Oval PG30, PG30EP Instructions Manual

Ins. No.

T-518-11-E

NONCONTACT PULSE GENERATORS

MODEL PG30/PG30EP

GENERAL

■

When used in conjunction with an OVAL flowmeter, the Model PG30/

PG30EP noncontact pulse generator provides voltage frequency pulses

proportional to the flowrate of process fluid. Incorporated in the pulse

generator are a premolded pulse generating element and a circuit

which prevents false pulses otherwise generated by minute vibration

of generator components. As the toothed disk rotates, a succession of

voltage pulses (quasi rectangular wave) is generated.

Generated pulses come either pulses in scaled units or unscaled

pulses, depending on the position of flowmeter at which the generator

is mounted. Pulses in scaled units can be used in remote totalizing,

batching, blending systems and the like built around an OVAL flowmeter

which serves as the sensing terminal. Unscaled pulses are converted

into an analog signal for use in flow indicator/recorder/controller

applications. Models PG30S/PG30SEP are compatible in the latter

applications.

★ For complete details of Models PG30S/PG30SEP,see OVAL Products

General Specifications GS No T-523-E.

MODEL PG30

MODEL PG30EP

Pulse generators come in the following two designs:

(1)Standard type……PG30

(2)Flameproof type…PG30EP (designed and fabricated according to the "Explosionproof Guide-

lines" recommended by the Technology Institution of Industrial Safety.)

Information about Models PG30S and PG30SEP appears in Instruction Manual No. T-523-E.

★

PULSE GENERATOR INSTALLATION EXAMPLES

■

Generated pulses in scaled units…The rotor revolution is guided into gear reduction and instrumental

error correction stages for the flowmeter to produce pulses of required scaled unit. The obtained pulse

signal is used primarily for remote totalization.

GB type

Pulse generator

for totalizer

Where pulses of scaled units or

unscaled pulses are required

Pulse generator

for totalizer

LW13 type CB type PB type

Meter sizes 52 or 53;

where pulses in scaled

units are required.

If unscaled pulses

uncompensated for

temperature are required, it is mounted to

the area encircled ( ○ )

of transmission gear

box GB.

Equipped with register Model LW11;where

pulses of scaled units

compensated for temperature are required.

Equipped with register Model LW42 or

43;where pulses of

scaled units compensated for temperature are required.

T-518-11-E

Receivecoil

Sendcoil

Waveform

Tootheddisk

HF

Oscillator

Detector

Recti-

fier

Waveshape

L

1

L

2

① ② ③ ④

(BLK)

(WHT)

Power+12V

OutputSIG

Power0V

(RED)

Send

coil

Receive

coil

V1

V1

V2

Output

(Output =V1XORV2)

Tootheddisk

V1

V2 V2

OPERATING PRINCIPLE

■

1. Operation can best be understood by referring to Fig.1. Oscillator coil L1 in the HF oscillator continuously

generates a 1MHz high frequency wave (waveform ① ). As a toothed disk, located between the coil and

detector rotates, a high frequency induction field created is intermittently interrupted. The resultant signal

induced in pickup coil L2 of detector is a wave modulated by the toothed disk (waveform ② ). The signal is

then detected(waveform ③ ) and further shaped into a rectangular signal (waveform ④ ).

Hysteresis characteristics are also provided electrically by changing trigger levels at the leading edge and

trailing edge of the signal.

2. Fig.2 shows how our proprietary double pulse generator works. With two pairs of HF send/receive coils

arranged opposite to each other, intermittent interruption of the magnetic field takes place by the rotating

toothed disk and causes each coil to produce a single pulse per gap (or slot) between the teeth.

Because two coils are so located as to produce pulses 90°out of phase from each other, by exclusive OR (XOR)

of pulses from these two coils, two pulses per gap between the teeth are obtained after all.

