Page 1

SUPERFLY

MANTAS 28

RIGGING MANUAL

Page 2

INDICE

1. SAFETY REGULATIONS .................................................................................................. 3

1.1. DISPOSAL OF WASTE MATERIALS ....................................................................................................... 3

1.2. CONFORMITY AND WARRANTY ............................................................................................................ 3

2. COMPONENTS OVERVIEW .............................................................................................4

2.1. LOAD CAPACITY .................................................................................................................................... 4

2.2. FRAME BAR SPECIFICATIONS ............................................................................................................. 5

2.3. INTEGRATED HARDWARE OF LINE ARRAY ELEMENTS ...................................................................... 7

2.4. LOCKING PINS ...................................................................................................................................... 8

2.5. HARDWARE INSPECTION ..................................................................................................................... 9

3. OPEN ARRAY 2 - PRE-RIGGING .....................................................................................10

4. RIGGING PROCEDURE ...................................................................................................13

4.1. PREPARATION ...................................................................................................................................... 13

4.1.1. SPLAY ANGLES .............................................................................................................................................. 13

4.1.2. PREPARATION OF THE FRAME BAR ............................................................................................................. 15

4.2. ASSEMBLING ........................................................................................................................................ 17

4.3. INTERMEDIATE PHASE ........................................................................................................................ 19

4.3.1. RIGGING THE CABLES ................................................................................................................................... 19

4.4. FINAL PHASE ........................................................................................................................................ 20

4.5. DERIGGING ........................................................................................................................................... 21

4.6. GROUND STACK CONFIGURATION ...................................................................................................... 22

5. TRANSPORT AND STORAGE ..........................................................................................24

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

2

www.outline.it

Page 3

1. SAFETY REGULATIONS

Welcome to the Outline World!

We suggest you take your time to reading this manual in order get to know this product in depth and

ensure you make the most of its use to guarantee

the correct mounting/dismantling of the system (as

a temporary or as a fixed installation).

Each rigging or derigging phase must be executed

by qualified staff in compliance with the general safety and prevention rules of your country and there

should be at least two operators, equipped with all

necessary personal protective equipment (PPE) and

valid occupational safety certificates in compliance

with local laws.

The staff must make sure that the following rules

are observed:

• all the necessary steps described in this manual are performed;

• for installation, the staff involved must know

and be familiar with the safety procedures to

follow in these situations;

• the integrity of the whole system must be

maintained and any defective component that

could compromise the safety must be discarded and replaced;

• nobody stays under the system, especially

when moving the clusters;

• respect the limits set for the mechanical parts

imposed by Outline “OpenArray2” software as

described in this manual;

• regular check up of the conditions and correct

operation of the mechanical parts.

Outline declines any and all responsibility for damage or faulty operation caused by using the system in a different way from that expressly forese-

en and specied

1.1. DISPOSAL OF WASTE MATERIALS

The product is designed and manufactured

with high quality materials and components,

which can be recycled and reused. When this

symbol of the crossed “wheelie” bin is attached to a product, it means that the product is covered by the European Directive 2012/19/EU and successive amendments. This means that the product

must NOT be disposed of with other household-type

waste.

1.2. CONFORMITY AND WARRANTY

All Outline electro-acoustic and electronic

devices are in conformity with the provisions of EC/EU directives (as stated in our

CE declaration of conformity).

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

Users are responsible for the disposal of their

electric and electronic equipment, consigning it

to an approved disposal facility. For further information on where it is possible to send equipment

for recycling, contact your local distributor. Correct

disposal of the old product will help to prevent potential negative consequences for the environment

and people’s health

The CE declaration of conformity is attached to the

product warranty certificate and is shipped with the

product.

3

www.outline.it

Page 4

2. COMPONENTS OVERVIEW

To perform all the rigging steps correctly, it is essential to know the components that make part of the sound

reinforcement system and their characteristics. These, in addition to the data provided by

that will be analyzed in chapter 3, will ensure compliance with all the established and certified parameters to

always guarantee public safety during the executive phases carried out by the authorized personnel.

2.1. LOAD CAPACITY

The whole structure (frame bar, single hardware

elements, locking pins etc.) to hang the array of

perfly /Mantas 28

a maximum load that is determined by the calculations made with OpenArray2 (for the arrays of Mantas 28, Superfly or both). It can be of help to remember the following maximum load capacity values:

enclosures is approved to support

Su-

OpenArray2

projects

• 24 x

• 16 x

DO NOT ABSOLUTELY exceed the limits imposed

by

OpenArray2

part of the project (chapter 3).

The weight distribution has been studied to be the

safest possible while respecting the load in relation

to the array’s center of gravity.

The above mentioned values refer to the total absence of lateral forces (strong wind for example).

In case these forces are present, it is necessary to

avoid any overload of the structure that could compromise its safety. It is highly recommended to use

special support means to keep the system still. In

case of potentially dangerous situations it is advisable to contact engineers and experts specialized

in suspended loads.

Mantas 28

Superfly

by adding other elements not making

………………. 576 kg (1270 lb)

………………….. 608 kg (1340 lb)

