Page 1

Assembly and Operating Instructions for Outback®

Stainless Steel Column Heater

0063

17

Drawings are not to scale.

Specifications subject to change

without prior notice.

FOR YOUR SAFETY

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flame.

3. If odor continues, immediately call your

gas supplier or your fire Department.

FOR YOUR SAFETY

1. Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

2.An LP cylinder not connected for use shall not be

stored in the vicinity of this or any other appliance .

OUT370663/PH500

Page 2

WARNlNG SAFETY RULES

PLEASE READ THE FOLLOWING SAFETY RULES PRlOR

TO OPERATION OF THE HEATER

FOR YOUR SAFETY

If you smell gas:

1ˊShut off gas to the appliance.

2ˊExtinguish any open flame.

3ˊIf odor continues, immediately call your gas supplier or your fire

Department.

FOR YOUR SAFETY

1.Do not store or use gasoline or other flammable vapors

and liquids in the vicinity of this or any other applianceˊ

2.An LP cylinder not connected for use shall not be stored in the

vicinity of this or any other applianceˊ

WARNlNG

1) For use outdoors or in amply ventilated areas.

2) An amply ventilated area must have a minimum of 25 % of the

surface area open.

3) The surface area is the sum of the walls surface.

WARNING˖ Improper installation, adjustment, alteration, service

or maintenance Can cause injury or property damage. Read the

installation, operating and maintenance instructions thoroughly

before installing or servicing this equipment.

Page 3

warning

Read the instructions before installation and use.

-This appliance must be installed and the gas cylinder stored in

accordance with the regulations in force;

-Do not obstruct the ventilation holes of the cylinder housing;

-Do not move the appliance when in operation;

-Shut off the valve at the gas cylinder or the regulator before moving

the appliance;

-The tubing or the flexible hose must be changed within the

prescribed intervals;

-Use only the type of gas and the type of cylinder specified by the

manufacturer;

The LP tank used with your patio heater must meet the following

requirements:

Purchase LP tanks only with these required measurements:

(31.8cm) (diameter) x 58 cm) (tall) with 15kg capacity maximum.

-In case of violent wind particular attention must be taken against

tilting of the appliance; Keep the appliance at least 1m from the gas

cylinder.

A regulator(compliees with EN16129:2013 and the national regulation)

of the correct pressure corresponding to the appliance category.

Use 30mbar regulator for butane/propane under the category I3B/P(30).

Use 30mbar regulator for butane under the category I3+(28-30/37).

Use 37mbar regulator for propane under the category I3+(28-30/37).

Use 50mbar regulator for butane/propane under the category I3B/P(50).

It's recommended to use flexible hose that approved by EN16436:2014.

Page 4

i

TABLE OF CONTENTS

Caution ……………………………………………………….

1

Heater Stand and Location …………………………………

2

Gas Requirements …………………………………………..

2

Leakage Test …………………………………………………

2

Operation and Storage ……………………………………...

3

Cleaning and Care …………………………………………..

4

Parts and Specifications ..…………………………………..

4

Assembly Parts and Procedures …………………………..

6

Problems Check List ………………………………………...

12

Page 5

-1-

CAUTION

PLEASE READ CAREFULLY THE FOLLOWING SAFETY GUIDELINES BEFORE OPERATION.

Do not use the patio heater for indoors, as it may cause personal injury or property damage.

This outdoor heater is not intended to be inst alled on recreational vehicles and/o r boats.

Installation and repair should be done by a qualified service person.

Improper installation, adjustment, alteration can cause personal injury or property damage.

Do not attempt to alter the unit in any manner.

Never replace or substitute the regul ator with any regulator other than the

factory-suggested replacement.

Do not store or use gasoline or other flammable vapors or liquids in the heater unit.

The whole gas system, hose, regulator, pilot or burner should be inspected for leaks or damage before

use, and at least annually by a qualified service person.

All leak tests should be done with a soap s olution. Never use an open flame t o check for leaks.

Do not use the heater until all connections have been le ak tested.

Do not transport heater while it’s operating.

Do not move the

heater after it has been turned off until the temperature has cooled down.

Keep the ventilation opening of the cylinder enclosure free and clear of debris.

Do not paint the radiant screen, control panel or top canop y reflector.

Control compartment, burner and circulation air passageways of the heater must be kept clean.

Frequent cleaning may be required as necessary.

The LP tank should be turned off when the heater is not in use.

Check the heater immediately if any of the following occurs:

- The heater does not reach temperature.

- The burner makes popping noise during use (a slight noise is norm al when the burner is extinguished).

