CAUTION

WARNING – EXPLOSION HAZARD – SUBSTITUTION OF COMPONENTS MAY IMPAIR

SUITABILITY FOR CLASS I, DIVISION 1, OR EQUIVALENT AS STATED IN USER MANUAL

AVERTISSEMENT – RISQUE D’EXPLOSION-LA SUBSTITUTION DE COMPOSANTS PEUT

RENDURE CE MATERIEL INACCEPTABLE POUR LES EMPLACEMENTS DE CLASSE I,

DIVISION

CAUTION: FOR SAFETY REASONS, THIS EQUIPMENT MUST BE OPERATED AND

SERVICED BY QUALIFIED PERSONNEL ONLY. READ AND UNDERSTAND THE

INSTRUCTION MANUAL COMPLETELY BEFORE OPERATING OR SERVICING.

ATTENTION: POUR DES RAISONS DE SECURITE, CET ÉQUIPEMENT DOIT ETRE

UTILISE ENTRETENU ET REPARER UNIQUEMENT PAR UN PERSONNEL QUALIFIE.

ETUDIER LE MANUEL D' INSTRUCTIONS EN ENTIER AVANT D' UTILISER, D'

ENTERETENIR OU DE RÉPARER L' ÉQUIPEMENT.

CAUTION: THIS AREA MUST BE FREE OF FLAMMABLE GASES DURING CALIBRATION.

ATTENTION : CETTE ZONE DOlT ETRE EXEMPTE DE GAZ INFLAMMABLES PENDANT

L'ETALONNAGE.

CAUTION:TO PREVENT IGNITION OF EXPLOSIVE ATMOSPHERES, REMOVE FROM

EXPLOSIVE ATMOSPHERE BEFORE SERVICING

WARNING: A CONDUIT SEAL MUST BE USED WITHIN 18 INCHES OF THE ENCLOSURE

WALL TO COMPLY WITH THE HAZARDOUS LOCATION RATING OF THIS PRODUCT

DANGER

DANGER: OTIS INSTRUMENTS INC. OI-6000-X-X-X-X-O IS AN AMBIENT AIR

HAZARDOUS GAS SENSOR ASSEMBLY AND ONLY MONITORS IN THE IMMEDIATE

VICINITY OF THE SENSOR HOUSING. A SITE SURVEY IS REQUIRED IN ORDER TO

DETERMINE THE BEST PLACEMENT AND QUANTITY OF SENSOR ASSEMBLIES.

IMPROPER INSTALLATION CAN LEAD TO AN UNDETECTABLE GAS LEAK WHICH

COULD RESULT IN PERSONAL INJURY OR LOSS OF LIFE.

TABLE OF CONTENTS

TABLE OF CONTENTS

1 PRODUCT OVERVIEW .......................................................................................................................................... 1

1.1 INTRODUCTION .................................................................................................................................................... 1

1.2 PRODUCT SPECIFICATIONS ............................................................................................................................... 2

1.3 SYSTEM DIAGRAMS ............................................................................................................................................. 3

1.3.1 EXTERNAL SYSTEM DIAGRAM ........................................................................................................................... 3

1.3.2 INTERNAL SYSTEM DIAGRAM............................................................................................................................. 4

1.3.3 ASSEMBLY DIAGRAM ........................................................................................................................................... 5

2 INSTALLATION AND START-UP .......................................................................................................................... 6

2.1 PRODUCT PLACEMENT ....................................................................................................................................... 6

2.2 PRODUCT MOUNTING ......................................................................................................................................... 7

2.3 WIRING CONFIGURATIONS ................................................................................................................................. 7

2.3.1 OPENING THE ENCLOSURE ................................................................................................................................ 8

2.3.2 CONNECTING POWER ......................................................................................................................................... 8

2.3.3 CONNECTING 4-20 MA OUTPUT ....................................................................................................................... 10

2.3.4 CONNECTING RS-485 ........................................................................................................................................ 12

2.3.5 CONNECTING RELAYS/ALARMS ....................................................................................................................... 14

2.3.6 CONNECTING THE FAULT TERMINAL .............................................................................................................. 21

2.3.7 CLOSING THE ENCLOSURE .............................................................................................................................. 23

2.4 SYSTEM START-UP ............................................................................................................................................ 23

2.5 NORMAL OPERATING MODE............................................................................................................................. 24

3 PRODUCT SETTINGS AND CONFIGURATION ................................................................................................. 25

3.1 RELAY TEST ........................................................................................................................................................ 25

3.1.1 PERFORMING THE RELAY TEST ...................................................................................................................... 26

3.2 NETWORK ID ....................................................................................................................................................... 26

3.3 SYSTEM INFORMATION ..................................................................................................................................... 27

3.4 NULL/CALIBRATION TIMER INFORMATION ..................................................................................................... 27

3.5 UNIT INFORMATION ........................................................................................................................................... 28

3.6 BACKGROUND SETTING.................................................................................................................................... 28

3.7 LATCHING AND NON-LATCHING RELAY SETTINGS ....................................................................................... 29

3.7.1 RELAY 1: LATCHING/NON-LATCHING SETTING ............................................................................................. 29

3.7.2 RELAY 2: LATCHING/NON-LATCHING SETTING ............................................................................................. 30

3.8 RELAY FAIL-SAFE SETTING .............................................................................................................................. 30

3.8.1 RELAY 1: FAIL-SAFE SETTING ......................................................................................................................... 31

3.8.2 RELAY 2: FAIL-SAFE SETTING ......................................................................................................................... 31

3.9 CALIBRATION METHOD ..................................................................................................................................... 32

3.10 MODBUS ADDRESS SETTING ........................................................................................................................... 33

3.11 MODBUS BAUD SETTING................................................................................................................................... 34

3.12 4-20 mA OFFSET SETTINGS .............................................................................................................................. 35

3.12.1 ZERO OFFSET SETTING .................................................................................................................................... 35

3.12.2 FULL-SCALE OFFSET SETTING ........................................................................................................................ 36

3.13 DISPLAY SCREEN CONTRAST SETTING ......................................................................................................... 36

3.14 RETURN TO FACTORY DEFAULT SETTINGS .................................................................................................. 37

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 i

TABLE OF CONTENTS

4 OPERATION SETTINGS ..................................................................................................................................... 39

4.1 POWERING THE DEVICE ................................................................................................................................... 39

4.1.1 POWERING OFF .................................................................................................................................................. 39

4.1.2 POWERING ON ................................................................................................................................................... 39

4.2 SENSOR CALIBRATION ...................................................................................................................................... 40

4.2.1 NULLING THE SENSOR (AUTO NULL) .............................................................................................................. 40

4.2.2 CALIBRATING THE SENSOR (MANUAL CAL) ................................................................................................... 42

4.2.3 CALIBRATING THE SENSOR (AUTO CAL) ........................................................................................................ 43

4.3 SENSOR ALARM SETTINGS .............................................................................................................................. 45

4.3.1 SENSOR LOW ALARM SETTING ........................................................................................................................ 45

4.3.2 SENSOR LOW ALARM RISE/FALL SETTING ..................................................................................................... 46

4.3.3 SENSOR HIGH ALARM SETTING ....................................................................................................................... 46

4.3.4 SENSOR HIGH ALARM RISE/FALL SETTING .................................................................................................... 47

4.4 SENSOR RADIO ADDRESS ................................................................................................................................ 47

4.5 MANUAL RESET FOR ACTIVATED LATCHING ALARMS ................................................................................. 48

5 PRODUCT MAINTENANCE................................................................................................................................. 49

5.1 SCHEDULED MAINTENANCE ............................................................................................................................. 49

5.2 SENSOR REPLACEMENT ................................................................................................................................... 50

5.3 PRODUCT TROUBLESHOOTING ....................................................................................................................... 51

5.4 PRODUCT REPLACEMENT PARTS AND ACCESSORIES ................................................................................ 52

APPENDIX A: INTRODUCTION TO 4-20 mA CURRENT LOOP SIGNALS ............................................................................ 54

APPENDIX B: MODBUS COMMUNICATIONS......................................................................................................................... 56

APPENDIX C: MODBUS REGISTER MAP ............................................................................................................................... 58

APPENDIX D: PRODUCT WARRANTY STATEMENT ............................................................................................................. 61

APPENDIX E: INFORMATION ABOUT RMA SERVICE REPAIRS ......................................................................................... 63

APPENDIX F: INFORMATION ABOUT RMA RETURNS FOR CREDIT .................................................................................. 65

ii OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

PRODUCT OVERVIEW

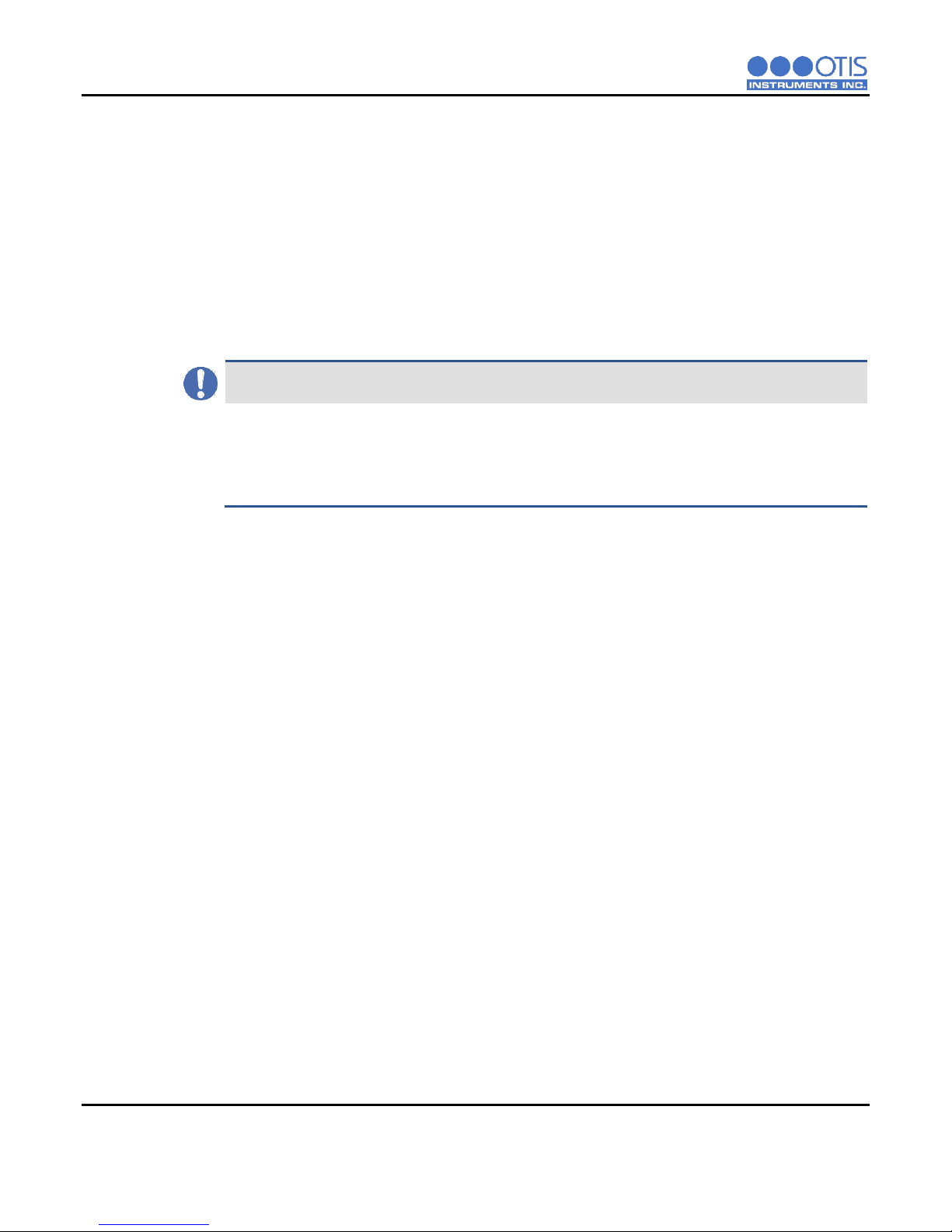

NOTICE

This document should be read in its entirety before the initial operation of the product.

1 PRODUCT OVERVIEW

1.1 INTRODUCTION

The Otis Instruments, Inc. (Otis) GEN II Model OI-6000-X-X-X-X-O (OI-6000) Explosion-Proof Ambient Air

Hazardous Gas Detector is designed to detect a wide range of toxic gases in potentially hazardous environments.

This product is CSA certified as Class I, Division 1, Groups C and D and rated for Zone 1, Group IIB. The OI-6000

features non-intrusive magnetic switches that allow for complete system configuration, regular calibration, and

product maintenance to be performed in the field, without opening the enclosure and breaking the seal of the

enclosure, thereby compromising the explosion-proof rating of the device. Non-intrusive interface with the OI-6000

is made possible by use of the Otis Magnetic Tool included in the purchase of the device. The OI-6000 display screen

will always show the present concentration of gas being detected by the sensor assembly.

