Oval EL1812 Instructions Manual

BATCH COUNTER

Ins. No.

E-216-5N-E

MODEL : EL1812

Every OVAL batch counter is fabricated, tested, inspected, and shipped from our factory under stringent quality

control. In order to maintain its design performance throughout its life, this manual offers the operator the

necessary installation, operation and maintenance information.

Be well familiar with these instructions before you place the counter in service and keep this manual at the field

location for ready reference.

Also refer to the instruction manual for the pulse generator (flowmeter) used.

1

E-216-5N-E

1. BEFORE YOU BEGIN ........................................................................................ 4

1.1 Confirmation of product name plate ............................................................... 4

1.2 Transportation Considerations ....................................................................... 4

1.3 Storage Considerations ................................................................................. 4

2. GENERAL ........................................................................................................... 5

2.1 Features and Functions ................................................................................. 5

3. PART NAMES ..................................................................................................... 5

4. INSTALLATION ................................................................................................... 6

4.1 Outline Dimensions ........................................................................................ 6

4.2 Installation ...................................................................................................... 6

4.2.1 Installation Location (Indoor only) ............................................................ 6

CONTENTS

4.2.2 Panel ........................................................................................................ 6

4.2.3 Installation ................................................................................................ 6

5. WIRING .............................................................................................................. 7

5.1 Cables for Field Wiring .................................................................................. 7

5.2 Wiring Connections ........................................................................................ 7

5.3 Identifying the External Connection Terminal Block ....................................... 7

5.4 External Connection Terminals ...................................................................... 8

5.5 Flow rate input and used Terminals ............................................................... 9

5.6 Example of wire connection diagram of flowmeter signal .............................. 9

5.7 Example of Hookup ....................................................................................... 10

6. FRONT DISPLAY PART AND BATCH PROCESSING PART ............................. 12

6.1 Functions of front display part and batch processing part ............................. 12

7. BLOCK DIAGRAM .............................................................................................. 13

8. OPERATION ....................................................................................................... 14

8.1 Preparation Before Operation ........................................................................ 14

8.2 Preoperational Checks .................................................................................. 14

8.3 Operation Sequence ...................................................................................... 14

8.4 How to set the batch setting quantity ............................................................. 15

8.5 Batch processing and various functions ........................................................ 17

8.6 Alarm processing ........................................................................................... 29

2

E-216-5N-E

9. CHANGE OF SETTING VALUE ............................................................................ 31

9.1 Parameter setting ............................................................................................. 31

9.2 Configuration of internal device ........................................................................ 35

9.3 Removal of inner assembly .............................................................................. 35

9.4 Installation of internal assembly ....................................................................... 36

9.4.1 How to assemble power supply / input board and output board ................. 36

9.4.2 How to assemble display unit ...................................................................... 36

9.5 Change of setting on input board and CPU board ............................................ 37

10. TROUBLESHOOTING......................................................................................... 38

10.1 Inspection Items .............................................................................................. 38

10.2 Q&A about Counter Behavior in Standby Mod ............................................... 39

10.3 Inspection of fuse ............................................................................................ 39

11. GENERAL SPECIFICATIONS ............................................................................. 40

12. PRODUCT SYMBOL ........................................................................................... 41

Shown in this manual are the signal words

NOTE, CAUTION and WARNING, as described in the examples below:

NOTE:

Notes are separated from the general text to bring the user’s

attention to important information.

CAUTION:

Caution statements signal the user about hazards or unsafe

practices which could result in minor personal injury or product or

property damages.

WARNING:

Warning statements signal the user about hazards or unsafe

practices which could result in severe personal injury or death.

3

E-216-5N-E

Product

name plate

COM

1. BEFORE YOU BEGIN

This device is shipped after sufficient inspection at factory. After receiving this device, check if there is no

damage on the external appearance.

When received, it should be carefully inspected for any indication of rough handling during transit. In this section,

instructions necessary for handling this instrument are described. Make yourself familiar with these instructions.

As for other instructions, refer to respective sections.

If you have something to inquire, contact the nearest OVAL authorized service station in your district.

1.1 Confirmation of product name plate

This device is shipped according to the

specifications. The product name plate is

attached to the right side surface of batch

counter. Check the standard specifications and description of product number

of device correspond t o the ordered

specifications.

Fig. 1.1 Example of attachment of product name plate

◆ When you make an inquiry, please inform us of product name, product symbol (TYPE),

and production number (SERIAL No.) etc. described on the product name plate. ◆

1.2 Transportation Considerations

(1) The batch counter should be transported and stored in the same package used for transportation from our

factory if circumstances permit.

(2) Avoid giving impact shocks to the batch counter during transportation.

1.3 Storage Considerations

If the batch counter upon receipt is to be stored for extended periods of time before installation, unexpected

problems could arise. In a case like this, the following considerations should be taken:

(1) The batch counter can best be stored in the original package used for transit from the factory.

(2) Select a storage location that meets the following requirements:

• Free from rainwater and moisture

• Least vibration and impact shock

• In the room temperature and humidity environment (around 25°C and 65% R.H.)

