OutBack Power EnergyCell 2200RE, EnergyCell 1100RE, EnergyCell 2000RE, EnergyCell 2700RE, EnergyCell 1300RE Installation Manual And Owner's Manual

...

EnergyCell® RE High Capacity Battery

Installation Guide and Owner’s Manual

Purpose

This document provides the EnergyCell RE High Capacity Installation Guide and Operation Manual.

Scope

This document applies to all models of the EnergyCell RE High Capacity series. The reference table below shows the Outback part

number cross referenced with the manufacturer part number. When using this document for installation and service operations,

please refer to the manufacturer part number when referencing critical information.

Should you have ANY questions concerning how to perform the required maintenance or installation please contact Outback

Power at the oce number listed below and ask for Outback Power Tech Support.

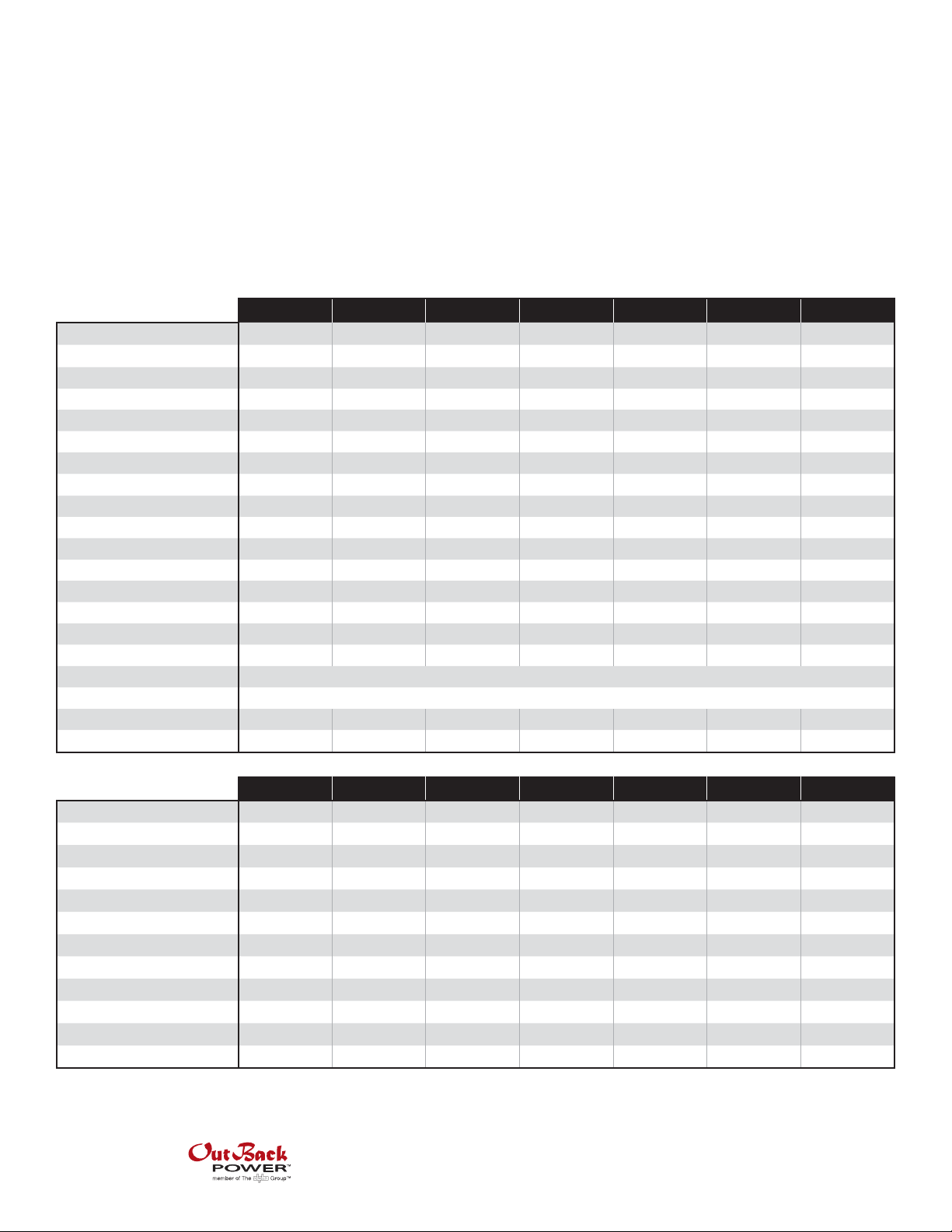

EnergyCell RE High Capacity Specications

Models: 800RE 1100RE 1300RE 1600RE 2000RE 2200RE 2700RE

EnerSys Part Number

Nominal Voltage Per Cell

Capacity 20Hr Rate (1.75VPC)

Capacity 100Hr Rate (1.75VPC)

Watts Per Cell 15min Rate (1.67VPC)

Cycle Life 50% DOD (25°C)

Optimal Operating Temperature Range

OCV Per Cell Limit

Initial Charge Voltage Per Cell

Float Voltage Per Cell (25°C)

Float Voltage Per Cell (35°C)

Equalize Voltage Per Cell (21 to 32°C)

Maximum Charge Current (A)

Shelf Life (25°C)

Short Circuit Current (A)

Internal Resistance (micro Ω)

Terminal Torque (Intercell Connects)

Hardware Specication (Intercell Connects)

Weight Per Cell (lbs)

Dimensions Per Cell L x W x H (in)

Models: 800RE 1100RE 1300RE 1600RE 2000RE 2200RE 2700RE

1 hour

2 hours

3 hours

4 hours

5 hours

6 hours

8 hours

10 hours

12 hours

20 hours

24 hours

100 hours

DDm85-15 DDm85-21 DDm100-21 DDm100-25 DDm125-25 DDm100-33 DDm125-33

2V 2V 2V 2V 2V 2V 2V

672 960 1148 1378 1716 1836 2288

810 1150 1340 1600 2070 2140 2770

1230 1757 1995 2394 3071 3192 4094

1800 cycles 1800 cycles 1800 cycles 1800 cycles 1800 cycles 1800 cycles 1800 cycles

23 to 26°C 23 to 26°C 23 to 26°C 23 to 26°C 23 to 26°C 23 to 26°C 23 to 26°C

*

2.05 2.05 2.05 2.05 2.05 2.05 2.05

**

2.27 2.27 2.27 2.27 2.27 2.27 2.27

2.25 2.25 2.25 2.25 2.25 2.25 2.25

2.21 2.21 2.21 2.21 2.21 2.21 2.21

2.32 2.32 2.32 2.32 2.32 2.32 2.32

148.75 212.5 250 300 375 400 500

6 months 6 months 6 months 6 months 6 months 6 months 6 months

4728 6748 7722 9267 12411 12337 16548

441 309 270 225 167 169 126

88 in-lbs

M8 bolt, lock and at washer

114.3 162.3 188.3 222.3 272.3 290.3 358.3

21.8 x 11.9 x 6.5

21.8 x 8.4 x 6.5 24.5 x 8.4 x 6.5 24.5 x 9.9 x 6.5 23.5 x 9.9 x 8.9 24.5 x 12.9 x 6.5 23.5 x 12.9 x 8.9

Ah Capacity to 1.75VPC @ 25°C

347 495 575 690 886 920 1182

440 631 738 884 1138 1180 1518

492 702 822 987 1260 1317 1680

528 752 876 1052 1332 1404 1776

555 790 920 1105 1390 1470 1850

576 822 954 1146 1440 1524 1914

600 864 1008 1208 1512 1616 2016

610 870 1040 1250 1550 1660 2060

624 888 1068 1284 1584 1704 2112

672 960 1148 1378 1716 1836 2288

676 984 1176 1416 1776 1872 2352

810 1150 1340 1600 2070 2140 2770

The following PowerSafe DDM Modular Battery Systems Installation Manual is copyright 2003 by EnerSys. This document cannot

be copied or reproduced without the express written permission of EnerSys Inc.

