Ins. No.

B-149-4N-E

High Temp./Low Temp. Service and Jacketed

SMART ULTRA OVAL FLOWMETERS

Meter Sizes 50, 52, 53, 55, 56, and 57

Meter size 50

Cooling tube provided

Meter sizes 52, 53, 55, 56

Meter size 57

Cooling tube provided

Every SMART ULTRA OVAL is fabricated and shipped from our factory under stringent quality control. In

order to maintain its design performance throughout the life of the meter, this manual offers the operator the

necessary installation, operation and maintenance information.

Be well familiar with these instructions before you place the meter in service and keep this manual at the eld

location for ready reference.

The standard, high temperature-service, low temperature-service, and jacketed type meters all have in

common the same specifications described in this instruction manual except for some differences in the

jacketed type on its piping procedure and operating precautions. Be careful to observe the instructions given

with a reminder "See also page 15 for the jacketed type".

About Meter Size Designation

◆

The size of OVAL positive-displacement owmeters is basically identied by a two-digit code. For complete

details, see Section 17 PRODUCT CODE EXPLANATION.

◆

Heating tube provided

1

B-149-4N-E

CONTENTS

1. BEFORE YOU BEGIN ........................................................................................................................4

1.1 Conrming the Tag .........................................................................................................................4

1.2 Transportation Considerations .......................................................................................................4

1.3 Storage Considerations .................................................................................................................4

1.4 Structural Considerations ..............................................................................................................5

2. OPERATING CONDITIONS ...............................................................................................................5

3. GENERAL DESCRIPTION .................................................................................................................6

4. PART NAMES .....................................................................................................................................6

5. LCD COUNTER DISPLAY ..................................................................................................................7

5.1 About "MODE" Switch ................................................................................................................... 7

5.2 Display Functions ........................................................................................................................... 7

5.3 Display Mode Selection .................................................................................................................7

5.4 Total Counter Reset ........................................................................................................................8

5.5 Considerations with Pulse Output Type ......................................................................................... 8

6. INSTALLATION ................................................................................................................................... 9

6.1 Considerations at Installation ......................................................................................................... 9

6.2 Standard Installation, Horizontal Line ............................................................................................9

6.3 Standard Installation, Vertical Line

6.4 Example of Faulty Piping ...............................................................................................................9

7. HOW TO CHANGE FLOW DIRECTIONS ........................................................................................10

8. WIRING INSTRUCTIONS ................................................................................................................11

8.1 Wiring Guidelines ........................................................................................................................11

8.2 Terminal Connections ...................................................................................................................11

8.3 Preamplier-to-Receiving Instrument Hookup ............................................................................. 12

9. OPERATING INSTRUCTIONS .........................................................................................................13

9.1 Operation .....................................................................................................................................13

9.2 Operating Precautions .................................................................................................................13

9.3 Precautions at Operation Shutdown ............................................................................................14

9.4 About Register Life ......................................................................................................................14

9.5 Piping Instructions and Operating Precautions of Jacketed Meters ...........................................15

10. DISASSEMBLY AND INSPECTION ...............................................................................................16

10.1 Size 50 Meter Body Disassembly and Inspection ......................................................................16

10.2 Size 50 Meter Body Assembly Procedure .................................................................................17

10.3 Sizes 52, 53, 55, 56, 57 Meter Body Disassembly and Inspection ............................................18

10.4 Sizes 52, 53, 55, 56, 57 Meter Body Assembly Procedure ........................................................19

........................................................................................................................................... 9

11. REGISTER SWITCH FUNCTIONS AND PARAMETER SETTING ................................................ 20

11.1 Switch Names and Functions ....................................................................................................20

11.2 Individual Test Pin Functions ......................................................................................................21

11.3 About Meter Factor .................................................................................................................... 21

2

B-149-4N-E

12. SENSOR REPLACEMENT PROCEDURE .....................................................................................22

13. TROUBLESHOOTING ....................................................................................................................23

14. EXPLODED VIEWS AND PARTS LIST .......................................................................................... 24

14.1 Meter Size 50 Exploded View and Parts List .............................................................................24

14.2 Meter Sizes 52 and 53 Exploded View and Parts List ...............................................................25

14.3 Meter Sizes 55 and 56 Exploded View and Parts List ...............................................................26

14.4 Meter Size 57 Exploded View and Parts List .............................................................................27

15. GENERAL SPECIFICATIONS ........................................................................................................28

16. OUTLINE DIMENSIONS ................................................................................................................29

17. PRODUCT CODE EXPLANATION .................................................................................................30

CONVENTIONS

Shown in this manual are the signal words NOTE, CAUTION and WARNING, as described in the

examples below:

NOTE: Notes are separated from the general text to bring the user's attention to

important information.

CAUTION: Caution statements signal the user about hazards or unsafe practices

which could result in minor personal injury or product or property damage.

WARNING: Warning statements signal the user about hazards or unsafe practices

which could result in severe personal injury or death.

3

B-149-4N-E

NAMEPLATE

(RATINGS SHOWN)

1. BEFORE YOU BEGIN

Every Smart Ultra OVAL is thoroughly tested before it leaves the factory. When received, it should be thoroughly

inspected for indication of rough handling during transit. Necessary handling precautions are described in this

section; read the instructions carefully.

As for other information, nd the respective sections from "CONTENTS" on pages 2.

For any inquiries, contact your nearest OVAL designated sales ofce.

CAUTION: When you make inquiries, include the product name, model number,

product number, ratings and other pertinent information.

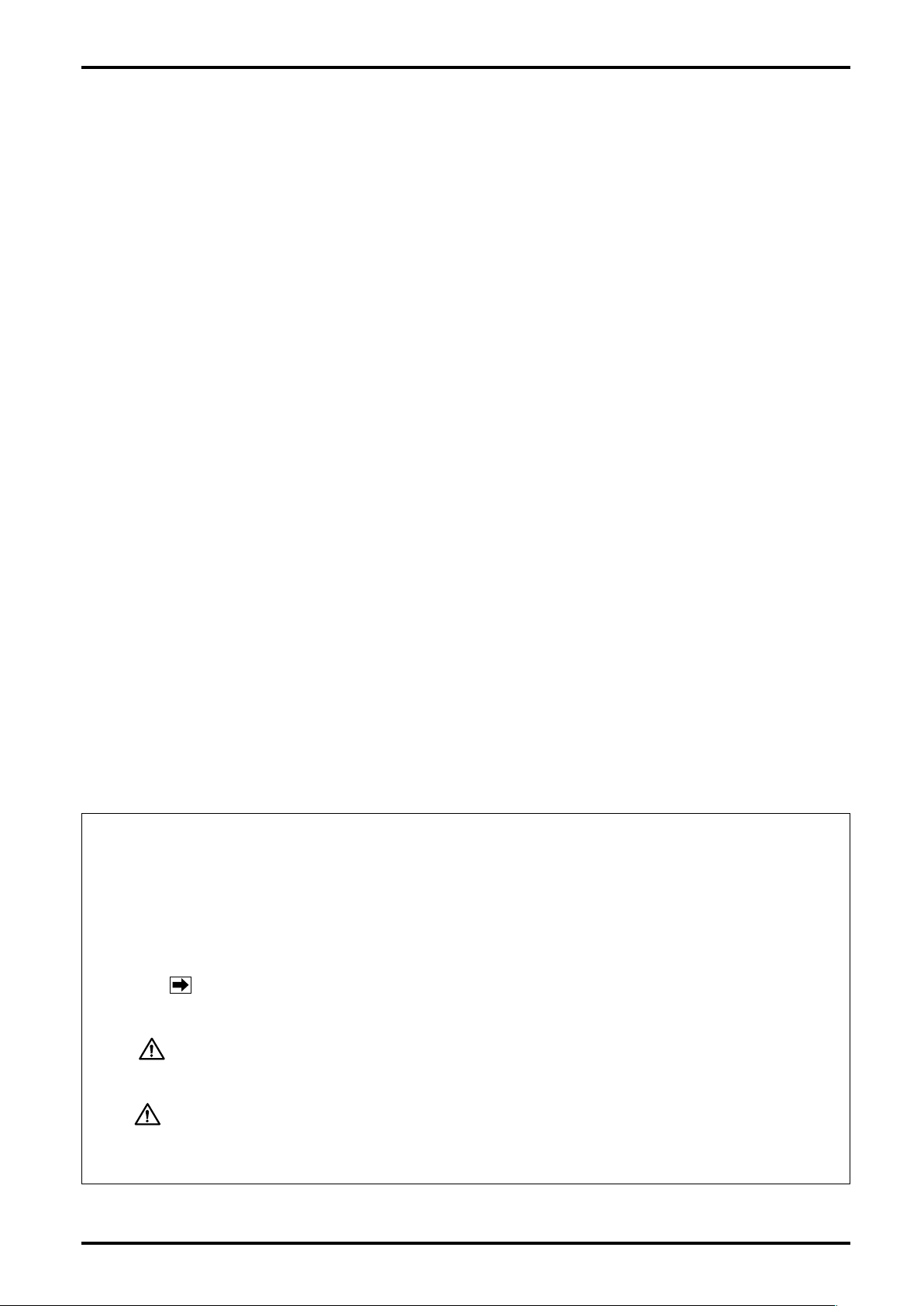

1.1 Confirming the Tag

Every Smart Ultra OVAL is assembled and adjusted

ac cordi ng to indivi dual s pec ifications. Produ ct

code number and ratings are stated on the register

tag. Make sure that, by referring to the general

specifications on pages 28 and the product code

explanation on page 29, the ratings shown conform

to your particular specication.

1.2 Transportation Considerations

(1) To safeguard against damage during transit, transport your Smart Ultra OVAL to the installation site in the

same container used for transportation from the factory if circumstances permit.

(2) Smart Ultra OVAL is adjusted and inspected as an assembly consisting of the meter body, sensor and

register. It should therefore be handled as an integral assembly.

(3) The register is accurately congured and adjusted. Do not attempt to remove the front cover to gain access

to its internal assembly.

1.3 Storage Considerations

If your Smart Ultra OVAL is stored for long periods of time upon receipt before installation, unexpected faulty

conditions could result. If a long-term storage is anticipated, take the following precautions:

(1) Keep your Smart Ultra OVAL in store in the same shipping container used for transportation from OVAL if

possible.

(2) Place of storage should conform to the following requirements:

- Free from rain and water.

- Free from vibration and impact shocks.

- Temperature and relative humidity in the storage place are at or near room temperature and humidity

(3) Purge the Smart Ultra OVAL that has once been placed in service with clean air, N2 gas, etc. to prevent the

metered uid from adhering to the meter connections, piping inner walls, housing, etc. before storage. (Wash

clean with suitable detergent if necessary.)

(4) In case of storage for extended periods of time, good practice is to keep in store in the same containers

used for shipment from the factory.

(around 25°C and 65%).

