Page 1

February 2012 876-0183-000 Rev. A Rel. 1

Automated Steering Kit

Installation Guide

Kit: EDX-VD6, P/N 911-2039-000

Fits Versatile Tractor Models:

836 936

846 946

856 956

876 976

Read and Follow Safety Messages

• In these instructions, you will see the heading WARNING and the safety alert symbol . They indicate a hazardous

situation that, if not avoided, could result in death or serious injury. The safety messages provide information to identify a

hazard associated with potential injury.

• Before installing, operating, or performing maintenance or service on any part of the system:

– Read and understand this installation guide and all of the safety information.

– Read and understand the Automated Steering System User Guide.

• Do not allow anyone to operate without instruction.

• Keep these instructions and all related safety information with the manual for your machine and other implements.

If you have any questions or need assistance, contact your local dealer or distributor.

Overview

A series of equipment specific kits has been developed to work in conjunction with your automated steering system . For the

machine models listed above, these kits contain the components for:

• the steering hydraulics

• the wheel angle sensor (WAS)

• the steering wheel switch (SWS - for steering override)

• the electronic control unit (ECU)

The items in each kit are detailed in the tables that follow the safety warnings beginning below. After the kit tables, there are

four step-by-step installation sections, one for each of the kits.

Please read this manual thoroughly before beginning the installation.

To avoid serious injury or death duri ng machine operation, install the appropriate kits for your machine make and model.

1

Page 2

2

Machine Preparation

Inspect the machine and perform any needed maintenance (for example, contaminated hydraulic fluid) before installing the

automated steering kit. This kit cannot perform as intended on a machine that is not maintained properly. Errors in

performance increase the risk of operator and bystander injury or death.

Failure to maintain clean hydraulic fluid and operational hydraulic components can cause loss of directional control resulting

in serious injury or death.

To avoid serious injury, wear hand and eye protection and use wood or cardboard when checking for leaks.

Turn off the machine and power off the automated steering controller when installing or performing maintenance.

Before attempting to install any of the components, park the machine on a clean level floor with adequate clearance to work all

around.

Before you perform any drilling, cutting or fastening, ensure that no other machine components, such as hydraulic hoses or

electrical wiring, will be damaged. Failure to follow this warning may cause physical injury and/or damage to the machine.

To prevent hydraulic system contamination, it is essential to thoroughly clean hydraulic system fittings and hose connections

prior to disconnecting or removing. Use a degreasing solvent spray cleaner such as a brake cleaner to prevent hydraulic system

contamination. Note that o-rings used on ORB and ORFF type fittings, referred to in the Kit Contents section, may be

damaged by degreasing solvent cleaners. If a fitting is to be cleaned internally, you should first remove and clean the o-ring

with a fiberless cloth.

Kit Contents - Steering Hydraulics

Unpack the hydraulics installation kit and identify the required parts as shown. Kit items are A, B, C etc. with an H

(Hydraulic) prefix.

