Page 1

Board Replacement Inst ructions for

FLEXmax Charge Controllers

Including Control Board, Button Board,

Power Board, and FLEXmax 60 Fan

Page 2

About OutBack Power Systems

Out Back Power Systems is a leader in advanced energy conversion technology. Our products include

true sine wave inverter/chargers, maximum power point tracking ch arg e con t ro ll ers, syst em

communi cat i on co m p onen t s, as wel l as b r eaker panel s, b r eakers, accessor ies, an d assem bl ed syst em s.

Contact Information

Tel ep hon e: +1.360.435.6030 (Nort h America)

+1.360.618.4363 (Technical Support)

+1.360.435.6019 (Fax)

Address: North America

19009 62nd Avenue NE

Arlington, WA USA

E-mail: Support@outbackpower.com

Web Site: www.outbackpower.com

+34.93.654.9568 (Barcelona, Spain)

Disclaimer

U N L ESS SPEC I F I CA L L Y A GREED TO I N W RI T I N G, O U TB A CK PO W ER SYST EM S:

( a ) M A K ES N O W A RRA N T Y A S T O TH E A CC U RA CY , SU FF I CI EN CY O R SU I T A BILITY OF ANY TECHNICAL

OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT, INDIRECT,

CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE

USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Notice of Copyright

Board Replacement Instruct ions for FLEXmax Charge Cont rollers © December 2009 by Out Back Power

Syst em s. Al l Rig ht s Reserv ed .

Trademarks

Out Back Power is a register ed t rademark of Out Back Power Systems.

Dat e and Rev i si on

December 2009, Revision A

Part Number

900-0054-01-00 Rev A

Page 3

Important Safety Instructions

READ AND SAVE THESE INSTRUCTI ONS!

This manual contains important safety instructions for replacing parts on the FLEXmax Series Charge

Cont rollers. Read all instruct i ons and caut ionary markings on t he FLEXmax Series Charge Cont roll ers

and on any accessories or addit i onal equipment included in t he installat ion. Failure t o adhere t o t hese

instruct ions could resul t in severe shock or possible electrocut ion. Exercise extreme caution at all

times to prevent accidents.

Sy m b o l s Used

Sy m bo l De scr i p t i o n

Ground

AC Current

DC Current

Single-Phase

Si n e W a v e

WA RNING: Hazar d t o Hu m an Li f e

This type of n ot at ion i ndicates that t he hazard coul d be harmful to human l ife.

CAUTION: Hazar d t o Eq ui pm en t

This type of n ot at ion i ndicates that t he hazard may cause damage t o t he equi pment.

IM PORTANT:

This type of notation indicates that the information provided is i mp ort an t t o

the installation, op eration and/or maint enance of the equip ment . Fail ure t o

follow the recommendations in such a notation could result in voiding the

equipm ent warrant y.

Audience

These instruct ions are f or use by qualified person nel w ho meet all local and governmental code

requirements for licensing and training for the installation of elect rical power systems wit h AC and DC

volt age up to 600 volts.

900-0054-01-00 Rev A 1

Page 4

Important Safety Instructions

Definit ions

Tab le 1 Ter ms and Acr onyms

Acronym Definition

But ton Board Flat board containing the push-buttons and LCD.

Control Board Narrow circuit board containing the unit’s programming.

FET

LCD

Power Board Large circuit board containing the unit’s power-switching circuitry.

PV

ield Effect Tran sistor. The FETs used f or p o w er swit ch i n g in t he FLEXmax are

F

classified as MOSFETs (Met al-Oxide-Semiconductor Field-Effect Transistors).

iquid-Crystal Displ ay; refers to t he FLEXmax d at a readout .

L

hotovoltaic; refers to the photovoltaic panels or modules used with the FLEXmax.

P

Per sonal Saf et y

WARNING: Personal Injury

Use standard safety equi pment such as safet y glasses, ear protection, steel-toed

safet y boots, safet y hard hat s, et c. as prescri bed by t he Occup ational Safety and

Healt h Associat i on (or other l ocal cod es) when w orkin g on t his equip ment.

Use standard safety pract ices when working with elect rical equi pment (e.g., rem ove

all jewelry, use insulated tools, wear cotton clothing, etc.)

Never wor k alo ne when i nstalli ng or servicin g t his equ ipment . Have someone

nearby that can come to your aid if necessary.

PV Saf et y

WARNING: Shock Hazar d

Phot ovolt aic (PV) arrays can be energized wit h minim al ambient light available.

Theref ore t o ensure a safe disconnect from t he system, be sure t o inst all a PV disconnect ,

breaker, or accessible f use box (dep endi ng on l ocal code requirement s).

CAUTION: Equ i p men t Dam ag e

PV Arrays must be wired with correct polarity (positive-to-positive, negative-tonegative). Connecting the cables incorrectly can damage or dest roy t he equi p ment .

2 900-0054-01-00 Rev A

Page 5

Eq u i p m en t Sa f et y

CAUTION: Equ ip men t Dam ag e f r om St at i c Di sch ar ge

A static-safeguarded workspace should be used to preserve the FLEXmax controller’s

static-sensitive components during the removal and installation procedure. This

includes grounding yourself and your workspace t o remove any possi bl e st at i c c har ge .

Practices that will help avoid static include standing on a concret e flo or, preferably on a

rubber flo or m at , doin g t he repai rs on a met al w orkbench, an d avoiding static-causing

synthetic clothing.

WA RNING: Let h al Vol t ag e

Review the system configuration to identify all sources of energy. (PV arrays can be

energized with minimal ambient light available.) Ensure ALL sources of power are

disconnected before performing any installation or maintenance on this equipment.

Confirm that t he terminals are de-energi zed using a vali d at ed volt met er (rat ed for a

minimum 1000 Vac and 1000 Vdc) to verify the de-energized condi tion.

