Oval MAG-OVAL III, MAG-OVAL III MGW, MAG-OVAL III MGS Instructions Manual

ER

R

.

ALM.

ER

R

.

ALM.

Electromagnetic flowmeter

Ins. No. C

−

102−1−E

Models MGW and MGS

Every MAG-OVAL III is manufactured under the stringent quality control and thoroughly tested and

inspected before shipment from our factory.

This manual is designed to assist the user to obtain the best performance of this product throughout

its service life. In order to take sufficient care, please read this instruction carefully before the use

and keep it handy for quick reference.

1

C−102-1-E

CONTENTS

1. GENERAL ............................................................................................................................4

2. BEFORE YOU BEGIN ..........................................................................................................5

3. PIPING INSTRUCTIONS .....................................................................................................6

3.1 Straight Pipe Section ..................................................................................................................................... 6

3.2 Keeping the Flow Tube Completely Filled ..................................................................................................... 6

3.3 Physical Orientation of the Probe .................................................................................................................. 7

3.4 Bypass Line ................................................................................................................................................... 7

3.5 Prevention of Negative Pressure ................................................................................................................... 8

3.6 Installation Location ....................................................................................................................................... 8

4. PROBE INSTALLATION ......................................................................................................8

4.1 Screw-in Type (nominal sizes 3 to 15mm) ..................................................................................................... 8

4.2 Wafer Type (nominal sizes 25 to 150mm) ...................................................................................................... 9

4.3 Transmitter Installation ................................................................................................................................. 10

5. GROUNDING .....................................................................................................................12

6. WIRING CONNECTIONS ..................................................................................................12

6.1 Power and Output Signal Wiring Connections ............................................................................................ 12

6.2 Wiring Connection Diagram ......................................................................................................................... 13

6.3 Power and Output Signal Terminal Identification......................................................................................... 13

6.4 Wiring Connection Instruction ..................................................................................................................... 14

7. START-UP ..........................................................................................................................15

8. MAINTENANCE .................................................................................................................15

9. TRANSMITTER DISPLAY AND OPERATION ...................................................................16

9.1 Explanation of Display ................................................................................................................................. 16

9.2 Operation Basics ......................................................................................................................................... 16

9.2.1 Setup Mode and Measure Mode .......................................................................................................... 16

9.2.2 Key Operations ..................................................................................................................................... 17

10. MEASURE MODE ...........................................................................................................18

10.1 Measure Mode Screen ............................................................................................................................... 18

10.2 Resetting Resettable Total ......................................................................................................................... 18

10.3 Error/Alarm and Status Display ................................................................................................................. 19

10.4 Screen Change for Instant and Total Flow Indication ................................................................................ 20

11. OPERATIONS IN SETUP MODE ....................................................................................21

11.1 Transition from Measure Mode to Setup Mode ......................................................................................... 21

11.2 Menu Operation in Setup Mode ................................................................................................................ 22

11.3 Changing Parameters ................................................................................................................................ 23

11.3.1 Parameter Setting in Selection System (Ex. Changing backlight setting) ........................................... 23

11.3.2 Setting Numeric Parameters (Ex. Changing flow range setting) ......................................................... 24

11.3.3 Viewing Exponential Indication ........................................................................................................... 25

12. DISPLAY TRANSITION ...................................................................................................26

12.1 Display Transition (1) Setting Display ...................................................................................................... 26

12.2 Display Transition (2) Setting Flow Parameter......................................................................................... 28

12.3 Display Transition (3) Setting Output Signal ............................................................................................ 30

12.4 Display Transition (4) Setting Error and Alarm Output............................................................................. 32

12.5 Display Transition (5) Setting Diagnosis and Maintenance Functions .................................................... 34

2

C−102-1-E

13. ANALOG OUTPUT FUNCTION ......................................................................................36

13.1 Setting Analog Output ............................................................................................................................... 36

13.2 Analog Output at Error/Alarm .................................................................................................................... 36

13.3 Adjusting Analog Output ............................................................................................................................ 37

14. PULSE OUTPUT AND TOTALIZING FUNCTION ...........................................................38

14.1 Setting Pulse Output .................................................................................................................................. 38

14.2 Pulse Output at Error/Alarm ....................................................................................................................... 39

15. STATUS OUTPUT FUNCTION ........................................................................................40

15.1 Selecting Status Output ............................................................................................................................. 40

15.2 High/Low Limit Alarm Function ................................................................................................................. 40

15.3 Flow Direction Output Function ................................................................................................................. 40

16. LOOP TEST (SIMULATIVE OUTPUT) FUNCTION .........................................................41

16.1 Simulative Output Operation ..................................................................................................................... 41

17. COMMUNICATION FUNCTION ......................................................................................42

17.1 Communication Specifications .................................................................................................................. 42

17.2 Setting Communication Functions ............................................................................................................ 43

18. SELF-DIAGNOSIS FUNCTION .......................................................................................44

18.1 Self-diagnosis Items .................................................................................................................................. 44

18.2 Diagnosing All Items .................................................................................................................................. 45

18.3 Diagnosing Self-diagnosis Items Individually ............................................................................................ 46

19. LCD CHECK ....................................................................................................................46

20. ERROR/ALARM STATUS LIST .......................................................................................47

20.1 Error/Alarm List .......................................................................................................................................... 47

20.2 Other Statuses ........................................................................................................................................... 48

21. PARAMETER LIST ..........................................................................................................49

22. GENERAL SPECIFICATIONS .........................................................................................50

23. FLOW RANGE .................................................................................................................51

24. PRODUCT CODE EXPLANATION ..................................................................................52

25. OUTLINE DIMENSIONS .................................................................................................53

This manual uses the precaution words "NOTE", "CAUTION", and "WARNING" as explained

below:

NOTE: Notes are separated from the general text to bring the user's attention to

important information.

CAUTION: Caution statements signal the user of hazards or unsafe practices which

could result in minor personal injury or product or property damage.

WARNING: Warning statements signal the user of hazards or unsafe practices

which could result in severe personal injury or death.

3

C−102-1-E

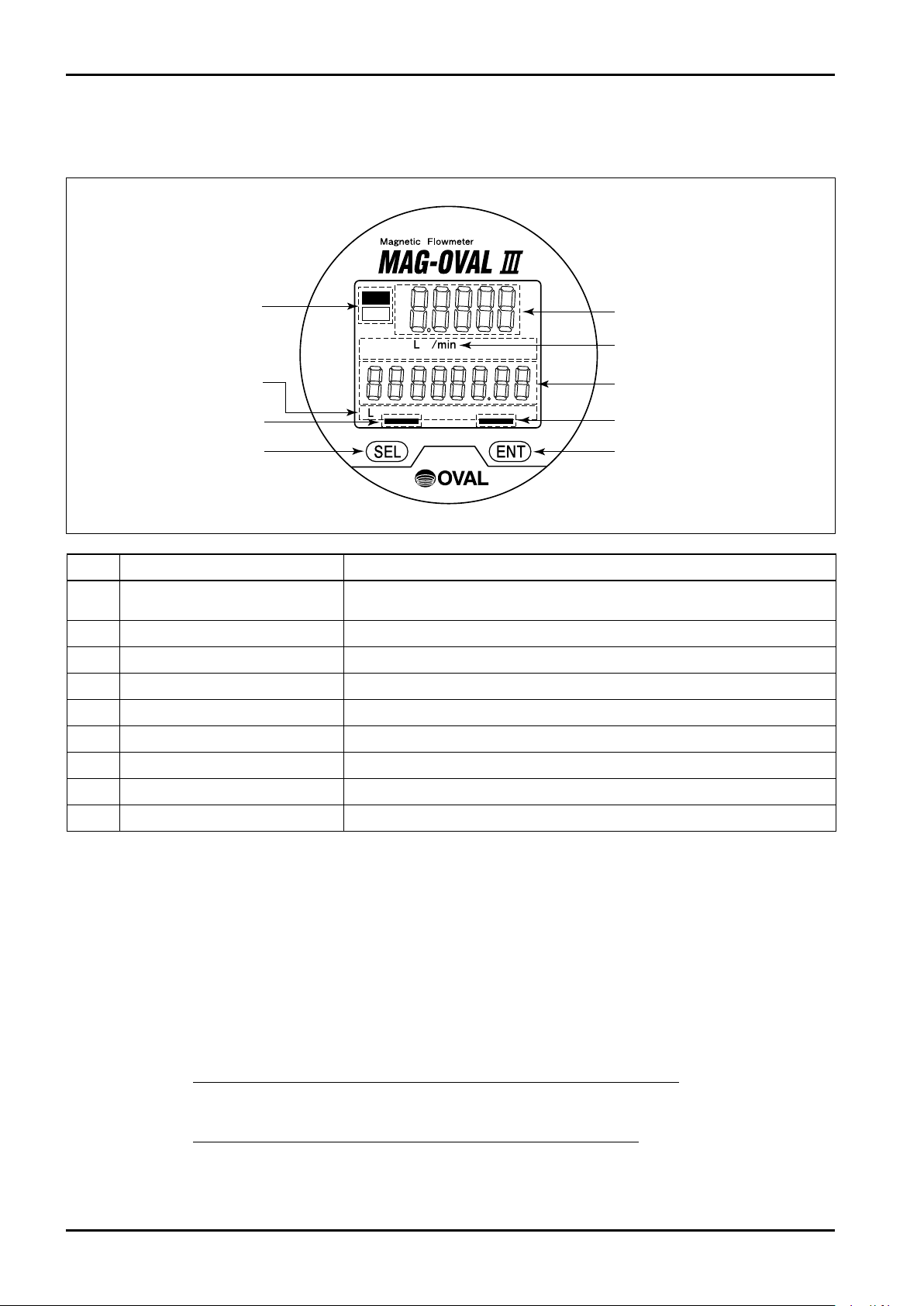

Electrodes

GND electrode

Cable entries

GND terminal

Transmitter

Adapter

Probe

Product nameplate

ERR.