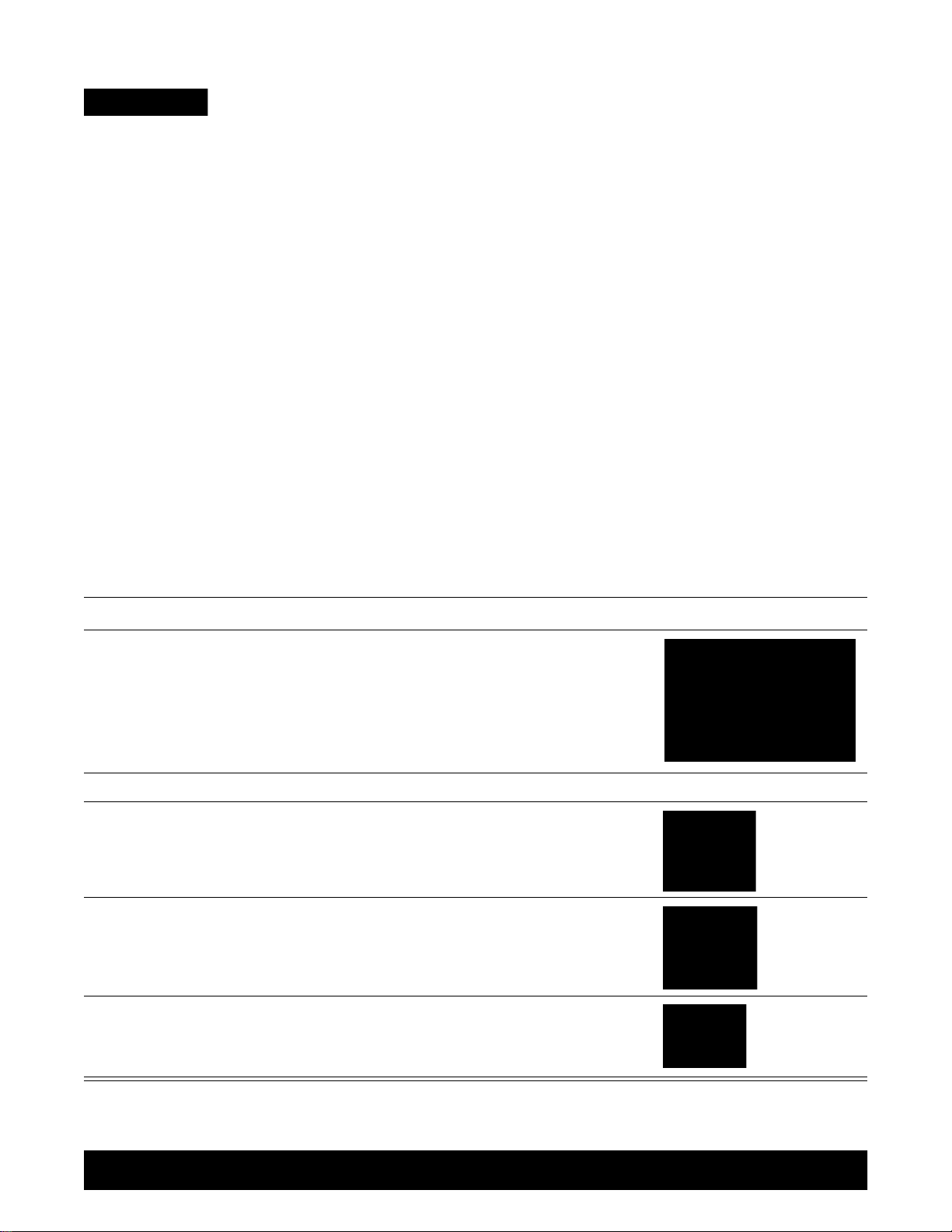

REF PART NUMBER QTY DESCRIPTION PHOTOGRAPH

HA 760-0021-000 1 Assembly, hyd valve block - 35L\proportional

(Hydraulic steering block)

Bag H1 of 6 contains HB, HC and HD

HB 760-2079-000 2 Adapter, hyd - #8maleJIC x #8maleORB

(P [pressure] and T [tank] ports on hydraulic

steering block)

HC 760-2060-000 2 Adapter, hyd - #6maleJIC x #8maleORB

(A and B steering ports on hydraulic steering

block)

HD 760-2058 1 Adapter, hyd 90 elbow - #6maleJIC x

#6maleORB

(LS port on hydraulic steering block)

