Page 1

FX Inverter/Charger

FX and VFX Mobile Series

Installation Manual

Page 2

About OutBack Power Technologies

OutBack Power Technologies is a leader in advanced energy conversion technology. OutBack products include true sine wave

inverter/chargers, maximum power point tracking charge controllers, and system communication components, as well as circuit

breakers, batteries, accessories, and assembled systems.

Applicability

These instructions apply to OutBack inverter/charger models FX2012MT, FX2024M, FX2524MT, FX2532MT, FX2536MT, FX3048MT,

VFX2812M, VFX3524M, VFX3232M, VFX3236M, and VFX3648M only.

Contact Information

Address: Corporate Headquarters

17825 – 59

Suite B

Arlington, WA 98223 USA

Telephone:

Email: Support@outbackpower.com

Website: http://www.outbackpower.com

+1.360.435.6030

+1.360.618.4363 (Technical Support)

+1.360.435.6019 (Fax)

th

Avenue N.E.

European Office

Hansastrasse 8

D-91126

Schwabach, Germany

+49.9122.79889.0

+49.9122.79889.21 (Fax)

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, OUTBACK POWER TECHNOLOGIES:

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR OTHER INFORMATION

PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT, INDIRECT, CONSEQUENTIAL OR

INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE

ENTIRELY AT THE USER’S RISK.

OutBack Power Technologies cannot be responsible for system failure, damages, or injury resulting from improper installation of

their products.

Information included in this manual is subject to change without notice.

Notice of Copyright

FX and VFX Mobile Series Inverter/Charger Installation Manual © 2016 by OutBack Power Technologies. All Rights Reserved.

Trademarks

OutBack Power, the OutBack Power logo, FLEXware, and OPTICS RE are trademarks owned and used by OutBack Power

Technologies, Inc. The ALPHA logo and the phrase “member of the Alpha Group” are trademarks owned and used by Alpha

Technologies Inc. These trademarks may be registered in the United States and other countries.

Date and Revision

August 2016, Revision A

Part Number

900-0197-01-00 Rev A

Page 3

Table of Contents

Introduction ..................................................................................................... 5

Audience ......................................................................................................................................................................................... 5

Symbols Used ................................................................................................................................................................................ 5

Welcome to OutBack Power Technologies ......................................................................................................................... 6

General Safety ............................................................................................................................................................................... 6

Models .............................................................................................................................................................................................. 7

Sealed Mobile Models ............................................................................................................................................................................. 7

Vented Mobile Models ............................................................................................................................................................................ 7

Inverter Model Names ............................................................................................................................................................................. 7

Components and Accessories .............................................................................................................................................................. 8

Planning .......................................................................................................... 9

Applications ................................................................................................................................................................................... 9

Renewable Energy ................................................................................................................................................................................. 10

Battery Bank ............................................................................................................................................................................................. 10

Generator .................................................................................................................................................................................................. 12

Installation ..................................................................................................... 13

Location and Environmental Requirements .................................................................................................................... 13

Tools Required ............................................................................................................................................................................ 13

Mounting ...................................................................................................................................................................................... 14

Dimensions .................................................................................................................................................................................. 14

Terminals and Ports .................................................................................................................................................................. 15

Wiring ............................................................................................................................................................................................ 16

Grounding ................................................................................................................................................................................................ 16

DC Wiring ..................................................................................................................................................................................... 18

AC Wiring...................................................................................................................................................................................... 21

AC Sources ................................................................................................................................................................................................ 22

ON and OFF Wiring ................................................................................................................................................................... 23

Accessory Wiring .................................................................................................................................................................................... 23

AUX Wiring .................................................................................................................................................................................. 24

Generator Control .................................................................................................................................................................................. 25

AC Configurations ..................................................................................................................................................................... 27

Single-Inverter ......................................................................................................................................................................................... 27

Multiple-Inverter AC Installations (Stacking) ................................................................................................................................ 28

Stacking Configurations ...................................................................................................................................................................... 30

Commissioning .............................................................................................. 41

Functional Test ........................................................................................................................................................................... 41

Pre-startup Procedures ........................................................................................................................................................................ 41

Startup ....................................................................................................................................................................................................... 41

Powering Down ...................................................................................................................................................................................... 43

Adding New Devices ............................................................................................................................................................................. 43

Operation ..................................................................................................................................................................................... 43

Definitions .................................................................................................................................................................................... 43

Index ............................................................................................................. 45

900-0197-01-00 Rev A 3

Page 4

Table of Contents

List of Tables

Table1 ComponentsandAccessories..................................................................................................8

Table2 BatteryBankElements..........................................................................................................11

Table3 GroundConductorSizeandTorqueRequirements...............................................................16

Table4 DCConductorSizeandTorqueRequirements......................................................................18

Table5 StackingModesforMobileFXInverters................................................................................29

Table6 TermsandDefinitions............................................................................................................43

List of Figures

Figure1 FXMobileSeriesInverter/ChargerwithTurboFan.................................................................6

Figure2 Components.............................................................................................................................8

Figure3 Applications(Example)............................................................................................................9

Figure4 Dimensions............................................................................................................................14

Figure5 Terminals,Ports,andFeatures..............................................................................................15

Figure6 DCGroundLug.......................................................................................................................17

Figure7 ChassisGround......................................................................................................................17

Figure8 RequiredOrd

Figure9 BatteryTerminalCovers........................................................................................................19

Figure10 DCCoverAttachment............................................................................................................20

Figure11 TurboFanWiring...................................................................................................................20

Figure12 ACTerminals..........................................................................................................................21

Figure13 ACSources.............................................................................................................................22

Figure14 ACSourcesandTransferRelay..............................................................................................22

Figure15 ON/OFFJumperandConnections.........................................................................................23

Figure16 AccessoryConnections..........................................................................................................23

Figure17 AUXConnectionsforVentFan(Exa

Figure18 Two‐WireGeneratorStart(Example)....................................................................................25

Figure19 Three‐WireGeneratorStart(Example).................................................................................26

Figure20 Single‐InverterWiring............................................................................................................27

Figure21 OutBackHUB

Figure22 ExampleofClassicSeriesStackingArrangement..................................................................30

Figure23 ClassicSeriesWiring..............................................................................................................31

Figure24 ExampleofOutBackSeriesStackingArrangement...............................................................32

Figure25 OutBackSeriesWiring(TwoInverters)..................................................................................33

Figure26 ExampleofParallelStackingArrangement(ThreeIn

Figure27 ParallelWiring(FourInverters).............................................................................................35

Figure28 ExampleofSeries/ParallelStackingArrangement(FourInverters)......................................36

Figure29 Series/ParallelWiring(FourInverters).................................................................................37

Figure30 ExampleofThree‐PhaseStackingArrangement(ThreeInverters).......................................38

Figure31 Three‐PhaseWiring(ThreeInverters)...................................................................................39

Figure32 ACTermi

erofBatteryCableHardw

10.3,

MATE2,andMATE3...............................................................................28

n

als..........................................................................................................................42

are..........................................................................19

mple

).............................................................................24

verters)...............................................34

4 900-0197-01-00 Rev A

Page 5

Introduction

Audience

This book provides instructions for the physical installation and wiring of this product.

These instructions are for use by qualified personnel who meet all local and governmental code

requirements for licensing and training for the installation of electrical power systems with AC and DC

voltage up to 600 volts. This product is only serviceable by qualified personnel.

Symbols Used

WARNING: Hazard to Human Life

This type of notation indicates that the hazard could be harmful to human life.

CAUTION: Hazard to Equipment

This type of notation indicates that the hazard may cause damage to

the equipment.

IMPORTANT:

This type of notation indicates that the information provided is important to

the installation, operation and/or maintenance of the equipment. Failure to

follow the recommendations in such a notation could result in voiding the

equipment warranty.

NOTE:

This type of notation indicates that the information provided is important to

understanding the operation and limits of the equipment. Failure to follow the

recommendations in such a notation could result in improper or failed

operation.

MORE INFORMATION

When this symbol appears next to text, it means that more information is available in other

manuals relating to the subject. The most common reference is to the FX and VFX Mobile Series

Inverter/Charger Operator’s Manual. Another common reference is the system display manual.

900-0197-01-00 Rev A 5

Page 6

Introduction

WARNING: Limitations on Use

WARNING: Reduced Protection

CAUTION: Equipment Damage

12-, 24-, 32-, 36-, and 48-volt models

Welcome to OutBack Power Technologies

Thank you for purchasing the OutBack FX Mobile Series Inverter/Charger. This product offers a complete

power conversion system between batteries, shore power, and generator.

