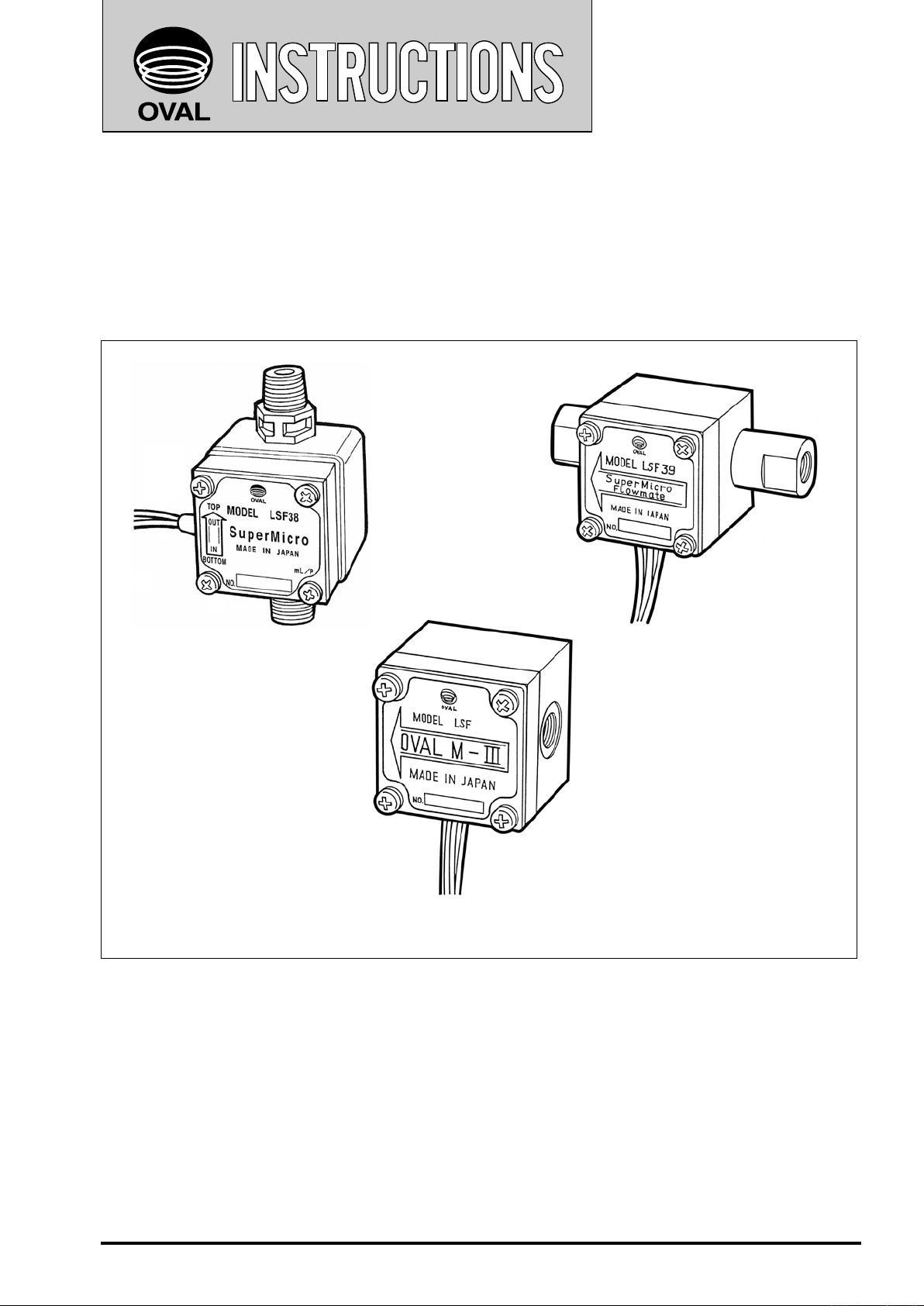

Oval LSF38, LSF41, LSF45, LSF39, LSF40 Instructions Manual

Super Micro Flow Mate

FLOW MATE (OVAL M-

Ins. No. S-176-9-E

)

Ⅲ

MODEL LSF

38

39

40

□□-□□

4

1

45

Super Micro 38

Meter Sizes 40, 4

Every OVAL product is manufactured and functionally tested under stringent quality control before

shipment. In order to maintain its design performance throughout its life, this manual offers the

operator the necessary installation, operation and maintenance information. Be well familiar with

these instructions before you place your meter in service and retain it at the eld location for ready

reference.