- Smell of gas in conjunction with extreme yellow tipping of the burner flames.

The LP regulator/hose assembly must be located out of pathways where people may trip over it or in

area where the hose will not be subject to accidental damage.

Any guard or other protective device removed for servicing the heater must be replaced before

operating the

heater.

Adults and children should stay away from high temperature surface to avoid burns or clothing ignition.

Children should be carefully supervised when they are in the area of the heater.

Cl

To change the gas cylinder in a amply ventilated area, away from any ignition

source (candle, cigarettes, other flame producing appliances, ...);

To check that the regulator seal is correctly fitted and able to fulfill its function

showed as photo right;

To not obstruct the ventilation holes of the cylinder housing;

To close the gas supply at the valve of the gas cylinder or the regulator after use;

In the event of gas leakage, the appliance shall not be used or if alight, the gas supply

shall be shut off and the appliance shall be investigated and rectified before it is used again;

To check the hose at least once per monthˈ each time the cylinder is changedˈor each time before long time no use.

If it shows signs of cracking, splitting or other deterioration it shall be exchanged for new hose of the same length and of the

equivalent quality;

The use of this appliance in enclosed areas can be dangerous and is PROHIBITED;

Read the instructions before using this appliance. The appliance must be installed in accordance with the instructions and

local regulations.

For connection of hose and regulator,and connection of regulator and hose, please refer to photo showed above.

othing or other flammable materials should not be hung on the heater or placed on or near the heater.

T

Regulator connection: tighten connection and perform another leak test. If bubbles continue appearing

should be returned to hose’s place of purchase. If leak is at Regulator/Cylinder Valve connection: disconnect,

reconnect, and perform another leak check. If you continue to see bubbles after several attempts, cylinder

valve is defective and should be returned to cylinder’s place of purchase.

urn off the gas valve immediately if smell of gas is detected. Turn Cylinder Valve OFF.If leak is at Hose/