This document is an operation manual containing diagrams and step-by-step instructions for the proper and safe

installation, start-up, configuration and settings, normal operation, and product maintenance of the OI-6000.

In this manual, the instructions reference the use of push-buttons, located on the front panel of the device. In certain

environments, the activation of the non-intrusive magnetic switches, through the use of the Otis Magnetic Tool, will

replace the directive of the button-press actions. To apply the Otis Magnetic Tool, hold the tool to the side of the

device enclosure adjacent to the push-button that you wish to activate. When the magnetic switch is toggled, an onscreen indicator will appear on the display screen, signifying that a connection was made.

Should a question arise during the use of the product, this document will serve as a first reference for the end-user.

For inquiries beyond the information and instructions provided within this manual, contact the sales representative

of this product for assistance.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 1

PRODUCT OVERVIEW

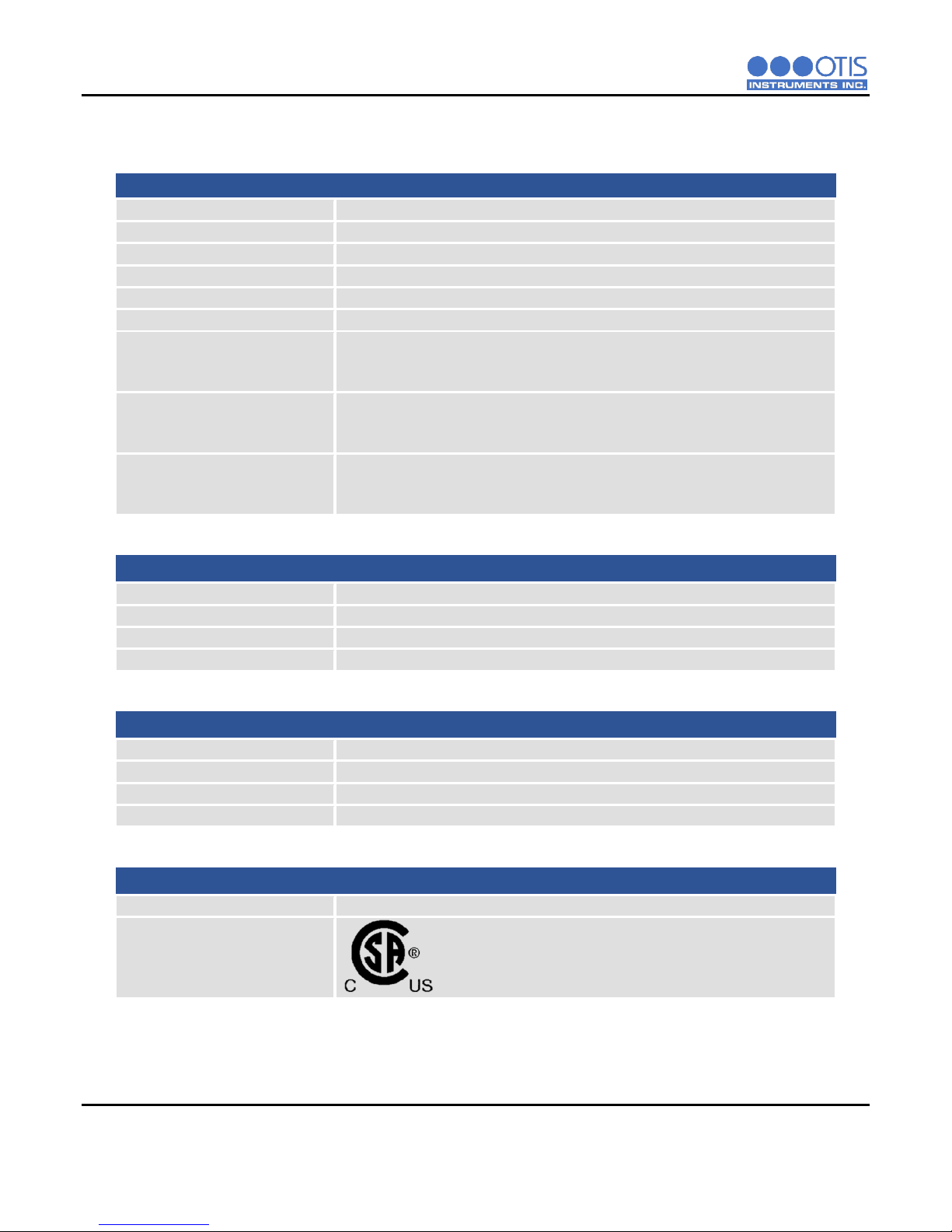

System Specifications

Operating Voltage

+12 to +35 VDC

Current Draw

250 mA Maximum

Operating Temperature Range

-40⁰C to +54⁰C

Humidity Range

0% to 98% Relative Humidity, Noncondensing

Measurement Range

Varies based on gas type

Response Time

Varies based on gas type

Protection

Power Electromagnetic Interference (EMI) Filter

4-20 mA Surge Suppression

RS-485 Modbus Surge Suppression

Display

Transflective (sunlight-readable)

102x64 LCD Screen

LED Back-Light

Interface

3 Push-Buttons (MENU, ADD, SUB)

3 Magnetic Switches for Non-Intrusive Operation

LOW and HIGH Alarm Indicator LEDs

Outputs

Wired (Analog)

4-20 mA (3-Wire)

Wired (Digital)

RS-485 Modbus RTU

WireFree (Optional)

GEN II 900 MHz or GEN II 2.4 GHz

Relays (Optional)

Two Dry Contact Relays with Replaceable 4 Amp Fuses

.

Mechanical Specifications

Enclosure Materials

Aluminum Device Enclosure

Sensor Housing Materials

303 Stainless Steel Sensor Housing

Product Dimensions

5.5” T x 6” W x 7” H (8” W x 17” H Maximum w/ Antenna Fitting and Antenna)

Product Weight

6 lbs.

Safety Approvals

Enclosure Ratings

Explosion/Flame-Proof

Hazardous Location Certification

Class I, Division 1, Groups C and D, T6

Ex d IIB T6

Zone 1, AEx d IIB T6

Tamb -40⁰C to +54⁰C

1.2 PRODUCT SPECIFICATIONS

2 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

PRODUCT OVERVIEW

⑰

⑱

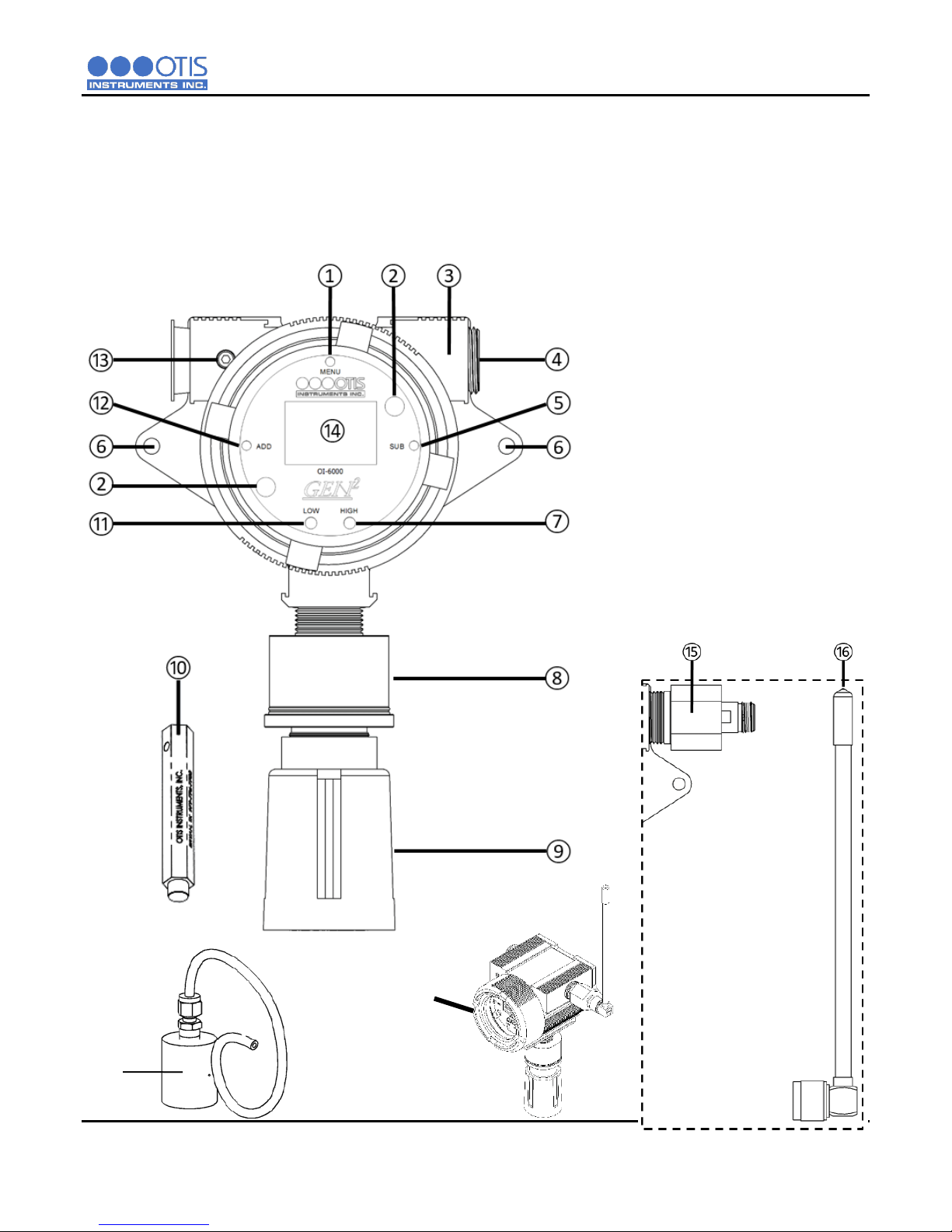

1.3 SYSTEM DIAGRAMS

Refer to the following diagrams for identification of the external and internal system components that may be referred

to in this manual.

1.3.1 EXTERNAL SYSTEM DIAGRAM

1 MENU Button

2 Front Panel Thumbscrew

3 Enclosure

4 Explosion Proof Plug

5 SUB Button

6 Mounting Hole

7 HIGH Alarm LED

8 Sensor Housing Assembly

9 Sensor Rain Guard

10 Otis Magnetic Tool

11 LOW Alarm LED

12 ADD Button

13 Enclosure Lid Locking Screw

14 Display Screen

15 Optional Antenna Fitting

(Replaces Item 4)