Output power from 2.0 kVA to 3.6 kVA

Designed to be integrated as part of a full system

using FLEXware™ components

Battery (DC)-to-AC inverting with single-phase

120 Vac output at 60 Hz

Shore power (AC)-to-battery (DC) charging

(FX systems are battery-based)

Rapid transfer between shore power (AC source)

and inverter output with minimal delay time

Uses the MATE™, MATE2™ or MATE3™ System Display

and Controller or the AXS Port™ SunSpec

Modbus Interface (all sold separately) for user interface

Supports the OPTICS RE™ online tool

cloud-based remote monitoring and control application

1

for a

~ Requires the MATE3 or the AXS Port

~ Visit www.outbackpower.com to download

Uses the HUB4™ or HUB10.3™ Communications Manager (sold separately) for stacking

~ Stackable in series (OutBack or Classic), parallel, series/parallel, and three-phase configurations

Automatic neutral-to-ground bond switching

Listed to ANSI/UL 458 (5th Edition) and CSA 22.2 by ETL

Figure 1 FX Mobile Series Inverter/Charger with Turbo Fan

General Safety

This equipment is NOT intended for use with life support equipment or other medical

equipment or devices.

If this product is used in a manner not specified by FX product literature, the product’s

internal safety protection may be impaired.

Only use components or accessories recommended or sold by OutBack Power

Technologies or its authorized agents.

1

Outback Power Technologies Intuitive Control System for Renewable Energy

6 900-0197-01-00 Rev A

Page 7

Introduction

Models

Sealed Mobile Models

Sealed inverter models are designed for dusty and humid environments and can survive casual exposure

to the elements. However, enclosed protection is still recommended. These inverters are internally

ventilated and do not use outside air for cooling. To compensate, most sealed models are also equipped

with the OutBack Turbo Fan assembly which uses external air to remove heat from the chassis.

FX2012MT (2.0 kVA output, 12 Vdc)

FX2024M (2.0 kVA output, 24 Vdc)

FX2524MT (2.5 kVA output, 24 Vdc)

FX2532MT (2.5 kVA output, 32 Vdc)

FX2536MT (2.5 kVA output, 36 Vdc)

FX3048MT (3.0 kVA output, 48 Vdc)

Vented Mobile Models

Vented inverter models are intended for indoor or protected installation only. On average, the wattage of

vented models is rated higher than sealed models. This is due to the greater cooling capabilities of the

vented models.

VFX2812M (2.8 kVA output, 12 Vdc)

VFX3524M (3.5 kVA output, 24 Vdc)

VFX3232M (3.2 kVA output, 32 Vdc)

VFX3236M (3.6 kVA output, 36 Vdc)

VFX3648M (3.6 kVA output, 48 Vdc)

Inverter Model Names

FX mobile model numbers use the following naming conventions.

The model number includes “FX” as the inverter series.

Vented models are preceded with “V”, as in “VFX3648M”.

The first two digits show the power of that model. For example, “FX2012MT” is 2000 watts.

The second pair of digits shows the inverter’s nominal DC voltage. For example, “FXR2524MT” is 24 volts.

Models equipped with a Turbo Fan end with the letter “T”. This designation indicates a sealed model. Vented FX

inverter models are not equipped with Turbo Fans. (Model FX2024M is a sealed model without a Turbo Fan.)

Mobile models (all models featured in this manual) use the letter “M” as either the last or second to

last character (as in “FX2012MT” or “VFX2012M”). These models are meant to be installed in a vehicle and should

not be installed anywhere else. Similarly, a non-mobile inverter should not normally be installed in a vehicle.

For this reason this manual refers to “M” series inverters as “mobile”.

installed accordingly.

IMPORTANT:

Installing an inverter in the wrong application invalidates its listing, may violate

installation codes, and may void the inverter’s warranty.

2

Other inverters, if they are referenced, are referred to as “permanently installed.”

900-0197-01-00 Rev A

2

The instructions assume they are

7

Page 8

Introduction

Components and Accessories

Table 1 Components and Accessories

Components to be Installed Accessories Included

Battery Terminal Cover, red FX Mobile Series Installation Manual (this book)

Battery Terminal Cover, black FX Mobile Series Operator’s Manual

AC Plate “WARNING ELECTRICAL SHOCK” sticker

DC Cover (DCC) or Turbo Fan Silicone Grease Packet

Remote Temperature Sensor (RTS)

DCC (DC Cover)

This covers the DC terminal area on vented inverters. The

DCC provides space to mount other components such as a

DC current shunt.

AC Plate

This plate is used for installations which do not utilize OutBack’s

optional FLEXware conduit boxes. The knockouts are used to

install strain relief for flexible cable.

NOTE: This plate is not to be connected to conduit.

Battery Terminal Cover

These protect the terminals from accidental contact. They are

made of stiff plastic with a snap-on design.

Always keep covers installed during operation.

Turbo Fan Cover

Included in place of the DCC on sealed inverters. Convectively cools

chassis with the external OutBack Turbo Fan to allow maximum power.

NOTE: Do not install the Turbo Fan on a vented inverter.

NOTE: The DC Cover or Turbo Fan does not replace the battery terminal

covers. These covers must be installed in addition to the DCC or fan.

8 900-0197-01-00 Rev A

Figure 2 Components

Page 9

Planning

o

y

Applications

OutBack inverter/chargers are designed to use a battery bank to store energy. In shore-based mobile and

marine connections, the shore power is used as the primary source. When the shore power is removed,

the inverter takes over to run the loads from the batteries. The settings can be changed to accommodate

many applications. Changes are made with the system display.

Mobile FX inverter/chargers work together with power from the utility grid (shore power), generator,

vehicle alternator, and/or renewable energy sources such as photovoltaic (PV) modules. When not using

the batteries, the inverter can charge it from an AC source. The alternator, PV harvest, or other DC sources

can also be used to recharge the batteries.

The FX inverter has one set of terminals for a single AC source. However, it can use two AC sources when

an external transfer switch is installed. The inverter can be independently programmed for each source. It

is common to use shore power and an AC generator. Other combinations of AC sources are possible.

Shore

Power

AC Generator

AC IN

Mobile FX or VFX

Inverter/Charger

r

Charge

Controller

PV Arra

Alternator

Loads

Programming

Selection of all inverter programming is performed using a system display such as the MATE, MATE2, or

MATE3. The system display can customize a wide range of parameters.

900-0197-01-00 Rev A 9

AC OUT

Figure 3 Applications (Example)

DC IN

or

DC OUT

or

Battery

Bank

Page 10

Planning

Renewable Energy

The inverter cannot connect directly to PV, alternators, or other DC sources. The batteries are the

inverter’s primary source of power. However, if the DC sources are used to charge the batteries, the

inverter can use their energy by drawing it from the batteries.

A renewable source is always treated as a battery charger, even if all of its power is used immediately.

The renewable source must have a charge controller, or some other regulation method, to prevent

overcharging. OutBack Power’s FLEXmax family of charge controllers can be used for this purpose, as

can other products.

Battery Bank

When planning a battery bank, consider the following:

Cables

determine the placement of the battery bank. Local codes or regulations may apply and will take priority over

OutBack recommendations.

Battery Type

~ The cycle was designed for lead-chemistry batteries intended for deep discharge. These include batteries for RV, marine,

~ Lithium-based batteries and other advanced battery technologies may require special considerations. Please contact

Nominal Voltage

depending on inverter model. Before constructing a battery bank, check the inverter model and confirm

nominal battery voltage.

Charger Settings and Maintenance

usually recommended for safety reasons. It may be necessary to use a fan to ventilate the battery enclosure.

Batteries must be regularly maintained according to the instructions of the battery manufacturer.

: Recommendations for battery cable size and length are shown on page 18. The maximum length will

: The FX inverter/charger uses a three-stage charge cycle.

golf-cart, and forklift applications. They also include gel-cell batteries and absorbed glass-mat (AGM) batteries. OutBack

Power recommends the use of batteries designed specifically for renewable energy applications. Automotive batteries

are strongly discouraged and will have a short life if used in inverter applications.

OutBack Technical Support at +1.360.618.4363 before implanting advanced technologies.

: These inverters are designed to work with specific battery bank voltages, which are different

: A vented battery enclosure may be required by electric code and is

IMPORTANT:

Battery charger settings need to be correct for a given battery type. Always follow

battery manufacturer recommendations. Making incorrect settings, or leaving them at

factory default settings, may cause the batteries to be undercharged or overcharged.

CAUTION: Hazard to Equipment

Batteries can emit vapors which are corrosive over long periods of time. Installing

the inverter in the battery compartment may cause corrosion which is not covered

by the product warranty. (Sealed batteries may be an exception.)

Bank Size:

Battery bank capacity is measured in amp-hours. Determine the required bank specifications as

accurately as possible, beginning with the items below. This avoids underperformance or wasted capacity.

These ten items are obtainable in different places, summarized in Table 2 on the next page. Some of the

information is specific to the site or application. Some can be obtained from the battery manufacturer.

Information on OutBack products is available from OutBack Power Technologies or its dealers.