4

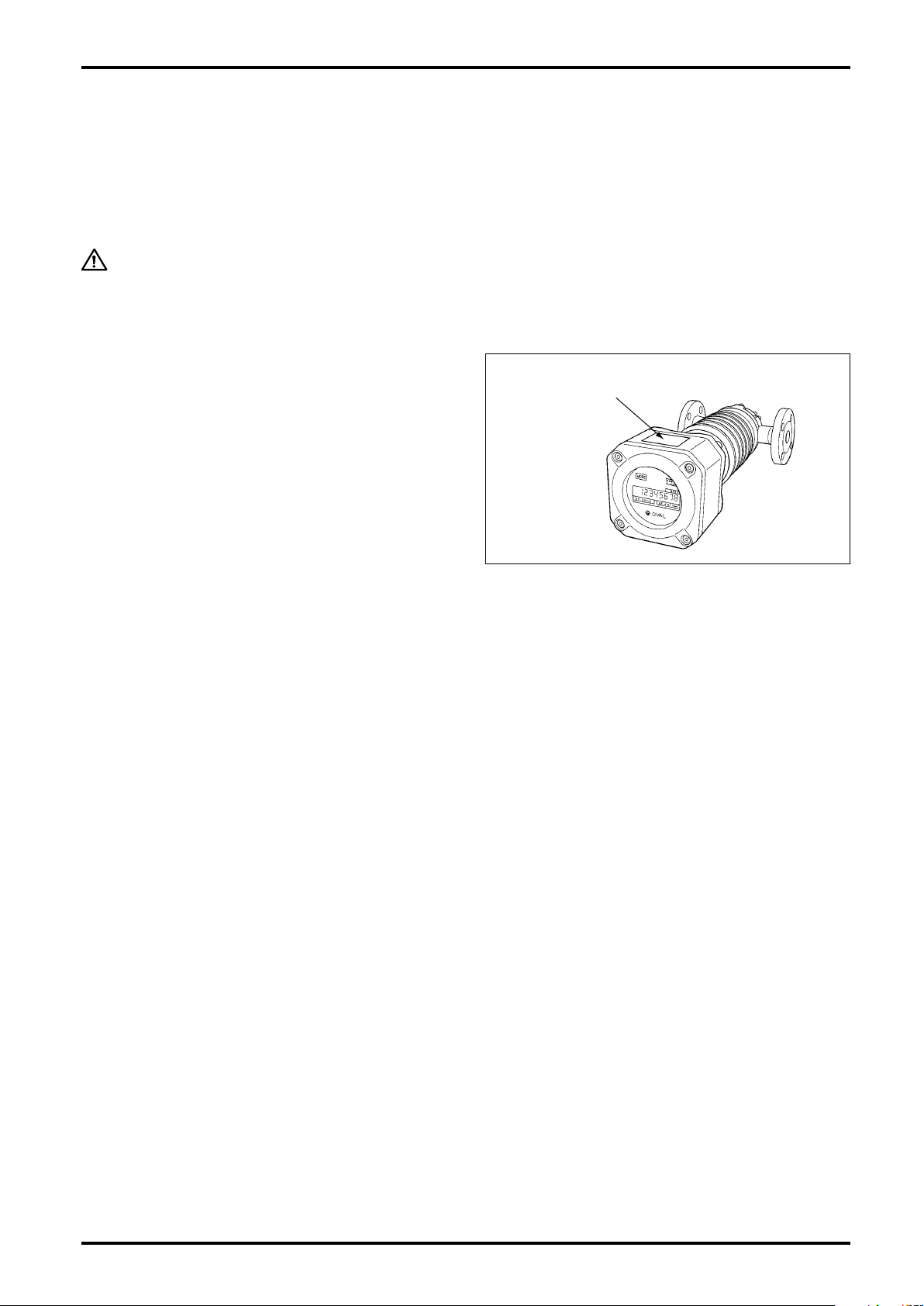

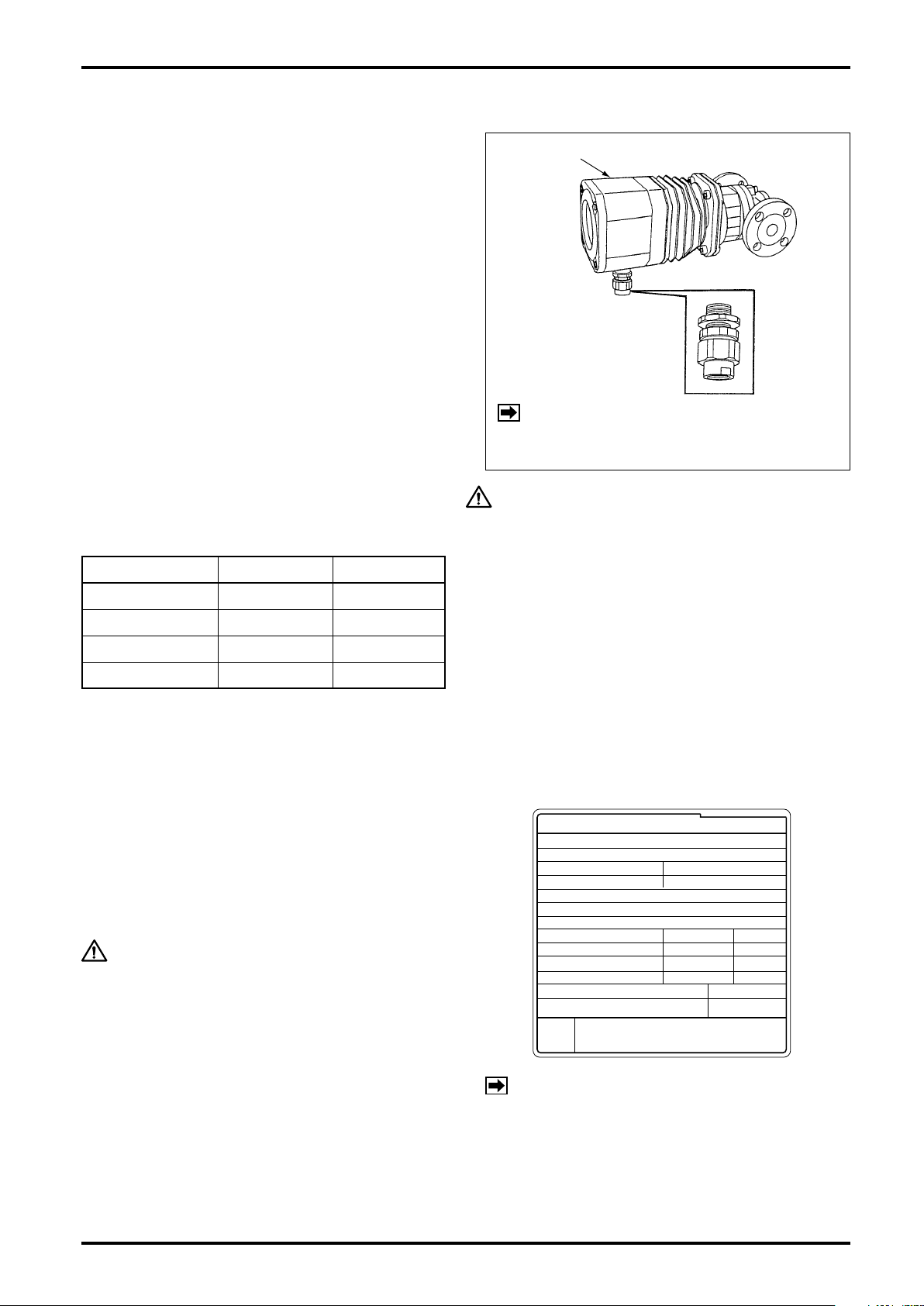

1.4 Structural Considerations

Register

Cable Lead-in

(Pressure-resistant

packing)

ULTRA OVAL

MADE IN JAPAN MNPJ-237

OVAL Corporation

MODEL

TAG. No

MAX PRESS.

FLOW RANGE

INT.

CONT.

~

~

FULL SCALE

TEMP.

PULSEUNIT

SERIAL No.

FLUID

DATE

SIZE

METER FACTOR

NOTES

1. When measuring other liquids, consult us.

2. Place the meter body (outer case) in a horizontal

position. For details, see instruction manual.

(1) The register is of waterproof construction for

outdoor service.

(2) The register is type approved. Do not attempt to

replace component parts with others or make

any circuit modication.

(3) The pressuretight packing furnished constitutes

pa rt of the fla mepro of construction . Do not

attempt to use any pressuretight packing other

than those furnished. The pressuretight packing

union s h o u l d be ti g h t e n e d s e c u r e l y up o n

completion of connections.

(4) Of the four different p re ssure tight packings

(φ9,

10, φ11 and φ12) furnished as standard

φ

accessories, a

in place.

Sele c t from t h e s e and insta l l the one that

best fits the finished outside diameter of your

particular cable.

Table 1.1 Applicable Cable Outside Dia. Unit in mm

Packing Code Packing I.D. Cable O.D.

9 9.0

10 10.0 9.1 to 10.0

11 11.0 10.1 to 11.0

12 12.0 11.1 to 12.0

11 packing is tentatively installed

φ

8.5 to 9.0

B-149-4N-E

NOTE:

CAUTION

Moisture allowed into the register wil cause

blurred display glass and functional trouble.

Pr e c au t i o n s o n cab l e l e a d - i n fit t i ng

(pressuretight packing), both explosionproof

and non-explosionproof models:

- Use a pressuretight packing that fits the finished

cable O.D.

- Tighten up properly to allow no clearance between

the pressuretight packing and the cable.

- If a pressuretight packing is not used, apply some

waterproof treatment to preclude any chance of

moisture getting into the equipment.

P r e s s u r e t i g h t p a c ki n gs a re n o t

supp l i ed with n onexplo s ionpro o f

models.

2. OPERATING CONDITIONS

To ma intain the sta ted hig h a ccuracy and lon g

servic e life o f SM ART ULTR A O VA L flowme ter,

make sure that owrate, pressure, temperature and

viscosity are within the ratings as stamped on the

meter register nameplate. Do not fail to confirm

these ratings before placing it in service.

CAUTION

1. Although allowable ambient temperature is

up to +60 °C for explosionproof units, it is

desirable that the meter be used at room

temperature and humidity.

2. In cases where the register is exposed to

elevated temperatures due to exposure to

direct rays of the sun or to radiant heat,

ensure, by providing a sunshade or similar

protection, that the meter is used within

the operating temperature range.

NOTE: Avoid such installation locations where

1. Not easy to access for servicing.

2. Large temperature variation and vibration.

3. Potential risk of submersion in water.

4. Corrosive gas atmosphere.

5. Not compatible with ex. construction.

6. Near sources of strong magnetic noises.

5

B-149-4N-E

MODE SWITCH LCD COUNTER

FRONT COVER REGISTER

FLOW DIRECTION

REAR COVER

SELECTOR

MAGNET

CONNECTING

FLANGE

METER BODY

COOLING TUBE

(OR HEATING TUBE)

PRESSURETIGHT

PACKING

POWER

SIGNAL

3. GENERAL DESCRIPTION

Smart Ultra OVAL has been developed to meet the needs of precise owrate measurement. The local direct-

reading total counter is an all-electronic register built around a single-chip CPU. With the latest electronic

technologies used throughout, this versatile register displays accumulated total ow, instantaneous owrate

(digital readout) and provides, by option, a pulse and analog output proportional to the rate of ow.

In this meter, uid ow is detected by sensing with an amorphous sensor the magnetic elds of permanent

magnets embedded in the oval rotors. As a result, high reliability is achieved.

Features

(1) Absence of any mechanically sliding components except for oval rotors contributes to long service life.

(2) Small wetted parts count and pocketless design makes this meter ideally suited for ow measurement of

chemical liquids.

(3) You can monitor accumulated total ow and instantaneous owrate locally on the digital display.

(4) When coupled with a remotely located receiving instrument, output signals can readily and simply be used

for applications including control, adjustment and recording.

(5) IEC explosionproof construction offers increased safety and the design is compact.

(6) A nonvolatile memory, both in the local totalizer type and externally powered type meters, retains

accumulated total in the event of power failure or when de-energized.

NOTE:

If you have any request, contact the supplier you purchased the product or our sales ofce.

With the use over an extended period of time, meter error will deviate more or less from the initial

point. Upon request, we may conduct an instrumental error testing once again and establish a

"new meter factor" in the scaler when your Smart Ultra OVAL is returned to the factory for periodic

inspection or for other reasons.

