Ins. No. E-883-4N-E

Temperature/pressure compensated

FLOW COMPUTER (Liquid service)

Model EL4131

This manual has been prepared to provide you with the information pertinent to the Temperature/

Pressure Compensated FLOW COMPUTER (Liquid service).

With the proper application of the information and knowledge contained in this manual, you can expect

the best possible results over a long service life of this instrument. Keep this manual for ready reference.

It is suggested that the instruction manuals for the companion pulse generator (flowmeter) and receiving

instrument be referred to at the same time.

1

E--883--4N--E

TABLE OF CONTENTS

1. BEFORE YOU BEGIN ............................................................................................................ 4

1.1 Confirming the Nameplate ..................................................................................................... 4

1.2 Transportation Precautions ..................................................................................................... 4

1.3 Storage Precautions .............................................................................................................. 4

2. GENERAL ................................................................................................................................ 5

2.1 Features ................................................................................................................................ 5

2.2 Part Names ........................................................................................................................... 5

3. INSTALLATION ....................................................................................................................... 6

3.1 Outline Dimensions ............................................................................................................... 6

3.2 Installation ............................................................................................................................. 6

3.2.1 Installation Location ...................................................................................................... 6

3.2.2 Panel ............................................................................................................................ 6

3.2.3 Installation .................................................................................................................... 6

4. WIRING ..................................................................................................................................... 7

4.1 Field Wiring Cables ............................................................................................................... 7

4.2 Wiring Connections ............................................................................................................... 7

4.3 Description of Terminal Blocks for External Connections ...................................................... 7

5. GENERAL SPECIFICATIONS ................................................................................................ 9

6. INTERNAL COMPONENTS AND FUNCTIONS .............................................................. 10

6.1 Front Panel ........................................................................................................................... 10

6.1.1 Display ......................................................................................................................... 10

6.1.2 On-Screen Menu Items ............................................................................................... 10

6.1.3 Error Messages ........................................................................................................... 10

6.1.4 Front Panel Keypad ...................................................................................................... 11

7. CALCULATION FORMULAS ............................................................................................... 12

7.1 Implementation of Meter Error Correction (Total flow before correction) ...............................12

7.2 Implementation of Temperature/Pressure Correction (Corrected total flow) .........................12

7.3 Instant Flowrate (Uncorrected) .............................................................................................. 12

7.4 Instant Flowrate (Corrected) ..................................................................................................12

8. PREPARATIONAL CHECKS AND OPERATION ............................................................. 13

8.1 Preparation Before Operation ...............................................................................................13

8.2 Preparational Checks ............................................................................................................ 13

8.3 Operation ...............................................................................................................................13

9. TROUBLESHOOTING ............................................................................................................ 14

10. ERROR MESSAGES............................................................................................................15

11. BEHAVIOR IN ERRATIC CONDITIONS ..........................................................................15

12. OVERALL BLOCK DIAGRAM ........................................................................................... 16

13. PRODUCT CODE EXPLANATION .................................................................................. 17

E--883--4N--E

COMPANION VOLUME

KEY OPERATION MANUAL Ins. No. E-880TM-E

CONTENTS

1. KEY ARRANGEMENT ……………………………………………………………………………… 10

2. DISPLAY SCREEN ………………………………………………………………………………… 11

3. INITIAL CHECK ……………………………………………………………………………………… 14

4. MODE SELECTION ………………………………………………………………………………… 18

5. RUN MODE SCREEN ……………………………………………………………………………… 23

6. SET MODE …………………………………………………………………………………………… 36

7. SYS MODE ………………………………………………………………………………………… 142

8. EL4401 …………………………………………………………………………………………… 170

9. EL4501 …………………………………………………………………………………………… 175

10. DIP SWITCH CONFIGURATION ……………………………………………………………… 182

(※: Model with communication capabilities)

COMMUNICATION MANUAL (※) Ins. No. E-880CM-E

CONTENTS

1. COMMUNICATION CAPABILITY OVERVIEW …………………………………………………… 5

2. NETWORK CONFIGURATION …………………………………………………………………… 5

3. MODE SELECTION ………………………………………………………………………………… 6

4. LOCAL / REMOTE SELECTION …………………………………………………………………… 8

5. SETUP ITEMS FOR COMMUNICATION ………………………………………………………… 10

6. COMMUNICATION PROCEDURE ………………………………………………………………… 11

7. COMMUNICATION FORMAT ……………………………………………………………………… 12

8. BCC / SUM CHECK ………………………………………………………………………………… 45

9. CR / LF ……………………………………………………………………………………………… 46

10. CODES ASSIGNED TO UNITS …………………………………………………………………… 48

11. ASCII CODE ………………………………………………………………………………………… 49

E--883--4N--E

1. BEFORE YOU BEGIN

Every OVAL product is thoroughly tested and inspected before shipment from our factory.

When received, its appearance should be inspected for possible damage by rough handling during

transit. First of all, thoroughly read the handling precautions described in this section. For topics other

than those covered in this section, refer to the respective sections of this manual.

If at any time in the future you seek our assistance, contact the nearest sales office in your area.

1.1 Confirming the Nameplate

The instrument is adjusted to individual specifications before shipment from our factory. Model

number appears on the nameplate attached to the

top of the housing.

Make sure to see that the instrument you received

conforms to the General Specifications and the

Product Code Explanation.

◆ When you inquire, supply complete informa-

tion as to the product name, model number,

product number, ratings, and other pertinent

information

1.2 Transportation Precautions

Nameplate (model number)

※

※ EL001 is the

generic designation of the

EL001 series

computers.