A. Size of load:

B. Daily hours of use:

C. Days of autonomy:

D. Application: This often helps define or prioritize the previous three items. Off-grid systems often require enough

capacity to last for an extended period before recharging. Grid-connected systems frequently need only enough

capacity for short-term backup during outages.

10

These are the most basic and

essential factors used to

determine bank size.

900-0197-01-00 Rev A

Page 11

Planning

E. Conductor efficiency: Wire size and other factors will waste

power due to resistance and voltage drop. Typical

acceptable efficiency is 96 to 99%.

F. Inverter efficiency: FX specifications list “Typical Efficiency”

to help estimate operating loss.

G. System DC voltage: Each inverter model requires a specific DC voltage to operate.

H. Battery voltage: Most individual battery voltages are less than the system DC voltage. The batteries may need to be

placed in series to deliver the correct voltage.

I. Capacity: Battery capacity, which is measured in

amp-hours, is not usually a fixed number. It is

specified based on the rate of discharge. For example,

the OutBack EnergyCell 200RE is rated at 134.5 Ahr

when discharged at the 5-hour rate (to terminal

voltage 1.85 Vpc). This is a high rate of discharge that

would hypothetically drain the battery in 5 hours.

The same battery is rated at 191 Ahr when used at the

100-hour rate. Use the appropriate discharge rate

(correlated to the expected loads) to measure the

capacity of a battery. Use battery specifications for

terminal voltage 1.85 Vpc whenever possible.

NOTE: Capacity ratings are for batteries at 25°C.

Capacity is reduced at cooler temperatures.

J. Maximum depth of discharge (DoD): Most batteries cannot be discharged below a certain level without damage. The

bank requires enough total capacity to keep this from happening.

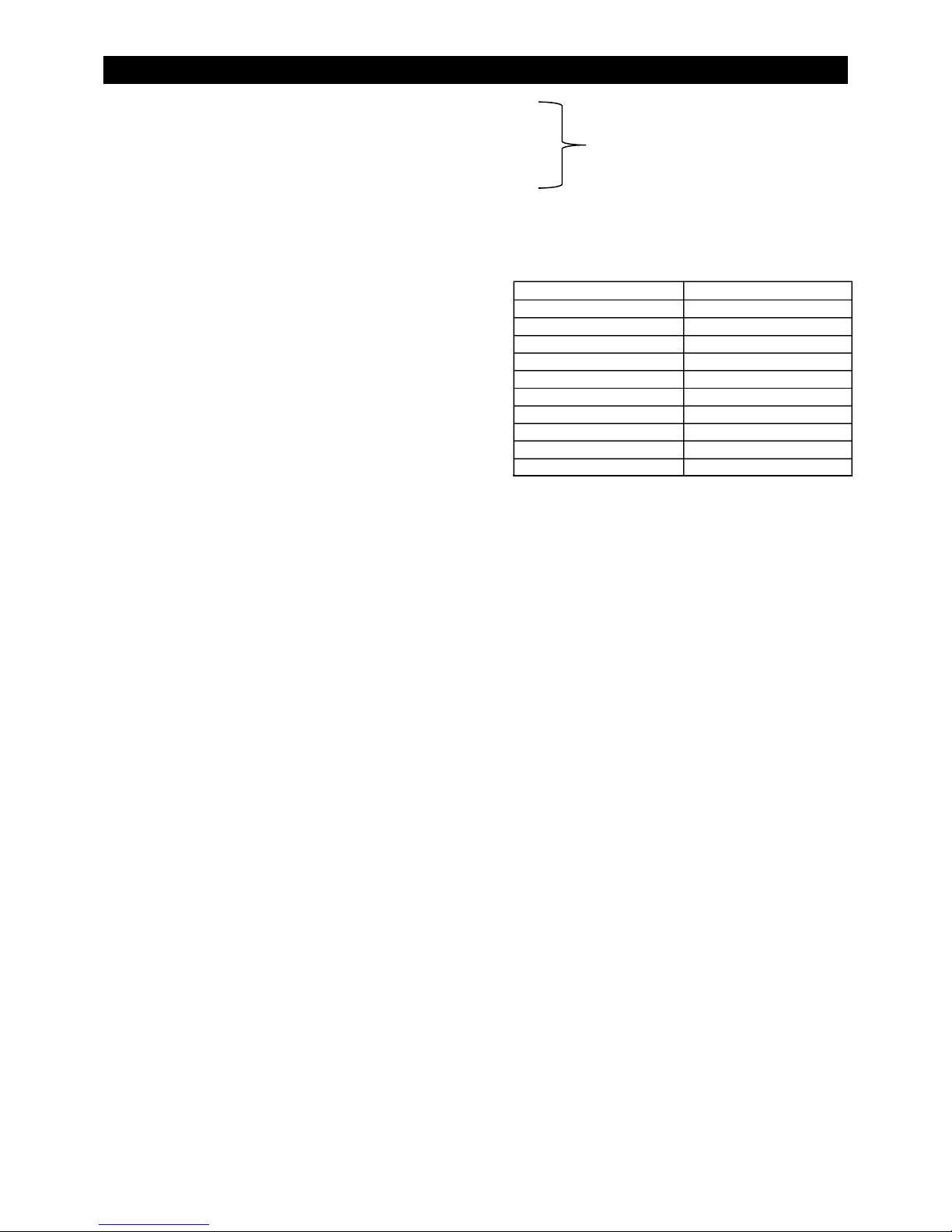

Table 2 Battery Bank Elements

Item Source of information

A. Load Size Site-specific

B. Daily Hours Site-specific

C. Days of Autonomy Site-specific

D. Application Site-specific

E. Conductor Efficiency Site-specific

F. Inverter Efficiency Inverter manufacturer

G. System Vdc Inverter manufacturer

H. Battery Vdc Battery manufacturer

I. Capacity Battery manufacturer

J. Maximum DoD Battery manufacturer

To Calculate Minimum Battery Bank Size (refer to Table 2 for letter designations):

Any losses are essentially amp-hour

capacity that the system cannot use. The

battery bank size can be increased to

account for losses.

1.

The load size, item A, is measured in watts. Compensate this figure for efficiency loss. Multiply the

conductor efficiency by the inverter efficiency (E x F). (These items are represented as percentages, but

may be displayed as decimals for calculation.) Divide item A by the result.

2. Convert the compensated load into amperes (Adc). Divide the step 1 result by the system voltage (item G).

3. Determine the daily load consumption in ampere-hours (amp-hours, or Ahr). Multiply the step 2 result by

the daily usage hours (item B).

4. Adjust the total for required days of autonomy (the days the system must operate without recharging)

and the maximum DoD. Multiply the step 3 result by C and divide by J.

The result is the total amp-hour capacity required for the battery bank.

5. Determine the number of parallel battery strings required. Divide the Ahr figure from step 4 by the

individual battery capacity (I). Round the result to the next highest whole number.

6. Determine the total number of batteries required. Divide the system voltage by the battery voltage

(G ÷ H). Multiply the result by the step 5 result.

The result is the total required quantity of the chosen battery model.

EXAMPLE #1

A. Loads: 0.5 kW (500 W)

B. Hours of use: 6

C. Days of autonomy: 1

D. Grid-interactive system (FX2012MT inverter)

E. Conductor efficiency: 98% (0.98)

F. Inverter efficiency: 90% (0.9)

G. System voltage: 12 Vdc

H. Batteries: OutBack EnergyCell 200RE (12 Vdc)

I. Capacity at 8-hour rate: 148.8 Ahr

J. Maximum DoD: 80% (0.8)

900-0197-01-00 Rev A 11

1) A ÷ [E x F] 500 ÷ (0.98 x 0.9) = 566.9 W

2) 1 ÷ G 566.9 ÷ 12 = 47.2 Adc

3) 2 × B 47.2 × 6 = 283.4 Ahr

4) [3 × C] ÷ J [283.4 × 1] ÷ 0.8 = 354.3 Ahr

5) 4 ÷ I 354.3 ÷ 148.8 = 2.38 (rounded to 3)

6) [G ÷ H] × 5 [12 ÷ 12] × 3 strings = 3 batteries

Page 12

Planning

Generator

EXAMPLE #2

A. Loads: 1 kW (1000 W)

B. Hours of use: 3

C. Days of autonomy: 1

D. Off-grid system (FX3048MT inverter)

E. Conductor efficiency: 97% (0.97)

F. Inverter efficiency: 93% (0.93)

G. System voltage: 48 Vdc

H. Batteries: OutBack EnergyCell 200RE (12 Vdc)

I. Capacity at 8-hour rate: 148.8 Ahr

J. Maximum DoD: 50% (0.5)

The FX inverter can accept single-phase input from a generator that delivers clean AC power in the range of

voltage and frequency specified for that model.

~ Inverters stacked for split-phase output (120/240 Vac) can work with both output lines of a split-phase generator.