Worldwide Corporate Oces

North America

Tel: +1 360.435.6030

Fax: +1 360.435.6019

Latin America

Tel: +1 561.792.9651

Fax: +1 561.792.7157

Europe

Tel: +49 9122.79889.0

Fax: +49 9122.79889.21

Asia Pacic

Tel: +852 2736.8663

Fax: +852 2199.7988

Installation Manual

PowerSafe DDM

Modular Battery Systems

DDm

Publication No. US-DDm-IM-003 November 2003

DDm

Installation Manual

PowerSafe DDm

Modular Battery Systems

IMPORTANT!

Read safety information first

See Safety, Storage, Operating and Maintenance Manual

Publication No. US-DDm-IM-003 November 2003

The installation manual is for reference only. To maximize safety and performance, read the

accompanying Safety, Storage, Operating and Maintenance Manual thoroughly. It provides full

instructions regarding safety, storage, operation and maintenance. Failure to observe the

precautions as presented may result in injury or loss of life.

Copyright ©2003 by EnerSys Inc. All rights reserved.

This document is proprietary to EnerSys Inc. This document cannot be copied or reproduced in

whole or in part, nor can its contents be revealed in any manner or to any person except to meet

the purpose for which it was delivered, without the express written permission of EnerSys Inc.

Please check our website for literature updates.

www.enersysinc.com

Publication No. US-DDm-IM-003

November 2003 www.enersysinc.com

PowerSafe DDm

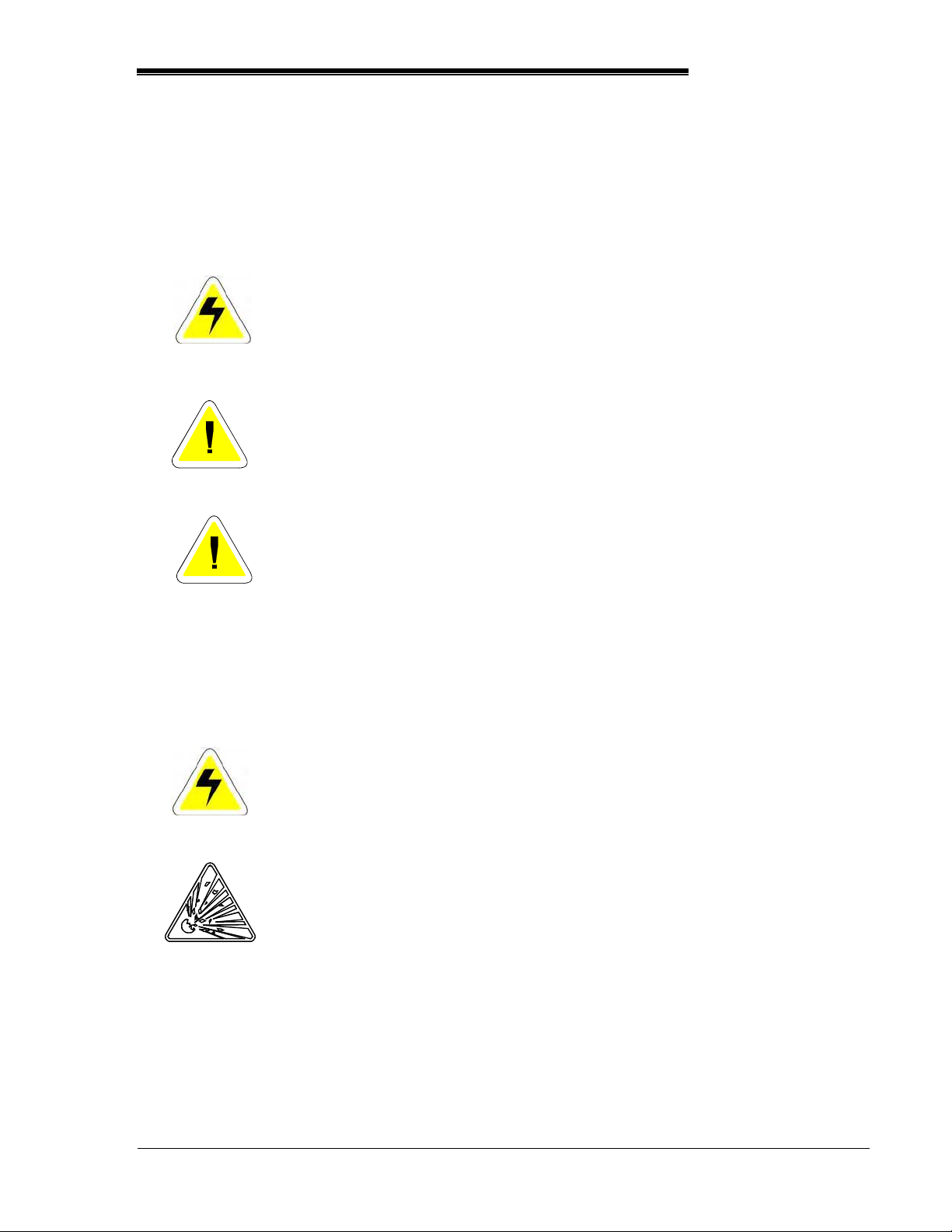

GENERAL SAFETY INSTRUCTIONS

Warnings in this manual appear in any of three ways:

Danger

Warning

Caution

Other warning symbols may appear along with the Danger and Caution symbol and are used to

specify special hazards. These warnings describe particular areas where special care and/or

procedures are required in order to prevent serious injury and possible death:

Electrical

warnings

Explosion

warnings

The danger symbol is a lightning bolt mark enclosed in

a triangle. The danger symbol is used to indicate

imminently hazardous situations, locations and

conditions which, if not avoided, WILL result in death,

serious injury and/or severe property damage.

The warning symbol is an exclamation mark in a

triangle. The warning symbol is used to indicate

potentially hazardous situations and conditions, which,

if not avoided COULD result in serious injury or death.

Severe property damage COULD also occur.

The caution symbol is an exclamation mark enclosed

in a triangle. The caution symbol is used to indicate

potentially hazardous situations and conditions, which,

if not avoided may result in injury. Equipment damage

may also occur.

The electrical warning symbol is a lightning bolt mark

enclosed in a triangle. The electrical warning symbol is

used to indicate high voltage locations and conditions,

which may cause serious injury or death if the proper

precautions are not observed.

The explosion warning symbol is an explosion mark

enclosed in a triangle. The explosion warning symbol is

used to indicate locations and conditions where

molten, exploding parts may cause serious injury or

death if the proper precautions are not observed.