ALM.

Alarm/Error

indicator

[ENT] key indicator

[SEL] key

indicator

[SEL] key

[ENT] key

Magnet

LCD Upper row

instant flow rate indicator

LCD bottom row

total flow indicator

Unit display

Unit display

1. GENERAL

Electromagnetic flowmeters operate on the basis of Faraday's law of electromagnetic induction. When a

conductive liquid flows through the magnetic field applied perpendicul ar to the direction of flow, an

electromotive force (EMF) is induced proportionally to the average velocity of flow according to Faraday's law. A

pair of electrodes located on the flow tube wall picks up the induced EMF which is then amplified in the

transmitter to determine the volumetric flow rate.

FEATURES

(1) Easy handling and low pressure loss contribute to low cost of installation and operation of the flowmeter,

providing excellent cost-effectiveness.

(2) Four kinds of electrodes are available for wetted area. Application to highly corrosive liquids is also

supported.

(3) In addition to magnet handling on the site, monitoring, various kinds of setting change, logging, loop test,

and self-diagnosis are available.

(4) Wide measuring range starting from zero.

■ Part names

4

C−102-1-E

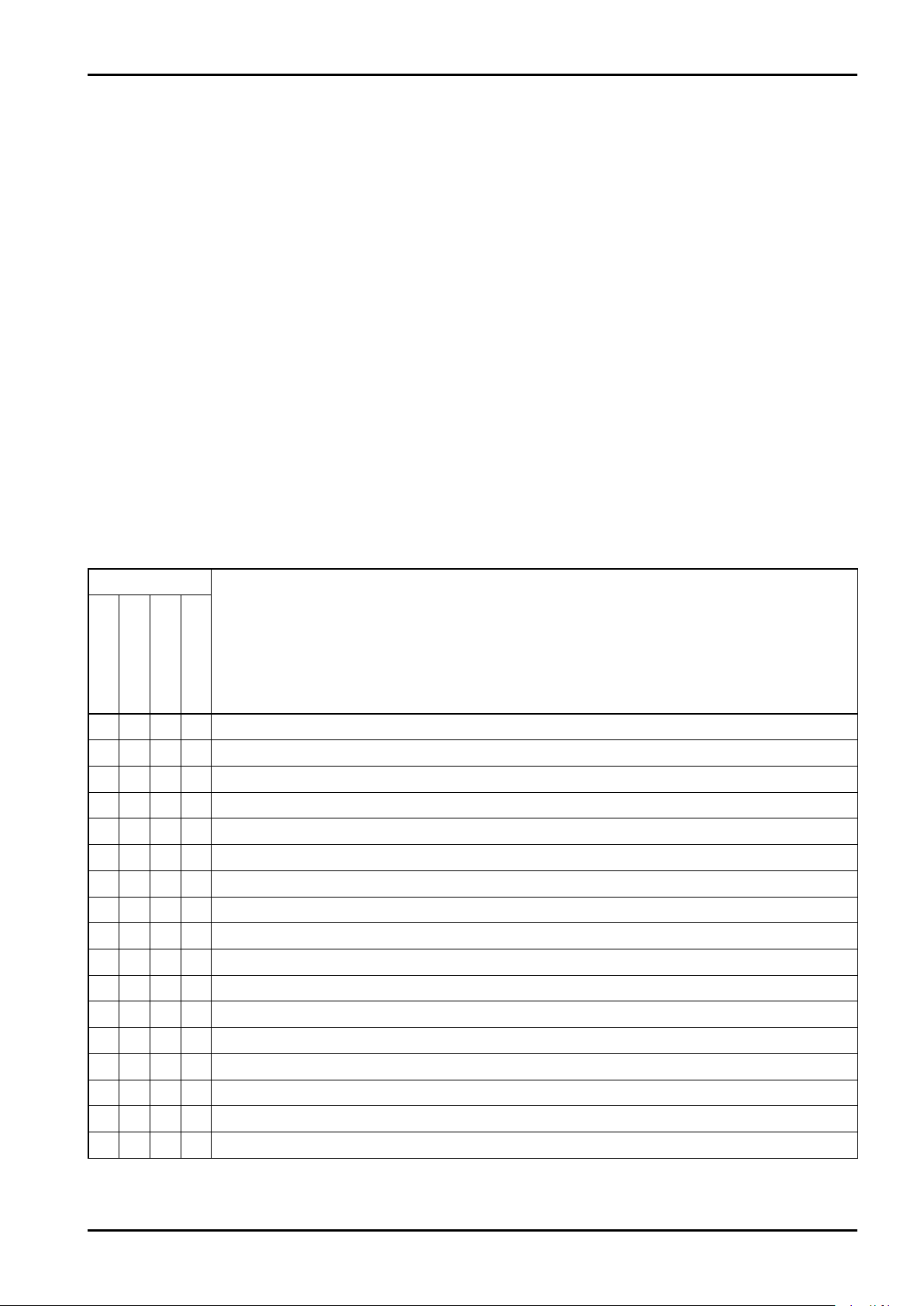

①

②

③

④

⑤

⑥

⑦

⑧

⑨

⑩

⑪

⑫

⑬

⑭

Magneti c F l ow m et e r

OVAL Corporation

MADEINJAPAN

MODEL

SERIALNo.

TAGNo.

FLUID

FLOWRANGE

MAX.PRESS

MAX.TEMP

ELECTRODE

POWER

DATE

ANALOGOUTPUT

PULSEOUTPUT

CAL.ZERO

CAL.FACTOR

A

Side view from Arrow A

2. BEFORE YOU BEGIN

Although this flowmeter is built and adjusted exactly to meet the customer specifications and, it is ready to

operate in your service by turning on the power, it is desirable for the operator to read this instruction manual

carefully for the best results in maintaining the stated accuracy and long life before initiating service operation.

You can avoid potential downtime of the equipment by observing the following instructions in particular.

(1) Confirm the operating conditions

The operating conditions and major specifications of this flowmeter appear on the nameplate attached to the

transmitter. Verify that the conditions indicated agree with your particular operating conditions. If you are to

make measurement of corrosive liquids in particular, make sure of the compatibility of electrode materials, etc.

(2) About grounding

An electromagnetic flowmeter requires earth grounding. See the Grounding Instruction on page 12 for proper

grounding.

(3) Use with the flow tube filled with liquid

An electromagnetic flowmeter requires its internal space to be completely filled with the process liquid.

Ensure of a fully filled flow tube during operation.

(4) About field wiring

For intercabling between the electromagnetic flowmeter and receiving instrument, see the section "Wiring

Connections".

Please remember to check terminal numbers for correct connections before operation.

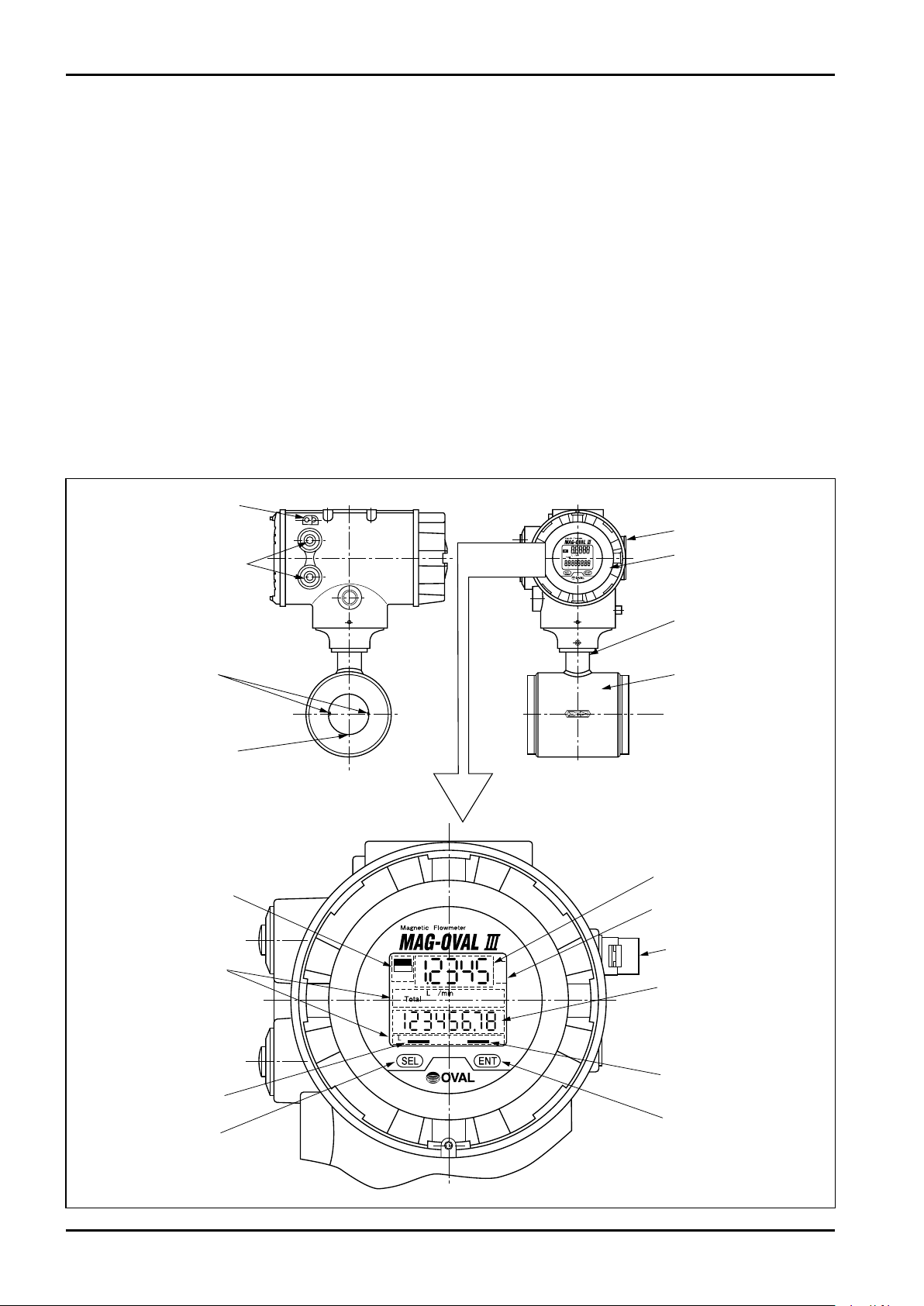

〈Explanation of items shown on nameplate〉

No. Item Description

(1) Product code Ex. MGW1-0501T17E-10A

(2) Product No.