Fig. 1.1 Nameplate Location

(1) In order to safeguard against damage during transit, transport your instrument to the installation

location in the original package used for shipment from the factory if possible.

(2) Use care to avoid impact shocks to the instrument during transit.

1.3 Storage Precautions

If the instrument upon receipt is to be stored for extended periods of time before installation, unexpected

problems could arise. If such is the case, the following considerations should be taken:

(1) The instrument can best be stored in the original package used for transit from the factory.

(2) The place of storage should meet the following requirements:

☆ Free from rain and water

☆ Free from vibration and impact shocks

☆ With minimal temperature and humidity variation (around 25°C and 65% R.H.)

E--883--4N--E

MODEL EL4001

TB

1

TB

2

TB

1

TB

2

TB

3

PLS OUT3 TEMP IN TEMP IN FLOW IN

0V

+−

B bA

+−

+−+− +−

+−

SIG SUP

SUP

ANA OUTGND POWER

N

(

−

)

H

(

+

)

PRESS INPLS OUT1

PLS OUT2

1/1

OUT

2. GENERAL

Using the most advanced electronic tehcnologies, this digital instrument has been developed specifically

to meet the most demanding liquid flow measurement applications where accuracy is the prime

requirement.

In response to the liquid flowrate and temperature information arriving from the sensing terminal, such as

a flowmeter, it totalizes the flow while implementing meter error and temperature corrections.

An analog output and instant flowrate (corrected for meter error and temperature) output are additional

provisions.

2.1 Features

(1) Changing the meter factor, ranges of temperature, pressure, or other parameters, of the companion

flowmeter is simple by keystrokes on the front-panel keypad, or by inserting an IC card into the slot.

(2) Built around a microprocessor, the instrument carries out calculations entirely in digital signal

processing circuits to achieve a high degree of accuracy and reliability.

(3) Variables, such as temperature and pressure, can be reviewed on command with the front panel

keypad, whether or not calculation is in progress.

(4) A nonvolatile memory (E2PROM) retains all parameters and variables. Variables are resettable

following a power cycle or reset if so configured.