WARNING: Burn Hazard

Int ernal p art s can becom e h ot dur ing o p eration . Do not remove the cover during

op erat i on o r t ouch any int ernal part s. Be sure to all ow t hem sufficient time to cool down

before at tem p t ing t o performance any main t enance.

Important Safety Instructions

WA RNING: Fi re Hazar d

Do n ot place combust ible or f lammab l e mat erials wit hin 12 feet (3.7 m) of

the equip ment.

Use only t he recom mended cabl e sizes (or g reat er) for AC and DC conductors in

compliance with local codes. Ensure all conductors are in good condition. Do not

operate the unit with damaged or substandard cabling.

CAUTION: Equ i p men t Dam ag e

Do n ot perform any servicin g ot her t han t hat speci fied in t hese instructions unless

qu alified t o do so and have b een instruct ed t o do so b y OutBack Power Syst em s

Technical Support personnel.

On ly u se co mp on ent s o r accesso ri es r ecom men de d o r sol d by Ou t Back Power

Systems or its authorized agents.

Thoroughly inspect the equipment prior to energizing. Verify t hat no tools or

equipment have been inadvertently left behind.

Ensur e cl earance requi rements are st rict l y enf orced and t hat all vents are clear of

obstructions that can prevent proper airflow around or through the unit.

900-0054-01-00 Rev A 3

Page 6

Important Safety Instructions

This page intentionally left blank.

4 900-0054-01-00 Rev A

Page 7

Table of Contents

Important Safety Instructions ........................................................................1

Symbols Used ........................................................................................................................................................................1

Audience .................................................................................................................................................................................1

Defi n i tions...............................................................................................................................................................................2

Personal Safet y......................................................................................................................................................................2

General Safet y .......................................................................................................................................................................2

Eq uipmen t Saf ety .................................................................................................................................................................3

PV Safety ......................................................................................................................Error! Bookmark not defined.

Introduction.................................................................................................7

Overview ..................................................................................................................................................................................7

Tools Required.......................................................................................................................................................................8

Prelimi n ary ..............................................................................................................................................................................8

Summary List of Instruct i ons.............................................................................................................................................................8

FLEXmax Charge Controller Disassembly........................................................9

Removi ng t he FLEXmax 80 Fan Cable ..........................................................................................................................9

Removi ng Chassis Screw s.............................................................................................................................................. 10

Removi n g t he Heat Sink ................................................................................................................................................. 11

Removi ng t he FET Bar...................................................................................................................................................... 12

Separat i ng t he Heat Sink from t h e Power Board ...................................................................................................14

Fan and Button Board .................................................................................17

Replacing t he FLEXmax 60 Fan .................................................................................................................................... 17

Removing t he Fan...............................................................................................................................................................................17

Replacing the Fan ...............................................................................................................................................................................17

Fan Test Proced ures ......................................................................................................................................................... 18

Replacing t he But t on Board .......................................................................................................................................... 19

Control Board and Power Board...................................................................23

Removi ng t he Con t rol Board ........................................................................................................................................ 23

Replacing t he Cont rol Board or Pow er Board .........................................................................................................24

Reassembly................................................................................................27

Reseating t he Cont rol or Power Boar d ...................................................................................................................... 27

Reconnect ing t he Heat Sink t o t he Pow er Board .................................................................................................. 28

Reconnect ing t he Heat Sink t o t he Chassis .............................................................................................................30

Reinstalli n g FLEXmax 80 Fan Plug .............................................................................................................................. 31

Syst em Funct ional Test ................................................................................................................................................... 32

Li st of Figu r es

Fi g ur e 1 Component s ........................................................................................................................................................7

Fi g ur e 2 Charg e Cont roller “ At Rest” ............................................................................................................................8

Fi g ur e 3 Removi n g Fan Cover .........................................................................................................................................9

900-0054-01-00 Rev A 5

Page 8

Tab le of Cont en t s

Fi g ur e 4 Removi ng Cable Jack........................................................................................................................................9

Fi g ur e 5 Back Screw Removal ...................................................................................................................................... 10

Fi g ur e 6 Si de Screw Removal (part 1)........................................................................................................................ 10

Fi g ur e 7 Si de Screw Removal (part 2)........................................................................................................................ 10

Fi g ur e 8 Heat Sink Removal........................................................................................................................................... 11

Fi g ur e 9 FET Bar Screw Removal ................................................................................................................................. 12

Fi g ur e 10 FET Bar Removal .............................................................................................................................................. 12

Fi g ur e 11 Freei n g t he FET from t he Insul at or .......................................................................................................... 13

Fi g ur e 12 Freei n g t he FET wit h Pli ers .......................................................................................................................... 13

Fi g ur e 13 Bot tom/ Crad l e Screw Remo val .................................................................................................................. 14

Fi g ur e 14 Removi ng Remaini n g Screw s..................................................................................................................... 14

Fi g ur e 15 Heat Sink Removal .......................................................................................................................................... 15

Fi g ur e 16 Heat Sink Connect ed t o Power Board ..................................................................................................... 15

Fi g ur e 17 Cable Removal ................................................................................................................................................. 16

Fi g ur e 18 Power Board - Top View ............................................................................................................................... 16

Fi g ur e 19 Fan Removal ..................................................................................................................................................... 17

Fi g ur e 20 Fan Replacem ent ............................................................................................................................................ 17

Fi g ur e 21 Fan Test Proced ure......................................................................................................................................... 18

Fi g ur e 22 Locati n g t he But t on Board .......................................................................................................................... 19

Figure 23 Disconnect ing t he Fan .................................................................................................................................. 19

Fi g ur e 24 Exposing the Button Board Mounting Peg............................................................................................ 20

Fi g ur e 25 Grippi ng t he Push-nut .................................................................................................................................. 20

