BATCH CONTROLLER

Ins. No. E-215-7-E

MODEL EL1810

Every OVAL batch controller is fabricated, tested, inspected, and shipped from our factory under stringent

quality control. In order to maintain its design performance throughout its life, this manual offers the

operator the necessary installation, operation and maintenance information.

Be well familiar with these instructions before you place the controller in service and keep this manual at

the eld location for ready reference.

Also refer to the instruction manual for the pulse generator (owmeter) used.

1

E-215-7-E

CONTENTS

1. BEFORE YOU BEGIN ................................................................................. 4

1.1 Conrming the Nameplate .............................................................................. 4

1.2 Transportation Considerations .......................................................................

1.3 Storage Considerations ..................................................................................

2. GENERAL ................................................................................................... 5

2.1 Features and Functions .................................................................................. 5

3. PART NAMES ............................................................................................. 5

4. INSTALLATION ........................................................................................... 6

4.1 Outline Dimensions ........................................................................................ 6

4.2 Installation ......................................................................................................

4.2.1 Installation Location (Indoor only) ........................................................

4.2.2 Panel ....................................................................................................

4.2.3 Installation ............................................................................................

4

4

6

6

6

6

5. WIRING ....................................................................................................... 7

5.1 Cables for Field Wiring ................................................................................... 7

5.2 Wiring Connections ........................................................................................

5.3 Identifying the External Connection Terminal Block .......................................

5.4 Identifying the External Connection Terminals ...............................................

5.5 Flowrate Input and their Terminals .................................................................

5.6 Flow Signal Input Wiring Connections ............................................................

5.7 Example of Hookup ......................................................................................

10

6. FRONT PANEL DISPLAY ......................................................................... 11

6.1 Front Panel Display Functions .......................................................................11

6.2 Control Key Functions (other than batch setup mode and other

setup mode) ..................................................................................................

6.3 Output Functions ..........................................................................................

12

13

7. BLOCK DIAGRAM .................................................................................... 16

8. OPERATION .............................................................................................. 17

8.1 Preparation Before Operation ....................................................................... 17

8.2 Preoperational Checks .................................................................................

8.3 Operation Sequence .....................................................................................

8.4 Conrming the Two-stage Valve Opening and Closure ................................

8.5 Description of Batch Operation .....................................................................

17

17

19

19

7

7

8

8

9

2

E-215-7-E

9. SETTING UP OR CHANGING PARAMETERS ........................................ 20

9.1 How to Change Parameters (batch setup and other setup modes) ............. 20

9.1.1 Batch Setup Mode ..............................................................................

9.1.1.1 Operation (batch setup mode) ............................................

9.1.1.2 Example of Batch Setup .....................................................

9.1.2 Setup Mode ........................................................................................

9.1.2.1 Operation (setup mode) ......................................................

9.2 Construction of Internal Assembly ................................................................

9.3 Removal of Internal Assembly ......................................................................

9.4 Assembling the Internal Assembly ................................................................

9.4.1 Installing the Power Supply Board and Output Board ........................

9.4.2 Installing the Front Panel ....................................................................

9.5 Setup or Change on the Power Supply Board

.............................................. 26

9.5.1 A change in the Power to Pulse Generator ........................................

9.5.2 Conguring the Flow Signal Input Circuit for the Companion

Pulse Generator .................................................................................

9.5.3 Input Frequency Division (hardware) Selection

.................................. 26

9.6 Setup on the Output Board ...........................................................................

9.6.1 Buzzer Sound Setup on Alarm (missing pulse, overmeasurement,

and parameter error) Detection ..........................................................

9.7 Reconguration on the Display Board ..........................................................

9.7.1 Total Counter Output Pulse Width Selection ......................................

20

20

21

22

23

24

24

25

25

25

26

26

27

27

27

27

10. TROUBLESHOOTING .............................................................................. 28

10.1 Inspection Items ......................................................................................... 28

10.2 Inspection of Fuse ......................................................................................

10.3 Dielectric Test Voltage ................................................................................

10.4 Q&A Controller Behavior in Standby Mode ................................................

29

29

29

11. GENERAL SPECIFICATIONS .................................................................. 30

12. PRODUCT CODE EXPLANATION ........................................................... 31

CONVENTIONS

Shown in this manual are the signal words NOTE, CAUTION and WARNING, as described in the

examples below:

NOTE: Notes are separated from the general text to bring the user’s attention to important

information.

CAUTION: Caution statements signal the user about hazards or unsafe practices which could

result in minor personal injury or product or property damages.

WARNING: Warning statements signal the user about hazards or unsafe practices which

could result in severe personal injury or death.

3

E-215-7-E

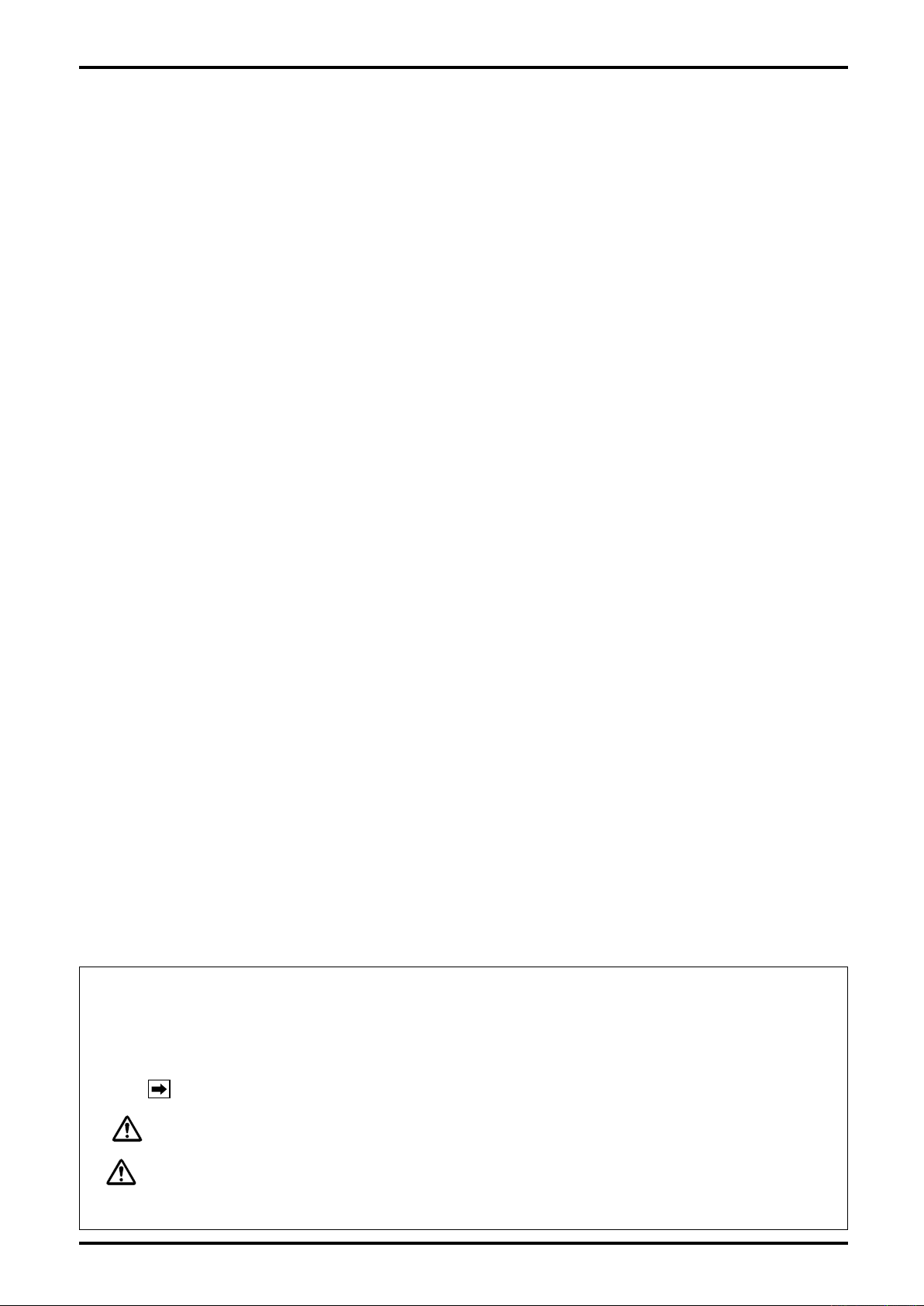

Nameplate

(product tag)

Terminal Identification label

Parameters

label

Fig. 1.1 Location of Nameplate

Nameplate

(product tag)

Terminal Identification label

Parameters

label

Fig. 1.1 Location of Nameplate

1. BEFORE YOU BEGIN

Before leaving the factory, every OVAL product is thoroughly inspected and tested and is shipped in rst-

class condition. When received, it should be carefully inspected for any indication of rough handling during

transit. In this section, instructions necessary for handling this instrument are described. Make yourself

familiar with these instructions. As for other instructions, refer to respective sections.

If you have something to inquire, contact the nearest OVAL authorized service station in your district.

1.1 Confirming the Nameplate

OVAL batch controllers are individually adjusted to the

customer specication.

Make sure, by comparing the model code and ratings

stated on the nameplate or tag attached to the top of

the housing against the GENERAL SPECIFICATIONS

(page 30) and PRODUCT CODE EXPLANATION (page

31), that the product you received conforms to the

specication in your order.

◆

When you inquire, please specify the product name,

model No., serial No., ratings, and other pertinent

information.

1.2 Transportation Considerations

(1) The batch controller should be transported and stored in the same package used for transportation

from our factory if circumstances permit.

(2) Avoid giving impact shocks to the batch controller during transportation.

1.3 Storage Considerations

If the batch controller upon receipt is to be stored for extended periods of time before installation,

unexpected problems could arise. In a case like this, the following considerations should be taken:

(1) The batch controller can best be stored in the original package used for transit from the factory.

(2) Select a storage location that meets the following requirements:

Free from rainwater and moisture

✩

Least vibration and impact shock

✩

In the room temperature and humidity environment (around 25°C and 65% R.H.)