16 Optional Antenna

17 Enclosure Lid

18 Calibration Kit (Sold Separately)

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 3

PRODUCT OVERVIEW

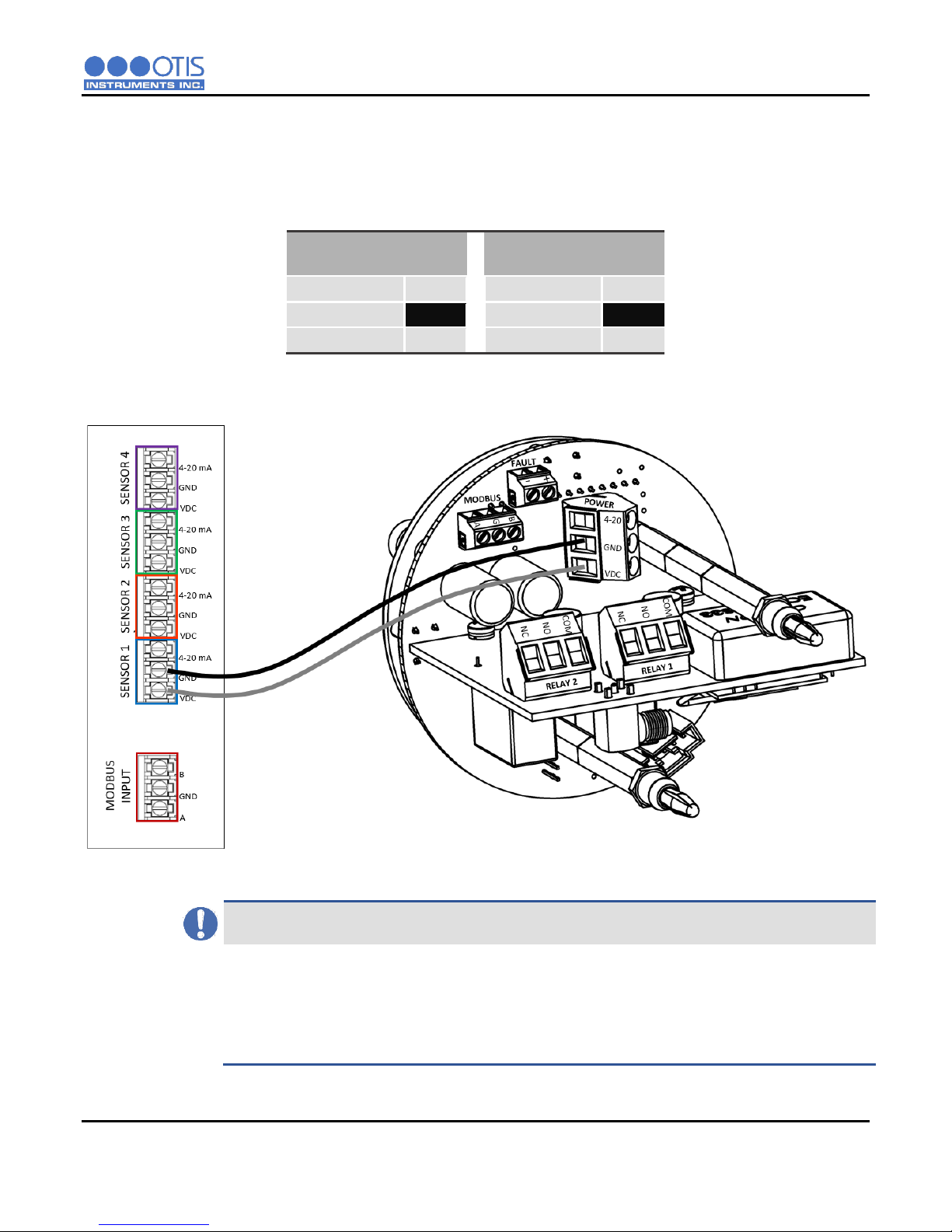

1.3.2 INTERNAL SYSTEM DIAGRAM

1 RS-485 Modbus Terminal Block

2 Fault Terminal Block

3 Power Input/4-20mA Output Terminal Block

4 Radio Module (If equipped)

5 Sensor Housing Socket

6 Antenna Fitting Connector (If equipped with a radio module)

7 Relay 1 Terminal Block (If equipped with relays)

8 Relay 2 Terminal Block (If equipped with relays)

4 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

PRODUCT OVERVIEW

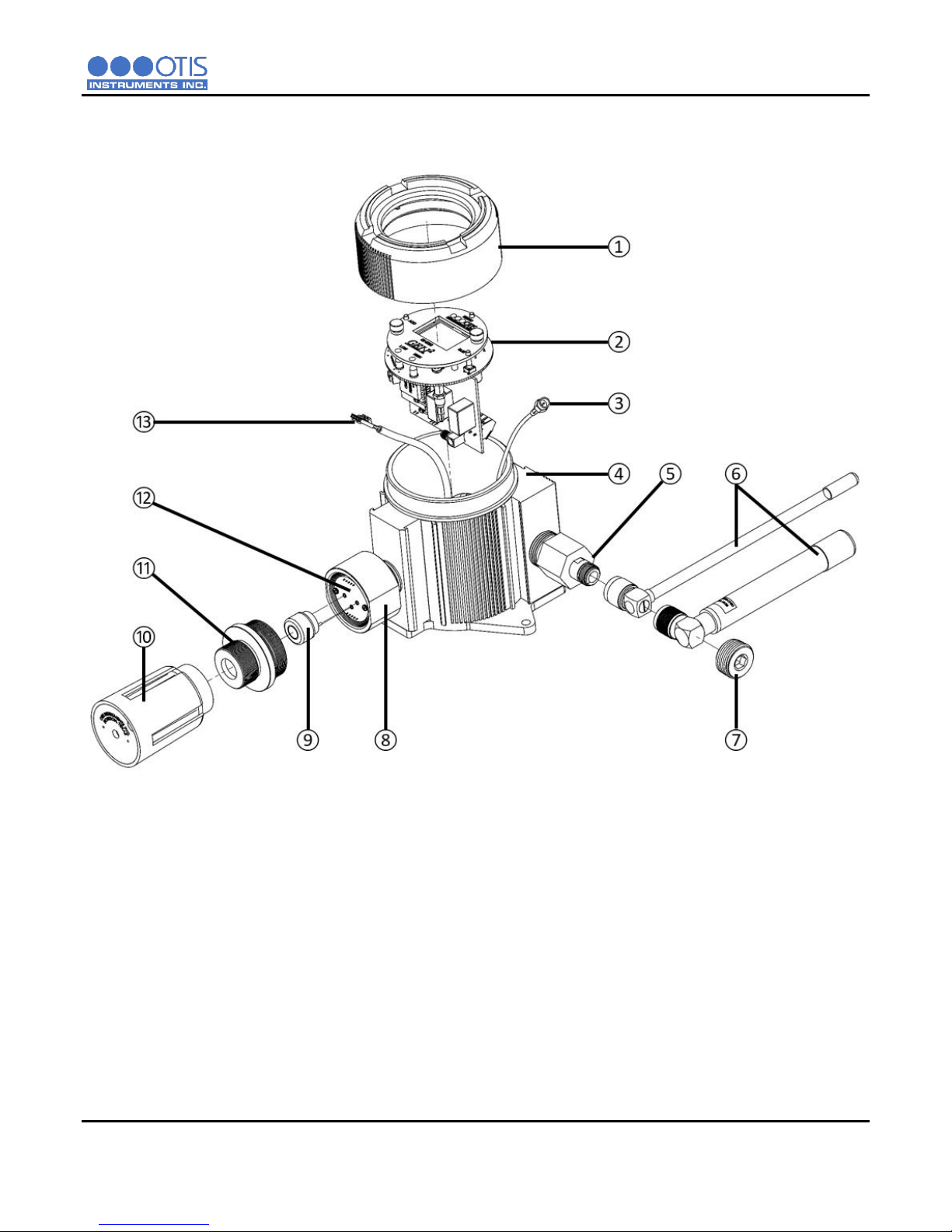

1.3.3 ASSEMBLY DIAGRAM

1 Enclosure Lid

2 Internal System

3 Antenna Fitting Plug (If equipped with a radio module)

4 Enclosure Body

5 Antenna Fitting (If equipped with a radio module) or #7 (If not equipped with a radio module)

6 900 MHz or 2.4 GHz Antenna (If equipped with a radio module)

7 Explosion Proof Plug (If not equipped with a radio module)

8 Sensor Housing Base

9 Sensor Element

10 Sensor Rain Guard

11 Sensor Housing Cap with Flame Arrestor

12 Analog Sensor Board

13 Sensor Housing Plug

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 5

INSTALLATION AND STARTUP

NOTICE

These guidelines are ONLY intended as a general directive for the placement of the OI-6000. This information

should NOT serve as a complete list when considering all potential parameters for the proper location of the unit.

It is STRONGLY advised that a third party Certified Industrial Hygienist, or other Certified Safety Professional,

conduct a site survey and annotate the location and quantity of detection devices that should be installed for

EVERY installation of EVERY site.

2 INSTALLATION AND START-UP

2.1 PRODUCT PLACEMENT

The installation instructions, and any other information supplied by Otis, provide only basic guidelines relating to the

properties of toxic gas and the effects of environmental conditions on the OI-6000 device. Sensor placement should

be determined in consultation with the site safety personnel, as well as those knowledgeable of: (1) the site/facility

where the equipment is being installed and (2) the potentially present gas types and their dispersion. Otis strongly

recommends that the end-user consults with the appropriate third party Health, Safety and Environmental (HSE) and

Industrial Hygiene (IH) professionals to determine the final quantity and placement of your gas detection devices.

The primary purpose of the OI-6000 is to provide an early warning of the accumulation of hazardous gas, in order to

minimize hazards to people and property. Proper placement of the device is paramount to achieving this goal.

The following general guidelines should be considered when determining the placement of the OI-6000:

Units with a radio installed should be placed greater than 6.5 Feet/2 Meters away from a monitor in order to

ensure reliable communications

The unit shall be placed such that the position of the sensor housing is pointing downward to the ground.

Avoid installing the unit in a location where airborne particles could cover or coat the sensor head.

The unit should be placed in an area that will produce the highest gas concentration. Enclosed corners and

stopping points of moving devices are two areas susceptible to a buildup of hazardous gas.

In order to provide an accurate representative sample of a room, care should be taken to avoid locating the

unit near a room entrance, fresh air intake vent, or vehicle/generator exhaust point.

The unit should be placed as close as physically possible to the source of the potential hazardous gas leak.

In consideration of possible ignition points, the unit should be placed between the potential leak source and

ignition point.

Consider placing the unit in a seldom used area, such as a warehouse, storage area, or other unfrequented

location.

Consider accessibility for regular calibration and other required maintenance.

When monitoring a ventilated gas cylinder storage area, the unit should be placed near the air return vent.

When monitoring an outdoor or open-air area, the unit should be placed near the air intake of the HVAC

system of the building.

When monitoring for the potential presence of multiple hazardous gas types, the unit should be calibrated for

the least cross-sensitive hazardous gas.

6 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

INSTALLATION AND STARTUP

CAUTION

VERIFY that the power source is disabled before beginning the following wiring steps or performing any

maintenance inside the device enclosure.

The internal components can be static sensitive. Use caution when opening the enclosure and handling

internal components.

DO NOT use any metal objects or tools to remove the terminal board from the internal system.

VERIFY that the label and color combination of the control board terminal exactly matches the

corresponding label and color combination of the power terminal.

WARNING

When securing the lid onto the device, tighten the enclosure lid by hand ONLY. Overtightening of the lid by

use of hand-tools could result in damage to the O-ring, potentially compromising the moisture seal, resulting

in an unsafe environment.

OI-6000 Terminal Block Wire Gauges

Terminal Block

Wire Gauge

Power Terminal

Relay 1 & 2 Terminal

Min: 26 AWG

Max: 14 AWG

Modbus Terminal

Fault Terminal

Min: 26 AWG

Max: 16 AWG

2.2 PRODUCT MOUNTING

It is recommended to mount the unit to a solid structure (such as a concrete wall, steel column, or angle iron) where

a minimum of vibration will be transmitted to the unit. Alternately, a pole may be used along with a strap or a U-bolt,

as long as it is rigid and of sufficient strength. Wooden structures are not recommended for mounting, as they trap

moisture (which could affect sensor performance) and their mounting rigidity degrades over time (screws/bolts

weaken and fall out or corrode).

Any style of bolt or screw may be used as long as it is steel and meets or exceeds the following:

Maximum ¼"-20 bolt or ؼ" screw (length varies with user need)

Flat washers for bolts/nuts/screws

Minimum Grade 5 (or better)

Corrosion protection for all hardware (paint, galvanize, zinc plating, etc.)

2.3 WIRING CONFIGURATIONS

The OI-6000 has several basic wiring configurations, dependent upon the desired usage and functionality intended

by the end-user. All OI-6000 units require +12 to +35 Volts of wired DC power to operate. Data communication from

the device, through either the 4-20 output or the RS-485 Modbus connection, to an external location are optional.

Consult the subsequent sections of wiring instructions for pertinent information and guidelines pertaining to the

installation of your device.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 7

AWG: American Wire Gauge

INSTALLATION AND STARTUP

NOTICE

Disconnecting the sensor connector plug from the sensor housing will allow for the complete removal

of the internal system from the device enclosure. Disconnecting the internal system may provide ease

in accessing the control board terminals for wiring. If this step is performed, it is essential that all

connections are rejoined before returning the internal system back into the enclosure.

2.3.1 OPENING THE ENCLOSURE

To prepare the OI-6000 for installation, you must first open the device, exposing the control board and its

components for wiring.

1. Remove the enclosure lid, unscrewing it from the device enclosure. Set aside.

2. Gripping the front panel thumbscrews, lift the internal system out of the enclosure and rest it against

the rim of the enclosure opening.

3. Locate the power cord grip on the top edge of the enclosure.

2.3.2 CONNECTING POWER

To provide power to the OI-6000, you will need to connect the power cable from the sensor terminal block

on an Otis monitor, or alternate user supplied power source, to the OI-6000 power terminal block located

on the back of the control board. Refer to the following instructions for how to wire your device:

On the GEN II Model OI-6000 Detector:

1. Feed the power wires through the power hub and into the enclosure.

2. Locate the power terminal block on the control board and complete the following:

a. Connect the power (WHITE) wire to the “+12 to +35 VDC” terminal.

b. Connect the ground (BLACK) wire to the “GND” terminal.

On the Otis Monitor:

1. Open the enclosure lid.

2. Using your thumb and forefinger, loosen the front panel thumbscrews that secure the internal system

into the enclosure.

