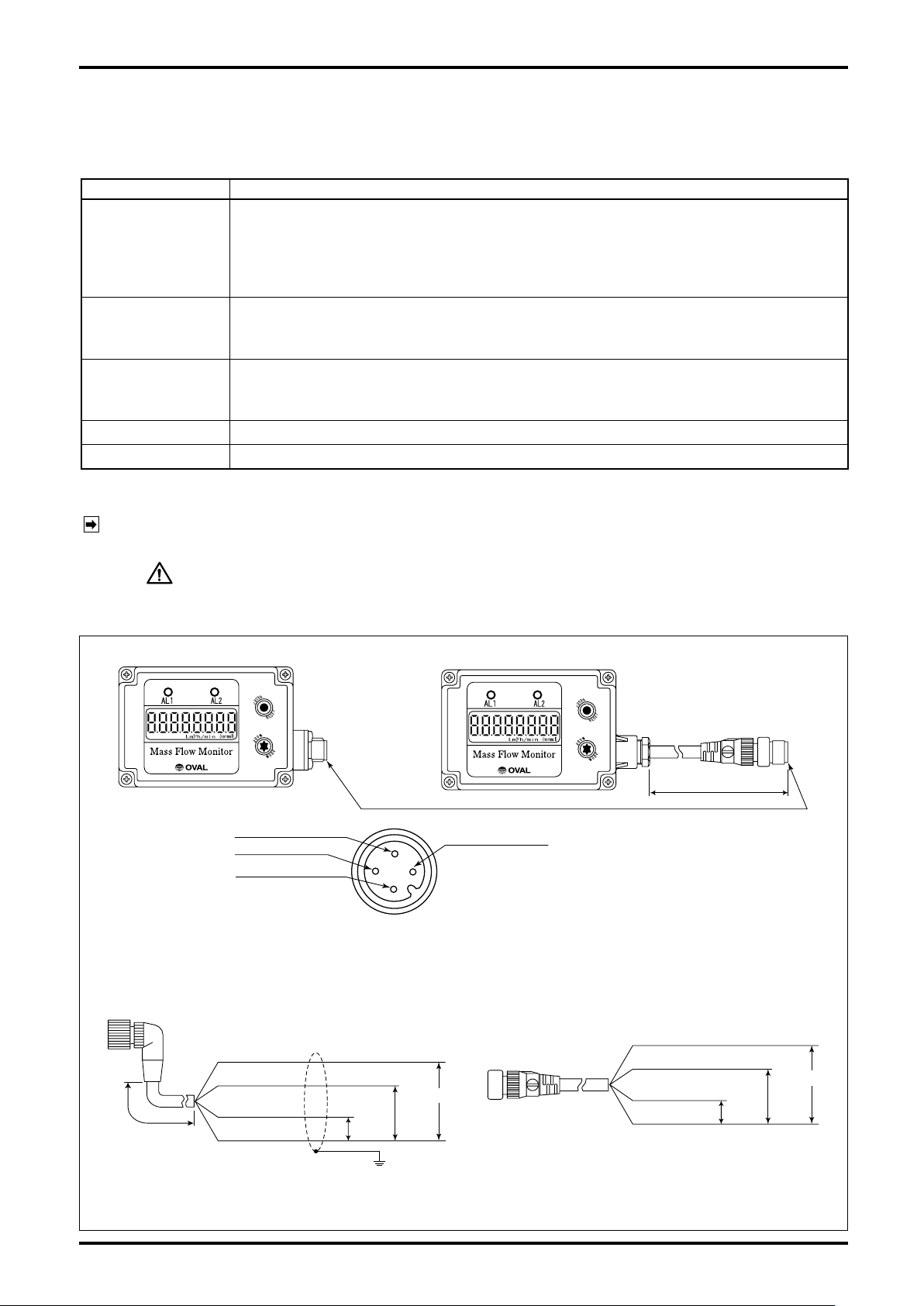

6. WIRING CONNECTIONS

6.1 Wiring Specifications

Table 6.1

Item Description

The following cables are supplied depending on the 15th digit of the product code.

Transmission cable

(Depends on your

specification).

[1]: 5-conductor shielded cable of 3 meters long (O.D.: 6.3mm) ... Fixed to this

unit.

[2][4]: 4-conductor shielded cable of 3 meters long (O.D.: 6.3mm, 4-pin connector is

provided at the one side of the cable) ... Supplied with this unit.

Open collector output

Alarm output

Allowable current: 20mADC

Max. voltage impression: 30VDC

Open collector output

Flow pulse output

Allowable current: 20mADC

Max. voltage impression: 30VDC

Flow analog output 4 to 20mA corresponding to 0 to F.S.

Supply Voltage 24VDC±10%

6.2 Wiring Diagram

NOTE: For output terminal types and styles, see "Explanation of Output Terminal Types" below NOTES in

Sec. 11.

CAUTION:

1. Use extra care about the polarities of power source.

2. Do not fail to earth ground the shielded wire to GND.

(1) Flow pulse output + single alarm point specifications (Fig. 6.1)

● Connector terminal

● Connector via interconnect cable

10

Fig. 6.1

1: SUP (power +)

4: Alarm 1 output

3: COM (power -)

GND

Shieldedwire

ConnecttheshieldedwiretoGND.

BRN:SUP(power+)

WHT:Flowanalogoutput

YEL:Alarm1output

GRN:COM(power-)

max.

30VDC,

20mADC

4to20mA

max.

500Ω

4to20mA

max.

500Ω

24VDC±10%

BRN:SUP(power+)

2: Flow analog output

Connector terminal

1

3

4

2

WHT:Flowanalogoutput

BLK:Alarm1output

BLU:COM(power-)

max.

30VDC,

20mADC

24VDC±10%

●Cable (OMRON)

●Cable (OVAL)

Model: XS2F-D42□-□80-F

Note: For cables, refer to the following figures.

• When product code "Output terminal" is [2] or [4], OVAL cable is supplied.

• When product code "Output terminal" is [3] or [5], cable must be prepared by the customer.

In this case, OMRON cable is recommended.

