OURASET ECOSET 151, ECOSET 302, ASSET 191, ASSET 192 Instruction Manual

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 1/35

©TANSUG MAKİNA LTD. 2008

TECHNICAL MANUAL FOR

THERMOSYPHONIC SYSTEMS

“CLOSEST TO THE SUN”

SOLAR THERMAL SYSTEMS

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 2/35

©TANSUG MAKİNA LTD. 2008

INDEX

CHAPTER I ................................................................................................................................................................................... 3

INSTRUCTIONS FOR INSTALLER ............................................................................................................................................. 3

1. INTRODUCTION .................................................................................................................................................................... 3

2. COMPONENTS AND PHYSICAL CHARACTERISTICS ................................................................................................ 4

2.3 Solar panel ....................................................................................................................................................................................... 6

2.3.1 Technical Spec Sheet ........................................................................................................................................... 6

2.3.2 Efficiency Curve ..................................................................................................................................................... 6

2.3.3 Cross Section of the Solar Panels .................................................................................................................... 8

2.4 Technical Specifications of Horizontal Boilers ....................................................................................................................... 9

3. GENERAL INSTRUCTIONS- PREPERATIONS FOR INSTALLATION .................................................................... 13

4. INSTALLATION OF PANELS ........................................................................................................................................... 14

4.1 Placement of Panels .................................................................................................................................................................... 14

4.2 Panel Angle .................................................................................................................................................................................... 14

4.3 Avoiding Shades ........................................................................................................................................................................... 14

5. INSTALLATION OF THE SYSTEM .................................................................................................................................. 15

5.1 Installation of Single- Panel Systems ...................................................................................................................................... 15

5.2 Installation of Double- Panel Systems .................................................................................................................................... 16

5.3

Mounting of Expansion Tank in Inclined Roof ..................................................................................................................... 16

6. MODULAR ROOF-TOP STAND ....................................................................................................................................... 17

6.1 Compatibility .................................................................................................................................................................................. 17

6.2 List of Components used in the structures. .......................................................................................................................... 17

6.3 Description of screws that are used in the mounting of the stands................................................................................ 18

6.4 Assembly of Thermosyphonic Flat Roof Stand (TFR45) ................................................................................................ 18

6.5 Assembly of Thermosyphonic Flat Roof Stand (TFR35) ................................................................................................ 21

Assembly of Thermosyphonic Flat Roof Stand (TFR35) ................................................................................................ 22

7. FILLING THE BOILER..........................................................................................ERROR! BOOKMARK NOT DEFINED.

8. ELECTRICAL ELEMENT ................................................................................................................................................... 27

9. AFLU-S HEAT TRANSFER FLUID .................................................................................................................................. 30

10. CHARGING THE CLOSE LOOP CIRCUIT ..................................................ERROR! BOOKMARK NOT DEFINED.

11. DISCHARGING THE SYSTEM ..................................................................................................................................... 30

CHAPTER II .................................................................................................................................................................. 31

INSTRUCTIONS FOR USER ...................................................................................................................................................... 25

12. SAFETY & SECURITY COMPONENTS ..................................................................................................................... 31

12.1 Primary Circuit (Closed Loop Line): ....................................................................................................................................... 31

12.2 Secondary Circuit (Cold Water Line): ..................................................................................................................................... 31

13. MAINTENANCE .............................................................................................................................................................. 31

13.1 Cleaning Panels ............................................................................................................................................................................ 32

13.2 Pipe Insulation ............................................................................................................................................................................... 32

13.3 Magnesium Anode ........................................................................................................................................................................ 32

14. TROUBLESHOOTING & IMPORTANT POINTS ...................................................................................................... 32

ANNEX 1: PARALLEL CONNECTION OF MULTIPLE SYSTEMS ...................................................................................................... 34

ANNEX 2: SERIAL CONNECTION OF MULTIPLE SYSTEMS ............................................................................................................ 34

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 3/35

©TANSUG MAKİNA LTD. 2008

CHAPTER I

INSTRUCTIONS FOR INST ALLER

1. INTRODUCTION

Thank you for your choosing an OURASET Solar Water Heating System. Not only

you secured the cleanest, safest and probably the most economic way to obtain hot

water but also you have fulfilled your responsibility against the environment. Buying

an OURASET is a gift to the “PLANET EARTH” as well as to the future generations.