Fi g ur e 26 Deforming t he Push-nut .............................................................................................................................. 21

Fi g ur e 27 Removi ng Push-nut ....................................................................................................................................... 21

Fi g ur e 28 Removi n g t he But t on Board ....................................................................................................................... 21

Fi g ur e 29 Insert i ng t he New But ton Board ................................................................................................................ 22

Fi g ur e 30 Insert i ng New Pu sh-nu t ................................................................................................................................ 22

Fi g ur e 31 Reconnect ing t he Fan ................................................................................................................................... 22

Fi g ur e 32 Lift ing t he Induct or Wires ............................................................................................................................ 23

Fi g ur e 33 Sl iding t he Cont rol Board Out .................................................................................................................... 23

Fi g ur e 34 Bent Pi n on Cont rol Board ........................................................................................................................... 24

Fi g ur e 35 Insert i ng Cont rol Board ................................................................................................................................ 24

Fi g ur e 36 Pins and Con nectors...................................................................................................................................... 24

Fi g ur e 37 FETs and Sil-Pad Insul ator on Heat Sink.................................................................................................. 25

Fi g ur e 38 Reseating Cont rol Board .............................................................................................................................. 27

Fi g ur e 39 Placing Induct or Wires.................................................................................................................................. 27

Fi g ur e 40 Reinstalli n g Ri b bon Cabl e ............................................................................................................................ 28

Fi g ur e 41 Gent ly Pull i ng On Rib bon Cabl e................................................................................................................ 28

Fi g ur e 42 Inst al l ing an d Tight ening Screw s.............................................................................................................. 28

Fi g ur e 43 Aligni ng FETs and Installing t he FET Bar................................................................................................. 29

Fi g ur e 44 Inst al l ing FET Bar Screws .............................................................................................................................. 29

Fi g ur e 45 Reinstalli ng t he Heat Sink onto t he Chassis .......................................................................................... 30

Fi g ur e 46 Replacing t he Chassis Scr ews..................................................................................................................... 30

Fi g ur e 47 Reinstalli n g Cable Jack.................................................................................................................................. 31

Fi g ur e 48 Reinstalli n g Cable Plu g ................................................................................................................................. 31

Fi g ur e 49 Fan Cover ........................................................................................................................................................... 31

6 900-0054-01-00 Rev A

Page 9

Introduction

Overview

This step-by-step guide illustrates the replacement of the Control Board, Power Board and Button Board

for all FLEXmax Series Charge Controllers. It also illustrates t h e r ep lacement of t he Fan for FLEXmax 60

charg e cont rollers only. It does not cover replacing the f an in a FLEXmax 80 charge controller.

A static-safeguarded workspace should be used to preserve the FLEXmax controller’s static-sensitive

compon ent s during t he removal and i n st al l at ion procedure. See the sect ion t it led Equipment Safet y on

page 3 for more speci f ic i nstruct ions.

Please review this guide and familiarize yourself with the complete repair procedure. OutBack technical

support is also available at

CAUTION: Equ ip men t Dam ag e

This procedure involves sensitive electronics which must be handled gently

and carefully during removal and installation. Applying excess force can

damage the components and cause the FLEXmax controller to malfunction.

(360) 618-4363

or

support@outbackpower.com

.