1, and 45

Super Micro 39

Fittings provided (option)

1

S-176-9-E

CONTENTS

1. BEFORE YOU BEGIN .................................................................................................................................... 3

1.1 Transit Considerations ............................................................................................................................... 3

1.2 Storage Considerations ............................................................................................................................. 3

1.3 Structural Consideration ............................................................................................................................ 3

2. OPERATING CONDITIONS ........................................................................................................................... 4

3. INSTALLATION .............................................................................................................................................. 4

3.1 Tubing Consideration ................................................................................................................................ 4

4. WIRING .......................................................................................................................................................... 5

4.1 Field Wiring ............................................................................................................................................... 5

4.2 Electrical Connections ............................................................................................................................... 5

5. OPERATING INSTRUCTIONS ....................................................................................................................... 6

5.1 Operation ................................................................................................................................................... 6

5.2 Operating Precautions ............................................................................................................................... 7

5.3 Precautions at Operation Shutdown .......................................................................................................... 8

6. DISASSEMBLY AND INSPECTION ............................................................................................................... 9

6.1 Meter Body Disassembly and Inspection .................................................................................................. 9

6.2 Meter Body Assembly .............................................................................................................................. 10

7. TROUBLESHOOTING ..................................................................................................................................11

8. EXPLODED VIEWS AND PARTS LIST ........................................................................................................ 12

8.1 Meter Size 38 .......................................................................................................................................... 12

8.2 Meter Size 39 .......................................................................................................................................... 13

8.3 Meter Sizes 40, 41 and 45 ...................................................................................................................... 14

9. GENERAL SPECIFICATIONS ...................................................................................................................... 15

10. OUTLINE DIMENSIONS .............................................................................................................................. 17

11. PRODUCT CODE EXPLANATION ............................................................................................................... 19

CONVENTIONS

Shown in this manual are the signal words NOTE, CAUTION and WARNING, as described

in the examples below:

2

NOTE: Notes are separated from the general text to bring the user's attention to

important information.

CAUTION: Caution statements signal the user about hazards or unsafe practices

which could result in minor personal injury or product or property

damage.

WARNING: Warning statements signal the user about hazards or unsafe

practices which could result in severe personal injury or death.

S-176-9-E

1.BEFORE YOU BEGIN

Every meter is thoroughly tested before it leaves the factory. When received, it should be thoroughly

inspected for any indication of damage during transit.

Necessary handling precautions are described in this section; read the instructions carefully. As for

other information, refer to the respective section. For any inquiries, contact your nearest OVAL sales

ofce.

CAUTION

When you make inquiries, include the product name, model code, serial number, ratings

and other pertinent information.

1.1 Transit Consideration

(1) To safeguard against damage during transit, transport FLOW MATE (OVAL M-Ⅲ) to the installation

site in the original cardboard container used for shipment from the factory if circumstances

permit.

FLOW MATE (OVAL M-Ⅲ) is adjusted and inspected completely with all the components of the meter-

(2)

sensor unit, pulse generator, etc. For this reason, treat them as one complete assembly.

1.2 Storage Considerations

If the meter is going to be stored for long periods of time upon receipt before installation, it could be

damaged or deteriorated due to unforeseen circumstances. If a lengthy storage is expected, the

following precautions should be taken:

Keep FLOW MATE (OVAL M-Ⅲ) in store in the same container used for shipment from OVAL if possible.

(1)

Place of storage should conform to the following requirements:

(2)

Free from rainwater.

★

Free from vibration and impact shocks.

★

Temperature and relative humidity in the storage place are at or near room temperature and

★

humidity (around 25℃ and 65% RH).

(3) If FLOW MATE (OVAL M-Ⅲ) that has once been placed in service is to be stored, it should be purged

2

ith clean air, N

w

inner walls, housing exterior and other components.

NOTE: Use clean detergent, etc. to remove contaminants if necessary.

spin too fast during the ushing or cleansing process.

CAUTION

(4)

The Super Micro 38 has a plastic resin molded joint ; therefore, excessive tightening

or repetition of mounting and dismounting more than necessary may result in broken

joint or loss of airtightness due to deformed taper screw.

(5) If you want to store the meter for extended periods of time, keep it stored under the conditions

similar to those during shipment.

gas, etc. to remove residual process uid from the meter interior, ttings, tubing

Do not allow the meter to

1.3 Structural Consideration

FLOW MATE (OVAL M-Ⅲ) is intended for indoor use. Do not expose it to rainwater or running water.

