OTMT SC4 User Manual And Installation Manual

1

SC4 Bench Lathe

User’s Guide and Installation Manual

Version date: 02-09-11

Please Read This Manual Carefully Before Operating this Machine.

Copyright by Travers Tool Co., Inc., February 2011

PDF created with pdfFactory Pro trial version www.pdffactory.com

2

Table of Contents

IMPORTANT SAFETY INSTRUCTIONS.............................................................................................4

Lathe Features...................................................................................................................................5

Welcome............................................................................................................................................6

User Manual....................................................................................................................................6

Capabilities of the Lathe..................................................................................................................6

Setting up the Lathe..........................................................................................................................7

Electrical Requirements...................................................................................................................7

Lifting the Lathe...............................................................................................................................7

Bench Mounting...............................................................................................................................8

Machine Cleanup.............................................................................................................................8

Operating Controls and Features.....................................................................................................9

Carriage Handwheel........................................................................................................................9

Cross-Feed Handwheel...................................................................................................................9

Compound Handwheel....................................................................................................................9

Carriage Lock Screw......................................................................................................................10

Power Feed (Half-Nut) Lever.........................................................................................................10

X-Y Auto Feed Lever.....................................................................................................................10

Tailstock Handwheel......................................................................................................................11

Tailstock Quill Lock........................................................................................................................11

Tailstock Locking Handle...............................................................................................................11

Tailstock Offset Feature.................................................................................................................11

Electronic Controls.........................................................................................................................12

Control Panel.................................................................................................................................12

Setting the Spindle Speed..............................................................................................................12

Emergency Stop Button.................................................................................................................12

Spindle Disengagement Knob........................................................................................................13

Tooling and Accessories................................................................................................................14

High Speed Steel Cutting Tools.....................................................................................................14

4-Jaw Independent Chuck.............................................................................................................14

Digital Caliper................................................................................................................................14

Center Drills...................................................................................................................................14

Tailstock Chuck and Arbor.............................................................................................................15

Drill Sets........................................................................................................................................16

End Mills........................................................................................................................................16

Eye Protection...............................................................................................................................16

Cutting Fluid...................................................................................................................................17

Initial Safety Checks........................................................................................................................18

Regular Safety Checks – Each Time Machine is Used..................................................................18

Using the 3-Jaw Chuck..................................................................................................................20

Basic Lathe Operations..................................................................................................................22

Stock Preparation..........................................................................................................................22

PDF created with pdfFactory Pro trial version www.pdffactory.com

3

Cutting Tool Selection....................................................................................................................22

Setting the Tool Height..................................................................................................................23

Quick Change Tool Posts..............................................................................................................24

Positioning the Tool.......................................................................................................................24

Rotational Speed Selection............................................................................................................25

Facing a Workpiece.......................................................................................................................25

Cleaning up a Facing Cut...............................................................................................................27

Facing with Power Feed................................................................................................................27

Center Drilling a Workpiece...........................................................................................................29

Drilling a Workpiece.......................................................................................................................30

Turning a Workpiece......................................................................................................................32

Turning with Power Feed...............................................................................................................33

Cutting Short Tapers......................................................................................................................35

Cutting Screw Threads..................................................................................................................37

Setting Up a Gear Train.................................................................................................................37

Thread Cutting Exercise................................................................................................................40

Maintenance....................................................................................................................................43

Periodic Lubrication.......................................................................................................................43

Bearing Race Lubrication...............................................................................................................43

Bare Metal Surfaces......................................................................................................................43

Adjusting the Gibs..........................................................................................................................43

Appendices......................................................................................................................................44

Appendix A – Specifications...........................................................................................................44

Lathe..........................................................................................................................................44

Milling Head Accessory..............................................................................................................44

Appendix B – Parts Diagrams........................................................................................................45

Appendix C – Parts List.................................................................................................................47

Appendix D – Circuit Diagram........................................................................................................49

Appendix E – Packing List.............................................................................................................50

PDF created with pdfFactory Pro trial version www.pdffactory.com

4

IMPORTANT SAFETY INSTRUCTIONS

Common sense and caution are factors which cannot be built into any product. These factors

must be supplied by the operator.

PLEASE REMEMBER:

1. When using electric tools, machines or equipment, basic safety precautions should

always be followed to reduce the risk of fire, electric shock, and personal injury.

2. Keep work area clean. Cluttered areas invite injuries.

3. Consider work area conditions. Do not use machines or power tools in damp, wet or

poorly lit locations. Don not expose equipment to rain, keep work areas well lit. do not

use tools in the presence of flammable gases or liquid.