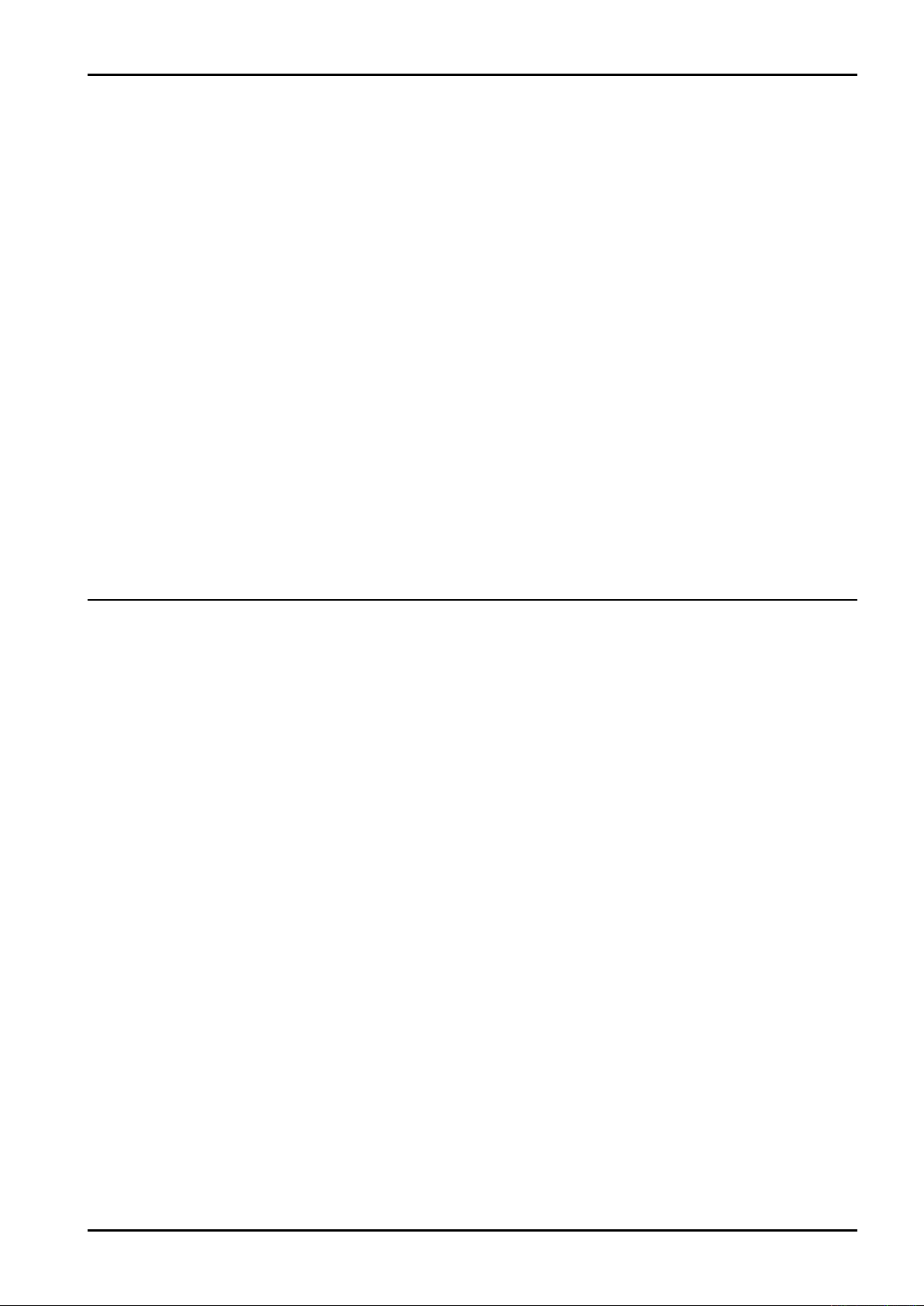

2.2 Part Names and Functions

Function Keys

Shift Keys

Seal Screw

IC Card

Display

Fig. 2.1 Part Names

Terminal Blocks

E--883--4N--E

TB

1

TB

2

TB

1

TB

2

TB

3

PLS OUT3 TEMP IN TEMP IN FLOW IN

0V

+−

B bA

+−

+−+− +−

+−

SIG SUP

SUP

PLS OUT2GND POWER

N

(

−

)

H

(

+

)

PRESS INANA

PLS OUT1

1/1

OUT

MODEL EL4001

912596

20 232.4

144

136

Min.120

Min.220

92

±0.8

+1

138 0

Optimum

Range

600

1800

450 Acceptable Range

2200

Computer

3. INSTALLATION

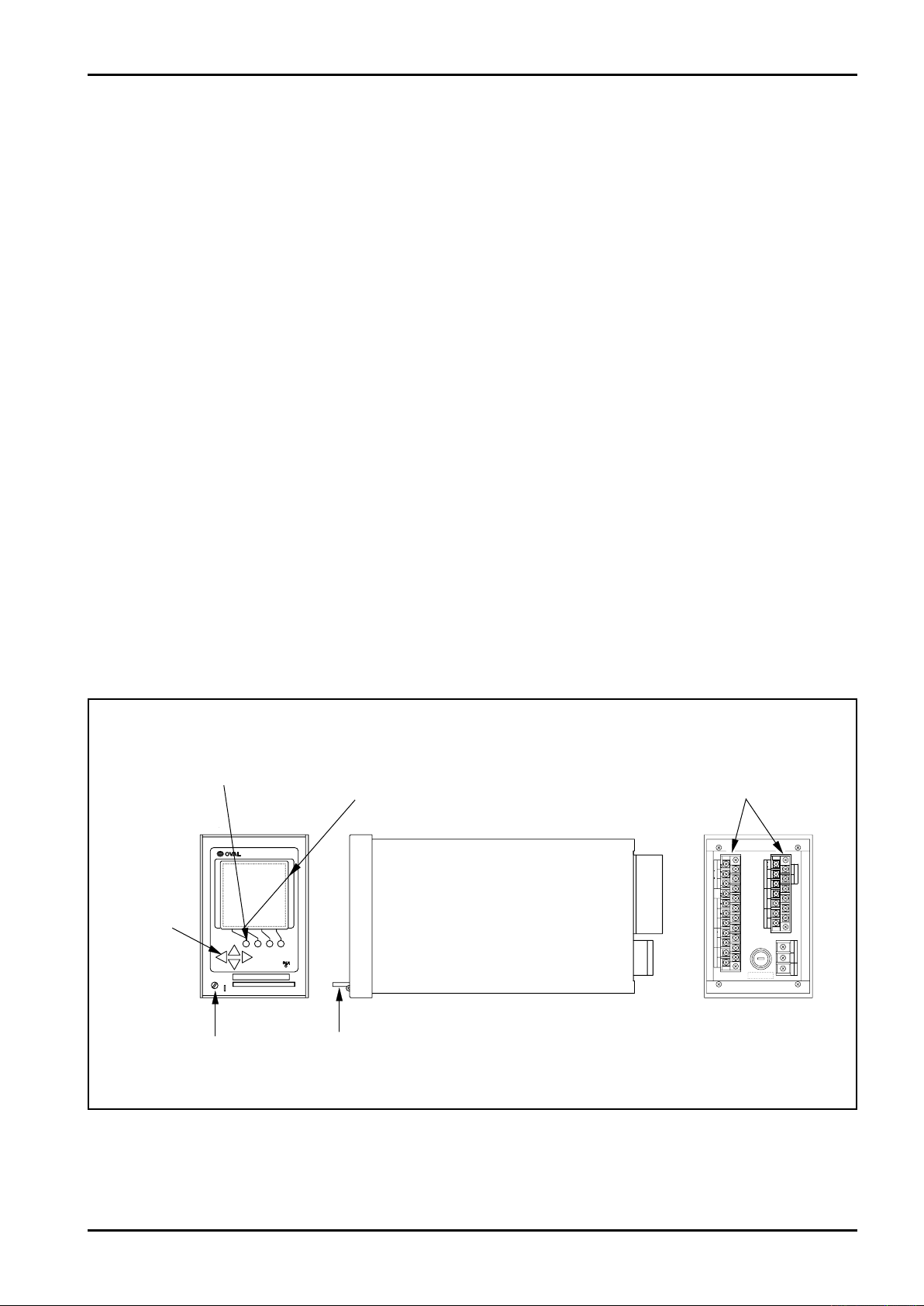

3.1 Outline Dimensions

All dimensions in millimeters

Hold-down Fitting

Fig. 3.1 Outline Dimensions

3.2 Installation

3.2.1 Installation Location

Select an installation site where:

(1) Mechanical vibration, shock and corrosive gases are

negligible.

(2) Air is dry and temperature at room temperature and

stable.

NOTE: Although the manufacturer guarantees stated

performance at ambient temperatures up to

+50°C, it is recommended that the instrument

be placed in service at room temperature.