(3) Instrument No. As designated

(4) Fluid measured Ex. Water

(5) Flow range Ex. 0 to 100m3/h

(6) Max. pressure Allowable max. pressure of flowmeter

(7) Max. temperature Allowable max. temperature of flowmeter

(8) Electrode material Ex. SUS316L (depending on selected type)

(9) Power spec. Ex. 85 to 264VAC 50/60Hz (depending on selected type)

(10)

Month/Year of shipment

(11)

Analog output 4 to 20mA

(12)

Pulse output At factored pulse Ex. 1L/P, At frequency pulse Ex. 1000Hz at F.S.

(13)

Calibration zero value

(14)

Calibration factor value

——

——

——

——

5

C−102-1-E

Flow

5D min.

Probe

Flow

Partially open valve

10D min.

Probe

(1)

(2)

D: Nominal pipe diameter

Flow

Flow

Probe Probe

Tank

(A) (B)

3. PIPING INSTRUCTIONS

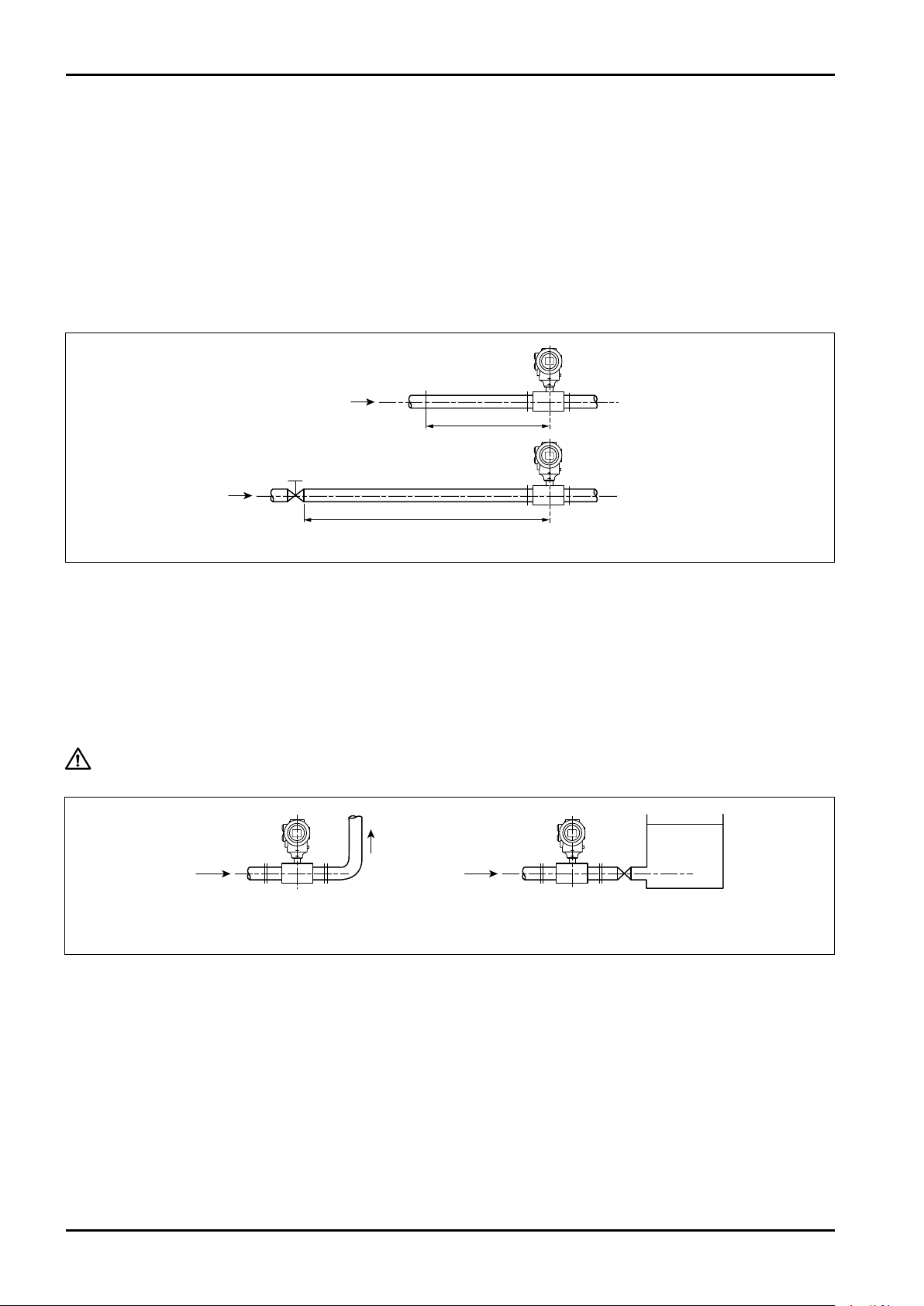

3.1 Straight Pipe Section

(1) Provide at least 5D (D: nominal pipe diameter) of straight piping upstream of the meter. For screw-in type

meters (3 to 15 mm in nominal diameter), no straight piping is required because of their long face-to-face

dimension with respect to their diameter.

(2) It is preferable that partially open valves or other devices that disturb the flow velocity pattern to be located

downstream of the meter. If such devices are desired to be placed upstream of the meter for some reason,

provide at least 10D of straight pipe section upstream of the probe.

Fig. 3.1 Standard Straight Pipes

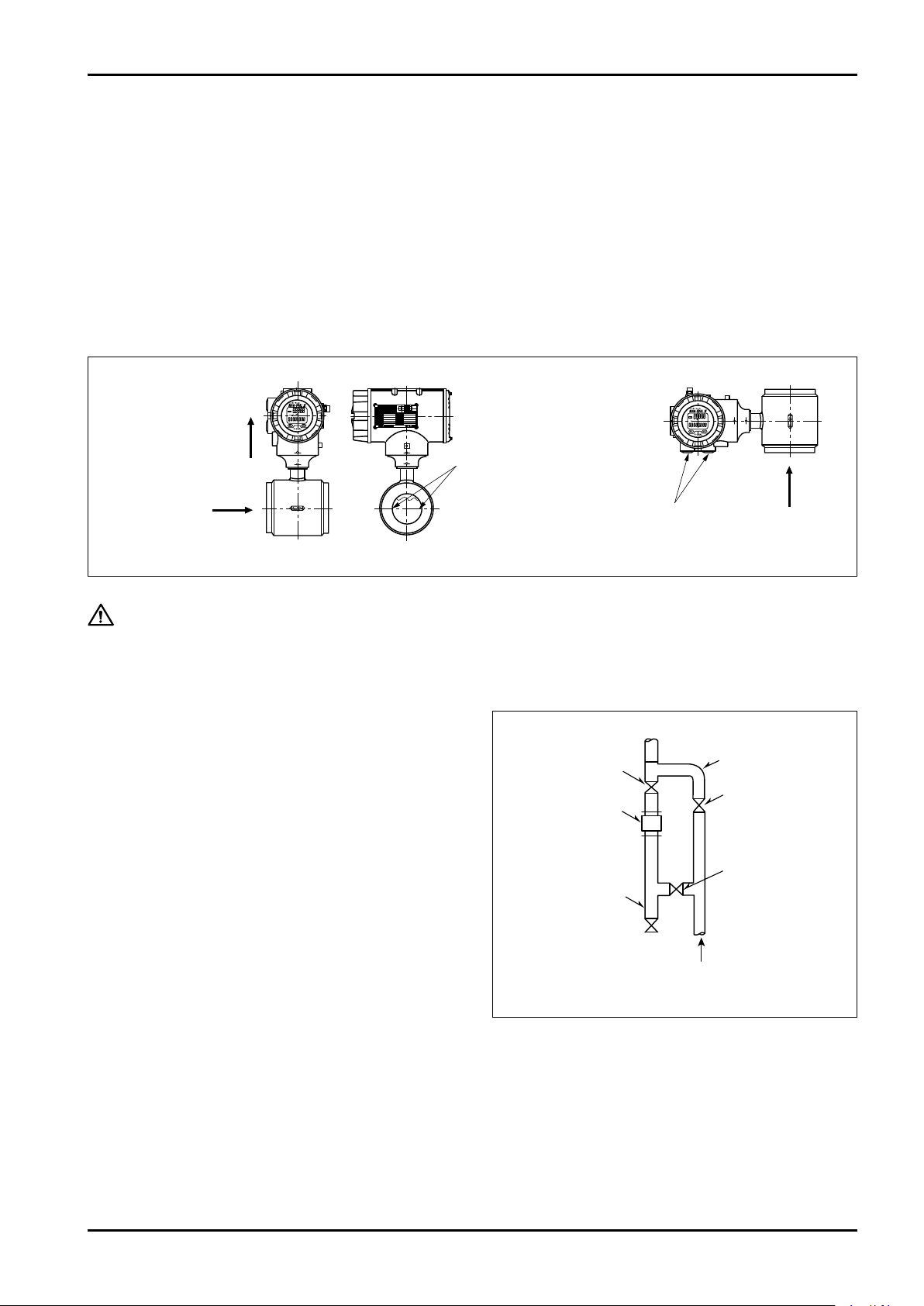

3.2 Keeping the Flow Tube Completely Filled

(1) It is essential that the electromagnetic flowmeter be installed in a pipeline completely filled with the process

fluid.