22

Page 3

3

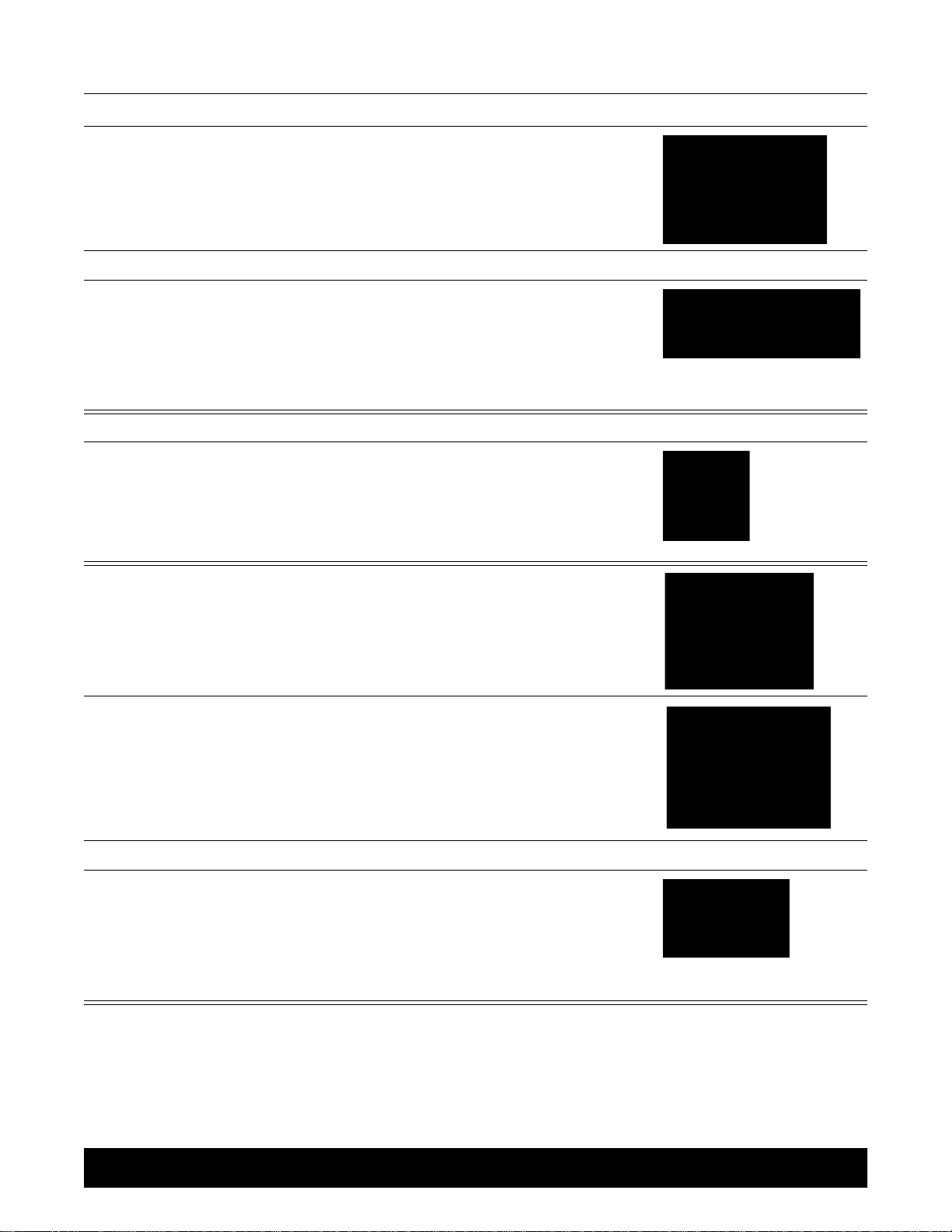

Kit Contents - Steering Hydraulics (continued)

REF PART NUMBER QTY DESCRIPTION PHOTOGRAPH

HE 640-0011 1 Hydraulic steering block mounting bracket

Bag H2 of 6 contains HF

HF 675-2006-000

678-1054-000

676-1035-000

Bag H3 of 6 contains HG

HG 675-2007

676-1035

HH 640-0063-000 1 Steering controller mounting bracket

HI 750-5003-000 1 Steering controller

2

2

2

2

2

Bolt - 3/8NC x 3-3/4" Gr5, ZP

Washer, flat - 3/8 ZP

Nut, nylock - 3/8NC ZP

(Mount HA on HE)

Bolt, 3/8NC x 3/4" Gr5 ZP

Nut, nylock - 3/8NC ZP

(Mount HE on machine)

Bag H4 of 6 contains HJ

HJ 675-2002

678-1053

676-1034

2

2

2

Bolt, 1/4NC x 2-1/2" Gr5 ZP

Washer, flat - 1/4" ZP

Nut, lock - 1/4NC ZP

(Mount HI on bracket HH)