4. Keep children away; all children should be kept away from the work area.

5. Guard against electric shock. Prevent body contact with grounded surfaces such as

pipes, radiators, ranges and refrigerator enclosures.

6. Stay alert. Never operate a power tool if you are tired.

7. Do not operate the product if under the influence of alcohol or drugs. Read warning labels

on prescriptions to determine if your judgment or reflexes might be impaired.

8. Do not wear loose clothing or jewelry as they can be caught in moving parts.

9. Wear restrictive hair covering to contain long hair.

10. Use eye and ear protection. Always wear.

11. Keep proper footing and balance at all times.

12. Do not reach over or across running machines.

Before operations

1. Be sure the power switch is OFF when not in use and before plugging in.

2. Do not attempt to use inappropriate attachments in an attempt to exceed the tool’s

capacity.

3. Check for damaged parts before using the machine. Any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function.

4. Check for alignment and binding of all moving parts, broken parts or mounting fixtures

and any other condition that may affect proper operation. Any part that is damaged

should be properly repaired or replaced by a qualified technician.

5. Do not use the machine if any switch does not turn off properly.

Operation

1. Never force the machine or attachment to do the work of a larger industrial machine. It is

designed to do the job better and more safely at the rate for which it was intended.

2. Always unplug the cord by the plug. Never yank the cord out of the wall.

3. Always turn off the machine before unplugging.

PDF created with pdfFactory Pro trial version www.pdffactory.com

5

Lathe Features

PDF created with pdfFactory Pro trial version www.pdffactory.com

6

Welcome

Congratulations on selecting the OTMT SC4

Bench Lathe (SC4). You have chosen a

precision machine tool that can perform a wide

range of complex and precise lathe operations.

With proper maintenance and care, it will

provide many years of service. Should you

have any questions regarding the operation of

your lathe, please contact Travers Technical

Support for assistance.

Technical Support

(1-800-234-9985, press 4)

Fax: 718-661-5637

Email: tech@travers.com

User Manual

The purpose of this manual is to familiarize the

lathe operator with the installation and controls

of the machine and basic lathe procedures. To

become proficient in using the lathe, the

operator should seek in-depth training using

reference books, resources available on the

Internet, training courses at community

technical schools or from an operator already

skilled in the use of a similar lathe.

Capabilities of the Lathe

A precision metal-working lathe is one of the

most useful and productive tools in the

machine shop. The lathe provides the

capability to produce cylindrical and tapered

shapes with very accurate dimensions in a

wide variety of materials such as steel, brass,

aluminum and many plastics. With appropriate

tooling it is even possible to create round,

concave and cubical shapes on the lathe.

The SC4 lathe is equipped with a powerful

1000-watt brushless DC motor with electronic

speed control, providing strong torque at all

speeds, electronic braking and instant direction

reversal for operations such as tapping. The

motor is completely sealed from dirt, dust, oil,

metal chips and other shop contaminants and

is permanently lubricated and maintenancefree.

While the ultimate precision of a finished

workpiece depends on many factors, such as

the material, shape of the cutting tool, proper

adjustment of the lathe and skill of the lathe

operator, dimensions of one-one-thousandth of

an inch (0.001”) or better are possible.

With the provided set of change gears, power

feed rates may be adjusted and a wide range

of both metric and SAE external and internal

threads can accurately be cut. The optional

milling head accessory (Item # 87-116-027)

adds light vertical milling and precision drill

press capabilities to the SC4.

PDF created with pdfFactory Pro trial version www.pdffactory.com

7

Setting up the Lathe

The SC4 lathe should be located in a welllighted and well-ventilated area free from

excessive humidity or moisture that could

cause rusting of the precision metal surfaces

or tooling.

Electrical Requirements

The SC4 lathe configured for U.S. operation

uses standard 120V AC 60-cycle single-phase

power and has a peak current demand of 12

amps. While a 15-amp circuit may be sufficient

for powering the lathe, a 20-amp circuit is

recommended. The circuit must not be shared

with other high-current devices, such as an air

compressor, window air conditioner or coffee

pot, that may be operating, or switch on, while

the lathe is in use. Low current devices, such

as a work lamp, may share the same circuit as

the lathe.

A plug-in power failure emergency light that will

automatically turn on in the event of a power

failure or tripping of an overloaded circuit

breaker is recommended for safety. In the

event that power to the lathe, or workspace

lighting, should be interrupted while the lathe is

in use, the emergency light will enable the

operator to safely turn off the power switch to

the lathe and move away from the lathe until

power is restored. Suitable lights are available

at most hardware and home-supply stores.