(3) Provide a sufficient working space behind the instru-

ment - at least 50 centimeters from the back panel of

the instrument to facilitate wiring and servicing.

3.2.2 Panel

(1) Use a rigid steel sheet with a minimum thickness of

1.6mm. 3.2mm thick is recommended.

(2) If it is required to install instruments alongside each

other, dimensions in Fig. 3.2 are suggested.

(3) Recommended mounting height is given in Fig. 3.3.

Fig. 3.2 Panel Cut

3.2.3 Installation

(1) Front mount the instrument through the cutout in the

panel.

(2) Fit the furnished enclosure hold-down fittings into the

top and bottom slots in the enclosure and, confirming

that the instrument is positioned horizontal, secure

the instrument to the panel with hold-down fittings

(Fig. 3.1).

Fig. 3.3 Instrument Mounting Height

E--883--4N--E

TB 1

TB 2

1

2

3

TB 3

PLS OUT3 TEMP IN TEMP IN FLOW IN

0V

+−

B bA

+−

+− −+−

+−+− +−

+−

SIG SUP

0V SIG SUP

SUP

ANA OUT

GND POWER

N(−) H(+)

PRESS INPLS OUT1

COMM1

COMM2

TEMP

PLS OUT2

1/1

OUT

DENSITY IN

4. WIRING

(See the "Wiring Guidelines" in the instruction manual of the companion pulse generator.)

4.1 Field Wiring Cables

(1) Use electrostatically shielded, polyethylene insulated, vinyl sheathed control cables (CEVS, 1.25-2

mm, 2-conductor or 3-conductor), or equivalent, for input signal cables from the flowmeter.

For output signal cables, use insulated vinyl sheathed cables (CVV, CVS ... JIS C 3401).

(2) Ground the end of shield wire to "G" terminal of the instrument. At the sensor end, leave the end of

shield wire unconnected.

4.2 Wiring Connections

(1) Field wiring through a conduit is recommended.

NOTE: In routing field wiring, use a separate conduit for power cable from other signal cables to

eliminate the possibility of stray current pickup.

(2) Separate field wiring from other power lines and power circuits to minimize the possibility of inductive

interference.

(3) Using crimp-type lugs for wiring, ensure good electrical connections.

Terminals are found on the back of the instrument (Fig. 4.1).