Page 4

4

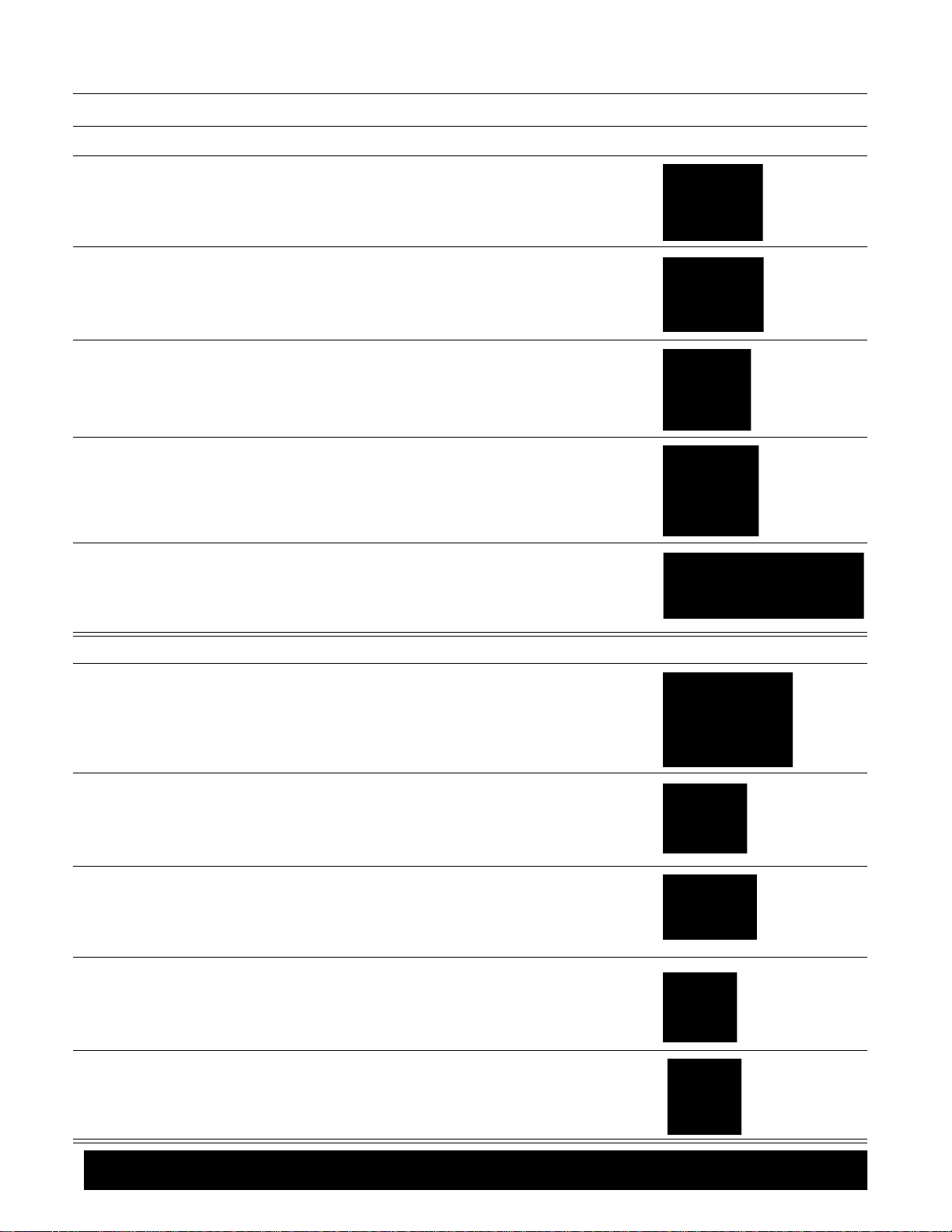

Kit Contents - Steering Hydraulics (continued)

REF PART NUMBER QTY DESCRIPTION PHOTOGRAPH

Bag H5 of 6 contains HK, HL, HM, HN and HO

HK 760-2016 1 Adapter, hyd run-tee - #12JIC

(Pressure line)

HL 760-2027 1 Adapter, hyd run-tee - #16JIC

(Tank line)

HM 760-2012 1 Adapter, hyd - #12femJIC x 8maleJIC

(Pressure line - use with HK)

HN 760-2026 1 Adapter, hyd - #16femJIC x 8maleJIC

(Tank line - use with HL)

HO 760-2077 2 Adapter, hyd run-tee - #8JIC

(Steering lines)

Bag H6 of 6 contains HP, HQ, HR, HS and HT

HP 760-0002 1 Assembly, hyd static load sense valve

HQ 760-2041 1 Adapter, hyd - #6maleORB x 6femJIC

(Function port of HP - with HR)

HR 760-2029 1 Adapter, hyd - #4femJIC x 6maleJIC

(Function port of HP with HQ - connect to valve

stack)

HS 760-2037 1 Adapter, hyd 90 elbow - #4maleJIC x 6maleORB

(Source port of HP - connect machine’s LS line)

HT 760-2058 1 Adapter, hyd 90 elbow - #6maleJIC x 6maleORB

(To hydraulic steering block - connect HW)

44

Page 5

5

Kit Contents - Steering Hydraulics (continued)

REF PART NUMBER QTY DESCRIPTION PHOTOGRAPH

HU 760-1122 2 Hose, hyd - 3/8" x 45", #8femJIC swivel x

#8femJIC 90 swivel

(Pressure and tank hoses)

HV 760-1115 1 Hose, hyd - 3/8" x 57", #6femJIC swivel x

#8femJIC 90 swivel

(Steering hose - to head end of steering cylinder)

HW 760-1117 1 Hose, hyd - 3/8" x 44", #6femJIC swivel x

#8femJIC 90 swivel

(Steering hose - to rod end of steering cylinder)

HX 760-1012 1 Hose, hyd - 1/4" x 48", #6femJIC swivel both

ends

(Load sense hose)

HY 677-2001 20 Tie strap, 11" heavy duty

Kit Contents - Wheel Angle Sensor

Unpack the wheel angle sensor kit and identify the required parts as shown. Kit items are A, B, C etc. with a W (Wheel) prefix.

REF PART NUMBER QTY DESCRIPTION PHOTOGRAPH

Bag 710-0099-000 (W1 of 3) contains WA to WF

WA 720-0045-000# 1 WAS assembly

WB 750-5002-000 1 Sensor, dual output, BEI

WC 602-1087-000 1 Connector arm, steering

Page 6

6

Kit Contents - Wheel Angle Sensor (continued)

WD 675-1191-000 2 Screw, mach, 8-32 x 3", PPH ZP

WE 676-1054-000 3 Nut, nylock 8-32NC, ZP

WF 675-1150-000 1 Screw, 8-32 x 1", Allen socket cap, ZP

WG 675-2031-000 1 Threaded rod, 5/16-24 x 12"

Bag W2 of 3 contains WH, WI and WJ

WH 676-1053-000 4 Nut, 5/16-24 standard ZP

WI 760-0018-000 2 Rod end swivel with stud, 5/16-24

WJ 675-2010 2 Bolt, 5/16NC x 3/4" Gr5 ZP

(Attach WAS assembly to WK)

WK 640-0147-000 1 WAS assembly mounting bracket

WL 640-0076-000 1 WAS link rod bracket

Bag W3 of 3 contains WM and WN

WM 675-2066-000 1 Bolt, 16-2.0 x 50mm, Gr8.8, ZP

(Attach WK - with machine’s nut)

WN 675-2065-000

2

Bolt, 7/16" x 1-1/2", Gr5, ZP

678-1081-000

676-1079-000

2

2

Washer, flat - 7/16" ZP

Nut, 7/16" - 14, Gr5, ZP

(Attach WL)

66

Page 7

7

Kit Contents - Steering Wheel Switch

Unpack the steering wheel switch kit and identify the required parts as shown. Kit items are A, B, C etc. with an S (Switch)

prefix.