Care should be taken to ensure a safe work

area with electrical wiring and grounding

approved by local electrical codes. The lathe

uses a three-prong electrical plug to protect the

operator from risk of shock or electrocution.

The lathe must be plugged into a properly

grounded outlet to ensure safe operation. Do

not attempt to modify the plug to fit a 2-prong

outlet or extension cord by removing the

ground conductor or by using an adaptor.

Doing so may result in shock or electrocution.

If it is necessary to plug the lathe into an

extension cord, the extension cord must have

a properly functioning 3-prong electrical ground

plug and outlet, plugged into a properly

grounded 3-prong wall outlet. The extension

cord must have at least 15 Amps of currentcarrying capacity to avoid overheating the cord,

which could cause a risk of fire. A cord rated

for 20 Amps or more is recommended. In no

case should the length of the extension cord

exceed 20 feet.

Lifting the Lathe

The SC4 lathe weighs approximately 275 lbs.

(125 kg.) and must be mounted on a strong

table or bench capable of supporting 350 lbs.

or more. A shop crane with a nylon lifting strap

or other suitable lifting apparatus should be

used to safely lift the machine onto the table or

bench.

Shop crane (Item # 96-004-166)

Using a shop crane to lift the lathe

Proper lifting techniques (e.g. bend at the

knees, not at the back) should be used to

minimize any risk of personal injury. Consult

the Internet for information on proper lifting

techniques.

PDF created with pdfFactory Pro trial version www.pdffactory.com

8

Bench Mounting

For stability and safe operation the lathe must

be bolted to a sturdy machine stand or

workbench capable of safely supporting at

least 350 lbs. A carpenters or machinists level

should be used to verify that the lathe bed is

level. Large diameter metal fender washers or

shims may be used under mounting feet to

level the lathe. Sufficient clearance must be

provided on the left side of the lathe to allow

the access door to swing open and provide

working room to adjust the gears

Machine Cleanup

The lathe is protected from rust during shipping

by a waxy red grease that must be removed

before putting the machine to use. This is best

done using disposable shop rags and paint

brushes together with a solvent such as

kerosene or WD-40. Avoid solvents such as

paint thinner that may damage the painted

surfaces of the lathe, and highly volatile

solvents such as acetone that present a fire

and inhalation hazard.

Good ventilation must be provided when

solvents are used and care must be taken to

avoid open flames, smoking materials or

electrical sparks that could ignite solvent fumes.

Care should be taken to clean the shipping

grease from all moving parts, including parts

that may be hidden from view, such as

leadscrews under the cross-slide and

compound slide.

PDF created with pdfFactory Pro trial version www.pdffactory.com

9

Operating Controls and Features

Carriage Handwheel

The carriage handwheel moves the carriage

back and forth along the ways. Turning the

handwheel clockwise moves the carriage

towards the tailstock; turning it counterclockwise moves the carriage towards the

headstock.

Carriage Handwheel

When the carriage is moved by power feed,

the carriage handwheel may be disengaged by

pulling it towards the operator. This prevents

the handwheel from rapidly rotating and

causing a potential hazard. To re-engage the

handwheel, press it inwards while slowly

rotating it until the gears engage.

Carriage Handwheel Disengaged

Cross-Feed Handwheel

The cross-feed handwheel (also known as the

cross-slide handwheel or cross-feed) advances

or retracts the carriage across the ways. This

motion may control the depth of a cut for a

turning or boring operation or may advance the

cutting tool across the face of a workpiece in a

facing operation.

