Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 1/35

©TANSUG MAKİNA LTD. 2008

TECHNICAL MANUAL FOR

THERMOSYPHONIC SYSTEMS

“CLOSEST TO THE SUN”

SOLAR THERMAL SYSTEMS

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 2/35

©TANSUG MAKİNA LTD. 2008

INDEX

CHAPTER I ................................................................................................................................................................................... 3

INSTRUCTIONS FOR INSTALLER ............................................................................................................................................. 3

1. INTRODUCTION .................................................................................................................................................................... 3

2. COMPONENTS AND PHYSICAL CHARACTERISTICS ................................................................................................ 4

2.3 Solar panel ....................................................................................................................................................................................... 6

2.3.1 Technical Spec Sheet ........................................................................................................................................... 6

2.3.2 Efficiency Curve ..................................................................................................................................................... 6

2.3.3 Cross Section of the Solar Panels .................................................................................................................... 8

2.4 Technical Specifications of Horizontal Boilers ....................................................................................................................... 9

3. GENERAL INSTRUCTIONS- PREPERATIONS FOR INSTALLATION .................................................................... 13

4. INSTALLATION OF PANELS ........................................................................................................................................... 14

4.1 Placement of Panels .................................................................................................................................................................... 14

4.2 Panel Angle .................................................................................................................................................................................... 14

4.3 Avoiding Shades ........................................................................................................................................................................... 14

5. INSTALLATION OF THE SYSTEM .................................................................................................................................. 15

5.1 Installation of Single- Panel Systems ...................................................................................................................................... 15

5.2 Installation of Double- Panel Systems .................................................................................................................................... 16

5.3

Mounting of Expansion Tank in Inclined Roof ..................................................................................................................... 16

6. MODULAR ROOF-TOP STAND ....................................................................................................................................... 17

6.1 Compatibility .................................................................................................................................................................................. 17

6.2 List of Components used in the structures. .......................................................................................................................... 17

6.3 Description of screws that are used in the mounting of the stands................................................................................ 18

6.4 Assembly of Thermosyphonic Flat Roof Stand (TFR45) ................................................................................................ 18

6.5 Assembly of Thermosyphonic Flat Roof Stand (TFR35) ................................................................................................ 21

Assembly of Thermosyphonic Flat Roof Stand (TFR35) ................................................................................................ 22

7. FILLING THE BOILER..........................................................................................ERROR! BOOKMARK NOT DEFINED.

8. ELECTRICAL ELEMENT ................................................................................................................................................... 27

9. AFLU-S HEAT TRANSFER FLUID .................................................................................................................................. 30

10. CHARGING THE CLOSE LOOP CIRCUIT ..................................................ERROR! BOOKMARK NOT DEFINED.

11. DISCHARGING THE SYSTEM ..................................................................................................................................... 30

CHAPTER II .................................................................................................................................................................. 31

INSTRUCTIONS FOR USER ...................................................................................................................................................... 25

12. SAFETY & SECURITY COMPONENTS ..................................................................................................................... 31

12.1 Primary Circuit (Closed Loop Line): ....................................................................................................................................... 31

12.2 Secondary Circuit (Cold Water Line): ..................................................................................................................................... 31

13. MAINTENANCE .............................................................................................................................................................. 31

13.1 Cleaning Panels ............................................................................................................................................................................ 32

13.2 Pipe Insulation ............................................................................................................................................................................... 32

13.3 Magnesium Anode ........................................................................................................................................................................ 32

14. TROUBLESHOOTING & IMPORTANT POINTS ...................................................................................................... 32

ANNEX 1: PARALLEL CONNECTION OF MULTIPLE SYSTEMS ...................................................................................................... 34

ANNEX 2: SERIAL CONNECTION OF MULTIPLE SYSTEMS ............................................................................................................ 34

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 3/35

©TANSUG MAKİNA LTD. 2008

CHAPTER I

INSTRUCTIONS FOR INST ALLER

1. INTRODUCTION

Thank you for your choosing an OURASET Solar Water Heating System. Not only

you secured the cleanest, safest and probably the most economic way to obtain hot

water but also you have fulfilled your responsibility against the environment. Buying

an OURASET is a gift to the “PLANET EARTH” as well as to the future generations.

OURASET solar water heater system is designed to provide problem free hot water

for many many years.

This manual has been prepared for two purposes:

• Assist the installation teams for the correct assembly of the system.

• Inform the home-owner about the capabilities of the system, and ensure that

they receive maximum benefit from their OURASET systems throughout its

life time by carrying out correct maintenance.

The manual consists of two chapters:

• Chapter 1 focuses on the characteristics of the system as well as the

assembly of the compa ct system.

• Chapter 2 sets the guidelines for both the installer and the homeowner for

maintenance of and maximizing the benefit from the Ouraset solar water

heating system.

All you need to do is read this manual and follow the installation instructions

carefully.

OURASET has been manufacturing solar boilers, solar panels and integrated

domestic hot water systems for over three decades. Thousands of home owners

around the world are enjoying hot water that comes as a gift of sun.

Until today you have probably been a consumer of energy - now you are a

generating energy on your roof!

Congratulations with your choice and happy sunny days with OURASET on your

roof!

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 4/35

©TANSUG MAKİNA LTD. 2008

2. COMPONENTS AND PHYSICAL CHARACTERIS TICS

Thermosyphonic Systems at a glance

*Capacity is estimated based on average daily hot water generation capacity calculated on the insulation values between 36th-38th parallel - Mediterranean climate.

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 5/35

©TANSUG MAKİNA LTD. 2008

2.2 System Dimensions and Weights*

*Refer to Section 4 : “Shading Scheme” to identify distances for placement of multiple units.

TANK SOLAR PANEL STAND TOTAL WEIGHT

MODEL

DIMENSIONS

(mm.)

Empty

WEIGHT (kg)

DIMENSIONS

(mm.)

QUANTITY

WEIGHT

(kg)

WEIGHT

(kg)

EMPTY

(kg.)

FULL

(kg)

Close

Open

P 121

Ø 500 X 1200

58,0

-

1945x1200

1

40,5

27

125,0

252,0

P 151

Ø 600 X 1000

66,5

53,0

1945x1200

1

40,5

27

134,0

284,0

P 191

Ø 600 X 1200

73,7 62,0

1945x1200

1

40,5

27

141,2

331,2

P 192

Ø 600 X 1200

73,7 62,0

1945x1970 2 65

31

168,7

358,7

P 302CL

Ø 600 X 1800

115,0 90,0

1945x2480 2 81

31

227,0

527,0

* In addition to to standard sets illustrated at section 2, various configurations are shown above. These schemes are illustrative only.

OURASET manufactures systems with different tank configurations only on an OEM basis with sufficient volume.

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 6/35

©TANSUG MAKİNA LTD. 2008

2.3 Solar panel

2.3.1 Technical Spec Sheet

Technical Specifications of the Panels – AA a nd AE S

MODEL AA 950 AA 1200 AES 950 AES 1200

Dimensions

950x1950 x105 mm. 1200x1950x105 mm. 950x1950x105 mm. 1200x1950 x105 mm.