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

4

www.outline.it

Page 5

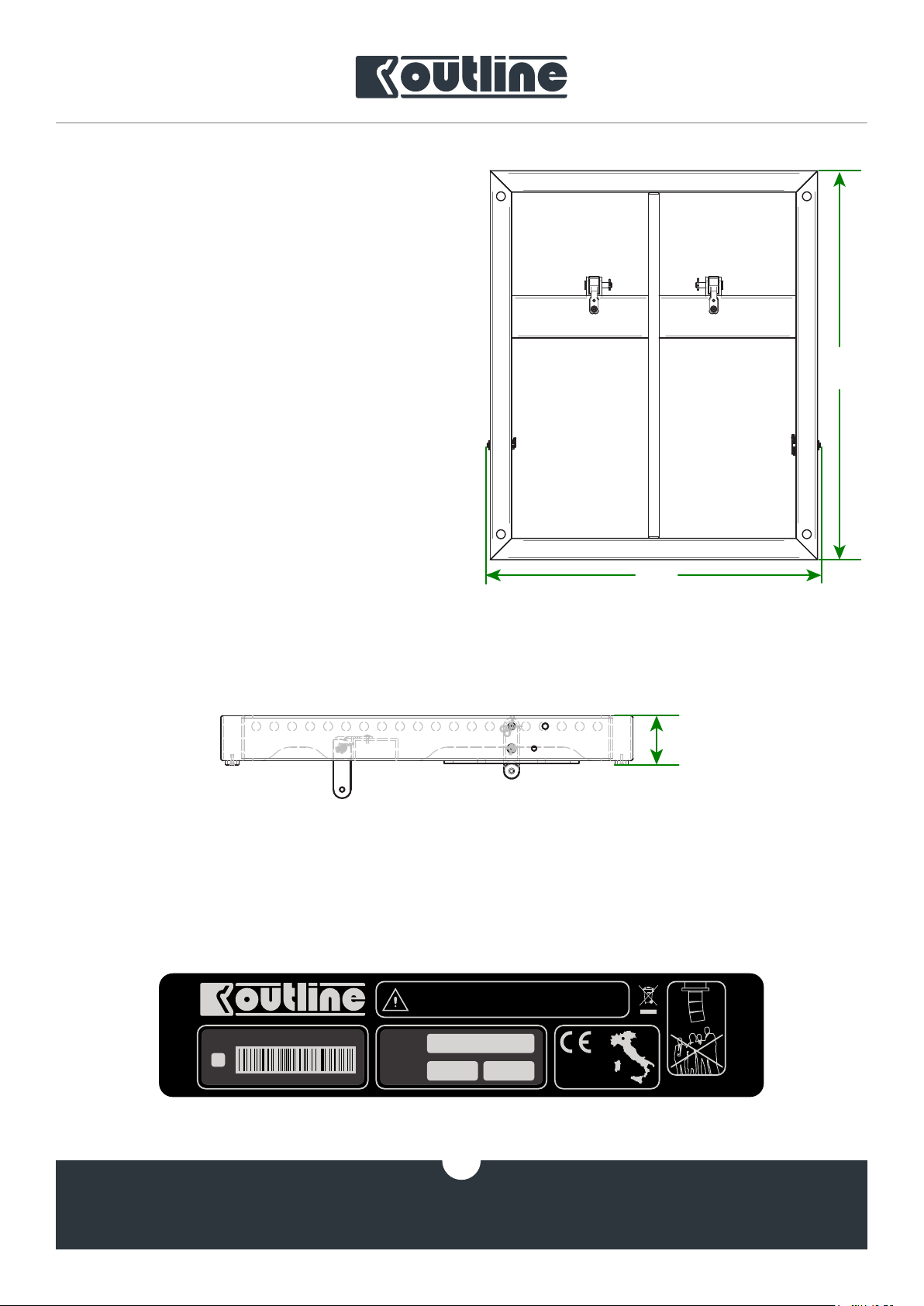

2.2. FRAME BAR SPECIFICATIONS

110

FRM1-AL630 Superfly/Mantas28

is a frame bar

approved and certified for these two line array elements that share the same integrated hardware.

Below you will find the specifications of the frame

bar:

• Weight…………………………….………………....... 28 kg

• Material.…………..... Ultra-resistant aluminium

• Width.......………………………………..………. 790 mm

• Length.....………………………………...……… 917 mm

• Height………………………………………..……. 110 mm

917

790

110

The maximum declared load is 630 kg, including the line array elements, their cables, spansets, shackles

and additional safety locks. It is necessary in any case to follow the parameters given in the chapter above and

respect the limits imposed by OpenArray2 in the design phase.

READ INSTRUCTIONS BEFORE USE.

DO NOT STAND OR WALK UNDER

THE SYSTEM WHEN IT IS FLOWN.

630 kg - 1388 lb

Designed and

manufactured

with pride in Italy

outline.it

SERIAL N°

TESTED

TESTED

MODEL: A FRM1-AL630

YEAR

S.N°: 000000000

CAUTION

MAX LOAD

MAX LOAD

WEIGHT

WEIGHT

21.5 kg 47.4 lb

5

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

www.outline.it

Page 6

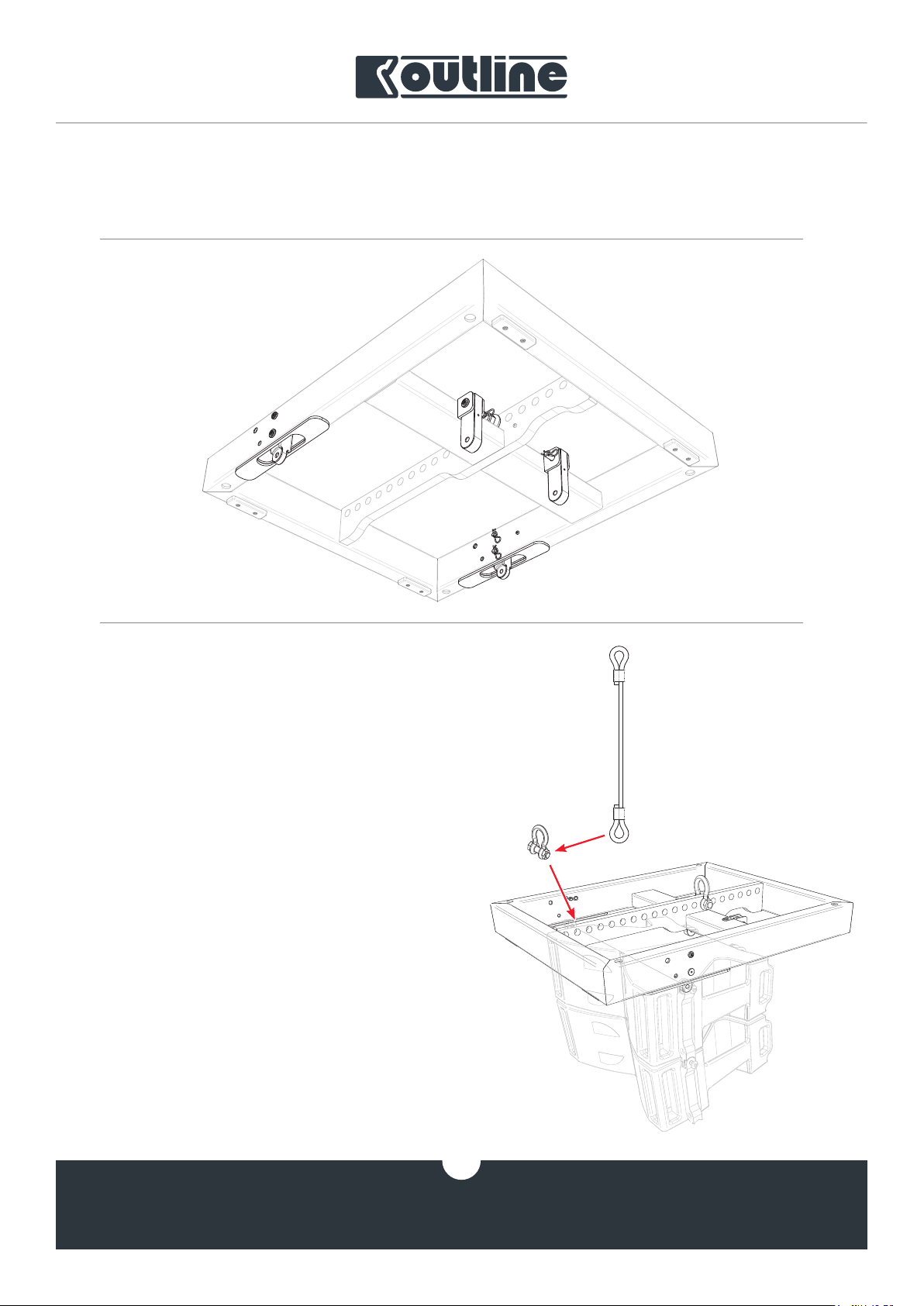

FRM1-AL630

is equipped with four solid rotatable hardware parts (two front and two rear ones), easy to

mount and fasten to the line array elements. Its load beam has 20 pick points for fastening the hoist(s), as

calculated by OpenArray2.