OURASET solar water heater system is designed to provide problem free hot water

for many many years.

This manual has been prepared for two purposes:

• Assist the installation teams for the correct assembly of the system.

• Inform the home-owner about the capabilities of the system, and ensure that

they receive maximum benefit from their OURASET systems throughout its

life time by carrying out correct maintenance.

The manual consists of two chapters:

• Chapter 1 focuses on the characteristics of the system as well as the

assembly of the compa ct system.

• Chapter 2 sets the guidelines for both the installer and the homeowner for

maintenance of and maximizing the benefit from the Ouraset solar water

heating system.

All you need to do is read this manual and follow the installation instructions

carefully.

OURASET has been manufacturing solar boilers, solar panels and integrated

domestic hot water systems for over three decades. Thousands of home owners

around the world are enjoying hot water that comes as a gift of sun.

Until today you have probably been a consumer of energy - now you are a

generating energy on your roof!

Congratulations with your choice and happy sunny days with OURASET on your

roof!

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 4/35

©TANSUG MAKİNA LTD. 2008

2. COMPONENTS AND PHYSICAL CHARACTERIS TICS

Thermosyphonic Systems at a glance

*Capacity is estimated based on average daily hot water generation capacity calculated on the insulation values between 36th-38th parallel - Mediterranean climate.

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 5/35

©TANSUG MAKİNA LTD. 2008

2.2 System Dimensions and Weights*

*Refer to Section 4 : “Shading Scheme” to identify distances for placement of multiple units.

TANK SOLAR PANEL STAND TOTAL WEIGHT

MODEL

DIMENSIONS

(mm.)

Empty

WEIGHT (kg)

DIMENSIONS

(mm.)

QUANTITY

WEIGHT

(kg)

WEIGHT

(kg)

EMPTY

(kg.)

FULL

(kg)

Close

Open

P 121

Ø 500 X 1200

58,0

-

1945x1200

1

40,5

27

125,0

252,0

P 151

Ø 600 X 1000

66,5

53,0

1945x1200

1

40,5

27

134,0

284,0

P 191

Ø 600 X 1200

73,7 62,0

1945x1200

1

40,5

27

141,2

331,2

P 192

Ø 600 X 1200

73,7 62,0

1945x1970 2 65

31

168,7

358,7

P 302CL

Ø 600 X 1800

115,0 90,0

1945x2480 2 81

31

227,0

527,0

* In addition to to standard sets illustrated at section 2, various configurations are shown above. These schemes are illustrative only.

OURASET manufactures systems with different tank configurations only on an OEM basis with sufficient volume.

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 6/35

©TANSUG MAKİNA LTD. 2008

2.3 Solar panel

2.3.1 Technical Spec Sheet

Technical Specifications of the Panels – AA a nd AE S

MODEL AA 950 AA 1200 AES 950 AES 1200

Dimensions

950x1950 x105 mm. 1200x1950x105 mm. 950x1950x105 mm. 1200x1950 x105 mm.

Net absorption area

1,57 m2 2,07 m2 1,57 m2 2,07 m2

Insulation

Bottom : 50 mm Rockwool coated with glass

tissue

Bottom : 50 mm glasswool coated with glass

tissue

Sides : 20 mm glasswool with glass tissue Sides : 20 mm. glasswool with glass tissue

Conductor

Copper absorbers welded to copper tubes by ultrasonic welding method

Absorber Coating

Highly selective blue-sputtered coating Solar matt paint

a: ,95 e: ,05 a:,95 e:,70-90

Glass (4 mm.)

4 mm Low-iron tempered (Prismatic) Tempered

Glass

Characteristics

transmissivity %91 transmissivity %83

reflexivity + absorbtivity %9 reflexivity + absorbtivity %17

Casing

Electrostatic painted extra-durable aluminum extruded prof il e

Bottom

Embossed Aluminum Sheet

Number of Tubes

8 10 8 10

Headers / Tubes

Ø 22 - 10 mm

Weight

33 kg. 43 kg. 33 kg. 43 kg.