REF PART NUMBER QTY DESCRIPTION PHOTOGRAPH

SA 478-0008 2 Magnet, flex -1/2" W x 1" L x 1/8" thk, plain 1

SB 675-0077 1 Epoxy, Hardman 04001 - single double bub

SC 602-1062 1 Bracket, steering wheel switch mounting

SD 726-1054 1 Assembly, steering wheel switch/cable

SE 677-2002 4 Tie strap, 7" releasable

Page 8

8

Kit Contents - Electronic Control Unit

Unpack the electronic control unit kit and identify the required parts as shown. Kit items are A, B, C etc. with an E (Electronic)

prefix.

REF PART NUMBER QTY DESCRIPTION PHOTOGRAPH

EA 051-0226-000# 1 Main cable

EB 054-0115-000# 1 Extension cable

EC 051-0228-000# 1 Steering controller main cable

ED 051-0231-000# 1 Valve cable

EE 051-0230-000# 1 WAS cable

EF 051-0229-000# 1 SWS cable

88

Page 9

9

Kit Contents - Electronic Control Unit (continued)

REF PART NUMBER QTY DESCRIPTION PHOTOGRAPH

EG 054-0117-000# 1 Power switch

EH 051-0166-000# 1 CAN-PWR cable

EI 806-1031-000# 1 Controller (ECU)

EJ 640-0091-000 1 ECU (EI) mounting bracket

EK 726-1093-000 1 Switch bracket

Bag E1 of 1 contains EL and EM

EL 675-1197-000# 4 Screw, self-drilling, # 10-16 x 2½", Hex, ZP

EM 675-1188-000 4 Screw, mach, M6 x 12mm, PPH, ZP

Page 10

10

Installation - Automated Hydraulic Steering Kit

HB

HD

HC

HA

Install HE here

HE

8”

HG

HH

HE

HF

L/R solenoids

P and T ports

Before installing, disconnecting or repairing the hydraulic hoses and components, turn off the machine and relieve all pressure from the hydraulic system by turning the steering wheel left and right. Failure to remove the pressure can result in serious injury or death from unexpected machine movement.

T o avoid burn injury when installing, disconnecting or repairing the hydraulic hoses and components, turn off the machine and

allow the system to cool down prior to touching the parts of the machine that are heated.

See Appendix B for a schematic of the hydraulic circuits.

1. Prepare the hydraulic steering block.

Make sure the hydraulic steering block HA is clean

and dust free.

Remove the plastic plugs from hydraulic steering

block HA and install adapter fittings as follows

(Figure 1):

• HB in the P and T ports

• HC in the A and B ports

• HD in the LS port

Figure 1: Prepared hydraulic block

2. Install the steering block mounting bracket.

Using hydraulic steering block bracket HE as a

template mark the inner face of the left rear fender

(Figure 2) 8” from the bottom of the fender (Figure

2 left inset - outer face view) and just back from the

fender’s front edge. Drill two 7/16” holes and,

using hardware HG, attach bracket HE (Figure 2,

right inset).

3. Install the hydraulic steering block and steering

controller mounting bracket.

Using hardware HF, attach hydraulic steering block

HA and steering controller bracket HH to bracket

HE (Figure 3):

• Mount HH against HE with its short side

upward and outward (from mounting)

• Mount HA with its L/R solenoids upward (so

with the P and T ports rearward)

Figure 2 with insets: Steering block mounting

bracket location and installation

Figure 3: Steering block and steering controller

mounting bracket installed

1010

Page 11

11

4. Install the pressure, tank and load sense fittings.

HN on HL

HM on HK

HU

HX

HS

HQ

HS

HP

HT

HR

Pressure

Tank

LS

HR

HS

HK

HL

HL

Machine’s T, LS & P hoses

HU (to HB)

HX

HD

Plastic caps placed on the open ends of the fittings

will prevent excessive leakage prior to hose

installation. Leave run-tees loose to allow for

alignment when attaching hoses.

a. Prepare the load sense valve HP as follows:

• Adapter HQ in the function port, then adapter

HR in adapter HQ

• Adapter HS in source port

• Adapter HT in the load sense port

b. Locate the pressure, tank and load sense connec-

tions on the bottom of the hydraulic valve stack

located under the tractor on the left side near the

rear axle (Figure 4b with inset).

c. Disconnect the load sense line then connect the

assembled load sense valve HP to the valve stack

using fitting HR (Figure 4c inset). Connect the

machine’s load sens e hose to the load sense valve at

fitting HS (Figure 4c).

d. Disconnect the pressure and tank hoses and install

run-tees HK and HL to the pressure and tank ports

on the valve stack respectively. The tank port is the

larger of the two (#16). Reconnect the machine’s

pressure and tank hose to the open ‘T’ ends of the

two run-tees (Figure 4c with inset).