The shackle should be fastened to the pick point in-

dicated by the software.

In case common chain hoists are used, it coud be

of help to use a wire rope sling with thimbles to avoid

that the bag containing the chain leans upon the cluster causing chain lock or unwanted vertical displacement of the array.

It should be the authorized staff’s care to verify and

ensure the integrity and suitability of all additional rigging tools. Outline, besides providing advice, assumes

no responsibility for the choice of these tools. Furthermore, Outline considers itself unrelated to any

unauthorized modication of the mechanical parts

of the frame. Considering the high weights involved,

we remind you that these instruments must guarantee maximum safety under any circumstances (whith

their appropriate use as a necessary prerequisite).

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

6

www.outline.it

Page 7

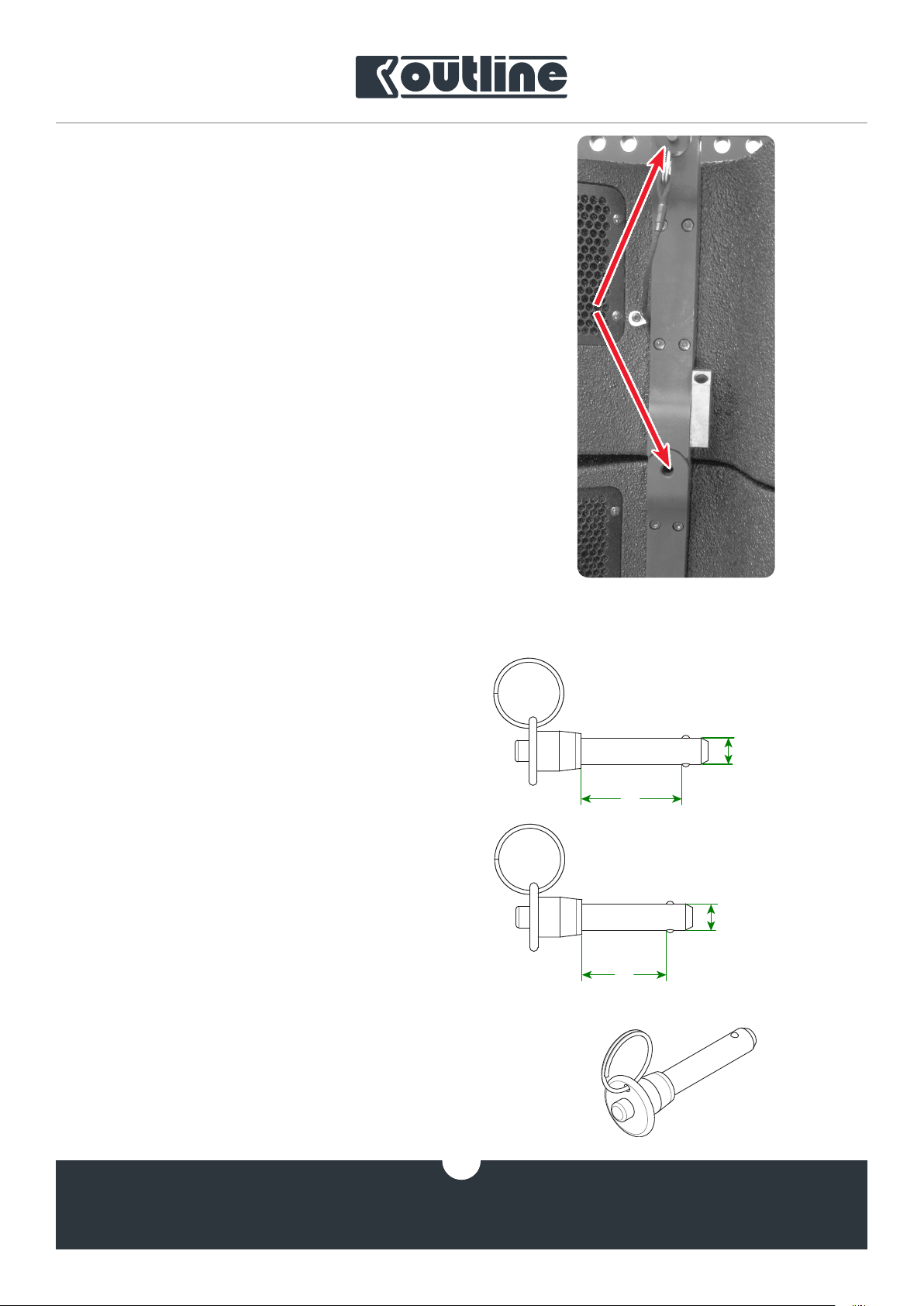

2.3. INTEGRATED HARDWARE OF LINE ARRAY ELEMENTS

Similar to the frame bar hardware, the

Mantas28

elements also have a simple but very effi-

Superfly /

cient hardware structure. These hardware elements

are made of ultra-light aluminium and are designed,

approved and certified to support the established loads.

The sliding bars, inserted in the rails on the back

of the cabinets, are easy to adjust and allow a vertical

inclination from 0 ° to 7.5 ° with 0.5 ° steps (with the

addition of the 0.25 ° angle) between the elements.

In the lower part (fig. 1) of each rail there are 4 holes

for locking pins corresponding to the “groups” of angles illustrated next to the rail.

This allows a very precise pointing choice which addresses any type of need. Further details on their use

in chapter 4.

In the upper part (figure 2), each rail receives the bar

of the previous element or of the frame bar, presenting a hole (“Default”) dedicated to all the selectable

degrees with the exception of the 0.25 ° angle, for which the dedicated hole (called “0.25 ° ONLY”) should be

used. For the connection to the frame bar the “Default” hole is used.

