Page 1

INSTALLATION GUIDE

October 2009 Edition

Page 2

Page 3

1 Therma Cable Floor Heating System 4

1.1 General Information 4

1.2 Always 6

1.3 Never 6

2 Technical Information 7

2.1 Surface Area and Power Output of Therma Cable Products 7

2.2 Insulation Test 8

2.3 Resistance Test 9

3 Types of Heating and Floor Covering 10

3.1 Floor Warming 10

3.2 Radiant Floor Heating 10

3.3 Typical Floor Coverings 11

4 Installation Instructions 12

4.1 Planning Work 12

4.2 Preparing the Subfloor 13

4.3 Marking the Floor 13

4.4 Installing the Therma Cable Floor Heating System 14

4.5 Installing the Temperature Sensor 17

4.6 Applying Self-Levelling Cement 18

4.7 Connecting the System 19

4.8 Measuring Resistance and Measures' Table 20

4.9 Using the Therma Cable System 20

5 Temperature Regulation 21

6 FAQ 22

6.1 Floor Heating System 22

6.2 Installation 22

7 Expert Tips: Installation and Floor Covering 24

7.1 Installation Tips 24

7.2 Floor Covering Tips 24

8 Warranty 25

8.1 Warranty Statement 25

3

Table of Contents

Page 4

1.1 General Information

The installation must meet the following building codes, as applicable:

- Canadian Electrical Code (CSA C22.1)

- American National Electricity Code (ANSI/NFPA 70)

- Any other national or local code

The Therma Cable floor heating system is composed of a heating cable along with

a lead for connection to an electrical power source. Therma Cable meets the following in The Canadian Electrical Code standard: series heating cables set.

Shut off power supply to the floor heating system to prevent electrical

shock.

Important informations

- The Therma Cable floor heating system is designed exclusively for interior floor

heating. The system is not designed for snow melting or any other outdoor uses;

- Therma Cable is mainly designed to complement a building’s primary heating

source by serving as a secondary (floor warming) or primary room heat source

(radiant floor heating);

- Refer to Section 3 for instructions on heating a room using the Therma Cable

system only;

- Floor temperature varies based on insulation and floor characteristics;

- The Therma Cable system can be installed under a shower floor only if the

floor is ceramic or natural stone. A waterproof membrane must be used to

maintain the heating cables in a dry environment. Canada: A ground fault

circuit interrupter (GFCI) must be used with this heating device in bathrooms.

USA: A ground fault circuit interrupter (GFCI) must be used with this heating

device in bathrooms and in hydromassage bathtub locations;

- The Therma Cable system must be embedded in cement or an equivalent

binder (cement glue, ceramic glue or self-levelling cement);

- The system must be installed by a master electrician who is: able to evaluate

proper electrical resistance and wattage, familiar with installation-related risks

and knowledgeable about construction techniques as well as the installation

and use of the Therma Cable floor heating system;

- The system is only one step in the floor construction process. Each trade is

responsible for the quality of its work and must ensure that the work performed

by the previous tradesman has been duly completed according to code. All

tradesmen are engaged in the installation process and share joint responsibility

for it.

4

1. Therma Cable Floor Heating System

IMPORTAN T!

IMPORTAN T!

Page 5

5

Components

aramid fiber roving

ground wire

(bare wire)

Two-phase conductor

120V: phase - neutral

240V/208V: phase - phase

heating cable

junction

cold lead

channel

strapping

cold lead

plywood

or concrete slab

strapping

heating cable

self-levelling

cement

cement glue

floor covering

aluminum

sheath

ground

wire

heating

wires

aramid fiber

roving

wire

insulation

PVC sheath

Fig. 1.1

Fig. 1.2

Technique for interlocking the plastic strappings

Page 6

1.2 Always

- Read this guide in full before installing the product;

- Install the Therma Cable system with a regulating device;

- Use copper wires only;

- Perform the mandatory tests described in this guide and record readings on the

table of measures;

- Only use cement or an equivalent binder compatible with floor heating systems

(cement glue, ceramic glue, self-levelling cement);

- Ensure that the black heating cable is completely embedded in cement or an

equivalent binder (cement glue, ceramic glue, self-levelling cement);

- Ensure that the voltage supplied equals the nominal voltage of the Therma

Cable system;

- Repair the product only using the Therma Cable repair kit available at your

authorized Ouellet Canada Inc. dealer;

- Consult Ouellet Canada Inc.’s team of technical specialists for any questions

or for more information;

- Install Therma Cable at temperatures over 5 °C (40 °F).

