Page 1

FT110DBMicro Series Installation & Operation Manual

Installation and Operation Manual

FTD110DBMicro Series

8-bit Digital Series

1 Bi-directional Data

Fiber Optic Converter

OT Systems Ltd., 2014

Rev 1.2

www.ot-systems.com 1

Page 2

FT110DBMicro Series Installation & Operation Manual

Models covered in this manual

Standalone Units

Single-Mode Transmitters

FTD110DBMicro-SST

FTD110DBMicro-SSTL

Single-Mode Receivers

FTD110DBMicro-SSR

FTD110DBMicro-SSRL

Multi-Mode Transmitter

FTD110DBMicro-SMT

Multi-Mode Receiver

FTD110DBMicro-SMR

Compatible with the following Series:

FTD110DB

FTD110DBM

Remark:

If the optical connector is FC type, the suffix in the model number will be “-FXX”. Eg.

FTD110DBMicro-FST

www.ot-systems.com 2

Page 3

FT110DBMicro Series Installation & Operation Manual

Table of Contents

(1) SAFETY INSTRUCTIONS .................................................................................................................................. 4

(2) PRODUCT OVERVIEW .................................................................................................................................... 5

2.1 INTRODUCTION ..................................................................................................................................................... 5

2.2 MODELS SELECTION TABLE ...................................................................................................................................... 6

(3) INSTALLATION................................................................................................................................................ 6

3.1 GENERAL ............................................................................................................................................................. 6

3.2 MICRO UNIT INSTALLATION ...................................................................................................................................... 7

(4) CABLE CONNECTIONS & SETUP PROCEDURES ................................................................................................ 8

4.1 SYSTEM CABLE CONNECTIONS .................................................................................................................................. 8

4.2 DATA PORT ASSIGNMENT AND PIN CONNECTIONS ......................................................................................................... 9

4.3 DIP SWITCH SETTING PROCEDURES .......................................................................................................................... 10

4.4 GROUND CONNECTION ......................................................................................................................................... 12

(5) OPERATIONAL GUIDES ................................................................................................................................. 12

5.1 FTD110DBMICRO SERIES TRANSMITTER ................................................................................................................ 12

5.2 FTD110DBMICRO SERIES RECEIVER ...................................................................................................................... 13

(6) SPECIFICATIONS ........................................................................................................................................... 14

(7) DRAWINGS .................................................................................................................................................. 15

(8) WARRANTY INFORMATION ......................................................................................................................... 15

(9) CONTACT INFORMATION ............................................................................................................................. 15

www.ot-systems.com 3

Page 4

FT110DBMicro Series Installation & Operation Manual

(1) Safety Instructions

Please be familiar with all information in this manual prior to installation and

operation.

Note 1: The products described contain a Class 1 laser or LED fiber optic emitter. The following

safety precautions apply.

Warning: Do not disconnect the fiber optic connector while the unit is powered up.

Exposure to Class I invisible optical radiation is possible when the internal fiber optic

connector is disconnected while the unit is powered up.

Caution: Any access to the controls, adjustments, or performing operations, which are

other than those specified may result in hazardous radiation exposure. Permanent eye

damage or other bodily injuries may be resulted from such exposure even for only

seconds.

Note 2: This assembly contains parts sensitive to damage by electrostatic discharge (ESD). ESD

precautionary procedures should be applied in the course of touching, removing or inserting parts

or assemblies.

www.ot-systems.com 4

Page 5

FT110DBMicro Series Installation & Operation Manual

(2) Product Overview

2.1 Introduction

The FTD110DBMicro Series products comprise of either single-mode or multi-mode fiber

optic transmitters and receivers for the optical transmission of ONE bi-directional (Tx ↔ Rx) data

signal on one fiber. The products work at wavelengths of 1310nm and 1550nm with either a

9/125um or 62.5/125um fiber for single-mode or multi-mode transmission respectively.

Transparent data transmission is also accomplished in RS232, RS422 and RS485 formats

regardless of the type of communication protocol implemented within the system. Time Division

Multiplex (TDM) technology is employed for digital transmission of forward data; whereas optical

Wavelength Division Multiplex (WDM) technology is employed for simultaneous reverse data

transmission as well as bi-directional data transmission.