Fluid Capacity

1,6 lt. 2,2 lt. 1,6 lt. 2,2 lt.

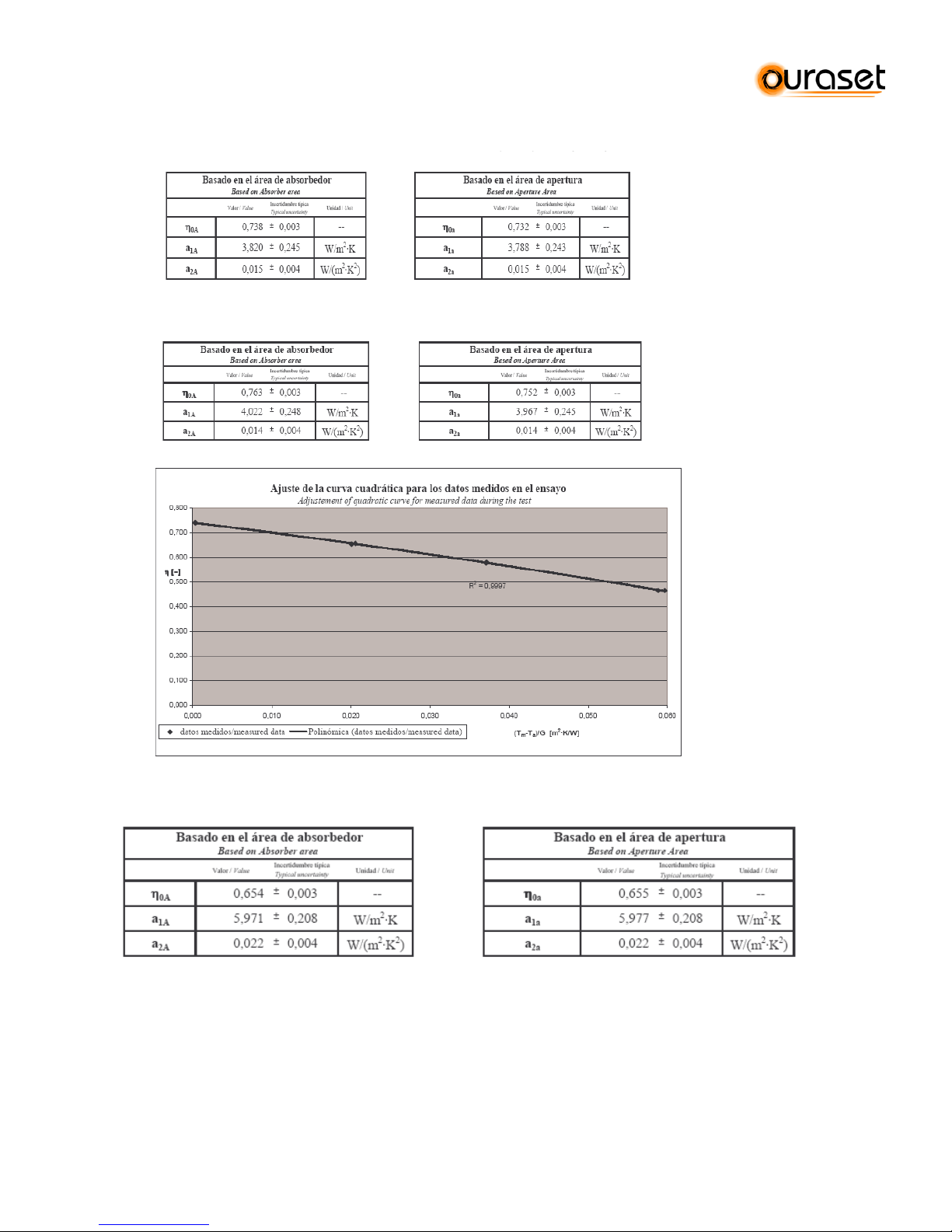

2.3.2 Efficiency Curve

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 7/35

©TANSUG MAKİNA LTD. 2008

Test Report for AA 1200, by CENER under SOLAR KEYMARK Scheme

Test Report and efficency curve for AA 950, by CENER under SOLAR KEYMARK Scheme