3

S-176-9-E

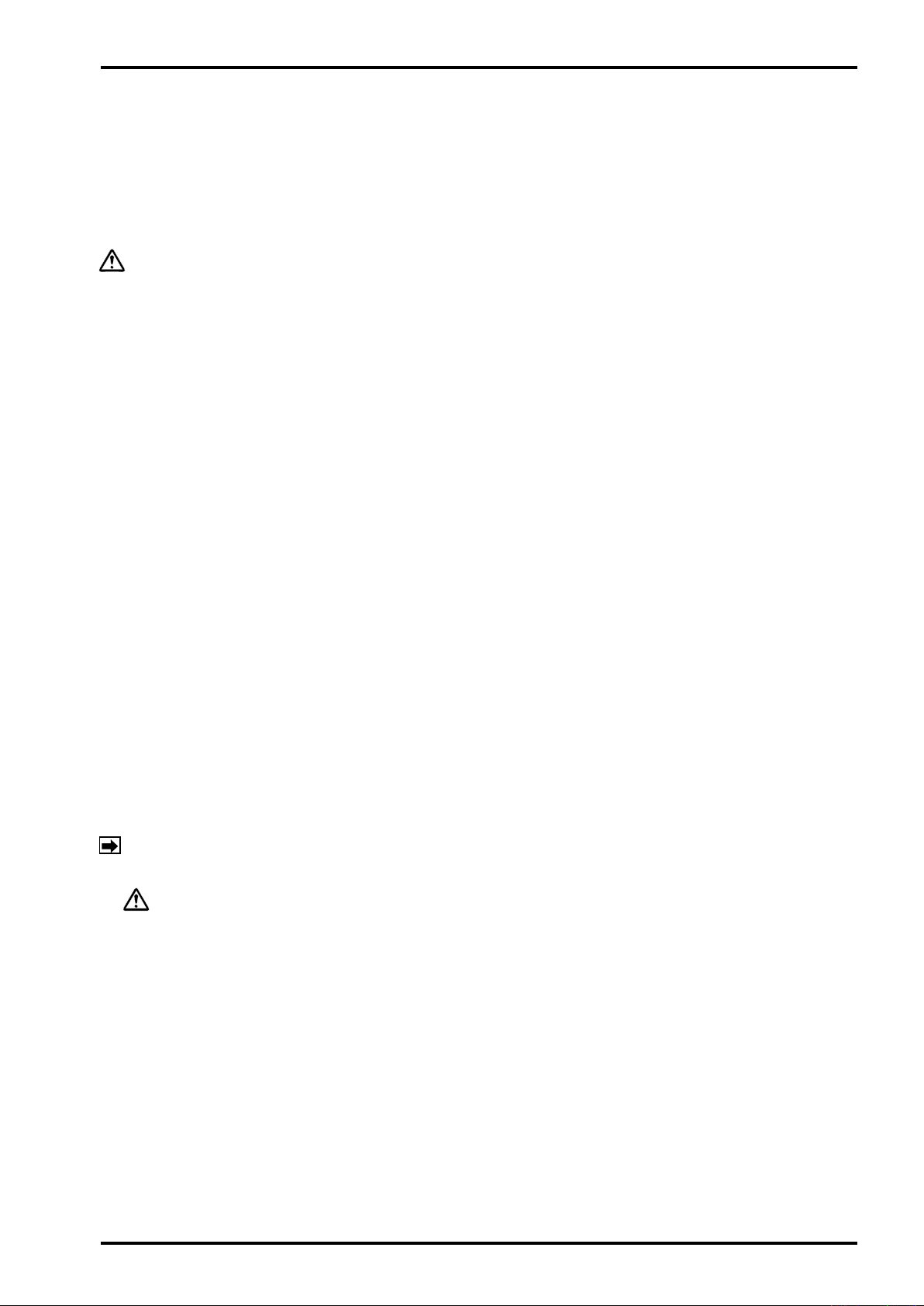

Bypass Loop

Strainer

Valve

Short Pipe

Flow Direction

2. OPERATING CONDITIONS

To maintain the stated high accuracy and long service life of FLOW MATE (OVAL M-Ⅲ), make sure

that the flowrate, pressure, temperature and viscosity are held within the ratings. The operating

conditions appear in the GENERAL SPECIFICATIONS on page 15. Conrm these ratings before

commencing operation.