See pages 30, 32, and 36.

~ Inverters stacked for three-phase output can work with three-phase generators. See page 38.

The inverter/charger can provide a start signal to control an automatic start generator. If automatic generator

starting is required, the generator must be an electric-start model with automatic choke. It should have two-wire

start capability. For other configurations, additional equipment may be required.

1) A ÷ [E x F] 1000 ÷ (0.97 x 0.93) = 1108.5 W

2) 1 ÷ G 1108.5 ÷ 48 = 23.1 Adc

3) 2 x B 23.1 x 3 = 69.3 Ahr

4) [3 x C] ÷ J [69.3 x 1] ÷ 0.5 = 138.6 Ahr

5) 4 ÷ I 138.6 ÷ 148.8 = 0.93 (rounded to 1)

6) [G ÷ H] x 5 [48 ÷ 12] x 1 strings = 4 batteries

In any configuration, the inverter may need to be specifically programmed using the system display.

Perform all programming according to the specifications of the generator and the required operation of the

inverter. Parameters to be programmed may include generator size, automatic starting requirements, and

potential fluctuations in generator AC voltage.

Mobile generators are usually equipped with a bond between the neutral and ground connections. Mobile FX

inverter models have neutral-ground switching. This function establishes a bond on the inverter when no

generator is present, but removes it when the generator is running. See page 15 for more information on

neutral-ground bonding.

Generator Sizing

A generator should be sized to provide enough power for all the loads and the battery charger.

The generator size should assume maximum loads and maximum charging at the same time.

Available generator power may be limited by ratings for circuit breakers and/or generator connectors.

The generator must be able to provide current to all inverters on a given phase or output. Minimum generator

3

is usually recommended to be twice the power of the inverter system. For example, a 2 kVA inverter should

size

have a 4 kVA (or larger) generator. Many generators may not be able to maintain AC voltage or frequency for

long periods of time if they are loaded more than 80% of rated capacity.

In addition, if a split-phase 120/240 Vac generator is powering a single-phase 120 Vac inverter system with no

other compensation, it is

required

heavily loaded on one output line may suffer severely from balancing issues. The OutBack FW-X240 or PSX-240

balancing transformers may compensate for this condition.

IMPORTANT:

In general, the generator output should match the stacking and output of the inverters.

A three-phase generator should not be used with a 120/240 Vac inverter system.

3

This is the generator size after derating for environment, use, and other factors.

A purely 240 Vac generator will cause damage if used with a 120 Vac inverter system.

12

to be at least twice the power of the inverters. A split-phase generator that is

900-0197-01-00 Rev A

Page 13

Installation

Location and Environmental Requirements

Sealed (FX) models are resistant to water and other elements but are not designed for permanent outdoor

installations. If installation on the outside of a vehicle is required, the FX inverter must be installed under

cover and protected from direct exposure to the environment. Vented (VFX) models are not resistant to

water and other elements. They must be installed in a weather-proof enclosure or enclosed area.

The inverter can often be mounted in any position or orientation. If there is any exposure to moisture or

condensation, the inverter must not be mounted upside-down. This ensures that water will not accumulate

under the DC cover. However, it can still be mounted in other positions or orientations.

For installations where the inverter may be exposed to moisture or condensation, a sealed model must be used

and mounted either with the base down (shelf mounting) or with the AC wiring compartment facing down

(wall mounting). If mounted with the base down, water cannot be allowed to accumulate around the inverter’s

base. There is a drainage system on the base of the inverter to dispel condensation. If submerged, water can

enter this drain and cause failure.

Vented inverters must be installed in a weather-proof enclosure or enclosed area. These models are not

designed for exposure to water or excessive wind-blown dust and debris.

When inverters are installed with an OutBack FLEXpower system, the system must be installed in the upright

orientation due to the requirements of the circuit breakers.

Any inverter will perform more efficiently in locations offering plenty of air circulation. The recommended

minimum clearance is 2 inches (5 cm) on all sides of the inverter.

Any inverter will function to all of its specifications if operated in a range of –4°F to 122°F (–20°C to 50°C).

The inverter will function, but will not necessarily meet its specifications, if operated in a temperature range of

–0°F to 140°F (–40°C to 60°C). This is also the allowable temperature range for storage.

The FX series of inverters carry an Ingress Protection (IP) rating of 20 and a Relative Humidity (RH) rating of 93%

(non-condensing).

Inverter specifications are listed in the FX Mobile Series Inverter/Charger Operator’s Manual.

Tools Required

Wire cutters/strippers

Torque wrenches

Assorted insulated screwdrivers

Digital voltmeter (DVM) or standard voltmeter

900-0197-01-00 Rev A 13

Page 14

Installation

Mounting

One person can install the FX inverter, but installation may be easier with two people.

The unit has four mounting holes, one in each corner. Use fasteners in all corners for a secure installation.

Due to the variance in other mounting methods, OutBack only endorses the use of FLEXware mounting

products or previous versions of OutBack mounting plates. Use M6 x 20 mm machine screws, one per corner,

to attach the inverter to the mounting plate. Follow the instructions with each mounting system.

Mount and secure each component before attaching any wiring.

When the inverter is used with other metal chassis, make sure that all chassis are grounded appropriately.

(See the grounding instructions on page 15.) Grounding other chassis may involve metal-to-metal contact, or

separate ground wires.

If using an OutBack FLEXware Mounting Plate, avoid large air gaps behind the plate. These can result in

louder mechanical noise during heavy inverting or charging. Mount the plate on a flat, solid

mounting surface.

IMPORTANT:

Use correct fasteners to secure the inverter to the mounting surface,

regardless of the type of surface. OutBack cannot be responsible for

damage to the product if it is attached with inadequate fasteners.

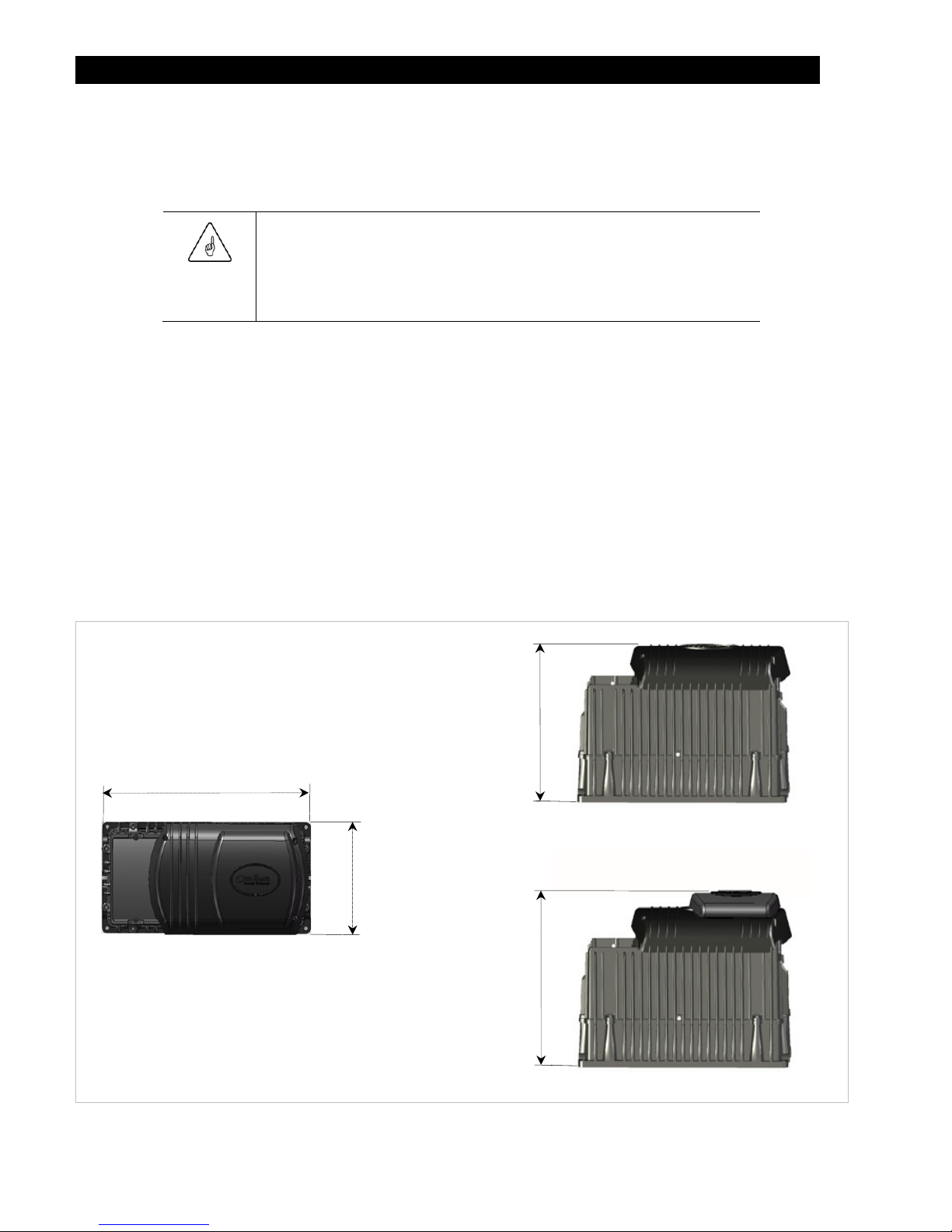

Dimensions

Length 16.25” (41 cm)