✩

4

E-215-7-E

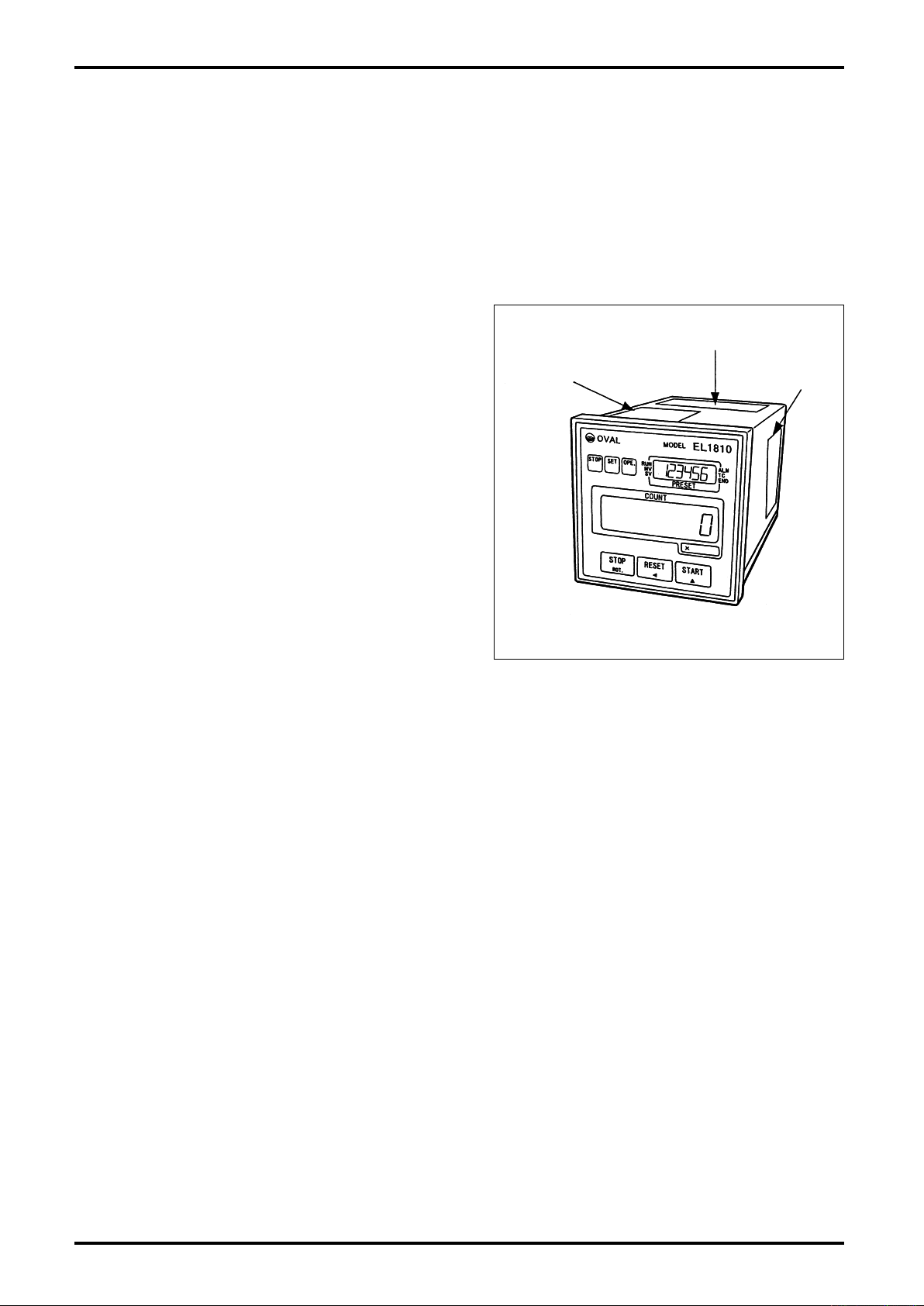

Nameplate

(product tag)

Front panel

Terminal Identification Label

Panel-mount Fitting

(two, top and bottom)

Backpanel (with terminal block

for external connections)

Parameter Label

Frames (top, bottom, right, left)

Fig. 3.1 Part Names

2. GENERAL

Combined with a owmeter and a shutoff valve, the batch controller passes a predetermined amount of the

process uid in batching operations. Built around a single chip microprocessor, this versatile, compact, and

lightweight controller is designed for ease of operation. It saves time and effort in many processes, such as

blending materials, dosing with additives, transferring materials from one tank to another, or shipping from

an outlet, at chemical, food, paint plants or elsewhere where streamlined production lines are desired.

2.1 Features and Functions

(1) Easy operation.

Front panel key switches for batch setup, start, stop, and reset for accurate operations.

(2) Accurate batch control.

Valve control output comes in two steps to open and shut off the valve for far more accurate metering

than with a single batch control output.

(3) Simple system conguration.

Can control the system with start, stop, and reset signal arriving from a remotely located point. Also

available is an end-of-batch signal. All these make interlocking with other control systems simple.

(4) Increased process safety.

Valve opens and shuts off in two steps (reducing the initial velocity); this arrangement prevents not

➀

only static electricity generation in the pipeline or in the tank at startup, but also water hammer, or

hydraulic shock, to the pipeline at valve closure.

If trouble occurs in the process for some reason, resulting in missing pulses, an overmeasurement,

➁

or parameter errors, an alarm can be made to go off.

(5) Reliable and simple to maintain.

Major circuits are built on printed circuit boards for reliability and simple maintenance.

➀

All inputs and outputs are isolated from each other by photocouplers.

➁

During power cycling, parameters and variables are retained in the E²PROM.

➂

3. PART NAMES

NOTES: 1. For terminal blocks for external connections, see Sec. 5.3 on page 7.

2. For the front panel display and controls, see Sec. 6.1 on page 11.

5

E-215-7-E

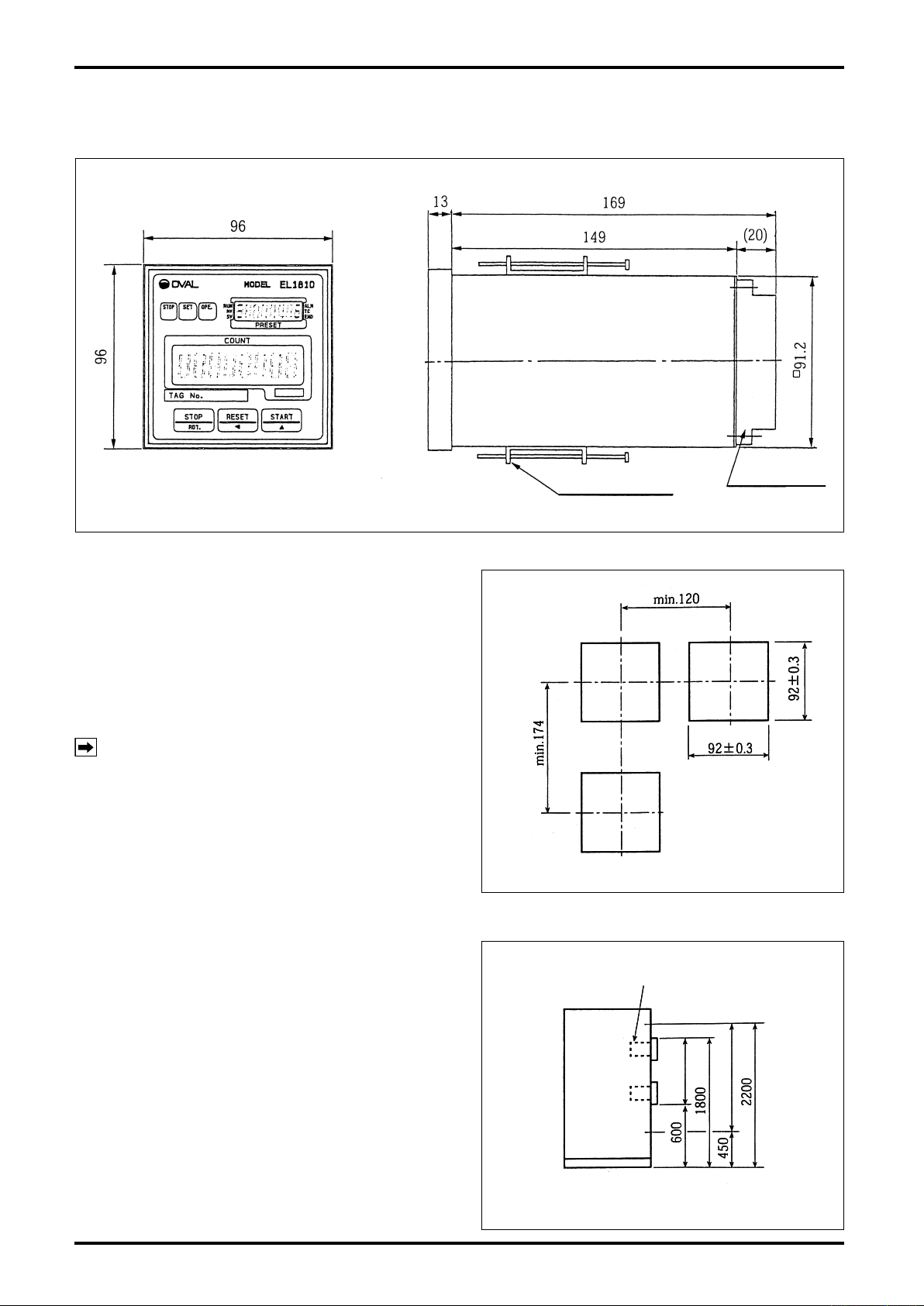

Terminal block

Panel-mount fitting

All dimensions in millimeters

Fig. 4.1 Outline Dimensions

All dimensions in millimeters

Fig. 4.2 Panel Cut

All dimensions in millimeters

Fig. 4.2 Panel Cut

All dimensions in millimeters

Batch controller

Fig. 4.3 Mounting Height

All dimensions in millimeters

Batch controller

Fig. 4.3 Mounting Height

4. INSTALLATION

4.1 Outline Dimensions

4.2 Installation

4.2.1 Installation Location (Indoor only)

Select an installation site where:

(1) Mechanical vibration, shock and corrosive gases

least exist.

(2) The air is dry and at around room temperature

and stable.

(3) A p l ace where is not e x p osed to the direc t

sunlight.

NOTE: Although the manufacturer guarantees

stated performance at ambient temperatures

from – 1 0 t o 5 0 ° C , i t is r e c o m m e n d e d t h a t

the ins trument be p laced in ser vice at room

temperature.

(4) Provide a sufficient working space behind the

instrument – at least 50 centimeters from the

back panel of the instrument to facilitate wiring

and servicing.

4.2.2 Panel

(1)

Use a rigid steel sheet with a minimum thickness of

1.6 millimeters. Recommended thickness is 3.2mm.

(2) If it is required to mount the computers side by

side, dimensions in Fig. 4.2 are suggested.

(3)

Recommended mounting height is given in Fig. 4.3.

4.2.3 Installation

(1) Insert the instrument through the opening in the

mounting panel.

(2) Hook the enclosure hold-down ttings to the slots

in the rear of the enclosure and, conrming that

the instrument is positioned on a level plane,

secure the instrument to the panel with panel-

mount ttings (Fig. 4.1).