CAUTION

If the body material of FLOW MATE (OVAL M -Ⅲ) is aluminum + anodized aluminum coating,

it is not serviceable for water and corrosive liquids.

3. INSTALLATION

3.1 Tubing Considerations

(1)The tubing assembly must be thoroughly flushed. Flushing must be performed before meter

installation. Couple a short pipe section in place of the meter (see the ushing set-up given below).

(2)The meter should be installed exercising due care to avoid pipe strains.

(3)When screwing in the ttings, be very careful not to allow metal chips and seal tape protrusions to

get into the meter

.

(4)The meter should be located downstream of the pump.

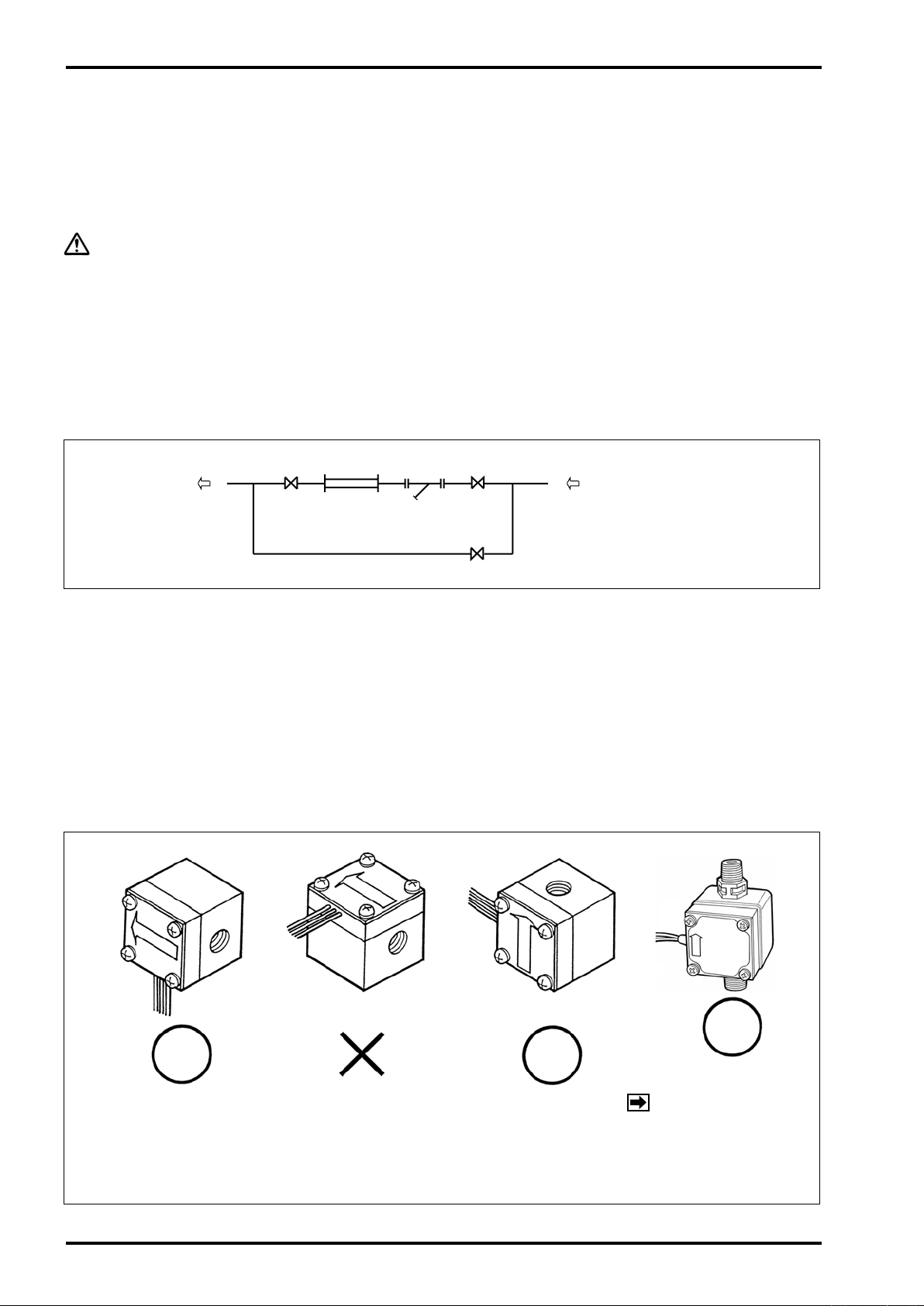

(5)Flow direction must conform to the arrow mark indicated on the meter body.