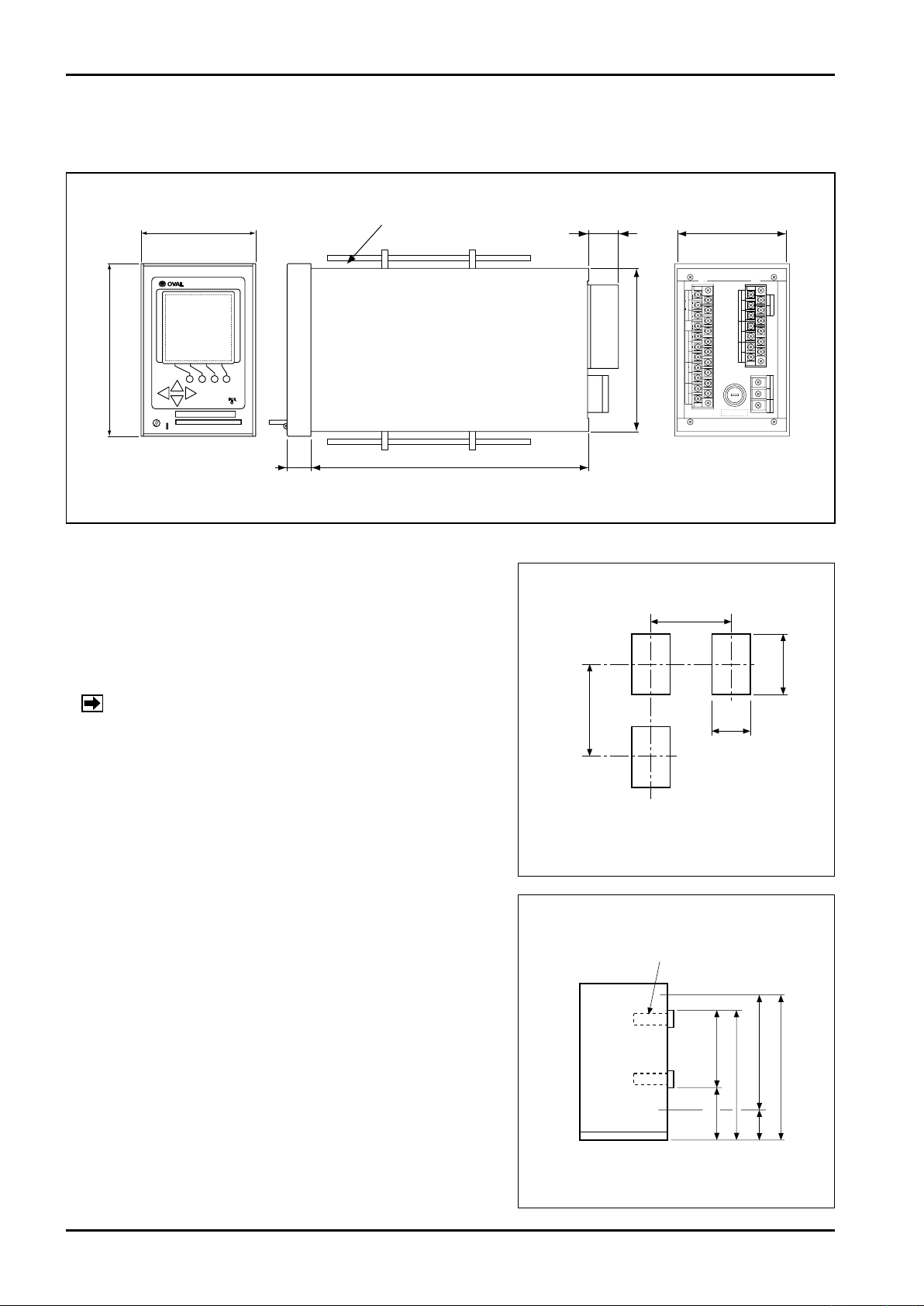

4.3 Description of Terminal Blocks for External Connections

Terminal blocks for external connections (TB1,

TB2, and TB3) are found on the back of the

instrument as shown in Fig. 4.1. Terminal identification appears in Table 4.1 while terminal connections

appear in Table 4.2.

NOTE: TB1 and TB2 terminal numbers are

indicated on the side of terminal blocks.

CAUTION

Make wiring connections upon confirmation of the validity of flowmeter (pulse

generator) to receiving instrument combination by their product code number,

instrument number, etc.

Fig. 4.1 Terminal Blocks for Ext. Connections

1 SUP.

2 SIG. 13 2 9 −

3 0V 14 3 10

4 OUT 1/1 15 4 +

5 b

Flow in

6 B 17 6 +

7 A 18 +

8 + 19 − TB3

9 − 20 +

10 +

11 − 3 GND

NOTE ※: Provided with communication interface.

Temp. in

Alarm out

Table 4.1 Terminal Identification and Functions

TB1 TB2

12 1

8 +

Press. in

16 5 − 12

COMM1

7 −

Analog out

Pulse out 1

11

13

※

COMM2

21 − 2 N(−)

※

1 H(+)

Terminal

Screws

(M.)

Pulse out 2

Power

E--883--4N--E

Table 4.2 Terminal Connections

TB1

No Label Description

1

SIG.

Flow in

0V

OUT 1/1

B

Temp. in

A

+

9 −

10

Pulse out

11

Screws on the terminal block: M.

SUP.

b

No

polarity

(+) -wire generator

(−) Output sync with

(+) input signal (O.C.)

Alarm out

Static relay

-wire generator

Pt100Ω -wire

to 0mADC/1 to VDC

No Label Description

1

2

3

4

Analog out

5 −

6

Pulse out 1

7

8

Pulse out 2

9

10

11

12

13

No Label Description

1

Power

2 N(−)

3 Ground

+

No

Polarity

No

polarity

H(+)

TB2

Uncorr. or corr. instant flowrate

4 to 20mADC/1 to 5VDC

Uncorrected total flow

Static relay

Corrected total flow

Static relay

TB3

85 to 264VAC

or 20 to 30VDC

5. GENERAL SPECIFICATIONS

Table 5.1

Item Description

Signal name

8V 2-wire current pulse OPTO 01, 02 8.5VDC

Contact closure pulse PG20

2-wire, 12VDC 3-wire

Input

signals

Output

signals

Display type

Menu

items

Computing

range

Computing

accuracy

Clock IC battery backup Lithium battery (Battery life: 10 years approx.)

Communication (when com.

interface is provided.)

Transmission cable

Power source 85 to 264VAC, 50/60Hz or 20 to 30VDC

Power consumption

Ambient temperature −10 to +50°C

Mounting

Finish Munsell N1.5

Weight

Flow input

Temperature input

Pulse output

Alarm output Static relay Capacity: 230VAC/340VDC 0.2A

Analog output

Uncorrected total flow Same as output pulse unit (m3, etc.)

Corrected total flow Same as output pulse unit (m3 (C), etc.)

Uncorr. instant flowrate

Corr. instant flowrate m3/h (C), etc.

Temperature To the 2nd decimal place (when °C is selected.)

Meter error corr. factor To the 5th decimal place

Temp. correction factor To the 5th decimal place

Error alarm Number of errors + error messages

Temperature

Corrected total flow ±0.2% of R.D.

Temperature

Voltage pulse

24VDC 2-wire

Current pulse (4/20mA)

12VDC 2-wire

Current pulse

Open collector pulse

Resist. thermometer Pt 100Ω at 0°C, 3-wire Rated current 2mA

Analog 4 to 20mADC or 1 to 5VDC

Uncorrected total flow

Corrected total flow

Output sync with flow input

signal

Corrected instant flowrate

Display: ST display (128×128 dots), back lighted (※1), (※2)

Information displayed: Data, units, error message simultaneously

m3/h, etc.

Pt 100Ω at 0℃

4 to 20mADC or 1 to 5VDC

Pt 100Ω at 0℃ ±0.3% of span

4 to 20mADC or 1 to 5VDC

Interface: RS485 Multipoint (Up to 16 units can be connected.)

Dedicated protocol Baud rate: 4800 bps standard 9600 bps max

Use 3-conductor shielded cable to the resistance thermometer bulb.

Loop resist. 5Ω max. Example: 300 meters max. with 3-conductor 1.25mm2

cable; 500 meters with 2.0mm2 cable

20W max.

Panel mount

2.5 kilograms, approx.

Pulse

generator

PG30,

NPG60A(F)

PA14, 15, 25

NPG60A(E)

PG30S

FlowPet-5G,

NPG60A (E3)

Static relay Capacity: 230VAC/340VDC 0.2A

Pulse width: 1ms/50ms

Open collector pulse

4 to 20mADC (Max. load resistance 500Ω)

or 1 to 5VDC (Output impedance 250Ω)

Conversion accuracy: ±0.1% of F.S.