5. Install the pressure, tank and load sense hoses.

Route all hoses with other machine plumbing free

from entanglement and secured with heavy tie

straps HY.

a. Using reducer fittings HM and HN on the stems of

run-tees HK (P) and HL (T) respectively (Figure

5a-i inset), install pressure and tank hoses HU

between their respective run-tees (Figure 5a-i) and

fittings HB in the P and T ports of the hydraulic

steering block (Figure 5a-ii).

Figure 4a: Prepared load sense valve

Figure 4b with inset: Pressure, tank and load

sense connections at valve stack

Install load sense hose HX between fitting HS in

the load sense valve and fitting HD in the LS port

of the steering block (Figures 5a-i and 5a-ii).

b. Securely tighten all hose fittings and connections.

Figure 5a-i: Pressure, tank and load sense

hoses connected at valve stack

Figure 4c: Load sense valve and run-tees installed, machine’s hoses reconnected

Figure 5a-ii: Pressure, tank and load sense

hoses installed at steering block

Page 12

12

6. Install the steering output fittings.

HO

Machine’s steering lines

HV

HW

HC

HV/HW

HH

HJ

HI

Plastic caps placed on the open ends of the fittings

will prevent excessive leakage prior to hose

installation.

Locate the steering lines at the head and rod ends of

the left steering cylinder at the center of the

machine (Figure 6, top). Disconnect the machine’s

steering hoses and install run-tees HO. Reconnect

the machine’s steering hoses to the open ‘T’ end of

each run-tee (Figure 6, bottom).

7. Install the steering output hoses.

a. Connect steering hoses HV (the longer) and HW to

the stem of the run-tees at the head and rod ends of

the steering cylinder respectively (Figure 7a).

Route the hoses, with other plumbing and clear of

moving parts back and up to the hydraulic steering

block. Use ties HY as necessary.

Figure 6: Steering hoses (top), run-tees installed

and machine’s hoses reconnected (bottom)

b. Connect the hoses HV and HW to adapter fittings

HC in the A and B ports of the hydraulic steering

block (Figure 7b).

8. Install the steering controller.

Using hardware HJ, install steering controller HI

on its mounting bracket HH. Mount HI with its

connector sockets inward and the pressure wash

warning on top (Figure 8).

9. Verify operation.

During tests of the hydraulic system, the

machine may move unexpectedly. Be

prepar ed for machine movement to avoid

injury.

Keep others away and stay clear of

mechanical steering linkages to prevent

serious injury or death from pinch point

hazards while manually operating the

hydraulic steering circuit.

a. Tighten all connections and clean up the installation

area around the machine and make certain that it is

safe to operate.

b. Start the machine and check hydraulic connections

for any leaks.

c. Rotate the steering wheel from one extreme to the

other and back.

Figure 7a: Steering hoses connected at steering cylinders

Figure 7b: Steering hoses connected to steering block

Figure 8: Steering controller attached to steering block

1212

Page 13

13

Installation - Wheel Angle Sensor

WG

WH WH

6½”

WB

WA

WE

WD

WC

Cut

WAS shaft mounting hole

WC

WB

WF WE

WH

7¾”

WI

WG

Switch off the machine’ s engine while installing or adjusting the WAS. Keep others away and stay clear of mechanical steering

linkages to prevent serious injury or death from pinch point hazards while manually operating the hydraulic steering circuit.

1. Prepare the wheel angle sensor.

a. Using the provided hardware WE (nuts) and WD

(bolts), attach the WAS wire connector WB to the

WAS housing WA. Install the bolts up through the

bottom of the housing. Mount WB with its right

edge in line with the right front corner of WA

(Figure 1a).

Figure 1a: Prepared WAS housing\connector

b. Cut four holes off WAS arm WC at the opposite

end from the WAS shaft mounting hole (Figure 1b).

c. Using hardware WF (screw) and WE (nut), attach

the WAS arm WC to the WAS assembly. Mount the

arm in the same direction as the WAS wire connector WB (Figure 1c with inset).

Before you cut the r od at step d, screw the pr ovided

nuts WH onto the threaded rod WG so that they

are inside the cut you will make. After you have cut

the rod, the nuts can help clean the threads.

d. Cut threaded rod WG to 6½” long (Figure 1d-i)

then screw swivel rod ends WI onto the cut rod to

achieve a center-to-center stud measurement of

7¾” (Figure 1d-ii). Leave WH loose until you

complete linkage adjustment at step 2f.