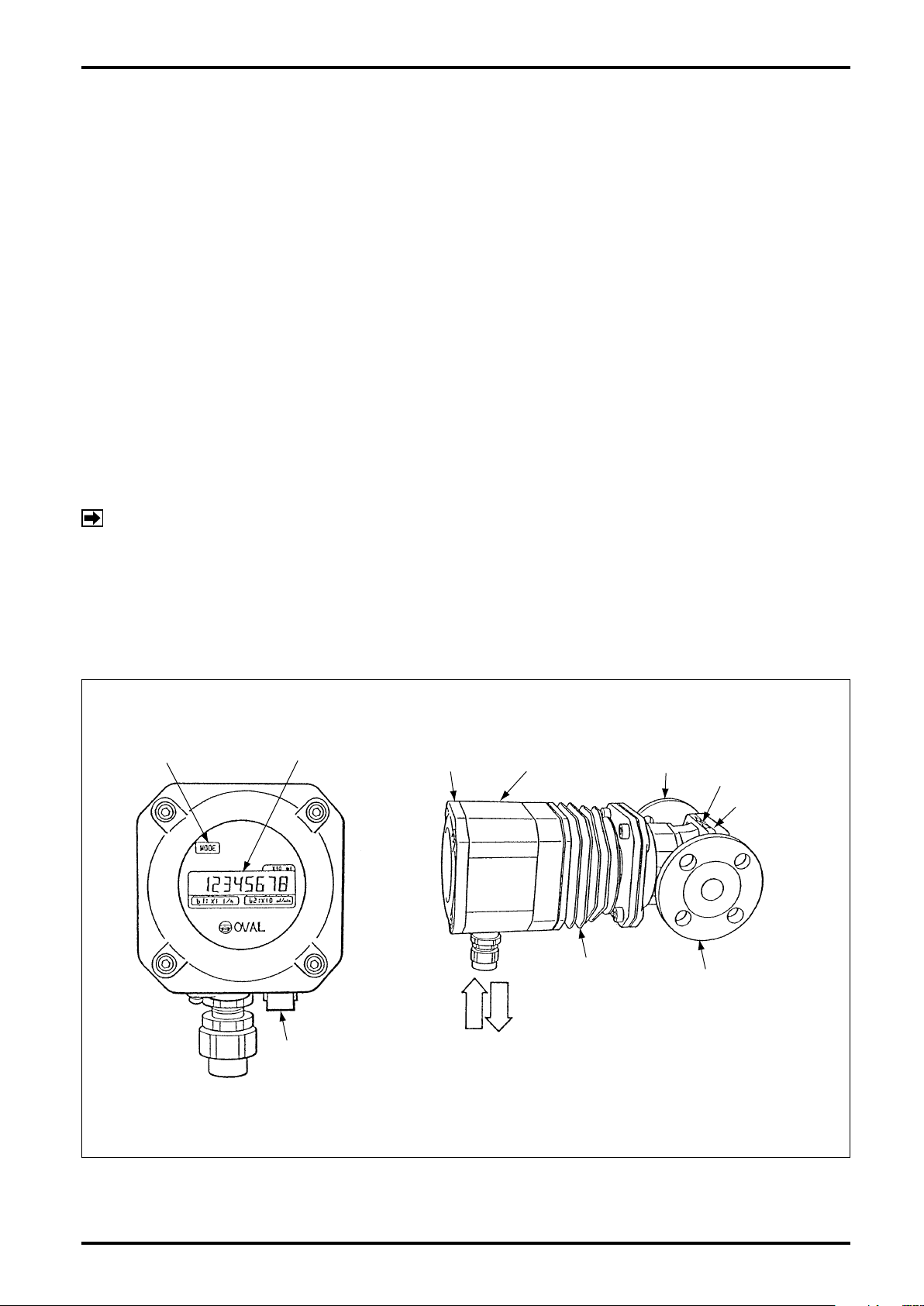

4. PART NAMES

Fig. 4.1

6

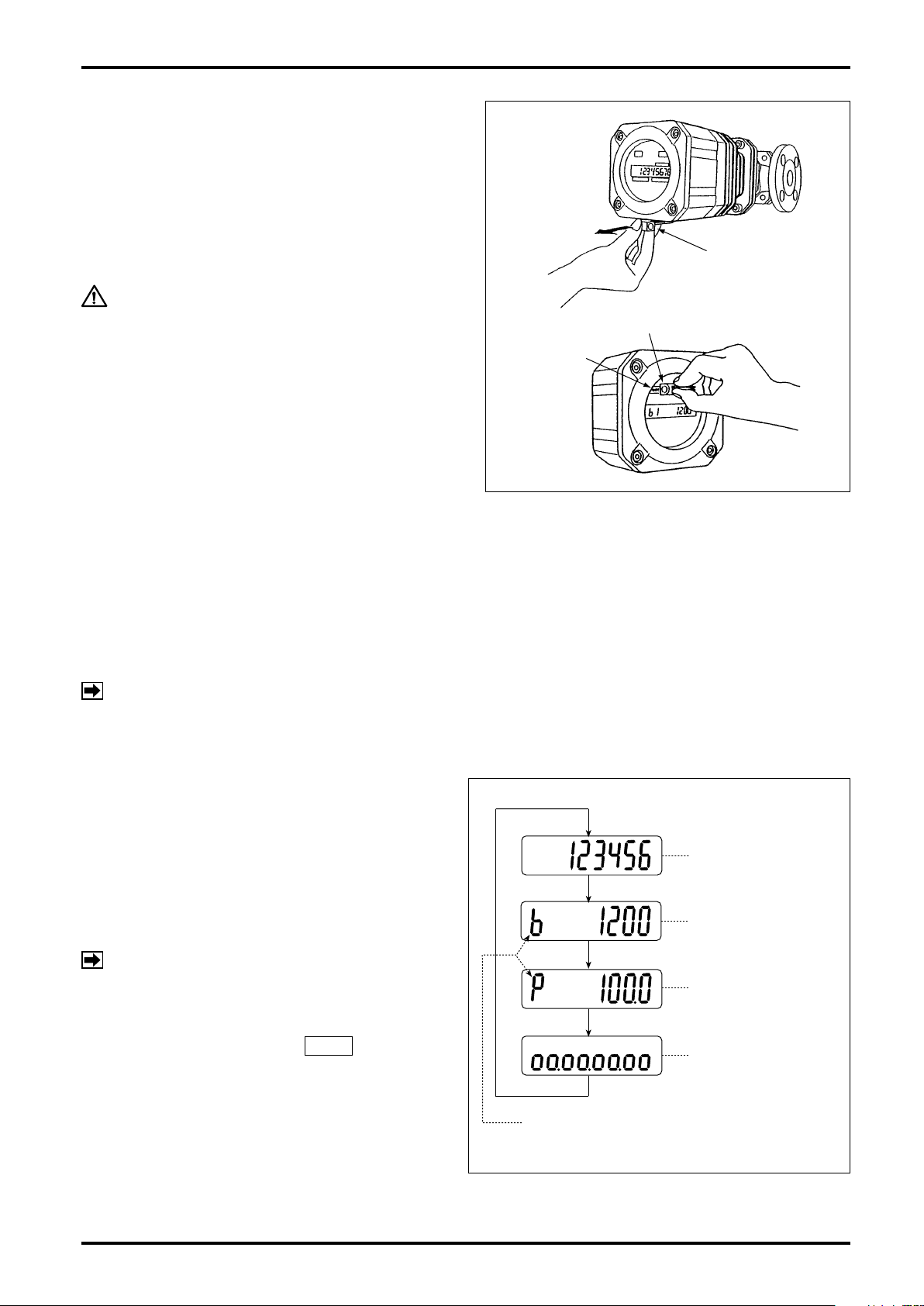

5. LCD COUNTER DISPLAY

SELECTOR MAGNET

SELECTOR MAGNET

"MODE"

EXAMPLE OF READINGS

MODE SYMBOL

TOTALIZED FLOW

INSTANTANEOUS

ACTUAL FLOWRATE

% INSTANTANEOUS

FLOWRATE

8-DIVISION

BAR GRAPH

5.1 About "MODE" Switch

Rem ovin g the sele ctor magn et ins erte d at the

bottom of the register, apply it to the label "MODE"

on the LCD counter face and the display will scroll

forward through the available readings as shown in

Fig. 5.1.

CAUTION

Do not fail to return the selector magnet

to its holder after use lest you will not

lose it. It uses an intensive magnet; never

hold it close to floppy disks or other

magnetic storage media.

B-149-4N-E

5.2 Display Functions

The display can show four different kinds of ow information - total ow, instantaneous actual owrate, percent

instantaneous owrate, and 8-division percent bar graph.

It also shows the following error messages:

Full scale exceeded : ErrorFS

Upper-limit owrate exceeded : ErrorOF

NOTE: Multiple errors will be indicated in priority order below:

ErrorOF > ErrorFS

5.3 Display Mode Selection

Two ways are available to select displays - with a

display select switch inside the register, or through

communications with the Smart Communication Unit

Model EL2310 (or HHC: Model EK10).

If your option is through communications, follow the

instructions outlined in the Smart Communication

Unit EL2310 (or HHC: EK10) instruction manual.

NOTE: Show "Measure" window at "View" menu

on the PC screen.

Selection with display select switch requires access

to the display sel ect switch SW1 by open ing

the register cover facing its internal assembly and

pressi ng this switch (see page 20) . T he display

scrolls forward through available information each

time you press this switch as shown in Fig. 5.1.

Fig. 5.1

7

B-149-4N-E

②

①

15 seconds after power on.

(Com Standby Mode)

Communication is started

within 15 seconds after

power on. (Com Mode)

5.4 Total Counter Reset

Displayed total flow can be reset either by the display select switch SW1 (see Fig. 11.1 on page 20) or

through communications with the Smart Communication Unit. It your option is through communications, follow

the instructions outlined in the Smart Communication Unit EL2310 (or HHC: EK10) instruction manual.

NOTE: Show "Measure" window at "View" menu on the PC screen.

With the display select switch, then, you can reset the totalizer by holding the display select switch SW1

depressed for more than 3 seconds while the total ow is shown.

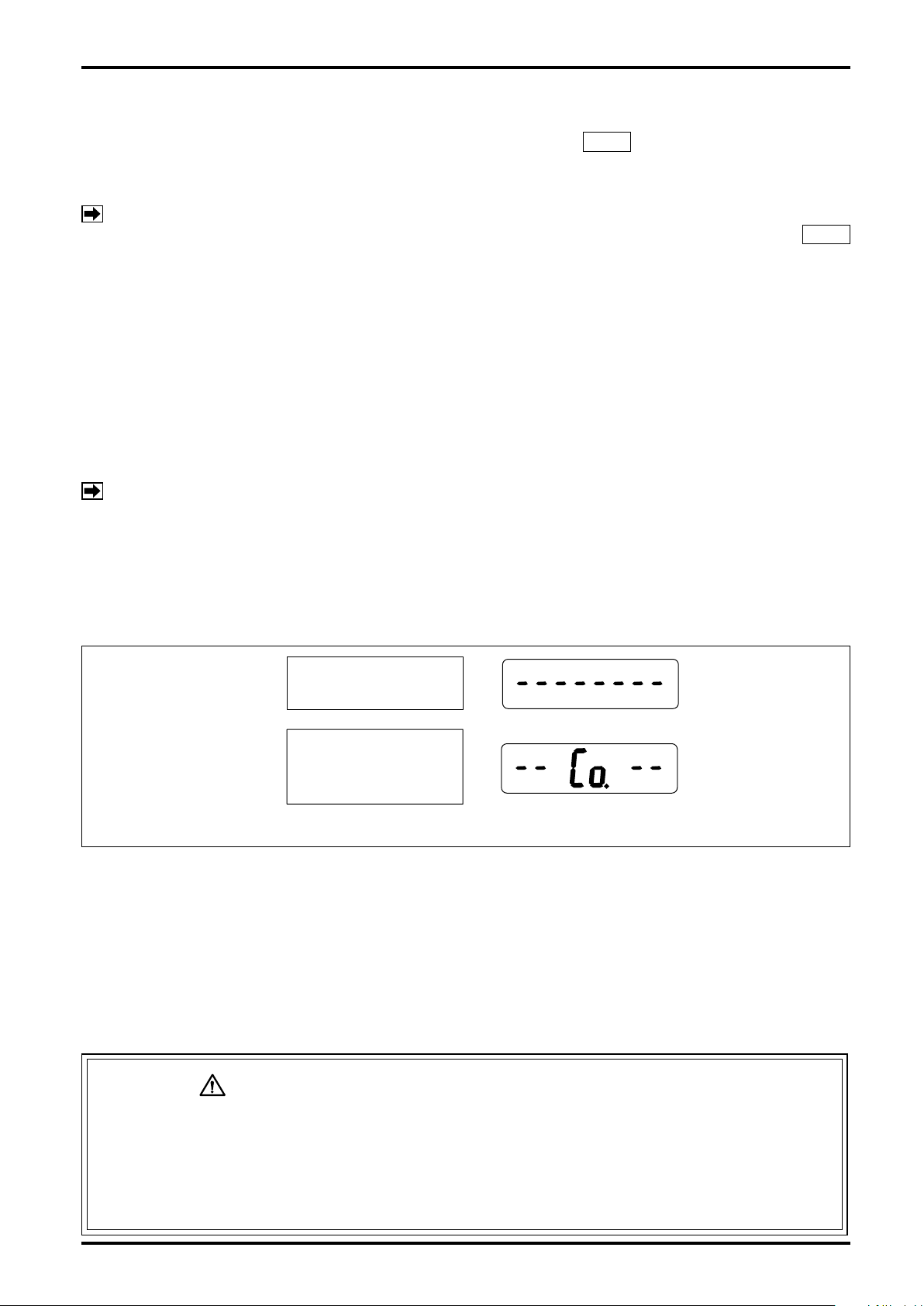

5.5 Considerations with Pulse Output Type

(1) If your model is of pulse output type, the pulse output and total counter remain inoperative for 15 seconds

approx. after power on and while communications with the Smart Communication Unit continue. For 15 seconds

approx. after termination of communications, the pulse output and total counter also remain inoperative.