Publication No. US-DDm-IM-003 Page i

November 2003 www.enersysinc.com

IMPORTANT SAFETY INSTRUCTIONS

A battery can present a risk of electrical shock and high short circuit current.

The following precautions should be observed when working with batteries.

1. Verify that the Uninterruptible Power Supply (UPS) is off and that the power cord is

disconnected from the power source.

2. Remove watches, rings or other metal objects.

3. Use tools with insulated handles to prevent inadvertent shorts.

4. Wear rubber gloves and boots.

5. Do not lay tools or metal parts on top of batteries.

6. Determine if the battery is inadvertently grounded. If inadvertently grounded, remove

source of ground. Contact with any part of a grounded battery can result in electrical

shock. The likelihood of such shock will be reduced if such grounds are removed during

installation and maintenance.

7. Verify circuit polarities before making connections.

8. Disconnect charging source and load before connecting or disconnecting terminals.

9. Valve-regulated lead-acid (VRLA) batteries contain an explosive mixture of hydrogen

gas. Do not smoke, cause a flame or spark in the immediate area of the batteries. This

includes static electricity from the body.

10. Use proper lifting means when moving batteries and wear all appropriate safety clothing

and equipment.

11. Do not dispose of lead acid batteries except through channels in accordance with local,

state and federal regulations.

Page ii Publication No. US-DDm-IM-003

www.enersysinc.com November 2003

PowerSafe DDm

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important instructions for PowerSafe DDm Lead-Acid Battery Systems

that should be followed during the installation and maintenance of the battery system.

Only a qualified EnerSys Inc. service representative who is knowledgeable in batteries and

the required precautions should perform servicing of the batteries. Keep unauthorized

personnel away from batteries.

Caution

Caution

Caution

Warning

Warning

Warning

Warning

Misuse of this equipment could result in human injury and

equipment damage. In no event will EnerSys be responsible or

liable for either indirect or consequential damage or injury that may

result from the use of this equipment.

Do not dispose of the batteries in a fire. The batteries may

explode.

Do not open or mutilate the batteries. Released electrolyte is

harmful to the eyes and skin and may also be toxic.

This unit contains sealed lead acid batteries. Lack of preventative

maintenance could result in batteries exploding and emitting

gasses and/or flame. An authorized, trained technician must

perform annual preventative maintenance.

Failure to replace a battery before it becomes exhausted may

cause the case to crack, possibly releasing electrolyte from inside

the battery and resulting in secondary faults such as odor, smoke

and fire.

Installation and servicing of batteries should be performed by

personnel knowledgeable about batteries and the required

precautions. Keep unauthorized personnel away from the

batteries.

Proper maintenance to the battery system of this unit must be done

by a qualified service technician. This is essential to the safety and

reliability of your Uninterruptible Power Supply (UPS) system.

Publication No. US-DDm-IM-003 Page iii

November 2003 www.enersysinc.com

IMPORTANT!

Read safety information first

See Safety, Storage, Operating and Maintenance Manual

Page iv Publication No. US-DDm-IM-003

www.enersysinc.com November 2003

PowerSafe DDm

TABLE OF CONTENTS

GENERAL SAFETY INSTRUCTIONS ...........................................................................................i

GENERAL INFORMATION...........................................................................................................2

RECOMMENDED INSTALLATION EQUIPMENT AND SUPPLIES .............................................4

SYSTEM LAYOUT ........................................................................................................................5

Anchor Spacing .........................................................................................................................6

FRAME ASSEMBLY AND INSTALLATION ..................................................................................7

Base Beams ..............................................................................................................................7

Vertical Channels ......................................................................................................................7

Horizontal Channels ..................................................................................................................8

Cell Support Shelves ...............................................................................................................10

BATTERY CELL INSTALLATION ...............................................................................................11

Module Retainers ....................................................................................................................12

Electrical Bonding Instructions ................................................................................................12

CONNECTIONS..........................................................................................................................13

Terminal Plates........................................................................................................................13

Inter-Cell Connectors...............................................................................................................14

Terminal Bars ..........................................................................................................................15

INITIAL SYSTEM READINGS ....................................................................................................16

SAFETY SHIELDS AND COVERS .............................................................................................17

Safety Shields..........................................................................................................................17

Terminal Plate Covers .............................................................................................................17