Net absorption area

1,57 m2 2,07 m2 1,57 m2 2,07 m2

Insulation

Bottom : 50 mm Rockwool coated with glass

tissue

Bottom : 50 mm glasswool coated with glass

tissue

Sides : 20 mm glasswool with glass tissue Sides : 20 mm. glasswool with glass tissue

Conductor

Copper absorbers welded to copper tubes by ultrasonic welding method

Absorber Coating

Highly selective blue-sputtered coating Solar matt paint

a: ,95 e: ,05 a:,95 e:,70-90

Glass (4 mm.)

4 mm Low-iron tempered (Prismatic) Tempered

Glass

Characteristics

transmissivity %91 transmissivity %83

reflexivity + absorbtivity %9 reflexivity + absorbtivity %17

Casing

Electrostatic painted extra-durable aluminum extruded prof il e

Bottom

Embossed Aluminum Sheet

Number of Tubes

8 10 8 10

Headers / Tubes

Ø 22 - 10 mm

Weight

33 kg. 43 kg. 33 kg. 43 kg.

Fluid Capacity

1,6 lt. 2,2 lt. 1,6 lt. 2,2 lt.

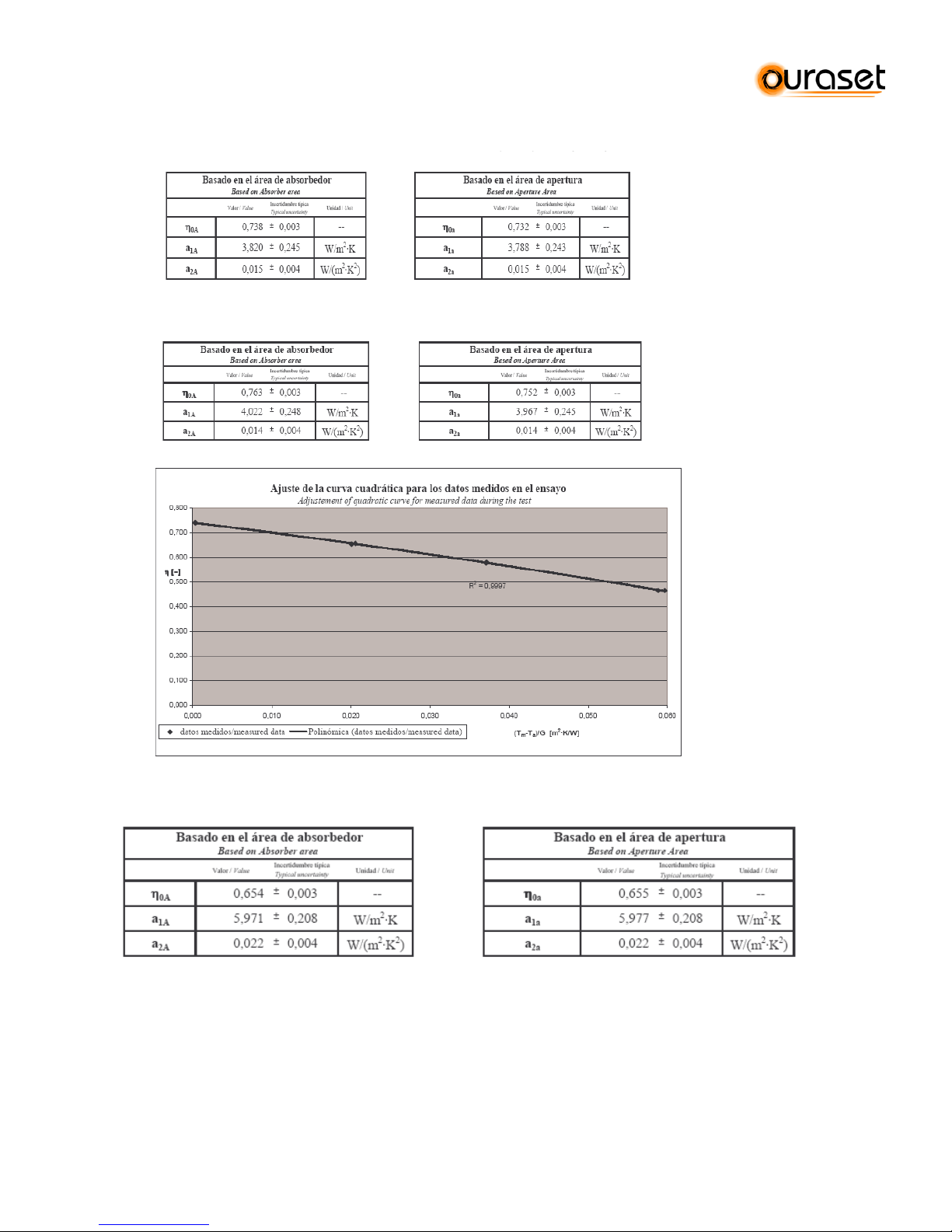

2.3.2 Efficiency Curve

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 7/35

©TANSUG MAKİNA LTD. 2008

Test Report for AA 1200, by CENER under SOLAR KEYMARK Scheme

Test Report and efficency curve for AA 950, by CENER under SOLAR KEYMARK Scheme

Test Report and efficency curve for AES 1200, by CENER under SOLAR KEYMARK

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 8/35

©TANSUG MAKİNA LTD. 2008

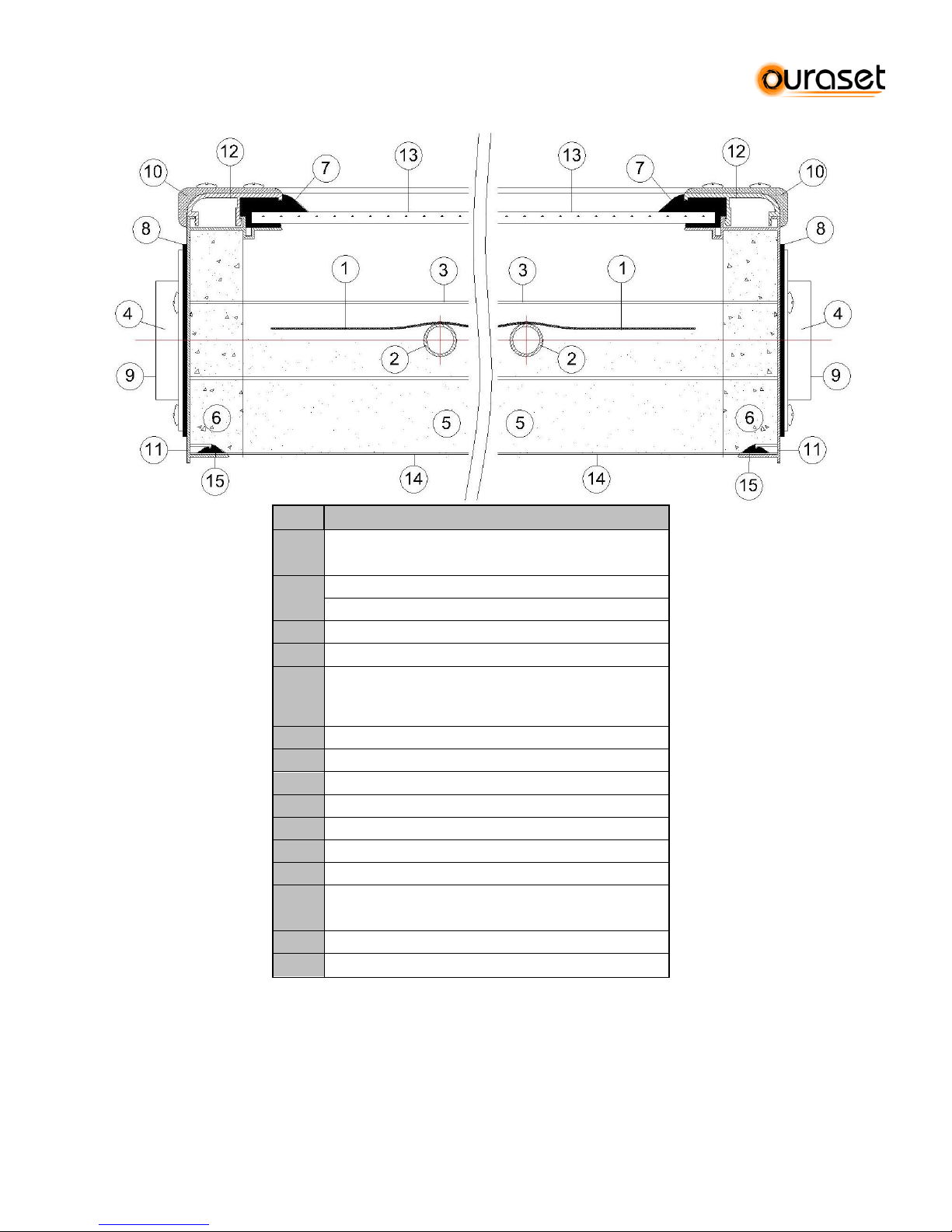

2.3.3 Cross Section of the Solar Panels

ITEM

SOLAR PANEL

1

Black painted (AES) / selective coated (AA)

copper absorber

2