6

E-215-7-E

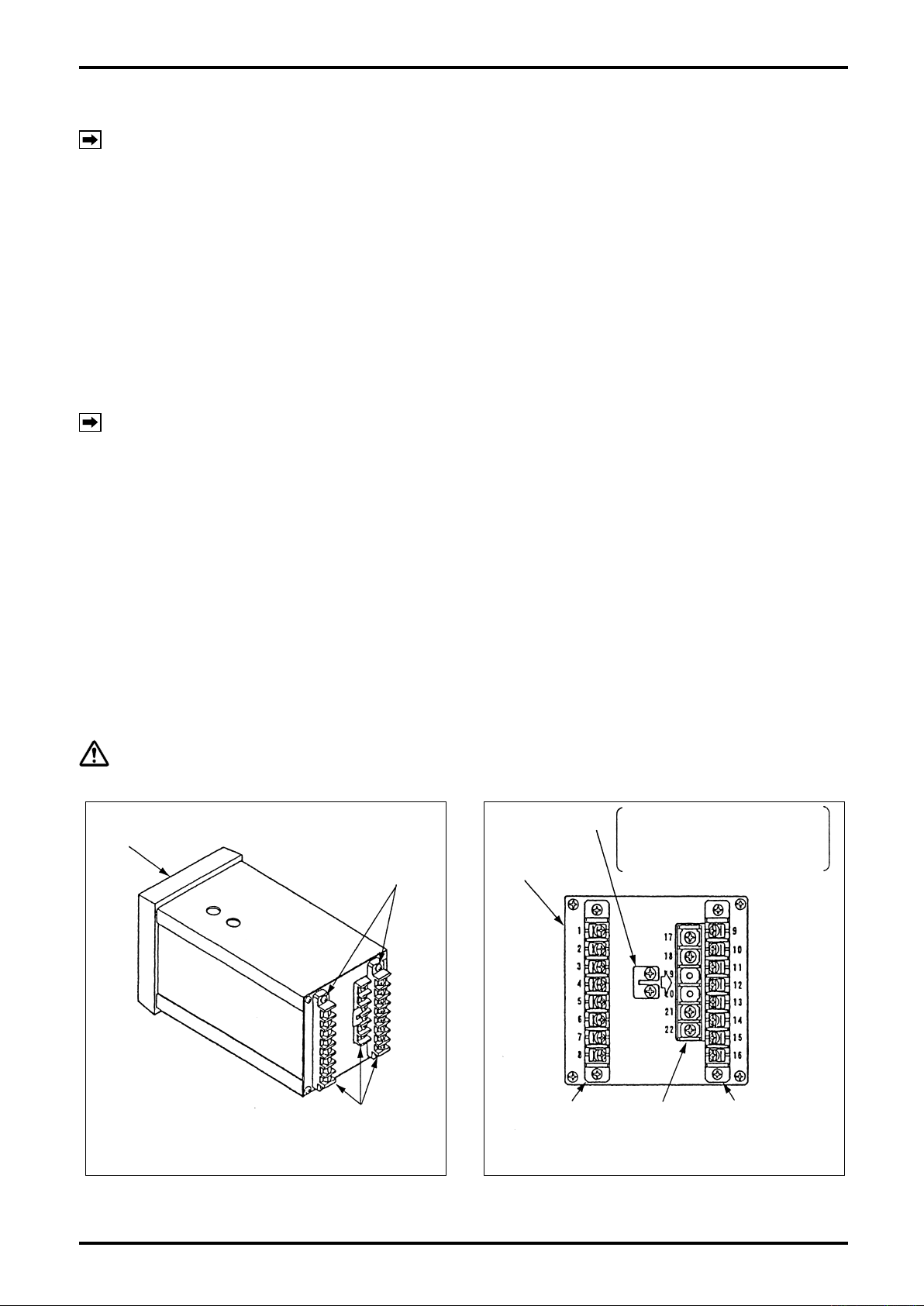

Front panel

Terminal block

fitting screws

Terminal block for

EXT. connections

Fig. 5.1

Fig. 5.2

Shorting strip If remote operate input STOP is

unused, short out terminals

STOP (19) and COM (20) with

this strip.

Terminal

Nos. 1-8

Rear panel

Terminal

Nos. 17-22

Terminal

Nos. 9-16

5. WIRING

NOTE: See “WIRING” in the pulse generator instruction manual.

5.1 Cables for Field Wiring

(1) For flowmeter input signal cable, electrostatically shielded, polyethylene insulated, vinyl-sheathed

control cables (CVES, 1.25 to 2mm

For output signal cables, insulated, vinyl-sheathed cables (CVV, CVS … JIS C 3401) are suggested.

(2) Cable shields must be connected to terminal “G” of the controller. At the probe end, leave the shield

wire end unprepared.

5.2 Wiring Connections

(1) Conduit work is suggested for eld wiring.

NOTE: In conduit work, use separate conduit for power cables and signal cables in order to minimize

the possibility of stray current pickup.

(2) Route cables sufciently away from other power lines or power circuits, if any, to reduce the possibility

of inductive interference to a minimum.

(3) Use crimp-style terminal lugs for connections and ensure good electrical contact. Connection terminals

are found at rear of the controller (Fig. 5.1).

(4) In applications where an inductive load (valve, counter, etc.) is driven, do not fail to use a surge

suppressor (see Fig. 5.3).

(5) Give a 30-centimeter approx. allowance to the wiring harness to allow internal assembly withdrawal for

servicing.

2

, 2- or 3-conductor), or equivalent, must be used.

5.3 Identifying the External Connection Terminal Block

At the rear of the controller, terminal block (terminal Nos. 17-22) secured to the output board and removable

terminals block (terminals Nos. 1-8, 9-16) secured with four screws are found.

CAUTION: Before making wiring connections, verify the validity of flowmeter (pulse generator)

and receiving instrument combination by referring to their product No., tag No., etc.

7

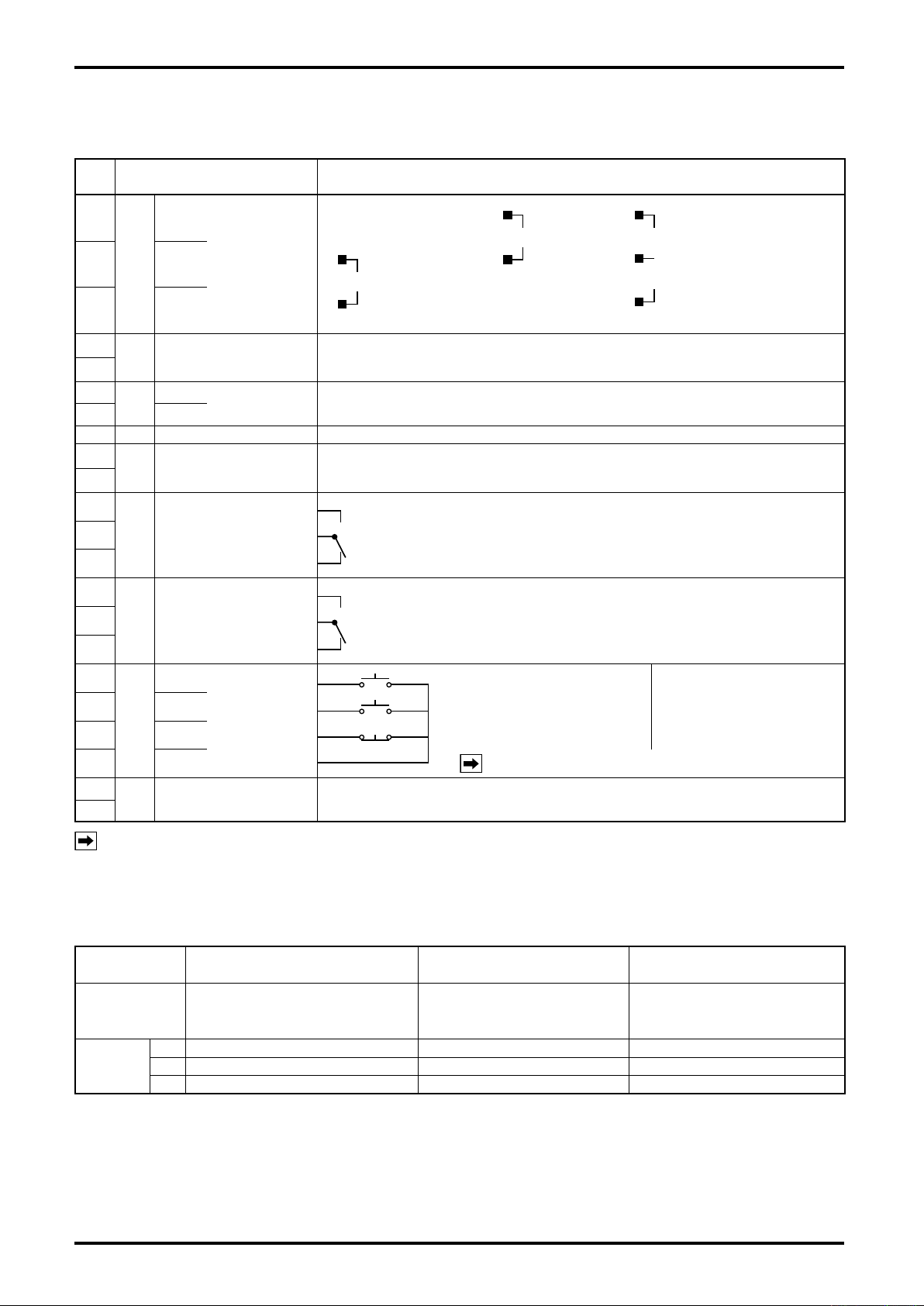

E-215-7-E

Current pulse

[PA14, 15, 25,

NPG60A (E)]

Contact-closure pulse

Open collector pulse

2-wire voltage pulse

(PG20, Coriolis meter)

3-wire open collector

3-wire voltage pulse

[PG30, NPG60A (F),

60 (E3), FLOWPET- EG]

Partial-flow signal (SV): Initial open signal

Relaycontact output, a set of Form “c” contact Capacity: 250VAC, 1A

a

c

b

a

c

b

Upper-limit flow signal (MV): Full-open signal

Relay contact output, a set of Form “c” contact Capacity: 250VAC, 1A

a

a

b

5.4 Identifying the External Connection Terminals

Table 5.1

Term.

No.

Label Required Conditions for Connections and Specications

1

2 SIG.

3 COM.

4

5

6

7 L2 (–)

8 GND Ground terminal

9

10

11

12

13

14

15

16

17

18

19

20 COM.

21

22

SUP.