4

E-216-5N-E

85〜264VAC

1A

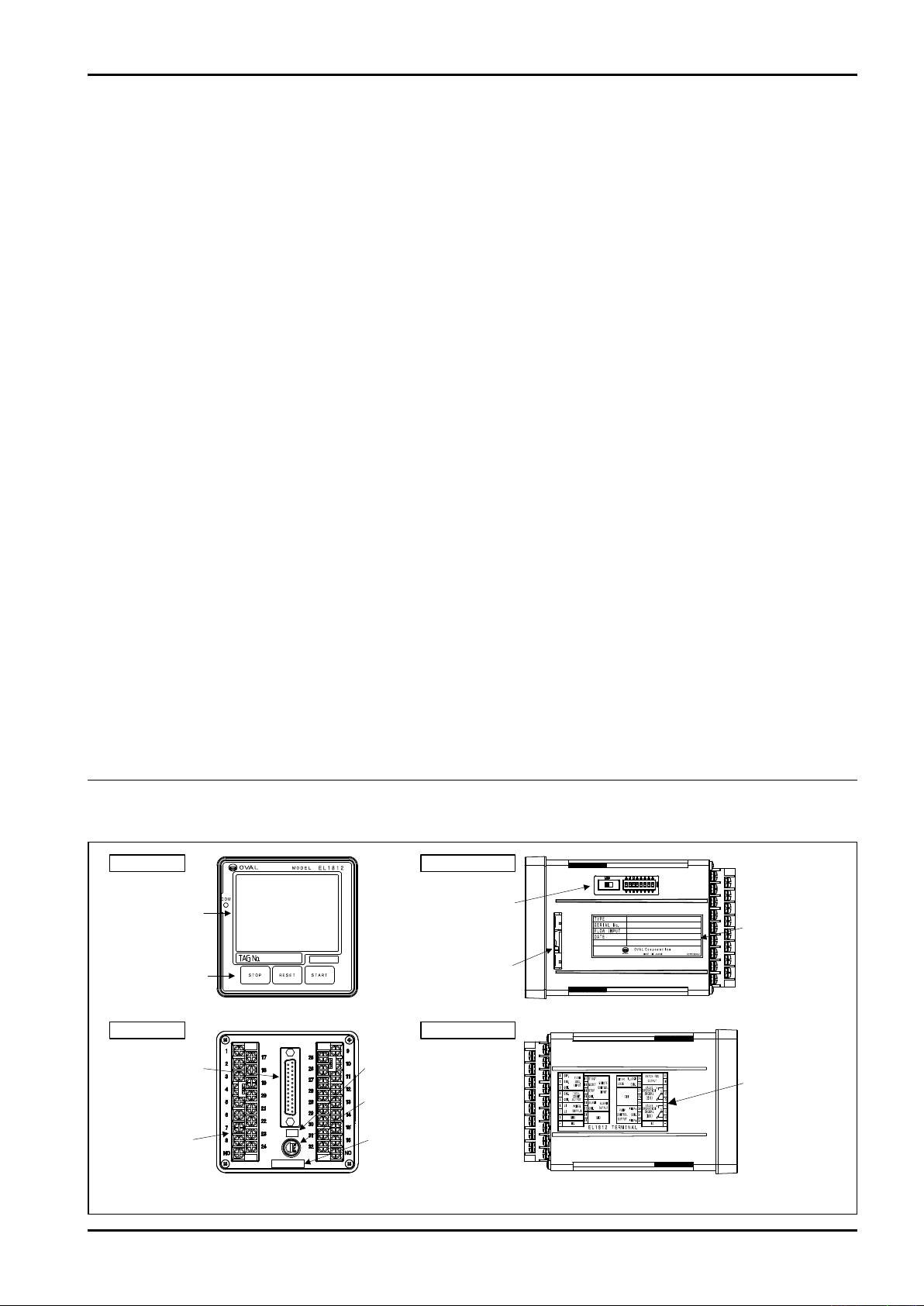

Front view

Front

display part

Push button switch

operation par t

Rear view

D-SUB connector

Externally

connected

terminal block

×2

Left side view

Fuse rating

silk

Fuse socket

Power supply

specications silk

Right side view

Input board

SW part

CPU board

SW part

Product

name plate

Terminal block

connection

diagram silk

2. GENERAL

Combined with a flowmeter and a shutoff valve, the batch counter passes a predetermined amount of the

process fluid in batching operations. Built around a single chip microprocessor, this versatile, compact, and

lightweight counter is designed for ease of operation.

It saves time and effort in many processes, such as blending materials, dosing with additives, transferring

materials from one tank to another, or shipping from an outlet, at chemical, food, paint plants or elsewhere where

streamlined production lines are desired.

2.1 Features and Functions

(1) Easy operation.

a. As setting, start, stop, and reset of batch quantity are carried out with touch panel in front of measuring

instrument and push button switches, assured operation is possible.

b.

The display part is equipped with color LCD module with 3.5-inch touch panel. Although it is small, it is easily viewable.

c.

Start and stop, and reset are operated with push button switches and setting of batch quantity is operated

with touch panel to prevent wrong operation.

(2) Wrong setting can be prevented.

As the operation of touch panel can read out nine types of batch quantities that have been registered, wrong

setting can be prevented.

(3) Correct quantitative control is possible.

a.

As an operation signal that opens or closes the valve at 2 stages, correct quantitative measurement is possible.

b.

As the overshoot quantity due to response delay of valve can be corrected by setting the forecasted overshoot

quantity, correct quantitative operation is possible.

(4) A system can be configured easily.

As start stop, and reset operations are enabled by external signal and the batch completion output can be

obtained, the interlocking with other control system is enabled easily.

(5) The safety of process can be ensured.

a.

The valve is operated by 2-stage open and 2-stage close. The generation of static electricity in piping or tank when the

operation is started is prevented and piping shock due to water hammering when the valve is closed is prevented.

b.

If a defect is generated in the process and the pulse is not input or fluid leaks exceeding the setting batch quantity, an

alarm signal will be output.

(6) This device is of high reliability and the maintenance can be implemented easily.

a. As the internal configuration is unitized, this device is of high reliability and the maintenance can be

implemented easily.

b. All I/O systems are isolated by photocoupler / relay etc.

c. When the power supply is turned OFF, total flow value and each setting value will be held in FeRAM.

3. PART NAMES

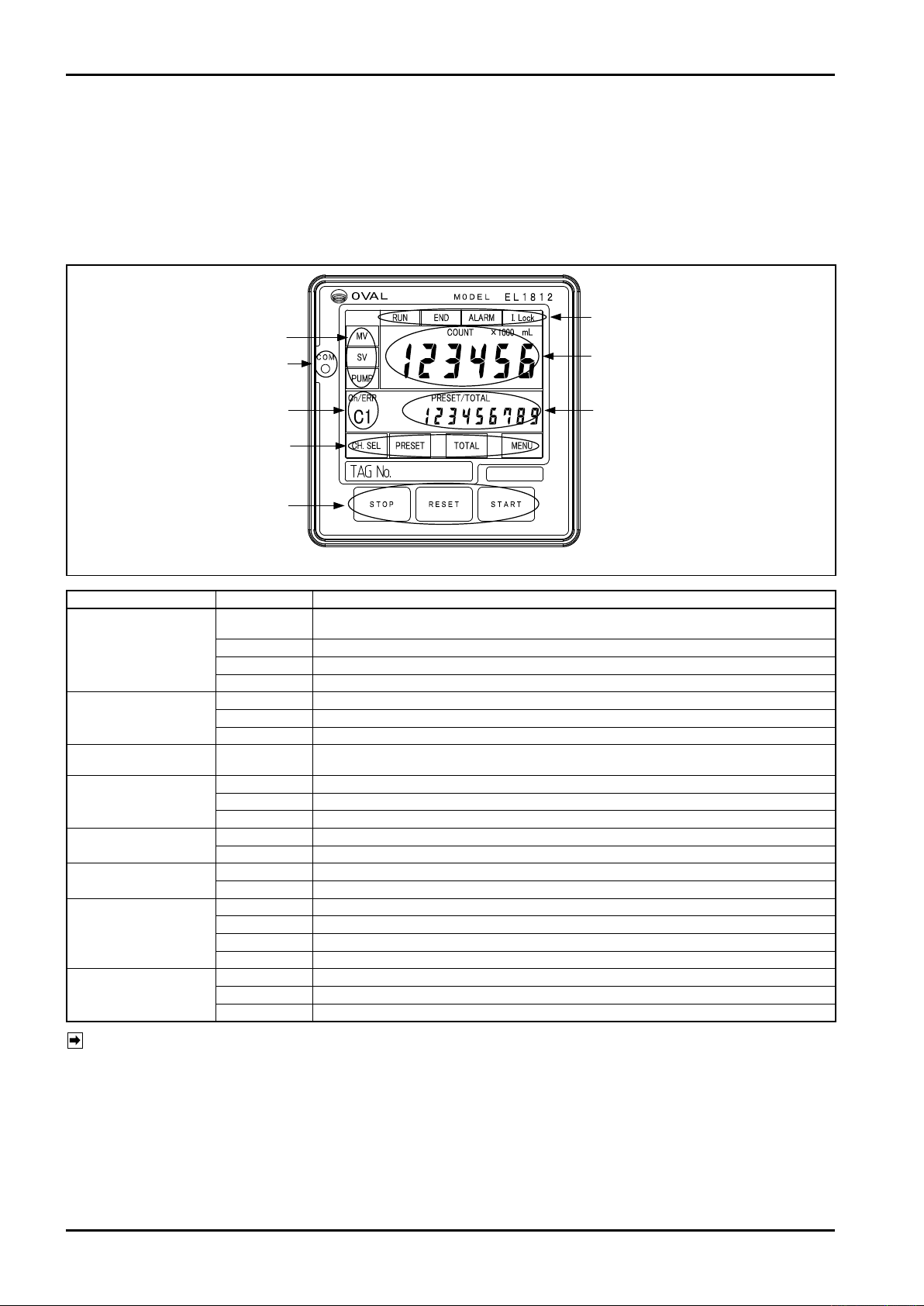

Fig. 3.1 Name of each part

5

E-216-5N-E

96

96

13

129.1

112

(17.1)