25 cm

3m

(2) Flow analog output + one alarm specifications (Fig. 6.2)

S-193-11-E

● Connector terminal

● Connector via interconnect cable

Fig. 6.2

11

S-193-11-E

GND

Shieldedwire

ConnecttheshieldedwiretoGND.

BRN:SUP(power+)

WHT:Flowanalogoutput

YEL:Flowpulseoutput

GRN:COM(power-)

max.

30VDC,

20mADC

4to20mA

max.

500Ω

4to20mA

max.

500Ω

24VDC±10%

BRN:SUP(power+)

Connector terminal

1

3

4

2

WHT:Flowanalogoutput

BLK:Flowpulseoutput

BLU:COM(power-)

max.

30VDC,

20mADC

24VDC±10%

Model: XS2F-D42□-□80-F

25 cm

3m

1: SUP (power +)

4: Alarm 1 output

3: COM (power -)

2: Flow analog output

●Cable (OMRON)

●Cable (OVAL)

Note: For cables, refer to the following figures.

• When product code "Output terminal" is [2] or [4], OVAL cable is supplied.

• When product code "Output terminal" is [3] or [5], cable must be prepared by the customer.

In this case, OMRON cable is recommended.

(3) Flow pulse output + flow analog output specifications (Fig. 6.3)

● Connector terminal

● Connector via interconnect cable

Fig. 6.3

12

GND

Shieldedwire

ConnecttheshieldedwiretoGND.

BRN:SUP(power+)

WHT:Alarm1output

YEL:Alarm2output

GRN:COM(power-)

max.

30VDC,

20mADC

max.

30VDC,

20mADC

24VDC±10%

BRN:SUP(power+)

Connector terminal

1

3

4

2

WHT:Alarm1output

BLK:Alarm2output

BLU:COM(power-)

max.

30VDC,

20mADC

max.

30VDC,

20mADC

24VDC±10%

Model: XS2F-D42□-□80-F

25 cm

3m

1: SUP (power +)

4: Alarm 1 output

3: COM (power -)

2: Flow analog output

●Cable (OMRON)

●Cable (OVAL)

Note: For cables, refer to the following figures.

• When product code "Output terminal" is [2] or [4], OVAL cable is supplied.

• When product code "Output terminal" is [3] or [5], cable must be prepared by the customer.

In this case, OMRON cable is recommended.

(4) Two alarm point specifications (Fig. 6.4)

S-193-11-E

● Connector terminal

● Connector via interconnect cable

Fig. 6.4

13

S-193-11-E

3m

GRY:Alarm1output

YEL:Flowpulseoutput

WHT:Alarm2output

BRN:SUP(power+)

GRN:COM(power-)

max.

30VDC,

20mADC

max.

30VDC,

20mADC

max.

30VDC,

20mADC

24VDC±10%

GND

Shieldedwire

ConnecttheshieldedwiretoGND.

GRY:Alarm1output

YEL:Flowpulseoutput

WHT:Flowanalogoutput

BRN:SUP(power+)

GRN:COM(power-)

max.

30VDC,

20mADC

max.

30VDC,

20mADC

4to20mA

max.

500Ω

24VDC±10%

GND

Shieldedwire

ConnecttheshieldedwiretoGND.

3m

(5) Flow pulse output + two alarm points specifications (Fig. 6.5)

● Direct coupled cable

Fig. 6.5

(6) Flow pulse output + flow analog output + single alarm point specifications (Fig. 6.6)

● Direct coupled cable

Fig. 6.6

CAUTION:

If "Without cable" is specified for the product, the cable shown in the wiring diagram

is not supplied with the product.

6.3 Cable Specifications

Applicable cable depends on the specifications of the 15th digit "Output Terminal" of the product code. Refer

to the following table.

15th digit of

product code

「1」 Cable coupled directly

「2」

「4」

「3」

「5」

※1 For the kind and shape of the output terminal, refer to the section "Explanation of Output Terminal".

"Output Terminal"

specifications ※1

Connector via

interconnect cable

(with cable)

Connector terminal

(with cable)

Connector via

interconnect cable

(without cable)

Connector terminal

(without cable)

Cable Specifications State at shipment from factory

[OVAL cable]

5-conductor shield cable

Length: 3 m, O.D.: 6.3 mm

[OVAL cable]

4-conductor shield cablewith connector

Length: 3 m, O.D: 6 mm

[Recommended cable]

Manufacturer: OMRON

Model: XS2F-D42□-□80-F

Name: Cabled connector socket single side connector

Length: As specified by the customer

O.D.: 6 mm

Directly coupled to the product body.

Packed together with product body.

Cable is not supplied with the product.

To be prepared by the customer. The cable shown on the left is recommended.

(Purchase the cabl e directl y from the

manufacturer.)

7. OPERATION

(1) Verify that the process fluid conditions (such as pressure and temperature) meet the ratings specified.

(2) After confirming the wiring connections, turn on power and see that the flowrate reads zero.

(3) Making sure there is no leaks at tube connections, carefully open the upstream valve.

1. Just after powering on, this equipment is ready for measurement. However, the optimum

CAUTION:

accuracy is available 30 minutes after power on.

2. To safeguard the monitor against damage, avoid sharp increase in flowrate.

14

S-193-11-E

8. TRANSMITTER DISPLAY FUNCTIONS AND RECONFIGURATION

8.1 Viewing the Flow Variables

The flow monitor can show seven flow variables, one at a time.

With each depression of the "MODE" button, the display scrolls through available variables as shown in the

diagram below. Keep on pressing the "MODE" button until the variable desired appears.

(Immediately after powerup, the display shows the most recently selected variable before power was turned

off. "X" in each box at left represents a numerical value of the variable).

Menu item Description

MODE

X

MODE

MODE

X

....................

.

....................

.

....................

.

....................

Accumulated

total flow

Instant

flowrate

(hourly)

Instant

flowrate

(per-minutes)

Resettable

total flow

Indicates the total flow accumulated until now.

(The accumulated total is not resettable to "0".)

Reads in m3 (normal).

Indicates the per-minute instant flowrate.

Reads in m3/h (normal).

Indicates the hourly instant flowrate.

Reads in L/min (normal).

Indicates the total flow that has flown since the last RESET operation. (Pressing the "RESET" button while total reset flow is

displayed sets the total flow to "0".)