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

figure 1

figure 2

7

www.outline.it

Page 8

The front of the cabinet (figure 3) has non-adju-

36

9.5

30

stable hardware parts on both sides, complementary

to the rear ones.

The example in Figure 3 shows a first element fastened to the frame and a second element ready to

be fastened. Learn more about the various steps in

Chapter 4.

2.4. LOCKING PINS

The locking pins on the back and front of the cabinets are practical and convenient to use, guaranteeing

maximum safety.

They are made of ultra-resistant steel and once inserted into the lock point the whole body of the line

array element remains stable mantaining the chosen

pointing angle. The pins chosen for

tas 28

the longer ones (

are of two types and differ only in their length:

BLC6BA14S

the rear hardware parts, while the shorter ones (

C6BA12S

) have been chosen for the front hardware

parts.

All the pins are fixed to the cabinet by means of a

lanyard, to avoid their loss.

Superfly

and

Man-

) have been chosen for

BL-

36

figure 3

9.5

item nr. BLC6BA14S

9.5

The specifications of the locking pins:

• Weight………………….....………….……………… 30 / 40 g

• Material.....………….............. Ultra-resistant steel

• Diameter (body)...……………………………...... 9.5 mm

• Depth (body).........……………….………..... 30 / 36 mm

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

item nr. BLC6BA12S

8

www.outline.it

Page 9

2.5. HARDWARE INSPECTION

It is of utmost importance to periodically check the

integrity of the entire structure of the hardware both

of the line array elements and of the frame bar.

Being these components placed under stress by

heavy weights, different places of use, continuous

transportation and more, they can be subject to damage in the long term, despite the excellent quality of

the materials.

Here below you will find some precautions to follow, at the discretion of the authorized staff:

1. Make sure there is no rust in the hardware or

locking pins. In case of rust use suitable and

certified products for its removal. The rust

could be deposited by other oxidized elements or due to the oxidation of the element itself.

In the first case, the integrity of the component

must be checked after removing the rust; in the

second case, if the rust is only superficial, it can

be removed; if in removing it you notice that it

goes in depth you have to replace the element;

4. Free the mechanical parts and the holes of the

hardware from any dust or other residues. This

will allow the correct insertion of the pins and

the right positioning of the hardware.

The inscriptions indicating the degrees of inclination are engraved in the hardware. This prevents any

cancellation, but in case of excessive corrosion for

other reasons, Outline can provide, if deemed appropriate, a replacement part and assistance.

All the hardware components are designed in compliance with the safety regulations in force following

in-depth studies of the Outline R&D department and

subsequent certification by specialized engineers, in

compliance with the laws based on the EEC / EU directives (chap. 1.2).

2. Check that the sliding bar of the rear hardware part remains in its rail (not above the “Rest

point” upwards and not more than at 0.25°

downwards). Otherwise the hardware part is

to be considered dangerous for any type of use

and, therefore, is to be replaced;

3. Check that the locking pins close correctly,

which means that the two steel balls come out

completely outside the locking pin body. It is

important to ensure the immobility of the pins

in the locking points;

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

9

www.outline.it

Page 10

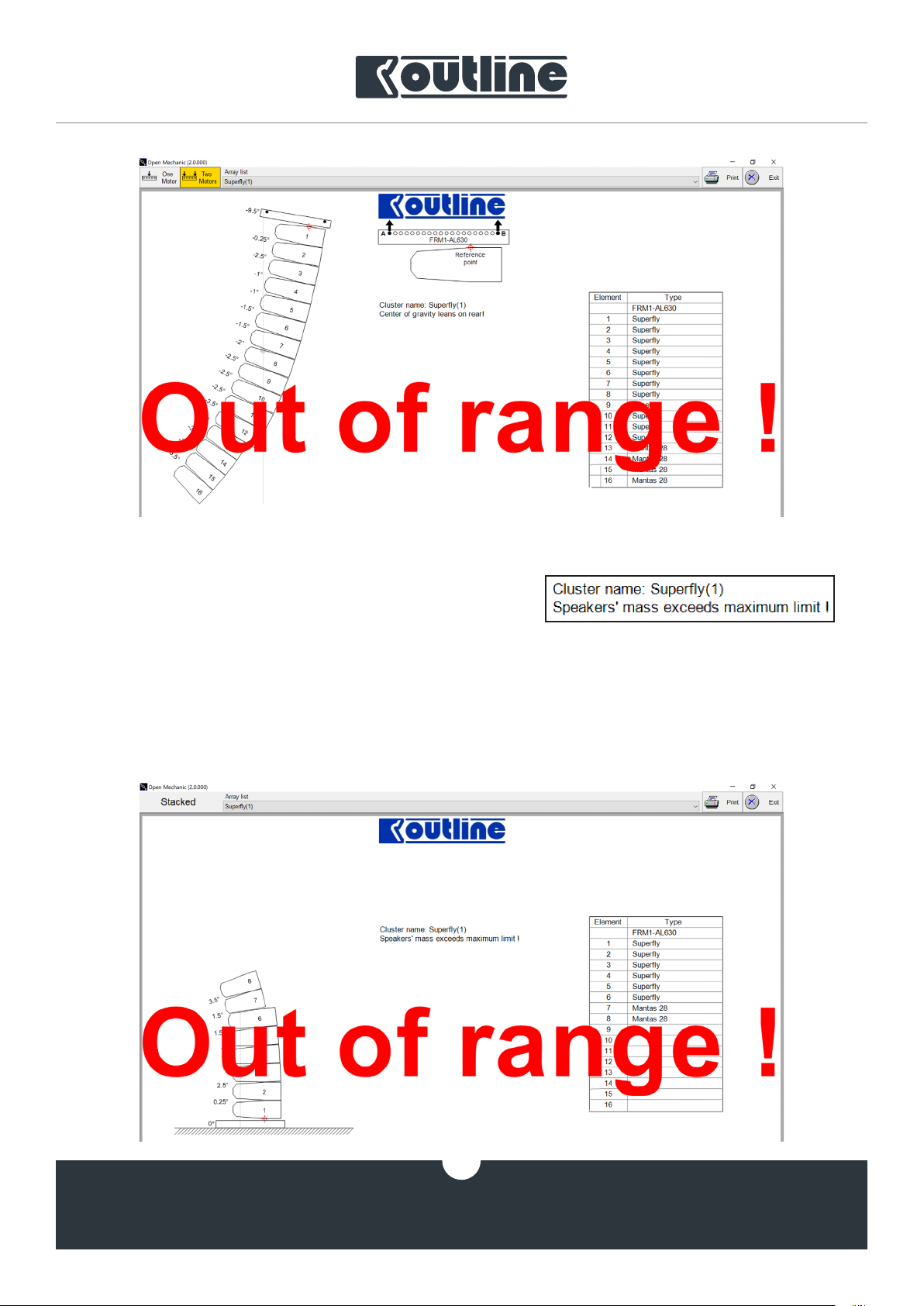

3. OPEN ARRAY 2 - PRE-RIGGING

OpenArray2

is a software which helps the system

engineer to calculate and establish a first relationship

between the sound system and the venue.