(2) Requirements for validating communications

Communications are made valid only when the following requirements are met:

- Flowrate at zero (There is no pulse output.)

- Within 15 seconds after power turn-on

NOTE:

If communications are started during this time period, a switchover to "Communication mode" takes

To start ow measurement routine, turn power on again. (After power cycling, the pulse output and

The period of 15 seconds immediately after power on is called "Communication standby mode." (The

built-in indicator, if so equipped, will display as shown in

place, permitting you to communicate until power is turned off the next time. (The built-in indicator

will display as shown in ② in the gure below.)

total counter will also remain inoperative for 15 seconds.)

in the gure below.)

①

(3) While communications continue, the receiving instrument (total counter, etc.) may overcount under certain

circumstances. To eliminate the possibility of such erratic extra counting, precautions should be taken by

either disconnecting the receiving instrument before starting communications, or recording the most recent

total reading and other important data on paper.

(4) Except for the purpose of communications, do not attempt to connect the probe of Smart Communication

Unit with the signal lines. If the probe remains connected, the influence of capacitive impedance the

interface has could go to the point of producing distorted signals in waveform and, as a result, the receiving

instrument would fail to receive pulse signals accurately.

The analog type permits communications with the Smart Communication Unit at any

time. However, if, in an attempt to alter current parameters, the meter is configured

by mistake such that the new parameters are incompatible with the specification,

re sultan t sharp change s in out put may d istur b the b ehavio r of the rece iving

instrument. It is good practice, therefore, to make parameter changes while the fluid

flow is at zero.

8

Fig. 5.2 Display in Response to Power ON, Pulse Output Type

CAUTION: PRECAUTIONS with ANALOG OUTPUT TYPE

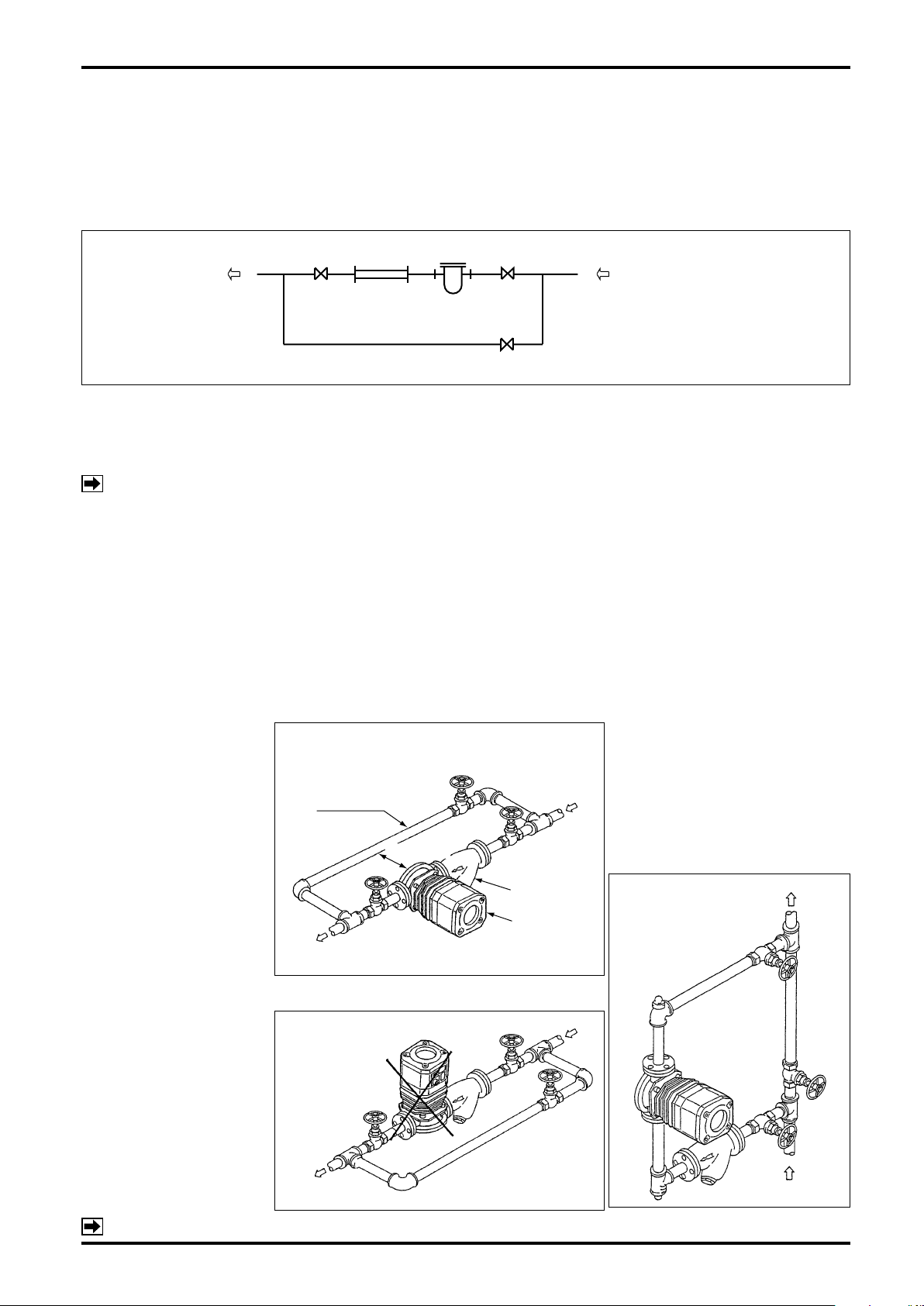

6. INSTALLATION

BYPASS LINE

STRAINER

VALVE

SHORT PIPE

FLOW

DIRECTION

OUT

IN

A

B

BYPASS

STRAINER

ULTRA OVAL

OU

T

IN

*(1100mm)

WRONG!

OUT

IN

B-149-4N-E

6.1 Considerations at Installation

"See also page 15 for the jacketed type".

(1) Flush the piping assembly.

Flushing must be performed before meter installation. Install a short pipe in place of the meter at this time (see

diagram below).

(2) Install the meter free from pipe strains.

(3) The meter must be installed on the discharge side of the pump.

(4) If the meter is to be used under tank head, give a head pressure greater than the losses with the piping

system, strainer, meter, etc.

NOTE: Pressure losses of the Smart Ultra OVAL and strainers are stated in the GENERAL SPECIFICATIONS.

(5) The meter installation is correct if the ow direction conforms to the arrow mark on the meter body.

(6) The strainer should be located upstream of, and as close to the meter as possible.

(7) Since the sensor in the Smart Ultra OVAL operates on the principle of sensing changes in magnetic ux

density, it must be isolated from the influence of any external magnetic flux. In order to minimize the

influence of external magnetic flux, select an installation location at least 5 meters away from existing

power equipment and conductors - potential sources of creating strong magnetic and electric elds, such

as motors and generators.

(8) In case electric heating is desired, consult the factory.

(9) In the heat retention work, aviod covering up the ns and heating tube with lagging material.

- Typical Smart Ultra OVAL Installations

6.2 Standard Installation, Horizontal Line

(1) In c a s e f l o w d i r e c t i o n

is fr o m R t o L , s w i t c h

the places of meter and

strainer.

(2) Arran ge piping so as to

facilitate drainage.

(3) S t r a i n e r s h o u l d b e

ins p ecte d on a regu l ar

basis.

6.4 Example of Faulty Piping

Do not install the meter in

a position like this.

Marked * is the space required for disassembly

and inspection.

6.3

Standard Installation, Vertical Line

(1) If the ow direction is from top to

bottom, switch the places of meter

and strainer.

(2) Installing the strainer at "A" will

make net reinstallation difficult at

cleaning; we recommend to install

the strainer at "B".

NOTE: For outline dimensions and pipe connection dimensions, see approval drawing.

9

B-149-4N-E

Size 50

Sizes 52, 53, 55, 56, 57

REGETER

ASSEMBLY

CAREFULLY

ROTATE.

SKIRT

Don’t separate!

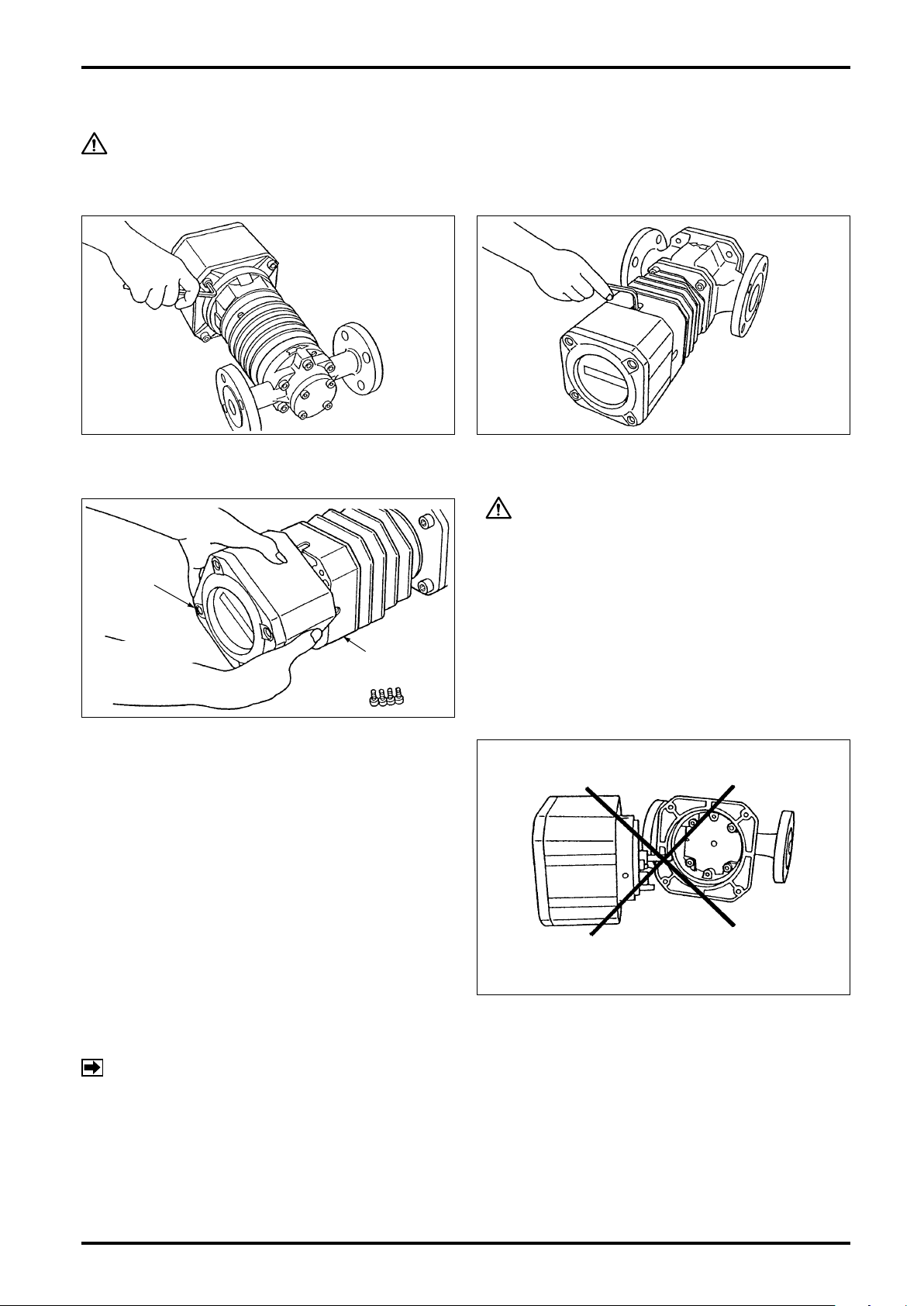

7. HOW TO CHANGE FLOW DIRECTIONS

CAUTION: Do not fail to turn power OFF if the meter is of remote output type.