Cross-Feed Handwheel

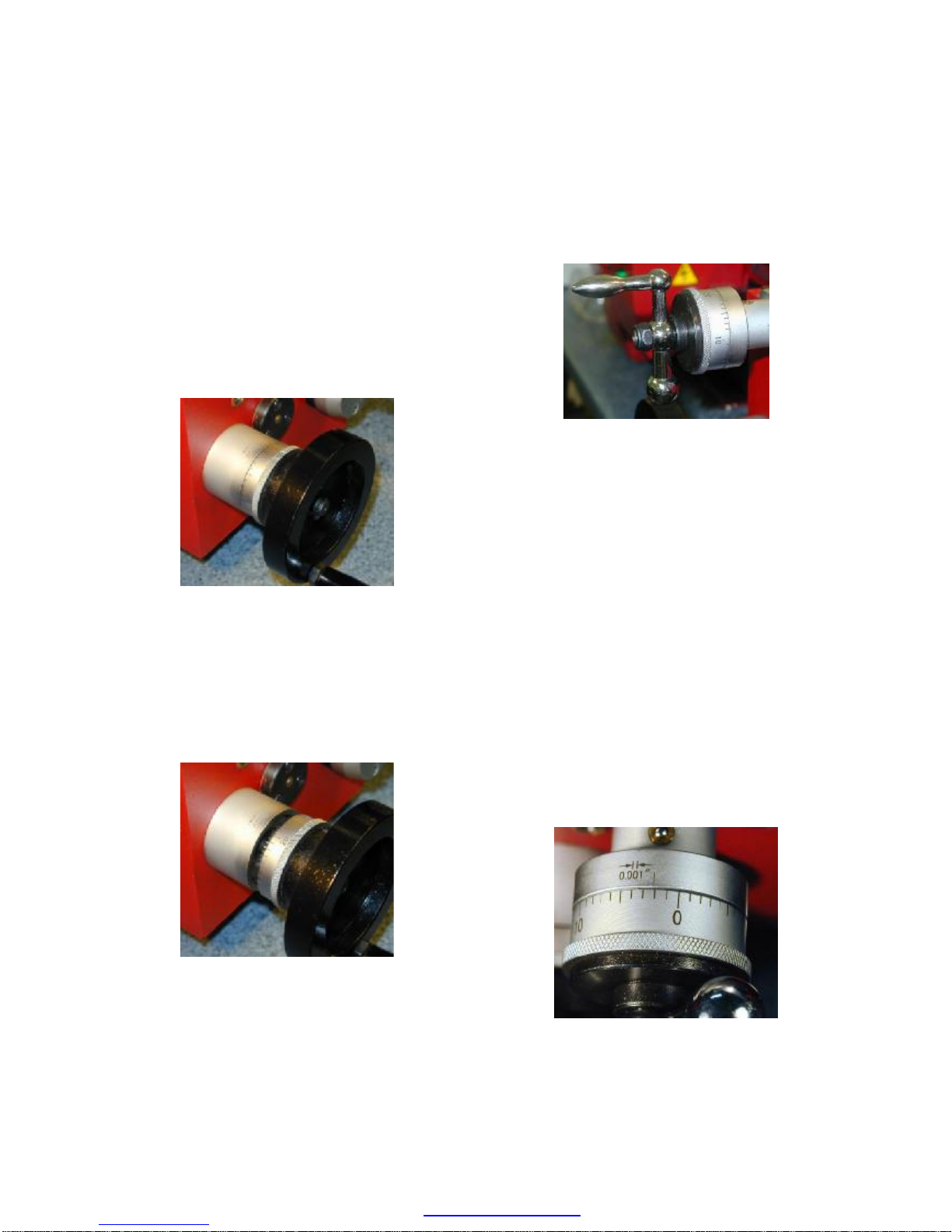

Compound Handwheel

The compound handwheel (also known as the

compound feed) advances or retracts the

toolpost along the angle at which the

compound is set as indicated by the protractor.

The compound handwheel typically is used for

making short tapered cuts, limited by the range

of motion of the compound slide, and for

thread cutting operations.

Both the cross-slide and compound

handwheels have graduated collars that can

be used to measure the movement of the

cutting tool towards or away from the

workpiece. By grasping the graduated dial

while holding the handwheel steady, the

graduated dial can be set to a zero reading to

facilitate making a cut to a specific depth.