(2) In cases of horizontal installation or vertical installation where the fluid flows top to bottom, we recommend

providing a rising pipe or maintaining sufficiently large hydraulic head downstream, for these piping

arrangements are likely to create empty or partially filled conditions. (See Figure 3.2)

CAUTION: False output pulses may be produced if the flow tube is not filled completely

with fluid.

Fig. 3.2 Proper Examples of Downstream Piping

6

C−102-1-E

Electrodes

FLOW

FLOW

Horizontal run

Transmitter up with

axis of electrodes

horizontal

Vertical run

Cable entries pointing

downward

Bottom → Top

flow direction

is preferable.

Cable entries

(face down)

UP

Probe

Blow pipe

Downstream

valve

Bypass

Upstream

valve

Vertical flow direction

Valve

3.3 Physical Orientation of the Probe

The probe may be installed in any physical orientation as long as the flow tube is completely filled with the

process fluid.

Keep in mind the following precautions, however.

(1) Horizontal run

In a horizontal line, keep electrodes axes on a level plane to minimize the risk of electrodes being insulated

momentarily due to suspended gas bubbles.

(2) Vertical run

In a vertical line, avoid a transmitter orientation with cable entry pointing upward to prevent rainwater from

entering the transmitter.

Fig. 3.3

CAUTION: With liquids that contain suspended solids or liquids that can separate easily, a

vertical run is suggested to reduce the possibility of solids deposition, wear and

separation to a minimum.

3.4 Bypass Line

We recommend to provide a bypass line to facilitate

maintenance and inspection.

Particularly in a vertical run, it is desirable that the

piping be arranged to facilitate removal of solids

build-up inside the pipe line.

Fig. 3.4 Vertical Piping Example

7

C−102-1-E

Flow

Probe

Flow control valve

Probe

Lining

Seal face

(A) (B)

Gasket

(Must be in place.)

Do not seal on threads.

Flow

Upstream valve

Probe

Negative press. relief valve

Downstream valve

3.5 Prevention of Negative Pressure

In order to maintain a long-term service life of the

pro be, take pos i t ive measu res to elimi n ate

circumstances that can create negative pressure

in the pipeline.

(1) If b oth upstream a nd do wnst ream val ves

remain closed with fluid temperature higher

than that of the atmosphere, fluid contraction

may ta ke place as the fluid co ols down ,

creating negative pressure in the enclosed

space of pipeline. You can solve this problem

by providing a negative pressure relief valve

near the probe.

(2) If a vertical piping continues downstream of

the probe:

While stopping or adjusting the fluid flow with

the upstream valve of flowmeter, negative

pressure can be created in the pipeline. To

prevent this condition, stop or adjust the fluid

flow with the downstream valve.

Fig. 3.5 Piping Example to Prevent Negative Pressure (1)

Fig. 3.6 Piping Example to Prevent Negative Pressure (2)

3.6 Installation Location

Avoid locations such as:

(1) Near motors, transformers, or heavy electrical equipment

(2) Inaccessible for maintenance and inspection

(3) Temperature varies widely or vibration is excessive

(4) Potential risk of submergence

4. PROBE INSTALLATION

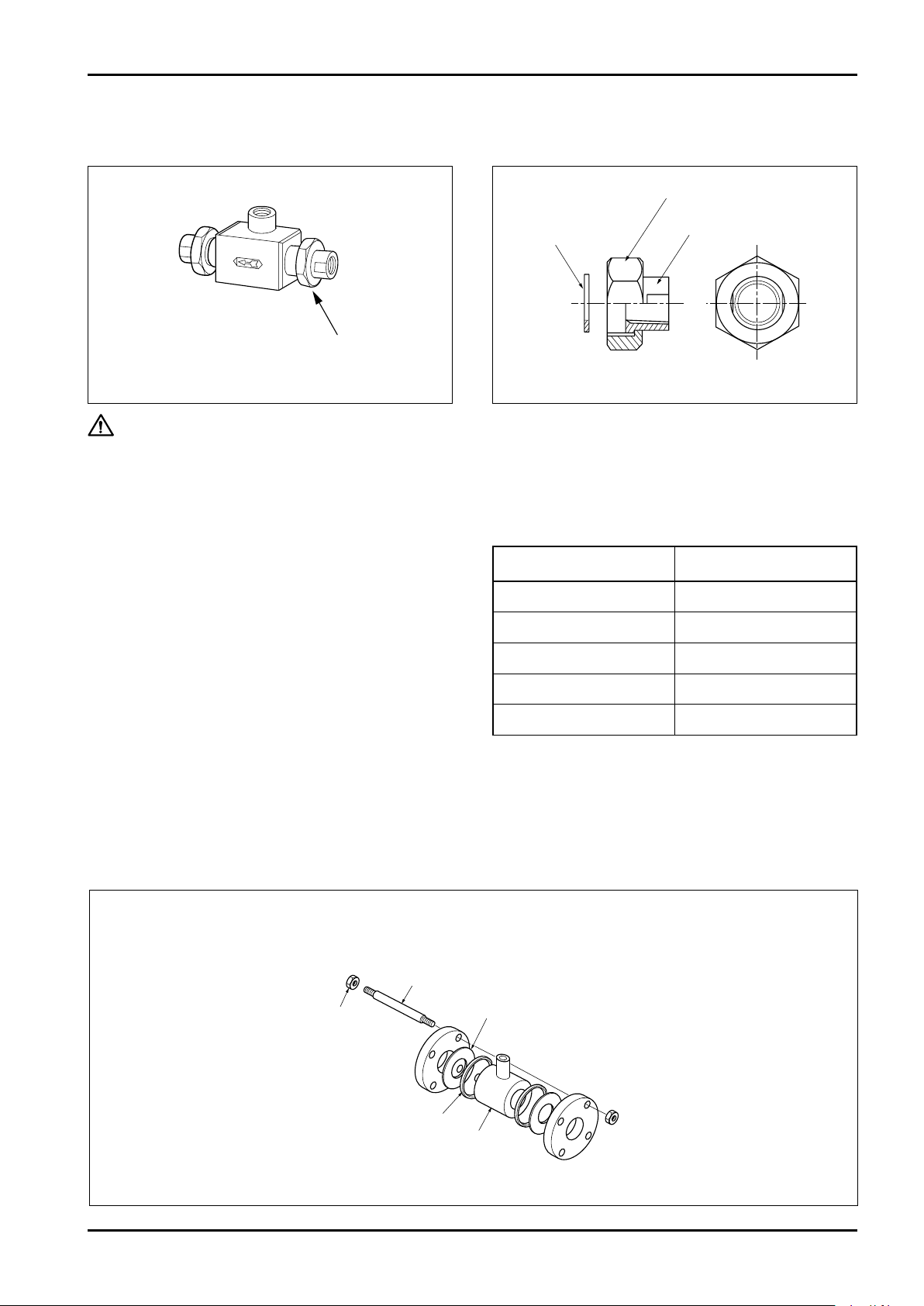

4.1 Screw-in Type (nominal sizes 3 to 15mm)

(1) Process connection is of screw-in type. By using dedicated unions, be sure to seal the end face of probe

(lining surface). Never apply a seal to threads as it is likely to cause unexpected trouble.

8

Fig. 4.1

(2) Union and other joints should be of dedicated accessories furnished for connecting pipes.

Union fitting

Tightening nut

Gasket

Rc (PT) screw adapter

Hex nut

Connecting bolt

Flange gasket

Adjust ring

Probe

Use of nonstandard fittings can lead to unexpected trouble.

Fig. 4.2 Example of Unions Installed in Place Fig. 4.3 Union Fitting (accessory for piping)

CAUTION: Install the transmitter securely.