10 channel (1200) - 8 channel (950)

Ø 10 Copper tubes

3

Ø 22 Copper tube header manifold

4

Hexagonal brass union

5

Insulation 50mm

Rock wool W/m °C:0,055 (AA)

Glasswool W/m °C:0,036 (AES)

6

Glasswool insulation 20mm

7

Glass sealing rubber (U-Type)

8

Manifold outlet scaling rubber

9

Manifold hexagonal union outlet cover

10

Corner supports

11

Alum. Extruded profile

12

Alum. Extruded trim

13

Low - iron tempered prismatic glass (AA)

Tempered solar glass (AES)

14

Al. Embossed sheet 0.40mm

15

Back plate sealing rubber

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 9/35

©TANSUG MAKİNA LTD. 2008

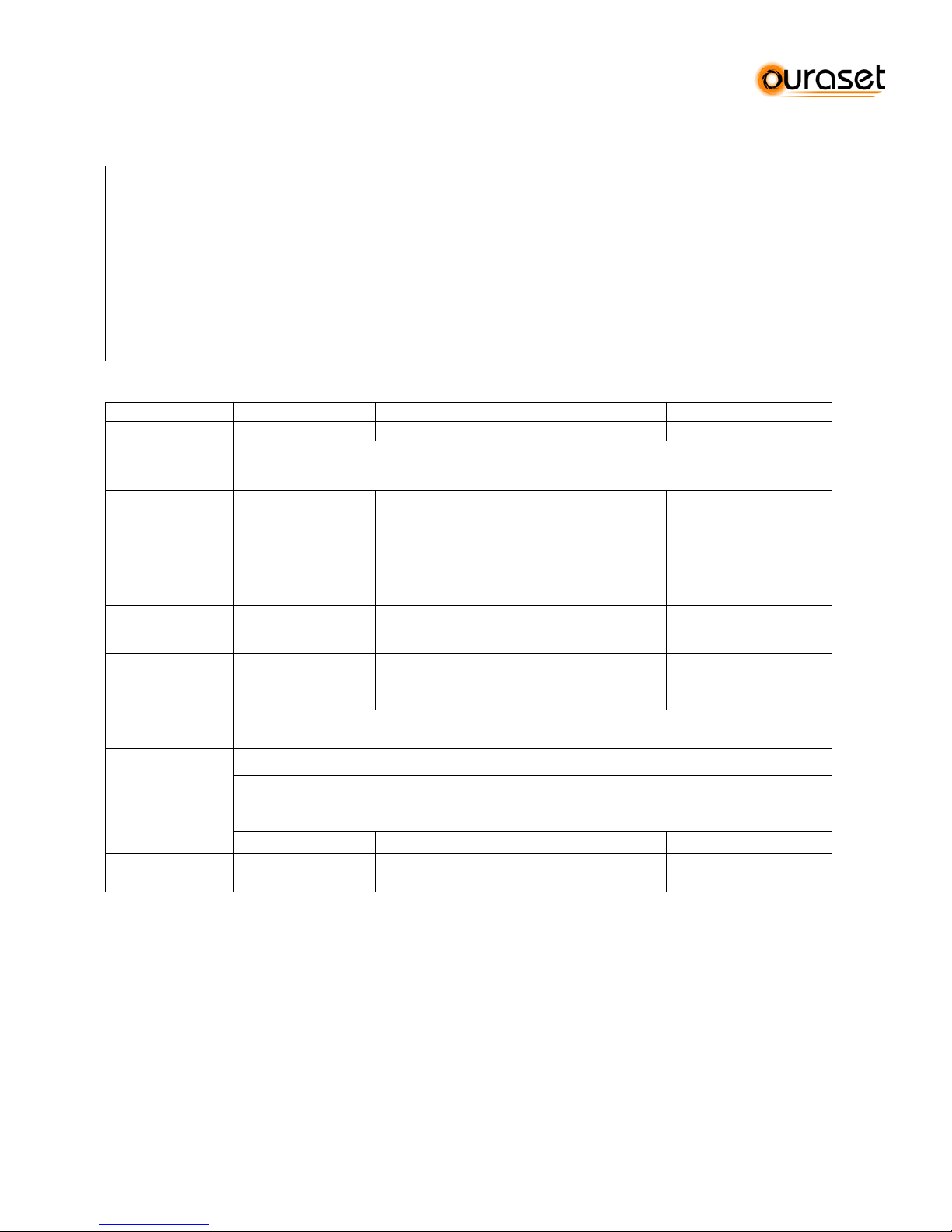

2.4 Technical Specifications of Horizontal Boilers

HIGHLIGHT S OF OU RASET P SERIES

*

Aesthetic Uv resistant ABS Plastic Caps designed for easy handling

*

Minimum heat loss due to dense polyurethane insulation

*

Enatech porcelain enamel coating to ensure hygienic water

*

Electrical heater inlet and cap available

*

Extra-durable external case, color coated galvanized, suitable to locate outdoors

*

Mg anode, enamel protection and inspection/cleaning hole for extended tank life

Code

P 120 P 150 P 190 P 300

Net Capacity

120 lt. 150 lt. 190 lt. 300 lt.

External Casing

*Case: Colorcoated® galvanized steel, coated with transparent folio for protection during

transport

* Caps: UV-Proof ABS plastic

Diameter ( ø )

(mm)

500 mm

600 mm

600 mm

600 mm

Length (L) (mm)

1200 mm

1000 mm

1500 mm

1800 mm.