Height

without

Turbo

12” (30.5 cm)

Width

8.25” (21 cm)

Height

with Turbo

13” (33 cm)

14

Figure 4 Dimensions

900-0197-01-00 Rev A

Page 15

Terminals and Ports

Installation

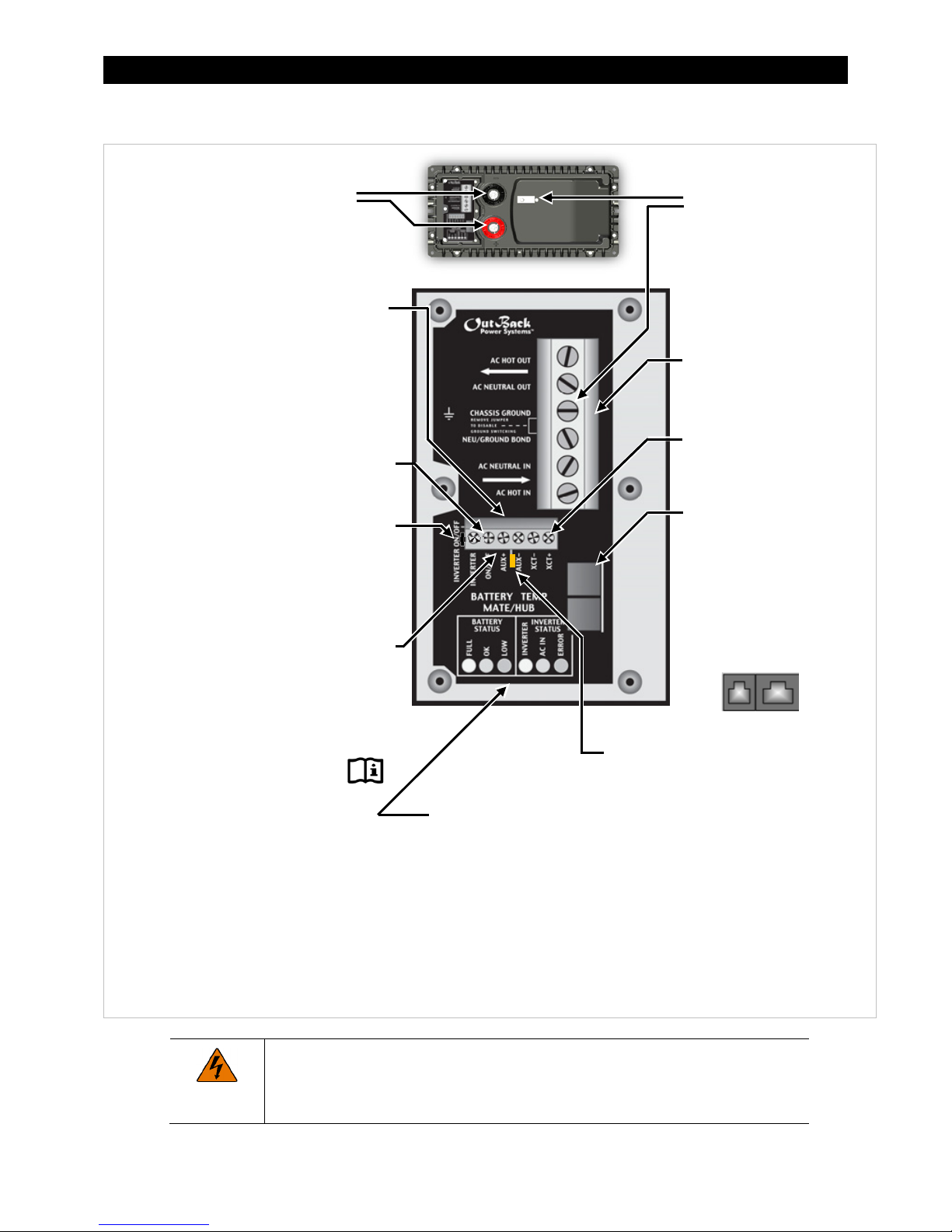

DC TERMINALS

These terminals connect to the

battery cables and the DC system.

See page 18 for instructions.

CONTROL WIRING TERMINAL BLOCK

These terminals receive control wires for a

variety of functions including generator control.

See pages 24 and 25 for instructions and the

Operator’s Manual for more information.

The Terminal Block can be unplugged from the

AC board for convenience. While installed, keep

screws tight and the block itself secured tightly

to the AC board to prevent malfunction.

INVERTER ON/OFF

These terminals receive wires for a manual on/off

The jumper alongside these terminals overrides

them and turns the inverter on. (See page 23 for

instructions.) With the jumper installed, a switch

cannot turn the inverter off, but the system

display can turn it off or on. The system display

cannot turn it on if the jumper is not installed.

These terminals deliver 12 Vdc up to 0.7 amps

(8.4 watts). The output can be switched on and

off for many functions. The default function is to

The functions for the AUX output can be

programmed using the system display.

switch to control the inverter.

ON/OFF JUMPER

AUX OUTPUT (AUX+/AUX-)

drive a cooling fan or the Turbo Fan.

See page 24 for details.

DC and AC

GROUND TERMINALS

These terminals connect to

a grounding system for

both batteries and AC. See

page 15 for instructions.

AC TERMINAL BLOCK

These terminals receive AC

input and output wires. See

page 21 for instructions.

XCT+/XCT-

Non-operational terminals.

Do not connect anything

to them.

MATE/HUB and RTS PORTS

These ports receive the RJ45

and RJ11 plugs from the

system display and Remote

Temp Sensor. See page 23

for instructions.

The ports are mounted

sideways. When viewed

from the left side, they

appear as shown below.

AUX LED INDICATOR

Orange LED indicator turns on when

12 Vdc output is present.

Figure 5 Terminals, Ports, and Features

WARNING: Shock Hazard

The inverter’s AC output is defaulted to ON from the factory. It will deliver AC voltage as

soon as the power is connected.

900-0197-01-00 Rev A

LED INDICATORS

These indicators display the inverter status and battery voltage.

The three BATTERY LED indicators (green, yellow, and red) are based on

DC voltage, and provide a very general idea of battery state.

The green INVERTER LED indicator shows if the inverting function is on.

The yellow AC IN LED indicator shows if an AC source is present.

The red ERROR LED indicator shows either a Warning or an Error. A

Warning is an alert for a problem that is not severe enough for

shutdown. An Error usually accompanies inverter shutdown.

15

Page 16

Installation

Wiring

It will be necessary to remove knockouts from the AC Plate to run wires. The AC Plate has one knockout of

½” size and two knockouts of ¾” size. Install appropriate bushings to protect the wires.

Use copper wire only. Wire must be rated at 75°C or higher.

Grounding

Table 3 Ground Conductor Size and Torque Requirements

WARNING: Shock Hazard

Mobile models perform automatic neutral-to-ground bond switching. When this

function is engaged, the chassis ground is electrically common with the output

neutral conductor. When disengaged, the chassis ground is isolated from the AC

system. See pages 17, 21, and 22.

Make sure that no more than one bond is present in the AC system at any time.

WARNING: Shock Hazard

For all installations, the negative battery conductor should be bonded to the grounding

system at only one point. If the OutBack GFDI is present, it can provide the bond.

IMPORTANT:

Not all OutBack products can be used in a positive-ground system. If it is necessary to

build a positive-ground system with OutBack products, contact OutBack Technical

Support at +1.360.618.4363 before proceeding. Additionally, consult the online forum

at www.outbackpower.com/forum/, where this subject has been discussed extensively.

Terminal Location Minimum Conductor Size Torque Requirements

Central AC Terminals

DC Box Lug

#10 AWG (0.009 in) or 6 mm 25 in-lb (2.8 Nm)

#6 AWG (0.025 in) or 16 mm 45 in-lb (5.1 Nm)

Table 3 contains OutBack’s recommendations for minimum safe cable sizes. Other codes for mobile

or marine applications may supersede OutBack’s recommendations. Consult applicable codes for final

size requirements.

16

900-0197-01-00 Rev A

Page 17

Installation

The inverter’s DC ground is a box lug located next to the negative DC battery terminal. This lug accepts

up to 1/0 AWG (70 mm or 0.109 in) wire. Local codes or regulations may require the DC ground to be run

separately from the AC ground. Also, if present, it will be necessary to remove the DC Cover or Turbo Fan

before making the ground connection. (See page 20.)