Test Report and efficency curve for AES 1200, by CENER under SOLAR KEYMARK

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 8/35

©TANSUG MAKİNA LTD. 2008

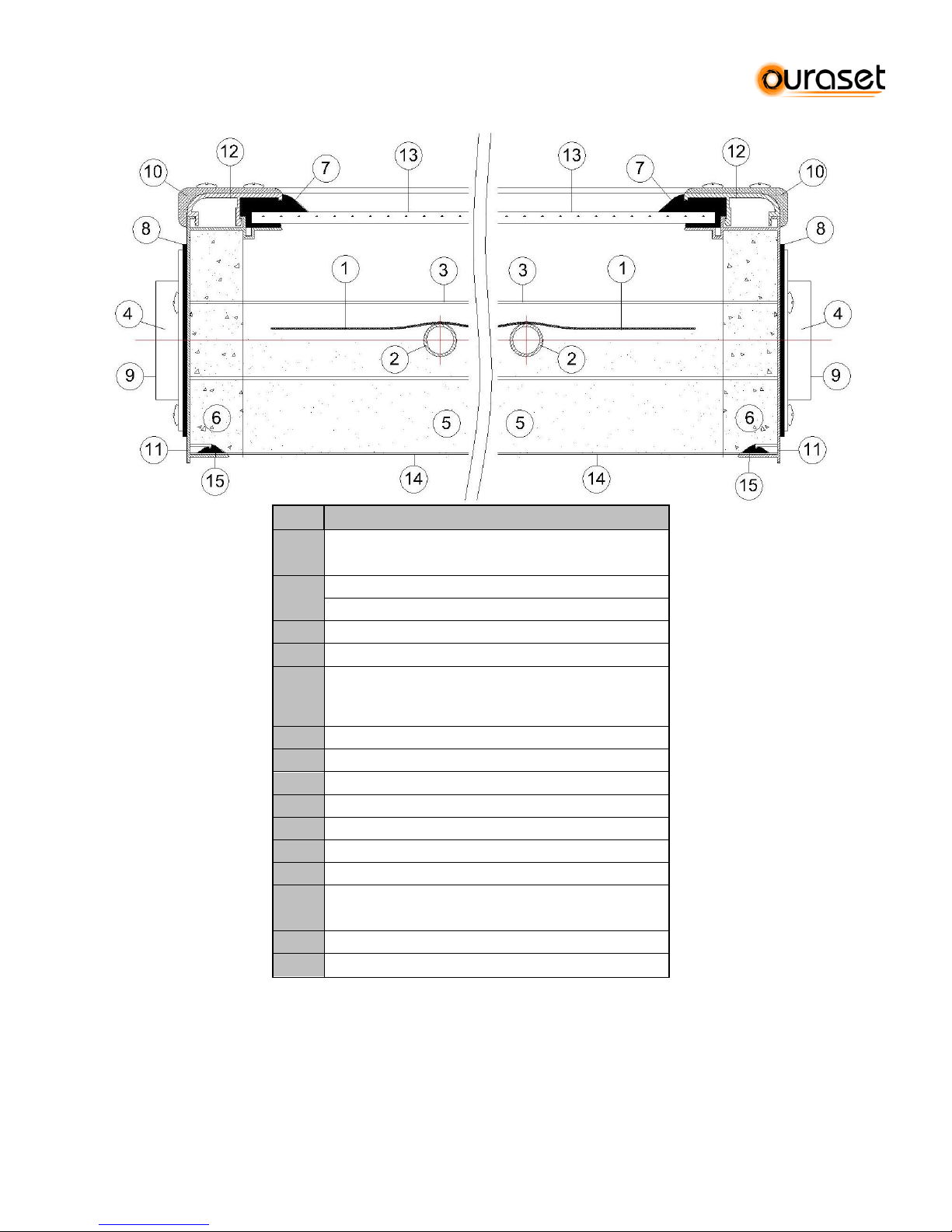

2.3.3 Cross Section of the Solar Panels

ITEM

SOLAR PANEL

1

Black painted (AES) / selective coated (AA)

copper absorber

2

10 channel (1200) - 8 channel (950)

