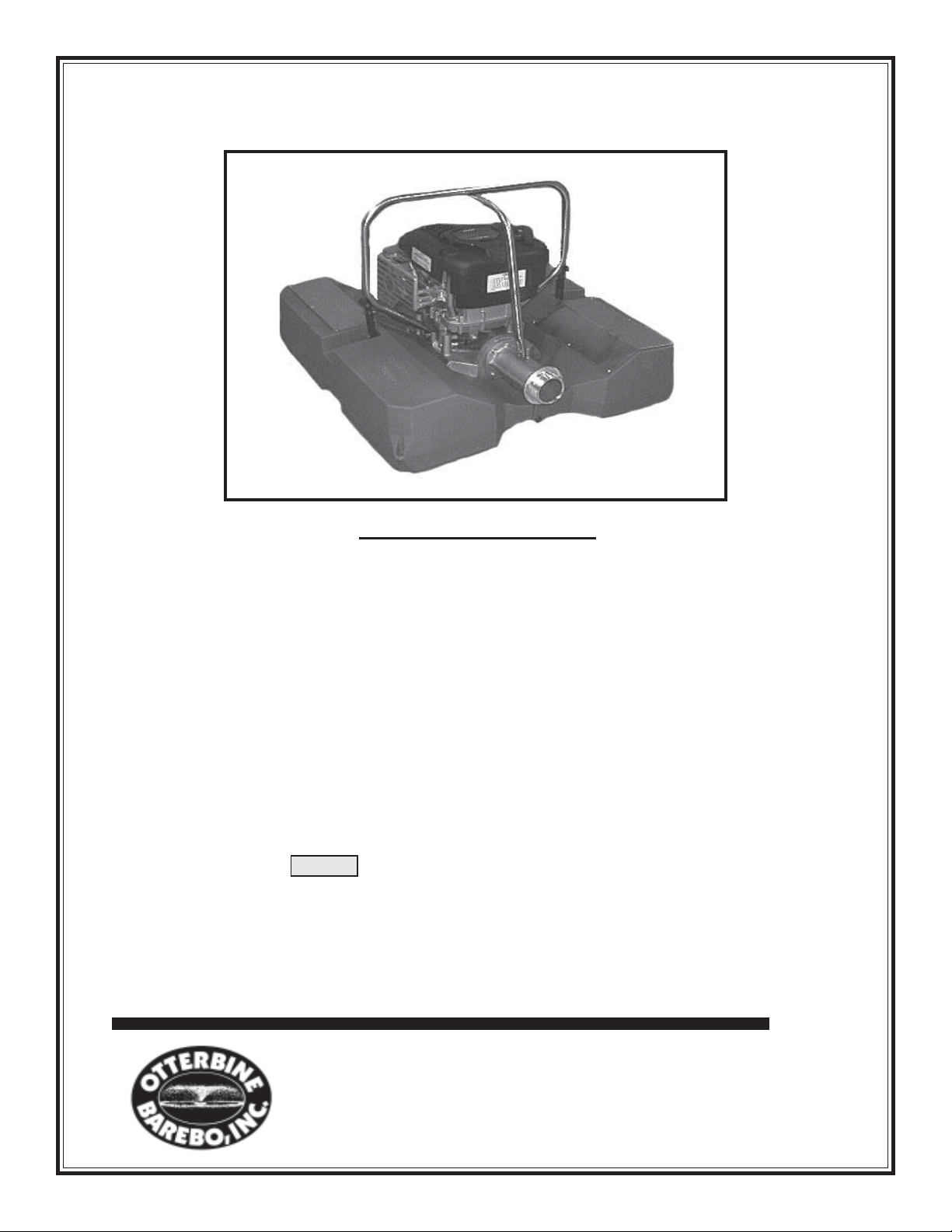

Otterbine Bunker-pumper User Manual

Owner's Manual

Otterbine® Bunker-Pumper

3

CUSTOMER CHECK LIST:

Please do the following immediately upon receipt of

your pump:

• Inspect pump for shipping damage.