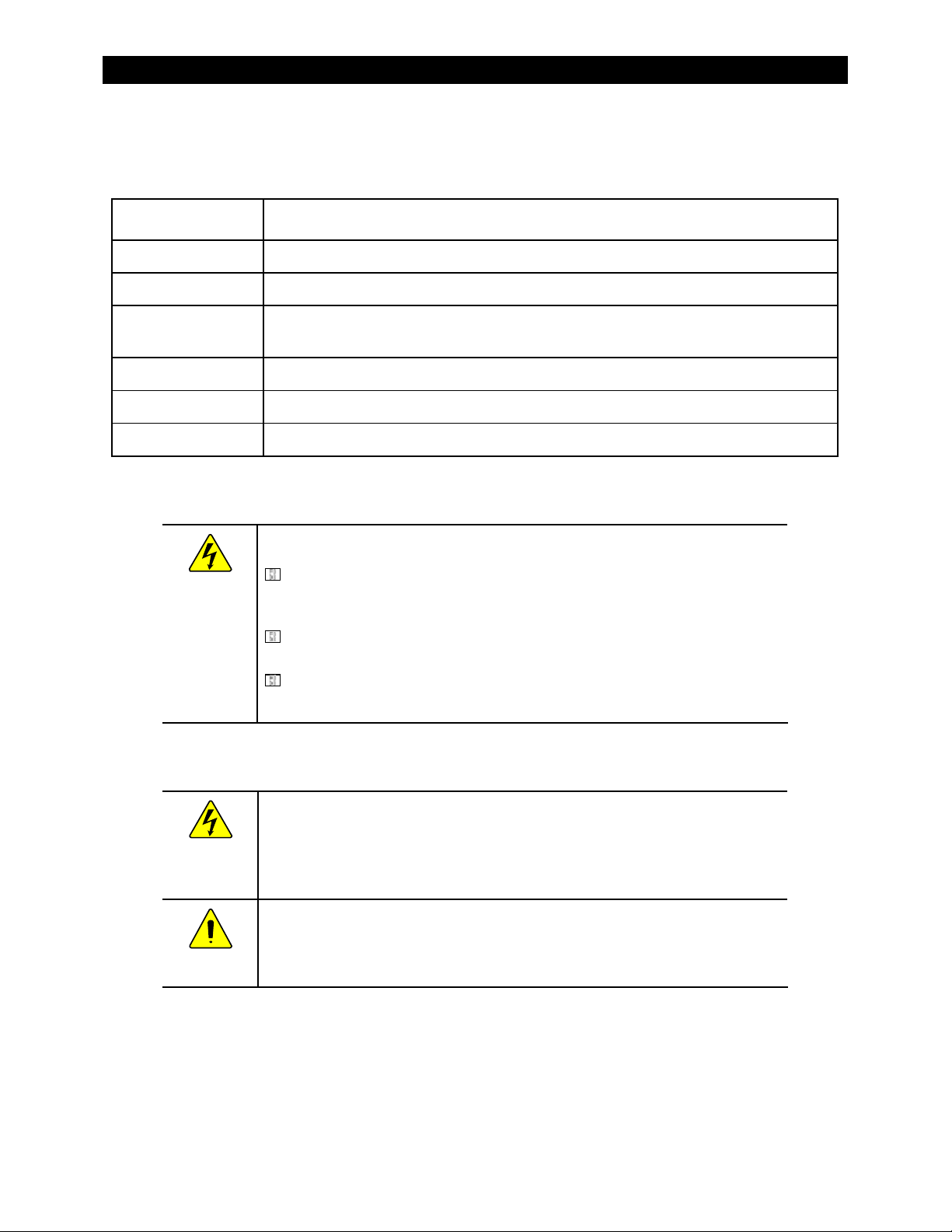

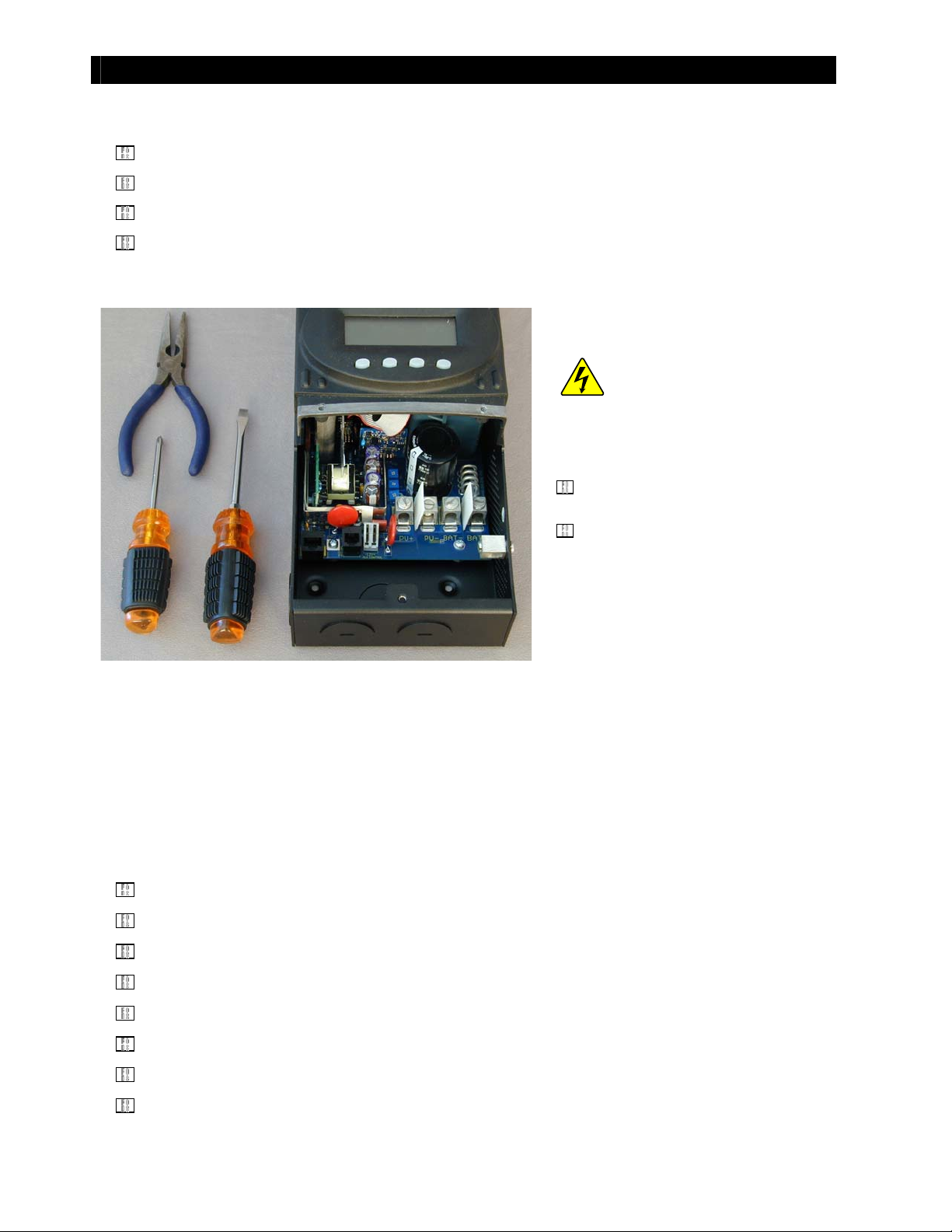

But t on Boar d

(front )

Power Boar d

Cont rol Board

Power Boar d

(back)