□91.5

Packing

COM

min.120

min.174

920.3

920.3

Panel

Batchcounter

600

1800

2200

450

Optimumrange

Availablerange

min.120

min.174

920.3

920.3

4. INSTALLATION

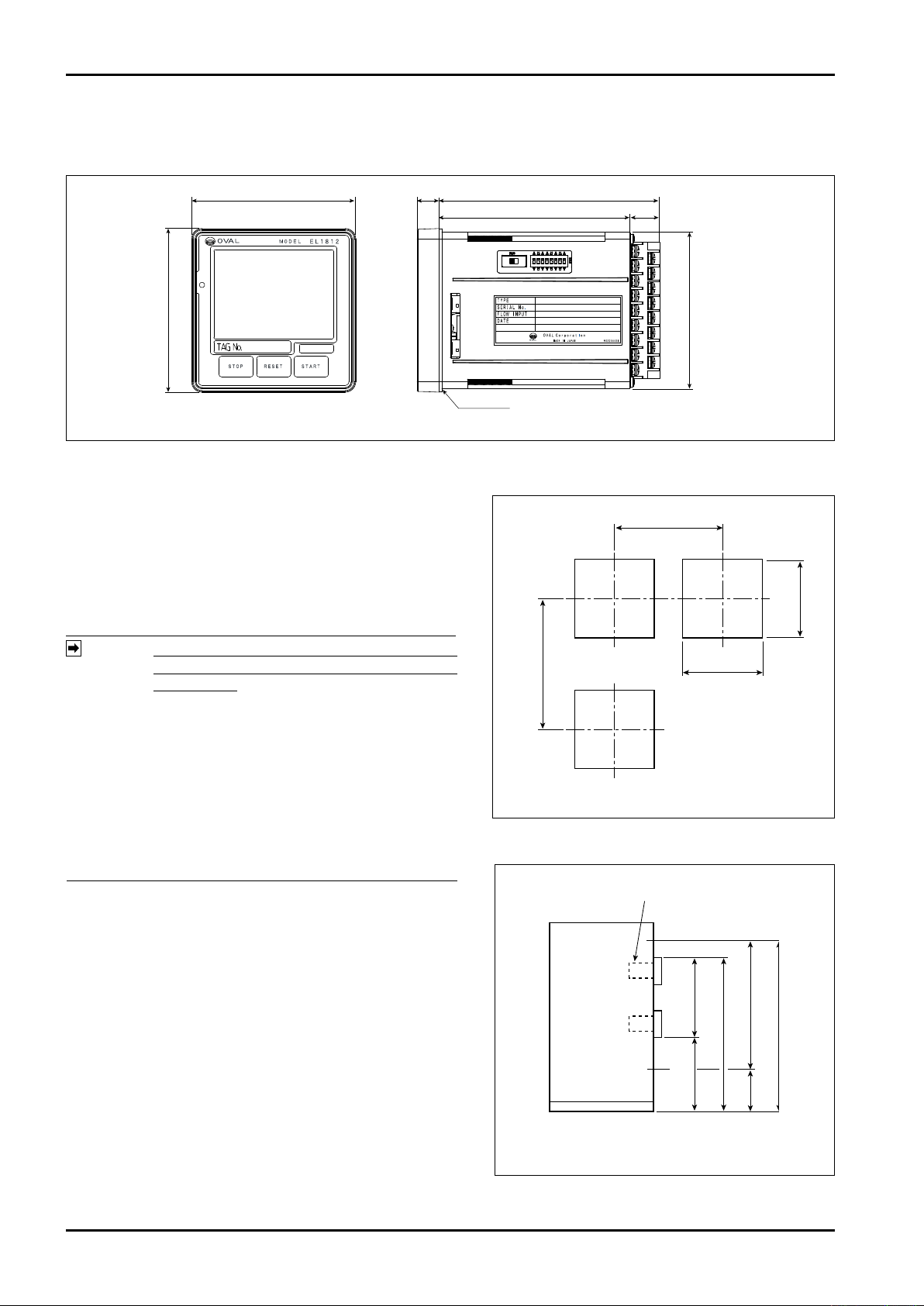

4.1 Outline Dimensions

4.2 Installation

Unit: mm

Fig. 4.1 Outline Dimensions

4.2.1 Installation Location (Indoor only)

Choose to install in the place where:

(1) Mechanical vibration, shock and corrosive gases least

exist.

(2)

The air is dry and at around room temperature and stable.

(3) A place not exposed to the direct sunlight.

(4)

A place where dust is almost none

NOTE:

1. In installation and through daily operation,

pay due care so as dust not to accumulate

in the place.

2.If chemical solvent etc. may be attached to

the front surface, it is recommended to use

the protection sheet or touch pen separately

to protect the decorative sheet on the front

surface.

Although the manufacturer g u a r a n t e e s

3.

stated

performance at ambient temperatures

from –10 to 50℃ , it is recommended that

the instrument be placed in service at room

(5)

Pr o vi de a s uf f ic i e n t wo r ki n g s pa ce be hi n d t he

temperature.

instrument – at least 50 centimeters from the back panel

of the instrument to facilitate wiring and servicing.

.

Unit: mm

Fig. 4.2 Panel Cut

Unit: mm

4.2.2 Panel

(1) Use a rigid steel sheet with a minimum thickness of

1.6 mm as min. Recommended thickness is 3.2mm.

(2) If it is required to mount the computers side by side,

dimensions in Fig. 4.2 are suggested.

(3) Recommended mounting height is given in Fig. 4.3.

4.2.3 Installation

(1)

Install the ancillary packing on the batch counter

insert it from the front surface of panel. (Fig. 4.1)

(2) Hook the enclosure hold-down fittings to the slots in

the re a r o f t he enc l o sure

instrument is positioned on a level plane, then secure

the instrument to the panel with panel mount fittings.