Reads in m3 (normal).

X.X.X.X.X.X.X.X

Accumulated total

Press

X.X.X.X.X.

Instant. flowrate (hourly)

Press

X.X.X.X.X.X

Instant. flowrate

(per-min)

Press

X.X.X.X.X.X.

Resettable total

MODE

Press

X.X.X.X.X.X.

Yen converted accum.

total

X.X.X.X.X.

Yen converted instant.

Flowrate (hourly)

X.X.X.X.X.

Yen converted

resettable total

Press

Press

Press

X

MODE

X

MODE

X

MODE

.

....................

Accumulated

total flow in

terms of Yen

Accumulated total flow in terms of Yen which is the product of

flowrate and Yen conversion factor.

Reads in Yen. (Unit of registration is not shown.)

※1

.

....................

.

....................

.

Instant

flowrate in

terms of Yen

(hourly) ※1

Resettable

total flow in

terms of Yen

※1

Instant flowrate in terms of Yen which is the product of flowrate

and Yen conversion factor.

Reads in Yen/h.

(Only /h appears for the unit of registration.)

Resettable total flow in terms of Yen which is the product of

flowrate and Yen conversion factor.

Reads in Yen. (Unit of registration is not shown.)

Indicates the total flow that has flown since the last RESET operation. (Pressing the "RESET" button while the resettable total

flow in terms of Yen appears resets this reading to "0".)

NOTE ※1: By establishing the Yen value per unit fluid volume of 1m3 (normal) to the

Yen conversion factor, the monitor can show accumulated total, instant

flowrate, and resettable total, each in terms of Yen.

(When "0" is set to the Yen conversion factor, the accumulated total, instant

flowrate, and resettable total, each in terms of Yen, will not appear. Factoryset default Yen conversion factor is "0".)

15

S-193-11-E

8.2 Parameter Display

Alarm-related parameters are shown on the left half; remaining parameters and special functions are on the

right half of the diagram. To change parameters, scroll through menu items until the parameter you want to

change is shown before you make necessary changes.

To restore flow variables, hold the "MODE" button depressed for 5 seconds either at,

Flow variables (accum. total, instant flowrate, resettable total and accum, total, instant. flowrate, resettable total, each in terms of Yen)

MODE

Press

Press

for 5 sec.

RESET

.

ALA

, or

bdAtA

window.

Alarm menu

MODE

Press

X.X.X.X.

Alarm 1 setpoing

Press

X.X.X.X.

Alarm 1 hysteresis

Press

Alarm 1 status

Press

X.X.X.X.

Alarm 2 setpoing

Press

X.X.X.X.

Alarm 2 hysteresis

Press

Alarm 2 status

Press

X.X.X.X.

Low alarm dead zone

Press

Alarm dead duration

Press

MODE

MODE

X.X

MODE

MODE

MODE

X.X

MODE

MODE

X.X

MODE

.

X

.

X

.

.

X

.

X

.

.

X

.

.

....................

....................

....................

....................

....................

....................

....................

....................

Menu item Description

Alarm 1

setpoint

Alarm 1 setpoint.

Beyond this setpoint, an alarmed condition takes place. (During

the time of alarm dead zone, alarm output and LED indication

remain inactive, however).

Set the flowrate to activate an alarm.

Setpoint reads in L/min (normal).

Alarm 1

hysteresis

Alarm 1 hysteresis.

If flowrate fluctuation is excessive, causing frequent alarm ONOFF trips, select a larger value.

Setpoint reads in L/min (normal).

Alarm 1

status

Alarm I status setpoint.

By selecting either code of the following to the upper digit, you

can set up the type of errors to be identified.

H: High alarm L: Low alarm

By setting either code of the following, you can set up the status of open collector output in an error.

o: OFF in an error S: ON in an error

Alarm 2

setpoint

Alarm 2

hysteresis

Alarm 2

status

Low alarm

dead zone

Alarm 2 setpoint.

The functions remain the same as Alarm 1 setpoint.

Alarm 2 hysteresis.

The functions remain the same as Alarm I hysteresis.

Alarm 2 detailed status setting.

The functions remain the same as alarm 1 status.

The lower limit to activate an alarm. Below this flowrate, alarm

remains inoperative even if alarm conditions are met.

Reads in L/min (normal).

Alarm dead

duration

Delay time of identifying an alarm. Any alarm condition does

not activate an alarm at once; only after the expiration of this

duration.

Read in seconds.

Press

RESET

.

16

S-193-11-E

To view parameters of interest, hold the "MODE" button depressed for 5 seconds at the flow variables

window to show

"RESET" buttons until the parameter desired appears.

("XXX" in each box at left represents a numerical value of the variable).

Basic data menu

Press

X.X.X.X.X.X.

Press

X.X.X.X.X.

Press

X.X.

Press

X.X.

Press

Press

X.X.X.X.X.X

Press

Press

X.X.X.X.X

Press

X.X.X.X.X

Press

Press

Press

Press

ALA

window. The diagram below will lead you the rest of the way using the "MODE" and

MODE

Press

MODE

.

....................

X

Yen conversion

factor

MODE

.

....................

X

Pulse weight

MODE

.

....................

X

Pulse ON width

MODE

.

....................

X

Cutoff

MODE

.

....................

Dummy output

MODE

.

....................

Full scale flowrate

MODE

.

X.X.X.X

Damping time

MODE

....................

.

....................

Analog trim (4mA)

MODE

.

....................

Analog trim (20mA)

MODE

.

....................

Zeroing

MODE

.

X.X

Backlight setting

MODE

....................

.

....................

All figure places

illuminated

MODE

.

NOTES: 1. See Sec. 8.3 for acceptable parameter setting

for 5 sec.

2. ※1: Models not provided with an analog

range and factory set defaults.

output do not show these menu items.

Menu item Description

Yen

conversion

factor

Pulse weight Unit flowrate per single output pulse.

Pulse ON

width

Cutoff Instantaneous flowrate cutoff setpoint.