Figure 1 Components

900-0054-01-00 Rev A 7

Page 10

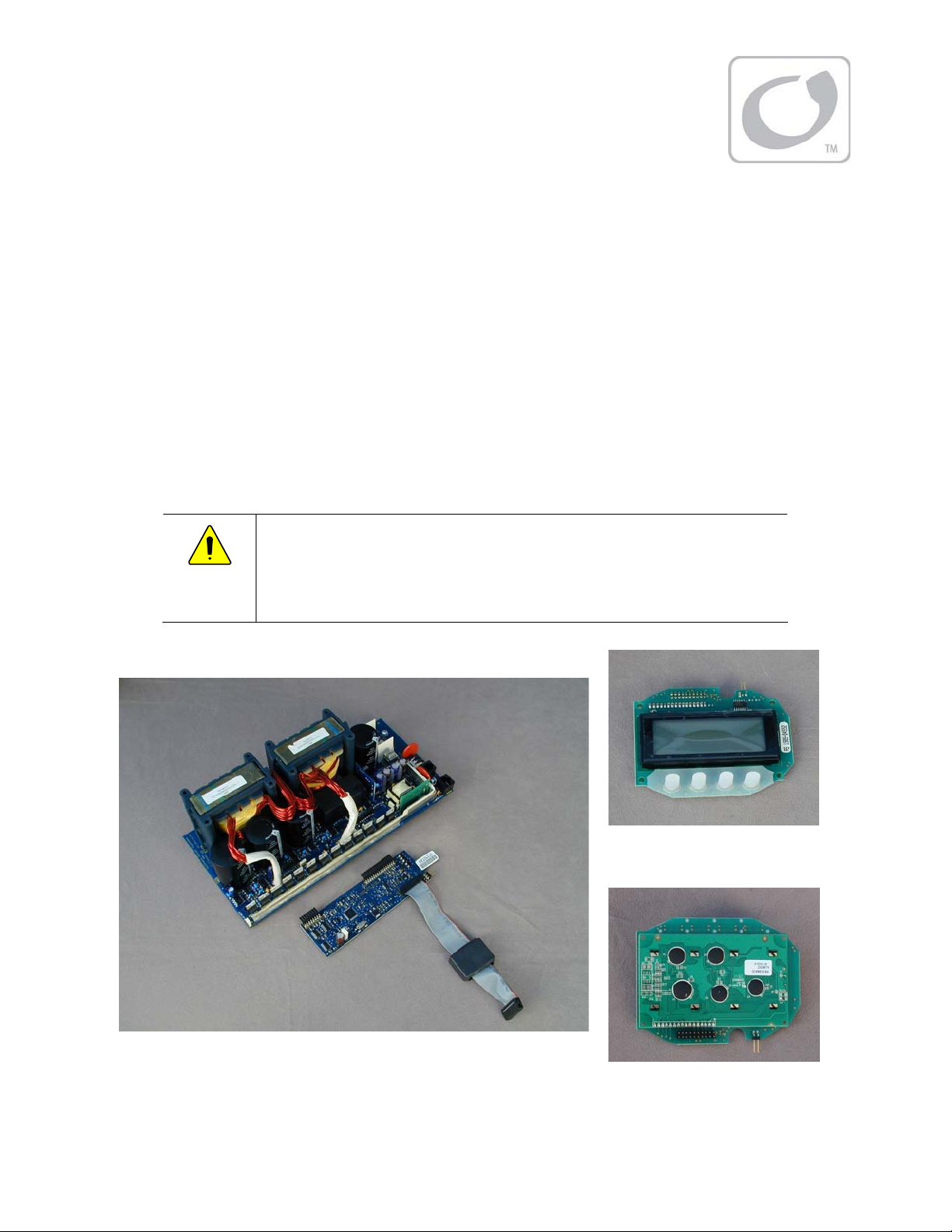

Tools Requi r ed

Phillips Screwdriver

Fl at Scr ew d r i ve r

Long-Nose Pli er s

Diagonal Wire Cutters (not shown)

Preliminary

Introduction

WARNING: Shock Hazar d

If the unit has been in use, power can

still be present even after the unit has

been disconnect ed.

Remove all electrical connections

fro m t he FLEXmax cont roller.

Allow the cont rol ler to “ rest” for

approximately ten minutes to fully

di scharge t he PV inp ut capacit ors.

Figure 2 Charge Controller “ At Rest”

: As many as 33 screws may be removed duri n g t his proced ure. Be sure to put them aside in t he

NOTE

order they are removed.

Summary List of Instructions

The following is a list of the instructions that are included in this document.

For instructions for

For instructions for

For instructions for

For instructions for

For instructions for

For instructions for

For instructions for

For instructions for

Removing the FLEXmax 80 Fan Cable

Di sassem b li ng t he Chassi s

Removing the Heat Sink

Rem ov in g t h e FET Bar

Sep ar at i ng t h e Heat Si nk f ro m t he Po wer Bo ar d

Replacing the Fan and Button Board

Replacing the Control Board and Power Board

Reassembling the Char ge Cont roller

, start on page 10.

, see page 11.

, see page 12

8 900-0054-01-00 Rev A

, see page 9.

, see page 14.

, see page 17.

, see page 23.

, see page 27.

Page 11

FLEXmax Charge Controller Disassembly

p

If you have a FLEXmax 60, proceed w i th removing t he chassis screws as described on page 10.

Removing the FLEXmax 80 Fan Cable

1. Remove t he machine screw t hat secures the

fan cover.

Pre ss

Pr es s

6. Not e the jack for t he fan

cable, whi ch is snapped

into t he f an bracket.

2. Press bot h sides of t he f an cover t o release t h e

tabs. Pull up on the cover.

3. Remove t he fan cover once t he t abs have

cleared t heir slot s. Keep t he fan cover and

machine screw in a safe place.

4. Note the fan cable plugged into the jack.

5.

Rem ove t he fan cable

by squeezing the tabs

on eit her side of t he

plug. You can do this

wit h your f i n gers, or

wit h a pair of longnose

liers.

Figure 3 Removing Fan Cover

7. Remove the cabl e jack by

pinching the retaining

tabs on eit her side of the

jack, using long-nose

pliers. The jack can b e

taken out through the

rear of t he bracket .