For single-mode transmission, we also offer specifically designed products for long-haul

transmissions up to 60km. These models include the letter “L” in the suffix, e.g.

FTD110DBMicro-SSTL for Tx, FTD110DBMicro-SSRL for Rx, etc.

The FTD110DBMicro Series units are available as Micro unit, which can be mounted

horizontally or vertically wall-mounted on any fixture. The Micro unit comes with an external

power supply FT-PA/12V, which can be powered by local 110/220V power.

www.ot-systems.com 5

Page 6

FT110DBMicro Series Installation & Operation Manual

Mode

Models1

Descriptions

Installation

requirements

Remarks

SIngle-Mode

FTD110DBMicro-SST

Single-mode Data Transceiver Micro

Unit

Horizontally or

vertically

wall-mounted

Micro sized

unit

FT-PA/12V

external

power

supply is

included for

the Micro

unit

2

FTD110DBMicro-SSTL

Single-mode Long-haul Data

Transceiver Micro Unit

FTD110DBMicro-SSR

Single-mode Data Transceiver Micro

Unit

FTD110DBMicro-SSRL

Single-mode Long-haul Data

Transceiver Micro Unit

Multi-Mode

FTD110DBMicro-SMT

Multi-mode Data Transceiver Micro

Unit

FTD110DBMicro-SMR

Multi-mode Data Transceiver Micro

Unit

2.2 Models selection table

1

2

(3) Installation

3.1 General

delivery to ensure a stable, intact and trouble-free service. Please check the equipment upon

receipt for any visible damage which may have been caused during shipping.

or mounted on any fixture, etc. works with an external power supply FT-PA/12V powered by local

110/220V power.

If the optical connector is FC type, the suffix in the model number will be “-FXX”. Eg. FTD110DB-FST