FLOW SIG

INPUT

Flow Signal Input

TOTAL COUNT OUTPUT

External

Totalizer

Output to

L1 (+)

Power

BATCH END OUTPUT Non-contact relay output, a set of Form “a” contact Capacity: 250V AC/DC 0.15A

Batch

Output

End-of-

VALVE OPERATION

SIGNAL (SV)

Signal

Valve Control

VALVE OPERATION

SIGNAL (MV)

Signal

Valve Control

START

RESET

Input

STOP

Remote Control

ALARM OUTPUT

Alarm

Output

POWER

SUPPLY

REMOTE

CONTROL

INPUT

Non-contact relay output, a set of Form “a” contact Capacity: 250V AC/DC 0.15A

Output pulse width: 1ms (standard) or 50ms

85 to 264VAC 50/60Hz

An output on detection of missing pulses, overmeasurement, parameter error Relay

contact output, Form “a” output Capacity: 250V AC, 1A

Contact current:

START: Form “a” contact

RESET: Form “a” contact

STOP: Form “b” contact

NOTE: Short STOP when not in use.

10mA max. at 15VDC

Signal width:

Instantaneous signal

※:

1 sec.

NOTE ※: Provide at least 2 seconds between individual signals (see page 10).

5.5 Flowrate Input and their Terminals

Table 5.2

Signal Type

Generator PG20, Coriolis owmeter PA 14, 15, 25, NPG60A (E)

Terminals

: Terminals in use

○

8

Contact-closure Pulse, 2-wire

Voltage Pulse, Open Collector Pulse

1

2

3

—— ○

+

○

–

○

Current pulse

3-wire open collector pulse

3-wire voltage pulse

PG30, NPG60A (F),

NPG60A (E3),

FLOWPET-EG

+

–

○

—— ○

SUP.

○

SIG.

○

COM. (0V)

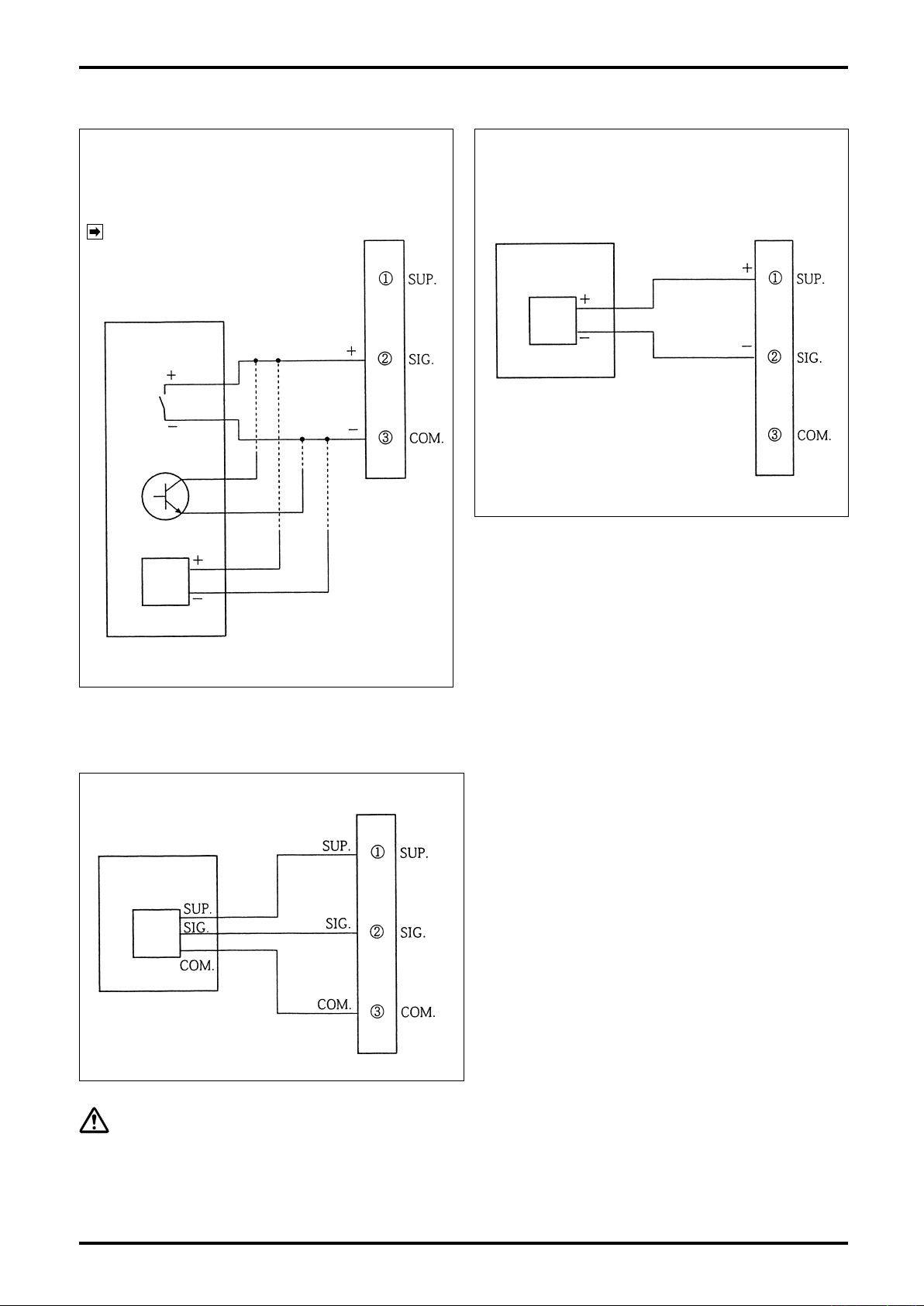

5.6 Flow Signal Input Wiring Connections

Contact-closure

pulse

NOTE:

This does not mean to accept three

different types of pulse generators

at the same time.

EL1810

Terminal block

EL1810

Terminal block

Current pulse

Open collector

Pulse

Voltage pulse

Pulse generator

Pulse generator

Fig. 5.3

Fig. 5.4

EL1810

Terminal block

Current pulse

Pulse generator

Fig. 5.4

EL1810

Terminal block

Pulse generator

Fig. 5.5

E-215-7-E

(1) C o n t act - c l osu r e p uls e , 2-w i r e vol t a g e

pulse,open collector pulse (PG20, Coriolis

owmeter)

(2) Current pulse [(PA14, 15, 25, NPG60A(E)]

(3) 3-wire open collector pulse

3-wire voltage pulse

[PG30, NPG60A (F), NPG60A (E3), FLOWPET-EG]

CAUTION: Before making wiring connections, verify the validity of flowmeter (pulse generator)

and receiving instrument combination by referring to their product No., tag No., etc.

9

E-215-7-E

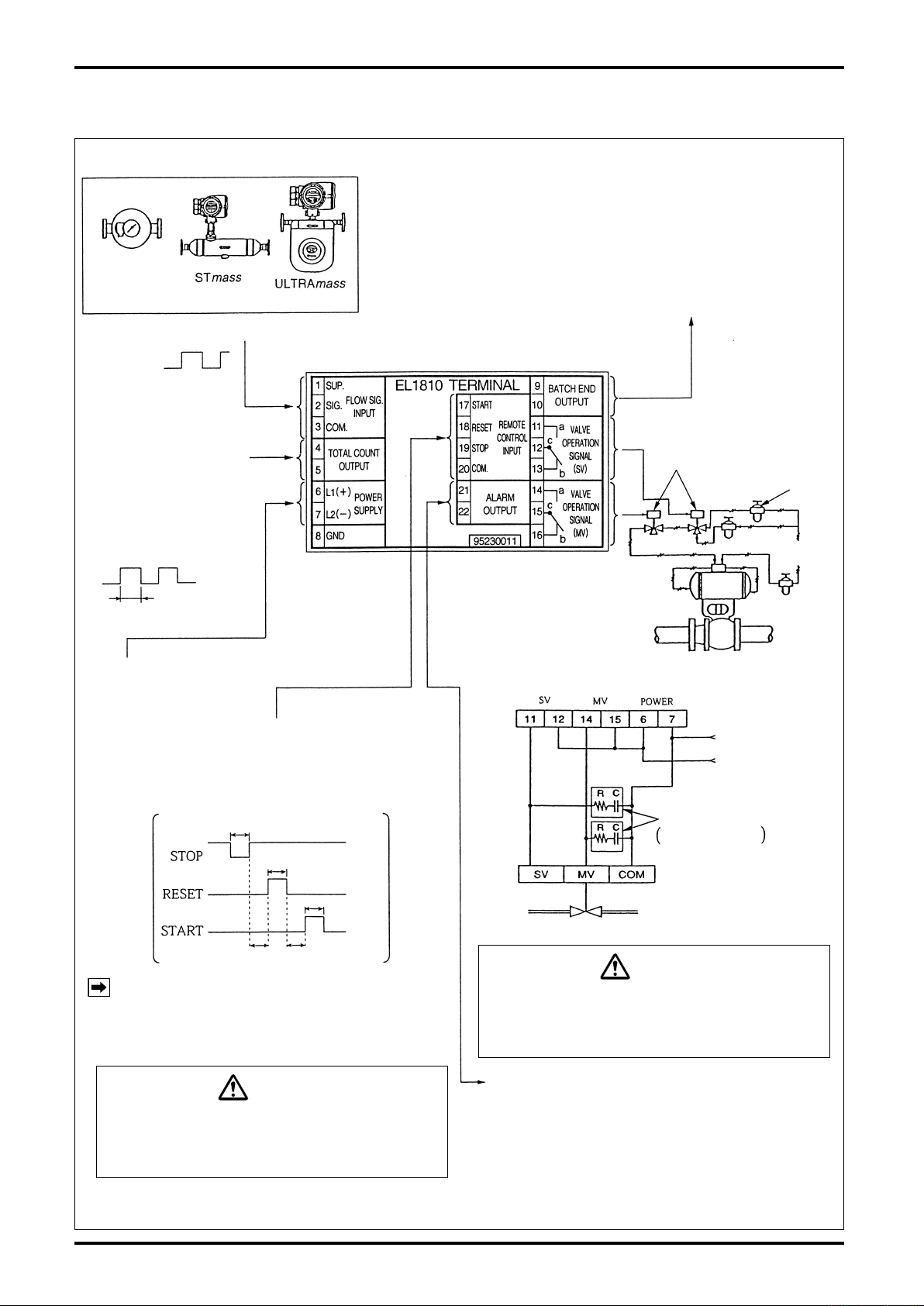

OVAL flowmeters, Coriolis flowmeters, etc.

1ms (std.) or 50ms

ON duration

1 sec.

1 sec.