Hose/ Regulator connection and

Regulator / Cylinder connection

seal

hose

regulater

cylinder

Page 6

-2-

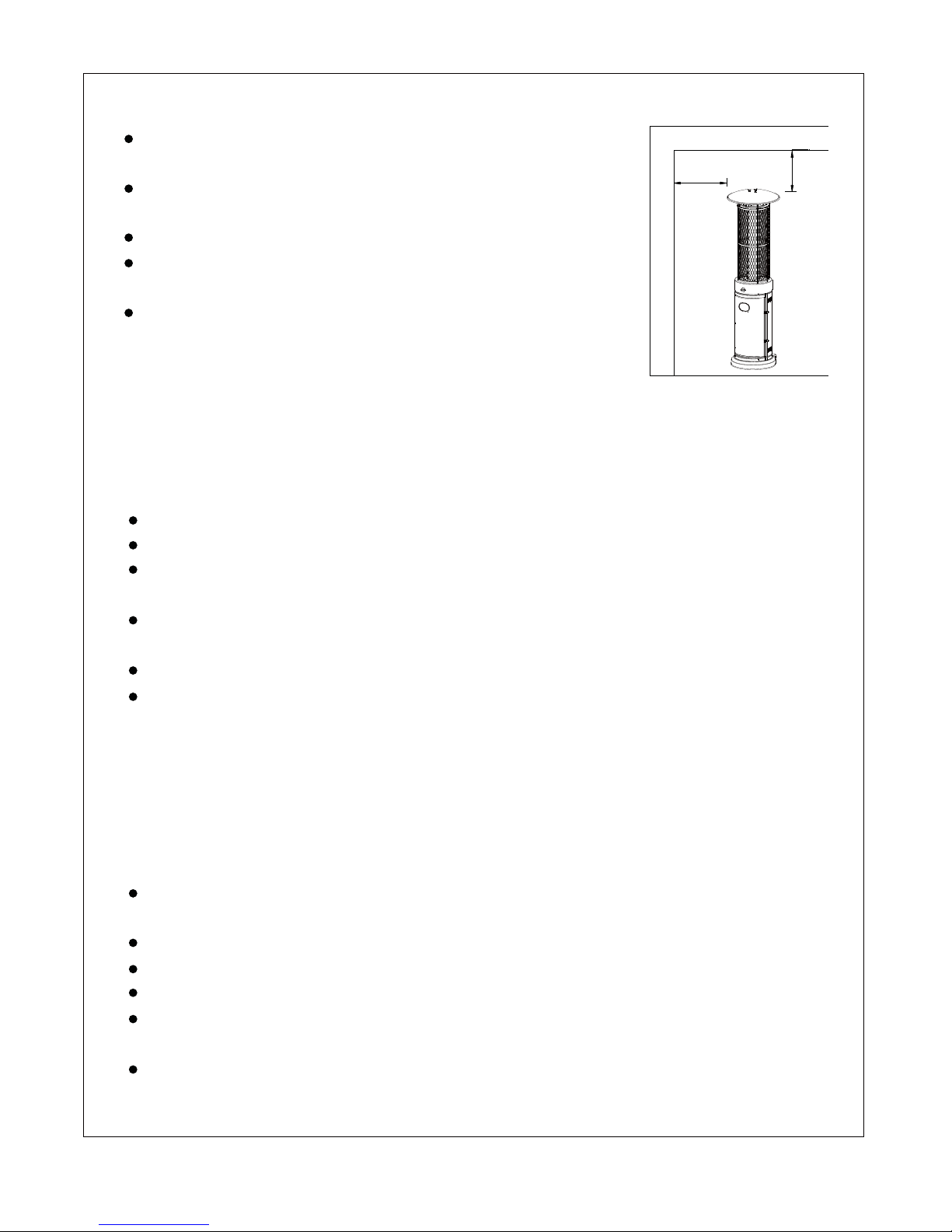

HEATER STAND AND LOCATION

The heater is primarily for outdoor use only. Always ensure that

adequate fresh air ventilation is provided.

Always maintain proper clearance to

non protected combustible materials

i.e. top 100 cm and sides 100 cm minimum.

Heater must be placed on level firm ground.

Never operate heater in an explosive atmosphere like in areas where

gasoline or other flammable liquids or vapors are stored.

To protect heater from strong wind, anchor the base securely to the

ground with screws.

CEILING

WALL

100 cm

100 cm

GAS REQUIREMENTS

Use propane, butane or their mixtures gas only.

The pressure regulator and hose assembly to be used must conform to local standard codes.

The installation must conform to local codes, or in the absence of local codes, with the standard for the

storage and handling of liquid petroleum gases.

A dented, rusted or damaged tank m ay be hazardous and should be checked by your tank

supplier. Never use a tank with a damaged valve connection.

The tank must be arranged to provide for vapor withdrawal from th

e operating cylinder.

Never connect an unregulated tank to the heater.

LEAKAGE TEST

Gas connections on the heater are leak tested at the factory prior to shipment. A complete gas tightness

check must be performed at the installation site due to possible mishandling in shipm e nt or excessive

pressure being applied to the heater.

Make a soap solution of one part liquid detergent and one part water. The soap solution can be applied

with a spray bottle, brush or rag. Soap bubbles will appear in case of a leak.

The heater must be checked with a full cylinder.

Make sure the safety control valve is in the OFF position.

Turn the gas supply ON.

In case of a leak, turn off the gas supply. Tighten any leaking fittings, then turn the gas supply on and recheck.

Never leak test while smoking.

Page 7

regulator

Off: the heater stop work

Hi: maximum temperature position

Lo: minimum temperature position

1. Fully close gas valve.

2. Turn control knob clockwise to OFF position.

Variable control knob

Pointer

Warning˖check that no broken on the glass is found before operation.

1. Depress and turn control knob clockwise to OFF position.

2. Fully open gas valve.

3. Depress control knob and turn knob counterclockwise to IGNITE position, then to PILOT position

(You should hear a clicking sound).

4. Keep the control knob depressed last for 60 seconds,then turn the control knob back to ‘OFF’position.

5.Repeat step 3 several times until the pilot lights.

NOTE: If the pilot light has not ignited, turn heater control knob to OFF position, fully close gas valve,

wait 5 minutes, then repeat steps 2–4 of the Lighting Instructions.

6. Push in and turn the control knob to LOW position, then release control knob. If you want a higher

temperature,push in the control knob and turn counterclockwise to HIGH position.

LOW

HIGH

PILOT

OFF

I

G

N

I

T

E

P

u

s

h

t

o

t

u

r

n

Page 8

CLEANING AND CARE

• Wipe off powder coated surfaces with soft, moist rag. Do not clean heater with cleaners that

are combustible or corrosive.

• Remove debris from the burner to keep it clean and safe for use.

• Cover the burner unit with the optional protective cover when the heater is not in use.

PARTS AND SPECIFICATIONS

- 4 -

1830 mm

890 mm

770 mm

535 mm

460 mm

Reflector

Upper Protective Mesh

Rhombic Protective Mesh

Control Box

Tank housing

Base

Wheel

Page 9

-5-

A. Construction and characteristics

Transportable terrace/garden heater with tank housing.