FT-PA/12V works under 100 -240VAC, 50/60Hz power supply

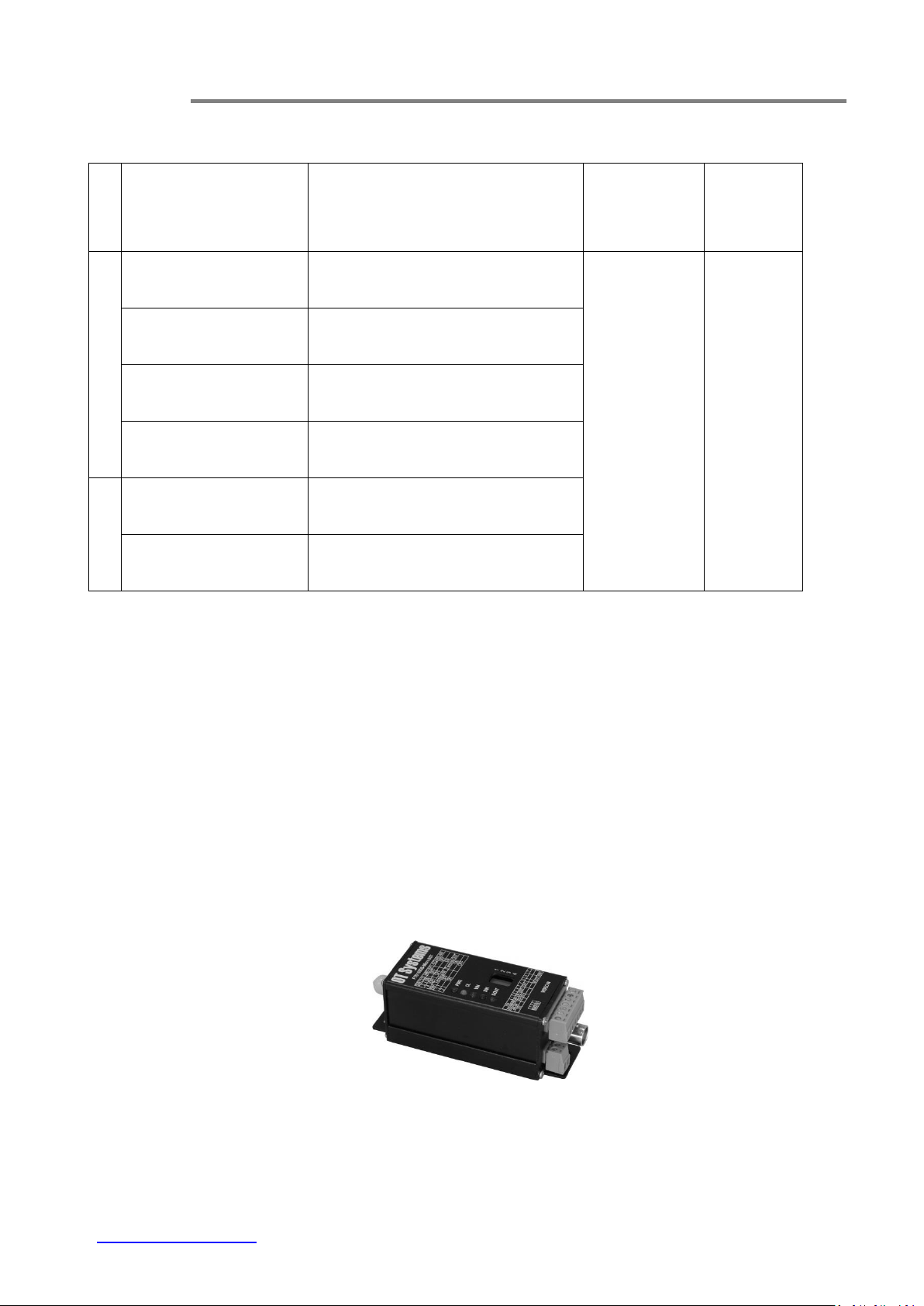

All OT Systems products are thoroughly inspected, tested and securely packaged before

The FTD110DBMicro Series (Fig. 3.1) can be either horizontally or vertically wall-mounted,