Given the potential of this software for acoustic forecasts and the possibilities of creating projects of various types (which are not covered by this manual), it

will be possible to know precisely if the configuration

is feasible in relation to the model and the number of

elements of the arrays used, to the inclination of the

clusters, motor coupling points and all the necessary

data for the PA man for a correct rigging in the field.

figure 4 figure 5

Some of the data regarding arrays vary based on

the use of one (figure 4) or two motors (figure 5). Logically the use of more motors guarantees greater maneuverability (during the rigging phases) and stability

of the array.

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

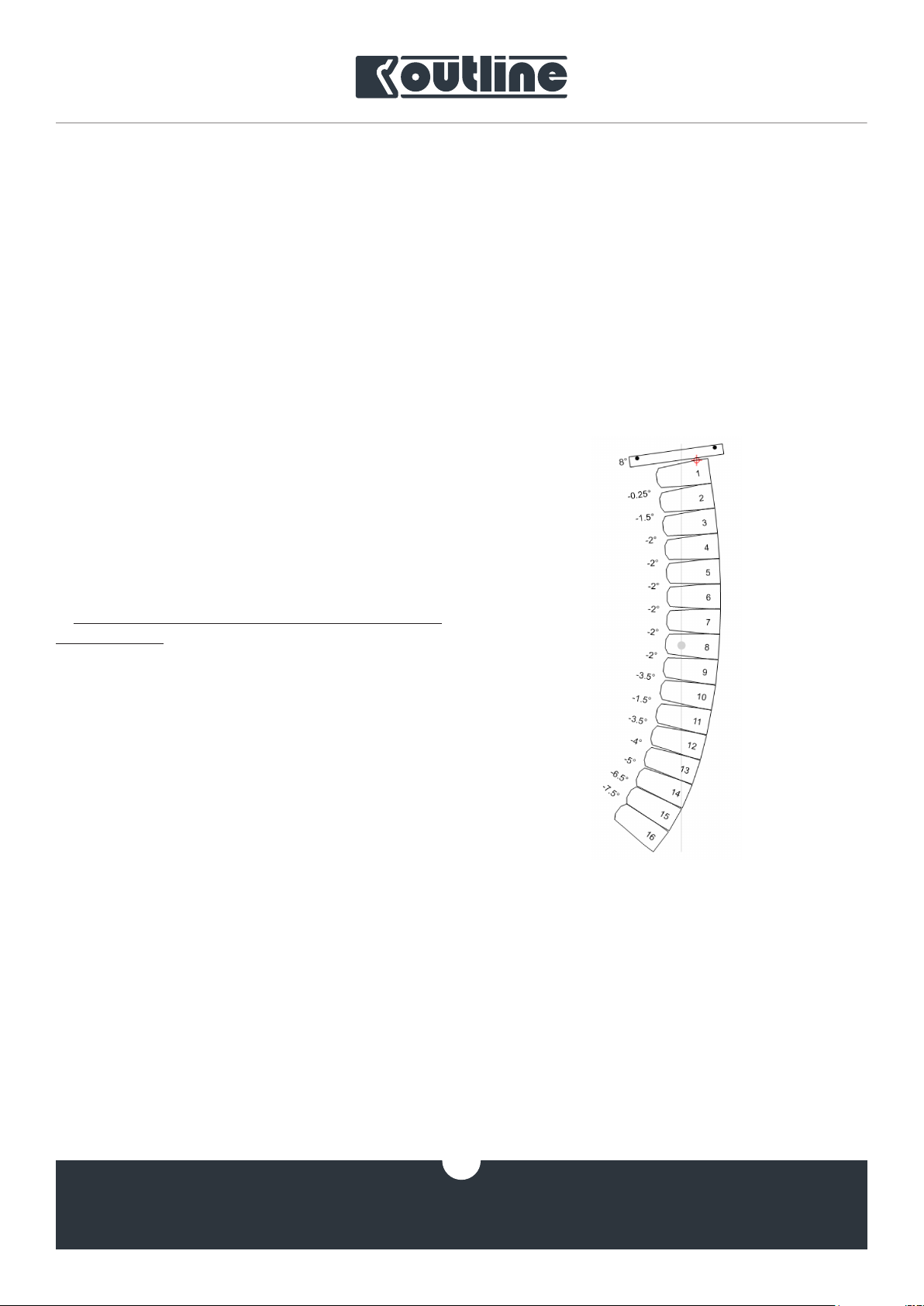

The angles selected for each element will be visible

in correspondence with the load bars in the relative

box on the OpenArray2 mechanic paper.

It is advisable to print and always carry the mechanic paper while doing the rigging.

10

www.outline.it

Page 11

figure 6

Attention! When the software indicates the array is

out of range (as in figures 6 and 7), it could be necessary to:

• reassess the overall inclination of the array in

case the center of gravity is out of range;

• remove some line array elements because the

maximum limit weight has been exceeded;

figure 7

• both of the above.

These cases can also occur with ground stack con-

figurations (figure 8).

figure 8

11

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

www.outline.it

Page 12

Based on what stated in chap. 2.1, as in the example in figure 9, when setting 16 Superfly elements in

the project the final weight of the array (array mass)

will be different from the declared 608 kg (1340 lb).

This happens because the software sums also the

weight of the frame and the approximate weight of

other elements, such as cables, spansets, inclinometers and other small accessories, to the array weight.

Once all these points have been cleared, we can

proceed to the rigging execution phase.

figure 9

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

12

www.outline.it

Page 13

4. RIGGING PROCEDURE

4.1. PREPARATION

Once the necessary motors have been arranged

according to the project and the elements are out of

their flightcases, it is possible to proceed with the rigging.

However, we suggest you follow the steps described below to do everything with ease.

4.1.1. SPLAY ANGLES

Pre-set the splay angles between the array elements in pairs, according to OpenArray2 project instructions, while still positioned on their trolleys:

1. unlock the sliding bars (figure 11);

figure 10

figure 11

2. position the sliding bars aligning the chosen

degree point with the marker (white line) on the

rails containing them (figures 12 - 13);

figure 12 figure 13

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

13

www.outline.it

Page 14

3. lock the bars with the locking pins using one of

the corresponding holes, according to the chosen degree (figure 14);

figure 14

4. align the bars with the rails of the next array

element and fasten them with the locking pin in

the “Default” position if you’ve chosen the degree value between 0° and 7.5°, or in the “0.25°

ONLY” position if the 0.25° value has been chosen (figures 2 and 15);

5. once the angles for each couple of line array

elements are ready and put in order in which

they are to be flown, it is possible to proceed

with the installation of the frame bar.