Casing in steel with powder-coating or in stainless steel.

Gas hose connections with metal clamp (screw caps for Germany).

Heat emission from reflector.

B. Specifications

Use propane,butane or their mixtures gas only.

Max. wattage: 11000 watts

Min. wattage: 5000 watts

Consumption:

The hose and regulator assembly must conform to local standard codes.

Regulator outlet pressure should meet the corresponding appliance category in B. Specification.

The appliance requires approved hose in 0.6m length.

Using the proper regulator according to outlet pressure of regulator as showed in the table above.

C. Table of injector

APPLIANCE CATEGORY:

TYPES OF GAS:

Butane Propane

GAS PRESSURE:

28-30mbar 37 mbar 30 mbar 50mbar 37mbar

TOTAL HEAT

INPUT (Hs): (Qn)

11kW (G30:800g/h; G31:786g/h)

INJECTOR SIZE:

The markingˈ for exampleˈ 1.70 on the injectorˈindicates that the size of injector is 1.70mm

1.70 mm for main burner

0.22 mm for pilot burner

1.35 mm for main burner

0.22 mm for pilot burner

1.48 mm for main burner

0.22 mm for pilot burner

APPLIANCE CATEGORY:

TYPES OF GAS:

Butane Propane

GAS PRESSURE:

28-30mbar 37 mbar 30 mbar 50mbar 37mbar

30mbar 37 mbar 30 mbar 50mbar 37mbar

Butane, propane

or their mixtures

Butane, propane

or their mixtures

Butane, propane

or their mixtures

Butane, propane

or their mixtures

Butane, propane

or their mixtures

Butane, propane

or their mixtures

OUTLET PRESSURE

OF REGULATOR:

3+(28-30/37)

I

I

3+(28-30/37)

I

I

3B/P(30)

I

3B/P(30)

3B/P(50)

I

3B/P(50)

I

3B/P(37)

I

3B/P(37)

Page 10

-6-

ASSEMBLY PARTS

Tools needed:

Philips screwdriver w/ medium blade

Spray bottle of soap solution for leakage test

Parts List:

Upper Protective Mesh

NOITPIRCSED TRAP QUANTITY

A

Reflector

1

B 1

Mesh

C 1

D

Heating Body

E

Gas Hose

F

1

1

G

H

1

Base

Cylinder Housing

Wheel

1

1

Reflector

Upper Protective Mesh

Heating Body

Cylinder Housing

Base

Wheel

A

B

D

F

G

Mesh

C

Gas Hose

E

H

Page 11

-7-

ASSEMBLY PARTS

HARDWARE CONTENTS (shown actual size)

AA BB DD

CC

Wing nut

Qty. 3

Washer Φ6

Qty. 15

Screw M5 X 10

Qty. 11

Stud

Qty. 3

Philips

screwdriver

Qty. 1

Wrench

Qty. 1

II

EE

Ground Fixer

Qty. 3

FF

Bolt M6 x 10

Qty. 6

GG HH

Nut M6

Qty. 6

Page 12

-8-

ASSEMBLY PROCEDURES

Hardware Used

HH

2. Assemble the tank housing.

Secure the tank housing to the base using

4pcs screw M5X10.

x 1

Philips

screwdriver

DD

x 4

Screw M5X10

2

1

F

DD

Hardware Used

1. To protect heater from strong wind, anchor

the base securely to the ground with screws.

Reverse the base, fix the ground fixer to the

base with bolt M6X10 and washer Φ6 like

picture shows. Secure the ground fixer with

nut M6 Fix another two ground fixer with

bolts and nuts, and reverse the base.

BB

x 6

Washer Φ6

EE

x 3

Ground Fixer

FF

x 6

Bolt M6X10

GG

x 6

Nut M6

II

x 1

Wrench

FF

EE

BB

GG

Page 13

-9-

Hardware Used

4. Assemble the mesh.

Secure the mesh to the Heating Body using

3pcs screw M5X10.

DD

HH

x 3

x 1

Philips

screwdriver

Screw M5X10

Hardware Used

3. Assemble the heating body.

Secue the heating body to the tank housing

using 4pcs screw M5X10.

DD

HH

x 4

x 1

Philips

screwdriver

Screw M5X10

3

D

DD

4

C

DD

Page 14

-10-

Hardware Used

6. Assemble the reflector.

a. Screw 3pcs stud to the top of mesh, using

3pcs washerΦ6 to the bottom and 3pcs

washerΦ6 to the top.

b. Put the reflector on the stud and secure

them using 3pcs wing nut and 3pcs

washer.

x 3

x 3

x 9

AA

BB

Wing nut

Washer Φ6

CC

Stud

5. Assemble the upper protective mesh

to the heating body directly.