Calibrated Handwheel Dial

PDF created with pdfFactory Pro trial version www.pdffactory.com

10

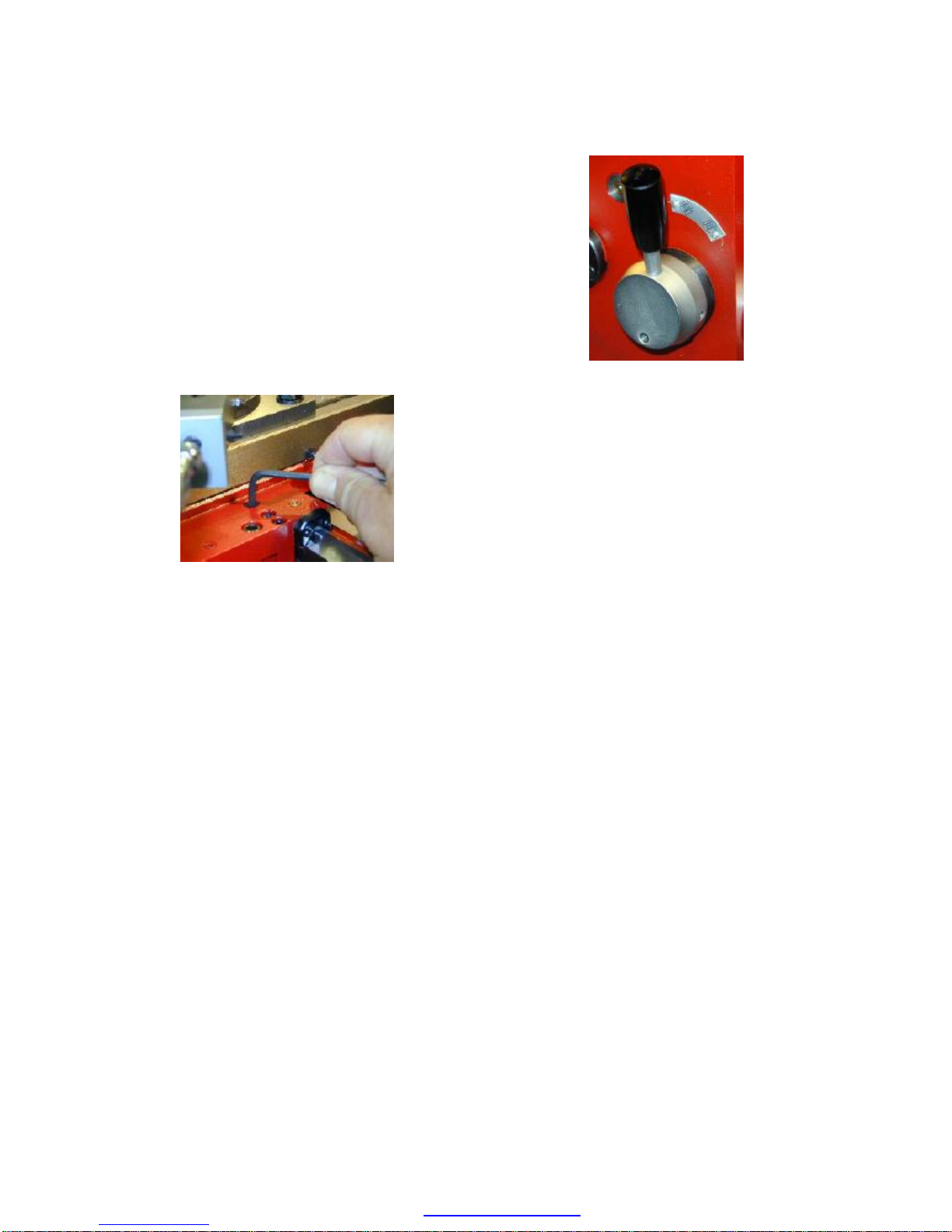

Carriage Lock Screw

For certain operations such as facing, in which

the tool is advanced across the face of the

work by the cross-feed handwheel, it is good

practice to lock the carriage to the ways to

prevent the carriage from moving during the

cut. If the carriage were to move during a

facing cut, the result would be a slightly

concave or convex cone-shape rather than a

perfectly flat surface on the end of the

workpiece.

Locking the carriage

The carriage is locked by turning the carriage

lock screw clockwise using a 5mm hex wrench.

When the locking screw is used for the first

time it may be in the locked position as

shipped from the factory to prevent the

carriage from shifting position during shipment.

Always check to make sure that the locking

screw is unlocked before attempting to move

the carriage with the carriage handwheel or

power feed.

Power Feed (Half-Nut) Lever

The Power Feed Lever, also known as the

Half-Nut Lever, is located on the right side of

the apron at the front of the lathe, next to the

carriage handwheel. It is used to drive the

carriage under power for turning and threading

operations.

Power Feed (Half-Nut) Lever

When turned about 45 degrees to the right, it

clamps a pair of “half-nuts” around the thread

of the lead screw. If the lead screw is engaged

and rotating, the carriage will be moved along

the ways under power from the leadscrew.

Before engaging the Power Feed Lever,

ensure that the carriage is not locked to the

ways by the Carriage Lock Screw.

When the spindle is rotating in the Forward

direction, the carriage is moved towards the

headstock. With the spindle rotating in the

Reverse direction, the carriage moves away

from the headstock. Moving the lever back to

the vertical position disengages the half-nuts

from the leadscrew and stops the motion of the

carriage.