- Heating cables must be at least 13 mm (1/2”) away from any combustible surface.

- Metal structures or materials used for the support of or on which cables or sets

are installed be grounded in accordance with the Canadian Electrical Code

(CSA C22.1 Section 10 and National Electrical Code).

- Installer of series heating cable sets must inspect and remove damaged or

defective heating cable sets before they are covered or concealed;

- Installer of series heating cable sets must mark the appropriate circuit breaker

reference (label) indicating which branch circuit supplies the circuit to those

electric heating cables.

1.3 Never

- Install Therma Cable sections so that the heating cables are less than 76 mm

(3”) from each other. The temperature could be too high and could cause

damages;

- Shorten or alter any part of the heating cable (fig. 1.3);

- Cross, overlap, or stack heating cables (they must not touch);

- Connect a 120V product to a 240V/208V power source;

- Use a bending radius under 20 mm (3/4”);

- Install a temperature regulator (thermostat or other) where it is accessible from

the shower or bath (install at least 1 m [3’ 4”] away);

- Staple heating cable or floor sensor end to the subfloor (fig. 1.3);

- Install the Therma Cable system if the safety seal is broken;

- Install the Therma Cable system under a closet or fixed items.

- Series heating cable sets shall not extend from beyond the room or area in

which they originate;

- Series heating cable sets are not to be installed in walls.