Range:−50 to 350°C

±0.1% of span

Power to generator

13.5VDC

24.0VDC

13.5VDC

Allowable

current

40mA app.

Shortcircuit

protection

circuit

provided

Display capacity: 8 digits

Std. Span: 70℃

Std. Span:200℃

E--883--4N--E

Speed of

response

2kHz

50Hz

2kHz

NOTES (※1): ST display stands for Super Twisted Nematic display.

(※2): Backlight life (luminance declined to one half of its original luminance): 2500 hours, approx.

9

E--883--4N--E

6. INTERNAL COMPONENTS AND FUNCTIONS

6.1 Front Panel

6.1.1 Display

The display is a 128 X 128-dot multiple function display capable of showing the data, units of measure,

error messages, and other information at the same time. (The display is backlighted.)

6.1.2 On-Screen Menu Items

The units of measurement vary with configuration. Their selection is made in the SET mode. Available

menu items are:

(1) Uncorrected total flow (TOTAL COUNT)

Incoming flow pulses are calibrated for meter error, integrated before correction for temperature,

and the obtained totalized flow is indicated. Resolution, or the minimum unit of measurement, which

varies with customer specifications, is set up with front-panel keys. This unit automatically becomes

identical with the output pulse unit.

While the total flow is retained irrespective of power cycling, it is resettable to zero following a power

cycle if so configured in the SYS mode.

(2) Corrected total flow (TOTAL COUNT(C))

The reading calibrated for meter error and temperature is integrated. Other specifications remain

the same as (1).

(3) Uncorrected instant flowrate (FLOW RATE)

The instant flowrate calibrated for meter error is indicated before temperature correction.

(4) Corrected Instant flowrate (FLOW RATE(C))

The instant flowrate calibrated for meter error and corrected for temperature is indicated.

(5) Temperature (TEMPERATURE)

The temperature value currently fed to the instrument is indicated. If a problem arises in the course

of temperature conversion, such as out-of-scale, a default fallback value is indicated.

(6) Meter error correction factor (METER ERROR)

Meter error correction factor corresponding to the flowrate currently fed to the instrument is

indicated.

Based on this reading, the total before correction is calibrated for meter error.

[Indicated reading] = 1 + −−−

(7) Temperature correction factor (TEMP. COMPEN.)

The temperature correction factor calculated based on the temperature currently fed to the

instrument is indicated. The corrected total flow is compensated based on this reading.

(See Section 7.2 "Implementation of Temperature Correction".)

E

100

NOTE: For more information about menu items and options, see "KEY OPERATION MANUAL".

6.1.3 Error Messages

When an erratic condition arises, an error message automatically appears on the display. (The

information represented by error messages are listed on page 15.)

If two or more concurrent errors are involved, individual messages will be scrolled at intervals of

approximately 3 seconds. When an error condition disappears, an error message automatically goes out

and the normal display is resumed.

NOTE: An error logging function can store a maximum of 20 events each of which consists of year,

month, day, hour and minutes of error occurrence and recovery. (Complete details are

covered in the Key Operation Manual.)

10

E--883--4N--E

MO DE L

EL4001

RUN

6.1.4 Front Panel Keypad

The eight front panel key switches consist of two kinds of keys - functions keys and shift keys.

・Function keys: Four round keys

Mainly used for function selection, such as activating the input conditions selected and reconfiguration.

・Shift keys: Four triangular keys

Used for moving the cursor, moving between menu items, or changing numerical values.

Function Keys

Shift Keys

Fig. 6.1 Front Panel Keys

Fig. 6.2 Touch Key Operation

11

E--883--4N--E

+

0

−

F

1

F

2

F

3

E

1

E

2

E

3

E

4

F

4

F

8

E

8

E

F

9

}

9

7. CALCULATION FORMULAS

7.1 Implementation of Meter Error Correction (Total flow before correction)

Q1 = a×Ip×(1 + E/100)

where Q1: Total flow corrected for meter error[l]

a: Meter factor[l/P]

Ip: Number of input pulses

E: Meter error correction value[%]

The line graph in Fig. 7.1 below shows how meter error curve linearization is achieved. E is

approximate-ly determined by the relationships between input pulse frequency and instrumental

error correction value set at multipoint error points which are programmable along the flowmeter's

instrumental error curve with front-panel keys, and the frequency pulse information (flowrate)

Flowrate

(frequency)

Meter error

F1 thru F9 Frequency (Hz)

E1 thru E9 Meter error correction value (%)

Programmable with keys

Fig. 7.1

7.2 Implementation of Temperature Correction (Corrected total flow)

Q2 = Q1×K

K = {a + b・(t0−t) + c・(t0−t)2}

where Q2: Total flow corrected for temperature[l (normal)]

Q1: Total flow calibrated for meter error[l]

K: Temperature correction factor

t0: Reference temperature[°C]

t: Line temperature[°C]

a thru c: Correction factors

7.3 Instant Flowrate (Uncorrected)

Qm = a×f×(1 + E/100)×3600

where Qm: Instant flowrate corrected for meter error[l/h]

f: Input pulse frequency[Hz]

7.4 Instant Flowrate (Corrected)

where Qmc: Instant flowrate corrected for temperature[l/h (normal)]

1

Qmc = Qm×K

E--883--4N--E

8. PREPARATIONAL CHECKS AND OPERATION

8.1 Preparation Before Operation

(1) Ensure that the instrument and related equipment are correctly installed and wired with no place left

unfinished.

