Ins. No.

T-518-9-E

NONCONTACT PULSE GENERATORS

MODEL PG30D/PG30DEP

2-wire system, operating on 24V

MODEL PG30D

GENERAL

■

When used in conjunction with an OVAL flowmeter, the Model PG30D/PG30DEP noncontact pulse

generator provides voltage frequency pulses proportional to the flowrate of process fluid. The pulse

generator contains a pulse generating element of molded type and a protective circuit which prevents

erratic pulses otherwise generated by minute vibration of generator components. As the slit disc revolves,

a succession of voltage pulses (rectangular wave) is generated which can be used in a remote totalizing,

batching or blending system built around an OVAL flowmeter as the front end of signal pickup.

The pulse generator also offers compatibility: for example, PG30D may be replaced by PG30EP, PG20,

or PG20EP, while PG30DEP with PG30, PG20, or PG20EP.

By construction, this pulse generator comes in two types: PG30D (standard) and PG30DEP (flameproof).

MODEL PG30DEP

TYPICAL PULSE GENERATOR INSTALLATIONS

■

Engineering-unit pulse generation … The rotor revolution is, after gear reduction and instrumental error

correction for the flowmeter, picked up and used primarily for remote totalization.

GB type

Pulse generator

for totalizer

Where engineering-unit pulses are required

Pulse generator

for totalizer

LW13 type CB type PB type

Sizes 52 and 53 in

applications where

engineering unit pulses

are required.

Mounts as shown

in the circle on

converter "GB" when

non-engineering-unit

pulses before temp.

compensation are

required.

Where unit pulse after

temp. compensation

is desired with model

LW11register.

Where unit pulse after

temp. compensation

is desired with model

LW42, 43 register.

T-518-9-E

SLITDISC

WAVESHAPING

&OUTPUT

L

1

L

2

① ② ③ ④

BLACK

DC24V

0V

RED

(B)

(A)

LOADRESISTOR510Ω

1

0

RECTIFIER

DETECTOR

PICKUPCOIL

OSC.COIL

H-F

OSCILLATOR

WAVEFORMS

δ

δ:HYSTERESISWIDTH

a

b

φ1

(D)

(D)

a

b

φ2

(B)

(B)

a

b

φ2

φ1

(A)

(A) (A)

a

b

φ1

φ2

(C)

(C)