6

N

e

v

e

r

c

u

t

t

h

e

h

e

a

t

i

n

g

c

a

b

l

e

N

e

v

e

r

s

t

a

p

l

e

t

h

e

h

e

a

t

i

n

g

c

a

b

l

e

t

o

t

h

e

s

u

b

f

l

o

o

r

N

e

v

e

r

s

t

a

p

l

e

t

h

e

f

l

o

o

r

s

e

n

s

o

r

t

o

t

h

e

s

u

b

f

l

o

o

r

D

o

n

o

t

l

a

y

h

e

a

v

y

i

t

e

m

s

o

n

t

h

e

c

a

b

l

e

Fig. 1.3

Page 7

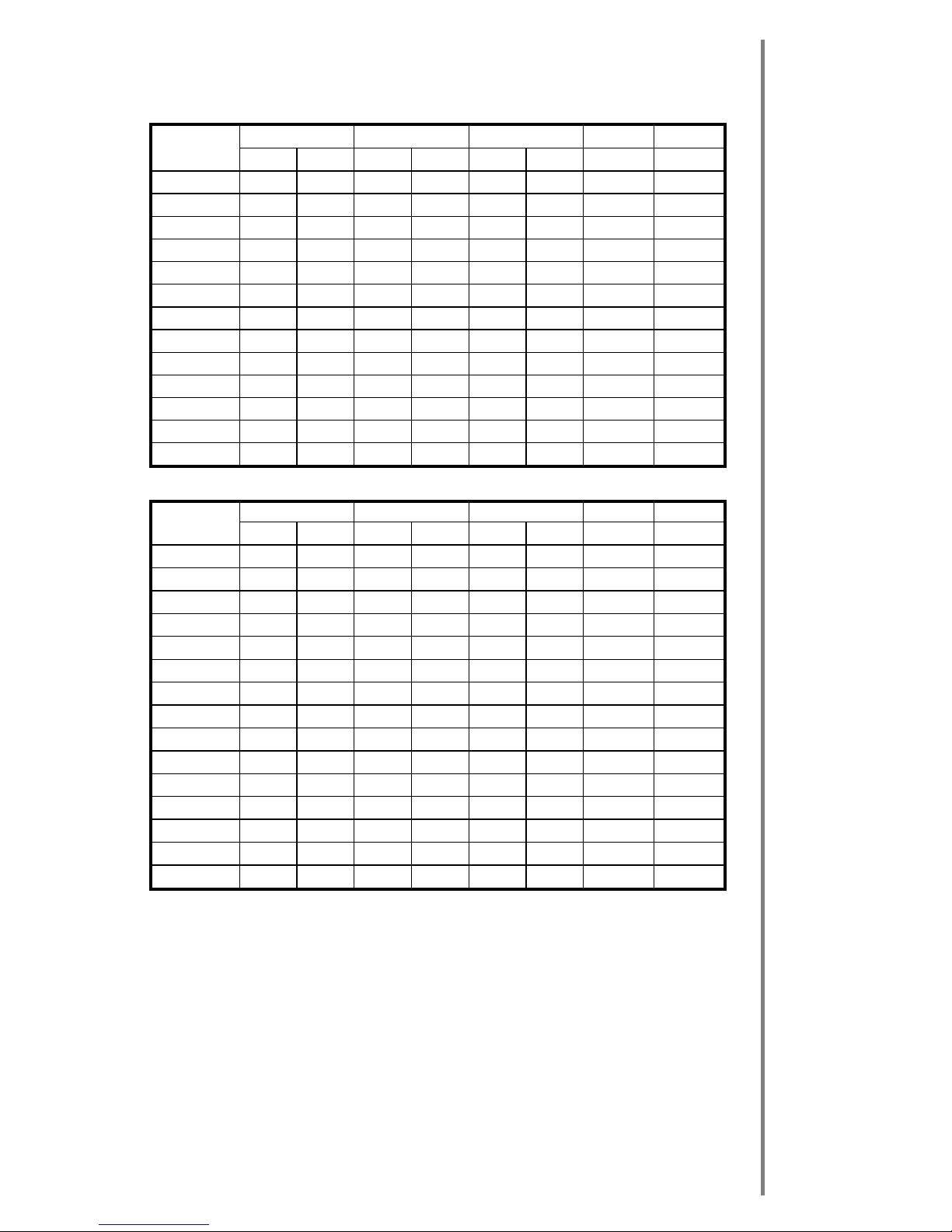

2.1 Surface Area and Power Output

of Therma Cable Products

208V = 75% of wattage at 240V.

7

2. Technical Information

P

roduct #

120V

Length Surface 12W/sq. ft. Surface 9 W/sq. ft. Power Resistance

f

t.

m s

q. ft.sq. msq. ft.sq. m

W

atts

o

hm

OTR0082

32 9.75 8 0.7 11 1.0 85 169.4

O

TR0122

4

0

1

2.19

1

0

0

.9

1

3

1

.2

1

20

1

20.0

O

TR0152

52 15.85 13 1.2 17 1.6 150 96.0

O

TR0172

6

0

1

8.29

1

5

1

.4

2

0

1

.9

1

70

8

4.6

OTR0242

8

0

2

4.38

2

0

1

.9

2

7

2

.5

2

40

5

9.9

O

TR0302

1

00

3

0.48

2

5

2

.3

3

3

3

.1

3

00

4

7.5

OTR0362

120 36.58 30 2.8 40 3.7 360 39.6

OTR0422

140 42.67 35 3.3 47 4.3 420 33.7

OTR0472

160 48.77 40 3.7 53 5.0 475 29.8

OTR0602

200 60.96 50 4.6 67 6.2 600 23.3

OTR0722

240 73.15 60 5.6 80 7.4 720 19.0

OTR0842

280 85.34 70 6.5 93 8.7 840 16.2

OTR0962

320 97.54 80 7.4 107 9.9 960 14.2

Product #

240V/208V

Length Surface 12W/sq. ft. Surface 9 W/sq. ft.

Power Resistance

ft. m sq. ft. sq. m sq. ft. sq. m Watts ohm

OTR0170 60 18.29 15 1.4 20 1.9 170 338.8

OTR0240 80 24.38 20 1.9 27 2.5 240 240.0

OTR0300 100 30.48 25 2.3 33 3.1 300 192.0

OTR0360 120 36.58 30 2.8 40 3.7 360 159.8

OTR0420 140 42.67 35 3.3 47 4.3 420 137.0

OTR0475 160 48.77 40 3.7 53 5.0 475 121.1

OTR0600 200 60.96 50 4.6 67 6.2 600 95.0

OTR0720 240 73.15 60 5.6 80 7.4 720 79.2

OTR0840 280 85.34 70 6.5 93 8.7 840 67.4

OTR0960 320 97.54 80 7.4 107 9.9 960 59.0

OTR1080 360 109.73 90 8.4 120 11.2 1080 51.8

OTR1200 400 121.92 100 9.3 133 12.4 1200 46.6

OTR1440 480 146.30 120 11.1 160 14.9 1440 37.9

OTR1600 560 170.69 140 13.0 187 17.4 1600 34.1

OTR1920 640 195.07 160 14.9 213 19.8 1920 28.4

Page 8

2.2 Insulation Test

Measure Therma Cable’s insulation resistance at each step using a megohmeter (fig. 2.2) and record readings on the measures’ table (this label is

available at the opening of the product).