(6)The strainer should be located upstream of, and as close to the meter as possible.

(7)The physical orientation of the meter should be such that its nameplate is vertical as shown below.

(8)When installing Size 38 meter in the tubing assembly, screwing torque at the tting should be

held with in

10N・m.

Measures flow in either

※

direction (from left to right

or from right to left).

4

Avoid meter orientation

※

with nameplate top or

bottom.

Measures ow in either

※

irection (from top to

d

bottom or from top to

bottom).

NOTE: Making measurement with Size 38 meter

is acceptable only in this

orientation (ow direction

from bottom to top).

S-176-9-E

200mm approx.

4. WIRING

NOTE : Also see the topic "WIRING" in the instruction

manual of the receiving instrument used.

4.1 Field Wiring

(1)Cables for eld wiring

The following cables should be used unless otherwise specied.

Shielded chloroprene cabtyre cables (kind 2, JIS C 3327, shielded) or shielded vinyl cabtyre

2

cables (JIS C 3312, shielded) with a conductor area 1.25mm

3-conductor cables may be used to suit your specic application. Shielded end should be grounded

t the ground terminal of the receiving instrument.

a

(2)Transmission length

With transmission cables conforming to JIS C 3327 or C 3312 conductor area 1.25mm

maximum transmission length is typically one kilometer.

If

NOTE:

it exceeds one kilometer, consult factory.

(3)Prevention of inductive interference

T

o minimize the possibility of stray current pickup, route the eld wiring sufciently away from other

power cables and power circuits.

.

2

, the

CAUTION: Verify the validity of flowmeter (pulse generator) to receiving instrument

combination by their product No., instrument No., etc. before making wiring

connections.