To reverse the ow direction, change the orientation of both the register and owmeter body to the new ow

direction.

(1) Take off four hex socket head screws (M6) with hex wrench.

(2) Holding the register assembly in both hands,

carefully rotate it and then secure it with hex

socket head screws in line with the new direction

of ow.

CAUTION

1. Rotate the register assembly without separating

it from the skirt.

2. Do not attempt to rotate the register assembly

more than one complete revolution.

Do not attempt to change ow directions by

separating the register assembly like this.

NOTE: If you have separated the register assembly, first return it to the state before changing the flow

direction, then follow the correct procedure in step (2) (without separating the register assembly)

again to change ow directions.

10

B-149-4N-E

HEX

WRENCH

COVER

HEX SOCKET

HEAD BOLTS

O-RING

REMOTE OUTPUT

TERMINALS

EXTERNAL GROUND

TERMINAL

INTERNAL GROUND

TERMINAL

8. WIRING INSTRUCTIONS

(Refer also to the wiring instructions of respective receiving instrument

instruction manual.)

8.1 Wiring Guidelines

(1) Cables for field wiring

The following cables should be used unless otherwise specied:

Use cables of conductor area 1.25mm2 and nished O.D. 12mm, selecting from 2 to 4pcs. according to your

application. It is recommended that their shield be grounded at the receiving instrument.

CAUTION: In case of TIIS explosionproof type used under the ambient temperature of

50°C or higher, use a cable resistant to the temperature of 70°C or higher.

(2) Transmission length

The maximum transmission length is typically one kilometer.

NOTE: If it exceeds one kilometer, consult us.

(3) Inductive interference prevention

To minimize the possibility of stray current pickup, the eld wiring should be routed sufciently away from

existing power cables or power circuits.

(4) Considerations on connections

1) M3.5 terminal posts are used on the terminal block. Use crimp-style terminals that t the conductors at the

cable end.

2) Be sure to earth ground the preamplier's ground terminal.

3) Pitch down the cable from the cable entry so that rainwater will not have a chance to enter the equipment

through the cable.

4) In areas where lightning strokes are expected, provide a lightning arrestor for protection.

8.2 Terminal Connections

(1) Take off four hex socket head bolts (402) on the

(3) U s i ng crimp e d-lug t ermina l s , ensur e good

CAUTION: Make sure of the validity of meter (register) and receiving instrument

combination by referring to their model numbers, serial numbers, etc.

before you make electrical connections.

(2) Remove the cover to gain access to a 4-post

front of register assembly and remove the cover

(401).

electrical connections.

terminal block. Terminal identication is found on

the back of cover.

NOTE:

1. Pressuretight packing is not furnished with non-

explosionproof models and non-output models

(see page 5).

2. Connect the external earth ground terminal to

instrumentation earth ground before use.

11

B-149-4N-E

Supply Voltage (VDC)

Acceptable Load Resistance Range.

RL(Load Resist.)

0 12V

17.25V

45V

1000Ω

1571Ω

250Ω

33V

Area: Operating range

Area: Acceptable Communication range

R

=

L

E−12V

21mA

EXAMPLE:

If supply voltage is 24V DC with load

resistance 250Ω, then a 1 to 5V DC

output is obtained.

(

(

L

PC POWER

R

+

−

VOLT. SIGNAL

TO RECEIVING

INSTRUMENT

+

−

OPEN COLLECTOR

OUTPUT

30V, 50mA max.

FLOWMETER

REGISTER

GND

+

−

2

1

4

3

+

−

(SMART COMMUNICATION UNIT)

(OR HHC:EK10)

PC

(SMART COMMUNICATION UNIT)

(OR HHC:EK10)

PC

8.3 Preamplifier-to-Receiving Instrument Hookup

The 2-wire signal transmission system used in this owmeter furnishes DC power to the meter. It serves as the

power line and signal line as well with pulse or analog current output.

An OVAL receiving instrument can be coupled directly, but instruments in general which are designed to

accept a voltage signal input require a load resistor RL connected in series for voltage conversion. Since the

voltage signal level varies with the load resistance value, determine the load resistance value by referring to the

receiving instrument specications and the acceptable load resistance range shown below.

Communications with a PC (Smart Communication Unit) requires a 250 to 1000Ω load.

In case a voltage input is fed to the receiving instrument

●

R

L

Output Voltage Signal (V)

Pulse

Output

Analog

Output

(20mA × RL) / (4mA × RL)

(4mA × RL) − (20mA × RL)

ON/OFF =

at 0 ro FS

NOTE: With the relationship with supply

voltage E, select the load resistance

value RL such th a t t he c u r r e n t

flowing into the transistor is held

below 50mA.

Fig. 8.1

12

Fig. 8.2

9. OPERATING INSTRUCTIONS

A

B

C

BYPASS LINE

METER

STRAINER

VALVE

FLOW DIRECTION

EXCESSIVE

FLOW

RAPID FLOW

VARIATION

RAPID TEMPERATURE

CHANGES

B-149-4N-E

9.1 Operation

At rst-time operation, carefully operate in the following sequence, allowing the ow within the ow range

specied. (Refer to the piping diagram below.)

(1) Shut off the valve (A) on the inlet side and the valve (B) on the outlet side and then open the bypass line

valve (C) to allow the uid in the bypass line, thereby removing weld chips, scales and other foreign matter

left in the piping assembly.

"See also page 15 for the jacketed type".

CAUTION: This is particularly important on new installations.

(2) Carefully and slightly at rst, open the valve (A) upstream of the meter progressively and then, slightly at

rst, open the valve (B) downstream progressively.

(3) Slowly close the bypass line valve (C) and make sure that the total counter in the register advances in

response. Maintain a owrate 10 to 20% of the maximum owrate (conrm it in the instantaneous owrate

display mode) at this time, allow the ow for more than 15 minutes and make sure that air in the piping

assembly has totally escaped.

In applications where temperature exceeds 60°C, run the system at least for 30 minutes in this state to

ensure uniform heat distribution in the measuring chamber.

(4) Following the break-in operation (preheating), shut off the bypass line valve (C) completely and open the

upstream valve (A) progressively until fully open and slowly open the downstream valve (B) until the rated

ow is obtained.

(5) Flowrate should be regulated with the valve (B) downstream of the meter and should be held within the

rating.

(6) The strainer net should be inspected for condition and cleaned on a regular basis. On a new installation, in

particular, inspect daily rst and, according to the clogged condition of the net being observed, inspection

intervals may be reduced progressively to, say, once a week.

9.2 Operating Precautions

(1) When changing flowrates

In applications where the flowrate varies or where

shutoff valve opening and closure takes place in

batch operation, avoid rapid changes in flowrate

across the meter.

Ope r ating the m e ter a t flow r ates i n exce ss of

th e maximum allowable fl owrate wi ll nul lify the

guaranteed accuracy, reduce the meter life and may

result in faulty conditions, such as the seizure of

bearings or the rotor-to-measuring chamber contact.

(2) Whe re the t e mpera t u re o f metere d fluid

changes

Avoid rapid tem per atu re changes i n th e me ter.

Temperature changes of the uid in the meter should

be held within 3°C per minute.

Extra care should be used particularly when making

a ow measurement in batch operation without the

provision of heat tracing of the piping where the uid

temperature differs from atmospheric temperature.

If rapid temperature changes are anticipated, heat

trace the piping assembly as well as the meter.

13

B-149-4N-E

TAKE PRECAUTIONS

AGAINST BEARING SEIZURE!

(3) Liquids of low steam pressure

Temperature and pressure of LPG, polyvinyl chloride

monomers or anything with low viscosity and low

steam pressure that are too ready to vaporize should

strictly be controlled.

During operation, the temperature of bearings in the

meter is usually higher than that of the metered uid.

Vapors around the bearings can be causes of faulty

conditions, including generation of unusual noise

and bearing seizure.

(4) Corrosive liquids

When you make a measurement of highly corrosive

liqui d s , such as nitric a c i d a n d sulfuric a c i d,

appropriate materials should be used for tanks

an d p iping assem bly. He terogeneous m aterials

originally contained in the metered uid or corrosive

substances liquated out from tanks and pipes of

inappropriate materials may lead to costly downtime,

as a result of locked rotors, for example, when they

are allowed into the measuring chamber.

CAUTION: If it is a jacketed model, see page 15.

9.3 Precautions at Operation Shutdown

(1) Valves should be closed progressively.

Rapid valve closure could, under certain piping conditions, cause a sharp pressure rise by water hammer, or

hydraulic shock, resulting in damage to the meter.

(2) Precautions against pressure buildup on closure

Complete closure of valves upstream and downstream of the meter makes the affected section a totally

enclosed chamber and could cause a rise of internal pressure due to a rise of atmospheric temperature,

resulting in an unexpected damage to the meter.

(3) Liquids ready to adhere or gel at zero flow velocity

Liquids that tend to adhere and solidify or gel at ow velocities around zero must thoroughly be washed away

from the meter interior by running cleaning uid before shutdown. Negligence of this instruction may leave the

meter as an immovable unit when the operator attempts to resume meter operation the next time.

CAUTION

9.4 About Register Life

Due to the life expectancy of components incorporated, such as the LCD and nonvolatile memory, the internal

electronics are designed to be replaced in about 10 years. The electronics life depends on the environment in

which they are used; if any of the following operating conditions applies, we recommend you to replace them

an assembly in ve to six years:

- High temperature environment.

- High temperature process uid measurement.

- Field installation with widely varying temperatures.

- LCD counter display is directly exposed to the rays of the sun (ultraviolet rays).

- Frequent process uid ow interruptions.

14

B-149-4N-E

STEAM IN

OUT

FLOW

DIRECTION

IN

OUT

FLOW

DIRECTION

HOT WATER

CAUTION

9.5 Piping Instructions and Operating Precautions of Jacketed Meters

Hot water or steam jacketed meters require piping work in the following manner:

(1) Piping to the meter body remains the same as that of standard meters (meters not jacketed).

(2) Adhere to the following instructions for the piping to the jacket:

Steam Jacketed

Basically, the piping should be so arranged that

steam ows in from the top and out from the bottom.

Provi de stea m traps at outl et port s (s ee figu re

below).

⇩

Steam Jacketed Type, Horizontal Run

Hot-water Jacketed

Basically, the piping should be so arranged that hot

water ows in from the top and out from the top (see

gure below).

Hot Water Jacketed Type, Horizontal Run

⇩

(3) Although the measuring chamber is heat treated, due consideration should be taken not to give piping

elongation or contraction by sharp temperature changes or pipe strains.

Progressive heating is suggested at least four hours before commencing service operation.

(4) As for outline dimensions and tubing connection dimensions, see approval drawings.

(5) If heat tracing is desired, considerations should be taken to facilitate maintenance and servicing.

Make sure, if it is the case, that there is no liquid leaks when related components are covered with lagging

material.

(6) Lagging should be so provided that the top cover of strainer is easily accessible. Also it is necessary that

the strainer net be cleaned on a regular basis.

(7) Never attempt to lag radiator ns.

Lagging them will cause excessive heat buildup in the register and pulse generator, possibly leading to

costly downtime.

NOTE: As for outline dimensions and tube connection dimensions, see approval

drawing.

15

B-149-4N-E

METER BODY

HEX SOCKET

HEAD BOLTS

FRONT COVER

O-RING

HEX SOCKET

HEAD BOLTS

ROTOR SHAFTS

ROTORS

MEASURING

CHAMBER

10. DISASSEMBLY AND INSPECTION

Although it depends on individual operating conditions, periodic disassembly and inspection should be

performed at least once a year.