(Report any damage to freight company.)

• Check to see that any/all accessories that you

ordered are included.

• Record the pump serial number. This can be found

stamped on the top housing, and on the yellow

sticker located on the side of the engine.

• Fill out and return warranty card.

NOTE: Warranty is validated upon the receipt

of the completed Warrranty Registration Card.

• Read all operating and maintenance instructions.

Otterbine® Barebo, Inc.

3840 Main Road East

Emmaus, PA 18049 USA

Phone (610) 965-6018 Fax (610) 965-6050

800-AER8TER (237-8837)

www.otterbine.com

TABLE OF CONTENTS

Introduction & Applications............................... 1

Pump Operation.................................................. 2

Engine Maintenance ........................................... 3

Storage................................................................ 3

Pump Maintenance ..........................................4

Warnings/Safeguards.......................................... 5

Troubleshooting................................................... 5

Revised 3/29/04

Technical Specifications .........................6

Pump Curve ............................................7

Optional Accessories ..............................

Parts List and Diagrams .........................8-11

Warranty: Briggs & Stratton ...............12

Otterbine ............................13

7

INTRODUCTION

CONGRATULATIONS! You have just purchased the best pump on the market. At Otterbine®/Barebo, Inc.

we are committed to quality products and service. If you have any problems or questions regarding your new

pump, please contact your qualified Otterbine distributor or call us at 610-965-6018.

Your new pump is a rugged well-tested tool, but it requires some routine care and maintenance. Please read

this manual before operation.

WARRANTY

The Otterbine® pump is covered by a one-year limited warranty. The engine is warranted by Briggs &

Stratton. Both warranties are enclosed, see inside and outside back cover. The enclosed warranty card

must be filled out and returned for your warranty to be valid.

NOTE: Bunker Pumper3 is shipped with transport bolts (2 total) to secure the pump to the float. To detach the

pump from the float remove these bolts. Use the flexible draw latches to hold the pump to the float when in

operation.

APPLICATIONS

The Otterbine® pump is used by

• Golf Courses

• Construction Firms

• Landscaping Firms

• Airports

• Marinas

• Homeowners

• US Forest Service

• Fish Farmers

• Firefighters

Otterbine pumps work in many applications such as:

• water removal & transfer

(e.g. emptying swimming pools and sand traps)