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

figure 15

14

www.outline.it

Page 15

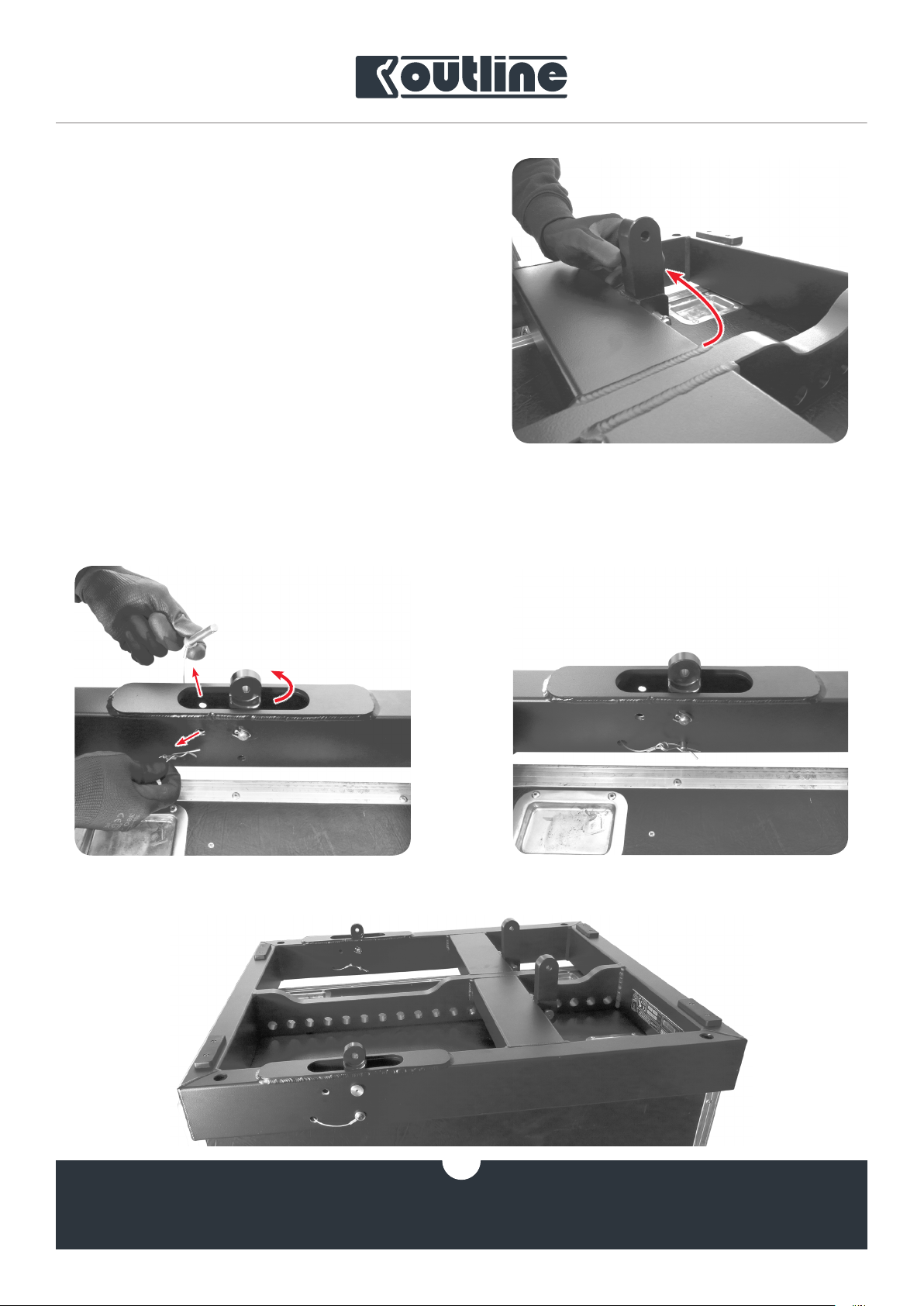

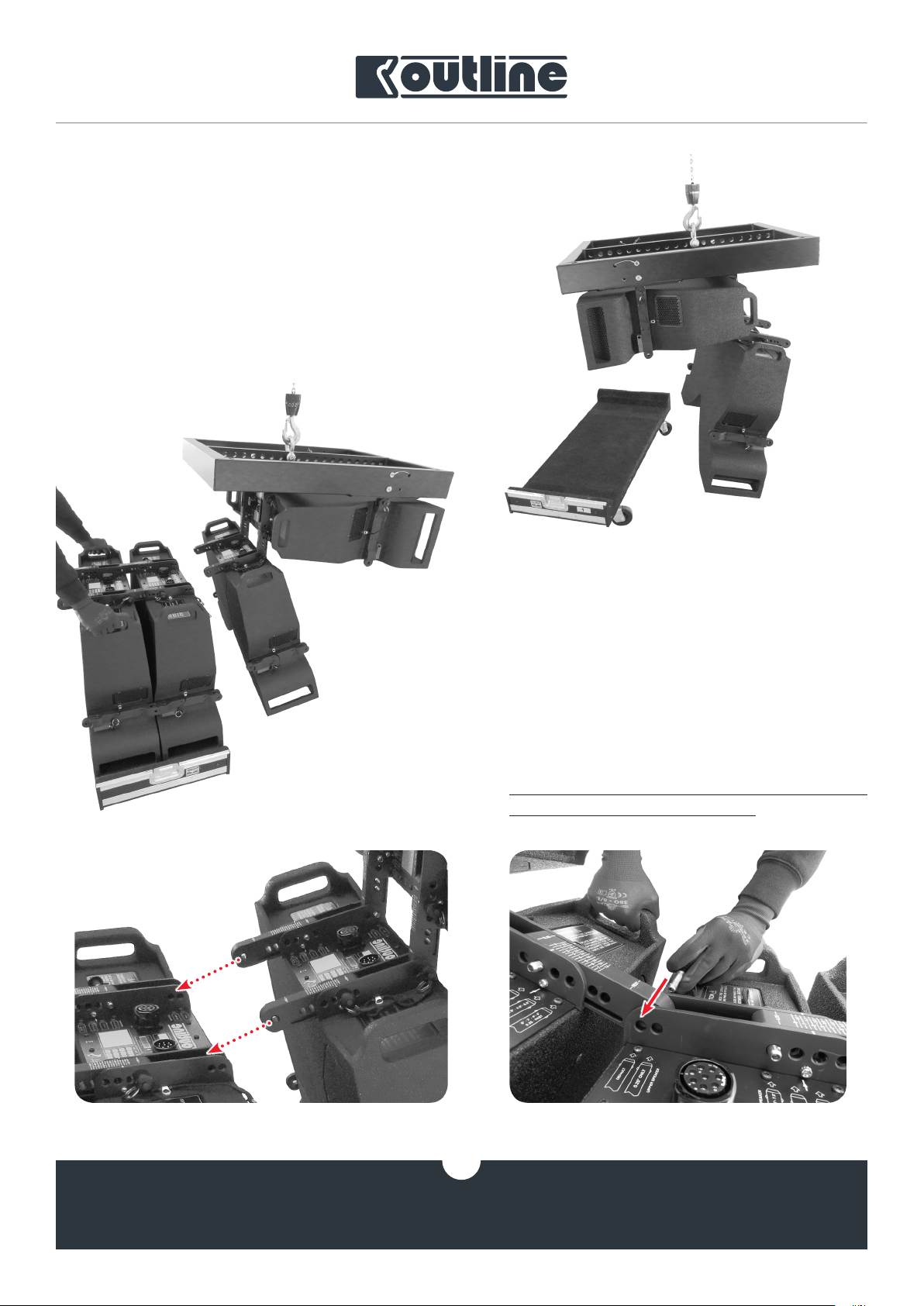

4.1.2. PREPARATION OF THE FRAME BAR

It is advisable to prepare the frame immediately to

be flown together with the first two elements of the

array, to make the job easier for the staff:

1. free the rear hardware parts of the frame by

simply lifting the movable bar that will be triggered, remaining stationary thanks to the automatic locking system (figure 16);

figure 16

2. remove the safety pins from the front locking

points and free the bar that will come out rotating by itself (figure 17);

3. reinsert the locking pin and its forelock to keep

the bar in place (figure 18);

figure 18figure 17

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

figure 19

15

www.outline.it

Page 16

4. align the rear hardware parts of the frame with

the rails of the fist line array element and lock

with the pins in the “Default” position. To simplify the procedure it could be of help to lift the

frame bar with one hand, keeping it steady with

a foot, and insert the pin with the other hand

(figure 20).

figure 20