RECTIFI ER

RECTIFI EROUTPUT

SLITDISC

OSC. COIL

PICKUPCOIL

1

0

TIME

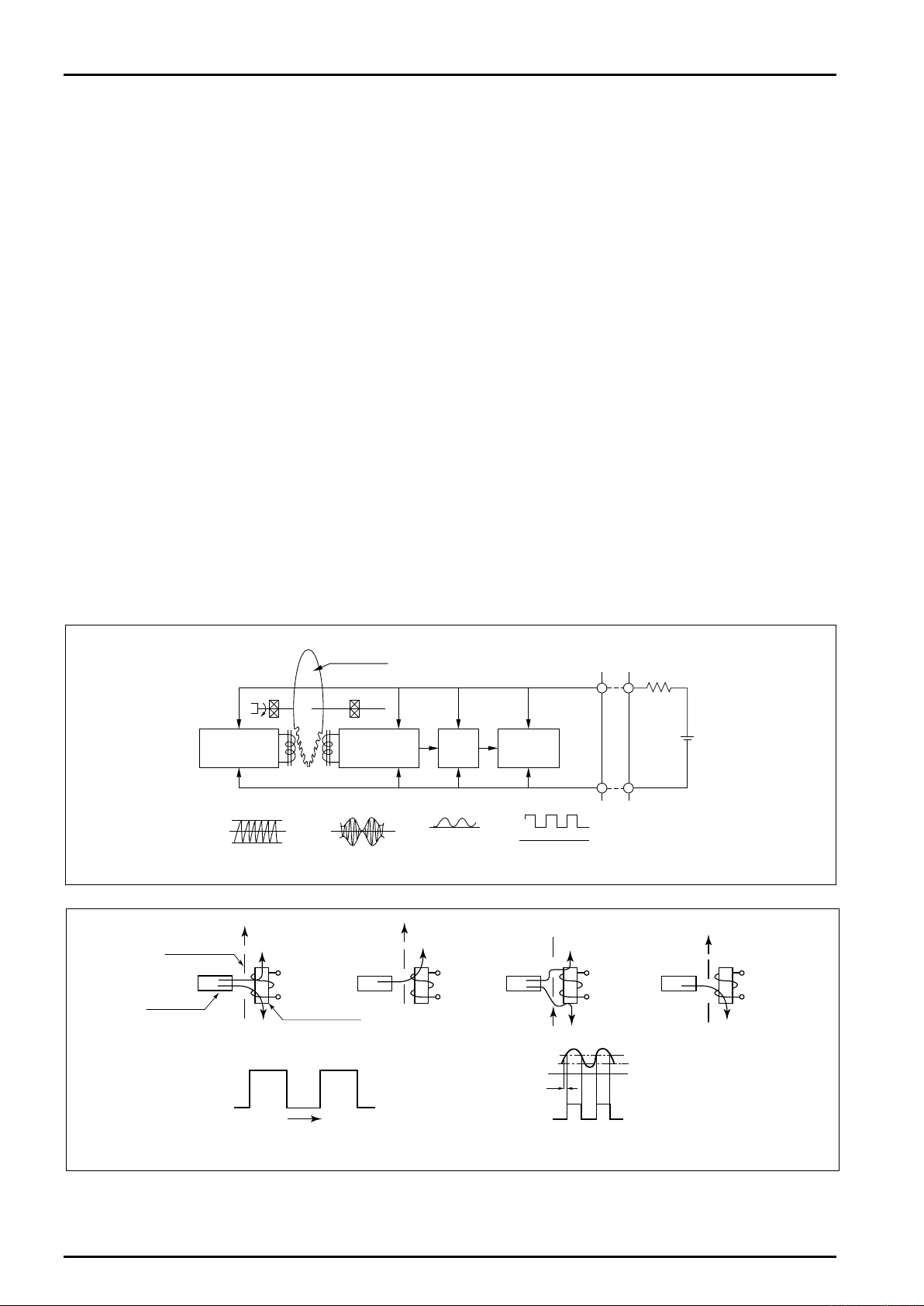

OPERATING PRINCIPLE

■

1. Operation can best be understood by referring to Fig. 1. The oscillator coil L1 in the H-F oscillator continuously

generates a 1 MHz frequency (waveform ① ). A disc, located between the oscillator coil L1 and pickup coil L2,

has many slots arranged at regular intervals along its periphery. As the disc revolves, the magnetic field of

induction created by the former coil is interrupted on and off. The result is a signal induced in the pickup coil L2

(waveform ② ), which is modulated by the slots along the slit disc. The signal is then rectified (waveform ③ ),

shaped, and processed for switching in the output circuit to control the current in the load. Part of its output

is fed back to change trigger levels at the rise and fall of the signal, thereby achieving improved hysteresis

characteristics.

2. Figures (A) through (D) in Fig. 2 show how the doubled pulse generation inherent to this pulse generator is

achieved. The oscillator coil L1 is located perpendicular to the pickup coil L2. Between these two coils is the

revolving disc which produces a single pulse signal at the leading edge in (B) and the trailing edge in (D) in the

course a slot in the slit disc moves past the magnetic field.

◎ Disc at position (A) …… Magnetic flux φ1 and φ2 cancel out with each other in the oscillator coil; no

voltage is induced in the pickup coil across its terminals a and b.

◎ Disc at position (B) …… Magnetic flux φ1 is interrupted by the disc and magnetic flux φ2 alone acts on the

pickup coil, inducing a voltage across its terminals a and b.

◎ Disc at position (C) …… Magnetic flux φ1 and φ2 are interrupted by the slit disc; flux φ1 and φ2 may reach

the pickup coil at the leading edge and at the trailing edge but being opposite to each other in direction, no

voltage is induced in the pickup coil across its terminals a and b.

◎ Disc at position (C) …… Magnetic flux φ2 is interrupted by the disc and magnetic flux φ1 alone acts on

the pickup coil, inducing a voltage across its terminals a and b.

2

Fig. 1

Fig. 2

T-518-9-E

WIRING INSTRUCTIONS

■

1. Cables

Recommended cables for field wiring are 2-conductor, shielded, chloroprene cabtyre cables (JIS C3311) or

2-conductor, shielded, vinyl cabtyre cables (JIS C3312) 1.25 mm2 to 2.0 mm2 in sectional area of the conductor

unless otherwise specified.