X-Y Auto Feed Lever

Located on the right side of the apron, next to

the Power Feed Lever, the X-Y Auto Feed

Lever controls the motion of the carriage when

used with the optional milling head accessory,

but can also be used for lathe operations.

When using the X-Y Auto Feed Lever, the

Power Feed lever must be disengaged.

PDF created with pdfFactory Pro trial version www.pdffactory.com

11

X-Y Auto Feed Lever

In the lower position, the X-Y Auto Feed lever

moves the carriage along the ways, much like

the Power Feed lever, but at a slower speed.

This feature is useful for making fine finishing

cuts using power feed.

In the upper position it functions as a power

cross-feed control and moves the cross slide

away from the operator towards the back of the

lathe. When the motor is reversed, the power

cross feed moves the cross slide towards the

operator. In the center, “0” or neutral position,

the feed is disengaged.

Tailstock Handwheel

Rotating the tailstock handwheel moves the

tailstock quill (also known as the tailstock ram)

in and out of the tailstock. This feature is used

during drilling operations and when a center is

used in the tailstock to support long stock.

Tailstock Quill Lock

When the tailstock is used in stationary

operations, as when supporting the end of long

stock, the quill may be locked in place using

the tailstock quill lock. A quarter turn of the

handle is sufficient to lock or unlock the quill.

Tailstock Locking Handle

The tailstock locking handle on the rear of the

tailstock locks the tailstock at any location

along the ways. The tailstock is locked by

pulling the lever towards the operator and

released by pushing the lever away from the

operator. If necessary, the clamping action

may be adjusted by removing the tailstock from

the end of the lathe ways and adjusting the

locking nut on the underside of the tailstock.

A stop screw located between the ways at the

right end of the lathe prevents the tailstock

from falling off the end of the lathe. This screw

must be removed before sliding the tailstock off

the end of the ways for adjustment.

Tailstock Offset Feature

To turn long tapers on a workpiece mounted

between centers, the tailstock may be offset

horizontally from the lathe centerline. To offset

the tailstock, loosen the two small setscrews

below the cam lever on the right side of the

tailstock, then loosen the two setscrews on the

front and back sides of the tailstock.

Tailstock Offset Indicator

The two screws on the front and back of the

tailstock work in opposition to each other to

offset the tailstock; as one screw is tightened

the other must be loosened by a corresponding

amount. The amount of offset may be gauged

by observing the offset indicator guide on the

right end of the tailstock.

After completing the taper operation, the

tailstock is restored to its normal position at the

horizontal centerline. Accurate alignment using

a test bar and dial indicator is recommended.

PDF created with pdfFactory Pro trial version www.pdffactory.com

12

Electronic Controls

The main power switch for the lathe is the red

rocker switch located on the control panel. A

green pilot lamp illuminates when the power is

on. A fuse holder above the pilot lamp contains

a replaceable 20 Amp fuse to protect the lathe

from electrical overloads.

Control Panel

Control Panel

A soft-touch panel of buttons controls the lathe

spindle speed and direction:

é - Increase spindle RPM speed

ê - decrease spindle RPM speed

Start – start the spindle motor

P – set spindle to forward rotational

direction

Q – set spindle to reverse rotational

direction

Stop – stop the spindle motor

Setting the Spindle Speed

To start the spindle rotation, press the Start

button. The current spindle rotational speed

and direction (FOR or REV) are displayed on

the digital display.

Spindle-speed tachometer

When the lathe is powered on or the

Emergency Stop button is reset, the display

will momentarily display 8888, then will display

0000.

To increase the speed of spindle rotation,

depress and hold down the é button. To

decrease spindle speed, depress and hold

down the ê button. Small incremental changes

to the spindle speed may be made by

momentarily pressing the buttons. To stop the

spindle rotation, press the Stop button.

The first time that the Start button is pressed

after turning on the power to the lathe, of after

resetting the Emergency Stop button, the

spindle will begin turning at its slowest speed,

about 100 RPM.

When the operating speed is adjusted to a

higher RPM, the new speed is saved when the

Stop button is pressed. When Start is pressed

again, the lathe will resume operating at the

saved speed. The saved speed is cleared

when the lathe is powered off or the

Emergency Stop button is pressed.