6

, a n d conf i r m

th a t t he

and

Fig. 4.3 Hight

E-216-5N-E

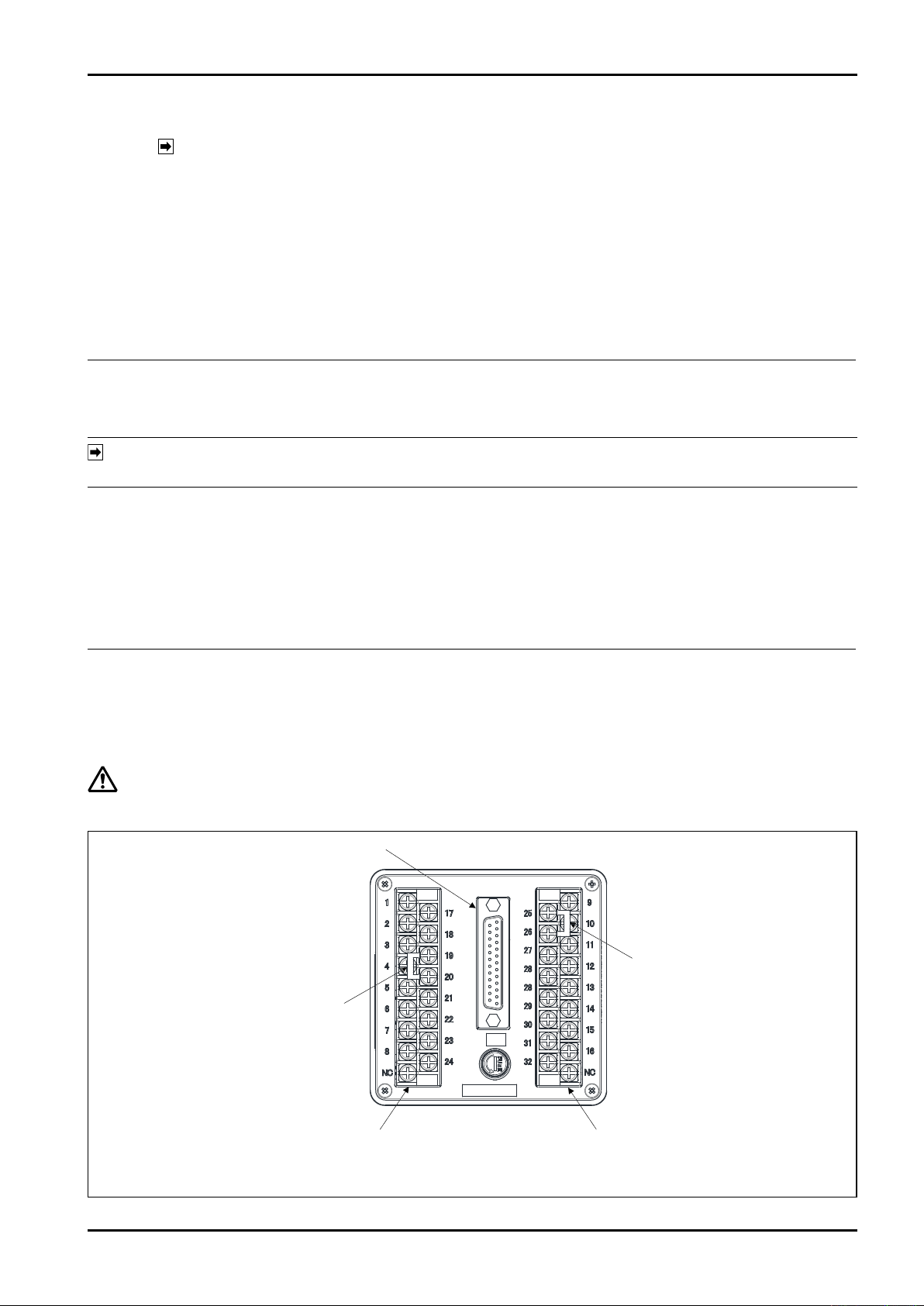

85〜264VAC

Short-circuit board

If the interlock is not used, attach the

short-circuit board in between 25

(I.Lock) and 26 (COM.1).

D-SUB connector

Short-circuit board

If the externally operated input STOP is not

used, attach the short-circuit board in

between 19 (STOP) and 20 (COM.1).

Terminal Nos.

1 to 8, 17 to 24

Terminal Nos.

9 to 16, 25 to 32

1A

5. WIRING

NOTE: See “WIRING” in the pulse generator instruction manual.

5.1 Cables for Field Wiring

(1) For flowmeter input signal cable, electrostatically shielded, polyethylene insulated, vinyl-sheathed control

cables (CEVS, 1.25 to 2mm2, 2- or 3-conductor), or equivalent, must be used.

For output signal cables, insulated, vinyl-sheathed cables (CVV, CVVS … JIS C 3401) are suggested.

(2) Cable shields must be connected to terminal “G” of the counter. At the probe end, leave the shield wire end

unprepared.

(3) For the connection cable to D-SUB connector, use 25-pin soldering type (male). Create it as a dedicated part.

For an electric wire, use the electric wire "equivalent to UL1007, 0.5mm2 ".

5.2 Wiring Connections

(1) Conduit work is suggested for field wiring.

NOTE: In conduit work, use separate conduit for power cables and signal cables in order to minimize the

possibility of stray current pickup.

(2) Route cables sufficiently away from other power lines or power circuits, if any, to reduce the possibility of

inductive interference to a minimum.

(3) Use crimp-style terminal lugs for connections and ensure good electrical contact. Connection terminals are

found at rear of the counter (Fig. 5.1).

(4) In applications where an inductive load (valve, counter, etc.) is driven, do not fail to use a surge suppressor

(see Fig. 5.2).

(5) For the wiring, ensure approx. 30cm of allowance to enable the easy maintenance.

5.3 Identifying the External Connection Terminal Block

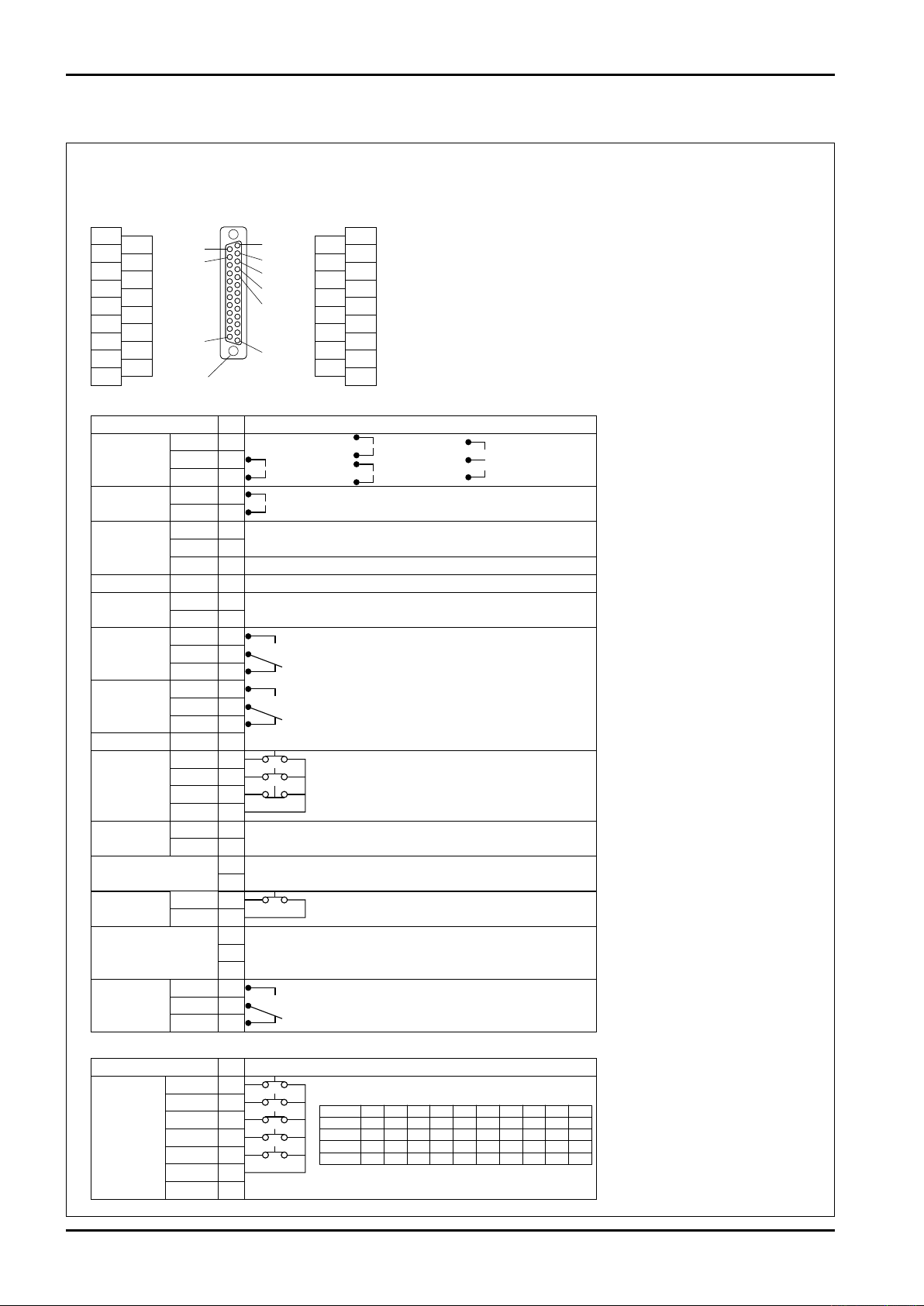

On the rear surface of this device, there are terminal block fixed to input board (terminals No.1 to 8, 17 to 24),