For the warranty to be valid, fill out the measures’ table and ensure that the

10 readings have been correctly noted.

A qualified electrician must measure the system’s insulation resistance as follows:

- Use a calibrated megohmeter only;

- Measure insulation resistance at the free end of the cold lead, between the

phase conductor and ground;

- Write the reading in the measures’ table;

- This reading must be over 1,000,000 ohms;

- If the reading is under 1,000,000 ohms, stop work and contact Ouellet Canada

Inc.'s technical specialists at 1 800 463-7043.

8

CAUTION!

cold lead

Fig. 2.2

CAUTION! Dangerous Test

Page 9

2.3 Resistance Test

Measure the resistance of the Therma Cable heating cable at each step

using a multimeter (fig. 2.3) and record readings on the measures’ table.

For the warranty to be valid, fill out the measures’ table and ensure that the

10 readings have been correctly noted.

A qualified electrician must measure the system’s resistance as follows:

- Use a calibrated multimeter only;

- Measure resistance at the free end of the cold lead, between the two phase

conductors;

- Write the reading in the measures’ table;

- Verify the heating cable integrity by comparing your reading to the value on

the cold lead label;

- If your reading is off or very different than the nominal resistance (see Table 2.1)

at any step, stop work and contact Ouellet Canada Inc.'s technical

specialists at 1 800 463-7043.

9

IMPORTAN T!

c

old lead

Fig. 2.3

Page 10

The Therma Cable floor heating system can be used for two purposes maximizing comfort.

Used as a secondary heat source (floor warming), it can help keep floor temperature comfortable year round. Used as a primary room heat source (radiant floor

heating), it provides uniform, comfortable, and enveloping warmth. For the latter

use, it is important to follow the specific recommendations outlined below.

In light of environmental factors beyond Ouellet Canada Inc.’s control—including

thermal insulation, heated area, floor covering emissivity, heat loss, and more—

we cannot guarantee that the Therma Cable system will provide a completely

uniform surface temperature in all cases, no matter how careful the installation.

Consequently, Ouellet Canada Inc. cannot be held liable for any discomfort (e.g.,

a cold area on the floor) caused by site-specific deficiencies. Ouellet Canada Inc.

liability is limited to the performance of its products.

3.1 Floor Warming

This type of heating is designed to enhance comfort and/or supplement the

room’s main heat source. It helps keep the floor at a pleasant temperature at all

times.

Installing this type of system is very easy: simply unroll the Therma Cable on the

floor, maintain it with the installation strappings, embed the heating cable in cement

or an equivalent binder (cement glue, ceramic glue, self-levelling cement) and install

the floor covering. Use the floor coverings listed in Section 3.3 and connect the

Therma Cable system to an appropriate thermostat, described in Section 5.

3.2 Radiant Floor Heating

Therma Cable can be used as the room’s primary heat source. It can heat the

room using the Therma Cable system only. Proceed as follows:

- Connect the system to an ambient temperature regulator;

- Calculate heat loss to ensure the system has enough power to heat the room;

- Sufficient insulation under the subfloor is very important. This insulation is to be

sure that the heat will rise into the room to be heated.

- Make sure to have a floor covering that meets the specifications listed in table 3.3.

10

3. Types of Heating and Floor Covering

Page 11

Do not install a radiant floor heating system on a noninsulated or poorly

insulated subfloor, or over a crawl space.

The efficiency of this type of primary room heating system will depend on

factors such as available surface of the room to be covered with heating cable

(or sufficient percentage of the surface to be heated), heat conductivity of

the floor covering, insulation on outside walls, etc. We recommend that you

verify these points and seek professional advice before investing time and

money.

3.3 Typical Floor Coverings

The thermal resistance of the floor covering must not exceed R = 1.40

(RSI = 0.246). There is no such limit for the subfloor.

Table 3.3 Thermal resistance values for floor coverings

* The floor covering highlighted in grey is prohibited.