Figure 1d-i: Threaded link rod preparation

Figure 1b: WAS arm preparation

Figure 1c with inset: WAS arm installed

Figure 1d-ii: Assembled threaded link rod

Page 14

14

2. Mount the wheel angle sensor.

Use WK

WM

WN

WL

WAS assembly

(WJ)

WB

WC

(Your)

WK

WH

Link rod assembly

WC

WL

Figures in this section show a prototype WAS

assembly mounting bracket. Install your supplied

bracket (WK) as described.

a. Locate and remove the fuel tank’s top mounting

bolt on the right side of the rear of the front section

of the machine (Figure 2a, top inset). Retain the

nut. Using hardware WM with the machine’s nut,

install WAS bracket WK (Figure 2a, bottom inset)

with its long arm inward and parallel to the ground

(Figure 2a).

b. Locate the two outer (leftmost) holes in the bottom

of the articulation coupling (Figure 2b) and, using

hardware WN (Figure 2b, bottom left inset), install

link rod bracket WL, its long arm pointing inward

(Figure 2b, top right inset).

Figure 2a with insets: Installed WAS mounting bracket (prototype bracket shown installed)

c. Using hardware WJ (not visible), mount the WAS

assembly from step 1 on the rear face of bracket

WK. Mount the WAS assembly with its arm WC

on top and, like wire connector WB, pointing outward (Figure 2c).

d. Using hardware WH, install the link rod assembly

from step 1 between the last hole in WAS arm WC

and bracket WL. Set the swivel stud downward into

WC and upward into WL (Figure 2d - leave swivel

nuts WH loose until you complete linkage adjustment at step 2f.).

Figure 2b with insets: WAS link rod bracket installed

Figure 2c: Installed WAS assembly

Figure 2d: Installed WAS link rod assembly

1414

Page 15

15

2. Mount the wheel angle sensor (continued).

WH

e. With all hardware WH loose, slowly tu rn the

machine full left lock then full right lock. Check

that the linkage moves freely without binding and

adjust the linkage as necessary (Figures 2e-i and

2e-ii. Note, you will connect the wheel angle sensor

cable later.)

Figure 2e-i: Full left lock

f. When the linkage does move freely and without

binding, tighten hardware WH on the rod and the

swivels (Figure 2e-ii).

Figure 2e-ii: Full right lock

Page 16

16

Installation - Steering Wheel Switch

1¼”

½”

7/16”

45° bend (up)

90° bend (down)

1”

SC

Steering shaft

Top cover

Magnet(s) at 180°

SC

SD

SC

1. Prepare the switch/sensor bracket.

Drill a 7/16” hole in switch bracket SC ½” from

the opposite end to the pre-drilled switch hole. Put a

90° bend in the bracket 1¼” from the newly-drilled

end. Put a 45° (approx) bend in the opposite direction to the first bend, 1” from the pre-drilled end

(Figure 1 with inset - not to scale).

2. Access the steering shaft.

Access the steering shaft in the control and cabling

compartment inside the firewall by removing the

top section of the steering console (release the hook

and loop fixing on the left side - Figure 2 with

inset).

Figure 1 with inset: Drilled/bent switch bracket

3. Install the switch bracket, magnets and switch.

a. Using the forward bolt of the brace bracket to the

b. Install switch/sensor SD in bracket SC and adjust

c. Route SD’s cable down and out through the clutch

right of the steering shaft universal joint, mount

prepared switch bracket SC (Figure 3a and right

inset).

Clean two magnet-sized areas on the steering shaft

below the lower universal yoke, 180° apart and in

line with the bracket’s switch/sensor hole.

Using the two-part epoxy SB, attach magnets SA

180° apart on the steering shaft. Set a short edge of

each magnet against the shaft yoke (Figure 3a, left

inset - you will install the switch/sensor at the next

step).

the bends in SC to align SD with the magnets.

Adjust the sensor face to 1/8” to 1/4” away from

the magnets.

pedal aperture. You will connect the cable later.

Figure 2 with inset: Steering shaft inside control/cabling compartment

Figure 3a with insets: Installed switch bracket

and magnets (install switch/sensor at next step)

Figure 3b: Installed switch/sensor

1616

Page 17

17

Installation - Electronic Control Unit (ECU)

1/2”

EL (4)

EJ

(EM - 4)

Indicators

EI

EA

ED (L, R &

ENABLE

solenoids)

EC

HI

See Appendix A for a schematic of the cable connections.

1. Install the ECU.

a. Identify the ECU mounting location on the cab

floor to the right of the driver’s seat.

Facing the one inch tabs of bracket EJ toward the

driver’s seat, align the bracket parallel to the seat

mounting box and with (Figure 1a):

• The front edge of the bracket in line with the

front face of the seat mounting box.

• The outer edge of the one inch tabs ½” from the

right face of the seat mounting box.