terminal block fixed to output board (terminals No.9 to 16, 25 to 32), D-SUB connector fixed to power supply

board (25-pin female).

CAUTION: Before making wiring connections, verify the validity of flowmeter (pulse generator) and receiving

instrument combination by referring to their product No., tag No., etc.

Fig. 5.1 External wire connection terminal diagram

7

E-216-5N-E

Signal DescriptionNo

Flow rate

input

SUP.

SIG.

COM.1

COM.2

L1

L2

GND1

NC

NC

START

RESET

STOP

COM.1

ALARM

COM.5

I.Lock

COM.1

PUMP

Select 1

PUMP

COM.6

END

END

SV a

COM.3

SV b

MV a

COM.4

MV b

SIG.

1

Signal DescriptionNo

9

Select 2

10

Select 4

11

Select 8

12

SET

13

COM.1

24

GND2

25

2

3

5

6

7

8

−

−

17

18

19

20

21

22

23

24

25

26

27

28

29

30

32

31

9

10

11

12

13

14

15

16

4

Pulse output

Power supply

Batch

completion

output

External

operation

input

Alarm output

GND1

GND1

Interlock

Pump

operation

signal

External CH.

input

Valve

operation

signal (SV)

Valve

operation

signal (MV)

Contact pulse/

open collector

Open collector output

85 to 264VAC 50/60Hz

Connection terminal (※2)

No-contact relay output contact Form "a" contact

External CH. input shielded grounding ※ Not conducted with GND1

1

2

3

4

5

6

7

8

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

25

13

12

11

10

9

24

−

9

10

11

12

13

14

15

16

−

Output board side

17P M3.5

Input board side

17P M3.5

D-SUB connector

Female 25P

(※1)

Terminal block

D-SUB connector female 25P

※ Each COM.1 terminal is conducted.

Each GND1 terminal is conducted.

※2: Grounding of equipment

Be sure to ground it to prevent electric shock/

fire and block external noise.

※1: D-SUB connector type

DBLC-J25SAF-23L6E

Japan Aviation Electronics Industry, Limited

※3: To use the external operation input, it is

necessary to prepare the connector of

D-SUB25 pin by yourself and connect the

circuit for selecting a channel to D-SUB

terminal on the rear surface of this machine.

※ The frame of D-SUB connector is

conducted with GND1.

※ External operation and batch setting volume

For "preset value" setting, refer to section 8.4.

Limit flow rate signal 1-stage open

Relay contact Form "c" contact

Relay contact Form "a" contact

Shielded grounding

Shielded grounding

Upper limit flow rate signal fully opened

STOP is short-circuited when it is not used

(※3)

Interlock is short-circuited when it is not used

Pump control output Relay contact Form "c" contact

Combination of select and CH.

Select 1

Select

2

Select

4

Select

8

CH.1 CH.2 CH.3 CH.4 CH.5 CH.6 CH.7 CH.8 CH.9 CH.F

ON OFF ON OFF ON OFF ON OFF ON OFF

OFF ON ON OFF OFF ON ON OFF OFF ON

OFF OFF OFF ON ON ON ON OFF OFF OFF

OFF OFF OFF OFF OFF OFF OFF ON ON ON

2-wire current

pulse (4/20mA)

3-wire voltage

pulse (PG30)

2-wire current

pulse (PG30S)

4-40-inch screw

14

1

5.4 External connection terminals

●

Terminal block and D-SUB connector

8

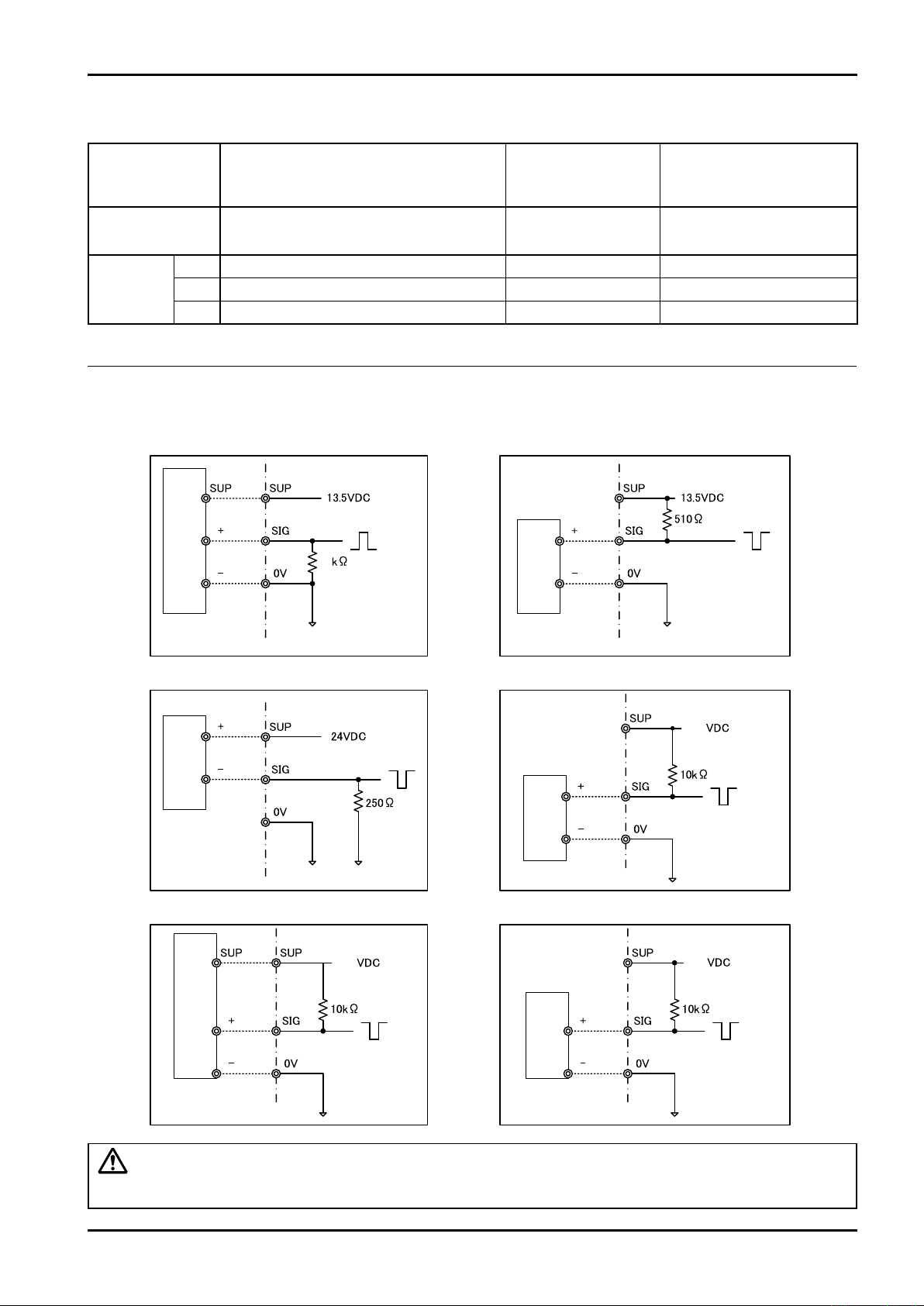

5.5 Flow rate input and used terminals

12VDC3-wiretypevoltagepulse(PG30) 12VDC2-wiretypecurrentpulse(PG30S)