Tank Body

Material (mm)

Low carbon steel

3 mm

Low carbon steel

3 mm

Low carbon steel

3 mm

Low carbon steel

3 mm

Jacket material

(mm)

Low carbon steel Low carbon steel Low carbon steel Low carbon steel

1,5 mm

1,5 mm

1,5 mm

1,5 mm

Tank Internal

Protection

enatech porcelain

Enamel coating

150-400 micrones

enatech porcelain

Enamel coating 150400 micrones

enatech porcelain

Enamel coating 150400 micrones

enatech porcelain

Enamel coating 150400 micrones

Cathodic

Protection

Magnesium anode rod 50 cm

Test Pressure

(bar)

Body: 9 bar

Jacket: 4 bar

Insulation (mm)

ASSET - Polyurethane Injection (42 kg/m³)

40 -50 mm 40 -50 mm 40 -50 mm 40 -50 mm

Water Inlet –

Outlet

¾” ¾” ¾” ¾”

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 10/35

©TANSUG MAKİNA LTD. 2008

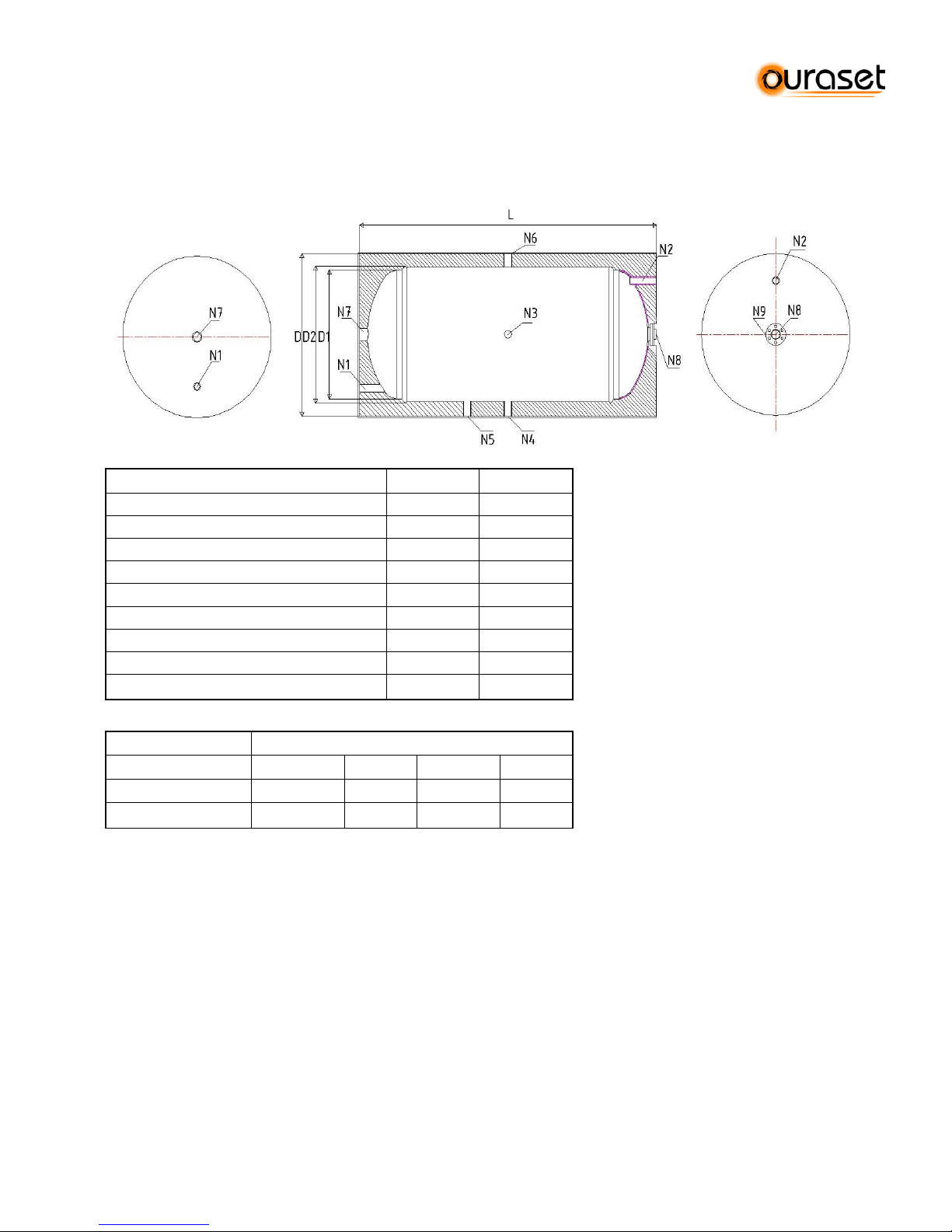

2.4.1 Horizontal Boilers, Middle connection (M), CLOSE loop (CL)

P 190M / CL

P 300M / CL

DESCRIPTION

NOZZLE

Ф

Cold water inlet

N1

3/4"

Hot Water Outlet

N2

3/4"

Solar Collector Outlet

N3

3/4"

Return to Collector

N4

3/4"

Expansion Tank Kit Connection

N5

3/4"

Air Vent

N6

3/4"

Anode

N7

1"

Electric Resistance Connection

N8

1 1/4"

Cleaning Flange

N9

DN80 TYPE

DIMENSIONS(mm)