Publication No. US-DDm-IM-003

November 2003 www.enersysinc.com

GENERAL INFORMATION

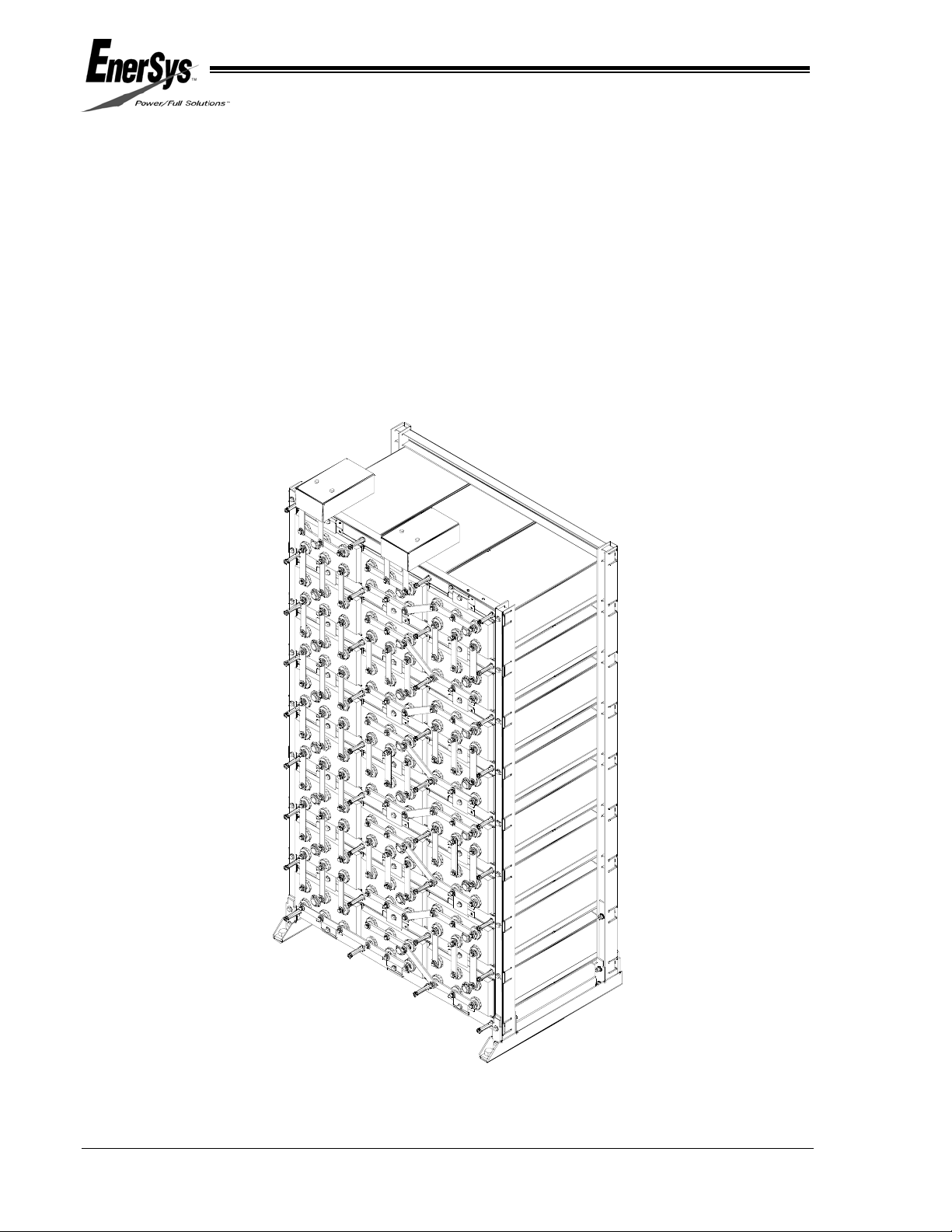

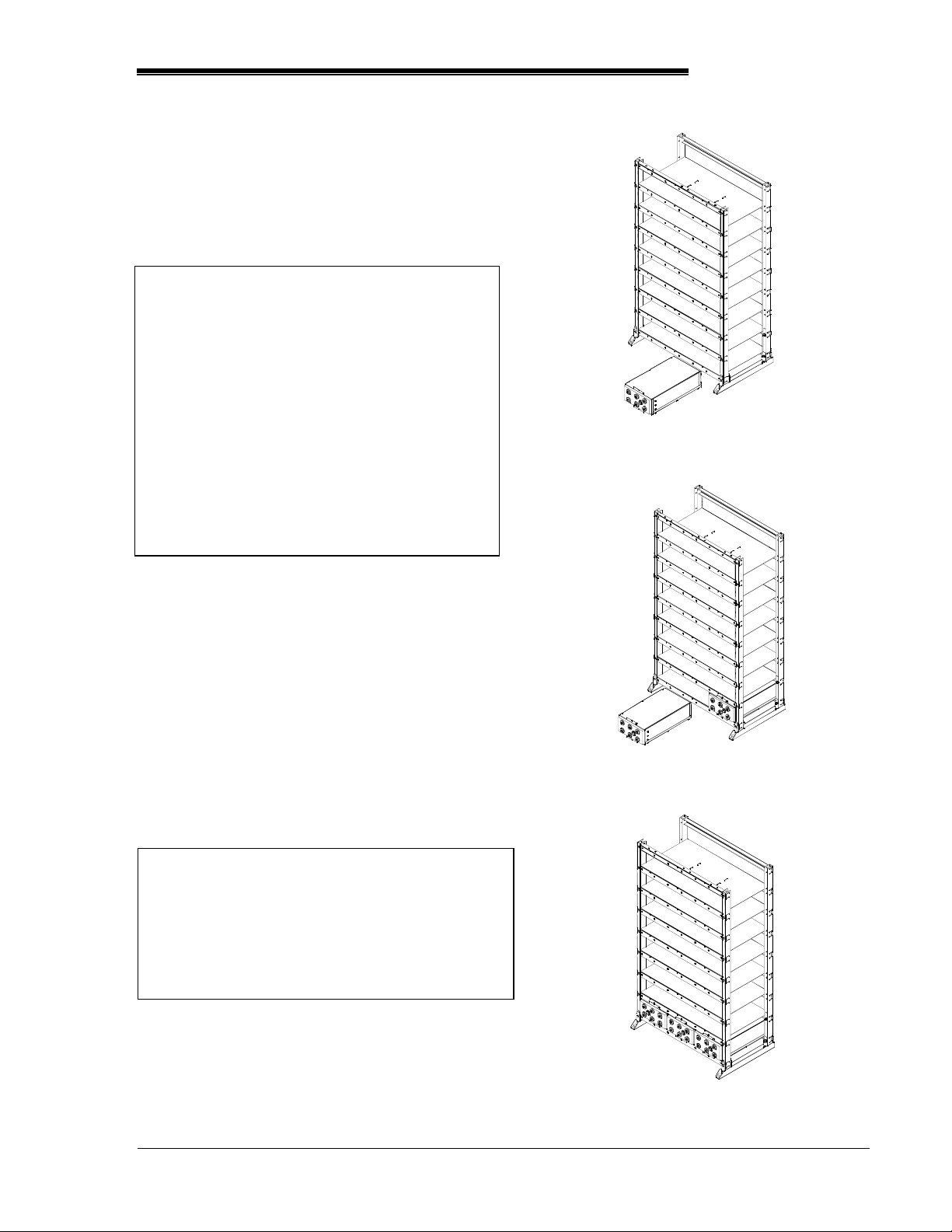

PowerSafe DDm battery systems are modular units that can be installed in a SINGLE STACK

(figure 1), a MULTI-STACK (figure 2), or a MULTI-STACK ZERO SEPARATION (Figure 3).

Systems are available in 24, 48 and other voltage configurations. These systems allow for

assembly at remote locations.

See the ASSEMBLY DRAWING to determine the configuration for your installation.

Before installation: Verify items received versus Bill of Lading. Verify parts against system Bill

of Materials.

SINGLE STACK

FIGURE 1

Page 2 Publication No. US-DDm-IM-003

www.enersysinc.com November 2003

MULTI-STACK

FIGURE 2

PowerSafe DDm

MULTI-STACK ZERO SEPARATION

FIGURE 3

Publication No. US-DDm-IM-003 Page 3

November 2003 www.enersysinc.com

RECOMMENDED INSTALLATION EQUIPMENT AND SUPPLIES

Before working with the battery system, be sure that you have the proper protective clothing,

safety equipment and insulated tools as specified in the Safety, Storage, Operating and

Maintenance Manual for the VRLA Modular Battery Systems.

The following is a recommended list of equipment required for installation of a PowerSafe DDm

Battery System.

TABLE 1

EQUIPMENT REQUIRED

CHECK IF ON HAND

Chalk Line

Torpedo Level (Plastic)

Torque Wrench (10-200 in-lbs) (SAE & Metric)

Torque Wrench (50-100 ft-lbs) (SAE & Metric)

Floor Anchors (User-supplied per battery system)

Floor Shims (User-supplied)

Drive Ratchet Wrench with Minimum 3” Extension (SAE & Metric)

Box Wrenches (SAE & Metric)

Screwdrivers

Wipes, Paper or Cloth

Stiff Bristle Nonmetallic Brush/Pad

Tape Measure (Nonmetallic)

Safety Equipment and Clothing

Small Paintbrush

Standard Allen Wrench Set

Be sure you have all the proper protective clothing, safety tools, and

equipment on hand before starting the installation.

Page 4 Publication No. US-DDm-IM-003

www.enersysinc.com November 2003

SYSTEM LAYOUT

Before installing the battery system, lay out

available floor space including aisles for

installation, maintenance and possible cell

replacement. Consult the local installation

considerations as determined in Section 5 of

the Safety, Storage, Operating and

Maintenance Manual for the VRLA Modular

Battery Systems. Recommended clearance

between these racks and any objects (including

walls and equipment) is 4 inches (102 mm).

1. Layout the system position for either a

SINGLE-STACK (Figure 4), a MULTISTACK (Figure 5), or MULTI-STACK WITH

ZERO SEPARATION (Figures 6, 7 & 8)

configuration with the dimensions defined in

Table 2.

2. Locate the position of the floor anchors

using the frame base beams.

NOTE:

• Floor anchoring is REQUIRED for all

installations.

• Allow sufficient clearance between

adjacent walls or equipment for

proper installation of anchors. Please

check your local codes for clearances

required.