24VDC2-wiretypecurrentpulse(4/20mA)

33

13.5

13.5

13.5

3-wiretypeopencollector

Opencollector

Contactpulse

Pulse

generator

Pulse

generator

Pulse

generator

Pulse

generator

Pulse

generator

Pulse

generator

E-216-5N-E

Signal type

Transmitter

Contact-closure pulse / 2-wire voltage pulse

Open collector pulse 12VDC 2-wire type

current pulse

PG20, Coriolis flowmeter

PG30S

24VDC 2-wire type

Current pulse

PA14, 15, 25

NPG60A

1 - ○ + ○ SUP.

Terminal

2 ○ + ○ - ○ SIG.

3 ○ -

-

○mark: used terminal

5.6 Example of wire connection diagram of flowmeter signal

3-line type open collector

3-wire voltage pulse

PG30, NPG60A

flow pet

○ COM.

CAUTION: In the wiring, connect the wires properly, while checking the combination of product number

and measuring instrument number etc. of flowmeter (transmitter) and receiver.

9

E-216-5N-E

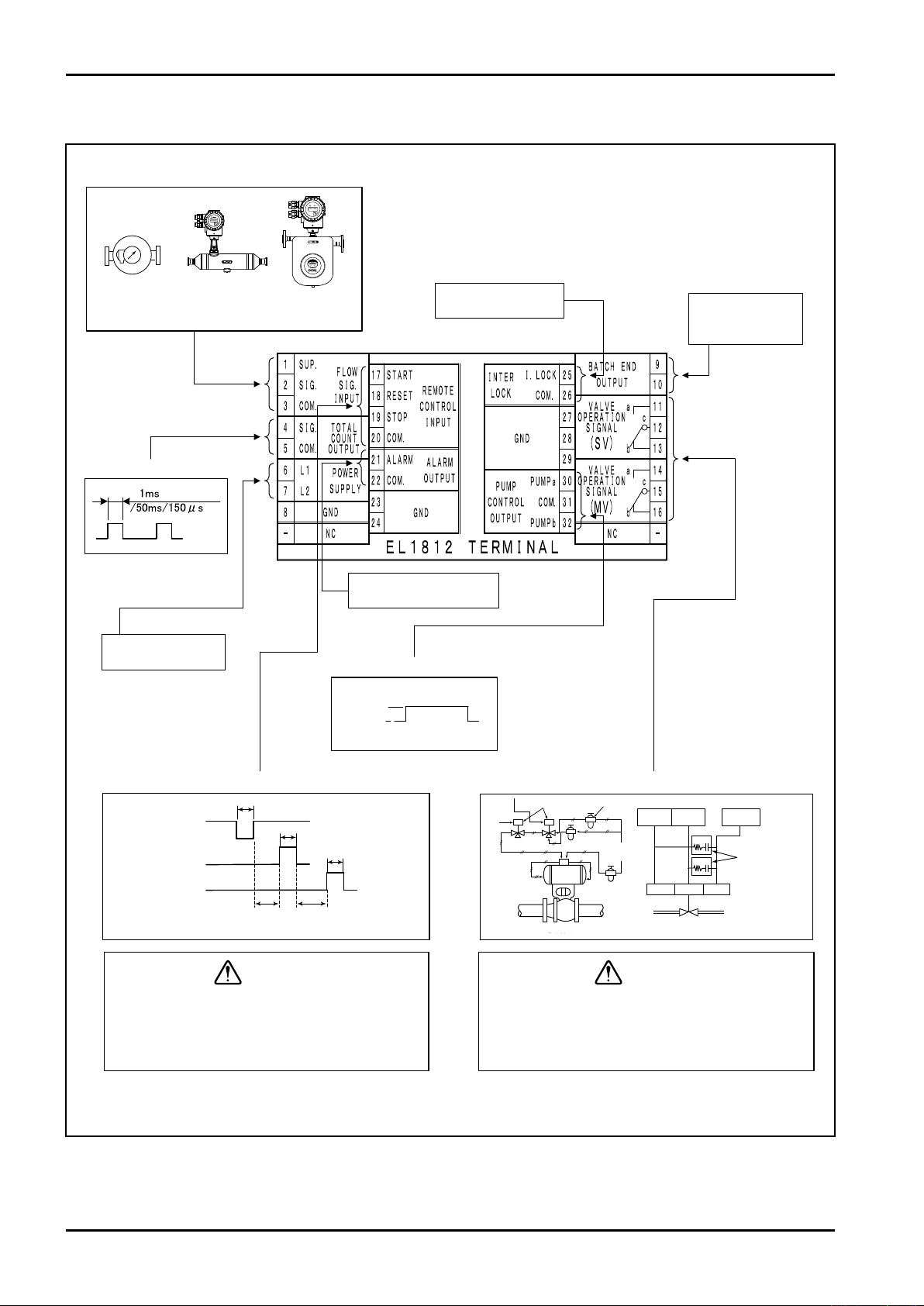

IftheexternaloperationinputSTOPisnotused,

STOP(19)toCOM.(20)shouldbealwaysshortcircuited.Iftheinterlockisnotused,I.LOCK(25)

toCOM.(26)shouldbealwaysshort-circuited.

Terminal connection diagram

(silk on left side of this device)

Output to remote totalizer

counter, etc.

Open collector

200msec.min.

200msec.min.

200msec.min.

200msec.

min.

200msec.

min.

Power: 85 to 264VAC

50/60Hz

Operation

Stopped

STOP (contact b)

RESET (contact a)

START (contact a)

Alarm output LED lamp etc.

can be driven

Pump can be operated /

stopped for batch

processing

CORIOLIS FLOWMETERS

OVAL FLOWMETER

ALTImass Type S

ALTImass Type U

ULTRA

MK

Flow signal input.

(std.)

Pump output

SV MV COM

SV

MV

COM

Valve

R

C

R

C

Surgesuppressor

Air

supply ?

Combinationfilter/reducingvalve

Two-stage shuto valve

3-wayDirectionalvalve

Valve operation output

Remote Control Input

Short-circuited when

an interlock is not used

Function such as LED

light up when batching

completes is enabled

Output to External Totalizer

OVAL owmeters,

Coriolis owmete rs,

etc.

CAUTION:

* The owme ter sh own h ere

is a n exa mple.

Itisrecommendedtoattachthesurgesuppressoretc.totheinductionloadsidetoprotectthe

contact.