Ø 10 Copper tubes

3

Ø 22 Copper tube header manifold

4

Hexagonal brass union

5

Insulation 50mm

Rock wool W/m °C:0,055 (AA)

Glasswool W/m °C:0,036 (AES)

6

Glasswool insulation 20mm

7

Glass sealing rubber (U-Type)

8

Manifold outlet scaling rubber

9

Manifold hexagonal union outlet cover

10

Corner supports

11

Alum. Extruded profile

12

Alum. Extruded trim

13

Low - iron tempered prismatic glass (AA)

Tempered solar glass (AES)

14

Al. Embossed sheet 0.40mm

15

Back plate sealing rubber

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 9/35

©TANSUG MAKİNA LTD. 2008

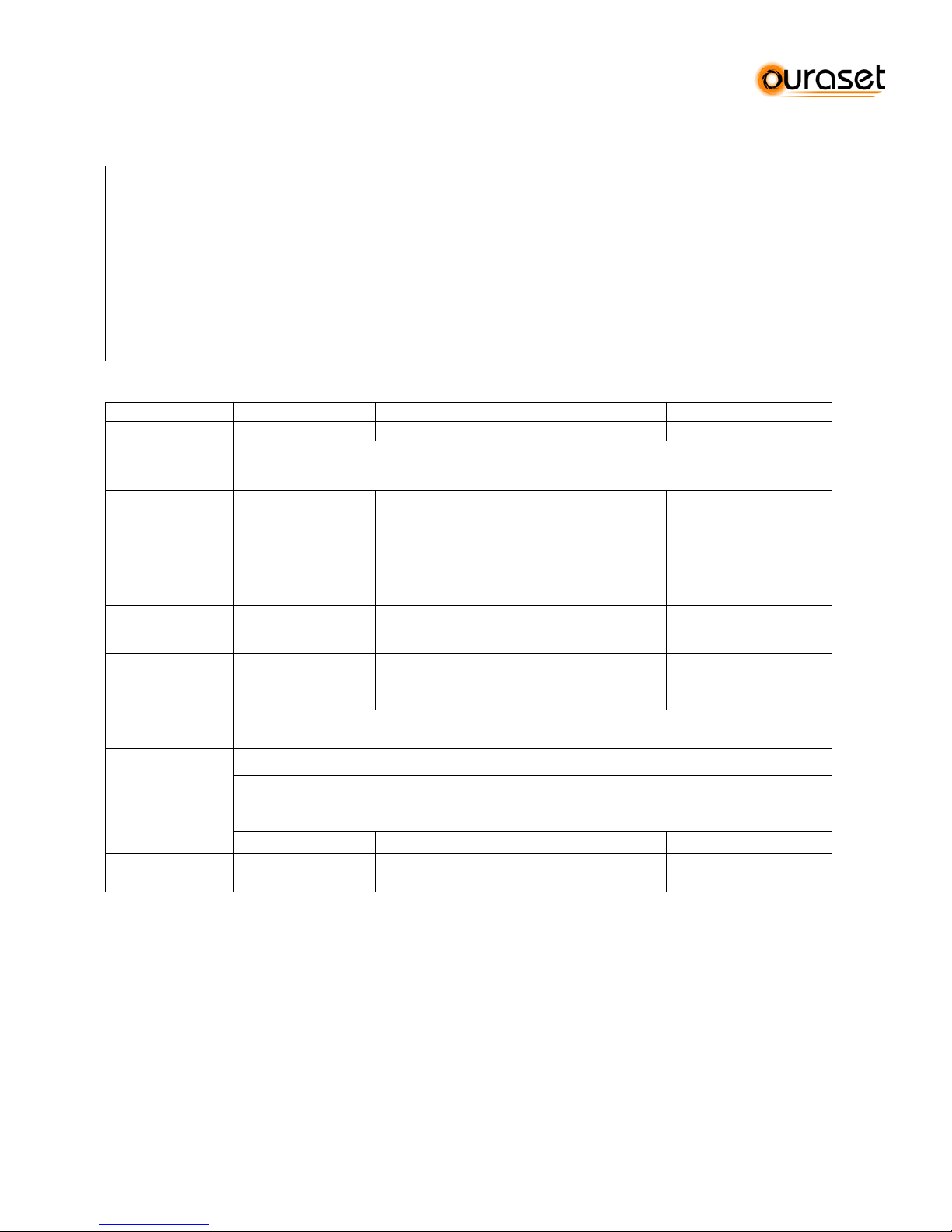

2.4 Technical Specifications of Horizontal Boilers

HIGHLIGHT S OF OU RASET P SERIES

*

Aesthetic Uv resistant ABS Plastic Caps designed for easy handling

*

Minimum heat loss due to dense polyurethane insulation

*

Enatech porcelain enamel coating to ensure hygienic water

*

Electrical heater inlet and cap available

*

Extra-durable external case, color coated galvanized, suitable to locate outdoors

*