www.ot-systems.com 6

Fig. 3.1 Micro unit

Page 7

FT110DBMicro Series Installation & Operation Manual

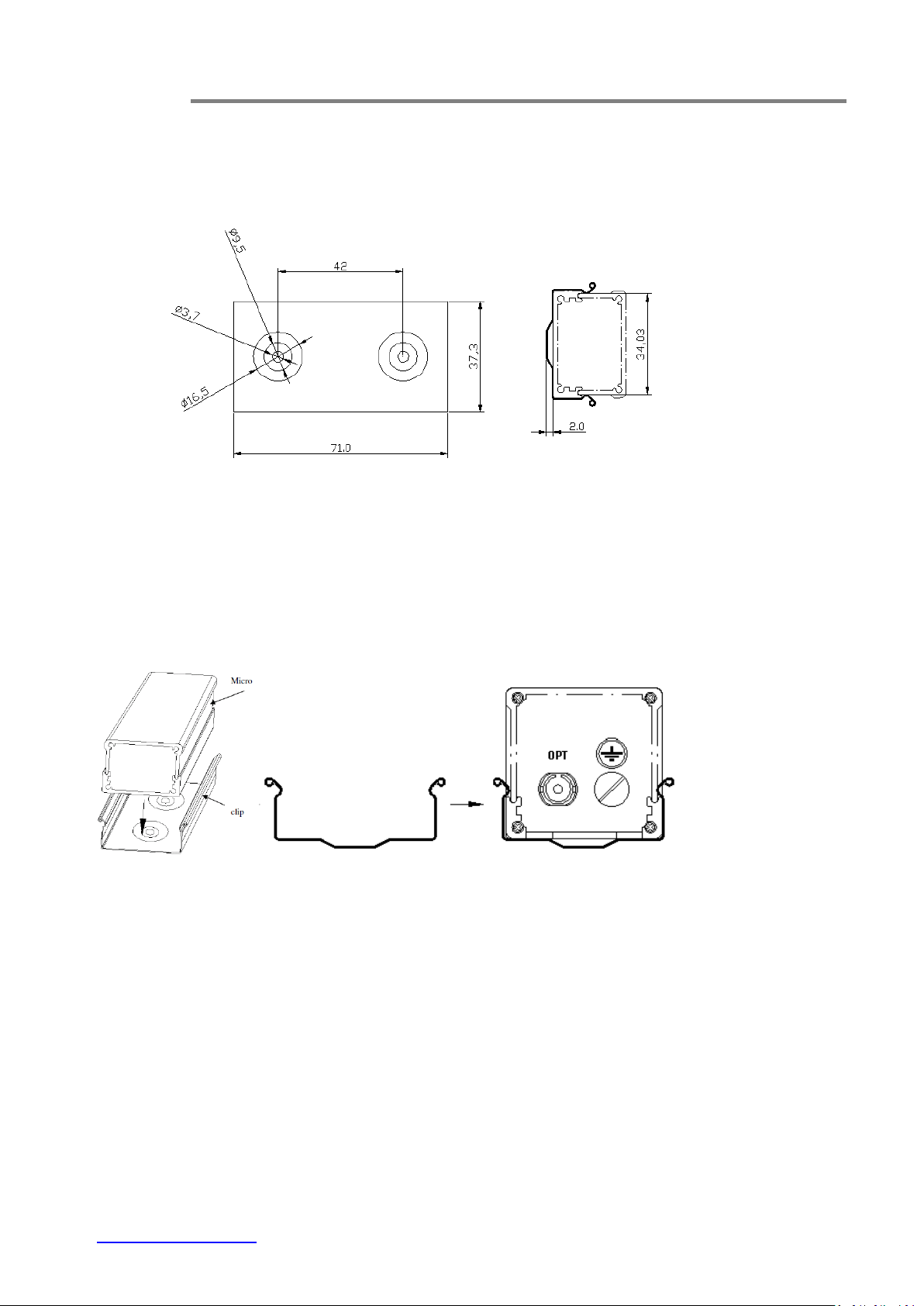

3.2 Micro unit installation

a) Mount the clip (Fig. 3.2) onto a fixture, e.g. a plank, (either on the wall or on a flat surface)

with two screws through the holes on the mounting frame to secure it in position.

(a) Front view (b) Side view

Fig. 3.2 Micro unit’s clip

b) The provided power supply should also be mounted on the same fixture or in the proximity

for connection of the supply cables to the unit, provided that an AC power supply socket is nearby

for powering the adaptor.

c) Push the Micro unit into the clip to secure it in position. For details, please follow Fig. 3.3.

(a) Installation (b) Side view of the clip (c) Side view of the Micro unit pushed into the clip

Fig. 3.3 Micro unit installation on the clip

d) Connect all the signal inputs and outputs at the back of the unit with appropriate cables: fiber

optic cable for optical link and UTP cable for data input/output (Tx/Rx).

e) Once the unit is powered up, check that the red POWER LED on the unit is lit. If not, check

the power supply cable connections between the unit and the power supply socket.

f) With all the signals available at the input and output ports, check the status of LEDs located

on the unit. With correct status of each LED, installation is now completed [for LEDs status, see

Operational Guides on this manual’s section (5)].

www.ot-systems.com 7

Page 8

FT110DBMicro Series Installation & Operation Manual

Signal Type

Cable Type

Connector

Optical

Single-mode or Multi-mode fiber

ST (or FC) Connector

Data

Twisted-pair Cable

Screw Terminal Block

(4) Cable Connections & Setup Procedures

4.1 System cable connections

Typical System Cable Connections Diagram:

www.ot-systems.com 8

Micro Transmitter Micro Receiver

Fig 4.1 Micro unit to Micro unit connection diagram

Page 9

FT110DBMicro Series Installation & Operation Manual

Pin Assignment

(Screw Terminal

Block)

Data format

1 2 3 4 5 6 7

RS422/485 (4-Wire)

IN(+)

IN(-)

OUT(+)

OUT(-)

N/A

N/A

N/A

RS485 (2-Wire)

IN/OUT (+)

IN/OUT (-)

N/A

N/A

N/A

N/A

N/A

RS232

N/A

N/A

N/A

N/A

IN

OUT

Sig. COM

User’s Equipment

DATA PORT

(7-PIN)

DATA PORT

(7-PIN)

User’s Equipment

TX(+)