2. Transmission Length

The maximum transmission length is typically one kilometer when cables 2 mm2 in conductor area conforming

to JIS C3311 or C3312 are used.

NOTE : If it exceeds one kilometer, consult factory.

3. Conduit work is suggested.

Cable connections : PG30D …… Rc3/4 (internal thread)

PG30DEP …… G3/4 (internal thread)

NOTE : Conduit should be connected by screwing in at least five threads.

4. MODEL PG30DEP (ameproof construction) Conduit Work

(1) Use steel conduit conforming to the requirements specified in JIS B8305.

(2) Conduit accessories, such as boxes, universals and couplings, should conform to the requirements

specified in JIS C0903.

(3) Sealing work should be taken into consideration where necessary.

(4) After thread engagement, externally apply a coat of non-drying compound.

5. Inductive Interference Prevention

Field wiring should be routed sufficiently away from existing power cables or power circuits, if any, to

prevent potential stray current pickup. If you want to use both a non-engineering-unit pulse generator and an

engineering-unit pulse generator, a separate cable should be used for each of them.

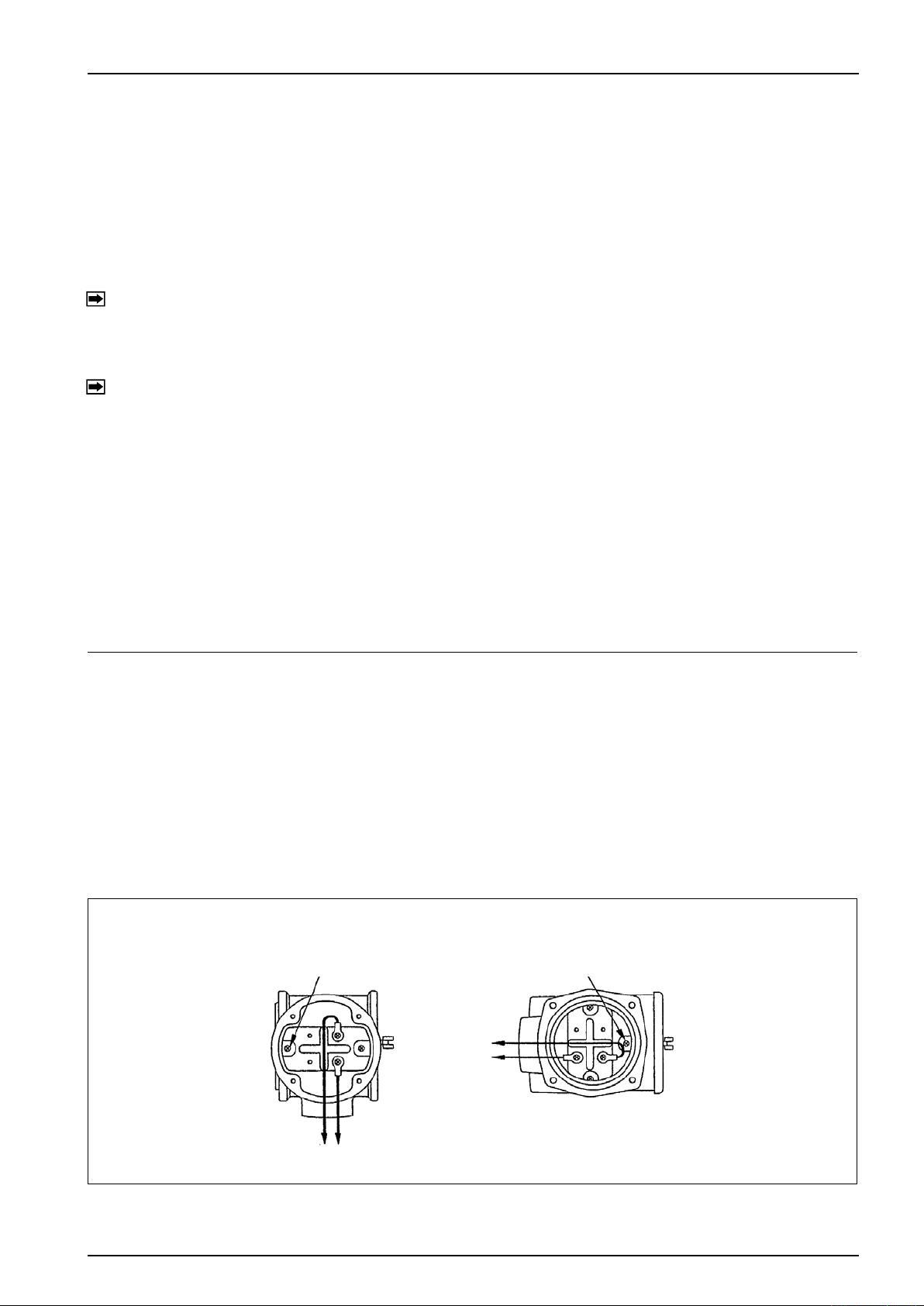

Wiring Connections

Removing the PG30D/PG30DEP outer housing lid (306) provides access to the 2-post terminal block.

Referring to the wiring connection label found on the back of the lid, make electrical connections correctly.

Terminal Identification 2 …… SIG (red)

3 …… 0V (black)