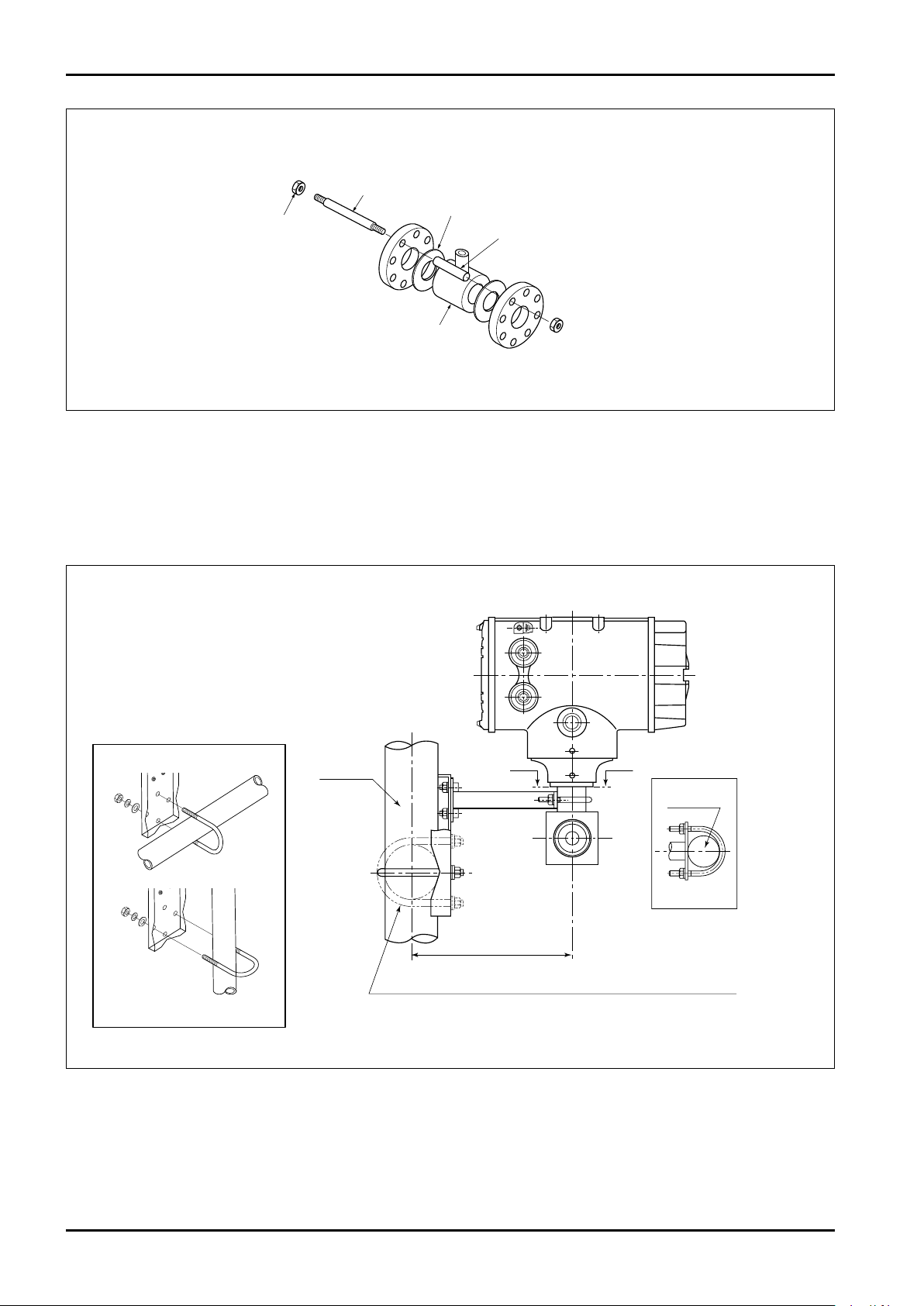

4.2 Wafer Type (nominal sizes 25 to 150mm)

C−102-1-E

Install the meter observing the following precautions:

Flange Tightening Torque Specifications

(1) Protection of probe's linings

a. Exercise care to avoid damage to the linings of

probe.

Nominal size (mm) Torque (N・m)

25, 40 39 to 54

b. Do not fail to use flange gaskets when making

pipe connections.

c. Tighten connecting bolts carefully to avoid

uneven tightening or over tightening.

( R efe r to th e f l an g e ti g ht e ni n g to r qu e

specifications in the table on the right.)

50 70

80 54

100 78

150 125

(2) Maintaining accuracy

a. To ensure concentric alignment of the probe,

do not fail to use the adjust rings furnished (or

adjust collars for nominal size 150mm meter

with JIS 10K flange rating).

b. Exercise care not to let flange gaskets protrude

inside the pipe.

◆ Installing adjust rings ◆ Nominal sizes 25mm to 150mm

(For nominal size of 150mm with flange rating of JIS 10K, see figure 4.5 on the next page.)

Fig. 4.4

9

C−102-1-E

Hex nut

Connecting bolt

Flange gasket

Adjust collar

(Install four adjust collars

uniformly 90° apart.)

Probe

Installation on a horizontal pipe is shown with dotted lines.

2″ Pipe

Adapter

Sec A-A

181.6

A A

◆ Installing adjust collars ◆ Nominal size 150mm, flange rating JIS 10K

Fig. 4.5

4.3 Transmitter Installation

(1) Securing the integral transmitter (nominal size 3 to 6mm):

For the screw-in type (nominal size 3 to 6mm), tubes are too thin to support the meter.

Therefore, secure the transmitter in the manner shown in the figure below.

Using the U-bolt and mounting bracket

supplied with the flowmeter, fix the

flowmeter to a horizontal or vertical pipe

with nominal diameter of 2″.

* Pipe is not supplied with the flowmeter.

Mounting to a horizontal pipe

Mounting to a vertical pipe

Fig. 4.6 MAG-OVAL III Transmitter Hold-down Hardware

10

C−102-1-E

Display cover

Hex key (M4)

Display cover

A flat tool that

does not damage

the finish

Turn

Fitting screw (M3)

Display unit

Display unit

Pull

Connector pins

Display unit

Connector

socket

Display unit

Press along

the guide

Guide hole

Guide pin

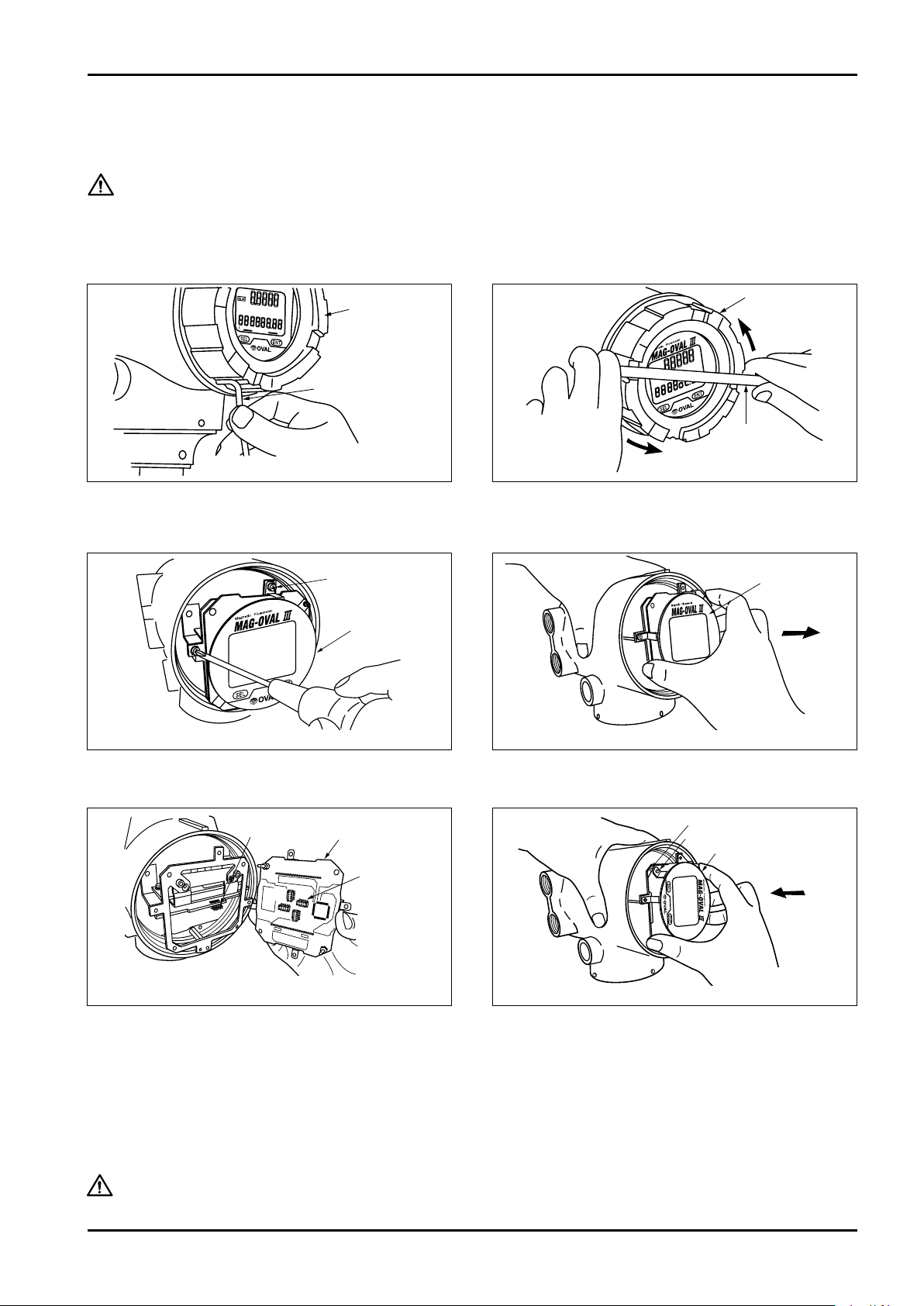

(2) Procedure to tilt the LCD display to the desired angle:

The display unit in its housing is rotatable in increments of 90 degrees through 360 degrees.

By changing the LCD display orientation, you can achieve optimum viewability also in a vertical line.

CAUTION: Do not forget to turn off the power before beginning this procedure. Another

precaution to remember is to eliminate static charges from the operator's body.

◆ Procedure to adjust angular orientation of display ◆

Fig. 4.7

(1) Using hex wrench, loosen the locking setscrew

(M4) securing the display cover in the locked

position.

Fig. 4.9

(3) Remove the mounting screws (4 places) with a

phillips screwdriver and detach the display unit.

Fig. 4.8

(2) Using a flat tool, loosen the display cover by

carefully turning it counterclockwise and hand

rotate it further until the cover comes off.

Fig. 4.10

(4) By pulling the display unit toward you, remove it.

Fig. 4.11

(5) The display unit is rotatable in 90° steps. Confirm

the locations of connector pins on the transmitter

body and mating sockets on the display unit.

(6) At the desired physical orientation of display unit,

rotatable in 90° steps, align four guide pins of the

unit with two mating guide holes and install into

Fig. 4.12

place by pressing it in a direction perpendicular

to its mating surface.

After determining the angular orientation of display unit, install display unit fitting screws, display cover, and

setscrew to lock the cover. Now the orientation adjustment is complete.