ØD

ØD1

ØD2 L P190M

600

480

500

1200

P300M

600

480

500

1795

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 11/35

©TANSUG MAKİNA LTD. 2008

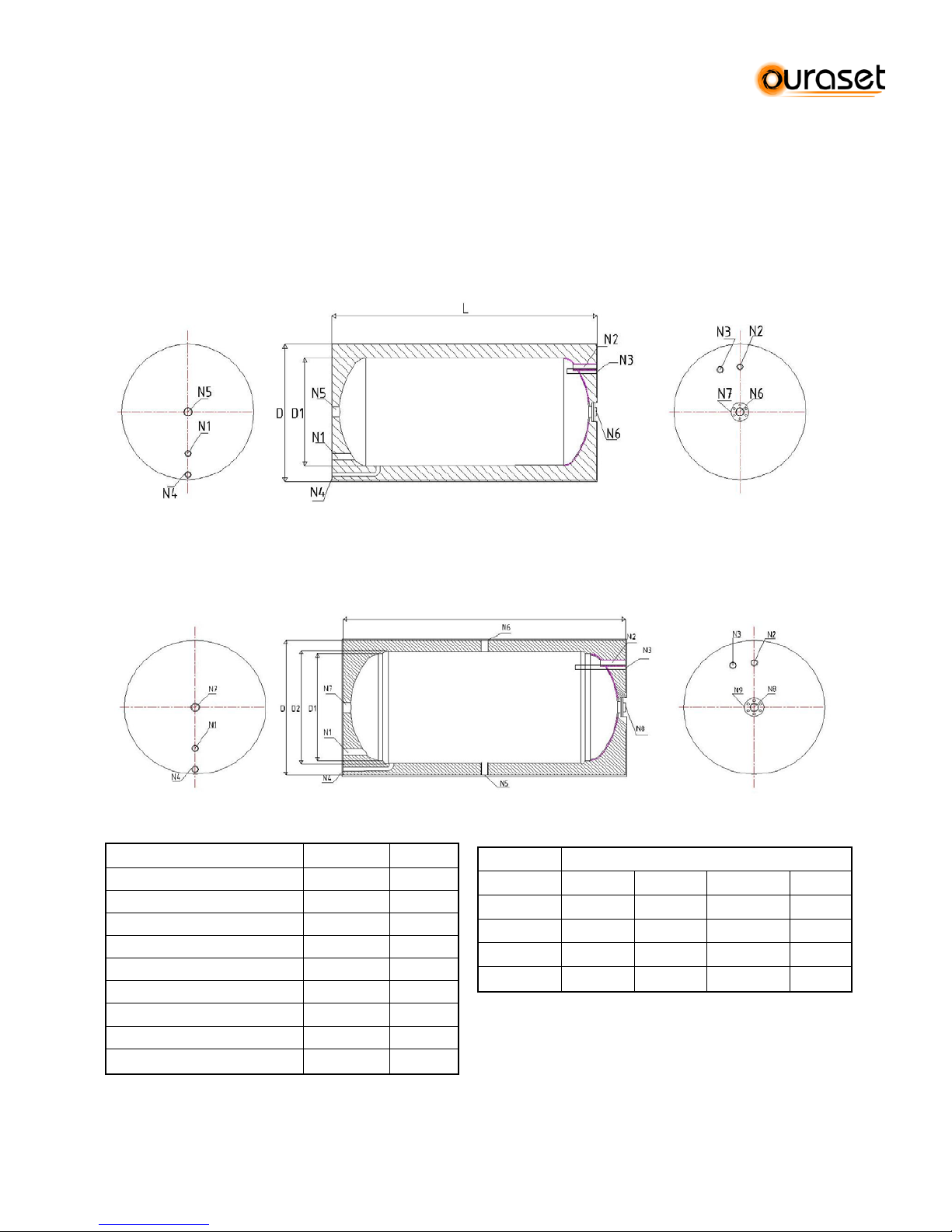

2.4.2. Horizontal Boilers, Side connection (S), OPEN (OL) or CLOSE (CL) loop

P 120S / CL

P 120S / OL

P 150S / CL

P 150S / OL

P 190S / CL

P 190S / OL

P 300S / CL

P 300S / OL

OPEN LOOP

CLOSE LOOP

DESCRIPTION

NOZZLE

Ф

Cold water inlet

N1

3/4"

Hot Water Outlet

N2

3/4"

Solar Collector Inlet

N3

3/4" Solar Collector Outlet

N4

3/4" Expansion Kit Inlet

N5

3/4" Air Vent

N6

3/4" Anode

N7

1" Electric Element Inlet

N8

1 1/4"

Cleaning Flange

N9

DN80

TYPE

DIMENSIONS(mm)

ØD

ØD1

ØD2

L

P120S

500

380

480

1200

P150S

600

480

500

1000

P190S

600

480

500

1200

P300S

600

480

500

1795

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 12/35

©TANSUG MAKİNA LTD. 2008

2.5 Components and Accessories

*Brands indicated are actual brands used at the date of preparation of this manual. Manufacturer may use any other brand which is same

or similar in technical features without any notice to its customers.

**

Supplied only if system is requested with expansion tank

Component

Brand*

Technical Features

More Specs

Structures

• 40x40x4 mm, perforated L profile,

electrogalvanized

• Extruded aluminum profile

See Section 6 for details

Expansion Tank **

Varem

6 or 7 lt capacity, precharged to 1 bar,

max. pressure 4 bars

temperature -10 + 99° C

Dimensions: Ø385x92 mm

Inlet: ¾”

Volume: 0,076 m

3

Manometer **

Pakkens

0-6 bar

G ¼” B

• EN 837

• Plastic Body

Electrical Element

& Thermostat

Thermowatt

2 kw, copper resistance See section 8 for details

Pressure Relief

Valve

Watts

3 bar, PN 10 bar,

T -10 + 110° C

¾” in – 1 “ out

• EN 12165-99 CW617N

• brass

• Manual discharge knob in

shockproof resin

• Nicr steel spring

Security Group

Air Vent **

Watts

10 bar, 160°C

Pressure Reducer

F.A.R.G.

Calibrated at 3 bars, ¾” in,

Max working pressure 10 bar

Outflow pressure adjustment field:

1,2- 5 bars

Max. using temperature 80°C

• EN 12165, EN 12164

• nickel

Non-return Valve

KVS

¾” DN 20

• brass

Flexible Hoses

Kuzuflex /

Ayvaz

Standard pitch metal hoses at different

dimensions

Operating Temperature 196°C + 800°C

Operating Pressure 64 bar

Nominal Diameters DN8 (5/16.) -

DN150 (2.)

• En 10380, EN 14800

Unions, T, Elbow,

etc

Various

All brass material

• Only major manufacturers

with ISO 9001:2008

certification and relevant En

norms are used.

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 13/35

©TANSUG MAKİNA LTD. 2008

3. GENERAL INSTRUCTIONS- PREPERATIONS FOR INSTALLATION

3.1 Installation should be carried out according to this manual, as well as in complete accordance

to your local and national standards and regulations.

3.2 Installation should be carried out by an authorized Ouraset installer.

3.3 Before you reach to the address of installation make sure that all the components in the

packages are complete.

3.4 System Design: All points concerning the correct installation of the solar system should

carefully be investigated before installation. Before starting the installation, determine the

location of the system and prepare a sketch of the site. Location of the installation, static

resistance of the base where the system will be installed, piping and wiring requirements

should be taken into account before starting the installation. Remember that it is best to

locate the system as close as possible to the consumption point.

3.5 You may need the following tools and devices for the installation of your OURASET system:

a. Small crane - for the lift of panels and stand on the roof

b. Safety equipments -harness, carabines, helmet, etc. to ensure safety of installation

crew during installation.

c. Drill Kit – you may need to do additional drilling on the roof to fit the panel stand to

the roof. You should be prepared to what you can possibly see when you remove

the tile to install the support legs of the stand.

d. Additional screws

e. 2 x 0, 75 – 1 mm signal cable – long enough to reach from solar panels to the

location where the boiler is going to be located.

f. Copper pipe - long enough for installation between the panels and the boiler.

g. Copper pipe plumbing eq ui pme nts .

h. Stand: The system comes with stands that include standard sets of anchorage

supports. However extra wires, bolts or frames to stabilize the system on your roof

may be required for different roof structures, or heavy climatic conditions.

3.6 Make sure that you ask for the consent of the home-owner for every action you take.

Removal of tiles on the roof, the route that tank-panel piping will follow, the location of the

boiler, etc.

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 14/35

©TANSUG MAKİNA LTD. 2008

4. INSTALLATION OF PANELS

4.1 Placement of Panels: The panel should face the direction of the equator. Panel should face

South in the Northern and North in the Southern Hemispheres. Use a compass to det er mi n e

the true south.

4.2 Panel Angle: The general application is that the panel is installed at the same angle as the

latitude of your location at all locations outside of the Tropic Zone. In complying to this rule,

a discrepancy of plus or minus 15 degrees is acceptable. Decreasing the angle will increase

the summer-time energy output while increasing will increase the winter time energy output.

4.3 Avoiding Shades: Shades are one of the biggest threats to your system’s energy output.

Make sure that the panels are not shaded especially between 10:00 - 15:00 when the sun is

most powerful. During a summer-time installation take into acc ou nt that shades will grow

bigger during winters.