Mg anode, enamel protection and inspection/cleaning hole for extended tank life

Code

P 120 P 150 P 190 P 300

Net Capacity

120 lt. 150 lt. 190 lt. 300 lt.

External Casing

*Case: Colorcoated® galvanized steel, coated with transparent folio for protection during

transport

* Caps: UV-Proof ABS plastic

Diameter ( ø )

(mm)

500 mm

600 mm

600 mm

600 mm

Length (L) (mm)

1200 mm

1000 mm

1500 mm

1800 mm.

Tank Body

Material (mm)

Low carbon steel

3 mm

Low carbon steel

3 mm

Low carbon steel

3 mm

Low carbon steel

3 mm

Jacket material

(mm)

Low carbon steel Low carbon steel Low carbon steel Low carbon steel

1,5 mm

1,5 mm

1,5 mm

1,5 mm

Tank Internal

Protection

enatech porcelain

Enamel coating

150-400 micrones

enatech porcelain

Enamel coating 150400 micrones

enatech porcelain

Enamel coating 150400 micrones

enatech porcelain

Enamel coating 150400 micrones

Cathodic

Protection

Magnesium anode rod 50 cm

Test Pressure

(bar)

Body: 9 bar

Jacket: 4 bar

Insulation (mm)

ASSET - Polyurethane Injection (42 kg/m³)

40 -50 mm 40 -50 mm 40 -50 mm 40 -50 mm

Water Inlet –

Outlet

¾” ¾” ¾” ¾”