• emergency aeration

• irrigation

• cleaning

• disaster relief

• firefighting --- on site & water refilling

Page 1

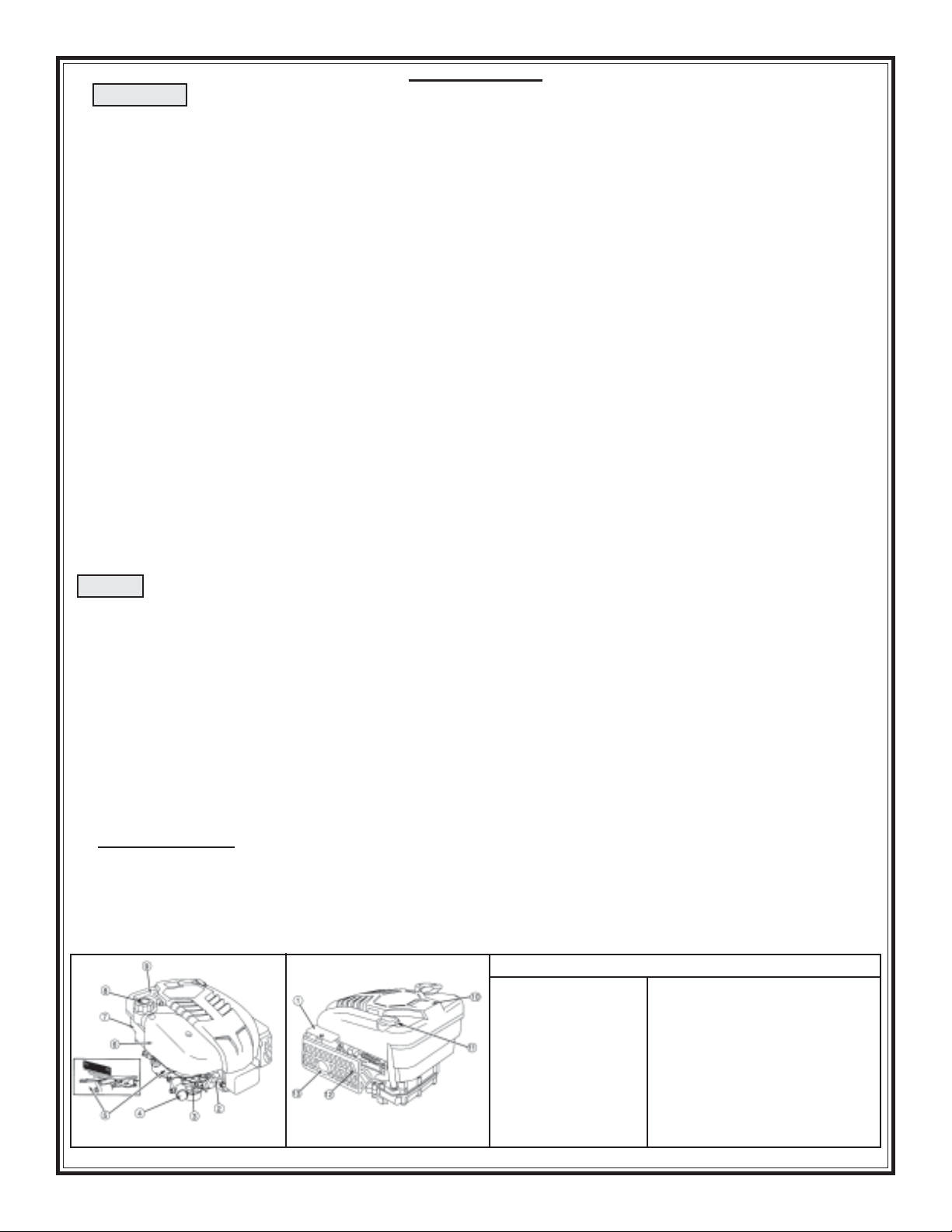

Pump Operation

1. Important: Fill crankcase with oil (There is no oil in the crankcase when you receive the pump).

Approx. 22 ounces / 0.65 liters (Figure 1)

• Summer: use SAE 30 Oil.

o

• Winter (under 40

F or 4oC): use SAE 5W-20 Oil.

2. Fill gas tank. Briggs & Stratton recommends using a lead-free gasoline (minimum of 85 octane). Allow

1/4" or 5 mm of tank space for fuel expansion (Figure 1).

3. To Start Engine

A. Open fuel valve. Turn fuel shut off valve to "ON" position. It is located underneath the gas tank.

B. Move choke to "CLOSE" position. The choke lever is white in color and located below the carburetor (Figure 1) Move the lever to the left.

C. Move throttle to "FAST" position. The throttle is located (Figure 1) above the choke lever and has a red

cover on it. Move the lever to the full left position.

D. Grasp rope handle (Figure 1) and pull slowly until resistance is felt. Then pull cord rapidly to overcome

compression, prevent kickback and start engine. Repeat if necessary with choke open.

E. When engine starts, move choke to mid position and then, to full right "OPEN" position when

warm.

NOTE: Minor adjustments to the carburetor and governor may be necessary to get pump running to

specs. Please refer to Briggs & Stratton engine Owner's Manual which was enclosed with this document.

4. Place pump in water and start for fastest prime.

A. Pump may fail to prime properly if started in fast idle position on shore first. For one person operation, start on shore at a low idle and then place it in the water.