For engineered wood floorings, laminated hardwood flooring, vinyl coverings, and linoleum glued to a concrete surface, consult your floor covering

manufacturer to ensure they are compatible with floor heating systems.

11

IMPORTAN T!

IMPORTAN T!

Typical floor covering

Thermal resistance

R RSI

Vinyl tiles 0.20 0.035

Linoleum 0.22 0.039

Ceramic 0.25 0.044

Low-pile carpet 0.70 0.123

Parquet flooring 0.70 0.123

Floating floor 10 mm to 16 mm (3/8” to 5/8”) 0.70 0.123

Wood on lathes (strapping)* 2.10 0.368

IMPORTAN T!

Page 12

4.1 Planning Work

Materials provided by Ouellet Canada Inc.

- Therma Cable heating cable kit

- Installation strappings

- Installation instructions

- Service panel label

- Floor temperature sensor

Material required

- Temperature control with GFCI (available at Ouellet Canada Inc.)

- Cable check tester (available at Ouellet Canada Inc.)

- Stapler

- Protective glasses

- Measuring tape

- Broom

- Felt marker

- Tape

- Hot glue gun

- Wood chisel

- Hammer

- Multimeter and megohmeter

- Electrician tools

- Electrical tape

For installation over a concrete slab, add the following:

- Concrete chisel

- Drilling machine

- Percussion drill for concrete

Room Layout and Corresponding Therma Cable Product

- Create a room layout plan to scale (for maximum accuracy, use the Ouellet

Canada Inc. form designed for this purpose);

- Identify all stationary elements (toilet, bath, shower, counters, drawers, and

permanent furnishings) and never install the heating cable under these

stationary elements (fig. 4.1);

- Determine thermostat or temperature control location;

- Note room dimensions;

- Determine the electric cable (cold lead) location that will be connected to the

heating control;

- Calculate the heating area in square meters (sq.m.) [square feet (sq.ft.)];

- Select the Therma Cable product from Table 2.1 to cover 80% of the surface,

or subtract a mimimum of 50 mm (2 in) around walls and stationary elements.

12

4. Installation Instructions

cold lead

temperature

sensor

10'

8'

Fig. 4.1

Page 13

We can help optimize your work plan.

Fax it to us at 1 800 662-7801. Clearly indicate all dimensions.

A minimum of one horizontal and one vertical dimensions are

necessary to validate the scale.

4.2 Preparing the Subfloor

- Clean and remove any debris, or protruding objects that could damage the

heating cable;

- Subfloor cracks must be filled with polyester wood filler (only for self-leveller);

- The subfloor must be solidly fastened in place to prevent movement;

- The application of a floor levelling product is recommended to prevent future

damage to the ceramic caused by subfloor movement;

- For concrete subfloors, apply a surface sealer that is compatible with electrical

heating systems in accordance with the cement glue manufacturer’s

instructions. Completely coat the surface;

- Let dry before installing the Therma Cable system (refer to the sealer's

instructions for drying time).

4.3 Marking the Floor

Felt marker

13

Fig. 4.3 a

Page 14

- On the floor of an empty room (under construction or major renovations),

draw the location of stationary elements (toilet, bath, shower, counters,

drawers, permanent furnishings) that will be installed later. These marks will

outline the heating area to ensure the Therma Cable system is not placed

under these stationary elements.

- The floor temperature sensor must be centered between two parallel heating

cables. The ideal location is one where it is likely to be away from stationary

objects and sheltered from outside influences (sunlight) that could skew floor

temperature readings. For maximum comfort, the area above the sensor must

be free of obstruction.

4.4 Installing the Therma Cable Floor Heating System

14

F

ig

.

4

.

3 b

Fig. 4.4 a

heating cable

junction

channel

cold lead

Page 15

Tape, hot glue gun, stapler

Remove the product from the box and verify the electrical and insulation resistance of the heating cable.

Therma Cable strappings’ installation:

- The strappings are fixed on the floor with staples (T50) (when the floor is made

of plywood or wood) or with a hot glue gun.

- The strappings must follow the outline draw on the room layout (section 4.1)

- If the lacing distance between two strappings is over 0,625 m (2 ft), it is

necessary to place an intermediate strapping to maintain the cable in position

during the pouring of self-leveller, this strapping is installed at the end, after the

lacing of the cable.