CAUTION: Because Smart Ultra OVAL is a prec ision indus trial instr ument,

disassembly and inspection should be performed indoors as a rule. If it is

desired to disassemble and inspect it as installed in the field, an important

precaution to remember is to reduce the internal pressure of the piping

assembly to a safe level, shut off valves upstream and downstream of

the meter fully, drain the piping assembly and then place a suitable fluid

receptacle directly below the Smart Ultra OVAL. Exercise care to keep

individual components disassembled free from grit and dust.

CAUTION: Be sure to deenergize before you disassemble.

Meter Body Inspection

◆

Complaint and possible cause: Process fluid will not run. Jammed with scales, the oval rotors fail

to rotate, resulting in an interrupted fluid flow.

10.1 Size 50 Meter Body Disassembly and Inspection

◆

(1) Take off all six front cover tting bolts (104) (M6),

using wrench.

With the bolts removed, the register integral with

the front cover is ready to be separated from the

meter body.

Be careful not to drop the register front cover

assembly.

(3) Remove oval rotors (201) from the measuring

chamber and inspect them for condition.

(a) Inspect the oval rotors to see if they are jammed

with foreign solids.

(b) Check the rotors, shafts and other members for

wear.

16

(2) Wi th the front cover (regi ster) remov ed, the

measuring chamber with oval rotors and other

components are now accessible.

(c) Inspect the measuring chamber and the inner

wall of front cover for damage or any other sign

of unusual condition.

Upon completion of these inspections, clean the

oval rotors, rotor shafts, measuring chamber and

front cover with clean water or suitable solvent

thoroughly.

CAUTION

1. Score marks, scratches, high spots due

to impressions, or other flaws should

be reconditioned flat with oil stone or

other tool.

2. If the areas which have been in contact

with rear cover jack bolts are distorted

outwardly, recondition it flat with oil

stone.

B-149-4N-E

MATCH MARKS

1ST ROTOR SIG.

MAGNETS

IN

1

2

OUT

2ND ROTOR

FLOW DIR. ARROW AND

2ND ROTOR NO.

FLOW DIRECTION

FLOW DIR. ARROW AND

1ST ROTOR NO.

IN

OUT

FRONT COVER

O-RING

HEX BOLTS

(REGISTER SIDE)

10.2 Size 50 Meter Body Assembly Procedure

CAUTION: PRECAUTIONS BEFORE ASSEMBLY

Oval rotors, inner walls of the rotor shafts, inner wall of the measuring chamber, inlet and outlet ports should be

thoroughly washed clean, completely removing dust, grime and other foreign matter.

Hot Water Jacketed Type, Horizontal Run

(1) Rotor Installation

Rotor installation is correct if the side where signal

generating magnets are embedded faces the register

(top in the measuring chamber) and the side with match

marks ( • ) ( • • ) faces the front cover.

Carefully install the rotors with the 1st rotor (match mark

" • ") on the shaft with "1" stamped on the outside of

measuring chamber and the 2nd rotor (match mark

" • • ") on the shaft with "2" stamped. Ensure that the

match marks are as shown in the inset.

(3) Front Cover Installation

Firstly install O-ring (108) on the front cover. If the

O-ring is damaged or swollen with metered liquid, it

will not t in the groove. If such is the case, replace

with a new one.

Align the locating pin of front cover with its pin slot

in the meter body and, fitting the rotor shafts into

rotor shaft sockets in the front cover, force the meter

body until the locating pin ts rmly in the pin slot

in the meter body without slanting the front cover.

Install six front cover fitting bolts (M6) and tighten

them evenly until the front cover is closely in contact

with the meter body.

(2) Confirming the Rotor Gear Engagement

Hand rotate the rotors to make sure of correct gear

mask.

(4) Confirming Freely Rotation

With air or water, make sure to see that the rotors

move freely and that the register counts in response.

CAUTION

Rotation check should be performed at

low rotor r.p.m.

Violent roto r s p inning m a y cause a

damage to the components, such as

bearing seizure.

CAUTION: Since the registers are not compatible each other, do not replace one

register with that of other meter.

17

B-149-4N-E

REAR

COVER

REAR COVER

HEX BOLTS

TOP COVER

REAR

COVER

GASKET

END PLATE

ROTOR SHAFT

REAR

COVER

TOP COVER

GASKET

ROTORS

10.3 Sizes 52, 53, 55, 56, 57 Meter Body Disassembly and Inspection

CAUTION: Be sure to deenergize before you disassemble.

(1) Take off all rear cover tting bolts, using wrench.

(3) Using cross slot screwdriver, remove all four

bolts securing the top cover in place. Then, use

two of them to jack up the top cover, eventually

to remove it.

CAUTION

When jacking the top cover off, turn the

jacking screws evenly and alternately so

that the top cover not slant.

(2) Remove the rear cover to gain access to the top

cover.

(4) W ith the top cov er rem oved, t he measuring

chamber with oval rotors and other components

are now accessible.

1. Score marks, scratches, high spots due to impressions, or other flaws should be

2. If the areas which have been in contact with rear cover forcing bolts are distorted

18

CAUTION

reconditioned flat with oil stone or other tool.

outwardly, recondition it flat with oil stone.

(5) Remove oval rotors and rotor shafts, in this order,

from the measuring chamber and inspect them

for condition. (The rotor shafts should be drawn

out straight.)

(a) Make sure to see if the o val rotors are

jammed with foreign matter.

(b) Check to see if the rotors, shafts and other

components are worn.

(c) Inspect if the measuring chamber and inner

wal l of the fron t cover have any sig n of

scratches or other damage.

Upon completion of these inspections, clean

the oval roto rs, rotor shaft s, mea s urin g

chamber and front cover with cleans water or

suitable solvent thoroughly.

B-149-4N-E

NON TURN

PIN

ROTOR

SHAFTS

SHAFT

SOCKET

ROTORS

2ND ROTOR "2" MARKS

1ST ROTOR "1" MARKS

FLOW

IN

OUT

MATCH MARKS

ROTORS

TOP COVER

REAR COVER

GASKET

10.4 Sizes 52, 53, 55, 56, 57 Meter Body Assembly Procedure

CAUTION: PRECAUTIONS BEFORE ASSEMBLY

Oval rotors, inner walls of the rotor shafts, inner wall of the measuring chamber, inlet and

outlet ports should be thoroughly washed clean, completely removing dust, grime and other

foreign matter.

(1) Rotor Shaft Installation

The non-turn pin end of each rotor shaft faces the

register (bottom of the measuring chamber). Install

the shafts, pin end first, into their sockets on the

bottom of measuring chamber (bottom of meter

body), forcing downward while turning each of them

with hands until they are rmly installed in position.

(Air in the sockets may resist to be compressed by

the shafts. So good practice is to hold the shafts

pressed down by hand for some time.)

(2) Rotor Installation

Rotor installation is correct if the side where signal

gener a t i ng magnets a re embedd e d faces the

register (bottom of the measuring chamber) and the

sides with match marks ( • ) ( • • ) faces the rear

cover. Carefully install the rotors with the 1st rotor

(match mark " • ") on the shaft with "1" stamped on

the outside of measuring chamber and the 2nd rotor

(match mark " • •" ) on the shaft with "2" stamped.

Ensure that the match marks are in alignment as

shown in the inset.

(3) Confirming the Rotor Gear Engagement

Hand rotate the rotors to make sure of correct gear

mesh. At this point, they may be shaky more or less

as the shafts not fixed firmly. Exercise care not to

damage the rotors and inner wall of the measuring

chamber by forcing them to rotate.

(5) Rear Cover Installation

Firstly install the gasket on the rear cover. If the

gasket is found damaged, replace it with a new one.

In stall rear cover fit tin g b olts a nd tig hten t hem

evenly.

(4) Installing top cover and confirming smooth rotor rotation

With the locating pin of top cover in line with its pin

slot in the meter body and tting the rotor shafts into

their sockets in the top cover, force them against the

meter body until the locating pin ts in its slot in the

meter body without slanting the top cover.

Install top cover fitting bolts and tighten each of

them evenly until the top cover is rmly in contact

with the meter body.

At this point, allowing air or water, make sure to

see that the rotors move freely and that the register

counts in response.

CAUTION

NOTE: We suggest to replace the gasket with a

new one at each disassembly.

Rotation check should be performed at low rotor

r.p.m. Violent rotor spinning may cause a damage

to meter components, such as bearing seizure.

CAUTION: Since the registers are not compatible each other, do not replace one

register with that of other meter.

19

B-149-4N-E

O-RING

FRONT

COVER

HEX SOCKET

HEAD BOLTS

TP-PIN

OUT 2 PIN

OUT 1 PIN

REV PINFWD PIN

MODE SELECT

SWITCH SW1

0V PICKUP POINT

EXTERNAL GND

TERMINAL

EXT. OUTPUT

TERMINAL

SELECTOR MAGNET

HOLDER

INTERNAL GND

TERMINAL

PARAMETER REWRITE

PROTECT SWITCH

(“ON” TO INHIBIT REWRITE)

IN PIN PLS PIN

11. REGISTER SWITCH FUNCTIONS AND PARAMETER SETTING

11.1 Switch Names and Functions

(1) Using a hex key, take off four hex socket head

bolts securing the front cover.

(2) Removing the front cover provides access to the

electronics unit.

20

Fig. 11.1 Part Names of Electronics Unit

11.2 Individual Test Pin Functions

10μs

200mV

200mV

1 to 1.5ms

3V

2ms

Depends on

"Pulse widt"setting.

20ms

T

NOTE: Connect the 0V end to the L.H. side fixed screw of the electronics unit.

PIN NAME FUNCTION WAVEFORM

An output of No. 1 amorphous sensor waveform

FWD

REV

PLS

IN

appears.

An output of No. 2 amorphous sensor waveform

appears. While the owmeter is making forward

revolutions, pulses are produced slightly behind the

FWD pulses.

A re c t a n gu l ar w a v e fo r m a f t e r F W D p u l s e

waveshaping appears. Timing remains the same

as tha t of FWD and its wav efor m is one bef ore

unfactored output amplication.

Accepts a square-wave pulse train from the pulse

checker (OVAL Model PC2201, for example).

Used for analog full scale adjustment, loop check, or

other servicing. Input mode is Model PC2201's PG30

mode. Also accepts pulses with levels "0": 1V max.

and "1": 7 to 12V min., or open collector.

Same as above.

B-149-4N-E

Provides a waveform corresponding to the power

(1) Unfactored pulse

signal which appears across remote output signal

terminals 1 and 2.

(2) Factored pulse

OUT1

(3) Analog output

T

2 to 10ms

≒

at 0 to FS

Produces a waveform corresponding to the open

OUT2

collector output which appears across remote output

terminals 3 and 4.

11.3 About Meter Factor

If it is desired to change meter factors in an instrumental error testing, for example, you may establish a new

meter factor by the following procedure.

Instrumental error testing must be conducted with proper facilities and procedures specied in the Weights and

Measures Law, Japanese Industrial Instruments Federation, JIS standards, or other established standards.

- How to Determine a New Meter Factor

New Meter Factor = (Current meter factor) × (1−

where current meter factor : Stated in the test report or on the tag of the product.

E : Instrumental error determined by the test (% )

CAUTION: The new meter factor should be put on paper for later reference.

E

100

) (mL/P)

21

B-149-4N-E

ELECTRONICS

UNIT

ELECTRONICS

UNIT

REGISTER

ASSEMBLY

SKIRT

HEX SOCKET

HEAD BOLTS

REGISTER

ASSEMBLY

SENSOR RETAINER

FITTING SCREW

ELECTRONICS

UNIT

CONNECTOR

CONNECTOR

C-SHAPED

STOP RING

SENSOR

FITTING DISC

SENSOR UNIT

153

152158

FLOW DIRECTION

ARROW

SENSOR

FITTING DISC

SENSOR

OPENING

BLIND PLUG

(153)

12. SENSOR REPLACEMENT PROCEDURE

NOTE: Size 55 meter body is shown here.

The same procedure applies to other size

models.

(1) Take off four hex socket head screws on the register.