5. To Stop Engine

A. Move throttle control to full right "Stop" position. Do not use Choke control to stop engine.

Operating Notes:

• Do not submerse the muffler in water. May cause damage to the engine.

• Use a 2.5" dia. discharge hose. BP3 pumps are low pressure/high volume. Any

thing less than 2.5" dia. will restrict flow and reduce GPM output.

• When using on grass remove the intake screen to prevent clogging.

Engine Part Locations (Figure 1 and Figure 2)

Figure 1 Figure 2

1. Engine

2. Spark Plug

3. Carburetor

4. Primer Bulb ***

5. Choke Lever ***

6. Air Cleaner

7. Fuel Tank

8. Fuel Fill

9. Rope Handle

10. Finger Guard

11. Oil Fill/Dip Stick

12. Muffler Guard

13. Muffler/Spark Arrestor ***

*** Option, may not be equiped

Page 2

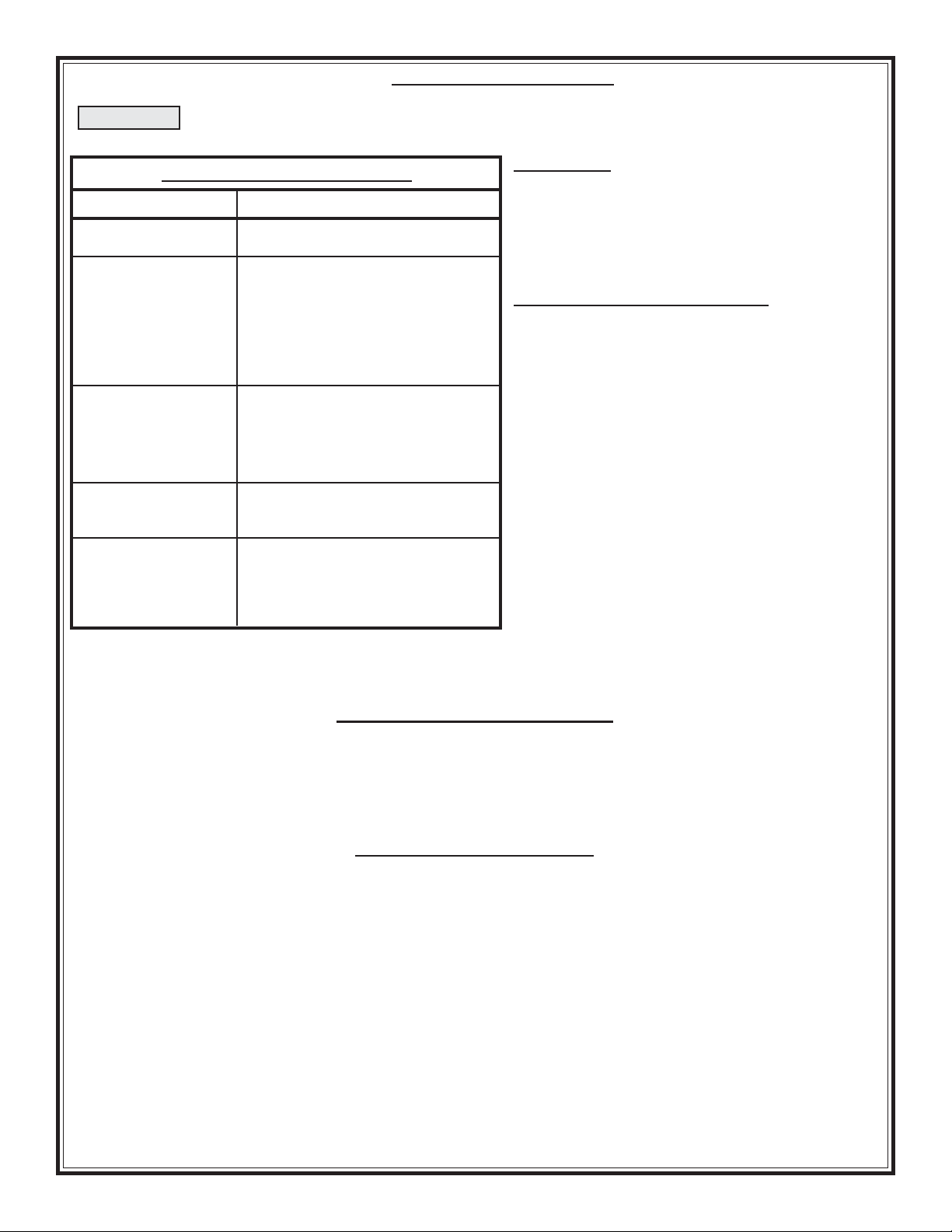

ENGINE MAINTENANCE

CAUTION: Always remove spark plug first. (This prevents accidental starting during servicing.)

MAINTENANCE SCHEDULE

TIME ACTION

After first 5 hours •Change Oil

After every 5 hours •Check Oil Level

•Remove dirt & debris from air

cleaner with a cloth or brush. Cleaning

with a forceful spray is not recom

mended as water can contaminate the

fuel system

Every 25 hours/season • Clean & re-oil foam element in air

cleaner.

* Change Oil

*service air cleaner cartridge

Every 50 hours/ • Change oil

Each season: * Inspect Spark plug

Every 100 hours/yearly • Service air cleaner cartridge

• Change oil filter

• Clean cooling system

* Replace spark plug

Change Oil: Drain oil from bottom of the

engine. Change oil while engine is warm, after

first 5 hours & every 50 hours/season thereafter.

Change every 25 hours if operated under heavy

load, or in high ambient temperatures.

Clean & re-oil foam air cleaner:

(Every 25hours/ season of use)

Replace if very dirty or damaged

Wash pre-cleaner in liquid detergent and water.