Dummy

output

Analog Full

scale flowrate

Analog

Damping time

Analog trim

(4mA)

Analog trim

(20mA)

Zeroing Adjusts the zero baseline. The product is shipped after calibration in

Backlight

setting

All figure

places

illuminated

A parameter to perform conversion to obtain Yen equivalent. Yen

equivalent represents the cost per unit flow of 1 m3 (normal) of metered process fluid.

Reads in Yen/m3 (normal).

When set to "0", Yen conversion does not take place.

Reads in L (normal).

To change the setpoint, be sure to meet the following conditions. Unless these conditions are satisfied, proper pulse output is not produced.

Max. service flowrate [L/min (normal)] / pulse weight

[L(normal)] x (pulse "ON" [msec] + 1) / 60 < 1000

Output pulse width.

Reads in msec.

Unless the same conditions as those of pulse weight are satisfied,

proper pulse output is not produced.

Any flow below this flowrate reads "0".

Reads in L/min (normal).

A 10Hz pulse output is available irrespective of the flowrate curently

in measurement. You can use this feature in verifying the connections

with other system, or for other purpose. (For the procedure of producing dummy output, see Sec. 8.6 "Dummy Pulse Output".)

Flowrate at analog output full scale (20mA).

※1

Sets damping time for analog output. (Due to inherent circuit properties, approx. 1 sec time const. exists besides software setting.)

※1

Reads in sec.

Trims analog output of 4mA.

(For details, see Sec. 8.7 "Analog Output Trim".)

※1

Trims analog output of 20mA.

(For details, see Sec. 8.7 "Analog Output Trim".)

※1

the factory. Normally, the product does not require Zero baseline adjustment.

To adjust, press ahd hold the "MODE" button for more than 5 seconds while pressing the "RESET" button in this mode.

You can select any one of four backlight activation modes.

On: Illuminated full time, EC: Illuminated full time at the half level of

illumination at On time, OF: Always unlit, SL: Illumination darkened to

half approx. 10 sec. after completing button operation.

This feature is useful in testing the illumination of LCD display and

alarm LED indicator lamps.

Illuminates all LCDs and alarm LEDs.

(Alarm output appears as usual.)

17

S-193-11-E

8.3 Default Parameter Settings

Parameters are set to the following default settings before shipment from the factory:

Top row: Parameter name

Middle row: Unit of numerical value

Bottom row: Settable range

Alarm 1 setting

L/min (normaI)

0 to 99999

Alarm 1 hysteresis

L/min (normal)

0 to 99999

Alarm 1 status

Ho, HS, Lo, LS

Alarm 2 setting

L/min (normal)

0 to 99999

Alarm 2 hysteresis

L/min (normal)

0 to 99999

Alarm 2 status

Ho, HS, Lo, LS

Low limit in alarm immunity range

L/min (normal)

0 to 99999

Alarm immune time

Seconds

0 to 99

Yen conversion factor

Yen 1m3 (normal)

0 to 999.999

Pulse weight

L (normal)

0.01 to 9999.99

Pulse width

msec

1 to 240

Cutoff ※1

L/min (normal)

0 to 99999

Analog full scale

L/min (normal)

0 to 99999

Analog Damping

sec

0 to 99

Backlight setting

On, EC, OF, SL

15mm 20mm 25mm 40mm 50mm

50 65 200 400 650

10 15 35 85 135

LS LS LS LS LS

600 800 2200 5000 8000

10 15 35 85 135

HS HS HS HS HS

10 15 35 85 135

3 3 3 3 3

2.000 2.000 2.000 2.000 2.000

0.1 0.1 1.00 1.00 1.00

5 5 5 5 3

9 14 34 84 134

600 800 2200 5000 8000

0 0 0 0 0

On On On On On

Factory default settings

Nominal size

NOTES: ※1: Cutoff set value must not be changed in other than the following cases.

(1) When output is given though the flow is stopped (※).

Set the cutoff value a little greater than the output value at that time.

(2) When you want to measure the flowrate of the area lower than the cutoff value, set the

cutoff value lower than the desired flowrate.

Under some condition, the difference at this area may be greater depending on the offset

value of the zero point. Therefore, adjust zero point while the flow is stopped (※) as

necessary.

※ The stoppage of flow refers to the status where the valve at the lower stream of this unit is

fully opened under the process condition in use and there is no leakage from the valve.

18

8.4 Parameter Reconfiguration

An example below shows the procedure to change Alarm 2 setting from 600 to 500.

For display operating procedure, see Section 8.2 "Parameter Display".

Description

600

Press

MODE

....................

for 2 sec.

[Show the alarm 2 setting.]

Hold the "MODE" button depressed for more than 2 seconds. When the screen

begins to blink, remove your finger from the button.

(Write mode becomes active and the figure in the ones place blinks.)

S-193-11-E

600

Press

600

Press

500

Press

500

MODE

RESET

MODE

....................

for 2 sec.

....................

9 times.

....................

for 2 sec.

....................

[The figure "0" in the right-most place blinks.]

Press the "MODE" switch twice to allow the digit in the hundreds place to blink.

(Pressing the "MODE" button moves the blinking digit one place to the left).

["6" in the hundreds place blinks.]

Press the "RESET" button 9 times to adjust the figure to 5.

(Pressing the "RESET" button increases the blinking figure.)

[The digit in the hundreds place changes to "5" while blinking].

Now the reading has been changed to 500.

To save this value, hold the "MODE" button depressed for more than 2 seconds.

When the screen begins to blink, remove your finger from the button. (The

setting is saved and you exit the write mode.)

If you want to exit the write mode without completing the setting, hold the

"RESET" button depressed for more than 2 seconds. When the screen begins

to blink, remove your finger from the button. (You exit the write mode without

saving any value.)

[The indicator stops blinking and stays on.]

Now the setup process is complete.

19

S-193-11-E

8.5 Alarm Features

In this monitor, settings of alarms 1 and 2 are adjustable to any levels to help you keep on monitoring the

process flow. And by setting up two parameters - "lower limit in alarm immunity range" and "alarm immunity

time," precise alarm settings can be established against leaks. Follow the instructions given in this manual

when you set up alarm set points. Examples of alarm setup are also given in this section.

CAUTION:

(1) Setting up the high alarm

Parameters related to the high alarm come in the following five, (1) through (5). Set each of them by

referring to the description given for individual parameters.