3. Open the internal system, exposing the internal hardware.

4. Feed the power wires through a cord grip and into the enclosure.

8 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

INSTALLATION AND STARTUP

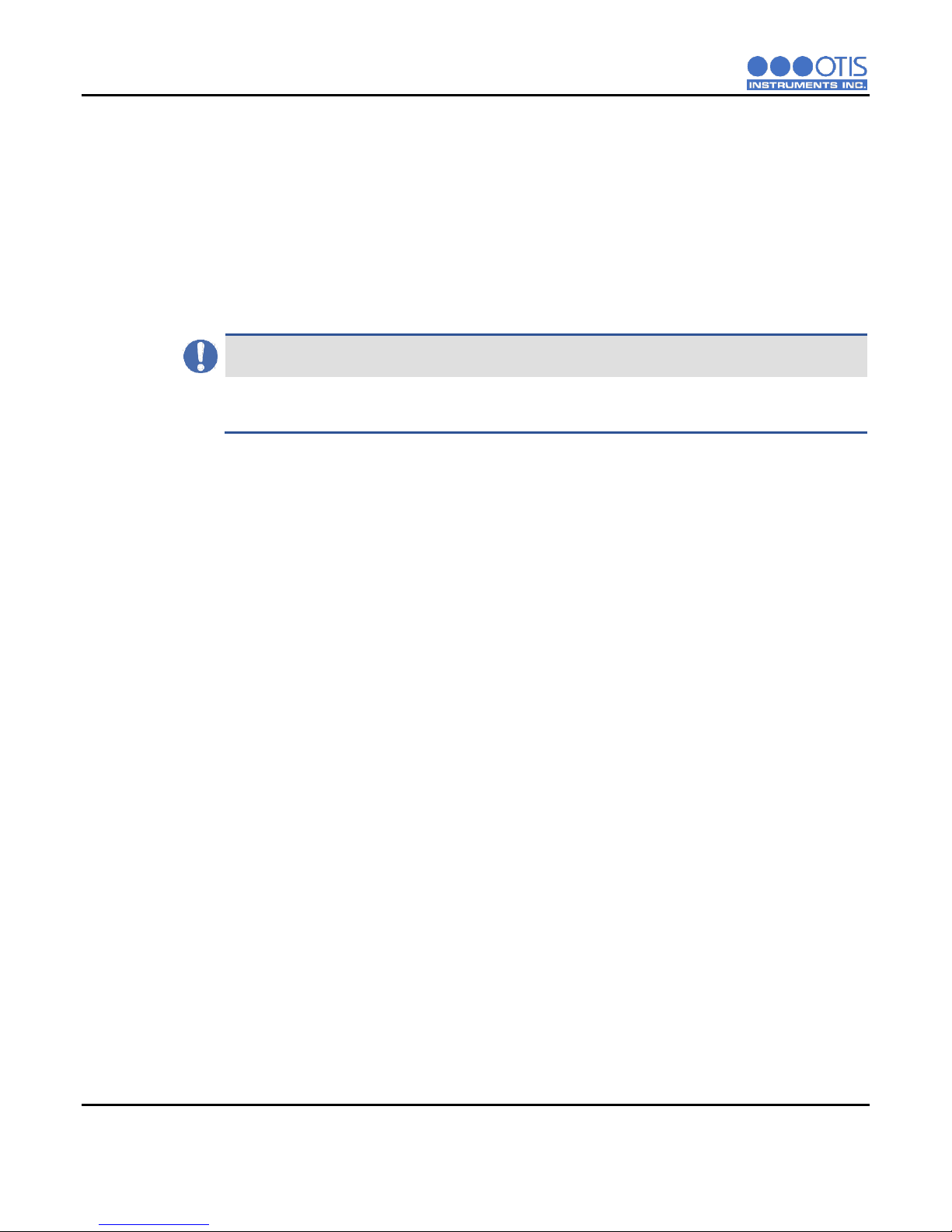

OTIS MONITOR

SENSOR TERMINALS

OI-6000

POWER TERMINALS

+12 to +35 VDC

WHITE

+12 to +35 VDC

WHITE

GND

BLACK

GND

BLACK

4-20 mA

4-20 mA

NOTICE

Wiring power to the device is the ONLY requirement for the OI-6000 to operate. With the provision of

power, the unit will function normally, indicating the presence of toxic gas at the sensor and providing

the gas level reading on the display screen. To utilize the added functionality of the device, additional

wiring is necessary. If an Otis Monitor is not used, the OI-6000 can be powered from any +12 to +35

VDC power supply that is capable of supplying at least 250 mA.

5. Locate the sensor terminal block on the control board and complete the following:

a. Connect the power (WHITE) wire to the “+12 to +35 VDC” terminal.

b. Connect the ground (BLACK) wire to the “GND” terminal.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 9

INSTALLATION AND STARTUP

NOTICE

The power and signal wires may be conjoined as a 3-wire cable, incorporating the power (WHITE),

ground (BLACK), and signal (GREEN) wires all into one jacketed cable.

2.3.3 CONNECTING 4-20 MA OUTPUT

To utilize the 4-20 mA wired data output feature of the OI-6000, you will need to connect the signal cable

from your Otis Monitor sensor terminal block to the OI-6000 power terminal block located on the control

board. Refer to the following instructions for how to wire your device:

On the GEN II Model OI-6000 Detector:

1. Feed the signal wire through the power hub and into the enclosure.

2. Locate the power terminal block on the control board and complete the following:

a. Connect the signal (GREEN) wire to the “4-20 mA” terminal.

On the Otis Monitor:

1. Feed the signal wire through the power hub and into the enclosure.

2. Locate the sensor terminal block on the control board and complete the following:

a. Connect the signal (GREEN) wire to the “4-20 mA” terminal.

10 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

INSTALLATION AND STARTUP

OTIS MONITOR

SENSOR TERMINAL

OI-6000

POWER TERMINAL

+12 to +35 VDC

WHITE

+12 to +35 VDC

WHITE

GND

BLACK

GND

BLACK

4-20 mA

GREEN

4-20 mA

GREEN

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 11

INSTALLATION AND STARTUP

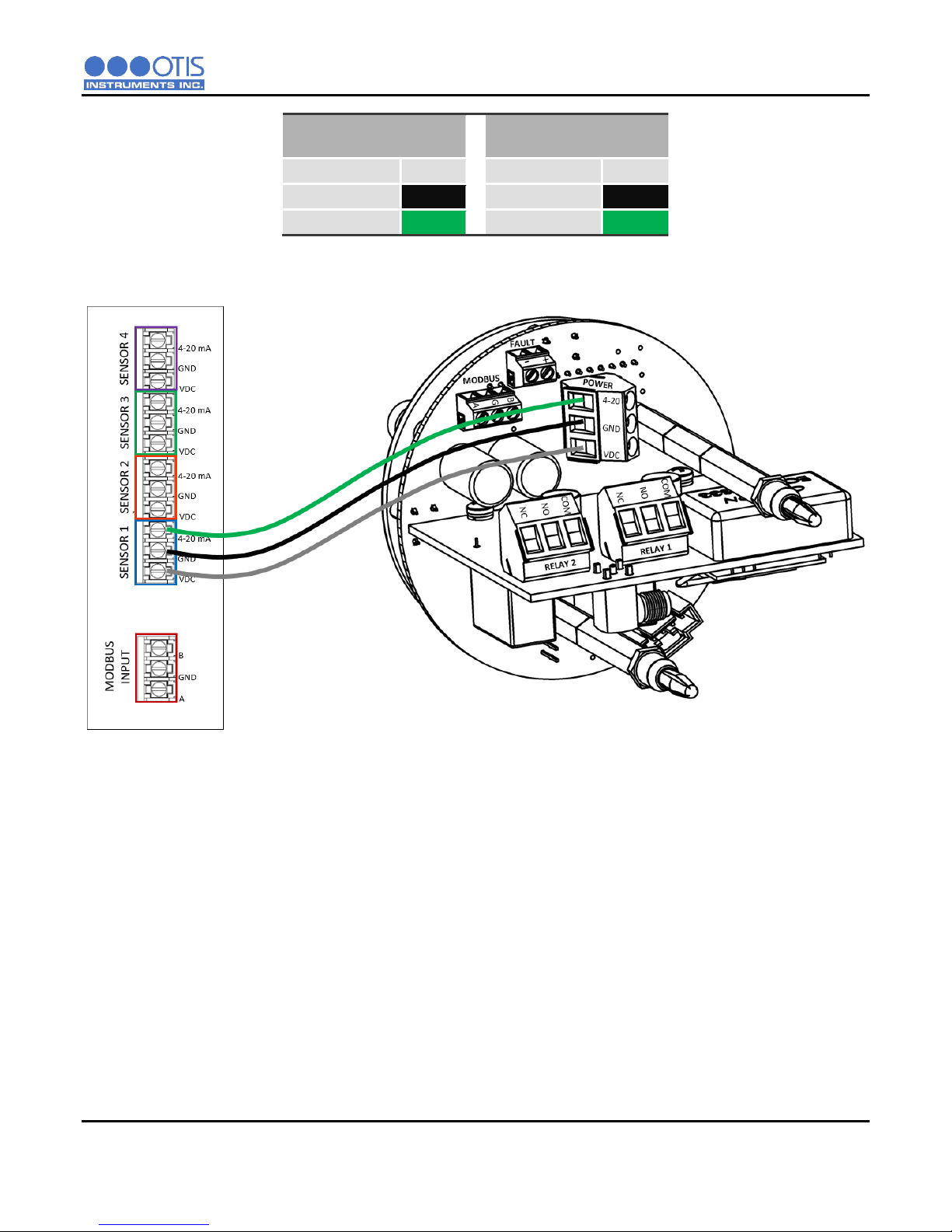

2.3.4 CONNECTING RS-485

The OI-6000 supports Modbus RTU over a RS-485 link. To integrate your device with RS-485 Modbus

data communications, you will need to connect the Modbus cable from your Otis Monitor RS-485 input

terminal block to the OI-6000 RS-485 output terminal block located on the control board of the unit. Refer

to the following instructions for how to wire your device:

On the GEN II Model OI-6000 Detector:

1. Feed the RS-485 cable through the power hub and into the enclosure.

2. Locate the RS-485 output terminal block on the control board and complete the following:

a. Connect the RS-485 B (BROWN) wire to the “B” terminal.

b. Connect the ground (WHITE) wire to the “GND” terminal.

c. Connect the RS-485 A (YELLOW) wire to the “A” terminal.

On the Otis Monitor:

1. Feed the RS-485 cable through the power hub and into the enclosure.

2. Locate the RS-485 input terminal block on the control board and complete the following:

a. Connect the RS-485 B (BROWN) wire to the “B” terminal.

b. Connect the ground (WHITE) wire to the “GND” terminal.

c. Connect the RS-485 A (YELLOW) wire to the “A” terminal.

12 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

INSTALLATION AND STARTUP

OTIS MONITOR

RS-485 TERMINAL

OI-6000

RS-485 TERMINAL

A

YELLOW

A

YELLOW

GND

WHITE

GND

WHITE

B

BROWN

B

BROWN

NOTICE

If an Otis Monitor is not used, the OI-6000 can be connected to a Programmable Logic Controller

(PLC) for RS-485 Modbus data communications. For integration and setup, refer to the Modbus

Register Map found in Appendix C of this manual.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 13

INSTALLATION AND STARTUP

NOTICE

Relays are protected by replaceable 4 Amp fuses.

The two protective fuses must only be replaced with OI-FUSE-4A-250.

2.3.5 CONNECTING RELAYS/ALARMS

The OI-6000 relays are commonly used to power and control external alarming devices, such as alarm

lights (visual) and horns (audio). Refer to the following instructions for how to wire your device. If you do

not have relays in your OI-6000 skip to section 2.3.6 CONNECTING THE FAULT TERMINAL.