In case of grounding on the pulse generator side

●

◎ Model PG30DEP has a ground terminal. Use this terminal to earth ground.

◎ Model PG30D is not provided with a ground terminal. So, take off the screw shown in the figure below and

earth ground using a lug.

PG30D PG30DEP

IF GROUNDING IS REQUIRED,

USE THIS TERMINAL.

GROUND TERMINAL

Fig. 3

3

T-518-9-E

DISASSEMBLY AND INSPECTION

■

The pulse generator should be disassembled for inspection once a year.

◎

(Make sure that the transmitter cables are not lodged between the casing parts while reassembling.)

If there is no or few (or too many) pulses from the pulse generator although the flowmeter register pointer or

counter do move, the pulse generator is suspected for a fault. Inspect its components according to the procedure

described below.

PG30D PG30D

Transmission gear box

167

1. Remove the pulse generator from the flowmeter.

Remove four screws (167) to gain access to the

transmission gear box. Check the transmission

gear box for any evidence of slippage or loose

2. Remove four screws (139) holding the rear lid (102)

in place and remove the lid. Make sure to see that

the slit disc (116) turns freely and that the brake

shoe (119) works properly.

103 102

139

119

116

Fig. 5Fig. 4

crimping.

NOTES : 1. The same procedure applies to Model PG30DEP.

2. If something is wrong with spring (122) and/or brake shoe (119), replace the brake shoe as an

assembly (plate (120) inclusive).