CAUTION:

5.7 Example of Hookup

Fig. 5.2 Exampl of Wiring Connections (Terminal block)

10

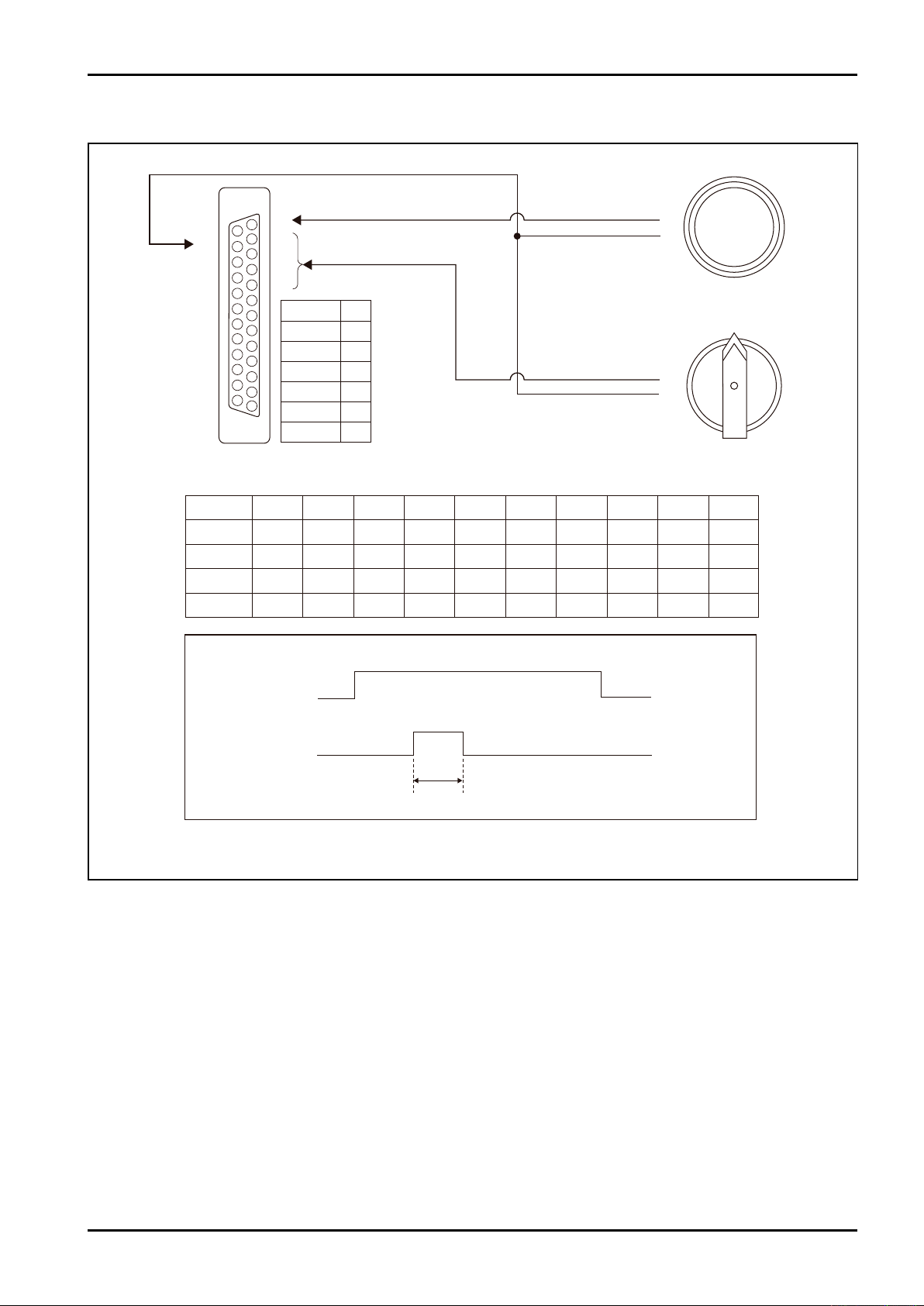

E-216-5N-E

Selector1

Selector2

Selector4

Selector8

SET

COM.1

GND2

Selector1

Selector2

Selector4

Selector8

CH.1

ON

OFF

OFF

OFF

CH.2

OFF

ON

OFF

OFF

CH.3

ON

ON

OFF

OFF

CH.4

OFF

OFF

ON

OFF

CH.5

ON

OFF

ON

OFF

CH.6

OFF

ON

ON

OFF

CH.7

ON

ON

ON

OFF

CH.8

OFF

OFF

OFF

ON

CH.9

ON

OFF

OFF

ON

CH.F

OFF

ON

OFF

ON

9

10

11

12

13

24

25

25

24

13

12

11

10

9

Rearsurfaceofenclosure

D-SUBconnector

Eachselection

(contacta)

SET

(contacta)

200msecormore

HeldbyONorOFF

Pushbuttonswitchetc.

(forfixingCH.)

Selectorswitch

(forselectingCH.)

Fig.5.3 Example of Hookup(D-SUB connector)

11

E-216-5N-E

Status display part

Integration display part

Batch quantity setting value

display part

Valve / pump

status display part

LCD module communication

monitoring part

Batch processing part

(push button switch)

Setting button part

Channel display part

6. FRONT DISPLAY PART AND BATCH PROCESSING PART

6.1 Functions of front display part and batch processing part

The display part has status indication lamps such as RUN and END. There are integration display, batch quantity

setting value, and channel display part in the center of upper stage. There are operation indication lamps of valve

and pump on the left side. The batch processing part has three push button switches; START, STOP, and RESET

and the control at batch processing is enabled only by three push button switches.

Status display part

Valve / pump

status display part

LCD module communication

monitoring part

Integration display part

Batch quantity setting

value display part

Channel display part

Setting button part

Batch processing part

(push button switch)

Fig. 6.1

Name Function

RUN

END Lights up when the batch is completed: green

ALARM Lights up when an alarm is generated: red

I.Lock Lights up when the interlock signal is turned ON; batch is enabled when it is turned ON: blue

MV Upper limit flow rate signal lights up when it is turned ON; goes out when it is turned OFF: red

SV Restricted flow rate signal lights up when it is turned ON; goes out when it is turned OFF: red

PUMP Pump control signal lights up when it is turned ON; goes out when it is turned OFF

COM Communication status between CPU board and LCD module can be monitored: blue LED

COUNT Batch quantity total flow value display 6 digits

Measurement unit

Integrated flow Displayed when any - (- blank), mL, L, kL, m3, g, kg, t, USG, barrel is set

PRESET Batch setting quantity display 6 digits

TOTAL Displays the total value by touching TOTAL button 9 digits *1

CH. No. Displays the selected channel number 2 digits *2

ERR. CODE Displays error number when an alarm is generated *3

CH.SEL Shifts to [CHANNEL SELECT] screen

PRESET Shifts to [PRESET SETTING (CH.F)] screen only when CH.F (free) is selected

TOTAL Displays the total value by touching the button

MENU Shifts to [MENU] screen

STOP Batch processing temporarily stops when an alarm is generated: buzzer stops

RESET Bach completion is reset when an alarm is generated: alarm is reset

START

Displays the batch processing status ; lights up when batch operation is ongoing; blinks when

the operation is interrupted: yellow

Displayed when any of ×1000, ×100, ×10, ×1, ×0.1, ×0.01, ×0.001 is set

Batch processing starts when the operation is temporarily stopped: batch processing is restarted

NOTE: *1: Displayed while you touch the TOTAL button. Display time can be set by setting parameter.