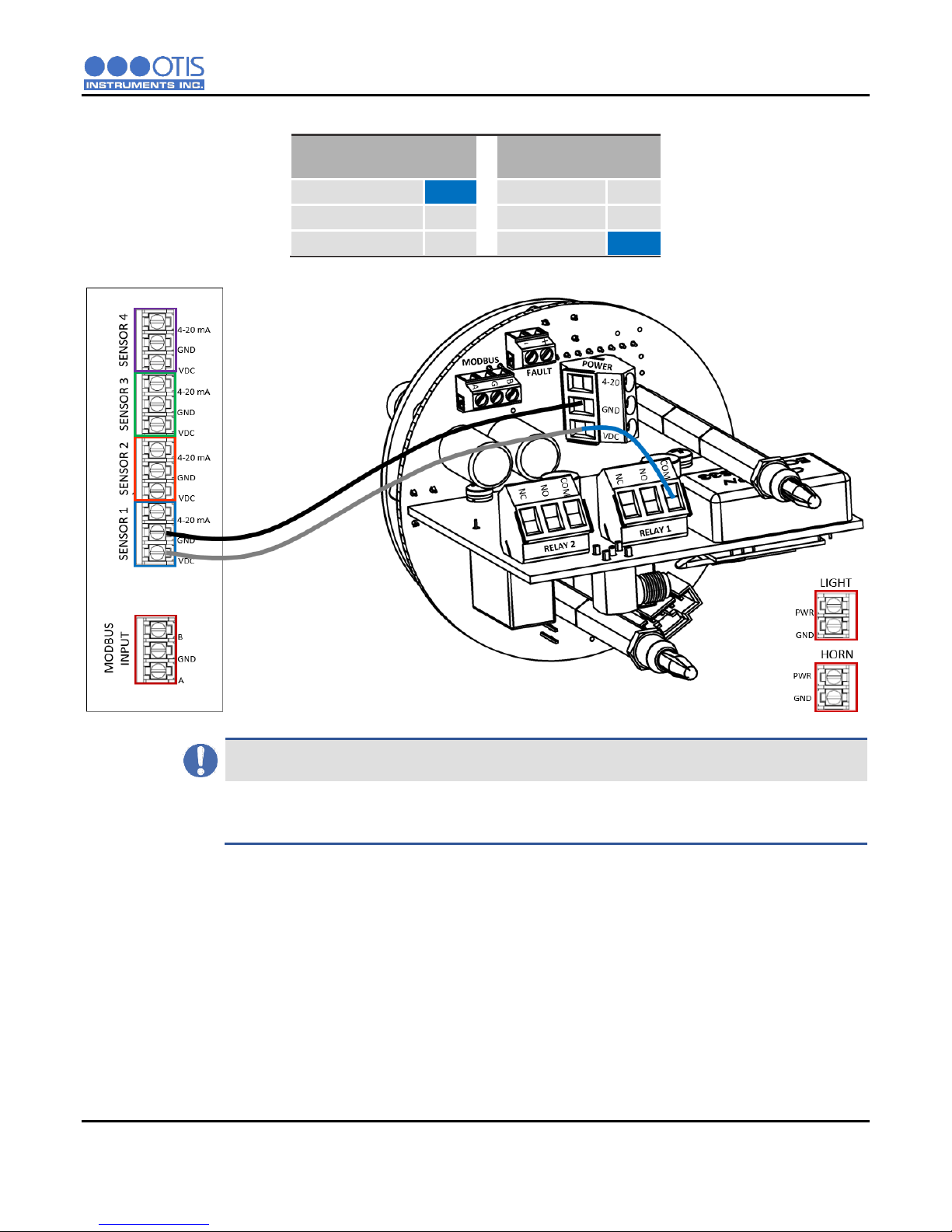

2.3.5.1 CONNECTING RELAY 1

On the OI-6000 Detector:

1. Locate the power terminal block on the control board and complete the following:

a. Connect a second power (BLUE) wire to the “+12 to +35 VDC” terminal.

2. Locate the Relay 1 terminal block on the radio/relay board and complete the following:

a. Connect the power (BLUE) wire from the “+12 to +35 VDC” terminal to the “COM” terminal.

14 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

INSTALLATION AND STARTUP

OI-6000

POWER TERMINAL

OI-6000

RELAY 1 TERMINAL

+12 to +35 VDC

BLUE

NC

GND

NO

4-20 mA

COM

BLUE

NOTICE

It is recommended that the relay connections are wired as normally-open (NO). However, normallyclosed (NC) wiring configurations provide an inherent fail-safe and may be preferred.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 15

INSTALLATION AND STARTUP

EXTERNAL

ALARMING DEVICE

OI-6000

RELAY 1 TERMINAL

OI-6000

POWER TERMINAL

PWR

RED

NC

+12 to +35 VDC

GND

BLACK

NO

RED

GND

BLACK

COM

4-20 mA

2.3.5.1.1 CONNECTING NORMALLY-OPEN (NO) RELAYS

On the external alarming device (light/horn):

1. Locate the power (RED) and ground (BLACK) wires on the alarming device.

On the GEN II Model OI-6000 Detector:

1. Feed the alarming device wires through the power hub and into the enclosure.

2. Locate the Relay 1 terminal block on the radio/relay board and complete the following:

a. Connect the external alarm device power (RED) wire to the “NO” terminal.

3. Locate the power terminal block on the control board and complete the following:

a. Connect the external alarm device ground (BLACK) wire to the “GND” terminal.

16 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

INSTALLATION AND STARTUP

EXTERNAL

ALARMING DEVICE

OI-6000

RELAY 1 TERMINAL

OI-6000

POWER TERMINAL

PWR

RED

NC

RED

+12 to +35 VDC

GND

BLACK

NO

GND

BLACK

COM

4-20 mA

2.3.5.1.2 CONNECTING NORMALLY-CLOSED (NC) RELAYS

On the external alarming device (light/horn):

1. Locate the power (RED) and ground (BLACK) wires on the alarming device.

On the GEN II Model OI-6000 Detector:

1. Feed the alarming device wires through the power hub and into the enclosure

2. Locate the Relay 1 terminal block on the radio/relay board and complete the following:

a. Connect the external alarm device power (RED) wire to the “NC” terminal.

3. Locate the power terminal block on the control board and complete the following:

a. Connect the external alarm device ground (BLACK) wire to the “GND” terminal.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 17

INSTALLATION AND STARTUP

OI-6000-IR-152

RELAY 1 TERMINAL

OI-6000-IR-152

RELAY 2 TERMINAL

NC

NC

NO

NO

COM

BLUE

COM

BLUE

2.3.5.2 CONNECTING RELAY 2

On the GEN II Model OI-6000-IR-152 Detector:

1. Locate the Relay 1 terminal block on the radio/relay board and complete the following:

a. Connect a second power (BLUE) wire to the “COM” terminal.

2. Locate the Relay 2 terminal block on the radio/relay board and complete the following:

a. Connect the power (BLUE) wire from the “COM” terminal of Relay 1 to the “COM” terminal.

18 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

INSTALLATION AND STARTUP

EXTERNAL

ALARMING DEVICE

OI-6000-IR-152

RELAY 2 TERMINAL

OI-6000-IR-152

POWER TERMINAL

PWR

RED

NC

+12 to +35 VDC

GND

BLACK

NO

RED

GND

BLACK

COM

4-20 mA

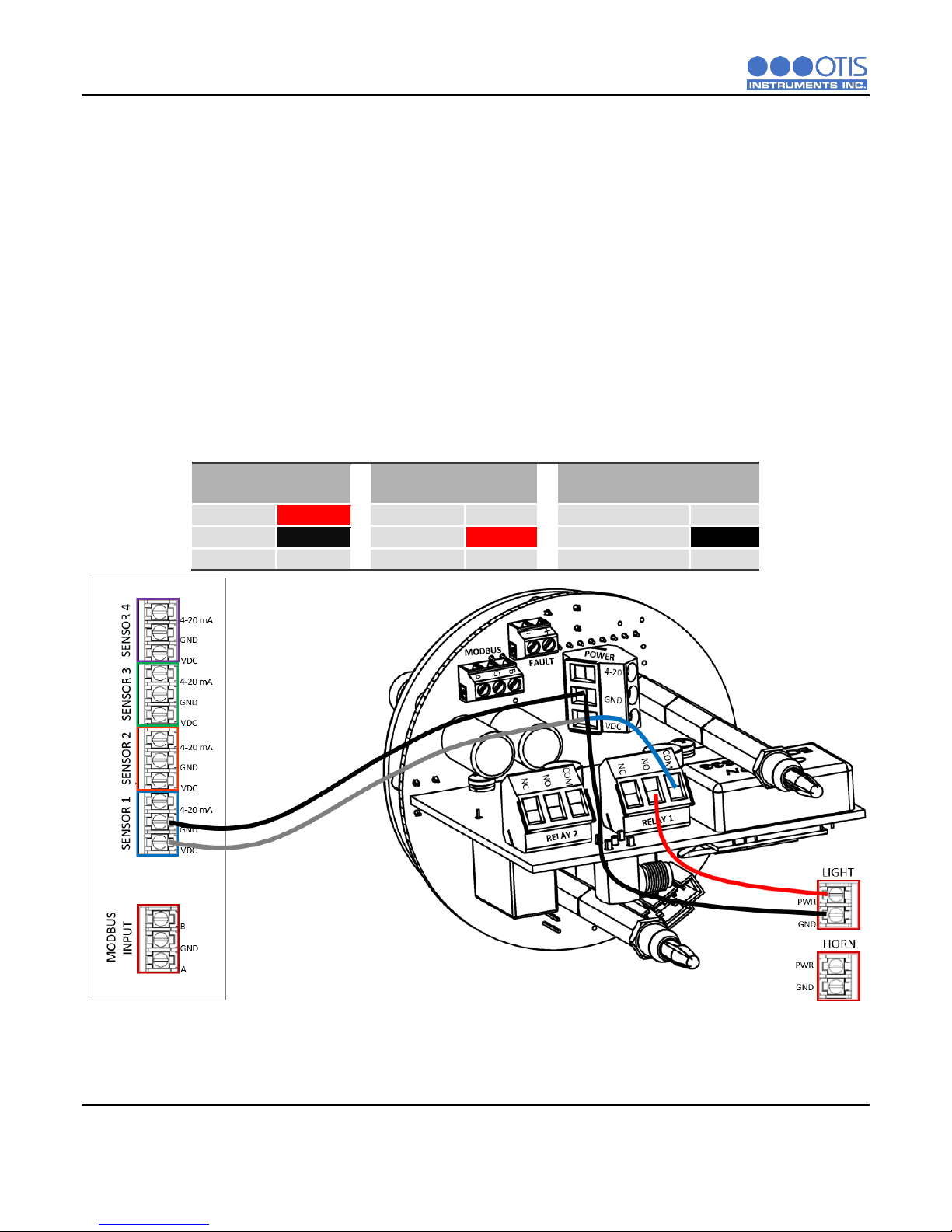

2.3.5.2.1 CONNECTING NORMALLY-OPEN (NO) RELAYS

On the external alarming device (light/horn):

1. Locate the power (RED) and ground (BLACK) wires on the alarming device.

On the GEN II Model OI-6000 Detector:

1. Feed the alarming device wires through the power hub and into the enclosure.

2. Locate the Relay 2 terminal block on the radio/relay board and complete the following:

a. Connect the external alarm device power (RED) wire to the “NO” terminal.

3. Locate the power terminal block on the control board and complete the following:

a. Connect the external alarm device ground (BLACK) wire to the “GND” terminal.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 19

INSTALLATION AND STARTUP

EXTERNAL

ALARMING DEVICE

OI-6000-IR-152

RELAY 2 TERMINAL

OI-6000-IR-152

POWER TERMINAL

PWR

RED

NC

RED

+12 to +35 VDC

GND

BLACK

NO

GND

BLACK

COM

4-20 mA

2.3.5.2.2 CONNECTING NORMALLY-CLOSED (NC) RELAYS

On the external alarming device (light/horn):

1. Locate the power (RED) and ground (BLACK) wires on the alarming device.

On the GEN II Model OI-6000-IR-152 Detector:

1. Feed the alarming device wires through the power hub and into the enclosure.

2. Locate the Relay 2 terminal block on the radio/relay board and complete the following:

a. Connect the external alarm device power (RED) wire to the “NC” terminal.

3. Locate the power terminal block on the control board and complete the following:

a. Connect the external alarm device ground (BLACK) wire to the “GND” terminal.

20 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

INSTALLATION AND STARTUP

EXTERNAL

FAULT DEVICE

OI-6000

FAULT TERMINAL

PWR/+

RED

+

RED

GND/-

BLACK

-

BLACK

2.3.6 CONNECTING THE FAULT TERMINAL

The fault terminal is used to provide indication of a device failure. The fault terminal is a normally-closed

(NC), or fail-safe, configuration, terminating power to the external fault device when prompted. Unlike

the optional relay terminals, the fault terminal is a wet-contact, requiring only the power and ground wires

of the external fault device to be wired during installation. Refer to the following instructions for how to

wire your device:

On the external fault device (light/horn):

1. Locate the power (RED) and ground (BLACK) wires on the alarming device.

On the GEN II Model OI-6000 Detector:

1. Feed the alarming device wires through the power hub and into the enclosure.

2. Locate the fault terminal block on the control board and complete the following:

a. Connect the external fault device power (RED) wire to the “+” terminal.

b. Connect the external fault device ground (BLACK) wire to the “-” terminal.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 21

INSTALLATION AND STARTUP

22 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

INSTALLATION AND STARTUP

NOTICE

The thumbscrews on the OI-6000 function ONLY as thumb-holds for ease in removal of the internal

system from the base of the enclosure. Do NOT attempt to loosen or tighten the thumbscrews when

opening or closing the enclosure.

2.3.7 CLOSING THE ENCLOSURE

1. Place the internal system back into the device enclosure, matching each mounting post to its

corresponding eyelet anchored within the base of the enclosure.

2. Using the thumbscrews, gently push to seat the internal system into the mounting posts.

3. Verify that the sealing ring, seated at the threaded opening of the device enclosure, is correctly in

place.

4. Affix the enclosure lid back onto the device, rotating the lid until it is tightly screwed into place.

2.4 SYSTEM START-UP

After the enclosure is closed and power is applied, the unit will start automatically and begin its 1-minute warmup

period. During warmup, the display will show a countdown of the time remaining until the system start-up is complete.

The Otis logo and the unit information will also show on the display screen during start-up.

At the end of the countdown, the device will be in normal operating mode.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 23

INSTALLATION AND STARTUP

NOTICE

After 5 minutes of no interaction with the device, the unit will automatically return to normal operating mode.