4.4 Refer to the “Shading Scheme” below, for the assembly of multiple units.

DISTANCES

UNIT MODEL

121-151

191-192-302

B

A X 1,85

C

D X 1,50

D

35°

1660 mm.

1760 mm.

45°

1930 mm.

2030 mm.

E

35°

1980 mm.

45°

1749 mm.

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 15/35

©TANSUG MAKİNA LTD. 2008

5. INSTALLATION OF THE SYSTEM

5.1 Installation of Single- Panel Systems

Nº

Descripción

Sistemas de

1 captador

Sistemas

de 2

captadores

Cantidad

Cantidad

1

Ouraset Collector

1 2 2

Ouraset Tank

1

1

3

Blind Plug ¾´´

3

5

4

Security valve 3 bar ½´´

female

1

1

5

Security Group 6 bar ½ ´´

1 1 6

Elbow ¾ ´´ MM

2 1 7

Adapter ¾ ´´ - ½´´

1 1 8

Ball valve ½´´ MF

1 1 9 a

Long Copper pipe

1

1

9 b

Short flexible stainless pipe -

insulated

1

1

10

Short flexible stainless pipe insulated

1

1

11

Elbow ½´´ MF

1 1 12

T ¾´´ H conica

0 2 13

Elbow ¾ ´´ MF

2

0

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 16/35

©TANSUG MAKİNA LTD. 2008

5.2 Installation of Double- Panel Systems

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 17/35

©TANSUG MAKİNA LTD. 2008

5 MODULAR ROOF-TOP STAND

5.2 Your Modular Compact System Structure is designed to be compatible among different

models. By changing only 1-2 parts you can build up all the different models of structures

that you may require.

NOTE: There are also many common parts in the ther mosyphonic stand parts that you can

also use to build up Villaset Stands. Refer to the Villaset Manual or ask for our “Manual

for Stands.”

5.3 List of Components used in the structures.

PARTS LIST FOR

Size

FORCE CIRCULATED

SYSTEMS

THERMOSYPHONIC SYSTEMS

STRUCTURES

VIR-2

VIR-3

VFR45-2 VFR45-

3

TFR

TFR

TFR

TFR

TIR-1

TIR-2

45-1

45-2

35-1

*

1

35-2

A

BASE FRAME

2000 mm

2 3 2 3 2 2 2 2 2

2

B35

VERTICAL FRAME

1220 mm

- - 2 3 2 2 -

-

B45

VERTICAL FRAME

1415 mm

2 2

C35

SIDE FRAME

780 mm

- - 2 3 2 2 2

2

C45

SIDE FRAME

585 mm

2 2

D1

ALUM.PANEL.FRAME

1000 mm

- - -

-

2 - 2 - 2

-

D2

ALUM.PANEL.FRAME

2000 mm

2 - 2 - - 2 - 2 -

2

D3

ALUM.PANEL .FRAME

3000 mm

- 2 - 2 - - - - -

-

E

BACK & SIDE DIAGONALS

1500 mm

2 4 4 7 4 4 4 4 2

4

F5

TANK SUPPORT BED*

Ø500

- - -

-

- - - - -

-

F6

TANK SUPPORT BED

Ø600

- - -

-

2 2 2 2 2

2

G

TANK WIND BELT

-

- - -

-

2 2 2 2 2

2

H

PANEL WIND GRIP

- 4 6 4 6 2 4 2 4 2

4

I

GROUND SUPPORTS

100 mm

- - 4 6 4 4 4 4 -

-

J

ROOF ANCHORS

4 6 - - - - - - 6

6

K2

SCREW TYPE 2 *2

M8x20mm

17

28

27

29

27

29

27

29

17

28

K3

SCREW TYPE 3

M8x15mm

- - - -

4 4 4 4 4 4 Compact System Models that use the

201,

202,

301/2,

302 /2

301/3,

302/3,

501,

502

201,

202,

301 /2 ,

302/2

301/3,

302/3,

501, 502

151

192

151

192

151

192

corresponding structure

191

302

191

302

191

302

*1

By changing only two parts B & C to B35 & C35 you can easily convert your thermosyphonic flat roof structure

from 45° inclination to 35°.

(See Section 5)

*2

30 units of K2 screws are supplied with all packages regardless of the exact amount of screws used.

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 18/35

©TANSUG MAKİNA LTD. 2008

6.3 Description of screws that are used in the mounting of the stands.

You will use two kinds of screws that will be sent with your structure.

6.4 Assembly of Thermosyphonic Flat Roof Stand (TFR45)

6.4.1 Connect the base frame (A) with the tank support beds (F6), then the support beds (F6)

to the vertical frame (B) and side frame (C). Use side diagonal (E) to complete one leg of

the structure. Measure the dimensions illustrated at Figure A.

6.4.2 Put together the second leg of the structure in the same way described at step 4.1.1.

6.4.3 Use back diagonals (E) to connect the two legs of the structure together. Measure 880

mm. between the center of tank beds for structure type TFR45-1 for systems 121-151191 when connecting the back diagonals. (See Figure A). Use the holes on the vertical

frames (B) that correspond to this distance between the two legs.

6.4.4 The distance between the center of tank beds is 1260 mm. for structure type TFR45-2 for

systems 192-302. (See Figure B)

6.4.5 Install the aluminum panel frames on the base frames (A) , first the bottom aluminum

frame(D) to the first hole of the base frame from the bottom. Then put the top aluminium

panel frame (D) on the correspondi ng hol e on the bas e fra me tha t measur es 19 50 m m.

Remember t hat solar panel will be located between these two aluminium frames.

6.4.6 Screw the tank wind belt (G) on the tank beds (F) from the front. Screw the belts from the

back of the stand only after you have placed the tank on the tank beds, after when you

have finished all steps of the installation of the structure.

TYPE 2 TYPE 3

TYPE 2 : Standard Structure

Assembly Screws

TYPE 3 : Flat Head Screws- used for

connection of tank support

bed to wind belt

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 19/35

©TANSUG MAKİNA LTD. 2008

6.4.7 Put your structure on the desired location on the roof to mark the points on which you

want to anchor the ground support (I).

6.4.8 Put the structure aside and drill the holes on the roof and insert plugs and nuts. Anchor

the ground supports (I) on the roof.

6.4.9 Move the structure on top of the ground supports (D) Install the ground supports on each

four points of the structure that touch the ground.

6.4.10 After you have placed the panels on the stand, install the panel grips. (H)

6.4.11 Put the tank on the support beds and screw the tank wind belt from the back of the

structure.

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 20/35

©TANSUG MAKİNA LTD. 2008

235 mm

FIGURE A: TFR45-1: T. Syphonic flat Roof Structure for 1 Panel

515 mm

210 mm

880 mm

235 mm.

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 21/35

©TANSUG MAKİNA LTD. 2008

515 mm

210 mm

FIGURE B: TFR45-2: T. Syphonic Flat Roof Structur e for 2 Panels

235 mm.

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 22/35

©TANSUG MAKİNA LTD. 2008

6.5 Assembly of Thermosyphonic Flat Roof Stand (TFR35)

By changing only two parts (B,C) that are listed at Section 2, you can easily convert your flat

roof structure from 45° inclination to 35°. During your installation you just need to take into

account the dimensions illustrated in Figure C, below:

6.5 Assembly of Thermosyphonic Inclined Roof Stand (TIR)

The way the inclined roof stand is assembled depends on whether you use the

components for 35° or 45° (C35 or C45) in your flat roof installations. The assembly is

very similar with a small difference which is illustrated at Figure E & F.