1 IN(+)

1 IN(+)

TX(+)

TX(-)

2 IN(-)

2 IN(-)

TX(-)

RX(+)

3 OUT(+)

3 OUT(+)

RX(+)

RX(-)

4 OUT(-)

4 OUT(-)

RX(-)

5 N/A

5 N/A

6 N/A

6 N/A

7 N/A

7 N/A

User’s Equipment

DATA PORT

(7-PIN)

DATA PORT

(7-PIN)

User’s Equipment

TX/RX(+)

1 IN/OUT(+)

1 IN/OUT(+)

TX/RX(+)

TX/RX(-)

2 IN/OUT(-)

2 IN/OUT(-)

TX/RX(-)

3 N/A

3 N/A

4 N/A

4 N/A

5 N/A

5 N/A

6 N/A

6 N/A

7 N/A

7 N/A

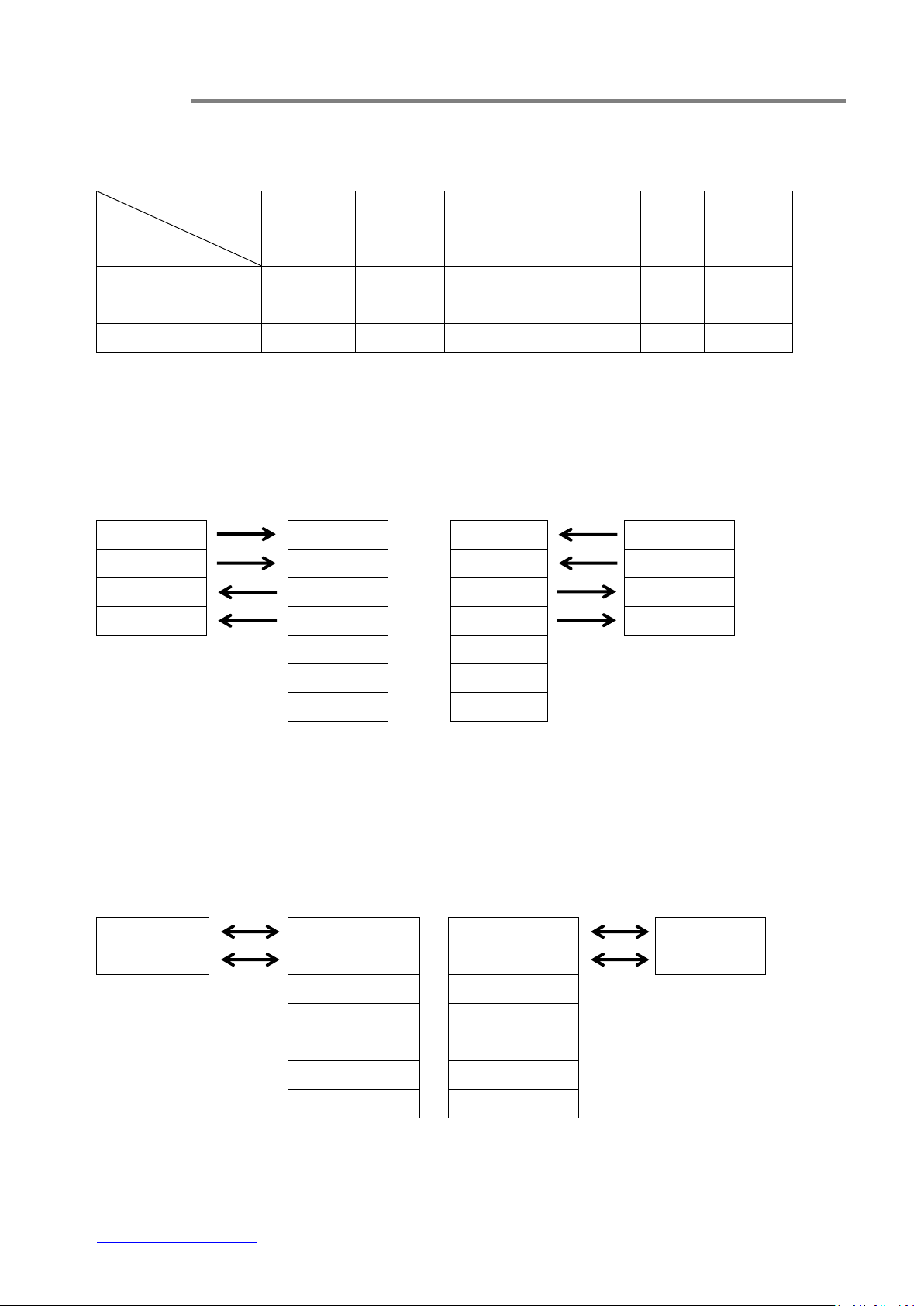

4.2 Data port assignment and pin connections

For data input and output connections, please note the following pin assignment:

4-Wire RS422/485 Full Duplex Data communication connection diagram:

Transmitter End Receiver End

Fig. 4.4.1 Connector Pin Assignments for 4-wire RS422/485 data format at Data port

2-Wire RS485 Half Duplex Data communication connection diagram:

Transmitter End Receiver End

Fig. 4.4.2 Connector Pin Assignments for 2-wire RS485 data format at Data port.

www.ot-systems.com 9

Page 10

FT110DBMicro Series Installation & Operation Manual

User’s Equipment

DATA PORT

(7-PIN)

DATA PORT

(7-PIN)

User’s Equipment

1 N/A

1 N/A

2 N/A

2 N/A

3 N/A

3 N/A

4 N/A

4 N/A

TX 5 IN

5 IN

TX

RX 6 OUT

6 OUT

RX

Sig. COM

7 Sig. COM

7 Sig. COM

Sig. COM

Function / Switch No.

Sw. 3

Sw. 4

RS485 (2-Wire)

OFF

OFF

RS422/485 (4-Wire)*

OFF

ON

RS232

ON

OFF

RS232 Data communication connection diagram:

Transmitter End Receiver End

Fig. 4.4.3 Connector Pin Assignments for RS232 data format at Data port

4.3 Dip switch setting procedures

The only setup procedure is to select the appropriate line terminations and data

transmission formats. Selections must be made by setting the dip switches (Fig. 4.5) through the

access on the front panel.

Fig. 4.5 Location of Dip Switches

Dip switch settings for various types of data transmissions

www.ot-systems.com 10

* Factory setting [RS422/485 (4-Wire)]