(3) Take off four hex socket head bolts and separate the

cover.

(5) Holding the electronics unit in both hands, carefully draw

it out.

CAUTION: Use extra care not to damage the leads

by forcibly pulling the sensor fitting disc.

(2) Carefully draw the register assembly out. Exercising care

not to bump the sensor against adjacent components,

draw it out in the horizontal direction.

(4) With screwdriver, take off two tting screws holding the

electronics unit

(6) Uncouple the connector from the sensor unit at back of

the electronics unit.

(7) Using C-shaped stop ring pliers, remove the C-shaped

(9) Install a new sensor unit through the opening through

22

stop ring for the shaft. The sensor unit is now separable

from the register housing.

which the old sensor unit was removed and assemble in

the reverse order of disassembly.

(8) Loosen the sensor retainer fitting screws (M 4) with

screwdriver, remove the sensor retainer and draw out the

sensor unit.

LOCATION OF SENSOR INSTALLATION OPENING

(10) At register installation in the meter body, match the ow

direction of the meter body with the arrow on the sensor

tting disc.

13. TROUBLESHOOTING

PROBLEM PROBABLE CAUSE COPING ACTION

B-149-4N-E

1. Totalizer remains

inoperative.

2. Unusual noise.

3. Liquid leaks. 1. Incomplete seal of the pipeline. 1. Retighten bolts at pipeline connections or replace

4. Counts while valves

remain closed.

5. Analog output

unusual.

6. Accumulated total

too high.

7. Accumulated 1. Inuenced by external magnetic

1. Flowrate is low. 1. Open valves progressively.

2. Insufcient pump pressure or head

pressure.

3. Power line voltage is out of

specication or current carrying

capacity of power source is

inadequate.

4. Oval rotors jammed with foreign

matter; rotors locked; metered liquid

fails to run.

5. Oval rotors installed the wrong way. 5. Refer to 10.2 Meter Assembly

6. Sensor installed out of position. 6. Refer to "How to Change Flow

1. Air is entrapped.

2. Vaporized metered liquid in the

piping assembly.

3. Oval rotors revolving in contact with

measuring chamber.

2. Incomplete seal on front/rear cover

of meter body

1. Valve and pipeline leaks. 1. Inspect valves and pipeline.

2. Air pockets between valve and

Ultra OVAL; rotors in rocking motion

in response to pump's pulsating

pressure.

3. Supply power voltage uctuates. 3. Eliminate voltage uctuation.

1. Load resistance too great. 1. Referring to "Load Resistance

1. Rotors in rocking motion in response

to a pulsating ow.

2. Inuenced by external magnetic

elds (Meter sensor picks up external

magnetic elds created by a motor,

generator, etc.)

3. Air entrapped. 3. Provide an air vent.

elds.

2. T aking pressure loss of entire piping assembly into

consideration, correct pump pressure or head

pressure.

3. Provide a 14 to 45VDC power to the register. (12 to

24VDC for open collector or voltage pulse output.)

Current carrying capacity 30mA min. is required for

power. (With analog output, 24VDC, 60mA min. is

required.)

4. Referring to "Disassembly and Inspection" (Sec. 10),

disassemble the meter body and clean the rotors

thoroughly.

Procedure in the "Disassembly and Inspection", and

reassemble correctly.

Directions" (Sec. 7) and reinstall the sensor.

1. Reduce owrate and eliminate air completely in the

piping assembly.

2. Reduce owrate and control metered uid

temperature and pressure to prevent vaporization.

3. Refer to "Disassembly and Inspection" (Sec. 10), and

disassemble and inspect for condition.

gaskets with new ones.

2. Inspect front/rear cover tting bolts for tightness and

replace O-rings with new ones.

2. Vent air.

Provide a check valve and accumulator.

Range" on page 12, check load resistance to power

supply voltage relationship and keep them within the

specied range.

1. Add a check valve and accumulator.

2. Keep out external magnetic elds.

1. Keep out external magnetic elds.

23

B-149-4N-E

404

500

158

160

153

152

154

156

155

151

204

201

202

204 203

101

104

109

103

106

400

300

113

111

112

114

115

120

107

121

121

123A

123B

110

108

FLOW

14. EXPLODED VIEWS AND PARTS LIST

14.1 Meter Size 50 Exploded View and Parts List

- When you order replacement parts, specify the stock No., flowmeter model, instruction manual No.,

symbol No., part name and the quantity desired.

EXPLODED VIEW

PARTS LIST, Meter Size 50

Symbol

No.

101

103

104

106

107 O-Ring 1

▲

108

▲

109 O-Ring 1

▲

110

111 Skirt 1

112

113

114

115

120

121

151

152

153

: Recommended spare parts.

▲

: Rotors 201, 202 and rotor bearings 204 are available as an assembly.

※

24

Part Name Q'ty Remarks

Meter Body 1

Rear Cover 1

Front Cover Fitting Bolt 6 M8×35

Rear Cover Fitting Bolt 4 M6×15

G60

O-Ring 1

Front Cover Locating Pin

Skirt Locating Pin 2

Skirt Fitting Bolt 4 M8×20

Register Fitting Bolt 4 M6×15

Gasket 1

Sealing Flange 1

Iron Slug 1

Sensor Fitting Disc 1

Sensor Retainer 1

Blind Plug 1

G65

G40

2

Symbol

No.

154

155

156

158

160 Sensor 1

201 1st Rotor 1 w/Signal magnet

※

202

※

203

※

300

400

401

402

404

405

500

123 A

123 B Cooling Tube 1 set

204

Part Name Q'ty Remarks

O-Ring B 2 S10

O-Ring C 1 G65

C-shaped Stop Ring 1

Cross Recess Pan Head Screw

2nd Rotor 1 w/Signal magnet

Rotor Shaft 2

Rotor Bearing 4

Sensor Assembly 1 set (151 to 158, 160)

Register Assembly 1 set

Register Cover 1

Cover Fitting Bolt 4 M6 (w/washer)

Selector Magnet 1

Internal Assembly 1 set

Pressuretight Packing 1 set

Heating Tube 1 set

2

M4 X 8 (w/washer)

(w/screen, fr. cover)

(w/screen, fr. cover)

B-149-4N-E

404

500

158

160

153

154

156

155

151

203

204

204

211

201

213

107

104

102

400

300

108

103

114

113

101109

111

112

113

108

108

700B

700A

14.2 Meter Sizes 52 and 53 Exploded View and Parts List

- When you order replacement parts, specify the stock No., flowmeter model, instruction manual No.,

symbol No., part name and the quantity desired.

EXPLODED VIEW

4 PARTS LIST, Meter Sizes 52 and 53

Sym. No. Part Name

101

102

103

104

▲

107

108

109

Meter Body 1 1

Rear Cover 1 1

Skirt 1 1

Gasket 1 1

Rear Cover Fitting Bolt 4 M12×30 4 M12×30

Skirt Fitting Bolt 8 M10×20 8 M10×20

Gasket 1 t=1.5 1 t=1.5

Q'ty Remarks Q'ty Remarks

111 Meter Body Skirt 1 1

112

113

114

151

152

153

154

155

156

158

160

※201 First and Second Rotor

203

※204 Rotor Bearing 4 4

211

213

300

400

401

402

404

405

500

700A

700B

: Recommended spare parts.

▲

: Rotors 201 and rotor bearings 204 are available as an assembly.

※

Fitting Bolt 4 M8×12 4 M8×12

Gasket 2 t=1.5 2 t=1.5

Register Fitting Hex Socket Head Screw

Sensor Fitting Disc 1 1

4 M6×15 4 M6×15

Sensor Retainer 1 1

Blind Plug 1 1

O-Ring B 2 S10 2 S10

O-Ring C 1 G65 1 G65

C-shaped Stop Ring 1 1

Cross Recess Pan Head Screw

2 M4×8 (w/washer) 2 M4×8 (w/washer)

Sensor 1 1

1 each

Rotor Shaft 2 2

Top Cover 1 1

Top Cover Fitting Bolt 4 M6×12 4 M6×12

Sensor Assembly 1 set (151 to 158, 160) 1 set (151 to 158, 160)

Register Assembly 1 set 1 set

Register Cover 1 1

Cover Fitting Bolt 4 M6 (w/washer) 4 M6 (w/washer)

Selector Magnet 1 1

Internal Assembly 1 set 1 set

Pressuretight Packing 1 set Oprion 1 set Oprion

Cooling Tube 1 set 1 set

Heating Tube 1 set 1 set

Size 52 Size 53

w/signal magnet

1 each

w/signal magnet

25

B-149-4N-E

404

500

158

160

153

154

156

155

151

203

204

204

211

201

213

107

104

102

400

300

108

103

114

113

101

113

108

700B

700A

14.3 Meter Sizes 55 and 56 Exploded View and Parts List

- When you order replacement parts, specify the stock No., flowmeter model, instruction manual No.,

symbol No., part name and the quantity desired.

EXPLODED VIEW

PARTS LIST, Meter Sizes 55 and 56

Sym. No. Part Name

101

102

103

104

▲

107

108

113

114

151

152

153

154

155

156

158

160

201

※

203

※204 Rotor Bearing 4 4

211

213

300

400

401

402

404

405

500

700A

700B

26

Meter Body 1 1

Rear Cover 1 1

Skirt 1 1

Gasket 1 1

Rear Cover Fitting Bolt 6 M12×40 8 M12×45

Skirt Fitting Bolt 8 M12×20 8 M12×20

Gasket 2 t=1.5 2 t=1.5

Register Fitting Hex Socket Head Screw

Sensor Fitting Disc 1 1

Sensor Retainer 1 1

Blind Plug 1 1

O-Ring B 2 S10 2 S10

O-Ring C 1 G65 1 G65

C-shaped Stop Ring 1 1

Cross Recess Pan Head Screw

Sensor 1 1

First and Second Rotor

Rotor Shaft 2 2

Top Cover 1 1

Top Cover Fitting Bolt 4 M6×12 4 M6×12

Sensor Assembly 1 set (151 to 158, 160) 1 set (151 to 158, 160)

Register Assembly 1 set 1 set

Register Cover 1 1

Cover Fitting Bolt 4 M6 (w/washer) 4 M6 (w/washer)

Selector Magnet 1 1

Internal Assembly 1 set 1 set

Pressuretight Packing 1 set Option 1 set Option

Cooling Tube 1 set 1 set

Heating Tube 1 set 1 set

Q'ty Remarks Q'ty Remarks

4 M6×15 4 M6×15

2 M4×8 (w/washer) 2 M4×8 (w/washer)

1 each

Size 55 Size 56

w/signal magnet

1 each

w/signal magnet

: Recommended spare

▲

parts.

: Rotors 201 and rotor

※

bearings 204 are

available as an assembly.

B-149-4N-E

404

500

158

160

153

154

156

155

151

204

204

211

201

213

107

104

102

400

300

108

103

114

113

101

203

113

108

700B

700A

14.4 Meter Size 57 Exploded View and Parts List

- When you order replacement parts, specify the stock No., flowmeter model, instruction manual No.,

symbol No., part name and the quantity desired.

EXPLODED VIEW

PARTS LIST, Meter Sizes 57

Symbol No. Part Name Q'ty Remarks

101

102

103

104

▲

107

108

113

114

151

152

153

154

155

156

158

160

201

※

203

※204 Rotor Bearing 4

211

213

300

400

401

402

404

405

500

700A

700B

: Recommended spare parts.

▲

: Rotors 201 and rotor bearings 204 are available as an assembly.

※

Meter Body 1

Rear Cover 1

Skirt 1

Gasket 1

Rear Cover Fitting Bolt 16 M12×45

Skirt Fitting Bolt 8 M12 ×20

Gasket 2 t=1.5

Register Fitting Hex Soc. Hd. Scr.