Figure 4 Removing Cable Jack

900-0054-01-00 Rev A 9

Page 12

Disassembly

Removing Chassis Screws

1. Set t he unit on it s side t o remove t he t wo back screw s. Keep t he screws and star washers toget her.

Fi gur e 5 Back Scr ew Rem oval

2. With the unit still on its side, remove two side screws.

Figure 6 Side Screw Removal (part 1)

3. Set the unit on its other side and remove the two remaining screws.

Figure 7 Side Screw Removal (part 2)

The heat sink can now be removed from the chassis.

10 900-0054-01-00 Rev A

Page 13

Removing the Heat Sink

Disassembly

1. To remove the heat sink, grip it along

each flank and raise its lower end.

2. Slide t he cont rol board past t he

grounding lug. Make certain the power

board is raised high enough to avoid

the grounding lug

Grounding lug

3. Sli de t he heat sink aw ay f r o m

the chassis.

Fi gur e 8 Heat Sin k Remo val

900-0054-01-00 Rev A 11

Page 14

Disassembly

Remo v i ng t h e FET Bar

1. Set the unit on its side as shown in Figure 9 and remove the 12 screws securing the FET mounting bar

t o t he heat sink.

Fi gu re 9 FET Bar Scr ew Remo val

2. Rem ove t he FET mount i ng bar.

Fi gur e 10 FET Bar Rem o val

Continued on next page.

12 900-0054-01-00 Rev A

Page 15

Fi gur e 11 Fr eei ng t he FET fr om t he In sul at or

Disassembly

3. Lif t t he t ab of t he FETs off

from the Sil-Pad (gray

insulator pad) using your

finger and t humb.

CAUTION! Do not at tempt

to remove the FETs from

the power board. The FET

pins are soldered t o t he

board.

If t he FETs are difficul t to

break free, rock the tabs

gently with long-nose pliers

until they lift off the Sil-Pad.

Fi gur e 12 Fr eei ng t h e FET w it h Pl i er s

900-0054-01-00 Rev A 13

Page 16

Disassembly

Sep ar at i n g t h e Heat Si n k f r om t he Pow er Bo ar d

Place t he charge cont roller upside down and rem ove t he seven screws circled i n whit e in Figure 13, on

t he l eft . Do not remove the f our cradle screw s and w ashers identified wi t h t he X symb ol in Fi g ur e 13 on

the right.

Do NOT Remove the screws

id ent ified here wit h an “X” .

Figure 13 Bottom/Cradle Screw Removal

2. Remove t he last t hree (3)

remaining screws, circled

in whit e i n Figure 14.

Figure 14 Removing Remaining Screws

Continued on next page.

14 900-0054-01-00 Rev A

Page 17

Disassembly

p

3. With all the screws

removed, t he heat sin k can

be separated from the

power board. Set t he unit

up right and carefully pry

and l ift th e heat sink off t he

ower board.

Figure 15 Heat Sink Removal

CA UT I ON !

removal. The heat sin k is

connected to the power board

by a ribbon cable f rom t he

cont rol board.

Do not force t he

Fi gu re 1 6 Heat Sin k Co n nect ed t o Po w er Bo ar d

Continued on next page.

900-0054-01-00 Rev A 15

Page 18

Fi gur e 17 Cab le Remo val

Disassembly

4. Set t he heat sink on it s sid e and t he

power board down flat.

5. Remove the ri bbon cable connect or

from t he LCD connect or.

The connector may have a dollop of

sil i cone sealant o n it which must be

peeled off. When reassembling t he

controller, it is recommended to apply

more silicone sealant if available.)

If you have a FLEXmax 60 controller and

are only replacing the fan, it is not

necessary t o remove t he cable.

Figure 18 Power Board - Top View

For instructions on

For instructions on

For instructions on

For instructions on

Rep l a ci ng t he Fan in a FLEXm ax 60 Char ge Con t ro ll er

Replacing the Button Board

Replacing the Control Board and Power Board

Reassembling the Controller

, see page 17.

, see page 19

, see page 24.

, see page 27.

16 900-0054-01-00 Rev A

Page 19

Fan an d But t on Boar d

Replacing the FLEXmax 60 Fan

Disassemble the controller as described on page 9 through page 16.

Remo v i ng t h e Fan

To remove t he fan:

Disconnect the connector from the LCD. The

1.

Silicone Sealant

connector may have a dollop of silicone sealant to

ensure a firm connection. This should be peeled or

pulled off.

Rem ove t he four screw s holding the f an in place.

2.

The ribbon cable is shown d i sconnect ed

NOTE:

in this illustration for convenience only.

Fan Screw s (x 4)

Fan Connector

Fi gur e 19 Fan Rem ov al

Rep l aci n g t h e Fan

Scr e w Po st

Black Wire

Re d Wi r e

Scr e w Po st

Fi gur e 20 Fan Rep lacem ent

Silicone Sealant

To rep l a ce t h e f an :

1. Insert the new fan aligning the mounting holes to

the heat sink.

2. Al i g n t he connect or so t hat th e red w ire of t he

connector lines up wit h the posit ive (+) pin and the

black w i re wit h t h e neg at ive (-) pin as show n i n

Figure 20. Posit ion the wires bet ween the

scr ew p ost s.

3. Plug in the connector.

4. Tight en t he screw s so t h e f an is snug against t he

heat sink.

5. Reapply silicone sealant to secure the connector

(if possible).

If no other repairs are necessary, see the reassembly instructions on page 27. After reassembly, return to

page 18 for testing procedures.

900-0054-01-00 Rev A 17

Page 20

p

Fan Test Pr ocedures

Test t he fan using t he following procedures:.

1. Remove t he Remot e Temperature

Sensor (RTS) jack f rom the p ort , if

present .

2. Insert a flat screwdriver insid e t he RTS

port. Gently press the screwdriver tip

against all the pins at once. This will

creat e a f al se signal t hat w ill t urn the

fan on.