3-way

directional

valve

Combination

filter/reducing valve

Surge suppressor

Ratings

R: 120Ω

C:

0.1μF 250V AC

Air

supply

1 sec.

2 sec.

min.

2 sec.

min.

Signal duration

Power: 85 to 264V AC, 50/60Hz

Fig. 5.6 Example of Wiring Connections

Output to remote

totalizer counter, etc.

(Non-contact relay output,

Form “a” contact)

End-of-batch output,

LED indicator. etc.

(Non-contact relay output,

Form “a” contact)

START : Form “a” contact)

RESET : Form “a” contact)

STOP : Form “b” contact)

Power

Valve

Alarm output (missing pulses, overmeasurement,

parameter error, or other fault)

Can activate an LED indicator, etc.

(Relay contact output, Form “a” contact)

Two-stage shutoff valve

Flow signal input

Coriolis flowmeter

External connection terminal block

(at the top of controller)

OVAL

FLOWMETER

5.7 Example of Hookup

NOTE: Remote command inputs and front-panel

buttons have their functions in common.

See Sec. 8.3 “Operation Sequence” for

signal input procedures.

CAUTION

If remo te c ontrol i nput is n ot use d,

always shor t across STO P (19 ) and

COM. (20).

10

CAUTION

Coup le a surg e s uppres s or, e t c. i n

parallel with inductive load.

(R: 120Ω C: 0.1μF 250V AC)

E-215-7-E

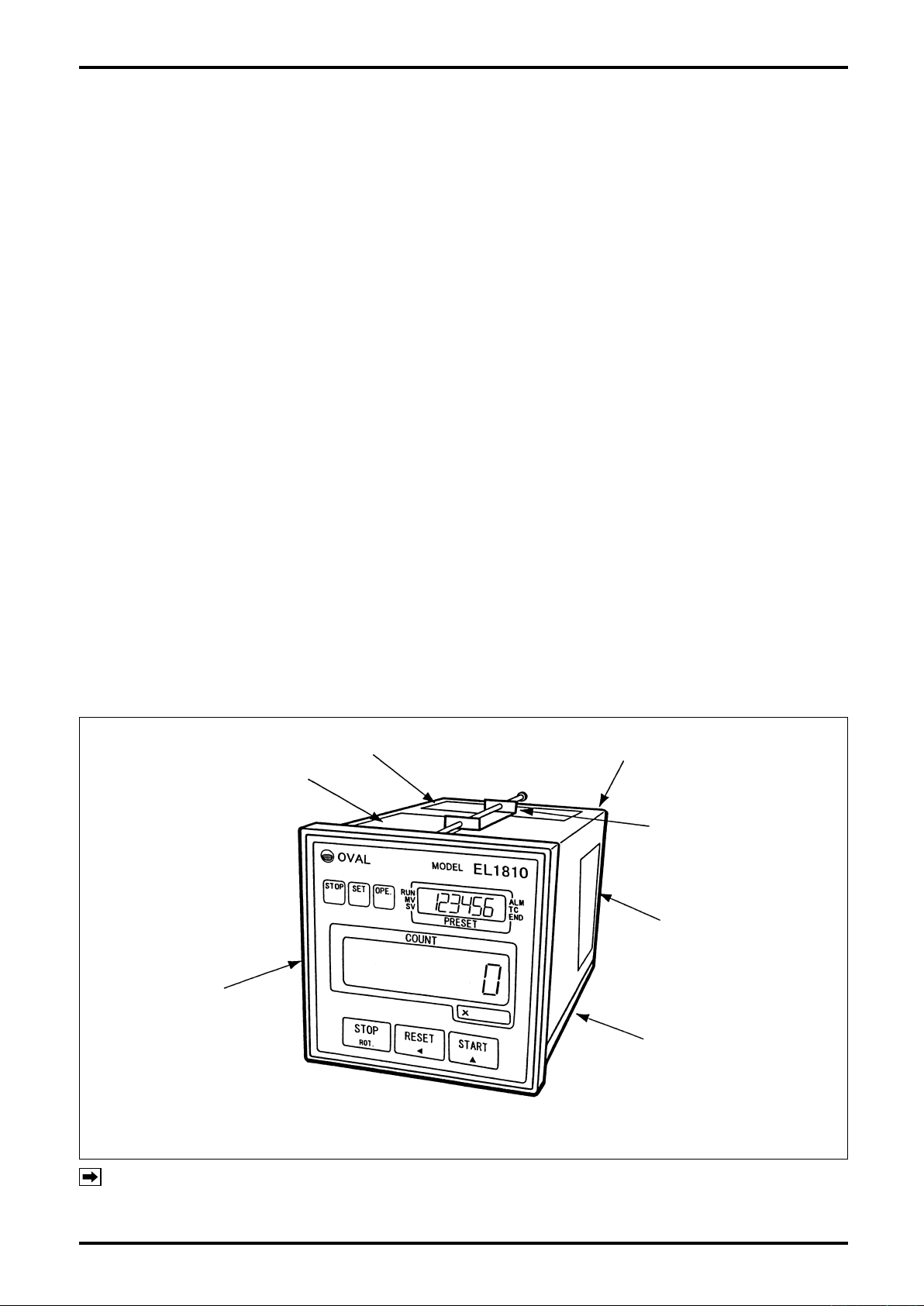

Operation Indicators

(RUN, MV, SV)

Operation status indicator LEDs

STOP (RED), SET (ORG), OPE (GRN)

Operation indicators

(ALM, TC, END)

Tag No. plate

Control keys

STOP (ROT.) RESET () START ()

Fig. 6.1 Front Panel Displays and Controls

Measurement unit label

LCD2 display

Batch setting (8-digit)

LCD1 display

s4ARGETBATCHSETPOINTDIGIT

Displays target batch setpoint only,

while batch process is in progress.

s'RANDTOTALDIGIT

s25.INDICATORSSTANDTHSEGMENTS

light up.)

6. FRONT PANEL DISPLAY

6.1 Front Panel Display Functions

The front panel has three control keys – STOP/ROT., RESET◀, START/▲ at the bottom and three LED

status indicators – STOP, SET, OPE (red, orange, green) at top left. The upper LCD 1 is an 8-digit display

with 7mm high characters and the central LCD 2 is an 8-digit display with 12.7mm high characters.

Labels Functions

STOP Stays on while the batch process is stopped.

LED indicator

LED 1 display

NOTES: ※1. For information about the batch setup mode, see Section 9.1 on page 20.

CAUTION:

SET Comes on while the batch setpoint is changed. ※1

OPE. Stays on while the batch process is in progress.

RUN Blinks on and off while power is on (in normal operation).

SV, MV Comes on in response to valve control signal output SV or MV. (Stays on until reset.)

ALM

TC Blinks in synchronism with each totalizer count and its output to the remote counter.

END Comes on at the end of batch. (Stays on until reset.)

※

2. ALM does not light upon detection of a parameter error.

RUN, SV, MV, ALM, TC

segments in its 1st and 8th digit. The display shows the batch setting on the 6-digit

Comes on while an alarm output (missing pulse, overmeasurement) is produced.

(Stays on until reset.) ※2

, and

are indic ated usin g the LCD 1 hor izon tal

END

display field, excluding these 1st and 8th digits at both ends.

In the grand total mode, the display becomes a full 8-digit counter.

11

E-215-7-E

6.2 Control Key Functions (other than batch setup mode and other setup mode)

NOTE: For control key locations, see Fig. 6.1 on page 11.

STOP

ROT.

Batch in progress

Upon detection of missing

pulses

LCD1 shows target batch

setpoint or grand total.

Key functions

Item Functions

Batch stops (

Missing pulses alarm output is reset (LCD 1

LCD 1 screen switches:

Batch setpoint (6-digit) + LED 1 operation indicators

RUN , SV , MV , ALM , TC , END ,

Shown alternately.

Grand total reading (8-digit)

OPE : goes out; Valve control signals SV, MV: close;

LCD 1

SV , MV : go out).

ALM : goes out).

CAUTION: You cannot switch the display from the batch setting to the grand total unless you

ALM

, end-of-

RESET

◀

reset the current batch process by resetting the missing pulse alarm

batch

END

, and overmeasurement alarm

ALM

.

Key functions

Item Functions

LCD 1 shows grand total.

LCD 1 shows batch setpoint

(not in operation)

START

LCD 1 shows grand total.

LCD 1 shows batch setpoint

(not in operation).

Key functions

▲

Item Functions

None

Batch process reset (LCD 2 batch reading is reset to zero).

End-of-batch output is reset (LCD 1

Overmeasurement alarm output is reset (LCD1

Parameter error alarm output is reset.

None

Simultaneously with the start of a batch process (OPE. : comes on),

valve operate signal SV opens (LCD 1

CAUTION: Simultaneously with

1 SV comes on). If the two-stage open mode remains disabled, the valve operate

signal MV also opens (LCD1 MV comes on), however.

END : goes out).

ALM : goes out).

SV : comes on).

illumination, the valve operate signal SV opens (LCD

OPE.

12

E-215-7-E

[Batch in progress]

Flow pulse signal stop Missing pulse alarm detected

STOP key

(alarm reset)

START key

(Restart)

Missing pulse duration set

ALM indicator

Alarm output

SV, MV indicator/output

Batch end output

Fig. 6.2

RESET key

(alarm reset/

batch total reset)

START key

(Batch start)

Fig. 6.3

Batch end

Overmeasurement preset

Overmeasurement alarm detected

ALM indicator

Alarm output

SV, MV indicator/output

Batch end output

6.3 Output Functions

NOTE: For the information about the front panel display functions not described in this section, see

Section 6.1 on page 11 and Table 11.1 on page 30.

(1) Alarm Output

Upon detection of missing pulse, overmeasurement, or parameter error, the controller produces an alarm

output.

The LCD 1

completes a circuit across terminals 21 and 22 (Relay contact output Form “a” contact) (upon detection of

all alarms).

a. Missing pulse alarm detection (Fig. 6.2)

Following

arrives within the time preset for missing pulse detection, an alarm output is produced. Immediately after

startup, however, time measurement begins approximately 5 seconds later.

For the setup procedure, refer to Sec. 9.1.

ALM

START

▲

then comes on (only upon detection of missing pulses or overmeasurement) and

key depression to start a batching process, if no ow pulse signal (terminals 1-2-3)

b. Overmeasurement alarm detection (Fig. 6.3)

When a ow pulse signal arrives while a batch process is in progress, a target batch quantity will eventually

be reached and an end-of-batch signal is generated. If ow pulses continue to arrive at this point and

exceed a preset overmeasurement quantity, an alarm output is produced.

For the setup procedure, refer to Sec. 9.1.

13

E-215-7-E

STOP key

(Confirm param.)