CAUTION: Install the display cover to the housing securely by tightening with a flat tool,

ensuring that no gap exists before tightening the locking setscrew.

11

C−102-1-E

Terminal block

cover

Terminal block cover

Turn

A flat tool that does

not damage the finish

GND terminal

Probe

Metal

pipe

GND terminal

Probe

Metal

pipe

GND terminal

Probe

Resin

pipe

Internal ground terminal

Power terminal

block

Terminal board

Output signal

terminal block

Cable entries

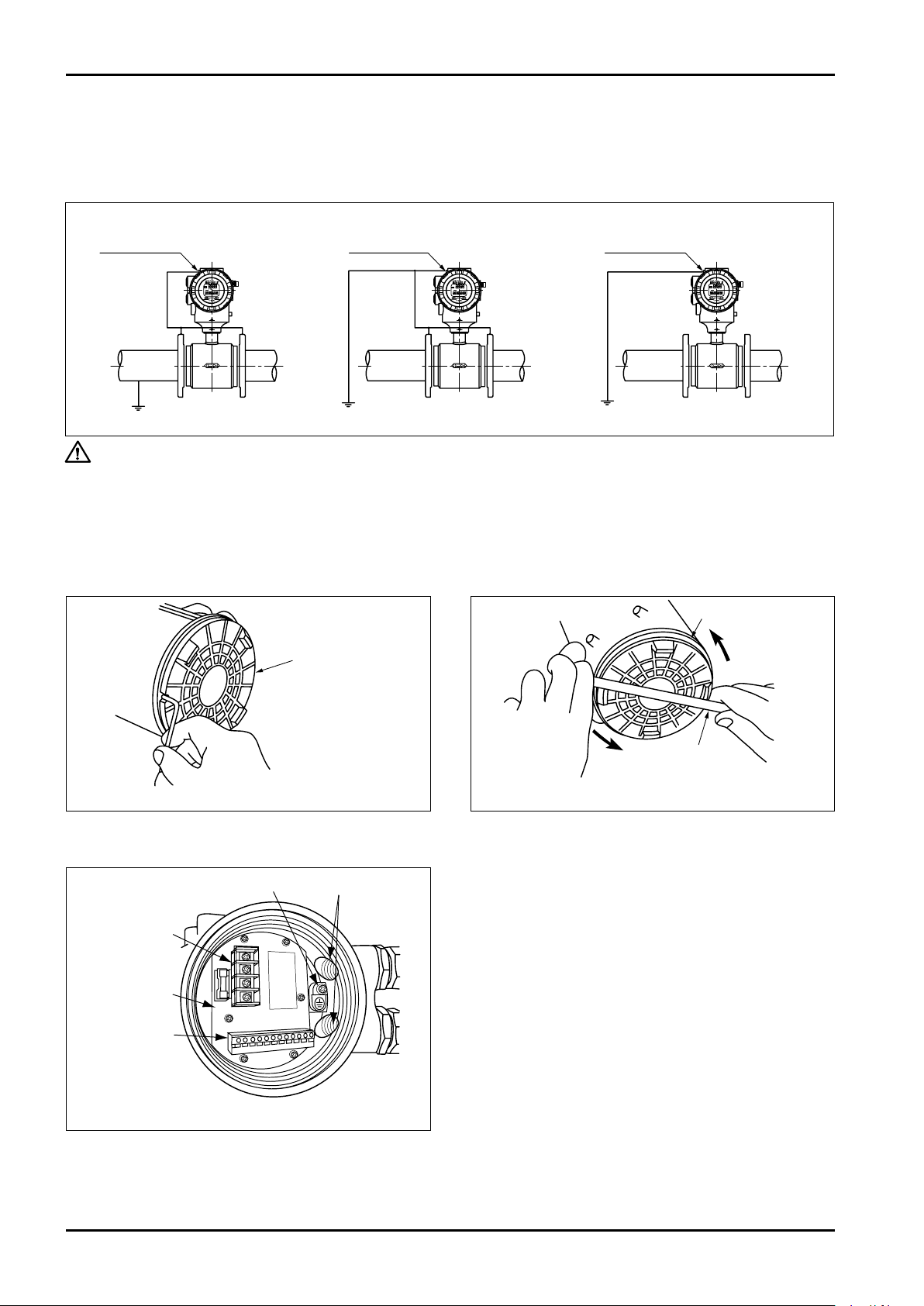

5. GROUNDING

The electromotive force detected across electrodes of the probe is a very weak voltage measured against the

reference potential of metered liquid. Accordingly, earth grounding (better than Class C grounding) is essential to

maintain the probe and metered liquid at the same potential. Illustrated below are the proper grounding procedures.

Grounded metal pipeline

Ungrounded metal pipeline Plastic or lined pipeline

Fig. 5.1

CAUTION: Do not connect to earth ground of heavy electrical equipment.

Connect the ground wire for the transmitter to external ground terminal or internal

ground terminal.

6. WIRING CONNECTIONS

6.1 Power and Output Signal Wiring Connections

Terminals for wiring connections are found at the back of transmitter housing. Remove the cover and make wiring connections.

(1) Using hex wrench, loosen the locking setscrew

(3) Separating the cover provides access to the

12

Fig. 6.1

(M4 hex socket head) securing the cover.

Fig. 6.3 Terminal Board

terminal board with cable entrance openings,

int ernal ear t h grou nd termi nal and ter minal

blocks for power and output signals.

Fig.6.2 Terminal Block Cover Removal

(2) Using a flat tool, carefully loosen the terminal

cover by rotating it counterclockwise and turning

further by hand until it comes off.

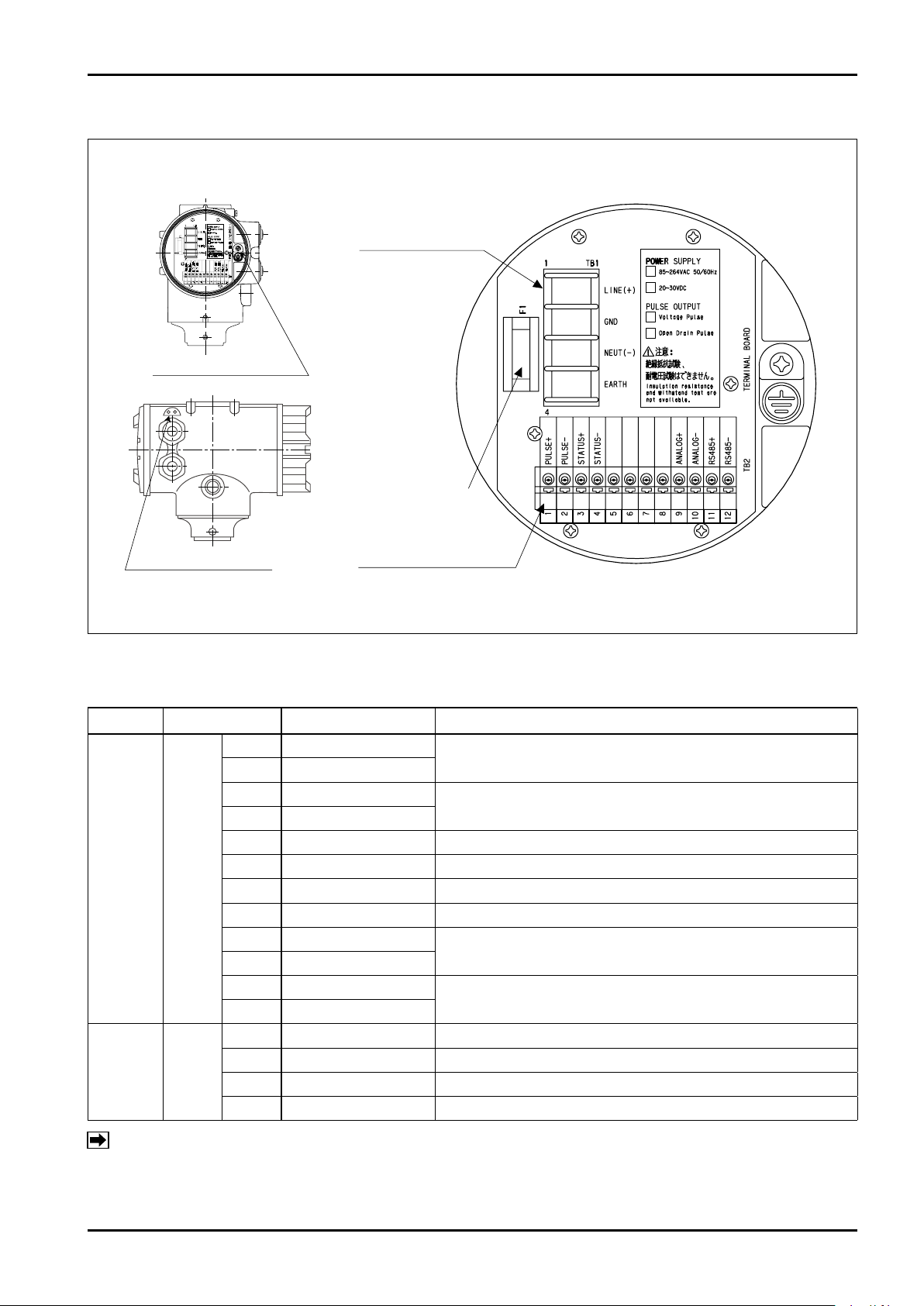

6.2 Wiring Connection Diagram

Power fuse

Output signal terminal (TB2)

screwless terminal

Internal ground terminal

External ground terminal

Power terminal (TB1)

screw size: M4

GND terminal location Details of terminal block

C−102-1-E

Fig. 6.4 Connecting Terminal Layout

6.3 Power and Output Signal Terminal Identification

Item Terminal No. Label Description

1 PULSE +

2 PULSE −

3 STATUS +

4 STATUS −

5 Unused

6 Unused

7 Unused

8 Unused

9 ANALOG +

10 ANALOG −

11 RS485 +

12 RS485 −

1 LINE(+) Power (with DC power: + )

2 GND Ground

3 NEUT(−) Power (with DC power: - )

4 EARTH Ground

Output signal

Power

TB2

TB1

Pulse output

(Open drain pulse output, or voltage pulse output)

Status output

(Open collector output)

Analog output

RS-485 communication

Note: Ground terminal "EARTH" shall be used for grounding. Ground terminal "EARTH" of this

flowmeter is internally connected to "GND".