Fan and Button Board

3. Check t h e LCD. The op erat ional mod e on

the FLEXmax screen should change from

“Sleeping” t o “BatTmpErr” . The fan will

begin running.

4. Once t he fan operat i on has been verified,

remove t he screw driver fro m t he RTS p o rt

and reconnect the RTS, if available.

RTS Po r t

LCD Display

IN 005 V OUT 25.0 V

00.0 A 00.0 A

Watts 0000 AuxOff

kWHrs 00.0 BatTm

Figure 21 Fan Test Procedure

You may now apply PV input to the FLEXmax Charge Controller to resume charging.

Err

18 900-0054-01-00 Rev A

Page 21

Replacing the Button Board

To locate the but t on board:

1. Disassemble the controller as described

on page 11 through page 18.

2. Remove t he Remote Temperature Sensor

(RTS) fro m t he port, if p r esent .

3. The Button Board is located on the inside

of the heat sink.

Fan and Button Board

Figure 22 Locating the Button Board

Fan Connector

But t on Boar d

Silicone Sealant

Fan Connector

To disconnect the fan:

1.

Disconnect the fan by gently pulling the

connector away from the butt on board..

Remove the Silicone Sealant if present.

2.

But t on Boar d

Figure 23 Disconnecting the Fan

900-0054-01-00 Rev A 19

Page 22

Fan and Button Board

The but t on board is mounted t o t he

heat sink on four met al peg s at t he

corn er s of t he b oard. It is retained in

place by push-nuts which slide over

each peg, and which are covered in

t urn by silicone sealant.

To ex p ose t he pegs:

1. Remove the silicone sealant from

all f our pegs.

Figure 24 Exposing the Button Board Mounting Peg

Figure 25 Gripping the Push-nut

Once the push-nuts are exposed,

t hey will need t o be removed wit hout

damaging the metal pegs. The pushnut is very t hin and does not have

much o f an edge. Using a sharp set

of wire cut ters, remove the push-nut s

by squeezing t hem on eit her side so

that they deform.

To remove the push-nut :

1. Carefully grip the push-nut on

either side with the wire cutters.

Be sure not to damage t he peg or

Continued on next page.

20 900-0054-01-00 Rev A

Page 23

Fi gu re 26 Def or mi ng t he Pu sh-n u t

Fan and Button Board

2. Slowly close the wire cutt ers, exerting

enough pressure to crush or deform

the push-nut. The push-nut cannot be

reused aft er doi ng t hi s.

Figure 27 Removing Push-nut

3. Once t he push-nut is deformed,

push t he wi re cut ters beneat h it

and p r y it off t he peg .

4. Fin all y, work t he but ton board free of

t he f our pegs and remove it f rom t he

housing.

Figure 28 Removing the Button Board

Continued on next page.

900-0054-01-00 Rev A 21

Page 24

Fan and Button Board

Figure 29 Inserting the New Button Board

5. Insert t he repl acement board and ali gn

it w i th the f our pegs.

6. Lay a repl acement push-nut over each peg.

The push-nuts are not flat. Make certain to

place t hem so t hat t he edges are lower and

the convex cent er is higher.

7. Using t he wire cut ters or long-nose pliers,

press along both sides of the push-nut so

that it is driven onto the peg. Continue

pressing until the push-nut is firmly against

t he b u t ton b oard.

8. Repeat w i th the ot her t hree push-nuts

and pegs.

Figure 30 Inserting New Push-nut

9. Reattach the connector for t he fan.

10. If possible, reapply silicone sealant to

secure t he fan connect or and t he four

push-nuts.

Pro ceed t o t h e n ext sect i on if you n eed t o

replace t he cont rol board or power board.

If not , p roceed to page 27 to begin

reassembling the charge controller.

Fi gu re 3 1 Reco nn ect i ng t he Fan

22 900-0054-01-00 Rev A

Page 25

Control Board and Power Board

p

Removing the Control Board

Cont rol Board

Do NOT r ai se t he se

inductor wires

1. Raise t he one set of i nduct or wires that

passes over t he cont rol board, to all ow

room for t he control board to move.

Do no t raise the ot her set of wires.

Raise t hese in duct or wir es

Figure 32 Lifting the Inductor Wires

Figure 33 Sliding the Control Board Out

2. Pinch t he ends of t he cont rol board and

pull upward.

3. If t he b oard resist s, gr adu all y p ul l u p o ne

end at a t ime, alt ernat i ng b et ween t he

two ends.

4. Remove the control board by sliding it out

of the power board, avoidi ng any

component s on the board.

The pins of t he cont rol board

CA UTI ON !

should not be obstructed by the components

on the

ower board.

900-0054-01-00 Rev A 23

Page 26

Control Board and Power Board

Replacing the Control Board or Power Board

1. Inspect the connector pins on the

control board for any bends.

St raight en any bent p i ns wi th a flat

screwdriver or your finger.

Figure 34 Bent Pin on Control Board

2. Slide t he cont rol board i nt o t he power

board. Do not hit any components on the

power board.

Figure 35 Inserting Control Board

3. Inspect the pins again before connecting

t he co nt rol board t o t h e p ower board .

4. Carefully align the control board connector

wit h t he power board connect or. Be sur e

t he p in s an d h ol es ar e l i ned up w it h each

other precisely.

5. When the pins and connectors line up,

push t he cont rol board i nt o t h e

power board.

Pi ns

Connector Holes

Continued on next page.

Figure 36 Pins and Connectors

24 900-0054-01-00 Rev A

Page 27

Control Board and Power Board

Scr e w Ho l e on

the Heat Sink

FET

Sil-Pad

Fi gu re 3 7 FETs an d Si l- Pad In sul at or on Heat Si nk

6. Using t he replacement t hat came wit h

t he new b oard, rep lace t he gray Sil-Pad

insulator on the heat sink.