① Alarm setpoint

Set the flowrate [(L/min (normal)) to be at the upper alarm.

② Alarm hysteresis

If alarm features are not desired, set the alarm set points to "0" (alarm status

either at high alarm or lower alarm).

Alarm is cancelled when the following conditions are met. Select the appropriate alarm hysteresis [L/

min (normal)].

Flowrate < Alarm setpoint - Alarm hysteresis

If variation in flowrate is excessive, resulting in frequent alarm ON-OFF cycling, set a little larger value.

③ Alarm status (higher digit)

Setting is to be made on the high alarm: set "H" to the higher digit.

④ Alarm status (lower digit)

Set up the output status to the lower digit in an alarmed condition.

Selecting "S" results in an "ON" output (Lo impedance) in an alarmed condition.

Setting "o" results in an "OFF" (Hi impedance) in an alarmed condition.

⑤ Alarm immunity time

Set the delay time [in sec] from the moment the flowrate exceeds the alarm set value to the moment

an alarm is activated. Remember that setting of this parameter is common to both alarms 1 and 2.

20

S-193-11-E

Stays off

Alarm 2 setpoint

Flowrate →

[L/min(normal)]

Alarm 2 hysteresis

Instant flowrate

OFF

Comes on

ON

Stays off

OFF

Comes on

ON

Alarm 2 LED

Alarm 2 output

Time

→

Withinalarmimmunitytime

→

Beyondalarmimmunitytime

→

Stays off

Alarm 2 setpoint

Flowrate →

[L/min(normal)]

Instant flowrate

OFF

Comes on

ON

Stays off

OFF

Comes on

ON

Alarm 2 LED

Alarm 2 output

Time

→

Alarm 2 hysteresis

■ Example of high alarm setup

Given below is an example of setting up the alarm 2 for high alarm.

● Setup example 1 (where "alarm hysteresis" and "alarm immunity time" are involved.)

・Alarm conditions: When the following condition continues beyond the alarm immunity time.

Instant flowrate ≧ Alarm setpoint

・Alarm cancel conditions: Instant flowrate < Alarm setpoint - Alarm hysteresis

Parameter Name Setting

Alarm 2 setpoint

[L/min (normal)]

Alarm 2 hysteresis

[L/min (normal)]

Alarm 2 status

(higher digit)

Alarm 2 status

(lower digit)

Alarm immunity

time

[sec]

NOTES: If alarm 2 status (lower digit) is set to "o", the "ON" and "OFF" of alarm 2 output become the

opposite states shown in the above figure.

● Setup example 2 (where "alarm hysteresis" exists and "alarm immunity time" is set to "0".)

・Alarm conditions : Instant flowrate ≧ Alarm setpoint

・Alarm cancel conditions : Instant flowrate < Alarm setpoint - Alarm hysteresis

550

20

H

S

3

Parameter Name Setting

Alarm 2 setpoint

[L/min (normal)]

Alarm 2 hysteresis

[L/min (normal)]

Alarm 2 status

(higher digit)

Alarm 2 status

(lower digit)

550

20

H

S

Alarm immunity

time

0

[sec]

NOTES: When alarm 2 status (lower digit) is set to "o", the "ON" and "OFF" of alarm 2 output become

the opposite states shown in the above figure.

21

S-193-11-E

(2) Setting up the low alarm

Parameters related to the low alarm come in the following six. Set each of them by referring to the

description given for individual parameters.

CAUTION:

① Alarm setpoint

Set the flowrate [(L/min (normal)) to be at the low alarm.

② Alarm hysteresis

Alarm is cancelled when the following condition is met. Select the appropriate alarm hysteresis [L/min

(normal)].

Flowrate > Alarm setpoint + Alarm hysteresis

If variation in flowrate is excessive, resulting in frequent alarm ON - OFF cycling, set a little larger

value.

③ Alarm status (higher digit)

Setting is to be made on the low alarm: set "L" to the higher digit.

Remember that at "0" flowrate, the alarm is disabled.

④ Alarm status (lower digit)

Set up the output status to the lower digit in an alarmed condition.

Selecting "S" results in an "ON" output (Lo impedance) in an alarmed condition.

Setting "o" results in an "OFF" (Hi impedance) in an alarmed condition.

⑤ Lower limit in the alarm immunity range

Set up the lower limit of flowrate [L/min (normal)] at which an alarm is activated.

In a line where multiple pneumatic equipment are in use, for example, certain equipment may have

leaks more or less, such as bleed type reducing valves, even when the system has been shut down.

By establishing a lower limit in the "alarm immunity range", this monitor can prevent the alarm from

being activated in a situation like this. While the following condition continues, the low alarm remains

inoperative:

Flowrate ≦ Low alarm in the alarm immunity range

Select a little larger setpoint than that at the system shutdown.

CAUTION:

Below the cutoff level [L/min (normal)], the monitor finds the flowrate

as "0". This requires setting up the lower limit in the alarm immunity

range to a value larger than the cutoff level and, at the same time,

smaller than the alarm setpoint. If a value larger than the alarm setpoint

is selected, priority is given to the lower limit in the alarm immunity

range: setting the low alarm setting then does not make any sense.

⑥ Alarm immunity time

Set the delay time (in sec) from the moment the flowrate reaches the alarm setpoint to the moment

an alarm is activated. At system shutdown, an alarm is normally not activated because the flowrate

falls below the lower limit in the alarm immunity range; at system startup, on the other hand, an alarm

remains inoperative because the flowrate exceeds the alarm setpoint. However, at the transition

from system shutoff to system startup, and vice versa, the monitor initiates an alarm momentarily. A

solution to get around this problem at system startup and at shutdown is to select a setting longer

than the duration of the alarmed condition. Remember that setting this parameter is common to both

alarms 1 and 2.