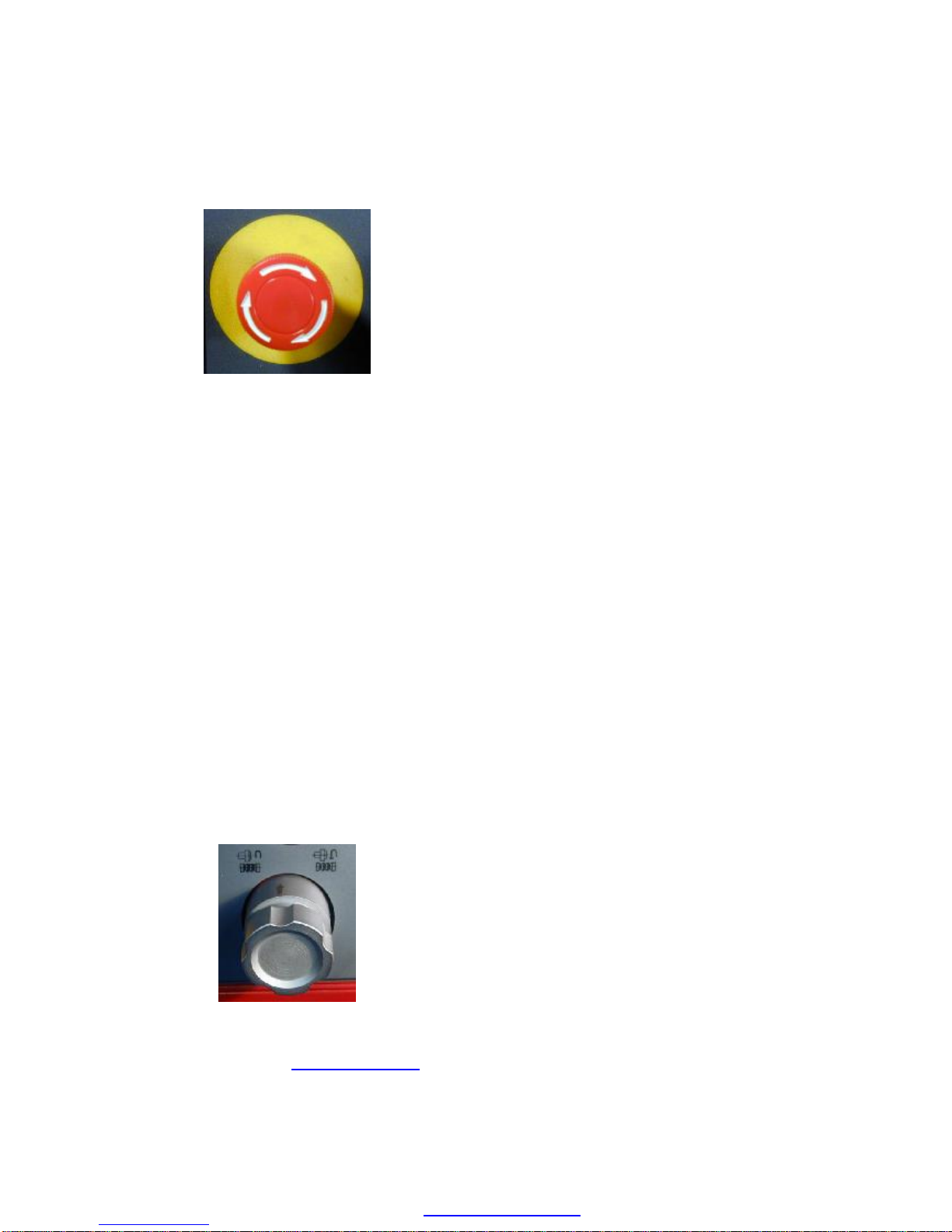

Emergency Stop Button

Located below the Start button, the red

Emergency Stop button is used to quickly

stop the spindle in the event of an emergency,

PDF created with pdfFactory Pro trial version www.pdffactory.com

13

such as a workpiece working loose from the

chuck.

Emergency Stop button

Pressing the Emergency Stop button firmly

with the heel of the hand will bring the spindle

to a stop and keep the lathe from restarting

until the Emergency Stop button is reset by

rotating the knurled rim of the button in a

clockwise direction.

Pressing the Start button, or any other control

on the panel, will have no effect until the

Emergency Stop button is reset. When the

Emergency Stop button is reset, the spindle

speed will also be reset to the minimum speed

of about 100 RPM.

Spindle Disengagement Knob

The large silver knob to the right of the

Emergency Stop button engages and

disengages the spindle from the motor drive

while still allowing the leadscrew to turn and

move the carriage under power from the gear

train.