Page 11

FT110DBMicro Series Installation & Operation Manual

Function / Switch No.

Sw. 1

Line Output Terminated

ON

Line Output Unterminated*

OFF Function / Switch No.

Sw. 2

Line Input Terminated

ON

Line Input Unterminated*

OFF

Dip switch settings for line terminations

Line Output Termination Line Input Termination

* Factory setting (Line Output and Line Input “Unterminated”)

Industrial practice for line terminations

For RS422 4-wire communication, it is suggested to keep the input and output lines

terminated in the ONE Tx to ONE Rx configuration.

For RS485 2/4-wire communication, the RS485 device can be disabled to stay in a Hi-Z

state. It is very important that the data lines have to be terminated with a resistor being connected

across the pair wires so as to eliminate the residual standing signal waves on the lines in the Hi-Z

line condition. So, it is recommended that the lines should be terminated with the appropriate

resistance. When more than one RS485 device are connected in a daisy-chain configuration,

only the farthest device on the loop, i.e. the device located at the end of the line, should be

terminated; whereas the middles ones are set to “Unterminated” status. See the figure 4.6 below

for reference.

(a) RS485/422 4-wires Bus structure (b) RS485 2-wire Bus structure

Fig. 4.6 Termination of different Bus structures

www.ot-systems.com 11

Page 12

FT110DBMicro Series Installation & Operation Manual

Indicator

Color

Description

PWR

Red

Lit when power is supplied to the Transmitter.

OL

Yellow

Lit when optical signal from receiver to transmitter is active.

DIN

Red

Blinks when input data is available at Tx.

DOUT

Green

Blinks when output data is available at Tx.

OPT -

ST (or FC) Optical Connector for fiber cable connection.

DATA -

7-pin Screw Terminal Block for data signal.