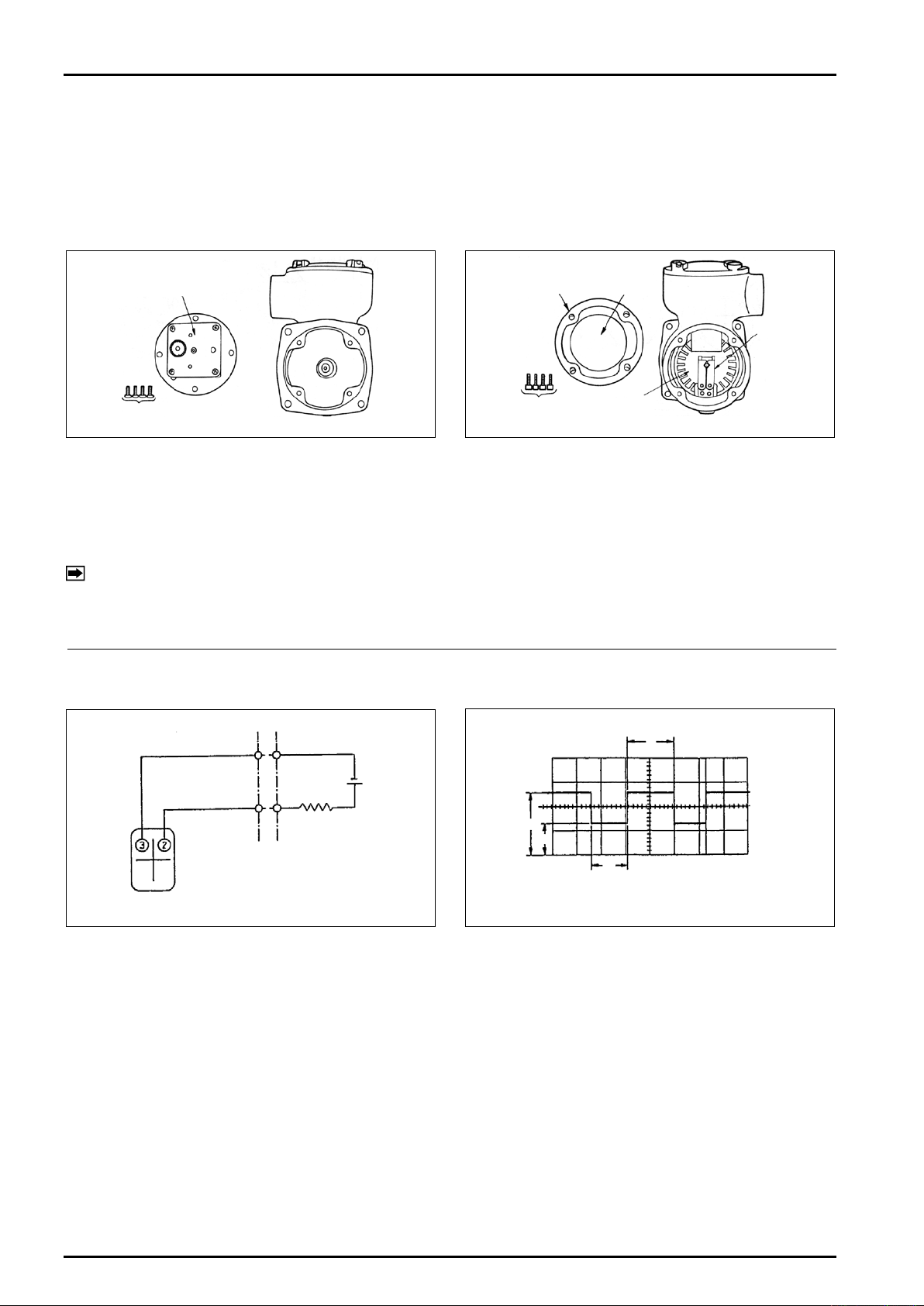

Monitoring the Output Waveform

●

D

DC

24V

0V

SIG

510 Ω

Fig. 6

Shown in Fig.6 above is the setup for observing the

output pulse waveform. Couple the oscilloscope or

synchroscope across terminals 2 and 3 and monitor

the waveform while allowing the pulse generator to

revolve at a constant rpm. Connecting the multimeter

across terminals 2 and 3 enables you to make an ON/

H

2

H

1

C

Fig. 7

Waveform ratio is correct of H1= 6.5V ± 1V and H

= 14V ± 1V when C/D is somewhere between 1/3

and 3/1. If a correct waveform like the one shown in

Fig. 7 does not appear, replace the noncontact switch

unit with a new one in the manner outlined in the next

section.

20V

10V

0V

OFF level measurement. However, you cannot make

a waveform ratio measurement with the multimeter

alone.

2

4

LUBRICATION

■

Do not fail to use proper lubricants shown below, or equivalent, at disassembly and inspection.

T-518-9-E

L: Lubricating oil

G: Grease

Lubricating Oil Specications and Examples of Products

●

Symbol Viscosity or Consistency Pour Point or Drop Point Example of Products by Trade Name

L3 36.4

G2 300/25℃ 300℃ and above

Noncontact Switch Unit Replacement

●

cst

/30℃ − 37.5℃

Gear Train Bearings

Spur Bevel Plain Ball

G2 G2 L3 L3 L3

Brake Shoe

Nisseki Launa 40

(Nippon Oil Co., Ltd.)

Jun BG Grease

(Nihon Tokushu-koyu Co., Ltd.)

PG30D PG30DEP

Fig. 8

111

109

110

※

Terminal box

126

Fig. 9

117

116

118 115

108

※

1. Disconnect wiring connections. Take off two terminal

fitting screws (105) and remove the terminals (104).

The noncontact switch unit (108) can be removed

after taking off two additional screws (130).

2. Remove nut (110) and toothed washer (109) holding

the noncontact switch unit (108) to the mounting

plate (111), and remove the switch unit (108).