6.5.1 Put the base frame (A) and the side frame (C) together to form one straight frame as

seen on Figures E & F. The frames will be connected by the use of two screws

6.5.2 Put together the second leg of the structure in the same way described at step 4.3.1.

6.5.3 Connect the tank beds (F) from the outer surface of the straight frame you have obtained

by putting together parts A and C together. You can count the holes to identify the exact

location of connection. Use back diagonals (E) to connect the two frames together. The

distance between the center of tank beds must be 880 mm. for structure type TIR45-1

FIGURE C: TFR35-1 /2: T. Syphonic flat Roof Structure for 1-2 Panel 35°

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 23/35

©TANSUG MAKİNA LTD. 2008

for systems 121-151-191 when connecting the back diagonals. Use the

holes on the vertical frames (B) that correspond to this distance between the two legs.

(See Figure A)

6.5.4 The distance between the two legs must be 1260 mm. for structure type TIR45-2 for

systems 192-302.

6.5.5 Install the aluminum panel frames on the base frames (A). First the top aluminum frame

(D) as illustrated at Figure E. Then put the bottom aluminum panel frame (D) on the

corresponding hole as shown in the Figure. It is crucial that you measure exactly 1950

mm. between the top and bottom aluminum frames. This is the distance required for

accurate placement of the solar panels.

6.5.6 Screw the tank wind belt (G) on the tank beds (F) from the front. Screw the belts from the

back of the stand only after you have placed the tank on the tank beds, after when you

have finished all steps of the installation of the structure.

FIGURE D: TIR-1 OR TIR-2: T. Syphonic Inclined Roof Structure for 1 or 2 Panel(s)

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 24/35

©TANSUG MAKİNA LTD. 2008

6.5.7 Remove the tiles on the roof and identify the location on the wooden, steel

or concrete beams on which it is possible to screw the roof anchors (J). Install the roof

anchors on the suitable locations alongside the beams. Try to locate the anchors in a way

that one pair is at the bottom and the other two pairs are closer to the top.

6.5.8 Put the structure aside and drill the holes on the roof and insert plugs and nuts. Anchor

the roof supports (I) on the roof.

6.5.9 Move the structure on top of the ground supports (D) Install the ground supports on each

four points of the structure that touch the ground.

6.5.10 After you have placed the panels on the stand, install the panel grips. (H)

6.5.11 Put the tank on the support beds and screw the tank wind belt from the back of the

structure.

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 25/35

©TANSUG MAKİNA LTD. 2008

FIGURE F:

Connection Details for

Inclined Roof Assembly – Using C35

FIGURE E: Connection Details for Inclined Roof Assembly – Using C45

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 26/35

©TANSUG MAKİNA LTD. 2008

5. CHARGING THE SYSTEM

5.1 Important points in the connection of the system to the house plumbing:

5.1.1 Install the equipment in such a way that the thermotank stays the closest possible to

the consumption points. The maximum distance between the collector and the most

distant consumption points should be around 30m, linear.

5.1.2 If the existing pipes network is made of steel or galvanized iron, that connection

should be made in latticed polyethylene or copper, adding dielectric sleeves of this

material so to avoid the par galvanic effect.

5.1.3 If the house pipes and tubes have a maximum temperature supported that is lower

than 100°C it’s convenient that you add a mixing valve to the installation so to avoid

the rise of the temperature to non supported levels. Examples of this are the

galvanized steel pipes that should not undertake more than 55 degrees.

5.1.4 All the pipes enduring hot water circulation should be insulated with minimum 20mm

for external pipes and 10mm for internal pipes. In the external pipes, such insulation

should be protected against the radiation effects.

5.2 Charging the secondary circuit

When charging the system always respect the filling order!

5.2.1 Open the gate valve on the cold water inlet to fill in the boiler. However hot water

outlet should be left open to let the air escape easily. ( You can leave a tap open in the

house.)

5.2.2 Verify that once the tank is filled there’s no leakage in any of the connections.

6.3 Char gi ng the Primary (heating) Circuit

6.3.1 Install the system as illustrated on the drawings.

6.3.2 Before putting the security valve, fill the secondary (heat exchangers and

collectors) with the respective amount of anti-freeze liquid according to the above diagram.

Refer to the below diagram for the amount of antifreeze to put in the system.

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 27/35

©TANSUG MAKİNA LTD. 2008

6.3.3 Proceed to fill the rest of the system with water. Take into account that the

maximum fluid capacity of the secondary circuit is approximately 10lt. (If the system is to be

put in an area risk free of frost, this filling can be made entirely with water).

6.3.4 Install the security valve. When the fluid in primary circuit reaches high

temperature, its pressure will raise as well. When this pressure exceeds 3 bar, the security

valve will open and some of the heat transfer fluid will be disposed through the valve. This

process will happen several times until finally when there is enough air in the upper part of

the jacket. After that, this space in the jacket will serve as an “expansion tank” and the

security valve will not work again.

6.3.5 Make sure there’s no leakage in the connections and repeat such test once

temperature, therefore pressure, rises.

6. ELECTRICAL ELEMENT

6.1 Your thermosyphonic system can be incorporated with an optional electrical heater of

2000 W, to be used as an auxiliary heating system during low irradiation or high consumption

seasons. (Remember that in some European markets auxiliary system is not allowed).

6.2 To connect the resistance to electrical net, the directives marked by the Low Tension

ElectroTechnical Regulation must be followed. For that, it is essential to use a three thread hose

with 2.5 mm section and it must be assured that proper grounding is established.

MODEL

P 101

P 121

P 151

P 191

P 192

P242

P 302

Close Loop Volume (lt.)

9,00

12,00

13,00

14,00

15,00

20,00

21,00

Temperature ºC

%

-5

AFLUS

1,35 lt

1,80

1,95

2,10

2,25

3,00

3,15

WATER 7,65 lt 10,20 10,20 11,90 12,75 17,00 17,85

-9

AFLUS

1,80 lt

2,40

2,40

2,80

3,00

4,00

4,20

WATER

7,20 lt

9,60

9,60

11,20

12,00

16,00

16,80

-13

AFLUS

2,25 lt

3,00

3,00

3,50

3,75

5,00

5,25

WATER

6,75 lt

9,00

9,00

10,50

11,25

15,00

15,75

-17*

AFLUS

2,70 lt

6,60

3,60

4,20

4,50

6,00

6,30

WATER

6,30 lt

8,40

8,40

9,80

10,50

14,00

14,70

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 28/35

©TANSUG MAKİNA LTD. 2008

6.3 On the side of your electrical element, there is a screw that goes through

the body of the element. The third hose is reserved for grounding. Connect this hose to the

screw attached to the body of the electrical element. Make sure that your home’s electrical

circuit has grounding.

6.4 The electrical heater comes with a built-in thermostat. The adjustment interval for

the thermostat is 0–80°C. Before installation the thermostat should be adjusted to the requested

temperature. Remember that setting a high

temperature on the thermostat can mean the

use of your electrical heater for longer time,

thereby consuming high levels of electricity. It

is recommended that a thermostat

temperature setting of minimum 45° C is set

on your electrical element. This is

important to avoid prolifer ati on of the

Legionella bacteria. Additionally, remember

that most people can not shower under more than 45º C.