- The cable can be installed under the ceramic tile of a shower or other wet

surfaces, the strappings and the heating cable must be glued under the

wateproofing membrane and not stapled, staples could damage the

waterproofing membrane.

Installation of Therma Cable

- Set the cable near the connection box and regularly lace the heating wire

respecting the distance between the sections; 76 mm (3”).

- Do not bend the cable at 90° when setting it in the strapping hooks; leave a

20 mm (3/4“) radius. This radius comes naturally; the cable must not be

forced to have a tight bend.

15

Fig. 4.4 b

on plywood

on concrete slab

Page 16

- A tag is located at 50% of the cable length. During installation of the product,

verify the cable half tag to compare with your cable layout planification. Adjust

pattern with the result to cover the surface. If the cable is too long, use the

buffer zone to spend the remaining cable. Never shorten the heating cable.

The heating cable must not be shortened, neither cut.

- Avoid walking on the Therma Cable system. If you must,wear soft rubbersoled shoes;

- Always start the Therma Cable at least 50 mm (2”) from the walls;

- It is important not to subject the heating cable to any mechanical strain

(stretching, bending radius under 20 mm [3/4”], scoring).

Never cut or score the heating cable.

Measure the cable’s electrical and insulation resistance and record

the readings on line 2) After installing the heating cable of the

measures’ table.

16

Fig. 4.4 c

IMPORTAN T!

Page 17

17

4.5 Installing the Temperature Sensor

Hot glue gun, hammer, wood chisel or concrete chisel

- To minimize floor height, chisel a 10 mm x 10 mm x 250 mm (3/8” x 3/8” x 10”)

channel in the subfloor to receive the floor sensor. The junction has an

insulation sheath and a slightly larger diameter than the heating cable.

The sensor must be embedded in cement or an equivalent binder (cement

glue, ceramic glue, self-levelling cement).

- Glue the sensor to the subfloor (fig. 4.5). The sensor must be solidly fastened

to the subfloor to ensure it stays in place when the cement or an equivalent

binder (cement glue, ceramic glue, self-levelling cement) is applied.

Fig. 4.5

IMPORTAN T!

c

hannel

temperature

s

ensor

Page 18

4.6 Applying Self-Levelling Cement

Measure the cable’s electrical and insulation resistance and record the

readings on line 3) Before embedding the heating cable in self-levelling cement

of the measures’ table.

- Consult the manufacturer’s instruction for the type of floor covering (ceramic,

linoleum, or other). See Section 7, Expert Tips;

- Completely embed the heating cable in self-levelling cement (fig. 4.6). It is

crucial that the ENTIRE heating cable (BLACK) be embedded. No part of the

heating cable (BLACK) must be exposed. (A small part [top] of the heating

cable may be exposed at the surface of the self-levelling cement ONLY IF a

ceramic glue is used afterward AND embeds that part);

- Level the subfloor with self-levelling cement or cover the cable with a layer of

cement glue when installing the stones or ceramics.

Do not turn on the Therma Cable floor heating system before the cement

has completely dried. Follow manufacturer recommandations (may take up

to 30 days, depending on the product).

Once the cement or binder has dried, measure the cable’s electrical resistance and record the readings on line 4) After embedding the heating cable

in cement of the measures’ table.

18

Fig. 4.6

IMPORTAN T!

Page 19

Final view

4.7 Connecting the System

The system must be connected by a master electrician.

Cold lead

- 240V/208V connection: - 120V connection:

Line 1 - Black Line - Black

Line 2 - Red Neutral - White

Bare wire - ground Bare wire - ground

Measure the cable’s electrical resistance and record the readings on line

5) Upon installing the thermostat of the measures’ table.

19

IMPORTAN T!

Self-levelling

cement

cement glue

f

loor

covering

Page 20

20

4.8 Measuring Resistance and Measures’ Table

- The master electrician who installed and connected the Therma Cable system

must complete the measures’ table (this label is available at the opening of the

product) and give it to the customer. This sheet must be kept near the

electrical service.

If this table is not duly completed, the warranty may be annulled. Warranty

terms are set out in Section 8.

4.9 Using the Therma Cable System

- The Therma Cable floor heating system is now ready for use. However, before

turning on the system, make sure the curing period specified by the cement or

binder manufacturer has expired. Adjust the thermostat's temperature based

on your needs and desired level of comfort.