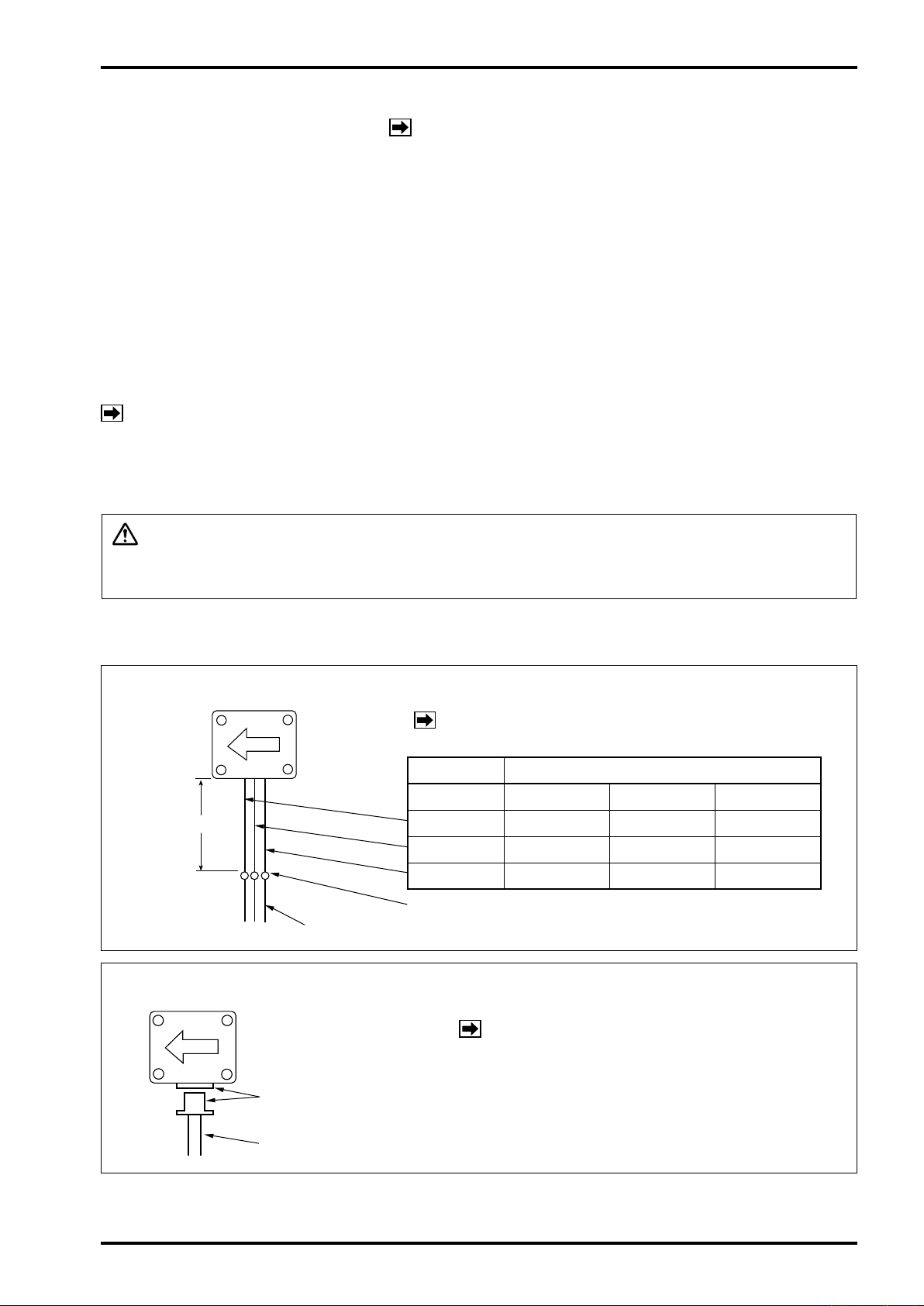

4.2 Electrical Connections

3-Wire System (MR sensor): Meter sizes 38, 39, 40, 4

◆

NOTE ※: Unfactored pulses only with Meter sizes

38 and 39 .

Unfactored pulse

All models

WHT: SIG GRN: SIG YEL: SIG GRN: SIG

Soldered or coupled with connector.

Wire leads (customer to furnish)

-Wire System (reed switch): Meter sizes 40, 4

2

◆

RED: +V RED: +V RED: +V RED: +V

BLK: 0V BLK: 0V BLK: 0V BLK: 0V

※

1, and 45 (unfactored pulses only)

1, and 45

Factored pulse

Size 40 (1mL/p) Size 41 (1mL/p) Size 45 (10mL/p)

Connector and Receptacle

Wire leads (customer to furnish)

NOTE: 1. Remove connector terminals and crimp

wire leads for installation.

2. The sensor is of reed switch type.

Polarity observation is not required.

5

S-176-9-E

Bypass Loop

Strainer

Valve

Meter

C

B A

Flow Direction

5. OPERATING INSTRUCTIONS

5.1 Operation

Adhere to the operations sequence outlined below for the first time operation, allowing the

process fluid flow within the flow range specified.

NOTE: See the tubing diagram below

(1) Shut off upstream valve (A) on the inlet side and valve (B) on the outlet side and then open bypass

line valve (C) to allow the uid in the bypass line, thereby removing weld spatters, metal chips, scales

and other foreign matter left in the tubing assembly.

CAUTION: This is particularly important for new or rebuilt tubing assemblies.

.

(2) Carefully and slightly at rst, open valve (A) upstream of the meter progressively and then, slightly

at rst, open valve (B) downstream of the meter progressively

.

(3) Slowly close bypass line valve (C) and make sure that the total counter in the receiving instrument

a

dvances in response. Bubbles in the measuring chamber can produce meter errors; bleeding all

air is essential at the time of meter installation in the tubing assembly.

With Meter Size 38, allowing the uid at 50ml/min. or so for more than one minute is suggested.

With meters other than Size 38, allow the uid at a rate 10 to 20% of the maximum owrate for

more than 15 minutes and ensure that all the air has escaped from the tubing assembly.

In applications where temperature exceeds 60℃, run the meter at least for 30 minutes in this state

to ensure that heat distribution in the measuring chamber becomes uniform.

(4) Following the break-in (preheating) period, shut off bypass line valve (C) completely and open

u

pstream valve (A) progressively until fully open and slowly open downstream valve (B) until the

rated ow is reached.

(5) Flowrate should be regulated with downstream valve (B) and should be held within the rating.

(6) The strainer net should be inspected for condition and cleaned on a regular basis.

newly installed tubing assembly in particular requires daily net inspection for condition to prevent

A

any ow obstructions. The service intervals may be reduced progressively to, say once a week

thereafter.

CAUTION: Use extra care to avoid running the meter too fast.

6

Loading...

Loading...