Box Lug

Figure 6 DC Ground Lug

One ground terminal is labeled CHASSIS GROUND.

This terminal connects to an external ground bar or

bus. The other terminal, labeled NEU/GROUND BOND,

is not common with CHASSIS GROUND, but is joined

to it by a copper jumper. No external connection is

made to NEU/GROUND BOND.

As long as the copper jumper is present, the FX

inverter will automatically perform neutral-ground

bond switching.

If removed, the inverter’s neutral and ground will

be isolated.

If only one mobile inverter is present, leave the

copper jumper in place.

If more than one mobile inverter is present, remove

the copper jumper from every Slave unit.

See the inverter Operator’s Manual for the general

operation of neutral-ground bond switching.

See page 22 for more information on the inverter’s

switching function.

Figure 7 Chassis Ground

900-0197-01-00 Rev A 17

Page 18

Installation

DC Wiring

WARNING: Shock Hazard

Use caution when working in the vicinity of the inverter’s battery terminals.

CAUTION: Equipment Damage

Never reverse the polarity of the battery cables. Always ensure correct polarity.

CAUTION: Fire Hazard

The installer is responsible for providing overcurrent protection.

Install a circuit breaker or overcurrent device on each DC positive (+)

conductor to protect the DC system.

Never install extra washers or hardware between the mounting surface

and the battery cable lug. The decreased surface area can build up heat.

See the hardware diagram on page 19.

IMPORTANT:

The DC terminals must be encased in an enclosure to meet the requirements

of some local or national codes.

Table 4 contains OutBack’s recommendations for minimum safe cable sizes.

Other codes may supersede OutBack’s recommendations. Consult applicable

codes for final size requirements.

Table 4 DC Conductor Size and Torque Requirements

Inverter

(Wattage/Voltage)

FX2012MT

FX2024M

FX2524MT

FX2532MT

FX2536MT

FX3048MT

VFX2812M

VFX3524M

VFX3232M

VFX3236M

VFX3648M

Nominal DC Amps

(Derated 125%)

200

100

125

94

83

75

280

175

120

107

90

Conductor Size4

(Minimum)

4/0 AWG (120 mm) or 0.186 in 250 Adc

2/0 AWG (70 mm) or 0.109 in 175 Adc

2/0 AWG (70 mm) or 0.109 in 175 Adc

1/0 AWG (70 mm) or 0.109 in 125 Adc

1/0 AWG (70 mm) or 0.109 in 125 Adc

1/0 AWG (70 mm) or 0.109 in 125 Adc

4/0 AWG (120 mm) or 0.186 in 300 Adc

4/0 AWG (120 mm) or 0.186 in 175 Adc

2/0 AWG (70 mm) or 0.109 in 175 Adc

2/0 AWG (70 mm) or 0.109 in 175 Adc

1/0 AWG (70 mm) or 0.109 in 125 Adc

Breaker Size

(Minimum)

Terminal Location Torque Requirements

Inverter DC Terminals 60 in-lb (6.9 Nm)

Battery Terminals See battery manufacturer’s recommendations

When installing DC cables:

Battery positive and negative cables should be no longer than 10 feet (3 meters) each, to minimize voltage loss

and other possible effects.

Turn off DC circuit breakers or remove fuses before proceeding.

Tie, tape, or twist cables together to reduce self-inductance. Run positive and negative cables through the same

knockouts and conduit.

The inverter’s battery terminal is a threaded stud which accepts a ring terminal lug. Use crimped and sealed

copper ring lugs with 5/16 inch (0.79 cm) holes, or use compression lugs.

Install all overcurrent devices on the positive cable.

4

Cable sizes are for each inverter in a system. In a system with multiple inverters, each inverter requires its own cables and overcurrent devices of

the size indicated.

18

900-0197-01-00 Rev A

Page 19

To install DC cables and hardware:

1. Install all DC cables.

Do not install hardware in a different order from Figure 8. The battery cable lug should be the first item

installed on the stud. It should make solid contact with the mounting surface.

Do not close the main DC disconnect until wiring is complete and the system is prepared for commissioning.

13 mm Nut

Flat Washer

Installation

M8 x 1.25 Stud

Lock Washer

Mounting Surface

Battery Cable Lug

Insulator

Figure 8 Required Order of Battery Cable Hardware

CAUTION: Fire Hazard

Never install extra washers or hardware between the mounting surface and the

battery cable lug. The decreased surface area can build up heat.

2. Install the battery terminal covers. These are made of stiff plastic with a snap-on design.

If it is necessary to remove the covers, remove

carefully using a flat screwdriver.

Insert the screwdriver into the slot on the

side of each cover and unsnap the cover..

900-0197-01-00 Rev A 19

REMOVAL SLOT

Figure 9 Battery Terminal Covers

Page 20

Installation

DC Cover or Turbo Fan Attachment

COVER ATTACHMENT

FX inverters are equipped with either the DC

Cover or the Turbo Fan.

To attach either cover, put the cover in place.

Insert a screw at each corner using a

Phillips screwdriver.

As part of attaching the Turbo Fan, follow the

wiring instructions in Figure 11.

Figure 10 DC Cover Attachment

TURBO FAN WIRING

Install the wires in the AC Wiring Compartment to

make the Turbo Fan operational. The AUX+ and

AUX– terminals receive the red (+) and black (–)

wires. Tighten with a Phillips screwdriver.

To safely run the wires into the AC compartment,

pass the wires through the notch in the

compartment cover.

Notch

Edge of Cover

Compartment

Figure 11 Turbo Fan Wiring

If it is necessary to remove the Turbo Fan:

1. Remove the compartment cover.

If necessary, the green terminal block can be unplugged

by pulling it gently away from the AC board.

Make certain the AUX programming is

correct for proper fan operation.

2. Unscrew the AUX+ and AUX– terminal screws.

3. Remove the wires.

4. Remove the screws at the four corners of the Turbo Fan.

5. Remove the Turbo Fan.

20

900-0197-01-00 Rev A

Page 21

AC Wiring

WARNING: Shock Hazard

All AC source neutral and ground conductors should be mechanically bonded. The

inverter’s neutral and ground conductors should be left isolated. The inverter

performs automatic neutral-ground bond switching during operation.

Ground fault circuit interrupter (GFCI) devices must be installed in a recreational

vehicle wiring system to protect all branch circuits.

WARNING: Fire Hazard

To reduce the risk of fire, do not connect to an AC load center (circuit breaker panel)

having multi-wire branch circuits connected.

IMPORTANT:

The installer is responsible for providing overcurrent protection.

approved 30 Aac circuit breaker on the inverter’s output.

This page contains OutBack’s recommendations for minimum safe cable sizes.

Other codes, particularly for mobile or marine applications, may supersede

OutBack’s recommendations. Consult applicable codes for final size requirements.

All system wiring must comply with national and local codes and regulations.

Installation

Install an

The inverter’s AC terminal block has six positions for AC wires. The minimum recommended size is #10

AWG (6 mm) or 0.009 in wire. The terminals should be tightened to a torque value of 25 in-lb (2.8 Nm).

AC HOT OUT

The AC HOT OUT terminal

connects to the output load

panel. The terminal can

AC NEUTRAL OUT

The AC NEUTRAL OUT

terminal connects to

the neutral bus on the

load panel.

AC NEUTRAL IN

The AC NEUTRAL IN

terminal connects to

the circuit breaker or

bus from an AC input

source, such as shore

power or generator.

Do not connect the AC NEUTRAL IN and AC NEUTRAL OUT terminals together.

These terminals are isolated from each other while inverting. When an AC source

is connected, the neutral terminals switch to become electrically common.

The neutral bus from the input source must be kept isolated from the load panel’s

output neutral bus. Loads must not bridge the input and output terminals, even if

the inverter does not power them. An example would be an air conditioner with

its hot wire connected to the AC source and its neutral wire connected to the

inverter’s output load panel.

Figure 12 AC Terminals

carry up to 30 amps using

the inverter’s transfer relay.

Use the inverter wattage to

size the actual maximum

output load. Size the circuit

breaker accordingly.

AC HOT IN

The AC HOT IN terminal

brings current from the

AC source. It powers both

battery charger and loads.

Use the source size to

determine actual current

draw. Size all circuit breakers

accordingly.

900-0197-01-00 Rev A

21

Page 22

Installation

AC Sources

The inverter has a single set of AC terminals which are intended to connect to a single AC source.

It cannot be directly wired to more than one AC source at the same time.

used, it is usually required to have a selector switch that changes from one to the next. The switch should

be the “break before make” type which disconnects from one source before contacting another. It must

also be a double-pole type which switches both the hot and neutral wires.

In mobile or marine installations, the AC source neutral and ground conductors are expected to be

mechanically bonded.