Install a new switch unit in alignment with locating

slot (marked ※ ). In making wiring connections,

observe the color codes (red and black) of the

leads.

1. Take off four bolts (329) and remove the outer

housing for pressuretight gasket (301) from the

outer housing (101). Take off two screws (126)

securing the noncontact switch unit (115) in place

and remove the switch unit.

2. Unsolder the wire leads (marked ※ ), take off

nut (117) and toothed washer (116) holding the

noncontact switch unit (115) to the mounting plate

(118), and remove the switch unit. Replace with a

new noncontact switch unit in the same manner as

described for PG30D pulse generator and solder

the wire leads to their connections.

5

T-518-9-E

ASSEMBLY DRAWING AND PARTS LIST, PG30DEP

■

Gear train engagement in the transmission

gear box shipped from our factory before April,

1987, is as shown in the inset above.

Pulse Generator Assembly

Sym.No. Part Name Q 'ty

101 Housing 1

102 Housing lid 1

103 Housing lid bolt (M3×15) 4

104 O-ring (JIS G70) 1

105 Washer, Housing lid (M5) 4

106 Shaft 1

107 Ball bearing (L-1040ZZ) 2

108

110 Setscrew (M3×4) 1

111 Toothed disk (with hub) 1

112 Thrust spacer 1

114 Holder 1

115 Detector (noncontact switch unit)

117 Nut, Detector

Blind plug

(Rc (PT)1/8, hex. socket head)

1set116 Toothed washer, Detector

}

* Upon disassembly, be sure to apply a liquid

packing (Herme-Seal #723 or equivalent).

▲:Replacement parts

Sym.No. Part Name Q 'ty

118 Mounting plate, Detector 1

119 Brake shoe

120 Plate

121 Shoe shaft

122 Spring

123 Clip ring

124 Thrust spacer 1

1

126

127

128 Plate fitting screw (M3×6) 2

129 Washer, Plate fitting screw (M3) 2

130 Holder fitting screw (M4×6) 2

131 Washer, Holder fitting screw (M4) 2

Fitting screw, Detector mounting

plate (M4×8)

Washer, Detector mounting

plate (M4)

▲

1set

}

2

2

Mounting Plate Assembly

Sym.No. Part Name Q 'ty

201 Mounting plate 1

202 Bearing 1

203 Transmission shaft 1

204 Bevel gear 1

205 Coupling 1

6

Sym.No. Part Name Q 'ty

206 Coupling retaining pin 2

207 Fitting bolt, Mounting plate 4

208 Thrust sheet 1

209 Gasket, Mounting plate 1

210 Oil retaining bearing 2

T-518-9-E

Transmission Gear Box

Sym.No. Part Name Q 'ty

150 Transmission Gear Box 1 set

162 Ball Bearing B (LF1260ZZ) 1

167

Fitting Screw, Transmission Gear

Box

(shaded area in the drawing)

4

NOTE: A replacement transmission gear box is available as an assembly. When ordering this box, please

specify the gear ratio (1/10 or 1/1, for example) stamped on its plate.

Terminal Box Assembly

Sym.No. Part Name Q 'ty

301

302 Pressuretight Gasket 1

303 Washer, Pressuretight Gasket 1

304 Pressuretight Gasket Retainer 1

305 Outer Housing, Terminal Box 1

306 Lid, Terminal Box Outer Housing 1

307

308 O-Ring (JIS G70) 1

309

310 Washer (M5 × 8) 4

311

312 Washer (M4) 2

313 Crimp-style Terminal (for φ4) 8

314 Terminal Block 1

Outer Housing for Pressuretight

Gasket

Fitting Bolt, Terminal Box Outer

Housing Lid

Bolt, Terminal Box Outer Housing

(M5×12)

Terminal Screw for Ground

(M4×8)

1

4

4

2

Sym.No. Part Name Q 'ty

315

316 Hex Bolt for Terminal (M4 ×18) 3

317 Washer (M4) 6

318 Washer (M4) 3

319 Nut (M4) 9

321

322 Washer (M4) 2

323

325 Wiring Connections Diagram Label 1

326

327 Washer 4

328 Cabtyre Cable 1

329

330 Washer (M5) 4

Flameproof Construction Rating

Label

Fitting Screw, Terminal Block

(M4×10)

Washer, Terminal Box Outer

Housing Lid (M5)

Pressuretight Gasket Retaining

Bolt (M5 ×15)

Bolt, Outer Housing Gasket

(M5×12)

1

2

4

4

4

7

T-518-9-E

ASSEMBLY DRAWING AND PARTS LIST, MODEL PG30D

■

Transmission gear box (150) and mounting plate (200)

are common to PG30DEP.