WIRING INSTRUCTIONS

■

1. Cables for eld wiring

Recommended cables for field wiring are 3-conductor, shielded, chloroprene cabtyre cables [kind 2] (JIS C

3311) or 2-conductor, shielded, vinyl cabtyre cables (JIS C 3312) 1.25mm2 to 2.0mm2 in conductor area unless

otherwise specified.

2. Transmission Length

The maximum Transmission length is one kilometer when cables 2mm2 in conductor area conforming to JIS C

3311 or C3312 are used.

NOTE: If it exceeds one kilometer, consult the factory.

3. Conduit work is suggested.

Cable connections: PG30 ……Rc (PT) 3/4 female

PG30EP…G (PF) 3/4 female

NOTE: With conduit, a minimum of five full threads should engage the mating thread.

Wiring connections

Remove the lid of PG30/PG30EP housing to gain access to

a 3-post terminal block. Terminal identification label is found

on the reverse side of the lid. Remove a wiring connection

instruction label put on the terminals.

1 → +12V WHT

Terminal No. 2 → SIG RED

3 → 0V BLK

If grounding at the pulse generator end is desired

With PG30EP, use the earth ground terminal furnished.

With PG30, no ground terminal is provided; take off a screw

as shown in Fig 3 and earth ground using a terminal lug.

2

Fig. 1

Fig. 2

Ground this terminal if

required.

Fig. 3

T-518-11-E

23

1

SIG0V

MODEL

PG30, PG30EP

12VDC

+12V

10k

Ω

a

+

b

C

0

1

D

4. Conduit work for Model PG30EP (ameproof type)

(1) Use steel conduit conforming to the requirements specified in JIS C 8305.

(2) Conduit accessories should be of flameproof rating.

(3) Sealing work should be taken into consideration.

(4) Where rusting the screw threads is anticipated, apply a coat of non-drying sealing compound externally

following the screw engagement of conduit.

5. Inductive Interference Prevention

Field wiring should be routed sufficiently away from existing power cables or power circuits, if any, to prevent

potential stray current pickup.

If you want to use both scaled unit pulses and unscaled pulses, use two separate cables.