If multiple sources are

Figure 13 AC Sources

In Figure 13, the shore power and generator are disconnected. The internal transfer relay automatically

bonds the inverter’s output neutral and ground connections as shown. This function can be disabled.

Figure 14 AC Sources and Transfer Relay

When either AC source is connected and accepted, the internal transfer relay switches to transfer the AC

source power to the loads. The internal transfer relay also opens the internal neutral-ground bond.

The AC Source bond is used instead. Figure 14 shows the shore power connected and shows the

shore power bond.

See the Operator’s Manual for the inverter’s criteria for accepting an AC source.

22 900-0197-01-00 Rev A

Page 23

T

T

ON and OFF Wiring

he INVERTER ON/OFF jumper bridges two pins. The ON/OFF jumper

parallels the two INVERTER ON/OFF terminals on the Control Wiring

Terminal Block. If either set of connections is closed, the inverter is ON.

Because the jumper is factory-installed, the inverter usually remains ON

unless given a command by the system display.

Installation

Jumper On

Jumper Off

Removing the jumper will turn the inverter OFF.

This requires long-nose pliers or a similar tool.

Once the jumper has been removed, the INVERTER ON/OFF

terminals on the Control Wiring Terminal Block can be used to

wire a manual on/off switch.

Figure 15 ON/OFF Jumper and Connections

Accessory Wiring

he AC Wiring Compartment Board has ports for both

the Remote Temperature Sensor (RTS) and the system

display. The system display port is labeled MATE/HUB.

If a HUB Communications Manager is in use, it occupies

the inverter’s MATE/HUB port.

RTS cable

RJ11,

4-conductor,

telephone)

MATE cable

RJ45, 8-conductor,

CAT5 non-crossover

RTS port

MATE/HUB port

See the

Operator’s

Manual for more

information on

the RTS.

Additional ports

900-0197-01-00 Rev A 23

When a HUB product occupies the inverter’s MATE/HUB port,

the system display connects directly to the HUB product.

If the system display is a MATE2, do not connect it during initial

startup. See the MATE Owner’s Manual for more information.

Inverters plug into ports 1 and above. Charge controllers and

other devices plug into unassigned ports not used by inverters.

See Stacking on page 28 for information on connecting

MATE

port

inverters. See the HUB product literature for other devices.

Figure 16 Accessory Connections

Page 24

Installation

AUX Wiring

The AUX+ and AUX– terminals are a switched 12 Vdc supply. The AUX can respond to different criteria

and control many functions. These include cooling fans, vent fans, load diversion, fault alarms, and the

Advanced Generator Start (AGS) function.

The terminals can supply up to 0.7 amps at 12 Vdc (8.4 watts). This is sufficient to drive a small fan or a

relay controlling a larger device. The terminals accept wire up to #14 AWG (2.5 mm). The

contains electronic overcurrent protection, which resets after being overloaded. No additional fuses are

required for the

The default setting for the AUX output is to control the Turbo Fan included with sealed models.

(See Figure 17.) The AUX output can only control one function at a time. It cannot be used for anything

else if the Turbo Fan is connected.

The control logic for the AUX output is not always located in the same device. Inverter AUX functions are

located within the inverter itself and are described accordingly. Although inverter-based functions require

the system display for programming, they will function even if the display is removed. However, AGS

programming is located within the system display and will not work if the display is removed. Other devices

may also be able to control the terminals. For generator control, see page 25.

AUX

terminals.

AUX

circuit

In this example, the AUX

directly drives a 12-volt

vent fan. The + and – wires

on the fan are connected to

the AUX+ and AUX–

terminals.

Fan

AUX LED

INDICATOR

The AUX indicator

illuminates when

the AUX output

becomes active.

Figure 17 AUX Connections for Vent Fan (Example)

24 900-0197-01-00 Rev A

Page 25

Generator Control

The AUX terminals can provide a signal to control an automatic-start generator. The control function

can be

Advanced Generator Start

(AGS), which is situated in the system display. AGS can start the

generator using settings from the system display, or it can use battery readings from the FLEXnet DC

battery monitor. Alternately, the control function can be

Gen Alert

, which is a simpler function based

directly in the FX inverter. The choice of control function depends on system needs and the capabilities

of each device.

The generator must be an electric-start model with automatic choke. It is recommended to have

“two-wire” start capability. A two-wire-start generator is the simplest type, where the cranking and

starting routine is automated. It usually has a single switch with two positions that is turned ON to start,

OFF to stop.

Two-Wire-Start

Installation

The 12 Vdc signal provided by the

output can be switched on and off to provide a start signal. It is

AUX

possible to send a 12-Vdc signal directly to the generator. However, this should never be done if it

connects the

output directly to the generator’s own battery. It is more common to use the

AUX

AUX

terminals to energize the coil of a 12 Vdc automotive or similar relay.

OBR-16-DIN, the OutBack FLEXware Relay Assembly depicted in Figure 18, is sold for this purpose. The

relay contacts can serve in place of the generator’s start switch. The battery shown below is depicted for

clarity. In most cases, it is part of the generator’s internal starting circuit and is not an external component.

The drawing below is one example of a possible arrangement. Specific arrangements, relays, and other

elements depend on the requirements of the installation and of the generator.

Relay

Contact

Generator

1

Battery

Figure 18 Two-Wire Generator Start (Example)

900-0197-01-00 Rev A

Relay

Coil

Starting

Terminals

1

Two-Wire-Start

Generator

25

Page 26

Installation

Three-Wire-Start

A “three-wire-start” generator has two or more starting circuits. It usually has a separate switch or position

for cranking the generator. A three-wire generator has fewer automated functions than a two-wire. It

usually requires multiple controls for starting, running, or stopping. The AUX terminals cannot control this

type of generator without using a three-wire to two-wire conversion kit.

Atkinson Electronics

(http://atkinsonelectronics.com)

is one company that makes these kits. The

Atkinson GSCM-Mini is intended to work with OutBack inverters.

The drawing below is one example of a possible arrangement. Specific arrangements, relays, and other

elements depend on the requirements of the installation and of the generator.

Atkinson

GSCM-Mini

Figure 19 Three-Wire Generator Start (Example)

26 900-0197-01-00 Rev A

Three-Wire-Start

Generator

Page 27

k

AC Configurations

Single-Inverter

When installing an inverter AC system, the following rules must be observed.

All overcurrent devices must be sized for 30 Aac or less.

All wiring must be sized for 30 Aac or more.

All output circuit breakers must be sized appropriately for loads and inverter power.

The AC input (generator or utility grid) must be a single-phase source of the proper voltage and frequency.

Installation

LEGEND

Hot

Neutral

Ground

TBB = Terminal Bus Bar

System

Display

CAT5 Cable

AC Source

(Shore Power or AC Generator)

AC Conduit Box

AC

GND

HUB/

MATE

HOT

AC

Hot

NEU

Neutral

Inverter/Charger

AC

Neutral

GROUND

AC

Hot

NOTES:

1. Neutral (common) conductor may be

connected from only one inverter

neutral terminal to a common bus bar in

the AC conduit box.

2. Colors depicted here may be different

from wiring standards.

Input

Circuit

Breaker

Ground TBB

(may be within AC

Conduit Box)

Primary

System

900-0197-01-00 Rev A 27

Mechanical

Interloc

Output

Circuit

Breaker

NEU GND HOT

AC Loads

Figure 20 Single-Inverter Wiring

Bypass

Circuit

Breaker

Page 28

Installation

Multiple-Inverter AC Installations (Stacking)

Installing multiple inverters in a single AC system allows larger loads than a single inverter can handle.

This requires stacking. Stacking inverters refers to how they are wired within the system and then

programmed to coordinate activity. Stacking allows all units to work together as a single system.

Examples of stacking configurations include “classic series”, “OutBack series”, “parallel”, “series/parallel”,

and “three-phase” configurations.

Stacking Connections

Stacking requires an OutBack communications manager and a system display.

If the MATE or MATE2 System Display is used, it must have firmware revision 4.1.6 or above.

A system of four or fewer units may use the HUB4 Communications Manager.

A system of up to ten units requires the HUB10.3 Communications Manager.

All interconnections between the products are made using CAT5 straight-through (non-crossover) cable.

HUB10.3

Communications

Manager

MATE2 System Display

Additional Ports

Port 1

MATE Port

MATE3 System Display

Figure 21 OutBack HUB10.3, MATE2 , and MATE3

Each inverter must be assigned a stacking mode depending on the configuration. Modes are described

below. Mode names sometimes vary with inverter model; see Table 5 on page 29.

The master provides the primary output phase. Other inverters in the system base their phase on that of the

master. If the master shuts off, all other inverters also shut off. The master must sense and connect to an AC

source before other inverters can connect.

~ In all cases, the master inverter must be connected to port 1 on the communications manager.