Using hardware EL, fasten the bracket to the cab

floor (Figure 1a). Use a small level (not shown) to

check the level of the bracket. Adjust accordingly.

Do not overtighten the self drilling screws. Overtightening could cause the fastener to fail.

b. Using hardware EM (not visible) attach the ECU

EI to bracket EJ. Have the power and communica-

tions indicators at the top (Figure 1b left) and the

wire connections toward the rear of the machine

(Figure 1b right).

Figure 1a: ECU mounting bracket installed

2. Assemble and install the cables.

On a clean surface, lay out all the cables and

become familiar with the connections and where

they are to be placed. See Appendix A.

Route all cables with other machine cabling,

plumbing or fixtures free from entanglement and

secured with heavy tie straps HY.

a. Connect cable EA to the ECU EI using an Allen

wrench to secure the cable to the ECU. The EA

connector will only fit the ECU socket that is in line

with the power and communications indicators at

the opposite end of the ECU - so the top socket in

this installation (Figure 2a).

b. Connect steering controller cable EC’s two 12-pin

connectors (black and gray) to their respective

sockets on the steering controller HI (Figure 2b).

c. Connect EC’s connector labeled ‘VALVE’ to valve

cable ED. Connect ED’s three 2-pin connectors

(labeled ‘LEFT’, ‘RIGHT’ and ‘ENABLE’) to the

enable valve and two solenoid valves on the

hydraulic steering block (Figure 2b).

Figure 1b: ECU installed

Figure 2a: ECU main cable installed (in top

socket)

Figure 2b: Steering controller main cable and

‘VALVE’ cable installed

Page 18

18

2. Assemble and install the cables (continued).

SC’s ‘SWS’ to EF,

‘ECU’ to EB

SC’s ‘VALVE’ to ED,

‘WAS’ to EE

EE

WB

EF

SD

EF (fromSD)

EB (from ECU)

d. Connect EC’s connector labeled ‘WAS’ to WAS

cable EE (Figure 2c). Route EE to the WAS assem-

bly in the articulation space. Connect EE to wire

connector WB (Figure 2d with inset).

e. Install SWS cable EF between EC’s connector

labeled ‘SWS’ (Figure 2c) and, in the cab, SD’s

cable (Figure 2e with inset). Route EF in/out of the

cab through the access hole in the right rear of the

cab (Figure 2f with inset).

f. Install extension cable EB between EC’s connector

labeled ‘ECU’ (Figure 2c) and, in the cab, the ECU

main cable EA’s connector labeled ‘STEERING

CONTROLLER’. Route EB in/out of the cab

through the access hole in the right rear of the cab

(Figure 2f with inset).

g. Attach power switch EG to cable EA’s connector

labeled ‘SWITCH’. Some machines are equipped

with pop out tabs that you can remove and replace

with switch EG. If no tab is available, you can use

bracket EK mounting it in the cab at the operator’s

preferred location.

Set the switch to OFF before connecting EA to the

battery at step i.

Figure 2c: Steering controller main cable connections to function cables

h. Connect CAN-PWR cable EH to EA’s open con-

nection labeled ‘TERMINAL/RECEIVER’. Route

the cable in the cab so that it is clear of any machine

operation controls. Connect the opposite end of

cable EH to the guidance terminal.

i. Route the power cable part of cable EA, through the

cab access hole with EF and EB (Figure 2f with

inset) to the machine’s 12V battery and connect it.

© Hemisphere GPS (2012). All rights reserved.

Figure 2d with inset: WAS cable from steering controller to WAS assembly

Figure 2e with inset: SWS cable routed to/from

switch/sensor cable in the cab

Figure 2f with inset: Cabling out from the cab

for routing to, and connecting at, steering controller

1818

Page 19

19

Appendix A - ECU Cables and Connections

ECU CABLES AND CONNECTIONS

SWS

WAS

VALV E

SWITCH

EF

TERMINAL/RECEIVER

STEERING CONTROLLER

USB

EB

ED

EC

054-0115-000#

051-0229-000#

051-0230-000#

051-0231-000#

054-0117-000#

051-0226-000#

BATTERY

SERIAL

EE

051-0228-000#

STEERING

CONTROLLER

ECU

SWS

WAS

VALV E

ECU

EA

B

A

A

B

EG

Page 20

20

Legend

Static Load

Pressure

Tank

Load Sense

B - Steering Line

A - Steering Line

Sense Shuttle

SS

Without AutoSteer With AutoSteer

Steering Cylinder

LS T

EF

CF

L

Machine

Operations

P

R

LS

P

Priority

Divider

Pump

Orbital

Steering Cylinder

LS T

EF

CF

L

Hydraulic Steering

Block

LS

P

P

T

R

BA

LS

P

A

B

Pilot

Priority

Divider

Pump

Machine

Operations

Orbital

SS

Appendix B - Hydraulic Circuits

2020

Loading...

Loading...