RESET key

(Initialize param.)

Parameter error alarm detected

ALM indicator

Reestablish param.Alarm output

“dAtA Err” indicator

Fig. 6.4

STOP

ROT.

PressParameters

s"ATCHSETTINGhBvAPPEARSATLEFTEND

s"ATCHTOTALCOUNT

s'RANDTOTALCOUNT

s3CALEFACTOR

s&REQUENCYREDUCTION

s)NITIALSETTING

s&INALSETTING

s-ISSINGPULSESETTING

s/VERSHOOTSETTING

KEY $ISPLAYEDALTERNATELY

&IG

Messages upon detection of a parameter error alarm

c. Parameter error alarm detection (Fig. 6.4)

When an error in any of parameter settings is found, an alarm output is produced and a data error

message “DATA Err” appears on the display (the LCD 1

Each time

•

STOP

ROT.

key is pressed, the LCD 1 display scrolls through the available data, enabling the

operator to identity which parameter causes a problem (see Fig. 6.5).

ALM

does not come on in this case).

Following the error identification, press

•

RESET

◀

key to cancel the alarm output.

(A message “DATA Err” disappears and all the data are reset (initialized).)

Following the reset step above, set up the parameters of interest and the target batch quantity once

•

again according to the specification. See Sec. 9.1 for the setup procedure.

14

E-215-7-E

(2) End-of-batch output

When a ow signal reaches the target batch quantity during a batch process, an output is produced.

The LCD 1

output, Form “a” contact).

(3) Scaler

If incoming pulse signal is of unfactored pulses, a constant inherent to the owmeter used is multiplied in

the scaler; conversion takes place into quantities in industrial engineering units of measure in integer; the

resultant quantities are used for batch processes.

For the setup procedure, refer to Sec. 9.1.

(4) Input frequency division (scaling)

There are two approaches in setting up the input frequency division. One is a frequency reduction by

hardware, using a jumper and the other is a frequency reduction by software, using the front panel control

keys.

For the setup procedure, refer to Sec. 9.1 and 9.5.

END

then comes on and completes a circuit across terminals 9 and 10 (Non-contact relay

15

E-215-7-E

LCD 2 Disp. (batch reading 8-digit) LCD 1 Disp. (batch setting 6-digit)

Power to generator

Flowrate signal

input

Remote control input

Power

1,3

4,5

9,10

21,22

11 to 16

2

17,18,19

20

6,7

24V

13.5V

START

RESET

STOP

85 to 264VDC

50/60Hz

Power to

generator

Wave-

shape

Regulated

Voltage

source

Power to

generator

Freq.

divide

Freq.

divide

One-shot

multivibrator

1ms or

50ms

Batching

microprocessor

6-digit

Batch counter

8-digit

Total counter

Scaler

Front-panel

control keys

Display boardPower board Output board

Non-contact

relay

Non-contact

relay

Relay

Relay

Output to external total counter

TC

Non-contact relay output

Form “a” contact

End-of-batch output

END

Non-contact relay output

Form “a” contact

Alarm output

ALM

Relay contact output

Form “a” contact

(missing pulse, overshoot,

param. error)

Valve control signals

SV, MV

Relay output

Form “c” contact, one set each

NOTES

Missing

pulse alarm

Overmeasure

alarm

Com-

pare

Batch setting

Initial setting

Final setting

6-digit

0 to 999 counts

0: No setting

Default: 80 counts

Toggle

switch

RUN ⇔ SET

RUN: Run mode

SET : Setup mode

Buzzer

Counter

About A

0 to 15 sec.

0: No alarm

Default: 10 sec.

About B

0 to 99 counts

0: No alarm

Std.: 10 counts

7. BLOCK DIAGRAM

16

E-215-7-E

key

key

key

Fig. 8.1

key

key

key

Fig. 8.1

8. OPERATION

8.1 Preparation Before Operation

(1) Make sure to see that the controller and associated equipment are correctly installed, connected and

wired with no place left unnished.

WARNING

Make sure to see that the power terminals are connected to a source of the rated voltage.

Connecting an incorrect power voltage source may ruin the controller.

(2) Make sure that the shutoff valve is correctly wired and set. For details, see the instruction manual for

the shutoff valve.

8.2 Preoperational Checks

Make sure to see that the shutoff valve operates properly without allowing the flow.

•

(Run this check daily before operation.)

(1) Supply power to the controller. Conrm that LED

STOP indicator becomes illuminated and that

displays LCD 1 and LCD 2 come on.

(2) Enter some arbitrarily set quantity of a batch.

NOTE: See Section 9.1.1.2, “Example of Bach

Setup” on page 21.

(3) Press

shutoff valve opens.

(4) Press

valve closes properly.

(5) Repeat steps (3) and (4) above several times to make certain that the shutoff valve opens and closes

properly.

(6) If the controller features remote start and stop, repeat steps (3), (4) and (5) above also at the remotely

located point.

START

STOP

ROT.

key to make c e r t a in that the

▲

key to make certain that the shutoff

8.3 Operation Sequence

(For information about the control keys, see Section 6. FRONT PANEL DISPLAY on page 12.)

(1) Turn on power.

(2) Allow the LCD 1 display to show the batch setting.

(3) Set the target batch quantity desired.

The unit of measure is indicated on the unit label at lower right below the LCD 2 display.

(4) Press

(5) Press

RESET

◀

START

▲

key to reset the batch total counter of LCD 2.

key to start up and the controller will start batching operations.

CAUTION

If the controller receives even a single pulse during the transitional time between RESET key

and START key depressions, it will fail to start. (For details, see Question 3 in Section 10.4

Q&A Controller Behavior in Standby Mode.)

17

E-215-7-E

(6) To perform a repeated metering of the last measured batch, all you need is to press the reset key to

bring the total counter of LCD 2 back to zero and then press the start key:

Press

Pressing

NOTE: For metering different batches, select a new target batch setting each time.

(7) Emergency shutoff (or temporary interruption)

To bring the controller to an emergency stop, press

closure.

Pressing

point of interruption.

In this way, safe and accurate measurement can be achieved.

RESET

◀

START

▲

START

▲

key to reset the total counter.

key readies to restart the last metered measurement.

STOP

ROT.

key will resume operation and continue metering the remaining quantity from the

key. The shutoff valve will come to a full

18

E-215-7-E

Fig. 8.2 Operation Time Chart

Valve

control

signals

Partial flow signal

(Partial open signal)

High limit

flow signal

(Full open signal)

High limit flow open

(MV: LCD 1 comes on.)

Partial flow open

(SV: LCD 1 1comes on.)

High limit flowrate

Flow

rate

Initial flowrate

Initial partial flow

(Initial setting)

START

signal

STOP

signal

Time

Final flowrate

Overshoot

End of batch

Batch setting

(Target quantity)

Final partial flow

(Final setting)

8.4 Confirming the Two-stage Valve Opening and Closure

You can conrm the valve opening and closing in two stages by one of the following two approaches:

Once set the initial and final setpoint at “0,” choose a batch setpoint somewhere above “1” and press

•

START

▲

If simulated pulses (from OVAL pulse checker PC2201, for example) are available, you can confirm

•

and

STOP

ROT.

key to verify proper shutoff valve actuation.

proper batch operation of the shutoff valve by setting the initial and final setpoint at any point, pressing

START

key, and then feeding a simulated pulse train.

▲

NOTE: The target batch setting should be greater than the sum of the initial and nal setting.

8.5 Description of Batch Operation

NOTE: Operation can best be understood by referring to the operation time chart in Fig. 8.2 below.

Upon depression of

predetermined quantity (from point A to point B) has been delivered, the valve opens fully; when metering

has reached point C, the valve automatically throttles the flow and maintains a predetermined valve

position (nal owrate).

At point D, a closure signal is generated. However, due to a time lag in valve actuation, inherent to the

type of valve used, the valve actually close at point E. If an overshoot, or overmeasurement, exceeds a

predetermined quantity, the controller produces an alarm.

Safe and accurate measurement is thus achieved. In this connection, valve positions A → B and C → D

must be preselected on the part of the valve.

START

▲

key, the valve opens to a predetermined position (initial owrate). When a

19

E-215-7-E

Batch Setup Mode

comes on and LCD 1 (batch setting) blinks.

6 digits

Batch

setting

Change

Figure adjust Shift Setup

A numerical value is finalized

with two control keys.

To RUN mode

omes on.

To exit without changing any setting

9. SETTING UP OR CHANGING PARAMETERS

Setting up parameters and variables other than those to be set up with controller’s front-panel control keys

requires internal assembly removal since it involves conguring the internal boards of the controller.

NOTE: Defaults (your specications inclusive) appear on the parameter settings label attached to the

side of the controller. ⇒ See page 22.

9.1 How to Change Parameters (batch setup and other setup modes)

9.1.1 Batch Setup Mode

To set up a batch, holding

STOP

ROT.

key depressed for more than 3 seconds while the following conditions

are met.

The front LED SET lights up and the LCD 1 (batch setting) blinks on and off. Target batch setpoint

alteration is now acceptable.

Conditions required for changing batch setpoints

(1) The display does not show the grand total.

(2) A missing pulse alarm has not been detected along with its output.

(3) An overshoot alarm has not been detected along with its output.

(4) An end-of-batch signal has not been produced.

(5) A batch operation is not in progress.

CAUTION: 1. If an alarm output exists, reset it before you work.

2. While the controller is not in the batch operation but is only counting

incoming flow pulses for totalization, a change in batch setting is

acceptable.

9.1.1.1 Operation (batch setup mode)

On seeing the front panel SET illuminated and the whole LCD 1 ickering (in response to the procedure

above), you can change the current setpoint by the following procedure.

Upon depression of

back to the RUN mode.

STOP

ROT.

key, the value entered is stored in the memory and the LCD 1 display goes

20

E-215-7-E

Hold key depressed for more than 3 seconds.

START

▲

RESET

STOP

ROT.

STOP

ROT.

STOP

ROT.

Blinks at the previous

setpoint.

Batch setup mode

comes on and LCD (batch setpoint) blinks.

In the operations below, absence of any key entry

for more than 10 seconds will cause the LCD to

return to the previous setting and to RUN mode

automatically (in the batch setup mode).

Set up from the most

significant digit:

“1” in this example.

If the figure has gone too far,

press the key a number of

times to readjust the figure.

If the figure has gone too far,

press the key a number of

times to readjust the figure.

If the figure has gone too far,

press the key a number of

times to readjust the figure.

Press

once.

Press

once.

Press

once.

Press

once.

Press

once.

Press

thrice.