Allow to dry thoroughly before using. Do not

oil pre-cleaner. Clean cartridge by tapping

gently on a flat surface. Do not use petroleum

solvents, e.g., kerosene, which will cause cartridge to deteriorate. Do not use pressurized air,

which can damage cartridge. Do not oil cartridge.

1. Loosen screws on lift cover

2. Carefully remove pre-cleaner (if equipped)

and cartridge assembly

3. Service pre-cleaner, cartridge and reassemble

4. Install cartridge/pre-cleaner into base

5. Place cover on air cleaner and tighten screws

securely to base.

SALT WATER MAINTENANCE

Otterbine floating pumps may be used in salt water applications providing the pump is immediately flushed

with fresh water after use for 7-10 minutes at full throttle. The exterior hardware must be rinsed and wiped

dry. Note, salt water is very corrosive, pump parts will wear faster under these conditions.

STORAGE INSTRUCTIONS

If the Otterbine pump is to be stored for 30+days, do the following:

1. To prevent dirt or gum deposits in the fuel system, drain engine of fuel. Run the engine until it stops

from lack of fuel.

2. Float assembly should be removed for easier maintenence. To remove the float assembly, disengage the

hold-down straps (see parts breakdown pg. 8-11). Lift engine/pump assembly up and away from the

floats.

3. While engine is still warm, drain oil from crankcase. Refill with oil.

4. Remove spark plug. Pour approximately .5 ounce/15ml of engine oil into cylinder and crank slowly to

distribute oil. Replace spark plug.

5. Clean dirt and chaff from cylinder, blower housing, rotating screen, and muffler area.

6. Store the pump in a clean and dry area.

Page 3

Pump Maintenence

1. Debris screen should be cleaned after every use.

2. Pump should be greased after every use.

A) Use purple marine grade grease (available in 14oz cartridge from Otterbine, P/N 48-0006).