IM PORTANT:

Make cert ai n t he new Sil-Pad i s lined up wit h t he screw hol es on the heat sink.

CAUTION: Equ i p men t Fai l ur e

Always replace t he Sil-Pad even if t he old Sil -Pad appears usable. It could easily

have been damaged when removing the heat sink from the power board. Even

a pin-sized hol e can lead t o cat astrophic board f ai l u re.

900-0054-01-00 Rev A 25

Page 28

Notes:

Control Board and Power Board

26 900-0054-01-00 Rev A

Page 29

Reseating the Control or Power Board

Reassembl y

1. Push on both ends of the

control board to confirm

it is still properly seated

on the power board.

Figure 38 Reseating Control Board

Figure 39 Placing Inductor Wires

2. Bend and move the

inductor wires over the

control board . These are

the same inductor wires

which were bent out of

the way in Figure 32.

Make sure the wires do

not strike the fan or

button board when the

heat sink is reinstalled.

900-0054-01-00 Rev A 27

Page 30

Reconnecting the Heat Sink to the Power Board

1. Wit h t he cont rol board secured t o t he

power board, connect the ribbon cable.

Reassemb ly

Fi gu re 4 0 Rei nst al l in g Ri bb on Cab le

CA UT I ON !

Do no t install it backward. In the correct

or i en t ation , t he red stripe must face t he

heat sink side wall.

In Figure 40, the cab l e is orient ed so t h at

t he red st ri p e i s on t he bot t om.

2. Set and align t he heat sink ont o t he

power board.

3. While aligning t he h eat sin k, t uck one

finger under the ribbon cable and pull

as indicat ed i n Figure 41. This wi l l take

up the slack in t h e ri b b on cable. It

keeps the cable from int erfering with

t he al i g nment of t h e h eat sink and t he

power board.

The ribbon cable i s not keyed.

Figure 41 Gently Pulling On Ribbon Cable

4. Set t he unit upside dow n, and align

the power board screw holes against

the heat sink screw holes.

5. Reinstall al l the screws that had been

removed previously and handtighten them.

Continued on next page.

Figure 42 Installing and Tightening Screws

28 900-0054-01-00 Rev A

Page 31

6. Set t he unit on it s sid e wit h t he FETs in

7. If you are reassembling the unit

Fi gu re 4 3 Al i gn i ng FETs an d I nst al l in g t h e FET Bar

Reassemb ly

between the screw holes on the

heat sink.

If t hey do no t line up, move the t abs on

the FETs to align them bet ween t he

screw holes. The alignment of the FETs

between the screw holes protects them

from damage when reinstalling the FET

mounting bar and screws.

(following fan replacement) and have

not already p erf ormed t hi s step: using

the replacement that came with the fan,

replace the gray Sil-Pad insulator on the

heat sink. Refer to t he illustration on

page 27 i f n ecessary.

CAUTION: Equ i p men t Dam ag e

Always replace t he Sil -Pad even i f t he old Sil-Pad appears usable. It

could easil y have b een damaged w hen removi n g t he heat sink f rom the

power b oard. Even a p in -sized h o l e can lead to cat astrophic board

failure.

Make sure t he new Sil-Pad i s lined up wit h t he screw holes on t he

heat sink.

8. Place the FET mounting bar on

the FETs.

9. Install the FET bar screws and

tighten.

Figure 44 Installing FET Bar Screws

900-0054-01-00 Rev A 29

Page 32

Reconnecting the Heat Sink to the Chassis

1. Slide the reassembled unit into

the chassis working around the

Grounding lug.

Grounding lug

Figure 45 Reinstalling the Heat Sink onto the Chassis

Reassemb ly

3. Replace and tighten down

scr ew s o n t h e si d es o f t he ch assi s.

all

t he

Fig ur e 46 Repl aci ng t he Chassi s Screws

2. Replace and tighten down

screws on t he back of t he chassis.

all

t he

30 900-0054-01-00 Rev A

Page 33

Reassemb ly

For the FLEXmax 80 Controller, follow the st eps on for reinstalling t he fan plug bef ore proceedi ng.

Reinstalling FLEXmax 80 Fan Plug

1. Sn ap t he fan cable j ack int o t he

bracket.

Figure 47 Reinstalling Cable Jack

Fi gu re 4 8 Rei nst al l in g Cab l e Pl ug

2. Sn ap t he fan cable i nt o t he j ack.

3. Replace the FLEXmax 80 fan cover.

Fi gur e 49 Fan Cover

900-0054-01-00 Rev A 31

Page 34

Reassemb ly

Syst em Fun ct i onal Test

Perform a Funct ional Test as fol l ows before putt ing t h e syst em back into full service.

1.

Rei n st al l FLEXmax Charge Cont roller b ack int o t he system.

Initially apply only battery power to the FLEXmax controller.

2.

3.

The display should “boot up” and the soft keys should function properly. Test t he soft keys by

cycling through the menus.

Once proper operation is verified, apply PV input to the FLEXmax Charge Controller to

4.

resume charging.

5.

Using a digital multimeter, test the applicable test points to confirm prop er volt age levels as they

are applied to the system.

6.

Replace all t h e app rop r i ate co m p onent covers and secure t he system for official use by the

customer.

If t he unit does not perform as expect ed or fails the Funct ional Test , di sco nn ect al l p ow er so urces

(i.e. open all breaker s or d i scon nects) and contact Out Back Technical Support f or addit ional assistance.

32 900-0054-01-00 Rev A

Page 35

Notes:

Reassemb ly

900-0054-01-00 Rev A 33

Page 36

Nort h Am erica

19009 62nd Avenue NE

Arlington, WA USA

+1.360.435.6030

900-0054-01-00 Rev A

European Office:

Bar cel o n a, Esp añ a

+34.93.654.9568

Loading...

Loading...