*2: Channel display *3: Error display

12

C1: channel 1 C6: channel 6 E1: pulse non-receipt alarm

C2: channel 2 C7: channel 7 E2: overrun alarm

C3: channel 3 C8: channel 8 E3: leak alarm

C4: channel 4 C9: channel 9 E4: interlock alarm

C5: channel 5 CF: free setting channel E5: emergency stop by RESET button

In case of external setting, C is displayed in small letter E7: WDT reset alarm

Front setting: C1 to CF E8: electric power failure alarm

External setting: c1 to cF E9: FeRAM alarm

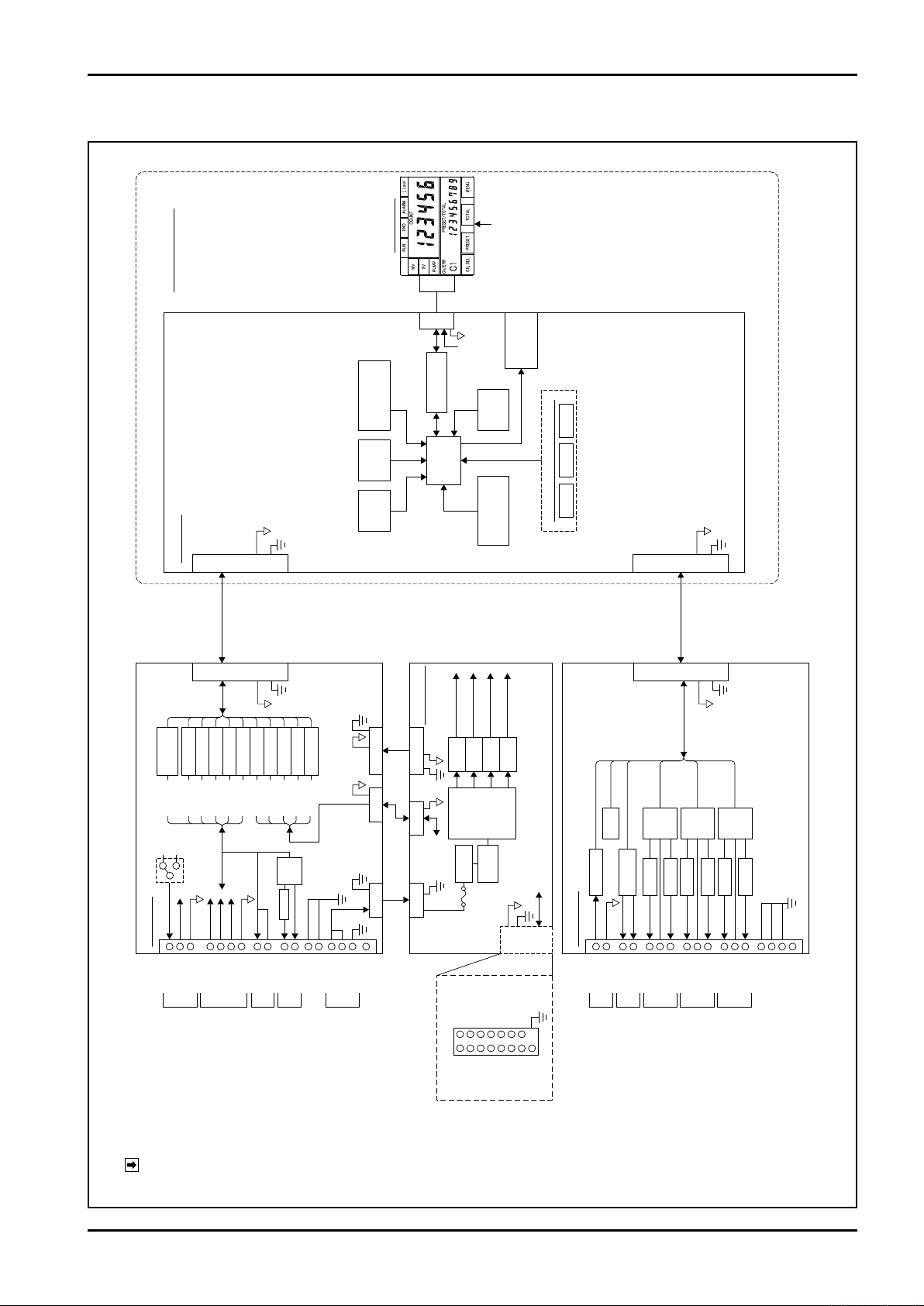

7. BLOCK DIAGRAM

External line

terminal block

External line

terminal block

Flow rate input

Interlock

Batch completion

output

Valve operation

output SV

Valve operation

output MV

Pump output

Form "c" contact

Power supply

for transmitter

+13.5V

+24V

Pulse output

External operation input

Alarm output

Form "a" contact

Supplied power AC

Input board

SUP. 1

I. Lock 25

COM.1 26

END 9

SV a 11

SV b 13

COM.3 12

MV a 14

MV b 16

COM.4 15

PUMP 30

PUMP 32

GND1 27

GND1 28

GND1 29

NC

COM.6 31

END 10

SIG. 2

COM.1 3

SIG. 4

COM. 2 5

ALARM 21

COM. 5 22

GND1 23

L1 6

L2 7

GND1 8

NC

GND1 24

START 17

RESET 18

STOP 19

COM.1 20

2 RXD

3 TXD

7 VD_G

9 select 1

10

select

2

11

select

4

TXD+ 14

TXD− 15

RXD+ 16

RXD− 17

VD_+ 18

COM.1 24

GND2 25

Frame

grounding

12

select

8

13 SET

SIG.

Pulse input

circuit

Photocoupler

START

RESET

STOP

SIG.

ALARM

Select 1

Select 2

Select 4

Select 8

SET

Photocoupler

Photocoupler

Photocoupler

Photocoupler

Photocoupler

Photocoupler

Varistor

Buzzer

Relay

Photo MOS

Photocoupler

Photocoupler

Photocoupler

Photocoupler

Connector

ConnectorConnector

Connector Connector

Varistor

Varistor

a

COM

Relay

AC/DC

Power supply

Input: 24VDC

D−

SUB

Noise

filter

Connector

CPU

debug

circuit

WDT

reset

circuit

CPU

Electric power

failure detection

circuit

Serial

interface

Connector

Connector

Connector

Connector

Connector

Connector

Select 1, 2, 4, 8

SET,

Communication

Select 1, 2, 4, 8

SET

Select 1, 2, 4, 8

SET

+24V,

+

13.5V,

+

5V,

+

5V

F

CPU board

Display unit

Output board

Operation buttons on front surface

Touch operation input

LED module

Power supply board

D−SUB 25P

+24V

+13.5V

circuit

+5V

circuit

+5V

circuit

Photocoupler/relay

Power supply for

transmitter

Power supply for

transmitter

LED module

Power supply for

internal control

85 to 264V

Varistor

Varistor

Varistor

Varistor

Varistor

Relay

Relay

SIG. IN

START, RESET, STOP

SIG. OUT, ALARM

Select 1, 2, 4, 8, SET

+24V,

+

5V,

+

5V

I.Lock

END

SV, MV, PUMP

Buzzer

+

24V,

+

5V

Communication

circuit

STOP RESET START

FeRAM

circuit

LED module

communication

monitoring LED

+5V

+5V communication

※1

※1

E-216-5N-E

NOTE:

Fig. 7.1 Block

※1: To use the external operation input, it is necessary to prepare the connector of D-SUB25 pin by yourself

and connect the circuit for selecting a channel to D-SUB terminal on the rear surface of this machine.

13

Loading...

Loading...