22

S-193-11-E

Stays off

Comes on

Stays off Stays off Comes on

Stays off

Alarm 1 setpoint

Lower limit of alarm

immunity range

Alarm 1 LED

Alarm 1 output

Time

→

Flowrate →

[L/min(normal)]

OFF ON OFF OFF OFFON

Comes on

ON

Alarm 1 hysteresis

Stays off

Alarm 1 setpoint

Lower limit of alarm

immunity range

Alarm 1 LED

Alarm 1 output

Flowrate →

[L/min(normal)]

OFF

Stays off

OFF

Stays off

OFF

Comes onComes on

ON

ON

Time

→

Withinalarmimmunitytime

→

Beyondalarmimmunitytime

→

Alarm 1 hysteresis

■ Example of low alarm setup

Given below is an example of setting up the low alarm for alarm 1.

● Setup example 1 (where "alarm hysteresis" and "alarm immunity duration" are involved.)

・Alarm conditions : When the following condition continues beyond the alarm immunity time.

Lower limit of alarm immunity zone < Instant flowrate <Alarm setpoint

・Alarm cancel conditions : Instant flowrate ≦ Lower limit of alarm immunity zone

or Instant flowrate > Alarm Setpoint + Alarm hysteresis

Parameter Name Setting

Alarm 1 setpoint

[L/min (normal)]

Alarm 1 hysteresis

[L/min (normal)]

Alarm 1 status

(higher digit)

Alarm 1 status

(lower digit)

Lower limit of

alarm immunity

range

[L/min (normal)]

Alarm immunity

time

[sec]

NOTES: When alarm 1 status (lower digit) is set to "o", the "ON" and "OFF" of alarm 1 output become

the opposite states shown in the above figure.

● Setup example 2 (where "alarm hysteresis" exists and "alarm immunity duration" is set to "0".)

・Alarm conditions : Lower limit of alarm immunity zone < Instant flowrate <Alarm setpoint

・Alarm cancel conditions : Instant flowrate ≦ Lower limit of alarm immunity zone

or Instant flowrate > Alarm Setpoint + Alarm hysteresis

50

10

L

S

20

3

NOTES: When alarm 1 status (lower digit) is set to "o", the "ON" and "OFF" of alarm 1 output become

the opposite states shown in the above figure.

Parameter Name Setting

Alarm 1 setpoint

[L/min (normal)]

Alarm 1 hysteresis

[L/min (normal)]

Alarm 1 status

(higher digit)

Alarm 1 status

(lower digit)

50

10

L

S

Lower limit of

alarm immunity

range

20

[L/min (normal)]

Alarm immunity

time

0

[sec]

23

S-193-11-E

8.6 Dummy Pulse Output

Thanks to the dummy pulse output feature, the monitor can provide a 10Hz simulated pulse output irrespective of

actual flowmeter operation. And it counts the number of pulses so produced on the total counter. With this feature,

you can easily run a connection and performance check between this monitor and other systems coupled.

Given below is the procedure to use this output. ("X" and "Y" represent numerical values of setting.)

CAUTION:

(1) Select Dummy pulse output.

Flowrate

MODE

Press

When this feature is enabled, the monitor produces a train of dummy pulses

irrespective of actual flowrate. In applications where the flowmeter output is

used as control data, this operation should be avoided, however. Incidentally,

dummy pulse accuracy is ±1 count with respect to the indicated reading.

Description

..........................

for 5 sec.

Show the flowrate window.

..........................

Alarm menu

RESET

Press

.

..........................

Basic data menu

MODE

Press

for 5 sec.

..........................

(2) Run dummy pulse output.

for 2 sec.

.

X

.

Y

..........................

..........................

..........................

..........................

MODE

Press

RESET

Press

.X.X.X.X.

MODE

Press

.Y.Y.Y.Y.

Hold the "MODE" button depressed for 5 sec. to show the alarm menu.

Press the "RESET" button once to show the basic data menu.

Press the "MODE" button 5 times to show the dummy pulse output.

Description

Dummy pulse output window

Hold the "MODE" button depressed for 2 sec. to bring up the dummy pulse output standby mode.

[The display reads as shown at left. At this point, pulse output is not activated.]

Upon depression of the "RESET" button, a 10Hz flowrate pulse output appears.

(To stop dummy pulse output, take step (3) to terminate dummy pulse output.)

["XXXX" in the diagram increases by one count with each pulse generation.]

To stop dummy pulse output, press the "MODE" button.

["YYYY" in the diagram shows the number of pulses produced as dummy pulses.]

(To reopen dummy pulse output, press the "RESET" button. To stop dummy

pulse output, take step (3) to terminate dummy pulse output.)

(3) Terminate the dummy pulse output

.Y.Y.Y.Y.

MODE

Press

MODE

Press

MODE

Press

Flowrate

Y

for 2 sec.

.

for 5 sec.

..........................

..........................

..........................

..........................

Dummy pulse output stopped.

Hold the "MODE" button depressed at least for more than 2 sec. to show the

dummy pulse output.

Press the "MODE" button 8 times to show the basic data menu.

Hold the "MODE" button depressed at least for more than 5 sec. to shown the

flowrate window.

24

Description

S-193-11-E

8.7 Analog Output Trim

You can trim the analog output at this window.

NOTES: 1. Output is accurately adjusted in the factory and normally requires no further adjustment.

Analog adjustment consists of 4mA trim and 20mA trim. In the 4mA trim the current (4mA) is

adjusted to 0 flow whereas the 20mA trim is adjusted to full scale flow.

2. Do not perform this adjustment on a model that has no provision of analog outputs.

8.7.1 Analog Trim (4mA)

(1) Select Analog Trim (4mA).

Description

Flowrate

MODE

Press

Alarm menu

RESET

Press

Basic data menu

MODE

Press

Analog trim (4mA)

.......................

for 5 sec.

.......................

once.

.......................

8 times.

.......................

Flowrate window

Hold the "MODE" button depressed for 5 sec. to show the alarm menu.

Press the "RESET" button once to show the basic data menu.

Press the "MODE" button 8 times to show the analog trim (4mA).

(2) Run Analog Trim (4mA).

Analog trim (4mA)

MODE

Press

Basic data menu

.......................

for 2 sec.

.......................

Analog trim (4mA) window

Press the "MODE" button for 2 sec. to show the analog trim (4mA) window [The

rightmost figure (0) begins to blink on and off..]

If analog output is deviated from 4mA, take the steps that follow. If not, take

steps necessary to terminate the analog trim (4mA) process in (3).