5. perform the same procedure for the front hardware parts of the frame, helping yourself with

one hand to align the parts (figures 21 and 22);

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

6. fix the shackles to the motor coupling points as

calculated by

figure 21

figure 22 figure 23

OpenArray2

16

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

www.outline.it

(figure 23);

Page 17

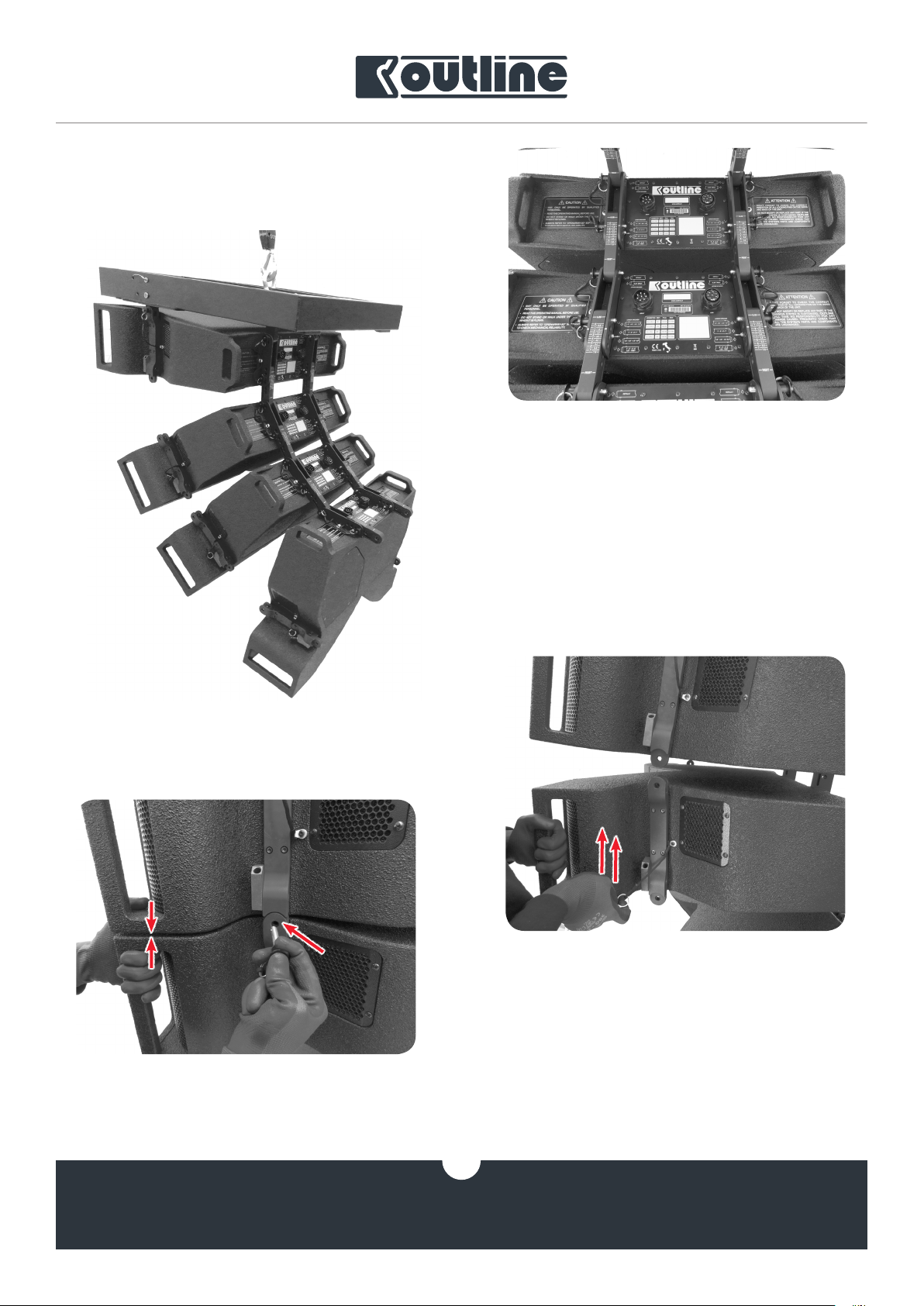

4.2. ASSEMBLING

Once the preparation phases have been completed, the array can be lifted starting with the first two

elements and then adding the remaining pairs, integrating any supplementary accessories (spansets,

cables, safety locks etc. - chap. 4.3):

1. lift the first two elements already fastened to

the frame and the hoist, keeping the front hardware parts of the second element free (this

will make the following step easier - figure 24);

figure 24

figure 25

2. align (figures 25 and 26) and fasten (figure 27)

the rear hardware parts of the last hanging

element to those of the first element of the following couple, holding the element by its handles to keep the array in place;

All these procedures are to be performed in the

presence of at least two persons.