13

C−102-1-E

ANALOG+

ANALOG-

R

R

R

STATUS+

STATUS -

Receiver

Receiver Receiver

Receiver

ON

PULSE+

PULSE-

PULSE-

E:18V

R

E

ON

PULSE+

30VDC

50mA Max.

30VDC

50mA Max.

Line

capacity C

Line

capacity C

R 2.2kΩ

510Ω Max.

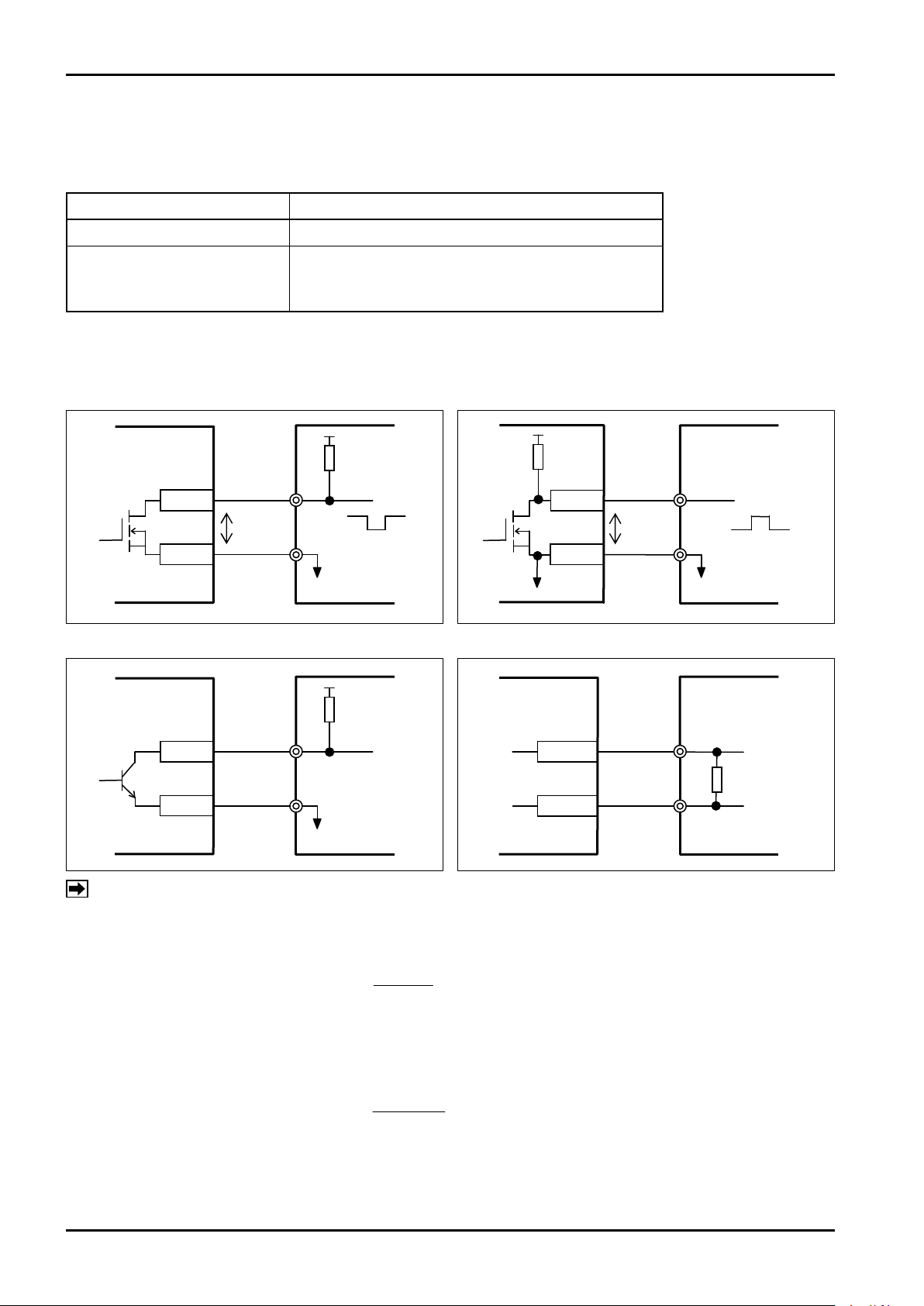

6.4 Wiring Connection Instruction

The screw size for cable entry is G1/2.

For connections to terminals, use the following crimping terminals.

Terminal name Recommended crimping terminal

Power terminal Round crimping terminal for M4

Output signal terminal

(Screwless terminal block)

No crimping terminal is required.

Use a cable of 0.2 to 1.25mm2.

Standard wire strip length: 11mm

■ Connection to receiver

Open drain pulse output Voltage pulse output

Status output Analog output

0.1

R X C

NOTE: The tran smission len gth of pulse output is restricted by the outpu t frequency or receiver

specifications.

When setting open drain pulse

The pulse output waveform is attenuated by resistance R and line capacity C of the receiver.

The output frequency shall be set to F [Hz] < .

Line capacity C shall be set to 0.1μF/km.

When setting voltage pulse

The pulse output waveform is attenuated by resistance R and line capacity C in the flowmeter.

(The resistance factor of R is included in the following coefficient.)

The output frequency shall be set to F [Hz] < .

0.1

4400 X C

Line capacity C shall be set to 0.1μF/km.

14

C−102-1-E

7. START-UP

(1) Upon completion of meter installation and field wiring connections, reaffirm the following:

a. Is the meter correctly installed? Is the flow direction correct?

b. Is the flow tube completely filled with the fluid?

c. Is the grounding correctly done?

(2) After filling the flow tube with the fluid, turn the power on.

a. On power-up, allow at least a 30 minute warm-up period.

b. When fluid flows, a signal (pulse and analog) proportionate to the flow is output and instantaneous flow

rate (default) is displayed on the top row of the LCD of the transmitter and accumulated total flow or

resettable total flow is displayed on the bottom row of the LCD. (The display can be selected by setting.)

(3) Using the two magnet switches in the transmitter, you can confirm or change parameters, such as full scale

and pulse units, and change the LCD display menus.

8. MAINTENANCE

Every MAG-OVAL III leaves the factory under stringent quality control. As long as it is placed under proper

conditions, it will perform satisfactorily over long periods of time. If trouble arises, diagnose the nature of trouble

according to the troubleshooting chart below for the possible solution.

When error alarm is being generated, check the detail of error in accordance with "20. ERROR/ALARM STATUS

LIST".

Problems

No Output

Unstable Zero

Unstable Output

○

○

○

○

○

○ ○

○ ○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○

○ ○

○ ○

○ ○

○

○

Quick Troubleshooting

Confirm

Large Meter Error

(1) The wiring is correct.

(2) The power is sufficiently supplied.

(3) The fuse is not interrupted.

(4) The fluid is flowing, or valves are open.

(5) Receiving instrument specifications are matching. (Input pulse width, etc.)

(6) There is no leak from pipeline connections and valves.

(7) Earth ground is properly completed.

(8) Flow tube is completely filled. (There is no bubble entrapment.)

(9) There are no pulsations in the flow.

(10) Motors, transformers, or other heavy electrical equipment are not near the probe.

(11) Lining (electrodes) is free from slurry deposits.

(12) Fluid conductivity is uniform.

(13) Fluid is free from magnetic slurries.

(14) Piping conditions are correct. (Inaccurate probe centering or insufficient upstream pipe length)

(15) Full scale (flow range) is correct.

(16) Calibration factor and zeroing const. are correct.

(17) Primary standard against which the meter is compared is correct.

15

C−102-1-E

ALM

(5) Error/Alarm indicator

(4) Total flow rate unit

display

(8) [SEL] key indicator

(9) [SEL] key

(1) Instant flow rate display

(Top row)

(2) Instant flow rate unit

(3) Total flow display

(Bottom row)