CAUTION: Do not hang clothing or any

other flammable materials from the heater,

or place on or near the heater. HOT! DO

NOT TOUCH!

CAUTION-HOT SURFACE

HOT WHILE IN OPERATION

DO NOT TOUCH

KEEP CHILDREN, CLOTHING

FURNITURE AND FLAMMABLES AWAY

5

B

6

AA

BB

CC

A

Page 15

-11-

7. Connect the gas hose and regulator after

that connect the regulator to the gas cylinder.

WARNING! Ensure the hose does not contact

any high temperature surfaces, or it may melt

and leak causing a fire.

After the cylinder is placed inside the heater, secure

the cylinder with block belt tightly.

8. Leak Check.

7

Regulator / Cylinder

Hose / Regulator

WARNING!

of the gas system is replaced.

WARNING!EĞǀĞƌƵƐĞĂŶŽƉĞŶŇĂŵĞƚŽĐhĞĐŬĨŽƌŐĂƐůĞĂŬƐĞĐĞƌƚĂŝŶŶŽƐƉĂƌŬƐŽƌŽƉĞŶŇĂŵĞƐĂƌĞ

in the area while you check for leaks. Sparks or ŽƉĞŶŇĂŵĞƐǁŝůůƌĞƐƵůƚŝŶĂĮƌĞŽƌĞdžƉůŽƐŝŽŶĚĂŵĂŐĞƚŽ

ƉƌŽƉĞƌƚLJƐĞƌŝŽƵƐďŽĚŝůLJŝŶũƵƌLJŽƌĚĞĂƚŚ

of the regulator, hose, manifolds and valves.

If the leak cannot be stopped, ŝŵŵĞĚŝĂƚĞůLJƐŚƵƚŽīƚŚĞŐĂƐƐƵƉƉůLJ

8

Page 16

-12-

PROBLEMS CHECK LIST

PROBLEM PROBABLE CAUSE SOLUTION

Pilot will not light Gas valve may be OFF Turn the gas valve ON

Tank fuel empty Refill LPG tank

Opening blocked Clean or replace opening

Air in supply system Purge air from lines

Loose connections Check all fittings

Pilot will not stay on Debris around pilot Clean dirty area

Loose connections Tighten connections

Thermocouple bad Replace thermocouple

Gas leak in line Check connections

Lack of fuel pressure Tank near empty. Refill LPG tank.

B

If the appliance is in case of any defaults or problems of assembly or useˈplease don’t try to modify it by yourselfˈ

contact your supplier or distributor to solve it.

urner will not light Pressure is low Tank near empty. Refill LPG tank.

Opening blocked Remove and clean

Contr

ol not ON Turn valve to ON

Thermocouple bad Replace thermocouple

Pilot light assembly bent Place pilot properly

Not in correct location Position properly and retry

Page 17

13

OUTBACK® WARRANTY

OUTBACK® heater are warranted for a period of one (1) year from the date of purchase to

the original purchaser against defects in materials and workmanship, OUTBACK® will

supply replacements for defective parts free of charge provided that:

xThe product has not been used for trade, professional or hire purposes.

xThe product has not been subjected to misuse or neglect, including fat fires and flare ups

or use of a faulty or incorrect regulator.

xThe product has not sustained damage through foreign objects, substances or accidents.

xThe care and maintenance instructions given in your Outback manual have been followed.

If the product includes one or a number of parts or accessories, only the defective accessory

or part will be replaced i.e. Hose, Regulator, Electric Ignitor and Reflector.

Fat fires are not covered under warranty.

Any warrany & guarantee claims shall be rendered void in the event of improper use of the

heater or the use of non approved fuels, discolouration , rusting or slight deformation of

parts exposed directly to the flames (burner) do not impair the function of the heater and do

not form a basis for any claims.

This warranty is offered as an extra benefit and is in addition to the customers’ statutory

rights.

OUTBACK® does not in any way warranty the gas cylinder.

In the unlikely event that you experience problems with this heater, please fill in our warranty

form at:

http://www.outbackbarbecues.com/warranty-form

One of our colleagues will be in contact with you shortly.

HELPLINE NUMBER: 0345 388 6032

For reference and correspondence, record

your serial number here.

(See sticker on side of barbecue body.)

Serial No.__________________

This number may be required when ordering

spare parts or accessories. A part reference

number may also be required where

applicable.

Loading...

Loading...