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 10/35

©TANSUG MAKİNA LTD. 2008

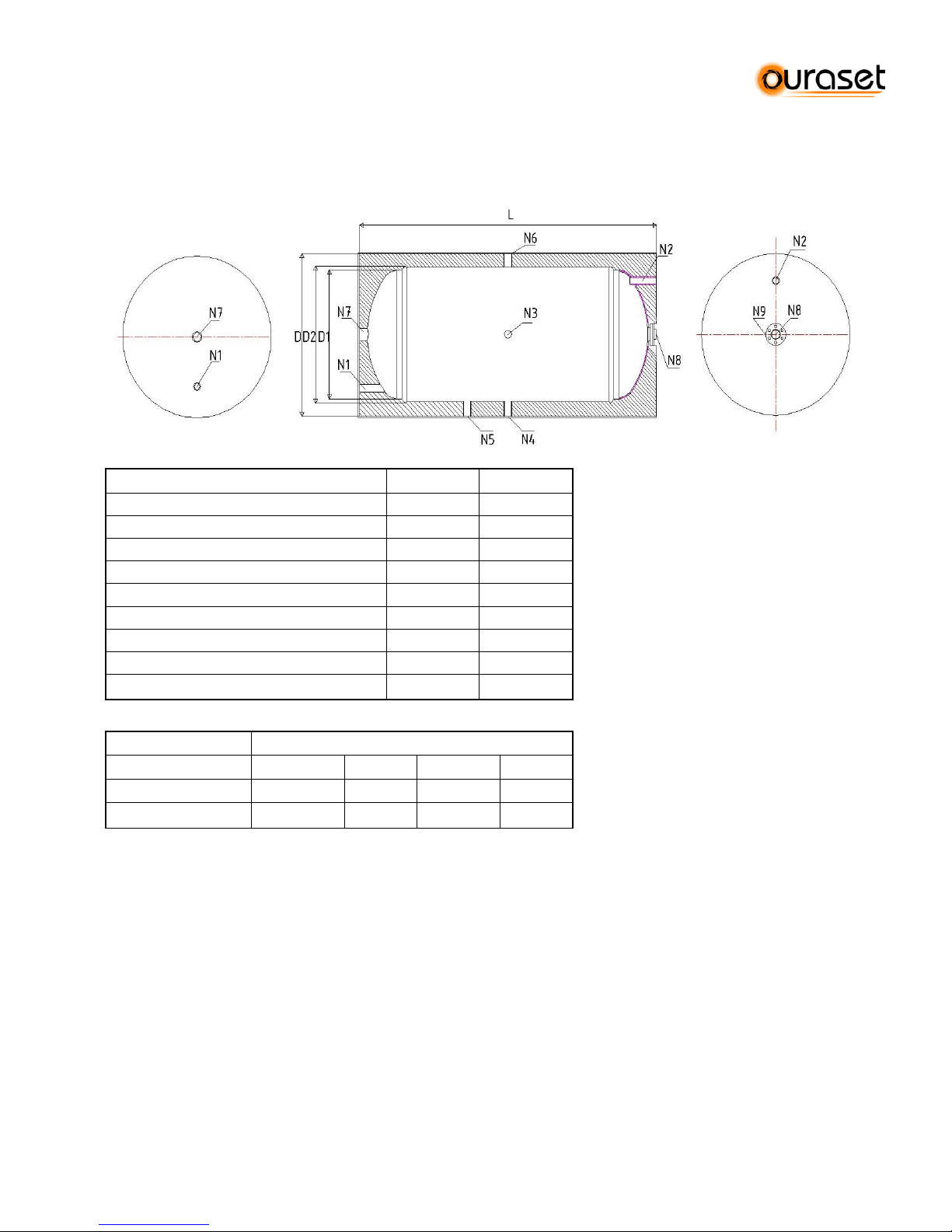

2.4.1 Horizontal Boilers, Middle connection (M), CLOSE loop (CL)

P 190M / CL

P 300M / CL

DESCRIPTION

NOZZLE

Ф

Cold water inlet

N1

3/4"

Hot Water Outlet

N2

3/4"

Solar Collector Outlet

N3

3/4"

Return to Collector

N4

3/4"

Expansion Tank Kit Connection

N5

3/4"

Air Vent

N6

3/4"

Anode

N7

1"

Electric Resistance Connection

N8

1 1/4"

Cleaning Flange

N9

DN80 TYPE

DIMENSIONS(mm)