(6) [ENT] key indicator

(7) [ENT] key

ERR

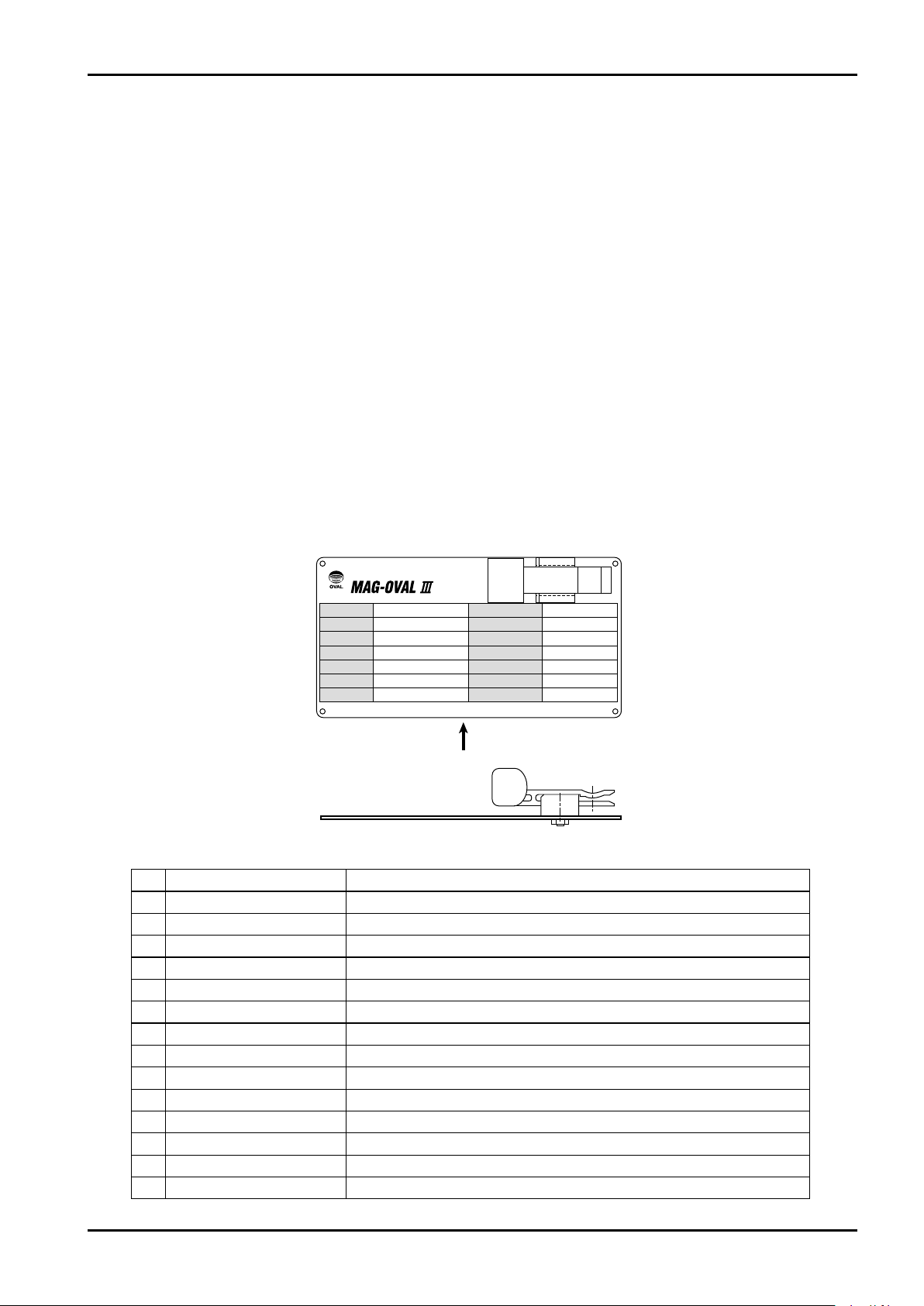

9. TRANSMITTER DISPLAY AND OPERATION

9.1 Explanation of Display

No. Item Description

Instant flow rate display (Top row)

(1)

Instant flow rate unit display Displays unit of instant flow rate.

(2)

Total flow display (Bottom row) Displays total flow or resettable total.

(3)

Total flow rate unit display Displays the unit of total flow.

(4)

Error/Alarm indicator Indicates the occurrence of error or alarm.

(5)

[ENT] key indicator Turns on when [ENT] key is operated.

(6)

[ENT] key [ENT] key. Operated by the use of attached selector magnet.

(7)

[SEL] key indicator Turns on when [SEL] key is operated.

(8)

[SEL] key [SEL] key. Operated by the use of attached selector magnet.

(9)

9.2 Operation Basics

9.2.1 Setup Mode and Measure Mode

This flowmeter is provided with two modes: "Measure mode" and "Setup mode".

"Measure mode" : The state after power on or at the completion of the Setup mode in item 11.

Displays instant flow rate and total flow.

The content of display can be changed by key operation.

After power on or at the completion of the Setup mode in item 11, the flowmeter returns to

→ Refer to "10.4 Screen Change for Instant and Total Flow Indication".

"Setup mode" : Checking and changing parameters and self-diagnosis are available from the Menu.

→ Refer to "11.1 Transition from Measure mode to Setup mode".

this state automatically.

Displays the instant flow rate. % flow rate and flow velocity can be selected

by switching.

16

C−102-1-E

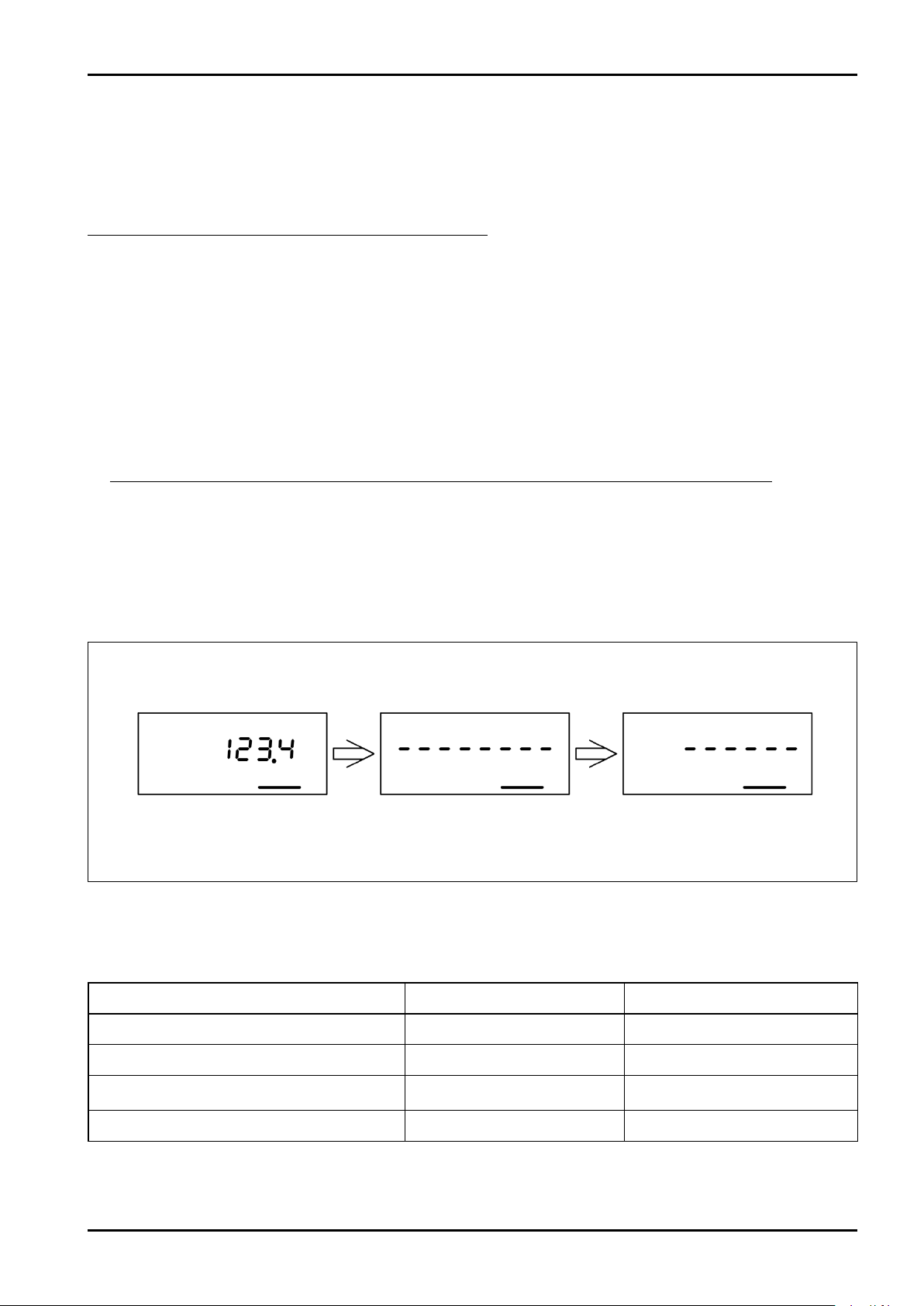

Ex. Indication when ENT key is set to ON

Indicator ON

Bar indication appears

on the bottom row display

Bars disappear

When all bars disappear,

press and hold ENT key

9.2.2 Key Operations

The keys of this flowmeter can be operated by placing the supplied magnet close to the "SEL" key and "ENT"

key in the magnet switch section.

Moving the magnet close to the SEL key or ENT key causes the magnet sensor to respond and the key entry is

set to ON.

The magnet sensor can respond through the glass screen.

■ Displayed messages during operation

Key operations include Ordinary depression (short key entry) and prolonged depression (press and hold key

entry).

(1) Ordinary depression

When the SEL key or ENT key is set to ON, the key indicator turns on. Setting the key entry OFF immediately

after the indicator turns on, starts ordinary operation.

If the key entry is kept ON, bars "- - - - - - -" appear on the bottom row display and then bars begin to

disappear at given time intervals.

If you set the key entry to OFF before the last bar disappears, it stays at the ordinary depression.

(2) Prolonged depression

Pressing and holding the SEL key or ENT key causes bars "- - - - - - -" to be displayed at the bottom row

display and then bars disappear one by one from the left.

Keeping the key ON until all bars disappear will start the prolonged depression.

(If you set the key to OFF before all bars disappear, it goes back to the ordinary operation (1).)

■ Description of each key operation

Each key operation executes the operation shown in the following table.

Key operation During Measure mode During Setup mode

SEL ((1) Ordinary depression) Changes display menu Switches operation, changes value

Press and hold SEL ((2) Prolonged depression)

ENT ((1) Ordinary depression)

Press and hold ENT ((2) Prolonged depression) Fixes the changes Fixes the changes

—

Switches between top and

bottom row displays

Return, Cancel

Shifts digits at the change of value

17

Loading...

Loading...