LCD1 Disp.: 0 → 1

LCD1 Disp.: 0 → 10

LCD1 Disp.: 10 → 12

LCD1 Disp.: 12 → 120

LCD1 Disp.: 120 → 123

LCD1 Disp.: 123 →1230

If you have taken the figure place up more than necessary,

like 1→10→100, press key a number of times until the LCD 1 display shows 0 and go back to → to

start all over again.

Press

twice.

If figure place has been taken

up more than necessary,

If figure place has been taken

up more than necessary,

In a similar way, keep on adjusting the figure at the rightmost of the LCD 1

with and taking the figure place up with key.

Adjust the figure until the LCD 1 displays 123456

and press key.

At touch of key, the figure is stored in the memory and the LCD display returns to the normal batch display.

SET

RESET

◀

STOP

ROT.

◀

9.1.1.2 Example of Batch Setup

Make sure that your batch setting meets the conditions required for changing batch setpoints outlined in

the previous paragraph.

To change batch setpoints, we recommend to press

shows 0 (ZERO) and then set up as outlined below.

●

Shown below is an example of setting of a batch of 123456.

RESET

◀

a number of times until the LCD displays

21

E-215-7-E

Output board

Take off two setscrews

securing the terminal

block and separate the

terminal block forward.

Terminal block

(Terminals 9 thru 16)

Rear of Batch Controller

Parameter settings label

Fig. 9.1

Toggle Switch

CAUTION

Be sure to turn off power before you work.

9.1.2 Setup Mode

CAUTION: Be sure to turn off power before you work.

Remove the terminal block holding terminals Nos. 9 through 16 and place toggle switch S1 at ★ mark in

Fig. 9.1 in the “SET”.

Turning power on will bring the controller into the setup and the entire LCD will icker.

In this setup mode, the following parameters can be congured. [Factory default settings appear on the

setup label attached to the side of the controller. See Fig. 9.1.]

NOTE: The controller is shipped at default settings unless otherwise specied by the customer.

CAUTION

During a batch process, in an interrupted or completed state of operation, or in an alarmed

condition, a transfer to the setup mode is disabled. Cancel the batch process or clear the

alarmed event by pressing RESET button first before you retry.

Table 9.1

Symbol Item Setup range Default setting

Total reading reset

(gure adjustment)

F Scale Factor 0.0001 to 1.9999

d Frequency division 0: 1/1, 1: 1/10, 2: 1/100 Default:0 (1/1) or customer’s specication

oP Initial setting

Final setting

cL

Missing pulse

PL

setting

oV Overshoot setting

00000000 to 99999999

0 to 999 counts

(Set to 0: Two-stage open disabled;

SV and MV open simultaneously.)

0 to 999 counts

(Set to 0: Two-stage close disabled;

SV and MV close simultaneously.)

0 to15sec

(Set to 0: Missing pulse alarm

detection disabled)

0 to 99 counts

(Set to 0: Overmeasurement alarm

detection disabled)

——

Meter factor the meter used

Default: 1.0000 or customer’s specication

or customer’s specication

or customer’s specication

or customer’s specication

or customer’s specication

Default: 80

Default: 80

Default: 10

Default: 10

22

E-215-7-E

Setup Mode LCD1 blinks.

If you go down to the next step without any

setpoint changes.

00000000

to 99999999

(8-digit)

Total counter setting at 0

Total

reading

Change

Change

Change

Change

Change

Change

Change

Adjust

numerals.

Shift Setup

Set up numeric value

with two control keys.

0.001

to 1.9999

Scale factor at 1.0000

Scaler

0:1/1 1:1/10

2:1/100

Frequency divide at 0 (1/1)

Freq.

divide

0 to 999

counts

(3-digit)

Initial setting at 80

Initial

setting

0 to 999

counts

(3-digit)

Final setting at 80

Final

setting

0 to 15 sec

(2-digit)

Missing pulse setting at 10 sec.

Missing

pulse

setting

0 to 99

counts

(2-digit)

Overmeasure setting at 10

Overmeas.

setting

9.1.2.1 Operation (setup mode)

On seeing that the entire front panel LCD1 is blinking (by the previously outlined steps), you can change

parameters and variables as follows. The procedure to enter a numerical value remains the same as

“Example of Batch Setup” in the previous section. Refer to that section. The LCD 1 readings shown below

are factory default settings.

CAUTION:

Upon completion of all setup procedures, turn off power and return the toggle

switch to “RUN”.

23

E-215-7-E

Display board

Front panel

Interconnect cable unit

Output board

Power supply board

Rear panel

Guide slot to hold the boards

(top and bottom)

Terminal block

(9-16)

Terminal block (17-22)

Terminal block (1-8)

Fitting screws (a total of 4)

Frame

Fig. 9.2

Fig. 9.3

Long screw

Fig. 9.4

Front panel

Display board

Separate.

9.2 Construction of Internal Assembly

The internal assembly of this controller consists of three boards – display board, power supply board, and

output board. The power supply board and output boards are individually coupled with connectors CN1 and

CN2 to their mating connectors CN1 and CN2 on the display board. The rear panel has terminal blocks for

external connections. (For details of the terminal blocks, see Sections 5.3 and 5.4.)

NOTE ※: Since the power board and output board are

connected with interconnect cable unit, slide

both of them out of the frame when you remove

them.

9.3 Removal of Internal Assembly

Remove the controller from the mounting panel before its internal assembly is removed.

CAUTION:

Take off long screws at back of the controller.

➀

24

Be sure to remove power before you work.

Separate the front panel (display board) from the

➁

housing.

E-215-7-E

Fig. 9.5

Separate.

Output board

Power supply board

Rear panel

Power supply board

terminal block

Fig. 9.6

Output board

Shorting strip

Fig. 9.7

Separate.

Output board

Output board

terminal block

Rear Panel

Power supply board

Extract the power supply board from the terminal

➂

block on the rear panel.

If a shortin g strip e x i sts, remo v e i t b efore

➄

extracting the output board from the terminal

block of rear panel.

9.4 Assembling the Internal Assembly

Make sure of a shorting strip which may possibly

➃

exist on the terminal block of rear panel before

extracting the output board.

9.4.1 Installing the Power Supply Board and Output Board

NOTE:

Install the output board and power supply board into the terminal block.

➀

NOTE: Installation is correct if the power supply board and output board face each other with their

Install the power supply board and output board into the groove of top and bottom frames until the rear

➁

panel of terminal blocks comes in contact with the frames.

9.4.2 Installing the Front Panel

In the state described in the previous section, install the front panel in place.

With the two boards installed on the top and bottom frames, press the rear panel to connect CN1 and

➀

CN2 of the display board with their mating connectors.

NOTES: 1. Misplaced board cannot be installed properly.

Upon completion of front panel attachment, install four long screws from the side of terminal block.

➁

If a shorting strip is attached to the terminal block of the output board, remove it before

assembly.

component parts.

2. Take your time to ensure correct engagement of the right and left connectors.

25

E-215-7-E

Fig.9.8 Power Supply Board

(an example of J1, J2, J3 positions)

Card edge connector

to slide into the terminal

block

Power supply board

13.5V

24V

J1

J2

J3

2

12

1

Fig.9.8 Power Supply Board

(an example of J1, J2, J3 positions)

Card edge connector

to slide into the terminal

block

Power supply board

13.5V

24V

J1

J2

J3

2

12

1

Fig.9.9 Power Board (an example of J4 setting)

Power supply board

Fig.9.9 Power Board (an example of J4 setting)

Power supply board

9.5 Setup or Change on the Power Supply Board

NOTE: Remove the power supply board before you set up.

CAUTION: Do not forget to remove power to the instrument before you work.

9.5.1 A change in the Power to Pulse Generator

A change in the power to the pulse

generator is made by changing jumper

J1 positions (4-coupled) on the power

supply board between 13.5V and 24V.

NOTE: Do not fail to replace all four

sockets at the same time.

J1 , J2, and J3 in Fig. 9.8

show an example of jumper

positions.

9.5.2 Configuring the Flow Signal Input Circuit for the Companion Pulse Generator

Referring to Table 9.2, set up the ow signal input

circuit for the companion pulse generator.

(See Fig. 9.8 for the location of jumpers J1, J2,

and J3.)

Companion pulse generator

Companion pulse generator

Contact-closure PG20 13.5V 1 2

Contact-closure PG20 13.5V 1 2

2-wire open collector 13.5V 1 1

2-wire open collector 13.5V 1 1

3-wire open

3-wire open

collector

collector

Voltage pulse

Voltage pulse

Current pulse

Current pulse

FLOWPET-EG,

FLOWPET-EG,

NPG60A(E3)

NPG60A(E3)

PG30,

PG30,

NPG60A(F),

NPG60A(F),

Coriolis owmeter

Coriolis owmeter

PA14, 15, 25,

PA14, 15, 25,

NPG60A(E)

NPG60A(E)

Table 9.2

Table 9.2

Power to pulse

Power to pulse

generator, J1

generator, J1

13.5V

13.5V

13.5V

13.5V

24V 2 1

24V 2 1

J2 J3

J2 J3

1 1

1 1

1 1

1 1

9.5.3 Input Frequency Division (hardware) Selection

Input frequency division (hardware) is

set up by selecting the position of

jumper J4 on the power supply board

for 1/1, 1/10, or 1/100.

Install the jumper socket into one of

positions 1/1, 1/10, or 1/100.

J4 in Fi g . 9. 9 s ho w s 1/ 1 ( def a u l t

setting).

26

E-215-7-E

Output board

Fig. 9.10 Output board (an example of J1 setting)

Output board

Fig. 9.10 Output board (an example of J1 setting)

Display board

Fig. 9.11 Display Board

Display board

Fig. 9.11 Display Board

9.6 Setup on the Output Board

NOTE: Remove the output board before conguring the board.

CAUTION: Do not forget to remove power to the instrument before you work.

9.6.1 Buzzer Sound Setup on Alarm (missing pulse, overmeasurement, and parameter

error) Detection

Buzzer sound upon alarm detection (missing

pulse, overmeasurement, and parameter error)

is set up by selecting the position of jumper J1.

Set the jumper J1 on the output board in the

position desired, referring to Table 9.3.

J1 i n Fig. 9.10 s hows t he stan dard ( 1-2)

position.

Table 9.3

Jumper Description

J1

1 – 2

2 – 3 Buzzer disabled

Buzzer sound (default)

NOTE: As for toggle switch S1 in Fig .9.10, refer to Sec. 9.1.2 on page 22.

9.7 Reconfiguration on the Display Board

NOTE: Work with the display board LCD (front panel) removed.

9.7.1 Total Counter Output Pulse Width Selection

Jumper (J1) located on the display board

selects the total counter output pulse width.

Set the position of jumper J1 on the display

board shown in the sketch at right to choose

between two pulse width positions according

to Table 9.4.