CAUTION!

Page 21

21

5. Temperature Regulation

5. IMPORTANT!

The Therma Cable system must be controlled by a temperature control system.

If Therma Cable is to be used for floor warming, an electronic floor temperature

control featuring a floor sensor is recommended to ensure heat levels never

exceed the floor covering’s maximum temperature tolerance.

If the system is to be used for radiant heating, the room thermostat controls heat

and is reacting to room and not floor temperature therefore a floor covering with

greater temperature resistance must be used.

The room temperature control and floor temperature sensor must never be

installed where they will be exposed to sunlight or air drafts.

The Therma Cable floor heating system must be connected to a ground fault

circuit interrupter (GFCI) when installed in a bathroom. Ouellet Canada Inc.

strongly recommends the use of a GFCI in all rooms featuring the Therma

Cable system.

Recommended temperature regulation devices:

1- Thermostat with floor sensor and integrated GFCI (floor warming only).

2- Rheostat dimmer switch with a GFCI.

3 Electronic ambient thermostat with a GFCI (radiant room heating).

IMPORTAN T!

Page 22

22

6. FAQ

6.1 Floor Heating System

Q.1 : Can I cut the Therma Cable heating cable to shorten it?

A.1 : NEVER. If the Therma Cable is too long, spread it on the floor in regular

loops. Keep the minimum distance from the walls and between parallel

runs of cable (radius bending of at least 20 mm [3/4”] for loops). Be sure

to keep 76 mm (3”) (other spacing option: 100 mm [4”]) between

each heating cable loop.

Q.2 : What should I do before choosing the Therma Cable system that’s

right for me?

A.2 : Sketch a plan to determine the surface area. We can help optimize your

work plan. Fax it to us at 1 800 662-7801.

Q.3 : How do I repair Therma Cable in case of a malfunction?

A.3 : First, as a PREVENTIVE measure during installation, test the cable each

time as specified in the installation guide. Also complete the measures’

table.

However, in case of a malfunction, an authorized Ouellet Canada Inc.

repair person will visit to LOCATE the fault and REPAIR it. It is recommended

that you keep spare ceramic tiles or flooring for this purpose.

Q.4 : Are there other watt densities per square foot available?

A.4 : Ouellet Canada Inc. believes that 12W/sq. ft. (130W/sq.m) at 76 mm

(3”) spacing is the best watt density to optimize comfort and prevent

floor overheating. Therma Cable can also be installed with a 100 mm

(4”) spacing for a 9W/sq.ft (96W/sq.m). Moreover, the 240V and 120V

systems provide equal heating power per square foot.

Q.5 : Can I crisscross, overlap, or touch two heating cables together?

A.5 : NEVER. This will cause overheating. Keep cables at least 76 mm (3”) or

100 mm (4”) apart.

Q.6 : Can the cable be bent 90°?

A.6 : Yes, but make sure the radius bending is at least 20 mm (3/4”). Any

bending smaller than this may damage the cable.

6.2 Installation

Q.7 : Can I install one Therma Cable system on top of another?

A.7 : NEVER. The system will overheat. Heating power must not exceed

12W/sq. ft (130W/m2).

Q.8 : Can Therma Cable be used for exterior snow melting?

A.8 : No. Therma Cable is designed to provide comfort and heating in indoor

residential applications only.

Q.9 : Is a GFCI necessary?

A.9 : A GFCI is required in the bathroom. It is recommended for all other rooms.

Q.10 : Is a floor sensor necessary?

A.10 : Yes, to control floor surface temperature so that it does not exceed the

floor covering's maximum temperature tolerance.

Even if it is not an obligation to use a floor sensor when using the system

with an ambient thermostat, Ouellet Canada Inc. recommends the use of

a floor sensor.

Page 23

23

Q.11 : Can I connect two Therma Cable systems to the same thermostat?

A.11 : Yes. You can even connect additional systems provided the connection is

parallel and total output does not exceed the thermostat’s capacities.

Q.12 : What happens if the voltage applied is the wrong one?

A.12 : Connecting a 120V product to a 240V/208V current will overheat the

system and lead to an overheating and failure. A 240V/208V product

connected to a 120V current will produce virtually no heat. It is therefore

very important to connect the right product to the right voltage.