Set a numerical value the analog output ammeter reads. For example, if the

ammeter reads "3.990," set a value "3.990".

• The figure place of interest (blinking digit) moves to the left each time

Press

MODE

.......................

for 2 sec.

• The blinking figure increases by one each time the "RESET" switch is turned on.

Holding the "MODE" button depressed for 2 seconds, the numerical value

becomes a blinking "4.000" and the transmitter produces an analog output

adjusted based on the established numerical value. If a deviation of analog

output is still large, repeat the procedure to establish the numerical value.

(3) Terminate Analog Trim (4mA).

MODE

Press

Analog trim (4mA)

MODE

Press

Basic data menu

MODE

Press

Flowrate

.......................

for 2 sec.

.......................

4 times.

.......................

for 5 sec.

.......................

Analog output adjusted to 4mA is shown.

(The rightmost figure (0) blinks on and off..)

Hold the "MODE" button for depressed for 2 seconds to show the analog trim

(4mA) window. (The rightmost figure (0) stops blinking.)

Press the "MODE" button 5 times to show the basic data menu.

Hold the "MODE" button depressed for 5 seconds. The flowrate window appears.

Description

"MODE" switch is turned on.

Description

25

S-193-11-E

8.7.2 Analog Trim (20mA)

(1) Select Analog Trim (20mA).

Flowrate

MODE

Press

Alarm menu

RESET

Press

Basic data menu

MODE

Press

Analog trim (20mA)

(2) Run Analog Trim (20mA).

Analog trim (20mA)

MODE

Press

.......................

for 5 sec.

.......................

once.

.......................

8 times.

.......................

.......................

for 2 sec.

.......................

Description

Flowrate window

Hold the "MODE" button depressed for 5 sec. to show the alarm menu.

Press the "RESET" button once to show the basic data menu.

Press the "MODE" button 9 times to show the analog trim (20mA).

Description

Analog trim (20mA) window

Press the "MODE" button for 2 sec. to show the analog trim (20mA) window

[The rightmost figure (0) begins to blink on and off..]

If analog output is deviated from 20mA, take the steps that follow. If not, take

steps necessary to terminate the analog trim (20mA) process.

Set a numerical value the analog output ammeter reads. For example, if the

ammeter reads "19.90," set a value "19.90".

• The figure place of interest (blinking digit) moves to the left each time the

Press

MODE

.......................

for 2 sec.

• The blinking figure increases by one each time the "RESET" switch is turned on.

Holding the "MODE" button depressed for 2 seconds, the numerical value

becomes a blinking "20.00" and the transmitter produces an analog output

adjusted based on the established numerical value. If a deviation of analog

output is still large, repeat the procedure to set the numerical value.

(3) Terminate Analog Trim (20mA).

MODE

Press

Analog trim (20mA)

RESET

Press

Basic data menu

MODE

Press

Flowrate

.......................

for 2 sec.

.......................

3 times.

.......................

for 5 sec.

.......................

Analog output adjusted to 20mA is shown.

(The rightmost figure (0) blinks on and off..)

Depress the "MODE" button for 2 seconds to show the analog trim (20mA)

window. (The rightmost figure (0) stops blinking.)

Press the "MODE" button 4 times to show the basic data menu.

Depress the "MODE" button for 5 seconds and the flowrate window appears.

"MODE" switch is turned on.

Description

26

8.8 Error Messages

When an error arises, the display shows alternately the flowrate and an error message.

Such a message may appear at the time power is turned on.

Kind of error Abnormal state Coping process

out.Err.

AnA.Err.

Description

Description

Pulse output

error

Fails to produce

pulses properly.

Analog error More than 115%

of analog full scale

value is flowing

due to excessive

flowrate or the like.

Make sure of the following three:

• Pulse weight (parameter)

• Pulse "ON" duration (parameter)

• Instant flowrate while an error message appears.

Select parameters such that the parameters

and variable above meet the following condition:

Flowrate with error message [L (normal)]

/pulse weight [L/min (normal)]

× (pulse "ON" duration [msec] + 1)

/60 < 1000

Take the following countermeasures.

• Lower the flowrate.

• Increase the set value of analog full-scale

value (parameter).

S-193-11-E

PA.Err.1

PA.Err.2

Ain1Err.

Ain2Err.

Description

Description

Description

Setting error Fails to calculate

the flow.

Accumulated

total error

Accumulated

total data is

unusual.

Sensor error Fails to measure

flowrate properly.

Transmitter is suspected to be at fault.

Consult factory for technical assistance.

Transmitter is suspected to be at fault.

Consult factory.

For a short term remedy, pressing the "RESET" button resets the accumulated total to 0,

but you can make flowmetering as usual.

Sensor or transmitter is suspected to be at

fault.

Consult factory for technical assistance.

27

S-193-11-E

9. GENERAL SPECIFICATIONS

Item Description

Model TF1015 TF1020 TF1025 TF1040 TF1050

Nominal Size 15mm 20mm 25mm 40mm 50mm

Acceptable Fluid

Flow Range

Fluid Temperature

Ambient Temperature

Pressure Range

Major Parts

Materials

Connection Rating

Connector

Material

Display

Output

Alarm

Pressure Loss 10kPa max. (flowing at the max. flowrate above 0.3MPa)

Response Time constant 1.5 sec. max.

Power 24 VDC ±10%, Max. 100 mA

Cable Refer to Section 6.2 Wiring Diagram.

Physical Orientation

Protection Grade

10 to 600 L/min

※1

※2

(normal)

Monitor body: PBT (Polybutylene Terephtalate) Monitor body: A5052 (Machined, anodized)

Sensor: SUS316

Display: Mixed resin consiting of PC (Polycarbonate) and PBT (polybuthylene terephthalate)

Transmitter case: PBT (Polybutylene Terephtalate)

O-rings: Viton

Rc1/2 (female) Rc3/4 (female) Rc1 (female) Rc1・1/2 (female) Rc2 (female)

ADC12

(Aluminum die cast,

Alodine (trivalent))

7-segment 8-digit LCD (with backlight and unit indicator). The display is rotatable in 90°

steps.