④

2.5 NORMAL OPERATING MODE

During normal operating mode, the OI-6000 continuously samples the air and updates the measured concentration

of the target gas on the display screen. The display, when in normal operation, appears as shown below.

1 Measured gas concentration (reading)

2 Gas concentration unit of measure

3 Sensor element gas type

4 Readings above full scale show as MAX and the 4-20 output is set to 25 mA

In the event of a device failure, the unit will alternate between the normal operating screen and a fault screen on the

display, in 5 second intervals, until the fault has been cleared, or is corrected. The fault code, located in the bottomleft corner of the display, appears on both screens. The unit continuously registers that the system is in fault, so that

even with at-a-glance instrument checks in the field, it can be seen. When the fault is corrected, the unit will return

to normal operating mode.

For a list of the fault codes and warning symbols of the OI-6000, and their associated meaning, refer to the Product

Troubleshooting section of this manual.

Both system menus are accessible from the normal operating mode. To access the product settings and

configuration menu, press and hold the MENU button, for approximately 6 seconds, until the menu is activated and

open on the display screen. To access the operation settings menu from the normal operating screen, press the

MENU button once and the menu will open and show on the display.

24 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

PRODUCT SETTINGS AND CONFIGURATION

NOTICE

The triggering of relays from the detector will also simulate low and high level alarm relays at the monitor. Monitors

cannot distinguish between real and simulated data received. When the monitor relays are triggered, alarming

devices will perform as intended, initiating emergency procedures as if a harmful or toxic gas was actually present.

To prevent this from occurring, set the monitor to calibration mode before performing the relay test. Calibration

mode of the monitor will allow the transmission of the data, without the activation of the monitor relays. Consult

the Sensor Calibration section of this manual for instructions on how to perform this procedure.

3 PRODUCT SETTINGS AND CONFIGURATION

The product settings and configuration menu allows the end-user to tailor the device settings to meet their required

specifications and/or site conditions.

The product settings and configuration menu consist of the following screens:

Relay Test

Network ID

System Information

Null/Calibration Timers

Unit Info

Background Setting

Relay 1: Latching/Non-Latching Setting

Relay 2: Latching/Non-Latching Setting

Relay 1: Fail-Safe Setting

Relay 2: Fail-Safe Setting

Calibration Method

RS-485 Modbus Address Setting

RS-485 Modbus Baud Setting

4-20 mA Offset Settings

o Zero Offset Setting

o Full-Scale Offset Setting

Display Screen Contrast Setting

Return to Factory Default Settings

While the device is in normal operating mode, press and hold the MENU button, for approximately 6 seconds, until the

product settings and configuration menu is activated and open on the display screen.

3.1 RELAY TEST

The relay test simulates a gas level reading, indicating the presence of a toxic gas at the sensor. The relay test is

used to ensure the proper functionality of the relay settings on the monitor. The test can also be used to simulate

emergency/safety drills onsite.

It is recommended that a relay test be conducted EVERY 30 days, alongside the maintenance and calibration of the

detector.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 25

PRODUCT SETTINGS AND CONFIGURATION

NOTICE

This page will not appear if no radio module is installed. Please skip to section 3.3 SYSTEM INFORMATION.

3.1.1 PERFORMING THE RELAY TEST

The relay test gas level reading can be increased or decreased in increments of 5% of the sensor scale,

up to 100% of the sensor scale.

1. Press the ADD button until the low and high alarm levels are reached and the relay(s) are triggered

to light all visual alarm(s) and sound all audio alarm(s) on the monitor.

2. Once all relays have been tested and the test is complete, press the SUB button to return the relay

test reading back to zero and to deactivate the monitor alarm(s).

3. Press the MENU button to advance to the System Information screen.

3.2 NETWORK ID

The Network ID is used to synchronize the communication between the Otis Monitor and Sensor Assembly:

There are 52 networks available with the GEN II 900 MHz radio.

There are 78 networks available with the GEN II 2.4 GHz radio.

The monitor and sensor assembly must have the same Network ID in order to communicate.

1. Press the ADD or SUB button until the Network ID matches the value being used on the Primary

Monitor.

2. Press the MENU button to advance to the System Information screen.

26 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

PRODUCT SETTINGS AND CONFIGURATION

3.3 SYSTEM INFORMATION

The system information screen allows the end-user to view the following information:

The status of the radio link (Only present if radio module is installed)

The scale of the sensor element.

The supply voltage of the sensor unit.

The voltage value the sensor was reading when nulled in Volts.

The current voltage value the sensor element is reading in Volts.

This screen is for informational purposes only.

1. Press the MENU button to advance to the Null/Calibration Time Information screen.

3.4 NULL/CALIBRATION TIMER INFORMATION

The null/calibration time information screen allows the end-user to view the following information:

The days since the sensor assembly was last nulled, only updates while the unit is turned on.

The days since the sensor assembly was last calibrated, only updates while the unit is turned on.

The calibration number of the sensor, used for diagnostic purposes.

This screen is for informational purposes only.

1. Press the MENU button to advance to the Unit Information screen.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 27

PRODUCT SETTINGS AND CONFIGURATION

NOTICE

This page will not appear if no radio module is installed. Please skip to section 3.7.

3.5 UNIT INFORMATION

The unit information screen allows the end-user to view the following information:

The number of missed radio transmissions to the monitor (Only present if radio module installed)

The date of manufacture of the sensor assembly.

The serial number of the sensor assembly.

This screen is for informational purposes only.

1. Press the MENU button to advance to the Background setting screen.

3.6 BACKGROUND SETTING

The background setting is the gas reading at which the radio transmission changes from once every minute to once

every five seconds. The background setting is adjustable so that if there is a consistent level of gas always present

the sensor will not increase the radio transmission rate.

The default background level is 4% of the sensor element scale.

The minimum that the background can be set to is 1% of the sensor element scale.

The maximum that the background can be set to is 10% of the sensor element scale.

1. Press the ADD or SUB button until the Background is set to the desired level.

2. Press the MENU button to advance to the Relay 1 latching/non-latching setting screen.

28 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

PRODUCT SETTINGS AND CONFIGURATION

Common Relay 1 and Relay 2 Settings

Relay

Alarm Setting

Latching/Non-Latching

Relay 1

Low

Non-Latching

Relay 2

High

Latching

NOTICE

For non-latching alarms, the alarms will NOT deactivate until the gas level reading at the sensor

has fallen 10% below the alarm set-point.

For latching alarms, the gas level reading MUST be below the alarm set-point before the alarm

can be deactivated.

The alarms will NOT activate, even in the presence of gas, until you have exited the menu mode

for approximately 1 minute.

3.7 LATCHING AND NON-LATCHING RELAY SETTINGS

Relay 1 and Relay 2 can be set to latching or non-latching. Relays set to non-latching will automatically deactivate

when the detected gas level falls below the corresponding alarm setting. Conversely, latching relays, once activated,

MUST be manually reset at the device, regardless of the change in gas detection level readings.

The factory default settings on the OI-6000-IR-152 for Relay 1 and Relay 2 are non-latching. During installation and

setup, Relay 1 and Relay 2 are commonly customized as the following:

3.7.1 RELAY 1: LATCHING/NON-LATCHING SETTING

1. Use the ADD and SUB buttons to toggle between the “UnLatch” and “Latch” options.

2. Press the MENU button to select the desired setting and to advance to the Relay 2 latching/non-

latching setting screen.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 29

PRODUCT SETTINGS AND CONFIGURATION

NOTICE

For maximum safety, the fault terminal MUST be used. A fail-safe relay will NOT notify the user of all potential

device failures. The fail-safe setting should ONLY be enabled to provide enhanced safety protection when the

fault terminal CANNOT be used.

3.7.2 RELAY 2: LATCHING/NON-LATCHING SETTING

1. Use the ADD and SUB buttons to toggle between the “UnLatch” and “Latch” options.

2. Press the MENU button to select the desired setting and to advance to the Relay 1 fail-safe setting

screen.

3.8 RELAY FAIL-SAFE SETTING

From a safety perspective, any unknown situation must be considered potentially hazardous. When a stand-alone

gas detector is unable to detect gas, an unknown condition is created and precautions must be taken to prevent

personal injury or loss of life. This means that the device must be able to alert the end-user that it is no longer fully

operational. This safety function is made possible by the fault terminal. For more information about the fault terminal

and for instructions on how to wire your device, refer to the Connecting the Fault Terminal section of this manual.

Site specific circumstances may prevent the use of the fault terminal, leading to potentially dangerous situations

without end-user notification. In response, the OI-6000 provides a relay fail-safe setting to enhance the safety

protection provided when the fault terminal cannot be used.

The relay fail-safe setting reverses the behavior of the relays and allows a deactivated relay to serve as a warning

of a potentially hazardous event. In fail-safe mode, the relays are activated upon device start-up and deactivated

during alarm conditions and when the device is turned off. Some device failures, such as loss of power and firmware

corruption, will also deactivate the relay.

The factory default settings on the OI-6000 for Relay 1 and Relay 2 fail-safe are No (Off).

30 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

PRODUCT SETTINGS AND CONFIGURATION

Recommended Configurations for Relay Fail-Safe Setting

Power Source

Relay Wiring

Fail-Safe

Outcome

OI-6000

Normally-Closed (NC)

No (Off)

Normal Operation: Closed

Alarm Activation: Open

OI-6000

Normally-Open (NO)

Yes (On)

Normal Operation: Closed

Alarm Activation: Open

External Power Supply

Normally-Closed (NC)

Yes (On)

Normal Operation: Open

Alarm Activation: Closed

External Power Supply

Normally-Open (NO)

Yes (On)

Normal Operation: Closed

Alarm Activation: Closed

If the fault terminal cannot be used, Otis Instruments recommends one of the following configurations:

3.8.1 RELAY 1: FAIL-SAFE SETTING

1. Use the ADD and SUB buttons to select the desired fail-safe setting for Relay 1. Select “Yes” to turn

the fail-safe setting on, or select “No” to leave the fail-safe setting off.

2. Press the MENU button to select the desired setting and to advance to the Relay 2 fail-safe setting

screen.

3.8.2 RELAY 2: FAIL-SAFE SETTING

1. Use the ADD and SUB buttons to select the desired fail-safe setting for Relay 2. Select “Yes” to turn

the fail-safe setting on, or select “No” to leave the fail-safe setting off.

2. Press the MENU button to select the desired setting and to advance to the Calibration Method setting

screen.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 31

PRODUCT SETTINGS AND CONFIGURATION

3.9 CALIBRATION METHOD

The calibration method selection allows you to choose how you calibrate the sensor element. Manual calibration is

the default method for all gas types.

Manual calibration lets you use the ADD and SUB buttons during calibration to match the reading shown

on the screen to the value of the gas being applied.

Auto calibration will set the reading, after a predetermined amount of time, during calibration to the value

entered during the auto calibration setup process.

1. Use the ADD button to select manual calibration and the SUB button to select auto calibration.

2. Press the MENU button to advance to the Modbus Address Setting screen.

32 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

PRODUCT SETTINGS AND CONFIGURATION

3.10 MODBUS ADDRESS SETTING

Modbus is the leading industrial open control protocol. Modbus is available in several different types, depending

upon the media over which it is transmitted. Like most communication protocols, Modbus uses a master/client type

behavior. The master sends a poll request for information to the client, the client decodes the request, and then

sends a response with the requested data back to the master.

A Modbus message includes a Modbus address, commonly referred to as a unit ID. The Modbus address is used

to identify the server address in RS-485 networks. Each server is assigned an address and listens for messages

which contain this number in the Modbus address field.

The OI-6000 uses the original Modbus RTU over the RS-485 link. RS-485 Modbus has 255 addresses, ranging from

1 to 255. Eight of the addresses are used for internal system settings, leaving addresses 1 to 247 available for your

device.

The RS-485 Modbus communication parameters used in Otis devices is 8 data bits, no parity, and 1 stop bit; these

parameters are fixed and cannot be changed. The floating point data values are presented with the least significant

bytes first.

When using Modbus over a RS-485 network, the communication parameters MUST be set correctly for all devices.

For multiple devices using Modbus, ensure that no two units are assigned the same address. A duplication of

addresses could cause errors in the transmission of data. Modbus addresses can be assigned sequentially or

another appropriate address scheme for the specific network setup.

The factory default setting on the OI-6000 for the Modbus address setting is 1.

1. Use the ADD and SUB buttons to increase and decrease the Modbus address number, respectively.

2. Press the MENU button to select the desired setting and to advance to the Modbus baud setting screen.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 33

PRODUCT SETTINGS AND CONFIGURATION

3.11 MODBUS BAUD SETTING

The baud rate is the speed of data transmitted within the Modbus system, measured in bits per second (bps). For

successful communication, the baud rate setting of the OI-6000 MUST match the baud rate setting on the attached

Otis Monitor, or other Modbus device.