Spindle Disengagement Knob

When performing milling operations using the

milling head accessory (Item # 87-116-027) the

spindle should be disengaged for safety so that

the rotating chuck does not pose a hazard.

With the lathe stopped, turn the knob to the

right about ¼ turn to disengage the spindle. To

re-engage it, rotate the knob to the left while

also turning the chuck by hand to allow the

gears inside the head to mesh. The knob

should not be moved while the motor is

running.

PDF created with pdfFactory Pro trial version www.pdffactory.com

14

Tooling and Accessories

Operation of the lathe requires certain basic

necessities such as cutting tools. Optional

accessories such as a 4-jaw chuck and milling

head extend the capabilities of the lathe to

perform advanced types of work. Safety gear,

such as safety glasses and eye shields help to

protect the lathe operator.

This section describes some useful

accessories and tooling for the SC4 lathe.

High Speed Steel Cutting Tools

For the home machinist and light industrial

user of the lathe, High Speed Steel (HSS)

cutting tools are used for most cutting

operations. Along with finished versions, these

tools can be purchased as blanks and ground

to the desired cutting shape using a bench

grinder.

Set of HSS cutting bits

Item # 22-501-102

Aside from low cost, the main benefit of HSS

tools is that specialized tool shapes can be

ground as needed for operations such as

chamfering, material cut-off and boring.

4-Jaw Independent Chuck

A 4-jaw chuck can hold stock with a square or

rectangular cross-section in addition to round

and octagonal stock. Unlike the standard 3-jaw

chuck, in which all of the jaws move together,

on the 4-jaw chuck the jaws adjust

independently, enabling them to clamp

irregularly-shaped stock.

4-Jaw Chuck

Item # 87-116-026

Adjusting the jaws individually makes it

possible to center a round workpiece, or a

reference point on an irregular workpiece, with

great precision. This feature is useful when a

workpiece has features on opposite ends that

must be machined on exactly the same axis.

Offsetting the workpiece also makes it possible

to drill off-center holes and to turn cam lobes.

Digital Caliper

Digital calipers are convenient measuring

tools for many lathe operations. They measure

outside and inside diameters as well as hole

depths to a resolution of 0.0005”. They switch

instantly between metric and inch units, so you

work in either format.

Digital Caliper

Item # 57-016-060

Center Drills

Center drills, also known as a drill &

countersink, are short and stiff and therefore

do not flex.

PDF created with pdfFactory Pro trial version www.pdffactory.com

15

Standard-length drills may flex and wander a

small amount when they first start to penetrate

the surface of the work. The flexing may cause

the starting point to be off-center and therefore

the drilled hole may be off-center and not

perfectly parallel to the axis of the workpiece.

Therefore, it recommended always to use a

center drill to start a drilled hole

Center Drill

Center drills are available in many sizes and

made of various materials, much like drill bits.

For work on the SC4, a set of 5 HSS center

drills, #1 through #5 in size, will meet most of

the needs the operator is likely to encounter.

Set of five Center Drills

Item # 01-095-000

Tailstock Chuck and Arbor

For most drilling operations, the drill bit is held

in a Jacobs-type chuck mounted in the

tailstock by means of a #2 Morse Taper arbor.

Jacobs-style chuck

Item # 63-100-004

Since the chuck and the arbor are purchased

separately, care must be taken that the front

taper of the arbor that mates with the chuck is

the proper size for the chuck.

Chucks for use on a lathe usually have a

female Jacobs Taper, so an arbor is needed

with a #2 Morse Taper on one end and a

Jacobs Taper matching the chuck taper on the

other end.

Arbor for tailstock chuck

Item # 63-004-821

Arbors, such as the one in the photograph,

often have a flat tang at the end of the Morse

Taper, used to drive the arbor in some types of

machinery. For use in the SC4 tailstock, the

tang needs to be cut off using a hacksaw,

metal-cutting bandsaw or abrasive cutoff wheel.

Part of the Morse Taper may also need to be

cut off in order for the arbor to fit properly in the

tailstock bore.

The chuck generally is permanently mounted

to the arbor. To do this, first wipe the JT end of

the arbor and the corresponding JT taper in the

end of the chuck with a clean shop rag to

remove any oil, grease, chips or grit. It is

important that both mating surfaces be free

from any contamination to ensure a tight,

secure fit. Insert the JT taper end loosely into

the chuck taper, then rap the opposite end of

the arbor firmly on a board to drive the tapered

PDF created with pdfFactory Pro trial version www.pdffactory.com

Loading...

Loading...