• Floor anchor design (including, but

not limited to size, quantity, and

capacity) and installation are the

responsibility of the user/installer.

• Follow the user’s design and the

manufacturer’s instructions.

3. Mark floor with the position of the floor

anchors.

L

D

D = DISTANCE BETWEEN BASES (VARIABLE)

MULTI-STACK

FIGURE 5

M

M

DDm50 MULTI-STACK

WITH ZERO SEPARATION

FIGURE 6

M

7.67

DDm85/100 MULTI-STACK

WITH ZERO SEPARATION

FIGURE 7

PowerSafe DDm

L

FRONT

FRONT

W

M

FRONT

W=

DDm85 = 17.46

DDm100 = 20.47

SINGLE-STACK

FIGURE 4

“L”

FRONT

M

10.75

M

Dm125 MULTI-STACK

WITH ZERO SEPARATION

19.81

FRONT

FIGURE 8

Publication No. US-DDm-IM-003 Page 5

November 2003 www.enersysinc.com

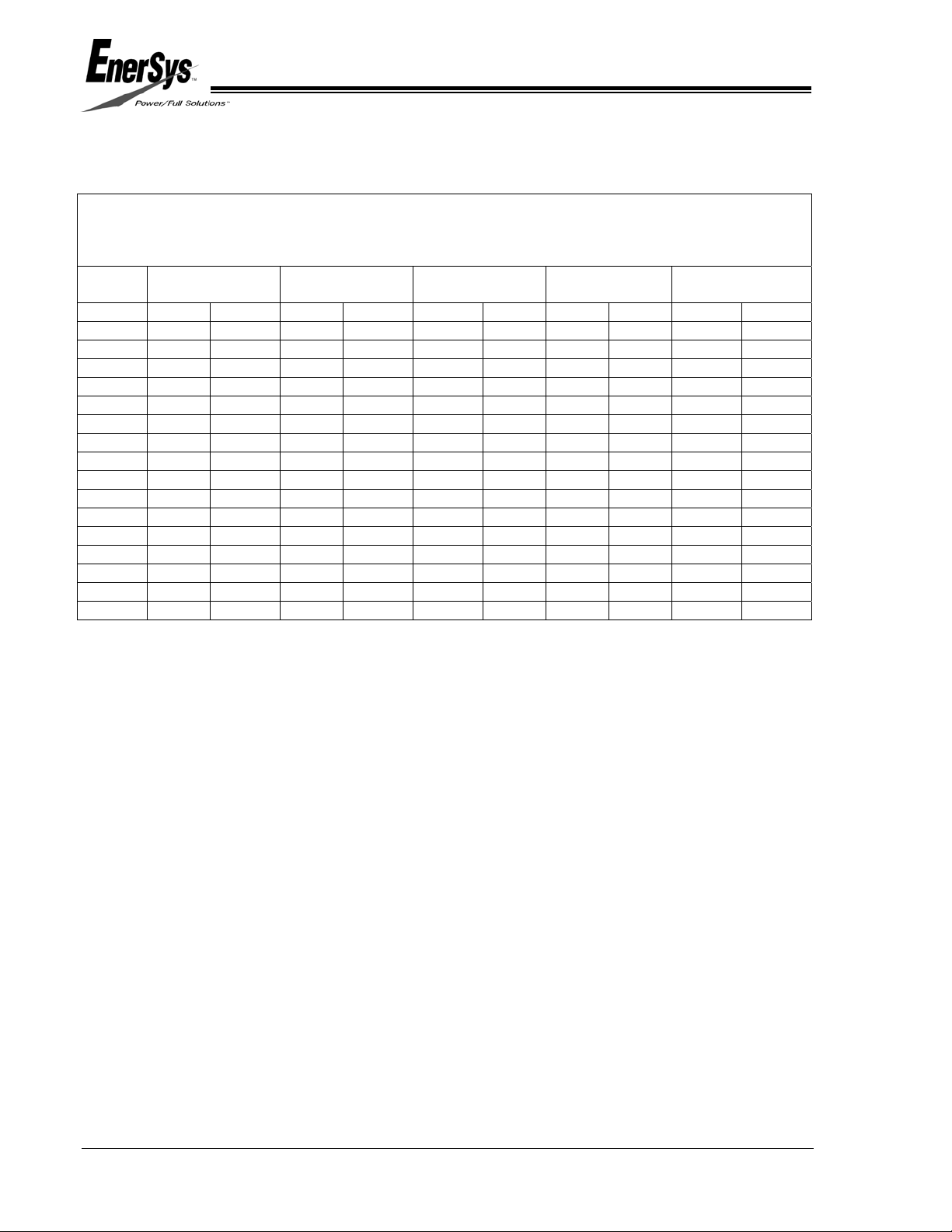

Anchor Spacing

TABLE 2

Base Beam Anchor Spacing

Cell

Model

L (in) L (cm) L (in) L (cm) L (in) L (cm) L (in) L (cm) M (in) M (cm)

50-09 9.04 23.0 N/A N/A 16.52 42.0 24.01 61.0 L+0.89 L+2.3

50-13 12.04 30.6 N/A N/A 22.52 57.2 33.01 83.8 L+0.89 L+2.3

50-17 15.49 39.3 22.48 57.1 29.26 74.3 43.17 109.7 L+0.89 L+2.3

85-13 12.04 30.6 N/A N/A 22.52 57.2 33.01 83.8 L-2.94 L-7.5

85-15 13.54 34.4 N/A N/A 25.52 64.8 37.51 95.3 L-2.94 L-7.5

85-21 18.48 46.9 26.93 68.4 35.26 89.6 53.71 136.4 L-2.94 L-7.5

85-25 21.48 54.6 31.43 79.8 41.26 104.8 62.68 159.2 L-2.94 L-7.5

85-27 22.98 58.4 33.69 85.6 44.27 112.4 67.22 170.7 L-2.94 L-7.5

85-33 27.48 69.8 40.43 102.7 53.26 135.3 80.71 205.0 L-2.94 L-7.5

100-21 18.48 46.9 26.93 68.4 35.26 89.6 53.71 136.4 L-2.94 L-7.5

100-25 21.48 54.6 31.43 79.8 41.26 104.8 62.68 159.2 L-2.94 L-7.5

100-27 22.98 58.4 33.69 85.6 44.27 112.4 67.22 170.7 L-2.94 L-7.5

100-33 27.48 69.8 40.43 102.7 53.26 135.3 80.71 205.0 L-2.94 L-7.5

125-25 22.09 56.1 31.88 81.0 41.98 106.6 63.29 160.8 L-4.24 L-10.8

125-27 23.59 59.9 34.14 86.7 44.98 114.2 67.83 172.3 L-4.24 L-10.8

125-33 28.09 71.3 40.88 103.8 53.98 137.1 81.32 206.6 L-4.24 L-10.8

2 Cells Wide 3 Cells Wide 4 Cells Wide 6 Cells Wide

Multi-Stack w/

zero spacing

EXAMPLE:

If you are installing a DDm85 MULTI-STACK WITH ZERO SEPARATION and

you have 21 plates/cell, 4 cells wide.