All Otis devices have factory default Modbus baud settings of 9600 bps. The RS-485 Modbus communication

parameters used in all Otis devices are 8 data bits, no parity bit, and 1 stop bit (8-N-1) these parameters are fixed

and cannot be changed. Some devices come with different Modbus baud rates. Check with your system

administrator to determine if a different Modbus baud setting is needed for your system.

The pre-set Modbus baud setting available for the OI-6000 are the following:

110 bps

300 bps

1200 bps

2400 bps

4800 bps

9600 bps

19200 bps

1. Use the ADD and SUB buttons to scroll through the available Modbus baud options.

2. Press the MENU button to select the desired setting and to advance to the 4-20 mA offset settings screen.

34 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

PRODUCT SETTINGS AND CONFIGURATION

3.12 4-20 mA OFFSET SETTINGS

Setting the 4-20 mA offset allows the end-user to calibrate the sensor’s analog output. Upon installation of the

device, if the detected gas reading on OI-6000 does not correspond to the reading on the Otis Monitor, or other

monitoring device, the zero offset (4 mA) and the full-scale offset (20 mA) can be adjusted on the unit.

Overtime, as electronic components suffer from normal wear and tear, the circuits will tend to drift. This drift can

cause variances in the amount of current output by the sensor, or in the current measurement by the monitor. If at

any time the reading on the OI-6000 no longer matches the reading on the monitoring device, the 4-20 mA offset will

need to be recalibrated.

The factory default settings on the OI-6000 for the 4-20 mA offset are 4.00 mA for the zero offset and 20.00 mA for

the full-scale offset.

1. Press the ADD button to select “Yes” to set the 4-20 mA offset and to advance to the zero offset setting screen.

If you do not wish to set the 4-20 mA offset, press the SUB button to select “No” to advance to the display screen

contrast setting screen.

3.12.1 ZERO OFFSET SETTING

If “Yes” is selected to set the 4-20 mA offset:

1. Use the ADD and SUB buttons to increase and decrease the zero offset on the unit, respectively,

until the Otis Monitor reads 0 %/PPM, depending on the gas type being detected.

2. Press the MENU button to save the desired setting and to advance to the full-scale offset setting

screen.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 35

PRODUCT SETTINGS AND CONFIGURATION

NOTICE

Setting the contrast too low will cause the display image to become faint or indistinguishable, especially when the

unit is located in areas with full-sun. The resulting field of view could be misinterpreted as an error within the

device. Be sure to verify that the selected contract is within an appropriate range of viewing.

3.12.2 FULL-SCALE OFFSET SETTING

1. Use the ADD and SUB buttons to increase and decrease the full-scale offset, respectively, until the

Otis Monitor reads the full scale value for that channel.

2. Press the MENU button to save the desired setting and to advance to the display screen contrast

setting screen.

3.13 DISPLAY SCREEN CONTRAST SETTING

The display screen contrast is the difference in luminance or color that makes the displayed images distinguishable.

Due to varying external elements, such as extreme sunlight, the brightness of the display screen may need to be

adjusted for optimum viewing.

The factory default setting on the OI-6000 for the display screen contrast is 29, approximately 45% of the contrast

scale. The contrast setting ranges from 1 to 64.

3. Use the ADD and SUB buttons to brighten and dim the contrast, respectively.

4. Press the MENU button to select the desired setting and to advance to the return to factory default settings

screen.

36 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

PRODUCT SETTINGS AND CONFIGURATION

OI-6000 Product and Configuration Factory Default Settings

Configuration

Setting

Relay Test

--

Network ID

5

System Information

--

Null/Calibration Timer

*Cleared*

Unit Information

--

Background Setting

4

Relay 1: Latching/Non-Latching

UnLatch

Relay 2: Latching/Non-Latching

UnLatch

Relay 1: Fail-Safe Setting

No (Off)

Relay 2: Fail-Safe Setting

No (Off)

Calibration Method

Manual

RS-485 Modbus Address Setting

1

RS-485 Modbus Baud Setting

9600 bps

4-20 mA Zero Offset Setting

4.00 mA

4-20 mA Full-Scale Offset Setting

20.00 mA

Contrast

--

OI-6000 Operation Factory Default Settings

Configuration

Setting

Sensor Element Null

*Cleared*

Sensor Element Calibration

*Cleared*

Sensor Assembly Low Alarm Setting

10% of Sensor Scale

Sensor Assembly Low Alarm Rise/Fall Setting

Rise

Sensor Assembly High Alarm Setting

15% of Sensor Scale

Sensor Assembly High Alarm Rise/Fall Setting

Rise

3.14 RETURN TO FACTORY DEFAULT SETTINGS

Returning the OI-6000 to its factory default settings will reset all customization of the device, including the null and

calibration settings of the sensor element.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 37

PRODUCT SETTINGS AND CONFIGURATION

NOTICE

If the OI-6000 is reset to the factory default settings, the configuration steps MUST be repeated and the device

MUST then be nulled and calibrated for proper operation of the device.

1. Press the ADD button to select “Yes” to return the device to its factory default settings and to advance to the

return to factory default settings confirmation screen. If you do not wish to return the device to its factory default

settings, press the SUB button to select “No” to leave the product settings and configuration menu and to return

the device to normal operating mode.

If “Yes” is selected to return the device to its factory default settings:

1. Press the ADD button to select “Yes” to confirm that you want to reset the device to its factory default settings and

to return the device to normal operating mode. If you do not wish to continue to return the device to its factory default

settings, press the SUB button to select “No” to leave the product settings and configuration menu and to return the

device to normal operating mode.

38 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

OPERATION SETTINGS

4 OPERATION SETTINGS

At the time of installation, when the power is first applied to the OI-6000, the unit is automatically powered on and begins

the startup sequence. During the 1-minute warmup, the display will show a countdown of the time remaining until the system

start-up is complete. The Otis logo and the unit information will also flash on the display screen and, at the end of the

countdown, the device will be in normal operating mode.

4.1 POWERING THE DEVICE

4.1.1 POWERING OFF

Powering off the device stops the operation of the unit. The product settings and configuration, as well

as the operation settings, including the null and calibration of the sensor, will be unaffected.

1. Press and hold the SUB button for approximately 6 seconds, until “OFF” shows on the display

screen.

The display screen will continue to show “OFF” for the duration of time that the unit is powered off, as

long as long as uninterrupted power is supplied to the unit.

4.1.2 POWERING ON

Powering on the device begins the operation of the unit, automatically initiating the system start-up cycle

and 1-minute warmup period. The OI-6000 will be in normal operating mode at the completion of the

system start-up.

1. Press the ADD button once to turn the unit on.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 39

OPERATION SETTINGS

4.2 SENSOR CALIBRATION

Calibration is the process of evaluating and adjusting the precision and accuracy of measurement equipment.

Although Otis calibrates every device at the factory, for best accuracy, the detector SHOULD be calibrated in the

environment where it is installed.

It is imperative that the calibration occur as part of the installation process, and then EVERY thirty (30) days

thereafter. Days since last calibration should NEVER exceed ninety (90) days. Otis recommends that you calibrate

your device regularly to ensure proper functionality and a safe work environment.

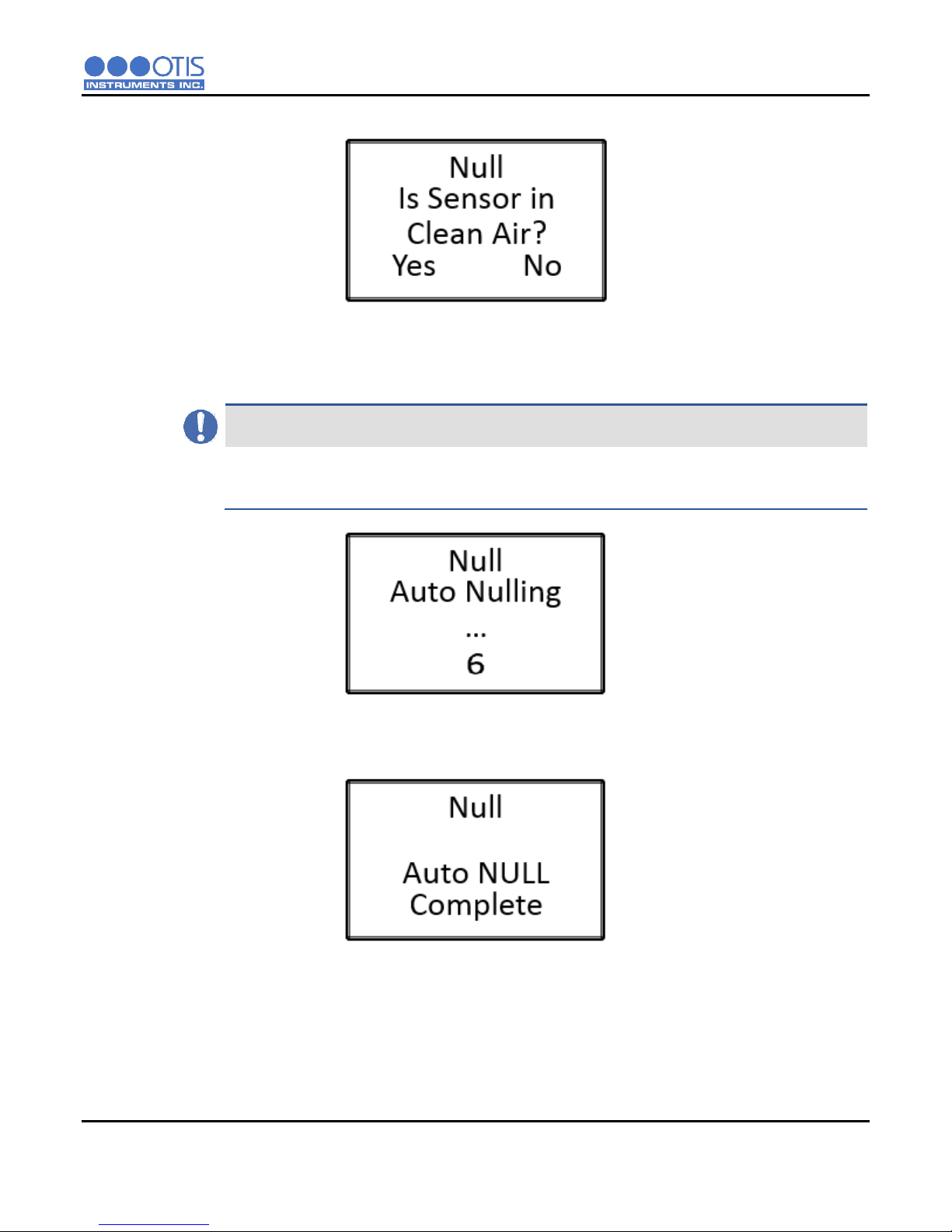

4.2.1 NULLING THE SENSOR (AUTO NULL)

The first step of calibration is nulling the sensor, sometimes referred to as “setting the zero” or “zeroing

the sensor.” The nulling process MUST be performed in known clean air, with no contaminants or

hazardous gasses present. If air quality cannot be guaranteed, a bottle of zero air will be required to

properly null the sensor.

1. While the product is in normal operating mode, press the MENU button to activate the operation

settings menu.

2. Press the ADD button to begin the null process and advance to the clean air confirmation screen.

40 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

OPERATION SETTINGS

NOTICE

If “Yes” is selected at this point, the null process cannot be stopped without disconnecting the power

from the unit.

3. Press the ADD button to select “Yes” to confirm that the sensor is in clean air and to begin nulling

the sensor. If the sensor is not in clean air, press the SUB button to select “No” to discontinue the

null process and to return to the previous screen.

4. The unit will automatically begin the 6-second null process. During null, the display will show a

countdown of the time remaining until the process is complete.

5. When null process is complete, press the MENU button to advance to the calibration screen.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 41

OPERATION SETTINGS

NOTICE

If the sensor responds extremely slow, or does not respond to the applied gas, it may indicate a failed

sensor element. The sensor element will need to be replaced before completing the null and calibration

process.

4.2.2 CALIBRATING THE SENSOR (MANUAL CAL)

You should ONLY perform the calibration of the sensor after the null process has been completed. For

best results, use 50% of the sensor scale of your target gas in an air balance with a flow rate of 0.25 to

0.5 LPM. The screen below will appear upon entering calibration mode. If Auto Cal was chosen during

the Product Settings and Configuration section please skip to section 4.2.3.

1. Unscrew and remove the sensor housing cap from the assembly.

2. Affix a Calibration Adapter Kit (sold separately) to the sensor housing of the device.

3. Affix a regulator to the calibration gas bottle.

4. Attach the tubing on the Calibration Adapter Kit to the regulator on the calibration gas bottle.

5. Ensure that the gas is flowing and watch the reading increase. When the reading stabilizes,

approximately 1 minute, use the ADD and SUB buttons to adjust the reading on the screen to match

the applied calibration gas concentration.

6. When calibration is complete, detach the Calibration Adapter Kit from the sensor housing and reaffix

the sensor housing cap. Press the MENU button to advance to the Low Alarm Setting screen.