Q.13 : Can Therma Cable be installed over concrete?

A.13 : Yes. Apply a concrete sealer before installing the Therma Cable system.

See Section 4.

Q.14 : Can carpet be installed over Therma Cable?

A.14 : Yes, if the system is completely embedded in self-levelling cement. You

can install low-pile carpet over the slab if the carpet’s thermal resistance

does not exceed R = 1.40 (RSI = 0.246).

Q.15 : Can wood flooring be installed over Therma Cable?

A.15 : Yes, you can install multilayer wood flooring (Engineered flooring), provi-

ded its thermal resistance does not exceed R = 1.40 (RSI = 0.246).

Q.16 : Is the use of self-levelling cement mandatory when installing

ceramic tile?

A.16 : If the room is small, an experienced tiler can do a good job without using

self-levelling cement, but this method is not recommended. The heating

cable must always be completely embedded in cement or an equivalent

binder (cement glue, ceramic glue, self-levelling cement). If the room is

medium-sized or large, the use of self-levelling cement is strongly recommended to ensure the ceramic is perfectly level.

Page 24

24

7. Expert Tips: Installation and Floor Covering

7.1 Installation Tips

- For multilayer wood flooring (engineered floor) or linoleum, it is recommended

that you consult the manufacturer to verify whether these floor coverings are

compatible with a floor heating system;

- Though unlikely, the floor temperature sensor may need to be replaced. Ouellet

Canada Inc. recommends installing a flexible plastic tube from the sensor to the

thermostat on the wall;

- Fasten the cold lead and floor sensor to a concrete subfloor with adhesive (hot

glue, tape).

7.2 Floor Covering Tips

- It is strongly recommended to coat the subfloor with a sealer before spreading

the self-levelling cement (which is very liquid). This is to prevent any leaks

under the floor;

- The use of a latex primer on a concrete subfloor is recommended to ensure the

self-levelling cement adheres better to the concrete;

- With multilayer wood flooring (engineered floor), applying a minimum 5 mm

(3/16”) layer of self-levelling cement on the heating cable is recommended. To

completely embed the cable in the cement or cement glue;

- It is important to respect the drying times recommended by the manufacturer

to prevent residual moisture from affecting the adherence of floor coverings

such as vinyl, linoleum, or wood.

Page 25

25

8. Warranty

8.1 Warranty Statement

Subject to the legal warranties relating to quality and durability of goods provided

for by the Consumer Protection Act:

Ouellet Canada Inc. warrants the Therma Cable heating cables (OTR) of its floor

heating system for a 25-year period beginning from the date of purchase, against

any malfunction or manufacturing defect.

Limitations and exclusions

The above mentioned warranties are restricted to the reimbursement of the original purchase cost and replacement of the heating cables and/or defective thermostat (hereinafter the “equipments”) excluding any other part also excluding

any cost or any expense relating to the connection, removal, installation or fixing

of the aforesaid equipments, including workmanship costs.

Ouellet Canada Inc. leaves the purchaser the care to choose between reimbursement of the purchase cost or replacement of the defective equipments, subject to

the abovementioned restrictions.

The present warranties are granted to the original purchaser of the equipments as

well as to the subsequent buyer of the building where it has been installed.

Terms of warranty

The present warranties are subject to the compliance of the following terms:

i. Purchaser must provide Ouellet Canada Inc. or an authorized distributor or

reseller with the original invoice for the defective equipments;

ii. Purchaser must notify Ouellet Canada Inc., in writing, of any defectiveness

with the equipments aimed by the present warranties, in a reasonable time

frame from the occurrence or knowledge of the defectiveness and give

permission to Ouellet Canada Inc.’s representatives, the case being, to

inspect the defective equipments;

iii. The equipments aimed by the present warranties must have been installed

in compliance with Ouellet Canada Inc.’s installation guidelines;

iv. The equipments aimed by the present warranties must have been used in

normal conditions and must have been kept under normal maintenance

from the purchase date.

Name and address of the person granting the present warranty:

Ouellet Canada Inc.

180, 3eAvenue

L’Islet (Québec) G0R 2C0 CANADA

Telephone: 1 800 463-7043 or 418 247-3947

Fax: 1 800 662-7801 or 418 247-7801

info@ouellet.com

www.ouellet.com

Loading...

Loading...