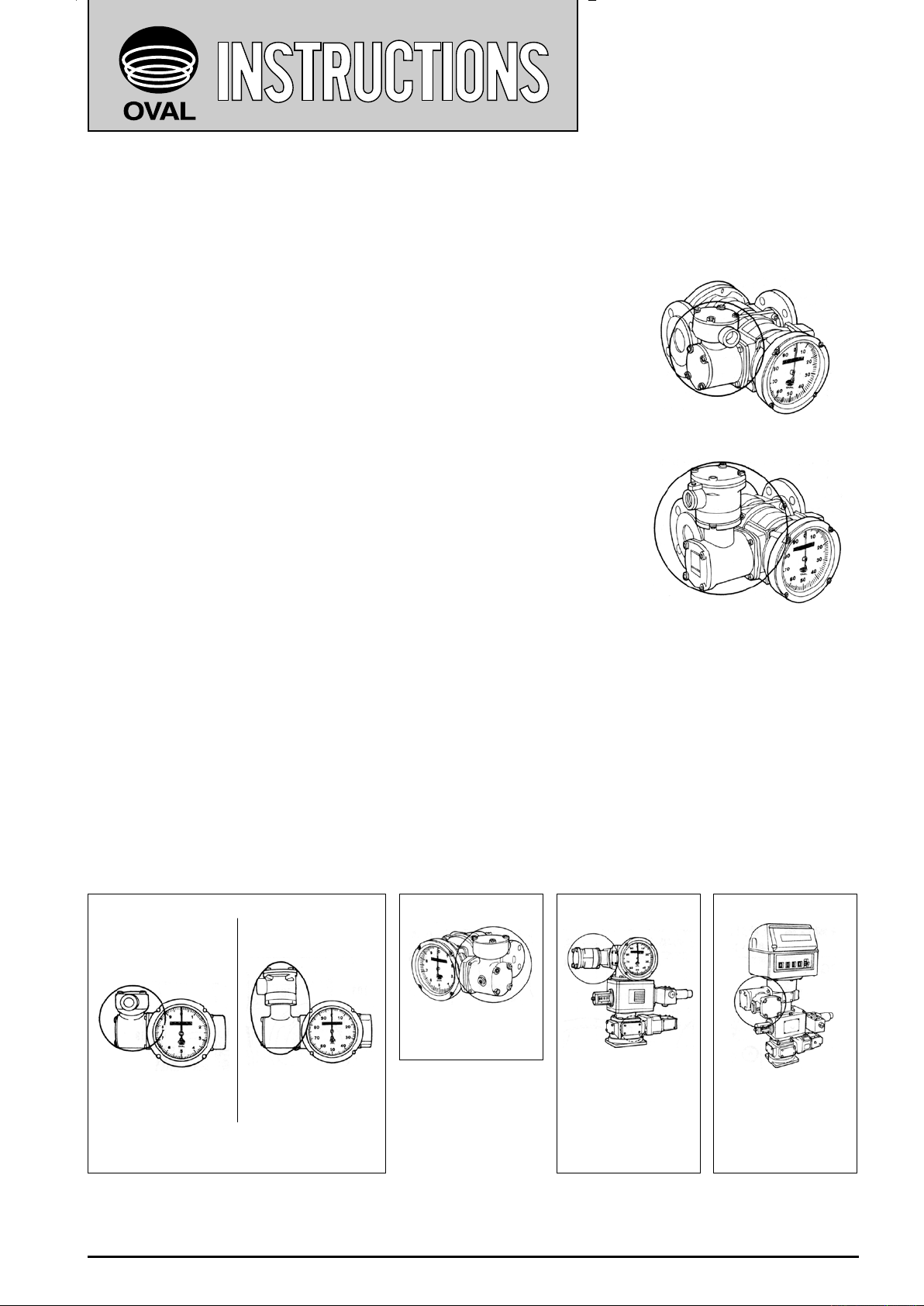

DISASSEMBLY AND INSPECTION

■

The pulse generator should be disassembled for inspection once a year.

◎

(Make sure that the transmitter cables are not lodged between the casing parts while reassembling.)

If there is no or few (or too many) pulses from the pulse generator while the flowmeter register pointer moves or

the counter operates properly, trouble is suspected in the pulse generator. Inspect its components according to

the procedure described below.

PG30 PG30

Transmission gear box

167

1. Remove the pulse generator from the flowmeter.

Take off four screws (167) to gain access to the

transmission gear box. Check for any gear slipping

on its shaft or crimp connections that are loose.

2. Take off four screws (139) holding the housing lid

(102) in place and remove the lid.

Check to see that toothed disk (116) turns smoothly

and that the brake shoe (119) works properly.

103 102

139

119

116

Fig. 5Fig. 4

The same procedure applies to Model PG30EP.

CAUTION: If something is wrong with spring (122) and/or brake shoe (119), replace the whole brake

shoe assembly (plate (120) inclusive).