See the Assembly Drawings on page 6.

Gear train engagement in the transmission gear

box shipped from our factory before April, 1987, is

as shown in the inset above.

Pulse Generator Assembly

Sym.No. Part Name Q 'ty

101 Outer Housing 1

102 Outer Housing Lid 2

103 Gasket, Outer Housing Lid 2

104 Terminal 1

105 Nut, Terminal (M4) 3

106 Screw 3

107 Washer 3

108

109

110 Nut, Detector Assembly

111 Mounting Plate, Detector Assembly 1

112 Crimp-style Terminal 6

114 Holder 1

115 Shaft 1

116 Slit Disc (with hub) 1

118 Ball Bearing (CF-1040ZZ) 2

119 Brake Shoe

120 Plate

121 Shoe shaft

122 Spring

123 Clip Ring

Detector Assembly

(noncontact switch unit)

Toothed Washer, Detector

Assembly

}

}

1set

▲

1set

▲:Replacement parts

Sym.No. Part Name Q 'ty

124 Thrust Spacer 1

125 Blind Plug (PT1/8) 1

126 Wiring Connections Label 1

127 Wiring Connections Diagram Label 1

129 Setscrew, Slip Disc (M3×4) 1

130

131

132 Plate Fitting Screw (M3×6) 2

133 Washer, Plate Fitting Screw (M3) 2

134 Holder Fitting Screw (M3×6) 2

135 Washer, Holder Fitting Screw (M4) 2

136 Terminal Fitting Screw (M4×10) 2

137

139 Bolt, Outer Housing Lid (M4×12) 8

140 Bolt, Outer Housing (M5×12) 4

Fitting Screw, Detector Mtg. Plate

(M4×8)

Washer, Detector Mounting Plate

(M4)

Washer, Terminal Fitting Screw

(M4)

2

2

2

When ordering replacement-parts, please specify the flowmeter model, flowmeter serial no., instruction manual

no., and symbol no. and quantity of the parts desired.

8

GENERAL SPECIFICATIONS

■

T-518-9-E

MODEL

Item

Output Pulses

(engineeringunit pulses for

remote total

counter)

System of Operation HF oscillation, double-pulse detection, Shmitt and hysteresis effect circuit built-in

Pulse

Generating

Assembly

Finished in

green

Construction

ON/OFF Ratio of Pulses "0"/"1" = 3/1 to 1/3

Model PG31D PG32D PG33D PG31DEP PG32DEP PG33DEP

Pulses per Revolution 10 P/rev 100 P/rev 1000 P/rev 10 P/rev 100 P/rev 1000 P/rev

Reduction Gear Ratio 1/5 2/1 20/1 1/5 2/1 20/1

Number of Slits 25 poles

Type SH-DS-24-2W

Power Source * 24VDC ± 10%

Current Drain 35mA max.

Operating Temp. Range − 10℃ to + 65℃

Output Signal Levels

Max. Operating Freq. 2.5kHz (at pickup terminal)

Transmission Length 1 kilometer max.

Explosionproof Const. Standard Flameproof

Explosionproof Rating

Cable Entry Rc3/4 (internal thread) G3/4 (internal thread)

Starting Torque

"1" : 14V ± 1V (Load resistance 510 Ω , supply voltage 24V DC at 20℃ )

PG30D PG30DEP

"0" : 6.5V ± 1V

TIIS(d2G4)

NEPSI(Exd IIBT4)

300g-cm max. at a reduction gear ratio 30/1

40g-cm at a reduction gear ratio 2/1

※ Standard supplies (DC power supplies) are available from OVAL. You can choose one of them as necessary.

9

T-518-9-E

10

T-518-9-E

11

T-518-9-E

All specifications are subject to change without notice for improvement.

12

2014.11 Revised

2006.04 Revised △

T-518-9-E(2)

Loading...

Loading...