WARNING: Make sure to see that the power terminals are connected to a power

source of the rated voltage. Applying a power source of incorrect voltage

could ruin your instrument.

(2) Supply power to this instrument and make certain to see that the front panel display is illuminated.

The display will remain unilluminated for one second after power on, which however is by no means

any indication of fault.

8.2 Preparational Checks

CAUTION: Allow a warmup period for 60 minutes or so after you turn on the power.

Verify if the instrument operates with no fluid flow.

How to Check

(1) Couple sources of simulated temperature and pressure signals.

(2) Using the shift keys, select menu items and verify the information displayed.

NOTE: See the KEY OPERATION MANUAL.

(3) Inject a simulated input pulse train or density signal representing the type of the companion pulse

generator.

(4) Select display menu items of the total mass flow and total calorific flow, and make sure that incoming

pulses are being accumulated. Also, verify that pulse output and analog output are properly

generated.

(5) Remove the simulated pulse input and compare the obtained readings on the display with cor-

responding theoretical values. Remember that this instrument is not equipped with a counter to

accumulate incoming pulses. Hence, an external counter is required.

8.3 Operation

CAUTION: Allow a warmup period for 60 minutes or so after you turn on the power.

(1) Select your power reset or non-reset (accumulated total) option.

NOTE: See the KEY OPERATION MANUAL.

(2) Turn on power. While the initial check screen remains displayed, indicating that the process of verify-

ing parameters and variables is in progress after you turned on the power, your instrument will not

accept any pulse input.

(3) Place your instrument in service operation by allowing the fluid to be metered.

1

E--883--4N--E

9. TROUBLESHOOTING

Reminder: If internal trouble is suspected, seek our service at the nearest sales office or

customer service representative in your area.

Table 9.1

Symptom Check Possible Causes

Display is dead. 1. Inspect fuse.

2. Make sure of power source voltage.

Faulty temperature indication.

Erratic reading

Error messages

TEMP 1 (PT) OVER

or TEMP 1 (PT) UNDER

or TEMP 1 (ANA) OVER

or TEMP 1 (ANA) UNDER

(Same also with TEMP 1.)

Faulty indication of meter error

correction factor and/or temperature

correction factor.

While

fluid

is

allowed

to flow.

Error messages

A/D CONVERT ERROR

or DENSITY CONVERT ERROR

or 4mA SCALER 1 UNDER

(Same also with SCALER 2.)

Error messages

DENSITY SIGNAL

or DENSITY OVER

or DENSITY UNDER

or 20mA SCALE OVER

Fails to count pulses;

fails to produce a pulse

output.

Faulty total counter

reading.

1. Input signal line correctly wired?

2. Input signal specifications

matched?

3. System configured correctly?

4. Temperature range set correctly?

1. Temperature reading correct? 1. A fault in internal assembly.

1. Input signal line correctly wired?

2. Pulse signal coming in?

3. Pulse generator specifications

matched?

1. Temperature reading correct?

2. Meter error and temperature

correction factor indications correct?

1. System configured correctly?

2. Input pulse signal correct?

3. Flowrate full scale set properly?

1. Fuse is blown.

2. Line voltage is improper.

3. A fault in internal assembly.

1. Input wiring is incorrect.

2.Thermometer resistance bulb is

open or shorted.

3. Temperature converter is faulty.

4. A fault in internal assembly.

1. Incorrect input wiring.

2. Pulse generator itself is faulty.

3. A fault in internal assembly.

1. Pulse generator itself is faulty.

2. A fault in internal assembly.

1. A fault in internal assembly.

1. A fault in internal assembly.

CAUTION: Once any printed circuit board(s) of the internal assembly has been

removed for servicing, do not fail to reestablish all parameters in the SET

mode.

1

10. ERROR MESSAGES

Table 10.1 List of Error Messages

No. Error Message Description

1 ADJUST DATA ERROR After adjusted, error of allowable range check

12 A/D CONVERT ERROR A/D converter circuit error

13 DENSITY CONVERT ERROR Density converter circuit error

14 TEMP 1 (PT) OVER Temperature Pt input 1 overflow

15 TENP 1 (PT) UNDER Temperature Pt input 1 underflow

16 TEMP 2 (PT) OVER Temperature Pt input 2 overflow

17 TEMP 2 (PT) UNDER Temperature Pt input 2 underflow

18 TEMP 1 (ANA) OVER Analog temperature input 1 overflow

19 TEMP 1 (ANA) UNDER Analog temperature input 1 underflow

20 TEMP 2 (ANA) OVER Analog temperature input 2 overflow

21 TEMP 2 (ANA) UNDER Analog temperature input 2 underflow

26 DENSITY OVER Density input overflow (unused)

E--883--4N--E

27 DENSITY UNDER Density input underflow (unused)

28 4mA SCALER 1 UNDER Analog output 1 underflow

29 20mA SCALER 1 OVER Analog output 1 overflow

30 4mA SCALER 2 UNDER Analog output 2 underflow

31 20mA SCALER 2 OVER Analog output 2 overflow

NOTE: Depending on the model in service, some of the messages are not shown.

11. BEHAVIOR IN ERRATIC CONDITIONS

(1) Erratic A/D Converter:

If, following energization of A/D converter circuit, the conversion process is not completed within

the specified time period, it is found that the circuit has a problem. At this point, temperature and

pressure fallback values are used for calculation.