Monitoring the Output Waveform

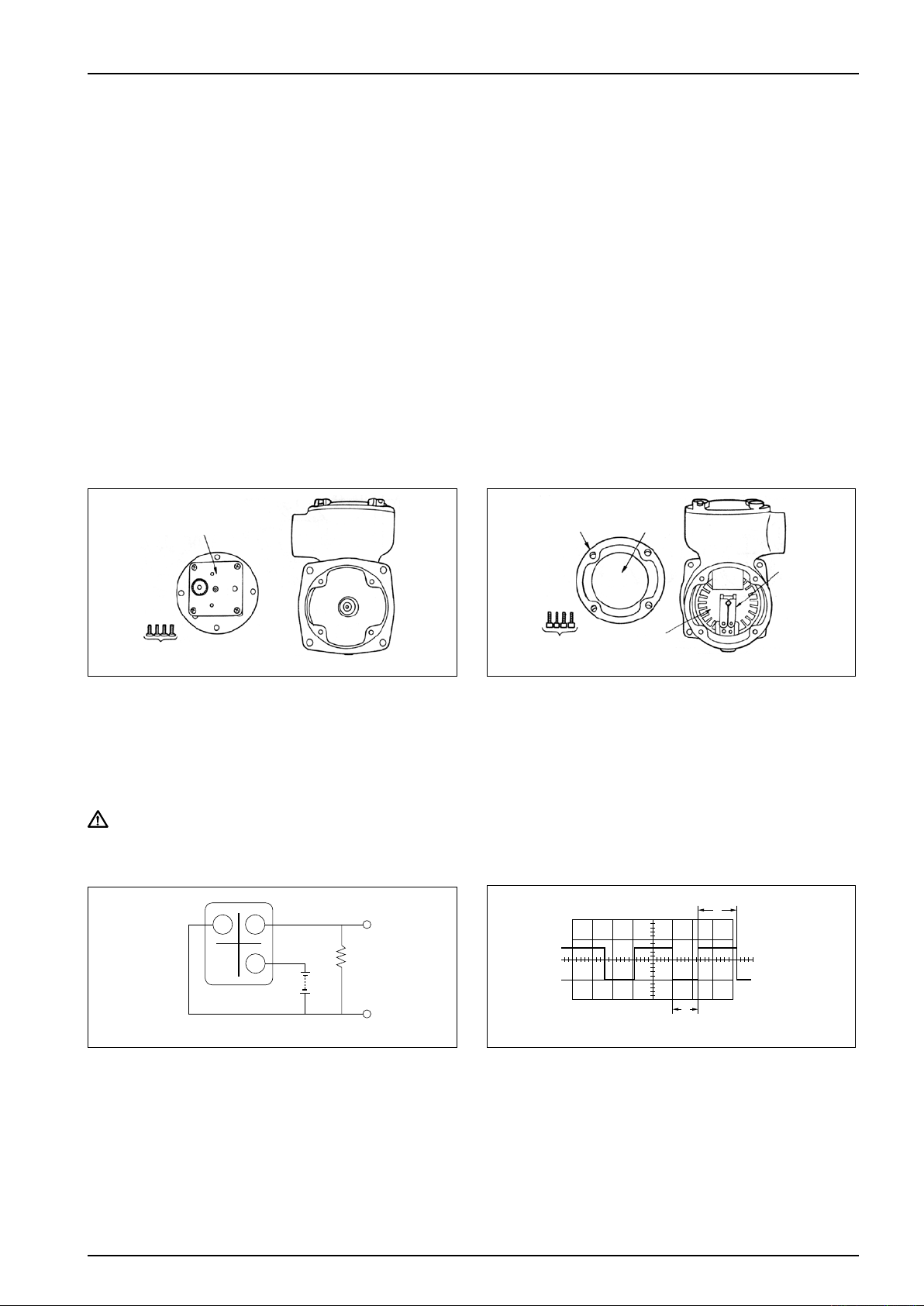

●

Fig. 7Fig. 6

Shown in Fig.6 above is the setup for observing the

output pulse wavefo rm. Couple the oscilloscope

across terminals a and b and monitor the waveform

while allowing the pulse generator to rotate at a

co n s t a n t rpm. Connecting the voltmeter across

terminals a and b enables you to make an ON/OFF

level measurement. However, you cannot make a

pulse ON/OFF ratio (or duty factor) measurement with

voltmeter alone.

Correct ON/OFF ratio C/D ranges from 35/65 to 60/40

when "1"= 6.2 to 7.6V and "0"= 0.5 max.

If a correct waveform like the one shown in Fig.7 is

not obtainable, replace the noncontact switch unit with

a new one according to the procedure outlined in the

next section.

(The ON/OFF ratio is a value measured under steady

state rotation.)

3

Loading...

Loading...