6.5 The following photos illustrate the installation of electrical heater.

Insert the power

cable through the

cable gate of the

heater service cap.

WARNING

ALL INSTALLATION OF ELECTRICAL DEVICES MUST BE CARRIED

ONLY BY AN AUTHROZIED ELECTRICIAN ACCORDING TO THE

INTERNATIONAL AND NATION AL REGULATIONS.

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 29/35

©TANSUG MAKİNA LTD. 2008

Connect the

grounding line on

the cable.

Screw the heater cap on the tank.

Then connect the

negative and positive

poles to the respective

lines on the cable.

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 30/35

©TANSUG MAKİNA LTD. 2008

Freezing Point: - 60 ° C

Boiling Point: + 187° C

Purity: % 99,69

Acidity: % 0,001

7. AFLU-S HEAT TRANSFER FLUID

Aflu-S is a special non toxic propylene glycol heat transfer fluid

used in the close circuit of your system to provide better heat

transfer at the same time protecting your system from

corrosion and frost.

11. DISCHARGING THE SYSTEM

11.1 Discharging the secondary circuit. : Rotate the pressure relief valve silghtly to

discharge the pressure in the circuit. Discharge the water by opening the gate valve at the

inlet.

11.2 Discharging the closed loop: Discharge pressure through the air vent. Remove the air

vent and then remove blind plug at the bottom of the solar panel.

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 31/35

©TANSUG MAKİNA LTD. 2008

CHAPTER II

INSTRUCTIONS FOR THE USER

WARNING: Make sure that all installation is carried out by your authorized installer. Check all

valves are properly working and the system is completely filled with water and antifreeze fluid.

In case of failure, read the instructions at the troubleshooting section. Always call your

authorized service store before taking any action.

12. SAFETY & SECURITY COMPONENTS

Your system has two circuits, each secured by a number of safety and security components.

The system comes equipped with safety components for the primary circuit. All safety

components required for the secondary circuit must also installed by your authorized installer.

12.1 Primary Circuit (Closed Loop Line):

• Expansion tank: preset 1,5 bar, working pressure 4 bar

• Pressure relief valve: 5 bar

• Air vent 160° C

12.2 Secondary Circuit (Cold Water Line):

• Pressure reducer : preset to 3 bars

• Non-return valve

• Pressure relief valve 5 bars

• Control Valve

13. MAINTENANCE

The following table lists the key components of your system that require regular inspection

and maintenance.

INSPECTION

Correct Status

Period of Control

Average Life

Mg Anode Must be complete Annually 2 years

Antifreeze Fluid

Must be full

Annually

1 year

Pipe Insulation

Must be intact and solid

Annually

3 years

Fittings Accessories

Must function properly & not leak

Annually

2 - 5 years

Panels

(Closed Loop)

Inside panel must remain completely water and

weather proof

Every 2 years 12-20 years

Boiler –closed circuit

No leakage and corrosion should occur in the tank

Annually 8-10 years

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 32/35

©TANSUG MAKİNA LTD. 2008

13.1 Cleaning Panels: Regular rainfall keeps your panels clean. In dusty or

drought areas, it is recommended that panels are cleaned by the help of warm water and

sponge when necessary.

13.2 Pipe Insulation: Insulation material for piping may worn out in time due to strong UV rays.

Renew when necessary.

13.3 Magnesium Anode: Depending on the quality of the water, the life of a magnesium anode

varies between 2 – 4 years. Make sure that the Mg anode is checked regularly and

replaced when required.

13.3.1 Replacing the Mg anode Only authorized installer should change the Mg anode.

13.3.2 Turn the water supply off and empty the water from the storage tank.

13.3.3 Remove the Mg anode.

13.3.4 Fix the new rod inside the tank and make sure that complete tightness is maintained.

13.3.5 Turn the water supply on and let the tank fill with water.

13.4 Heat Transfer Fluid The level of the heat transfer fluid in the closed circuit should be

checked regularly (once a year). Decrease of fluid in the close loop of the system may

cause dramatic decrease in the performance of the tank. When the anti -freeze fluid is

inadequate in the system, it can also result in the freezing of water in the close loop circuit

and damaging the collector.

13.5 Holiday Leave If you leave your house for a long period during the summer months put a

cover on your panel to avoid overheating. In case of overheating pressure relief valve

discharges water. Make sure that the system is located in a way that hot water discharge

will not cause any damage.

14. TROUBLESHOOTING & IMPORTANT POINTS

Complaints for Insufficient hot water may arise from a number of factors:

14.1 Design and Expectations

14.1.1 Please note that the performance of your solar thermal system is directly parallel to the

availability of sunlight. Note that a day time is the ideal time to consume hot water from

your solar water heating system. If the consumption is primarily during night, your

system performance may be lower.

14.1.2 Your system can meet all your hot water needs during summer months. However it is

normal that your system meets a fraction of your requirements during cloudy winter

days.

14.1.3 Note the following consumption patterns that can help you save hot water:

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 33/35

©TANSUG MAKİNA LTD. 2008

o Do not let the water running when there is no need.

o Use the hot water at a reasonable temperature (around 42 ° C)

o If the water pressure at your house is excessive, install a pressure reducer.

14.2 Proper Installation

When properly located (facing the right direction, installed in the right angle, located on an

unshaded spot, etc) your system should work at its best. Ensure that tank and panel

connections are proper and there is no water leakage in the system.

14.3 Common Problems

Some of the most frequently encountered problems are listed here:

OCCASION: No Hot Water despite a sunny day

1. Check all connections for possible leakage

2. Check the heat transfer fluid in the close loop. Make sure it is full.

3. Make sure that the connection piping is not damaged in a way that it prevents the flow of

fluid. ( Too many curves on the piping line dramatically decreases the performance of

your system) Check if possible air loops occurred inside your boiler or collector during

charging of your system.

4. Check that connections and placement of boiler and panels are carried out in the right

way as shown in diagrams in this manual.

5. Make sure that your system is exposed to direct sun light for at least a few of hours during

noon time. Make sure that your system has been exposed to at least 3 hours of direct

sun light after when your system is first taken into operation.

OCCASION: No ho t water at all from the hot water tap

1. Check your pressure reducer.

2. Check if the non-return valve functions properly. The lid of the non-return valve can

sometimes get stuck.

3. Check that there is water in the mains.

OCCASION: Manometer Displays “0” in the closed loop circuit

1. Heat transfer fluid may be missing in the closed loop. Charge the close loop as shown in

the relevant section.

2. After step 1, if the manometer still reads “0” check the expansion tank for possible f ail ur e.

Replace expansion tan k if nec ess ary.

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 34/35

©TANSUG MAKİNA LTD. 2008

ANNEX 1: PARALLEL CONNECTION OF MULTIPLE SYSTEMS

ANNEX 2: SERIAL CONNECTION OF MULTIPLE SYSTEMS

Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS 35/35

©TANSUG MAKİNA LTD. 2008

CONTACT DETAILS

TANSUĞ MAKİNA INDUSTRIAL FACILITIES

ADANA-CEYHAN YOLU 10. KM 01340

INCIRLIK ADANA

TURKEY

90-322-3464900

90-322-3465008

info@ouraset.com

WWW.OURASET.COM

“CLOSEST TO THE SUN”

Loading...

Loading...