Table 9.4

Jumper Description

J1

1 side

50 side Pulse width 50ms

Pulse width 1ms (default)

27

E-215-7-E

10. TROUBLESHOOTING

10.1 Inspection Items

NOTE: If trouble is found to be internal, isolate the problem according to the table below and seek our

service.

Table10.1

Symptom Inspect Possible causes

Display is dead. 1. Inspect fuse.

2. Check supply voltage.

AC version 85 to 264VAC

Valve fails to

respond to

START

depression.

▲

key

1. Check to see if terminals 19 and 20 (remote

control input Stop, From “b” contact) on the

terminal block are shorted.

2. Dose

Does LCD

3. Do valve control signals SV and MV actuate

SV : 11, 12, 13 on the terminal block

MV: 14, 15, 16 on the terminal block

OPE

START

▲

property?

key depression?

come on in response to

SV come on at the same time?

1. Fuse is blown. (⇒ See page 29.)

2. Supply voltage is incorrect.

3. A fault in the controller.

1. Unless terminal 19 and 20 (remote control input

STOP) on the terminal block are shorted by a

switch having a Form “b” contact or a shorting

STOP

strip,

ROT.

leaving that key inoperative.

2. A fault in the controller.

3. Valve control signal output relays are at fault.

key always remains depressed,

Valve operates

but the total

counter fails to

count.

Fails to perform

batch operation

at the setpoint.

Remote control

is inoperative.

4. Isn’t the batch set to 0?

4. At touch of key

START

an end-of-batch signal

▲

is produced at once.

5. Are valve control signal wiring and supply voltage

correct?

6. Are valve operating and control pressure settings

correct?

7. Has the batch process been reset?

(Alarm reset, end-of-batch output reset, etc.)

1. Is a owrate signal coming in from the owmeter? 1. Incorrect wiring or an open in the cable.

2. Is the incoming owrate signal within the

acceptable frequency range of response?

1. Do valve control signals SV and MV actuate

when the target batch quantity is reached?

2. Does LCD

when the target batch quantity is reached?

1. Is it possible to control with front panel control

keys?

2. Is remote control circuitry wired correctly? 2. Remote control circuitry is wired incorrectly, or

SV go out and LCD END come on

5. Valve control output lines are incorrectly wired or

an open in the cable.

6. Valve operating and control pressure settings are

incorrect.

7. Reset the batch process.

A fault in the owmeter itself or in the pulse

generator.

2. Outside the acceptable frequency range of

response. (The microprocessor accepts pulses

up to 200Hz.)

1. Valve control signal output relay is at fault.

2. A fault in the controller.

1. Remote control signals are incorrect if

controllable with front panel control keys.

the cable has an open.

Or a fault in the controller.

28

10.2 Inspection of Fuse

Fig. 10.1 Power Board and Fuse

Power supply board

Fuse cover

Holder

Glass-cartridge fuse

Fig. 10.1 Power Board and Fuse

Power supply board

Fuse cover

Holder

Glass-cartridge fuse

Remove the fuse cover on the power supply

board and inspect the glass cartridge fuse

(see Sec. 9.3 on pages 24 and 25 for power

supply board removal).

If the fuse is blown, extract from its holder

and replace it with a new one.

NOTE: When y ou remo v e and ins t all

a glass cartridge fuse, avoid

gripping it too hard. Too hard a

grip may crush the glass.

CAUTION: Do not use fuses of other rating.

E-215-7-E

10.3 Dielectric Test Voltage

A surge protector is incorporated in this controller: Do not attempt to conduct a dielectric withstanding

voltage test across power terminals.

10.4 Q&A Controller Behavior in Standby Mode

Questions and answers with the controller EL1810 in standby mode (

pressed) are given in Table 10.2.

1. What if a pulse train arrives

2. What if the counter counts

3. While the counter keeps

Table 10.2

Questions Answers

•

Counts. “TC” segment in LCD 1 display blinks in sync with incoming pulses.

in standby mode?

to the target batch setpoint

without pressing the

START?

counting without pressing

the START, what happens

if START is pressed?

Both the LCD 1 grand total counter and LCD 2 batch counter count.

•

SV and MV valve signals remain inoperative (remain in the OFF).

•

“END” segment in LCD 1 display comes on with BATCH END OUTPUT across terminals

•

– ➉ closed.

➈

The counter keeps counting even beyond the target batch setpoint.

However, if overshoot alarm is enabled, “ALARM” segment comes on at that setpoint and

ALARM OUTPUT contacts across terminals – come to close.

To reset, press

To restart while a batch process is in progress is inhibited.

•

Once the counter has started counting, even for a single count, from the initial state, a

transfer to the batch process is inhibited. Press

state) before you start.

NOTE: Except that frequency reduction d is set to “0” and, at the same time, scale F is

RESET

set to any value larger than “1”, the counter will remain at “0” in response to just

a single pulse arrival. In this case,

◀

key.

START

▲

RESET

◀

key remains under-

key once to return to “0” (initial

Pressing

RESET

◀

key once again is required.

29

E-215-7-E

11. GENERAL SPECIFICATIONS

Table 11.1

Item Description

Type of operation Pulse adding

Displays 7-segment 8-digit LCD × 2 (LCD 1 numerals 7mm high, LCD 2 numerals 12.7mm high)

Target batch setting readout LCD 2 shows to the 8th digit (resettable with RESET key). Batch setting to the 6th digit.

Grand total LCD 1 shows 8 digits

RUN, SV, MV, END, TC, ALM: LCD segments light.

•

Operating status indicators

Pulse generator Power to generator Signal levels Response speed

Contact-closure pulse PG20

2-wire open collector pulse Corioli owmeter

3-wire open collector pulse

Voltage pulse

Flow signal input

Current pulse PA14, 15, 25. NPG60A(E) 24VDC

Input signal

Start Instant make, Form “a” contact

Stop Instant make, Form “a” contact

Remote

Reset Instant break, Form ”b” contact

Batch setting

Grand total setting

Initial-and nal-count setting

Missing pulse setting

Overshoot setting

Parameter setting

Scaler setting

Frequency divide setting

Partial ow signal

Valve operate

signal

End-of-batch output

Output to remote totalizer

Output signal

Alarm output

Power failure back up Parameters and variables retained in E²PROM when power is interrupted.

Power source 85 to 264VAC, 50/60HZ

Power consumption 25VA 10W max.

Ambient temperature –10 to +50°C

Installation Panel mount

Finish Munsell N1.5 (standard)

Outline dimensions 96 × 96 × 170mm

Weight 1.0kg approx.

(SV)

High-limit ow

signal (MV)

Missing pulse

➀

Overshoot

➁

Parameter

➂

error

OPE (GRN), SET (ORG), STOP (RED): LED lights.

•

BATT: “BATT” mark in the LCD lights.

•

13.5VDC ON/OFF

FLOWPET-DG,

NPG60A (E3)

PG30, NPG60A(F),

Corioli owmeter

Any setting from 0 to 999999 counts

Preset by front-panel control keys (in the batch setup mode “RUN”).

Any setting from 00000000 to 99999999 counts

Preset by front-panel control keys (in the setup mode “SET”).

Any setting from 0 to 999 counts (default: 80) Set by front-panel control keys.

If set at “0,” the valve opens and closes in the single stage ( in the setup mode “SET”).

Any setting from 1 to 15 sec. (default 10 sec.) Preset by front-panel control keys.

When set to “0,” the alarm is disabled (in the setup mode “SET”).

Any setting from 1 to 99 counts (default 10) preset by front-panel control keys.

If set to “0,” the alarm is disabled (in the setup mode “SET”).

Any setting from 0.0001 to 1.9999 (default 1.0000) Preset by front-panel control keys (in the setup

mode “SET”).

Software frequency division – 0:1/1, 1:1/10, 2: 1/100

•

One chosen with front-panel control keys (in the setup mode “SET”).

Hardware frequency division – 1/1, 1/10, 1/100

•

One chosen with internal jumper (in the setup mode “SET”).

Holds from batch start to batch end.

“SV” area in the LCD lights. “S. VALVE” area in the LED lights.•

Holds from the end of initial partial ow to the start of nal partial Flow

open.

“MV” area in the LCD lights. “M. VALVE” area in the LED lights.•

Holds when the target batch setting is reached.

“End” area in the LCD lights. (Resettable with RESET key.)•

Pulse width: 1ms (default) or 50ms

“TC” area in the LCD blinks in synchronism with the output.•

Operates when no pulse is accepted within preset time.

“ALM” area in the LCD lights. (Resettable with STOP key.)•

Operates when both target batch and this setting are exceeded.

“ALM” area in the LCD lights. (Resettable with RESET button.)•

Operates upon detection of a parameter error.

A message “dAtA Err” appears. (Resettable with RESET key.)•

13.5VDC

Current

capacity

55mA

Contact-Closure signal or open collector signal

Contact current: 10mA max. at 15VDC

Instant signal width: 1 sec.

Note: Provide 2 sec. min. between signals.

(input load resistance:

10kΩ)

“1”: 5VDC min.

“0”: 1.5VDC max.

“1”: 20mADC

“0”: 4mADC

(Input resist: 24Ω)

Relay contact output

(Form “c” contact)

Contact capacity:

250VAC 1A

One set each

Non-contact relay output

(Form “a” contact)

Contact capacity:

250VAC/DC 0.15A

One set each

Relay contact output

(Form “a” contact)

One set

Contact capacity: 250VAC, 1A

An alarm output is

produced when any of

alarms ① , ② , or ③ has

occurred.

50Hz max.

200Hz max.

Input pulse

frequency

reduction

1/10…2kHz max.

1/100…3kHz max.

NOTE: A surge protector is built in: do not make insulation resistance test and dielectric withstanding

voltage test across power terminals.

30

12. PRODUCT CODE EXPLANATION

E-215-7-E

Table 12.1

Item

Product Code CodeSufx Code

➀ ➁ ➂ ➃ ➄ ➅−➆ ➇ ➈ ➉

Model E L 1 8 1 0 −

Power supply 7

4

Input signal

Actuation mode 1

Additional function I 1

Additional function II

Finish of frame 1

Version C

7

9

5

9

⑬

Description

Batch Controller

85 to 264V AC, 50/60Hz

4/20mA DC current pulse

Contact-closure, open collector, voltage pulse

Other than above

Add: Counts up from “0.”

Al arm ou tput (missi ng pul ses, ove rme asurement,

parameter error)

Output to an external totalizer

+ end-of-batch output

Other than above

Munsell N1.5 (standard)

31

E-215-7-E

All specications are subject to change without notice for improvement.

2016.05 Revised

2003.05

E-215-7-E(1)

Released

△

Loading...

Loading...