~ In a parallel-stacked or OutBack-stacked system, the master tends to be the most heavily used unit.

~ The selection for three-phase master is different from the single-phase master.

28 900-0197-01-00 Rev A

Page 29

Installation

There are two types of slave modes. The names used here are derived from their references onscreen.

A “classic” slave is used for stacking when the slave operates semi-independently of the master. Although the

master sets the phase relationship, the slave creates an output independent of the master. It is not possible to

balance the outputs with the FW-X240 transformer using this method. This type of system is used for the most

basic form of series stacking (two inverters only) and for three-phase stacking.

~ Classic-stacked inverters can go into Search mode independently of the master if necessary.

An “OutBack” slave is used for parallel or series/parallel systems. In parallel stacking, all slaves are in phase with

the master. In series/parallel systems, some slaves are in phase with the master and some are 180° out of phase.

The FW-X240 autoformer can balance the loads of OutBack-stacked inverters.

~ All slave outputs are pulse-width-matched to be precisely synchronized with the master inverter. This avoids potential

backfeed situations.

~ OutBack slaves can be placed in Power Save mode when not in use. They are activated by the master inverter as

needed. For this reason, the master is normally the only inverter to enter Search mode. See the Operator’s Manual for

descriptions of Power Save and Search mode.

In many cases the port assignments for secondary inverters (ports 2 to 4 or 2 to 10) is important. In

general it is always important to keep track of units and ports for programming purposes. See the

communications manager and system display literature for more information.

Programming involves using the system display to assign a status and stacking value to the inverter on

each port. Each inverter is assigned to power a specified phase of the system. These assignments can be

changed at any time as long as the master is plugged into port 1.

IMPORTANT:

Table 5 Stacking Modes for Mobile FX Inverters

Mode Name

(MATE3 or MATE)

1-2phase Master

1-2ph Master

Classic Slave

OB Slave L1

OB Slave L2

3phase Master

3ph Master

3phase Slave

5

Two inverters only

6

Three inverters only

900-0197-01-00 Rev A

3ph Slave

or

or

or

The master inverter must always be connected to port 1 on the

communications manager. Connecting it elsewhere, or connecting a slave

to port 1, will result in backfeed or output voltage errors which will shut the

system down immediately.

Installing multiple inverters without stacking them (or stacking them

incorrectly) will result in similar errors and shutdown.

Although stacking allows greater capacity, the loads, wiring, and

overcurrent devices must still be sized appropriately. Overloading may

cause circuit breakers to open or the inverters to shut down.

Table 5 shows all applicable modes for each inverter model.

When Used Function

Classic stack ,

OutBack stack

5

Classic stack (series)

Slave inverter for Classic series stack

OutBack stack (parallel or

series/parallel)

OutBack stack (series or

series/parallel)

Three-phase stack6 Phase A inverter for three-phase stack

6

Three-phase stack

Master inverter for all series and

parallel stacking

Slave inverter (in phase with master)

for parallel stack

Slave inverter (out of phase with master)

for OutBack series stack

Phase B or C inverter (phase is assigned

by port) for three-phase stack

29

Page 30

Installation

Stacking Configurations

Classic Series Stacking (Dual-Stack)

In series stacking, two inverters create two separate 120 Vac output phases. One inverter is the master.

The other is a slave that is intentionally 180° out of phase with the master. Each of these outputs can be

used to power a separate set of 120 Vac loads. Collectively they form a “split-phase” configuration which

produces 240 Vac. “Classic” series stacking is the simplest way to achieve this output.

The two outputs operate independently of each other. The 120 Vac loads on each output cannot exceed a given

inverter’s size. The second inverter cannot assist.

Only two inverters, one per output, may be classic series stacked. They must be the same model.

LOAD PANEL

1-2phase

Master

2.0 kVA

2.0 kVA 120 Vac

120 Vac

Classic

OR

Slave

2.0 kVA

2.0 kVA 120 Vac

120 Vac

Figure 22 Example of Classic Series Stacking Arrangement

When installing a series inverter system, observe the following rules.

Series stacking requires both a system display and a communications manager. Port assignments and jumper

positions vary with model and stacking configuration.

The master inverter is the L1 output. It must be connected to communications manager port 1. It is

programmed as

The L2 inverter must be programmed as

1-2phase Master

. Other inverters must not be selected as master.

Classic Slave

Manager literature for port assignments.

All overcurrent devices must be sized for 30 Aac or less. All wiring must be sized for 30 Aac or more.

All output circuit breakers must be sized appropriately for loads and inverter power.

during programming. See the HUB Communications

4.0 kVA

240 Vac

The AC input (generator or shore power) must be 120/240 Vac (split-phase).

30 900-0197-01-00 Rev A

Page 31

Installation

HUB 10.3

10 9 8 7 6 5 4 3 2 1 MATE

CAT5 Cables

System

Display

AC Neutral

IN

Inverter

GND

HUB/ MATE

L1 Master

(Shore Power or AC Generator)

AC Source

AC Conduit Box

Neutral TBB

Input

Circuit

Breaker

AC

Hot IN

(L1)

Neutral

Hot L1

TBB

HUB/ MATE

AC

IN

Inverter

L2 Slave

Hot IN

Hot L2

TBB

AC

(L2)

Input

Circuit

Breaker

Ground TBB

(may be within AC

Conduit Box)

AC

Neutral

OUT

GND

AC

Hot OUT

(L1)

Primary

System

Ground

LEGEND

Hot L1

Hot L2

Neutral

Ground

TBB = Terminal Bus Bar

GND

Neutral

TBB

AC Loads

Hot L1

TBB

NOTES:

1. Neutral (common) conductor may be connected from only one inverter neutral terminal to a

common bus bar in the AC conduit box.

2. Colors shown here may be different from wiring standards.

Figure 23 Classic Series Wiring

AC

Neutral

OUT

Hot L2

TBB

Output

Circuit

Breakers

Hot OUT

GND

Mechanical

Interlock

AC

(L2)

Bypass

Circuit

Breakers

900-0197-01-00 Rev A 31

Page 32

Installation

OutBack Series Stacking (Dual-Stack)

In OutBack’s unique series stacking, two inverters create a “split-phase” configuration. This configuration

creates two separate 120 Vac output legs. One output is the master. The other is a slave that is

intentionally 180° out of phase with the master. The collective voltage is 240 Vac, as in Classic stacking.

However, the output loads are balanced with the FW-X240 autotransformer.

The slave output is controlled directly by the master and cannot operate independently.

In the event of a load imbalance in a 120/240 Vac system, the FW-X240 transformer can transfer power from one

output to the other. The transfer balances the loads on each inverter. It also allows heavy 120 Vac loads on

either leg to use the full power of both inverters. (The loads below are marked “2+ kVA” per output. This means

the power of a 2 kVA inverter is assisted by the other output.)

The slave can go into Power Save mode when not in use. The FW-X240 autotransformer allows the master to

power loads on either output. This reduces idle power consumption and improves system efficiency.

Additional inverters can be added for combination series/parallel operation. See page 36. All inverters must be

the same model.

LOAD PANEL

OB Slave L2

2+ kVA

120 Vac

2+ kVA

120 Vac

OR

4.0 kVA

240 Vac

1-2phase

Master

2.0 kVA 120 Vac

FW-X240

2.0 kVA 120 Vac

Figure 24 Example of OutBack Series Stacking Arrangement

When installing an OutBack series system, the following rules must be observed.

Series stacking requires an FW-X240 autotransformer, a system display and a communications manager. Port

assignments and jumper positions vary with model and stacking configuration.

The inverter that is mounted physically lowest is designated as the master. It is the L1 output. Mounting the

master below the other inverters allows the master to avoid heat buildup and remain relatively cool.

The master must be connected to communications manager port 1. It is programmed as

Other inverters must not be selected as master.

1-2phase Master

.

The L2 inverter must be programmed as

Manager literature for port assignments.

All overcurrent devices must be sized for 30 Aac or less. All wiring must be sized for 30 Aac or more.

All output circuit breakers must be sized appropriately for loads and inverter wattage.

The AC input (generator or shore power) must be 120/240 Vac (split-phase).

32 900-0197-01-00 Rev A

OB Slave L2

during programming. See the HUB Communications

Page 33

Installation

HUB 10.3

10 9 8 7 6 5 4 3 2 1 MATE

CAT5 Cables

System

Display

AC

Neutral

IN

Inverter

L1 Master

AC

Neutral

OUT

HUB/

MATE

GND

(Shore Power or AC Generator)

AC Source

AC Conduit Box

Input

Circuit

Breaker

Neutral

TBB

Neutral

GND

AC

Hot IN

(L1)

AC

Hot OUT

(L1)

Hot L1

AC

Neutral

MATE

IN

Inverter

L2 Slave

AC

OUT

TBB

HUB/

GND

Hot L2

TBB

AC

Hot IN