Sensor Fitting Disc 1

Sensor Retainer 1

Blind Plug 1

O-Ring B 2 S10

O-Ring C 1 G65

C-shaped Stop Ring 1

Cross Recess Pan Head Screw 2 M4×8 (w/washer)

Sensor 1

First and Second Rotor

Rotor Shaft 2

Top Cover 1

Top Cover Fitting Bolt 4 M8×12

Sensor Assembly 1 set (151 to 158, 160)

Register Assembly 1 set

Register Cover 1

Cover Fitting Bolt 4 M6 (w/washer)

Selector Magnet 1

Internal Assembly 1 set

Pressuretight Packing 1 set Option

Cooling Tube 1 set

Heating Tube 1 set

4 M6×15

1 each

w/signal magnet

27

B-149-4N-E

15. GENERAL SPECIFICATIONS

Basic Meter

●

Meter Size 50 52 53 55 56, 57

Nominal Diameter 20mm 25mm 40mm

Flange Ratings

Operating Temperature Range*

Accuracy ± 0.5% and ± 0.2%

Meter Body SCS14 or SCS16

Rear Cover SUS316 or SUS316L

Rotors SUS316 or SUS316L

Bearings Special carbon or ceramics

Materials

Shafts SUS316 or SUS316L

Flow Direction Right → Left (standard), Left → Right, Top → Bottom, Bottom → Top

External Finish Meter body and rear cover: Not painted; Skirt: Painted

*: Size 50 operates in a range -30 to + 60° C (low temp. service) or +120 to + 200°C (high temp. service).

●

Max. Operating Pressure per Flange Rarting

1 JIS 10K RF, ASME 150 RF, JPI 150 RF

3 JIS 16, 20, 30K RF, ASME 300 RF, JPI 300 RF, DIN 10, 16, 20, 25

- 60 to +60° C (low temp. service), +120°C to 350°C (high temp. service)

Flange Code JIS 10K RF ASME 150 RF JIS 20K RF JIS 30K RF ASME 300 RF

1 1.18 at 120°C 1.50 at 120°C …… …… ……

3 …… …… 1.96 at 120°C 2.94 at 120°C 2.94 at 120°C

50mm

Unit: MPa

●

Register General Specifications

Local

Indicator

(LCD)

Mode

Select

Output

Output Pulse Width (ON duration) 1 ms (standard) 1 ms to 1000 ms (resolution 1ms) (Notes 1 and 2)

Power Supply 12 to 45VDC

Signal Transmission Cable

Operating Temperature Range -10 to + 50°C (Register itself -10 to + 60°C)

Construction

Protection rating of Enclosure IP66 (dusttight/watertight) IEC/EN60529, JIS C0920

Housing Material Aluminum die casting

Finish Munsell 2.5PB 5/8, baked

1. If pulse width in excess of 1ms is desired for minimum factored pulse unit, the max. owrate can possibly be

NOTE:

2. With meter size marked*, if standard factored pulse unit is selected, pulse width other than 1 ms is

Nominal Meter Factors

●

Size P/r Nominal Meter Factor

50 4 9.936 mL/P

52 4 9.664 mL/P

53 4 17.513 mL/P

Meter Size 50* 52 53* 55 56 57

Accumulated total, 8-digit reading units

Instantaneous owrate (b mode)

% Instantaneous owrate (P mode)

Bargraph mode 8-segment bargraph

Analog 0 to FS 4 to 20mA

Current pulse (unfactored) 0/1 4/20mA

Open collector factored pulse

Open collector unfactored pulse

Open collector alarm output

Open collector FWD/REV ow discrimination

restricted; consult the factory.

unacceptable.

0 to 100%

Shielded cable 1.25 mm

Transmission length one kilometer (cable D.D. 8.5 to 12 mm)

Explosionproof TIIS: Exd Ⅱ BT4

Explosionproof KCs: Exd Ⅱ BT4

Non-explosionproof construction

×10mL (standard) ×0.1L (standard)

×1 L/h (standard) ×10L/h (standard)

NOTE: One of them is chosen.Current pulse (factored) 0/1 4/20mA

Open collector

Max. allowable voltage: 30V DC

Allowable current: 50mA

(Acceptable load resistance range exists. See page 12.)

2

NOTE: One of them is chosen.

Size P/r Nominal Meter Factor

55 6 34.60 mL/P

56 8 74.66 mL/P

57 8 196.08 mL/P

×1 L (standard)

28

b1: ×1 1/h

b2: ×10 s1/sis

MIT

×10 ml

MODE

RESET

MODE

MODE

RESET

φ130

φ130

L

137

8

B

D

F

B

D

E

F

E

CABLE ENTRY G1/2

(Output signal type)

Heating tube

Cooling tube

b1: ×1 1/h

b2: ×10 s1/sis

MIT

×10 ml

MODE

RESET

MODE

MODE

RESET

B

D

φ130

L

8

137

B

D

E

φ130

G

CABLE ENTRY G1/2

Heating tube

Cooling tube

E

F

G

F

(Output signal type)

16. OUTLINE DIMENSIONS

(1) 10K TYPE DIMENSIONS

Size Flange Rating

50

JIS 10K RF 200

ASME, JPI, 150 RF 198

L (face-to-face)

B-149-4N-E

Unit: mm

B (overall) D E F Approx. Weight

296.8 43

96 211.8

φ

w/cool tube 14kg

w/heat tube 13kg

Size Flange Rating

52

53

JIS 10K RF 200

ASME 150 RF 200

JIS 10K RF 200

ASME 150 RF 200

Size Flange Rating

55

56

JIS 10K RF 230

ASME 150 RF 233

JIS 10K RF 250

ASME 150 RF 258

L (face-to-face)

L (face-to-face)

B (overall) D E F Approx. Weight

B (overall) D E F Approx. Weight

353.3 47

376.8 59.5

371.3 71

391.3

76

□

106 264.3

□

106 275.3

φ

φ

163

193

258.3

273.3

w/cool tube 17kg

w/heat tube 16kg

w/cool tube 18kg

w/heat tube 17kg

w/cool tube 23kg

w/heat tube 22kg

w/cool tube 27kg

w/heat tube 26kg

Unit: mm

NOTE: For outline dimensions of jacketed meters and pipeline connections dimentions, see the approval drawing.

(1) 10K TYPE DIMENSIONS

Size Flange Rating

57

JIS 10K RF 350

ASME 150 RF 357

L (face-to-face)

B (overall) D E F G Approx. Weight

424.3 87

260 295.3 171.5

φ

w/cool tube 43kg

w/heat tube 42kg

29

B-149-4N-E

⑧−⑥⑤④③②① ⑯⑮⑭−⑫⑪⑩⑨ − −㉑⑳ ㉔㉓ ㉖㉕⑲⑱

Model

Fluid category

Capacity (Nominal Diameter)

Nominal diameter

Register

Regulations

Power supply

Bearing

Special

Seal material

Viscosity category

Version

Output

Explosion-proof

Ex-proof temp. class

Temp. category

Process connection

Major material

Main code

/ / / Additional code

17. PRODUCT CODE EXPLANATION

●

Main code (Meter model: 50, 52, 53, 55, 56, 57)

① ② ③

L U S ULTRA OVAL (integral type) Single case all stainless

L U J ULTRA OVAL (single standard jacket) Element: stainless steel

Capacity (Nominal Diameter)

④ ⑤

5 0 20mm (3/4") ND (Big)

5 2 25mm (1") ND (Big)

5 3 25mm (1") ND (Big)

5 5 40mm (1·1/2") ND (Big)

5 6 50mm (2") ND (Big)

5 7 50mm (2") ND (Big)

Nominal diameter

⑥

4 Nominal diameter (Big) integral type

—

⑦

Fluid category

⑧

L Liquid

Temp. category

⑨

0 60℃ and lower

1 Over 60℃ up to 120℃

2 Over 120℃ up to 200℃ w/Cooling n

3 Over 200℃ and up to 260℃ w/Cooling n

5 Sudden temp. change (120℃ and lower)

6 Low temp. (−30℃ and over and below −10℃) Max. temp. 60℃ w/Heating tube

Major material

⑩

C SCS14 (SUS316)

S SCS16 (SUS316L)

Z Special

Process connection

⑪ ⑫

J 1 JIS10K RF

J B JIS16K RF

J 2 JIS20K RF

J 3 JIS30K RF

A 1 ASME150 RF

A 3 ASME300 RF

P 1 JPI150 RF

P 3 JPI300 RF

D 1 DIN10 RF

D B DIN16 RF

D 3 DIN25 RF

Z 9 Special

—

⑬

Explosion-proof

⑭

0 Non-explosionproof

2 TIIS

8 KCs

Ex-proof temp. class

⑮

0 Non-explosionproof

4 T4

30

Model

Regulations

⑯

0 Standard

G High Pressure Gas Safety Act (Approved product) w/Material test certicate

H High Pressure Gas Safety Act (Individual test)

High Pressure Gas Safety Act

J

(Completion inspection)

L Gas Business Act (Approved product)

M Gas Business Act w/Material test certicate

Q Electricity Business Act (Certicate required)

R Electricity Business Act w/Material test certicate

T Fire Service Act w/Material test certicate

A Nuclear power

F w/Material test certicate

Z Special

—

⑰

Register

⑱

H Smart Type ULTRA register

Power supply

⑲

0 External power supply (standard)

Output

⑳

A Analog

D Current pulse

M Current pulse + open collector pulse

W Open collector pulse + analog

Z Special

Version

A Version code: A

—

Bearing

0 Standard (carbon bearing)

2 Standard (strong alkali carbon)

8 Polymerizing liquid (carbon bearing)

5 Highly corrosive liquid (ceramic bearing)

6 Hydrogen peroxide solution (ceramic bearing)

7 Highly corrosive polymerizing liquid (ceramic bearing)

Viscosity category

2 Below 1000mPa·s R3 sintered rotor

3 1000mPa·s and over R3 special cut sintered rotor

Below 200mPa·s

5

(sintered rotors inapplicable)

200mPa·s and over

6

(sintered rotors inapplicable)

Below 1000mPa·s

7

(sintered rotors inapplicable)

1000mPa·s and over

8

(sintered rotors inapplicable)

Seal material

F O-ring (FPM), gasket (T#1120)

C O-ring (IIR), gasket (T#1120)

T O-ring (PTFE), gasket (V7020)

P O-ring (PTFE), gasket (V7035)

Z Special

Special

0 Standard

Z Special

w/Material test certicate

(Designed on PO issued)

w/Material test certicate

w/Material test certicate

(Designed on PO issued)

w/Material test certicate

(Designed on PO issued)

w/Material test certicate

(Designed on PO issued)

Cut rotor

Special cut cut rotor

R3 cut rotor

R3 special cut cut rotor

●

⑧−⑥⑤④③②① ⑯⑮⑭−⑫⑪⑩⑨ − −㉑⑳ ㉔㉓ ㉖㉕⑲⑱

Model

Fluid category

Capacity (Nominal Diameter)

Nominal diameter

Register

Regulations

Power supply

Bearing

Special

Seal material

Viscosity category

Version

Output

Explosion-proof

Ex-proof temp. class

Temp. category

Process connection

Major material

Main code

/ / / Additional code

Additional code

Category of High Pressure Gas

H P 0 Other than High Pressure Gas

H P 1 Toxic gas and ammable gas

H P 2 Toxic gas

H P 3 Flammable gas

H P 4 Other than toxic or ammable gas

Accuracy

R 0 5 ±0.50% ACCURACY

L 0 1 ±0.15% LINEARITY ※Only for export

L 0 3 ±0.35% LINEARITY ※Only for export

R 0 2 ±0.20% ACCURACY

R 9 9 Special

Operating condition

F C 0 Continuous

F M 0 Intermittent

Special test (instrumental error)

A 1 0 Taxed custody transfer

A 2 0 By certied measurer

A 6 0 Standard oil meter

A 7 0 Std. fuel oil meter, std. water meter

A 8 0 Std. fuel oil meter, std. water meter

A 9 9

Flow direction

F R 0 R→L

F L 0 L→R

F U 0 T

F D 0 B

Designated special paint on body

B C 0 Corrosion proof

B A 0 Salinity and acid tolerance 120℃ and lower

B X 0 Customer designation

Designated special paint on transmitter

S F 0 Corrosion proof Special treatment

S D 0 Salinity tolerance

S E 0 Acid tolerance Special treatment

S X 0 Customer designated paint Special treatment

Cleansing

T W 0 Non-oil and non-water treatment

T W 1 Non-oil and non-water treatment equivalent

T F 0 Food cleansing

T A 0 Nuclear cleansing