12VDC

2-pin Screw Terminal Block for power connection.

4.4 Ground connection

For enhanced safety to reduce the risks of electrical shock and physical damage, caused by

lightning and other power surges, as well as a connection to the surge suppresion devices in the

product, a screw terminal is provided on the Micro cabinets (Fig. 4.7). It is highly recommended

that the Micro unit have good ground connections to the buildings ground in accordance with the

local codes.

Fig. 4.7 Standalone unit earth ground terminal location

(5) Operational Guides

5.1 FTD110DBMicro Series Transmitter

LED Indicators

Signal Ports

www.ot-systems.com 12

Page 13

FT110DBMicro Series Installation & Operation Manual

Indicator

Color

Description

PWR

Red

Lit when power is supplied to the Receiver.

OL

Yellow

Lit when optical signal from transmitter to receiver is active.

DIN

Red

Blinks when input data is available at Rx.

DOUT

Green

Blinks when output data is available at Rx.

OPT -

ST (or FC) Optical Connector for fiber cable connection.

DATA -

7-pin Screw Terminal Block for data signal.

12VDC

2-pin Screw Terminal Block for power connection.

5.2 FTD110DBMicro Series Receiver

LED Indicators

Signal Ports

www.ot-systems.com 13

Page 14

FT110DBMicro Series Installation & Operation Manual

MODELS*

PARAMETERS

FTD110DBMicro-SST(R)

(Single-Mode)

FTD110DBMicro-SST(R)L

(Single-Mode)

FTD110DBMicro-SMT(R)

(Multi-Mode)

OPTICAL

No. of Fiber / Connector

1 / ST(or FC)

1 / ST(or FC)

1 / ST(or FC)

Wavelength

1310/1550 nm

1550/1310 nm

1310/1550 nm

Optical Power Budget

17 dB

24 dB

23 dB

Max Distance

40 km

60 km

4 km

DATA

Channel / Connector

1 / 7-pin Screw Terminal

Direction

Bi-directional (Duplex)

Electrical Format

RS232, RS422, RS485 (2-wire, 4-wire)

Transmission Rate

0~256 Kbps

POWER

Power consumption

12VDC @ 2.4W

Power Supply

FT/PA12V DC Adaptor

Connector (Micro unit)

2-pin Screw Terminal

PHYSICAL

Weight

0.1 kg

Dimensions (W x H x D)

36.2 x 35 x 101 mm (MAX)

ENVIRONMENTAL

Operating Temperature

-40oC ~ +75oC

Storage Temperature

-40oC ~ +85oC

Relative Humidity

0 ~ 95% non-condensing

MTBF

>100’000 Hours

*If the optical connector is FC type, the suffix in the model number will be “-FXX”. Eg. FTD110DBMicro-FST

(6) Specifications

www.ot-systems.com 14

Page 15

FT110DBMicro Series Installation & Operation Manual

(7) Drawings

Fig. 7.1 Dimensional drawings of Micro unit (mm)

(8) Warranty Information

All OT Systems FT Series products are subject to a limited life-time warranty offered by the

company in normal circumstances. Please refer to the OT Systems Products Warranty Statement

for details. Access to the statement is available in our company website at www.ot-systems.com.

(9) Contact Information

APAC Operation

Address:

Unit 1023, 10/F, Landmark North,

39 Lung Sum Avenue, Sheung

Shui, N.T., Hong Kong

Tel: (852) 2672 5153

Fax: (852) 2679 0756

Sales Inquiries

EMEA Operation

Address:

J. Slovackio str. 4, LT-11107,

Vilnius, Lithuania

Tel: (370) 60730087

Fax: (370) 52051855

Sales Inquiries

AMERICAS Operation

Address:

18 West Main Street, Plano,

IL 60545, U.S.A.

Tel: (1) 630 554 9178

Fax: (1) 630 554 9179

Sales Inquiries

sales@ot-systems.com

Technical Support

techsupport@ot-systems.com

www.ot-systems.com 15

sales@ot-systems.com

Technical Support

techsupport@ot-systems.com

sales.usa@ot-systems.com

Technical Support

techsupport.usa@ot-systems.com

Loading...

Loading...