ØD

ØD1

ØD2 L P190M

600

480

500

1200

P300M

600

480

500

1795

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 11/35

©TANSUG MAKİNA LTD. 2008

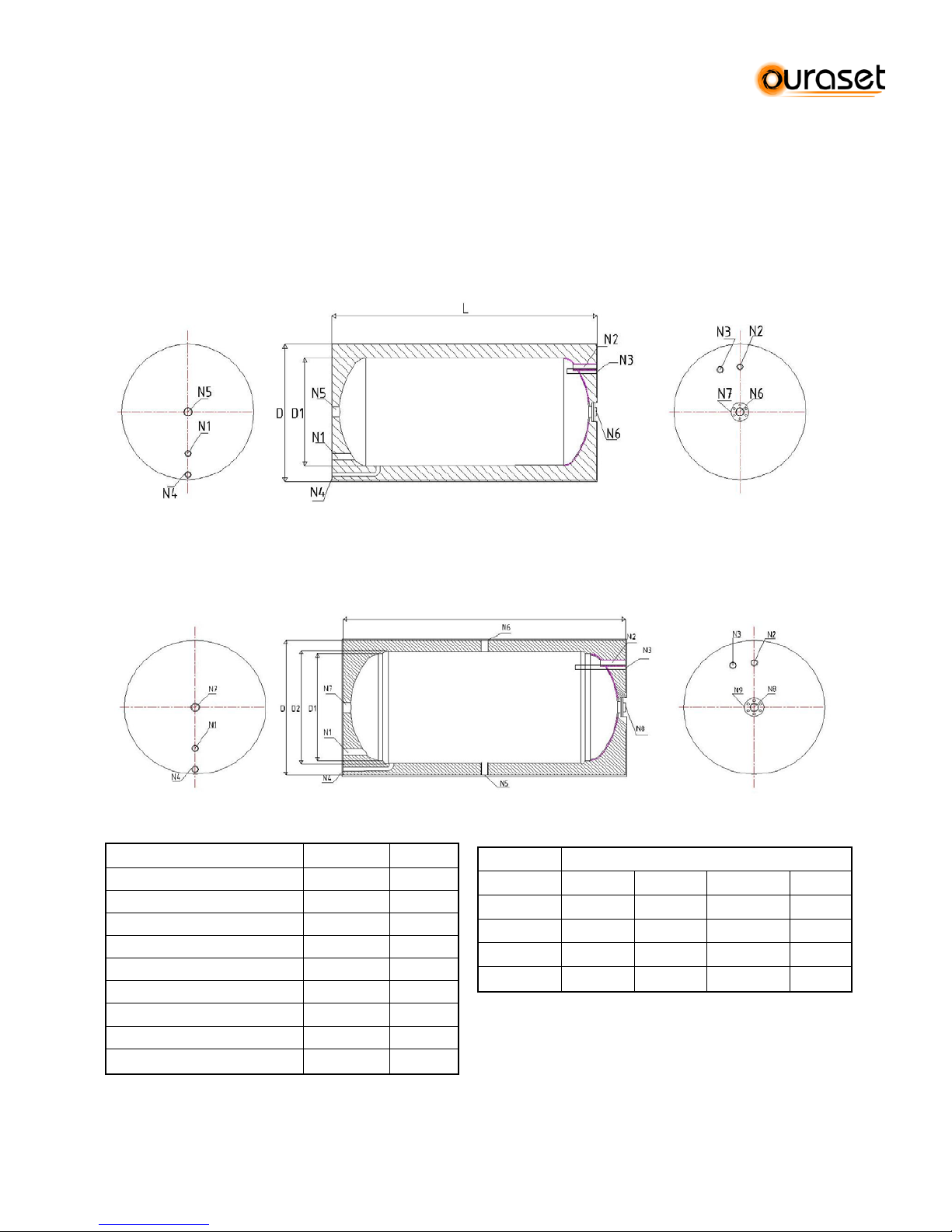

2.4.2. Horizontal Boilers, Side connection (S), OPEN (OL) or CLOSE (CL) loop

P 120S / CL

P 120S / OL

P 150S / CL

P 150S / OL

P 190S / CL

P 190S / OL

P 300S / CL

P 300S / OL

OPEN LOOP

CLOSE LOOP

DESCRIPTION

NOZZLE

Ф

Cold water inlet

N1

3/4"

Hot Water Outlet

N2

3/4"

Solar Collector Inlet

N3

3/4" Solar Collector Outlet

N4

3/4" Expansion Kit Inlet

N5

3/4" Air Vent

N6

3/4" Anode

N7

1" Electric Element Inlet

N8

1 1/4"

Cleaning Flange

N9

DN80

TYPE

DIMENSIONS(mm)

ØD

ØD1

ØD2

L

P120S

500

380

480

1200

P150S

600

480

500

1000

P190S

600

480

500

1200

P300S

600

480

500

1795

Loading...

Loading...