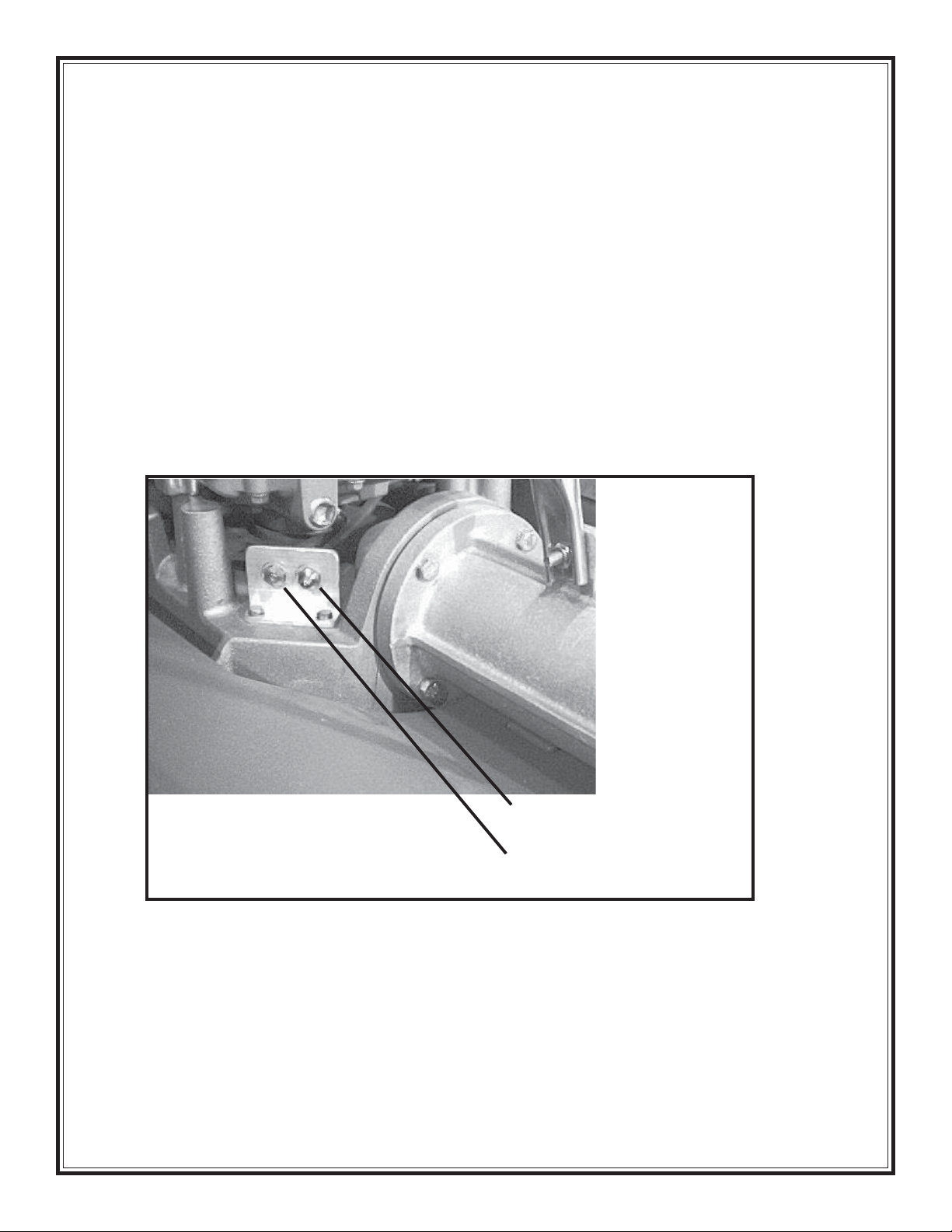

B) Place the tip of the grease gun on the grease fitting (Figure 3) located on the pump housing.

C) Fill with grease until all of the old grease has been pushed out of the relief valve(Figure 3) below the grease

fitting.

D) You should see the new (purple) grease come out. Once this has happened, you are done.

Figure3

Page 4

Grease Fitting

Relief Valve

Loading...

Loading...