(2) Temperature and Pressure Input Out of Range:

If the input exceeds the high limit or falls below the low limit, its default fallback value is used for

calculation.

(3) Analog Output Overflow:

A full scale output is produced across the analog output terminals.

1

E--883--4N--E

Power

Flow input

1/1 output

Density input

Press. input

Temp. input

Analog output

Pulse output 1

Pulse output 2

Pulse output 3

Com port

Terminal

Block

Address path

Data path

Power Board

Interface Board

Communication Board

CPU Board

I/O Board

Power Unit

Internal

Power

low Input Ckt.

Dens. Input Ckt.

A/D

Converter

Press. Input Ckt. (analog)

Temp. Input Ckt. (analog)

Temp. Input Ckt. (Pt)

Analog Output Circuit

Pulse Output Circuit 1

Pulse Output Circuit 2

Pulse Output Circuit 3

Multi

plexer

Isolation

Test Pins

Test Pins

Internal

Volt.

Buzzer

Motherboard

Keyboard

IC Card

128×128 dots

ST Display

RUN

×8 keys

Isolation

Isolation

Isolation

Isolation

Parallel I/O

Timer Counter

Parallel I/O

CPU

20MHz

Memory

RS485

Isolation

IC Card

Interface

Circuit

32.768kHz

Real Time

Clock

Lithium

Battery

Power Detect

Fuse

Isolation

12. OVERALL BLOCK DIAGRAM

Fig. 12.1 Overall Block Diagram

1

⑧−⑥⑤④③②① ⑯⑮−⑬⑫⑪⑩⑨ ⑰ ㉒㉑⑳ ㉓ ㉔ ㉕ ㉖ ㉗ − ㉙⑲⑱

Model

Power supply

Input pulse signal

Temp. input

Pressure input

Density input

Version code

Communication function

Analog output hard

Output item 4

Output item 3 affix code

Output item 3

Output item 2 affix code

Output item 2

Characteristic

Output item 1

Output item 1 affix code

Others

Main code

/ / / Additional code

13. PRODUCT CODE EXPLANATION

●

Main code

① ② ③ ④ ⑤ ⑥

E L 4 1 3 1 Flow computer for liquid temp. correction

—

⑦

Power supply

⑧

D 20 to 30VDC

J 85 to 264VAC 50Hz/60Hz

Input pulse signal

⑨

B Voltage pulse 12VDC 2 wires/3 wires

C Voltage pulse 12VDC (PG30S)

D Current pulse 24VDC (4/20mADC)

E Current pulse 8VDC (OPTO OD 01, etc.)

G Open collector pulse 12VDC 2 wires/3 wires

K Contact pulse 12VDC 2 wires/3 wires

Z Special

Temp. input

⑩

N Non

B 1 to 5V

E 4 to 20mA

F Pt100Ω

G JPt100Ω

Z Special

Pressure input

⑪

N Non

Density input

⑫

N Non

Others

⑬

N Non

—

⑭

Output item 1

⑮ ⑯

Pulse output 1

B 1 Before correction/pulse width 1ms

B 5 Before correction/pulse width 50ms

B 9 Before correction/special pulse width

C 1 After correction/pulse width 1ms

C 5 After correction/pulse width 50ms

C 9 After correction/special pulse width

A L Alarm output

Z Z Special

Output item 1 affix code

⑰

N Non

Output item 2

⑱ ⑲

Pulse output 2

B 1 Before correction/pulse width 1ms

B 5 Before correction/pulse width 50ms

B 9 Before correction/special pulse width

C 1 After correction/pulse width 1ms

C 5 After correction/pulse width 50ms

C 9 After correction/special pulse width

A L Alarm output

Z Z Special

Output item 2 affix code

⑳

N Non

Model

Pulse output 3

A L Alarm output

Z Z Special

Output item 3 affix code

N Non

Output item 4

Analog output assignment

N Non

B Before correction instantaneous analog output

C After correction instantaneous analog output

Z Special

Analog output hard

N Non

2 1 to 5V

5 4 to 20mA

Z Special

Communication function

N Non

R RS-485

Version code

A Version code: A

—

Characteristic

0 Standard

Z Special

E--883--4N--E

Output item 3

1

E--883--4N--E

Output item 1 affix code

Output item 1

Others

Density input

Pressure input

Temp. input

Input pulse signal

Power supply

Model

⑧−⑥⑤④③②① ⑯⑮−⑬⑫⑪⑩⑨ ⑰ ㉒㉑⑳ ㉓ ㉔ ㉕ ㉖ ㉗ − ㉙⑲⑱

●

Additional code

Special test

A 1 0 Taxed custody transfer

A 2 0 By certified measurer

A 3 0 Taxed alcohol

Document

D S J DWG and specifications for approval (Japanese)

D S E DWG and specifications for approval (English)

D R 0 Re-submission of DWG with specifications

D C J Final DWG (Japanese)

D C E Final DWG (English)

D W J Wiring diagram (Japanese)

D W E Wiring diagram (English)

D A J Compression coefficient calculation process (Japanese)

D A E Compression coefficient calculation process (English)

D T J Inspection procedure (Japanese)

D T E Inspection procedure (English)

C B J Inspection certificate: B set Only Japanese

Witnessed by customer

V 1 0 Required

Output item 2

Output item 2 affix code

Output item 3

Output item 3 affix code

Output item 4

Analog output hard

Communication function

Version code

Characteristic

/ / / Additional code

Main code

All specifications are subject to change without notice for improvement.

2018.01 Revised

2008.08 Released

E-883-4N-E (1)

Loading...

Loading...