M (inches) = L (in) - 2.94”

35.26” - 2.94” = 32.32”

M (cm) = L (cm) - 7.5 cm

89.6 cm - 7.5 cm = 82.1 cm

Page 6 Publication No. US-DDm-IM-003

www.enersysinc.com November 2003

FRAME ASSEMBLY AND INSTALLATION

To assemble and install the frame for the

PowerSafe DDm battery system, follow the

procedure below using the system layout

determined in the “System Layout” section.

Base Beams

1. LEVEL with customer-supplied floor shims,

and anchor in place. Do NOT torque

anchor bolts until frame assembly is

complete.

2. Install ALL base beams before continuing.

Vertical Channels

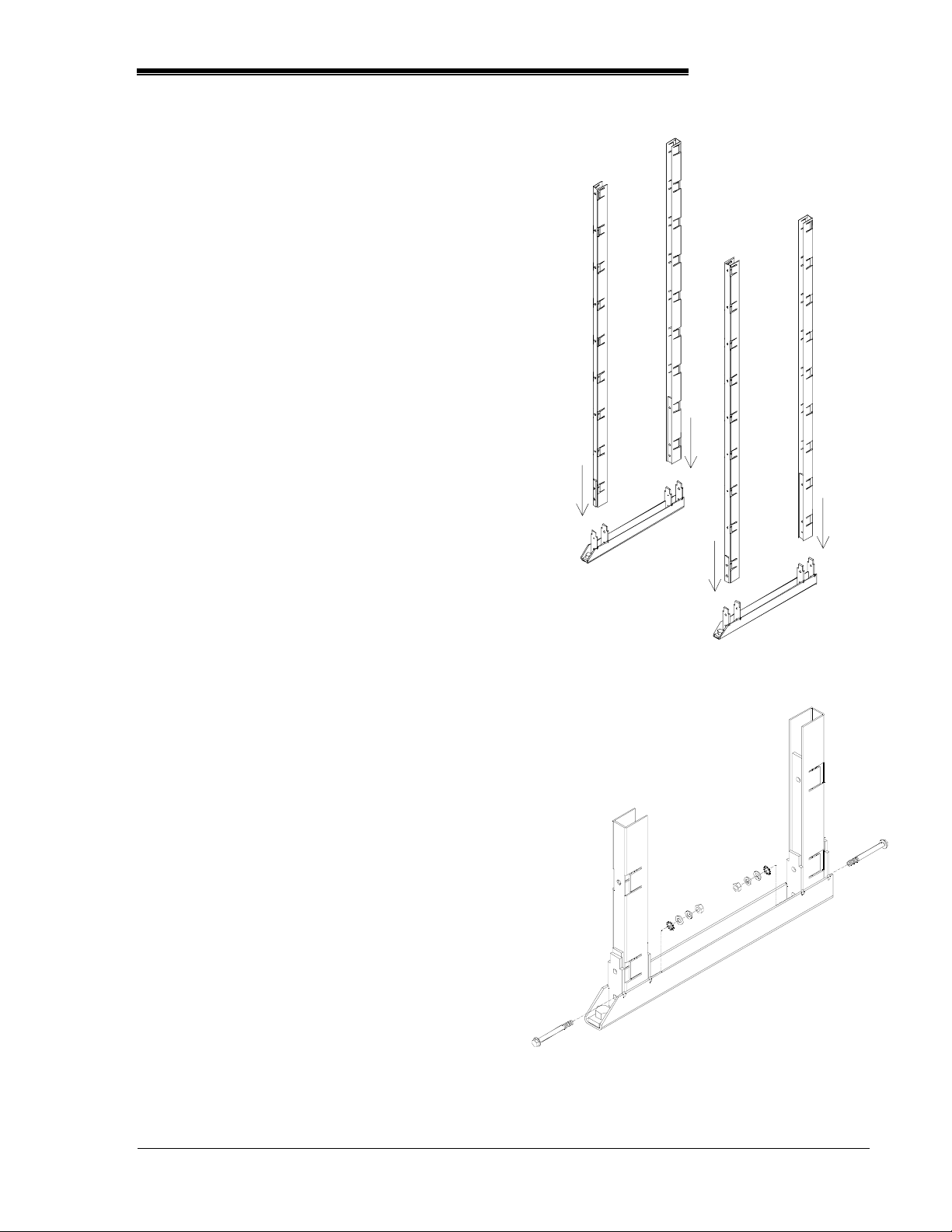

1. Insert vertical channels into base beams.

See Figure 9.

2. Bolt vertical channels to base beams. Refer

to below list for hardware order and Figure

10:

• Serrated Hex Bolt (M10x1.5 –

100mm),

• Rack Frame,

• External Tooth Washer,

• Flat Washer,

• Lock Washer,

• Hex Nut

3. Torque all connections (except anchor bolts)

to 40 ft-lbs.