• Instant flowrate (m3/h(normal), (L/min(normal))

• Resettable total flow, accumulated total flow (m3 (normal))

• Yen conversion (instant flowrate, accumulated total, resettable total)

NOTE: In the Yen converted mode, the unit of figure is "Yen".

• 2 independent set points can be chosen (settings, hysteresis, or high/low alarms.)

• The lowest limit of alarm can be set up. (Alarm can be cleared at around 0 flow.)

15 to 800L/min

(normal)

LED x 2 places (Lights up in an alarmed condition).

Flow pulse (compensation pulse, open collector output)

(Pulse width adjustable from 1 to 240 msec)

Flowrate analog 4 to 20mA, Max. load resistance 500 Ω

Compressed air and nitrogen

35 to 2200L/min

(normal)

0 to 50°C

0 to 50°C

0 to 0.7MPa

A5052 (Aluminum machined and anodized)

Alarm (2 points, open collector output)

Horizontal or vertical

Non-explosionproof, indoor use, IP65

85 to 5000L/min

(normal)

135 to 8000L/min

(normal)

NOTES: ※1. Reading in terms of "Normal" refers to the conversion value at 0°C and 1 atm. As the

maximum flowrate could camage the sensor, it is limited by the pressure inside the tubing

system. Refer to Section 5.6 Maximum Service Flowrate.

※2. You can select to optional output points. (For the combination, refet to the product code.)

●Accuracy(allmetersizes)

Flowrate below 40% of full scale Flowrate 40% or more of full scale

Reproducibility ±0.8% of full scale or better ±2% of reading or better

Linearity ±2% of full scale or better ±5% of reading or better

Pressure characteristics

Temperature characteristics

±0.12% of full scale/0.1 MPa or better ±0.3%/0.1 MPa of reading or better

±0.1%/°C of full scale ±0.2%/°C of reading

10. APPLICABLE STANDARDS

Applicable EU Directive

Applicable EN standards, etc.

28

EMC Directive: 2014/30/EU

RoHS Directive: 2011/65/EU

EMC Directive: EN61326-1: 2013 Class A

RoHS Directive: EN50581: 2012

11. PRODUCT CODE EXPLANATION

(Direct coupled cable) (Connector via interconnect cable) (Connector terminal)

Cable length: 25cm

Table 11.1

S-193-11-E

Item

① ② ③ ④ ⑤ ⑥ - ⑦ ⑧ ⑨ ⑩ - ⑪ ⑫ ⑬ ⑭ ⑮

Model

Type 1 Standard type

Nominal size

Body material

Max. operating pressure 1 0.7MPa

Sensor design

Metered fluid G - Compressed air and nitrogen

Connection rating (※1) 1 Rc thread (female)

Display 1 Totalizer and digital indicator

Output (※2)

Version A Standard

Output terminals

T F Mass flow monitor

0 1 5 - 15mm

0 2 0 - 20mm

0 2 5 - 25mm

0 4 0 - 40mm

0 5 0 - 50mm

Product Code

A Aluminum (meter sizes 25mm, 40mm and 50mm)

P PBT (meter sizes 15mm and 20mm)

1 Meter sizes 15mm and 20mm

2 Meter sizes 25mm, 40mm and 50mm

1 Output x 2: Flow pulse + single alarm point

2 Output x 2: Flow analog + single alarm point

3 Output x 2: Flow pulse + flow analog

4 Output x 2: Two alarm points

5 Output x 3: Flow pulse + two alarm points

7

Output x 3: Flow pulse + flow analog + single alarm point

Direct coupled cable

1

(output x 3, 5 conductor, 3 meters long)

Connector via cable (output x 2)

2

Cable furnished (4 conductor, 3 meters long)

Connector via cable (output x 2)

3

Less cable

Connector terminal (output x 3)

4

Cable furnished (4 conductor, 3 meters long)

Connector terminal (output x 3)

5

Less cable

Description

Nom. size (mm)

15 20 25 40 50

○ ○ ○ ○ ○

○ ○ × × ×

○ ○ × × ×

× × ○ ○ ○

× × ○ ○ ○

NOTES: ※1: 15mm: Rc1 /2, 20mm: Rc3/4, 25mm: Rcl, 40mm: Rc1-1 /2, 50mm: Rc2

※2: You can select either 2 outputs or 3 outputs, but the availability of "Output terminal" type is

limited depending on the number of outputs.

※3: Mounting hardware for nominal sizes 15mm and 20mm monitors (option) Product code:

TFB015

▲

● Explanation of Output Terminal Types

29

S-193-11-E

6

Mas s F Lo w M oni tor

Spec. label

43

137

21.5

1.6

86

30

4-φ4.5

Wiring label

CE mark label

Screw conn.

Meter body

LCD display

(backlit)

Alarm indicators (red LEDs)

Pushbuttons

Mtg. Hardware (option)

Model TFB015

(※3)

(※3)

(※3)

90

50

40

62

72

82

Wiring label

CE mark label

Spec. label

L

90

62

W

H2

H1/2

H1

Screw connection

(※2)

(※2)

(※2)

12. OUTLINE DIMENSIONS

Nominal sizes: 15mm and 20mm (※1) All dimensions in millimeters

NOTES ※1. Meter body style shown here

is of nominal size 15mm meter.

※2 3 meters long cable inclusive.

Mounting adapter not inclusive.

※3 The shape of the cable outlet

in the figure is an example.

Nominal size Connecting screws Weight (※2)

15mm Rc1/2 (female) 750g

20mm Rc3/4 (female) 760g

Nominal sizes; 25, 40 and 50mm All dimensions in millimeters

Nominal size

25mm 180 66 59 106 Rc1 (female) 1620g

40mm 180 83 83 130 Rc1・1/2 (female) 2560g

50mm 200 83 83 130 Rc2 (female) 2620g

L W H1 H2

Fig. 12.1

Connecting screws Weight (※1)

30

NOTES ※1. A cable of 3 meters long inclusive.

※2. The shape of the cable outlet in the figure is an example.

Fig. 12.2

S-193-11-E

31

S-193-11-E

All specifications are subject to change without notice for improvement.

32

2017.12 Revised △

2003.10 Released

S-193-11-E (1)

Loading...

Loading...