42 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

OPERATION SETTINGS

4.2.3 CALIBRATING THE SENSOR (AUTO CAL)

You should ONLY perform the calibration of the sensor after the null process has been completed. For

best results, use 50% of the sensor scale of your target gas in an air balance with a flow rate of 0.25 to

0.5 LPM.

1. Press the ADD button to select “Yes” to begin the calibration process and to advance to the

calibration confirmation screen. If you do not wish to calibrate the sensor, press the SUB button to

select “No” to advance to the sensor radio address setting screen.

2. Press the ADD button to select “Yes” to confirm that you want to calibrate the sensor and to continue

to the concentration setting screen. If you do not wish to continue to calibrate the sensor, press the

SUB button to select “No” to advance to the sensor radio address setting screen.

3. Use the ADD and SUB buttons to adjust the concentration to the calibration gas being used. Press

the MENU button to save the gas concentration setting and to advance to the calibration start screen.

4. Affix a Calibration Adapter Kit (sold separately) to the sensor housing of the device.

5. Affix a regulator to the calibration gas bottle.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 43

OPERATION SETTINGS

NOTICE

Once the calibration countdown has started, the process cannot be stopped without disconnecting the

power from the unit.

6. Attach the tubing on the Calibration Adapter Kit to the regulator on the calibration gas bottle.

7. Ensure that the gas is flowing and press the MENU button to begin calibrating the sensor, the unit

will automatically begin the calibration process, the amount of time on the timer will vary based on

the gas type. During calibration, the display will show a countdown of the time remaining until the

process is complete.

8. When calibration is complete, detach the Calibration Adapter Kit from the sensor housing and reaffix

the sensor housing cap. Press the MENU button to advance to the Low Alarm Setting screen.

44 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

OPERATION SETTINGS

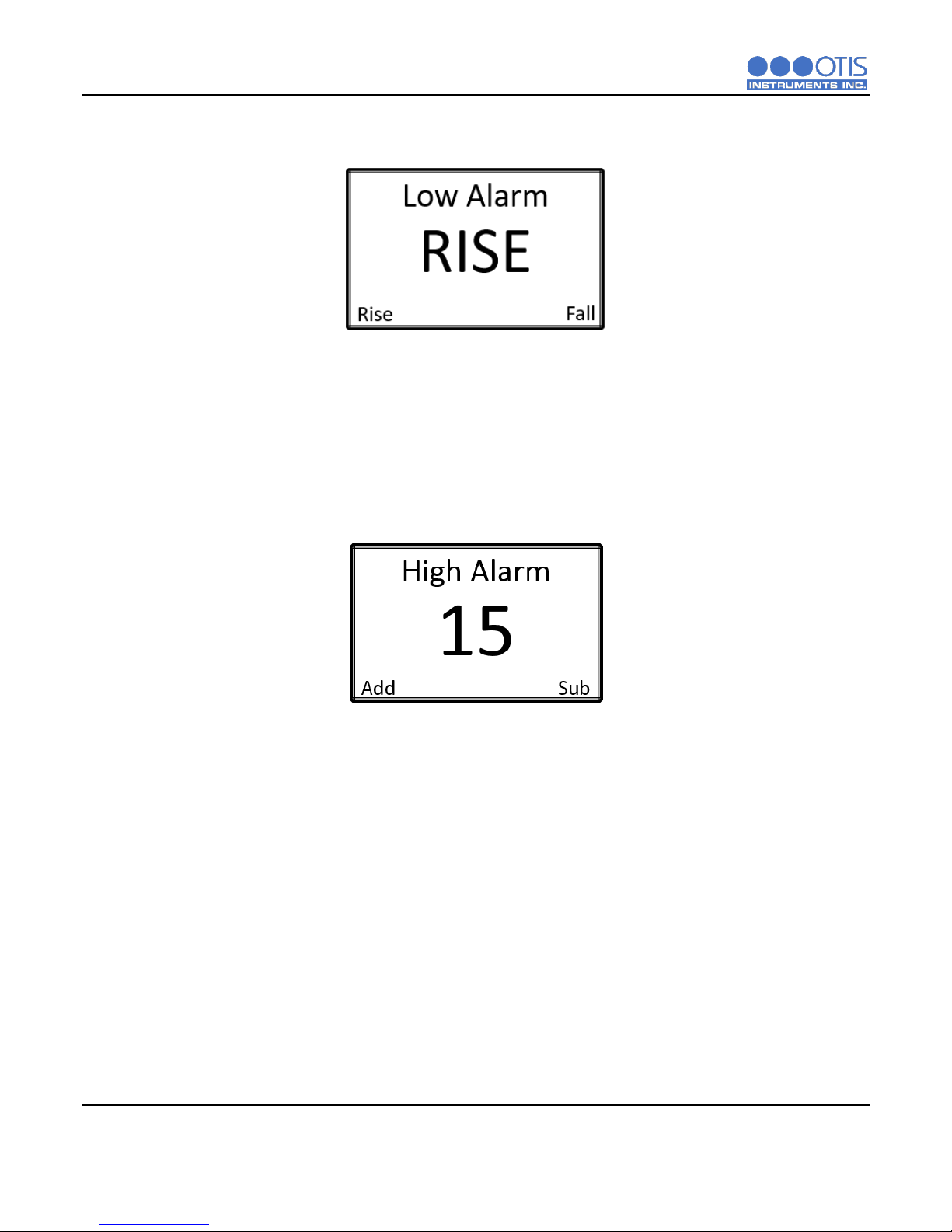

4.3 SENSOR ALARM SETTINGS

The OI-6000 has two alarm settings: LOW alarm and HIGH alarm. Regardless of whether the device includes the

optional two dry-contact relays, the system alarm settings are available on the device. All alarm set-points are field

adjustable up to 60% of the full scale gas concentration. The factory default setting on the OI-6000 for the LOW

alarm is 10% of full scale and 15% of full scale for the HIGH alarm. The LOW alarm set-point should NEVER be

programed to a higher setting than the HIGH alarm set-point.

Both alarms are configurable to activate on either a rising or falling level of gas. Most gas types activate alarms on

rising levels of gas. Oxygen is a special case and by default activates the LOW alarm when the detected gas

concentration FALLS below the LOW alarm set-point and the HIGH alarm when the detected gas concentration

RISES above the HIGH alarm set-point. The factory default setting for all other gas types is to activate when the

detected gas RISES above the alarm set-point.

When the gas concentration detected at the sensor meets or exceeds the LOW alarm set-point, the LOW alarm

indicator LED will illuminate amber. When the gas level meets or exceeds the HIGH alarm set-point, the HIGH alarm

indicator LED will illuminate red. The alarm indicator LEDs will not switch off until the gas level reading at the sensor

has fallen 10% below the alarm set-points or until the alarm is manually reset at the device, dependent upon the

relay latching/non-latching settings.

If the device includes the optional two dry-contact relays, Relay 1 and Relay 2, the LOW and HIGH alarm settings

will control the wired relays, respectively. When external alarming devices, such as alarm lights (visual) and horns

(audio) are wired to the device, as the alarm set-points are reached, the relays will become activated, as they are

wired and programmed to perform.

4.3.1 SENSOR LOW ALARM SETTING

1. Use the ADD and SUB buttons to increase and decrease the LOW alarm set-point, respectively.

2. Press the MENU button to save the desired setting and to advance to the sensor LOW alarm rise/fall

setting screen.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 45

OPERATION SETTINGS

4.3.2 SENSOR LOW ALARM RISE/FALL SETTING

1. Use the ADD and SUB buttons to select between activation on a Rising or a Falling gas level,

respectively.

2. Press the MENU button to save the desired setting and to advance to the sensor HIGH alarm setting

screen.

4.3.3 SENSOR HIGH ALARM SETTING

1. Use the ADD and SUB buttons to increase and decrease the HIGH alarm set-point, respectively.

2. Press the MENU button to save the desired setting and to advance to the sensor HIGH alarm rise/fall

setting screen.

46 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

OPERATION SETTINGS

NOTICE

The alarms will NOT activate, even in the presence of gas, until you have exited the menu mode for

approximately 1 minute.

For non-latching alarms, the alarms will NOT deactivate until the gas level reading at the sensor has fallen

10% below the alarm set-point.

4.3.4 SENSOR HIGH ALARM RISE/FALL SETTING

1. Use the ADD and SUB buttons to select between activation on a Rising or a Falling gas level,

respectively.

2. Press the MENU button to save the desired setting and to advance to setting the radio address (if

you have a radio module installed), otherwise you will return to Normal Operating Mode.

4.4 SENSOR RADIO ADDRESS

The OI-6000 radio address is adjustable from 1 to 255, each sensor assembly on the network needs a unique radio

address in order to avoid a fault at the receiving monitor. The default radio address is 1.

1. Use the ADD and SUB buttons to increase and decrease the sensor radio address, respectively.

2. Press the MENU button to save the desired setting and to exit the operation settings menu, and to

return the device to normal operating mode.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 47

OPERATION SETTINGS

NOTICE

The gas level reading MUST be below the alarm level setting before the alarm can be deactivated.

Press the MENU button ONLY once to deactivate the latching alarm(s). Pressing the MENU button more

than once will activate and open the operation settings menu.

The alarms will NOT activate, even in the presence of gas, until you have exited the menu mode for

approximately 1 minute.

4.5 MANUAL RESET FOR ACTIVATED LATCHING ALARMS

Relay alarms set to latching will not deactivate until the alarms are manually reset at the device. This includes LOW

and HIGH alarm indicator LEDs and optional wired relays. When latching alarms have been activated, refer to the

following instructions for how to manually deactivate the alarms on your device:

1. Verify that the gas level reading is below the alarm level setting.

2. Press the MENU button to deactivate latching alarm(s).

48 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

APPENDICES

5 PRODUCT MAINTENANCE

5.1 SCHEDULED MAINTENANCE

Otis recommends that our equipment be calibrated a MINIMUM of every 90 days, and STRONGLY advise that

calibration be performed every 30 days. Without knowing the specific application, sensor assembly location, gas

exposure and other factors, the company recommends monthly calibrations – assuming no damage or potential

damage has occurred to the sensor and that there has not been a power outage to the sensor assembly. If damage

has occurred or the power supplied to the sensor has changed, a calibration should be completed immediately.

Scheduled maintenance should include the null and calibration of the sensor and a relay test. Consult the Sensor

Calibration and Relay Test sections of this manual for further information and instructions on how to perform these

procedures.

The sensor head should be kept free of airborne particles, dirt, mud, spider webs, bugs and insects, and/or any other

debris that could potentially cover or coat the sensor. Keeping the sensor head clear of foreign articles will allow for

proper operation of the device. A brief inspection during scheduled maintenance should suffice, but dependent upon

the location and the environment in which the unit is installed, more frequent inspections may be warranted.

The OI-6000 may be adversely affected by the exposure to certain airborne substances. Loss of sensitivity or

corrosion may be gradual, if such materials are present in sufficient concentrations. The performance of the device

may be impaired during operation in the presence of substances that can cause corrosion on gold plating. Continuous

and high concentrations of corrosive gases may also have a detrimental long-term effect on the product’s service

life. The presence of such substances in an area does not preclude the use of this device, but the likelihood of the

shortened lifetime of the sensor element, as a result, should be noted. Use of the OI-6000 in these environments

may require more frequently scheduled maintenance to ensure safe and reliable system performance.

OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1 49

APPENDICES

CAUTION

The internal components can be static sensitive. Use caution when opening the enclosure and handling

internal components.

DO NOT use any metal objects or tools to remove the sensing element from the sensor adapter board.

5.2 SENSOR REPLACEMENT

The sensor elements used in the OI-6000 detects gas in either % or PPM concentrations, this element must be fully

functional in order for the system to operate correctly. Otis recommends replacing the sensing element whenever a

slow response to gas is observed during the normal calibration process. After replacing the sensing element the

device MUST then be nulled and calibrated for proper operation of the device.

1. Press and hold the SUB button for approximately 6 seconds, until “OFF” shows on the display

screen.

2. Unscrew and remove the sensor housing cap from the sensor housing base. Set aside.

3. Using the thumb and forefinger, gently unplug the sensing element from the sensor housing board.

4. Plug in the new sensing element into the sensor housing board. Ensure that the pins on the sensing

element align with the sockets on the sensor housing board.

5. Screw the sensor housing cap back onto the sensor housing base, ensuring that the sensor housing

cap is only tightened hand tight.

50 OI-6000-X-X-X-X-O OPS_GUIDE_REV 3.1

APPENDICES

OI-6000 Fault Codes

Problem

Cause(s)

Solution(s)

F1

Check

Sensor

Cable

1. The control board has lost communication with

the digital sensor interface adapter board.

1. Check connection between the sensor

housing connector header and the digital

sensor interface adapter board plug-in.

2. Replace the sensor interface adapter

board

F4

Check

Sensor

Board

1. The control board has lost communication with

the sensor interface board.

1. Replace the sensor interface board.

F5