PowerSafe DDm

INSTALL VERTICALS

FIGURE 9

VERTICAL CHANNEL TO BASE

BEAM HARDWARE DETAIL

FIGURE 10

Publication No. US-DDm-IM-003 Page 7

November 2003 www.enersysinc.com

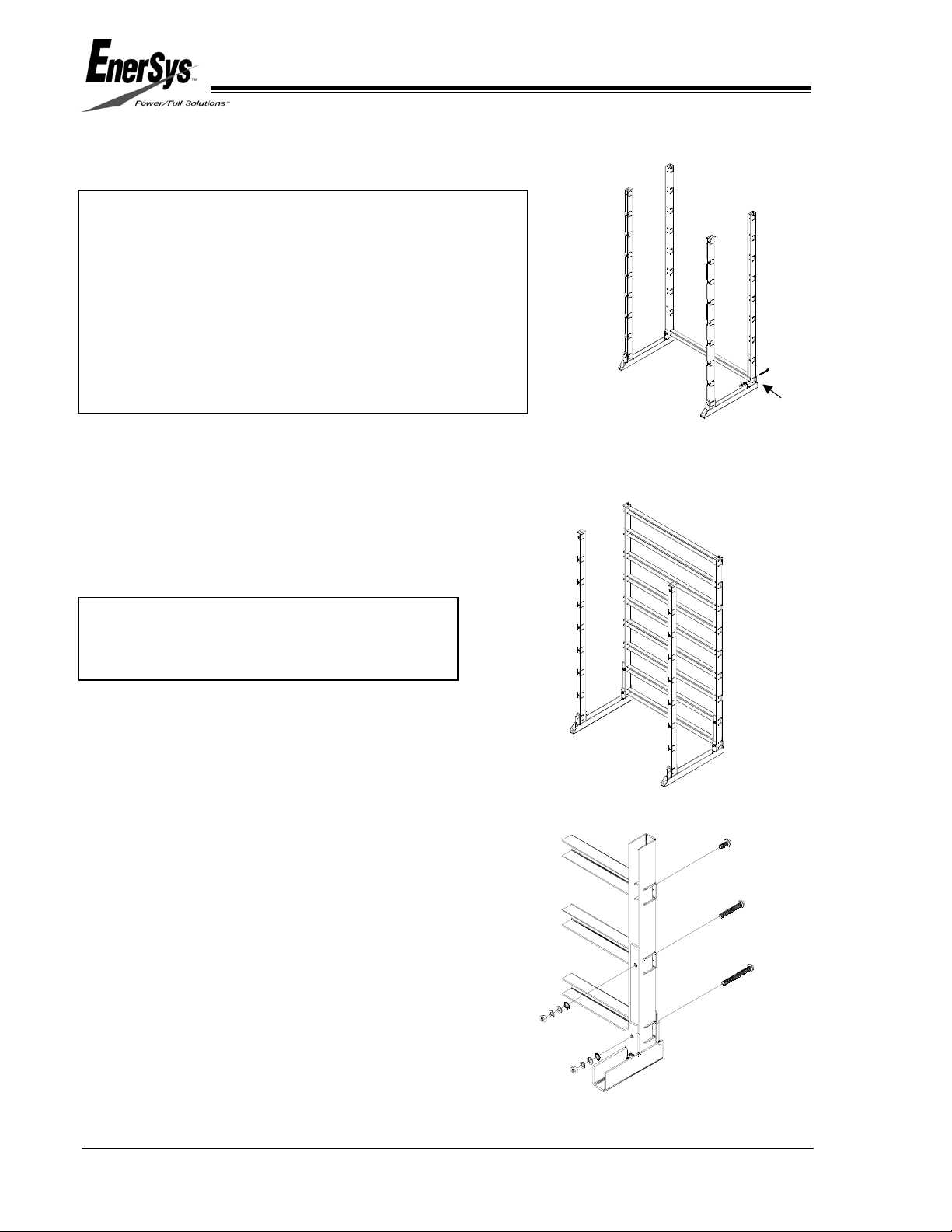

Horizontal Channels

NOTE:

There may be two types of horizontal channels with

your shipment:

1) Rear – have four weld nuts

2) Front – have more than four weld nuts

The front horizontals are universal and, in most

configurations, are substituted for the rear horizontals.

Front horizontals are to be installed with the flange

positioned with the holes facing up.

Starting at the bottom of the REAR verticals:

1. Insert REAR horizontal channels into the

vertical channels. Center the horizontals

between the verticals. See Figures 11a & b.

2. Bolt horizontal channels to vertical channels.

Refer to below list for hardware order and

Figure 12:

NOTE:

The bottom two horizontals require full

thread longer bolts at the vertical channel.

Bottom horizontal:

– Serrated Hex Bolt(M10x1.5 – 100mm

Full Threads),

– Rack Frame,

– External Tooth Washer,

– Flat Washer,

– Lock Washer,

– Hex Nut

Second from bottom horizontal:

– Serrated Hex Bolt (M10x1.5 – 75mm

Full Threads),

– Rack Frame,

– External Tooth Washer,

– Flat Washer,

– Lock Washer,

– Hex Nut

All other horizontals:

– Serrated Hex Bolt (M10x1.5 – 25mm)

3. Finger-tighten connections.

4. Install ALL REAR horizontals before

REAR HORIZONTAL CHANNEL HARDWARE DETAIL

continuing.

INSTALL REAR HORIZONTAL CHANNELS

FIGURE 11A

INSTALL REAR HORIZONTAL CHANNELS

FIGURE 11B

FIGURE 12

Page 8 Publication No. US-DDm-IM-003

www.enersysinc.com November 2003

PowerSafe DDm

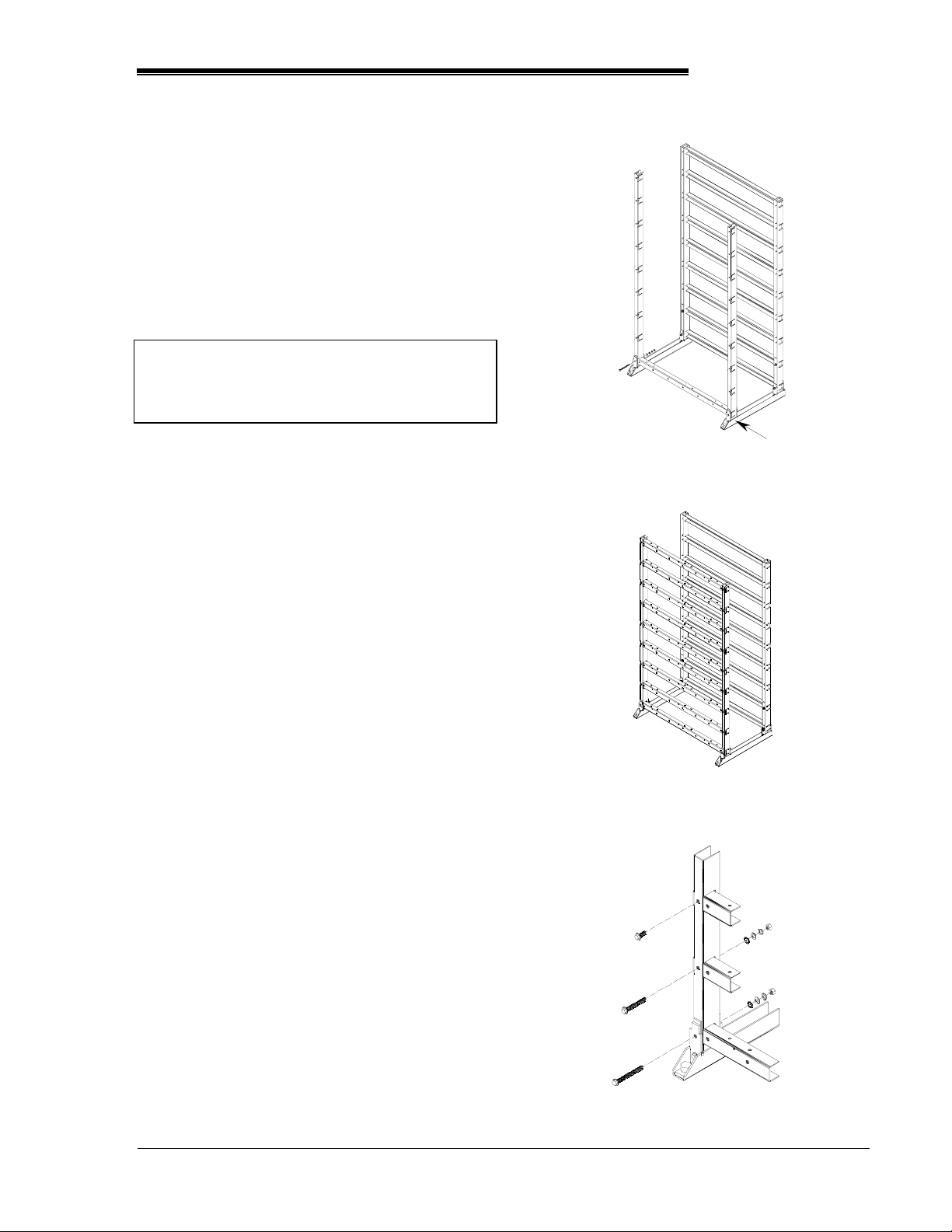

Starting at the bottom of the FRONT verticals:

1. Insert FRONT horizontal channels into the

vertical channels. Center the horizontals

between the verticals. See figures 13A &

13B.

2. Bolt horizontal channels to vertical channels.

Refer to below list for hardware order and

Figure 14.

NOTE:

The bottom two horizontals require full

thread longer bolts at the vertical channel.