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

figure 26 figure 27

17

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

www.outline.it

Page 18

3. using the hoist(s), lift the array from the trolley at a suitable height to simplify the following

procedure (figure 29);

figure 28

4. at this point, fasten the front hardware parts

of the first three elements that are now flown.

Help yourself with both hands to lift the element as shown in figure 30, to be able to insert

the locking pin in the hole (figure 31). Leave out

the front hardware parts of the last element (figure 32).

figure 29

figure 31

figure 30

18

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

www.outline.it

Page 19

4.3. INTERMEDIATE PHASE

When the first four elements are flown, before continuing it could be necessary to add the following accessories:

1. a spanset for rigging the cables (with a shackle

or simply knotting it to the frame) (figure 33);

2. a security rope attached with a shackle, keep

ing some distance from the hoist coupling

shackle (figura 33);

3. if used, an inclinometer to be applied to the

front part of the frame, centered respect to the

array’s axis and fixed steadily;

figure 33

4.3.1. RIGGING THE CABLES

After having attached the spanset as described

above, depending on the quantity of the line array elements, arrange the cables as follows:

1. pass the first cable through the spanset knot

and plug it into the first element (figure 34);

2. plug the three link cables;

3. prepare the other cables to pass them through

the spanset at the length approximately equal

to the distance from the fifth (and ninth) element

4. pass through the spanset the remaining cables

of the chain hoist(s), inclinometer and others

5. moderately tighten the knot of the spanset to

keep everything in place

Attention: it is advisable to leave the right length

of the cables to prevent them from being tightened

excessively.

figure 32

figure 34

In case only one chain hoist is used, the cables

influence the array’s inclination depending on their

overall weight (and consequently on their height from

the ground). It is advisable to consider these variables

and compensate them, if possible.

19

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

www.outline.it

Page 20

4.4. FINAL PHASE

Proceed with flying the remaining elements till you

complete the array, making sure that all the locking

pins are positioned correctly.

The last steps to follow are:

1. tie the cables together to create a well-ordered

bundle as the array goes up;

2. once reached the necessary height, fix the array

with the ropes to regulate the vertical and horizontal inclination according to the project;

3. fix the safety lock if used.

The same steps, with the only difference in the audio connector on the rear panel of the loudspeaker,

are to be followed both for Superfly and for Mantas 28.

The total compatibility between their hardware parts (figure 35) allows different configurations as long

as they are approved by OpenArray2 project.

figure 35

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

figure 36

20

www.outline.it

Page 21

4.5. DERIGGING

For the reverse process the steps to follow are

exactly the opposite to those just described.

After removing the ropes and the secure lock, when

starting to lower the array, it can be useful to consider

the following points:

1. place the trolleys under the array so that the

elements can be put on them in couples and remove the locking pins from the front hardware

parts of the last three elements, maintaining

the rear pins in their position (figure 37);

2. continue to lower the array with the hoists and

use the handles to couple the elements with the

trolley (figure 38);

3. when the first two elements are on the trolley,

release the rear pins of the second element,

with the third element still hanging (figure 39);

4. repeat the procedure for each couple of elements, unplugging the cables and removing

any other accessory;

5. uncouple the frame bar from the chain hoists

together with the last two array elements and

remove the locking pins.

It is highly recommended to put the hardware both

of the frame bar and of the line array element in the

“REST” position before closing the flight cases to preserve their integrity during transport.

figure 37

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

figure 38 figure 39

21

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

www.outline.it

Page 22

4.6. GROUND STACK CONFIGURATION

For a stack array configuration it is necessary to

follow a procedure where the frame bar and the array

elements are literally upside down and their maneuverability is reduced. Always keeping in mind the indications given by the OpenArray2 software, proceed

as follows:

1. prepare the frame bar with the released hardware and looking upwards (figure 40);

figure 40

figure 41

3. posizionare il frame montato a terra, predisponendo il puntamento orizzontale prima di collocare qualsiasi elemento che ne renderebbe

difficile lo spostamento (figura 43);

2. insert the “foot 01” accessory (figure 41) in the

rear holes (figure 42) and adjust its height. In

case the chosen element is

Mantas 28

, it will

be however possible to choose both positions

for the feet (front and rear). It is not possible to

choose the front position when using

Superfly

(the first element should be aimed downwards).

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

figure 43

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

figure 42

22

www.outline.it

Page 23

4. mount the element upon the frame upside

down (180°) to have the rear hardware looking

upwards;

5. secure the front hardware parts and then the

rear ones, remembering that the whole procedure will be the same but to be done on the

contrary (figure 44). This means that it will be

possible to choose the inclination once the element has been stacked and the front hardware has been locked (the higher the grade, the

higher will be the inclination of the upper element) (figure 45);

figure 44

6. repeat the procedure for all the elements according to the

OpenArray2

project, while also

doing the cabling (figure 46);

figure 45

7. perform the disassembly exactly on the contrary respect to the assembly procedure.

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

figure 46

23

www.outline.it

Page 24

5. TRANSPORT AND STORAGE

When transporting the system it is advisable:

• to move the elements couples as shown in figure 48 to avoid accidents (figure 47)

• although resistant, avoid placing any excessive

loads on the closed flight cases containing the

array elements;

• to lock the loads in the chosen means of transport.

Once in the warehouse, store your

Mantas 28

in their flight cases, keep them in covered

Superfly

and

and not very humid places, away from heat sources.

figure 47

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

figure 48

24

www.outline.it

Page 25

NOTES

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

25

www.outline.it

Page 26

NOTES

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

26

www.outline.it

Page 27

NOTES

OUTLINE S.R.L.

Via Leonardo da Vinci, 56

25020 Flero (Brescia) Italy

Tel.: +39 030.3581341

Fax +39 030.3580431

info@outline.it

27

www.outline.it

Page 28

Outline carries out on-going research for product improvement. New materials, manufacturing methods

and design upgrades are introduced to existing products without prior notice as a routine result of this philosophy. For this reason, any current Outline product may differ is some aspect from its description, but will

always equal or exceed the original design specifications unless otherwise stated.

© Outline 2019

Operating manual product code: Z RMSUPERFLY-MANTAS28

Release: 20190326

Printed in Italy

Loading...

Loading...