Bottom horizontal:

– Serrated Hex Bolt (M10x1.5 – 100mm

Full Threads),

INSTALL FRONT HORIZONTAL

CHANNELS

FIGURE 13A

– Rack Frame,

– External Tooth Washer,

– Flat Washer,

– Lock Washer,

– Hex Nut

Second from bottom horizontal:

– Serrated Hex Bolt

(M10x1.5 – 75mm Full Threads),

– Rack Frame,

– External Tooth Washer,

– Flat Washer,

– Lock Washer,

– Hex Nut

All other horizontals:

– Serrated Hex Bolt (M10x1.5 – 25mm)

INSTALL FRONT HORIZONTAL

CHANNELS

FIGURE 13B

3. Finger-tighten connections.

4. Install ALL FRONT horizontals before

continuing.

Publication No. US-DDm-IM-003 Page 9

November 2003 www.enersysinc.com

REAR HORIZONTAL CHANNEL HARDWARE

DETAIL

FIGURE 14

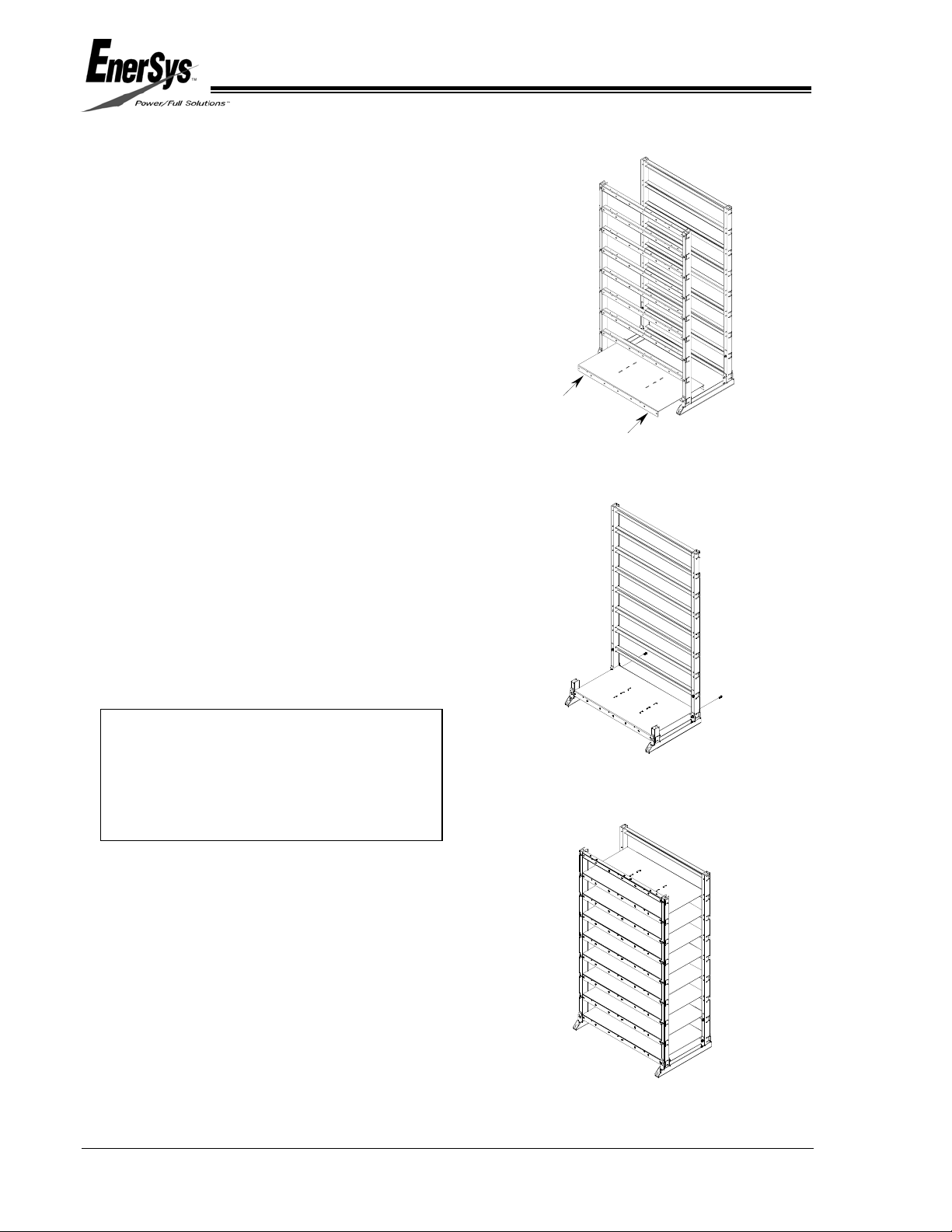

Cell Support Shelves

Starting at the bottom of the rack:

1. Place shelves over FRONT and REAR

horizontals. See Figure 15.

2. Align holes of shelf with holes of horizontal

channels. Bolt the shelf to the REAR

horizontal using (2) M10x1.5 – 25mm

Serrated Hex Bolts in the two OUTSIDE

holes of the shelf. See Figure 16.

3. Torque these bolts to 20 ft-lbs.

4. After ALL shelves for the rack are in place,

position the vertical channels so that the

front and rear horizontals fit tightly against

the shelves. See Figure 17.

5. Torque ALL bolts connecting the horizontals

to the verticals to 20 ft-lbs.

6. If you are installing a MULTI-STACK WITH

ZERO SEPARATION system, repeat

Procedures 1 through 5 until all shelves are

installed.

INSTALL BOTTOM CELL

SUPPORT SHELF

FIGURE 15

NOTE:

MULTI-STACK WITH ZERO

SEPARATION systems are fastened

together at the top front and top rear with

a tie bar.

CELL SUPPORT SHELF

REAR HARDWARE DETAIL

FIGURE 16

7. Torque all anchor bolts according to system

design and manufacturer’s

recommendations.

Page 10 Publication No. US-DDm-IM-003

www.enersysinc.com November 2003

INSTALL CELL SUPPORT

SHELVES

FIGURE 17

BATTERY CELL INSTALLATION

DDm battery cells are designed for shipment

and use in steel modules.

USE CAUTION WHEN HANDLING THE

DDm MODULES

After a cell has been inserted into a

module at the factory, a loose fit could

develop because of recombination. The

cell could slip very easily from the

module if the module/cell is turned so

that the open end of the module is lower

than the closed end of the module.

Serious personal injury could result if the

cell slides unintentionally from the

module. Keep shipping/installation

retainer in place until modules are safely

positioned on the shelves.

PowerSafe DDm

INSTALL FIRST MODULE

FIGURE 18

1. BEFORE installing the cells, check the

voltages. The minimum acceptable cell

voltage is 2.05 vpc.

If a cell has a voltage below 2.05 vpc, call

your nearest EnerSys sales/service

representative for resolution, or call the

corporate office number listed on the back of

this manual and ask for EnerSys Integrated

Systems & Services.

2. Inspect each terminal for visual signs of

mechanical defects.

INSTALL SECOND MODULE

FIGURE 19

NOTE:

Report any defects to your nearest

EnerSys sales/service representative for

resolution, or call the corporate office

number listed on the back of this manual

and ask for EnerSys Integrated Systems &

Services.

If terminals are acceptable:

3. Place the FIRST DDm module onto the

LOWEST EMPTY shelf, with the terminals

toward the front. See Figure 18.

Publication No. US-DDm-IM-003 Page 11

November 2003 www.enersysinc.com

INSTALL MODULES

FIGURE 20

Loading...

Loading...