High Lift Transmission Jack

525197

Head Assembly

Form No. 102737

Parts List &

Operating Instructions

for: 1728

014-00942

Max. Capacity: 1,000 lbs. at 90 PSI

The High Lift Transmission Jack is designed

for the installation and removal of automobile

transmissions.

Safety Precautions

CAUTION: To prevent personal injury and damage to equipment,

Read, understand, and follow all instructions, including the ANSI B30.1 safety code for

•

jacks.

Wear eye protection that meets the requirements of ANSI Z87.1 and OSHA.

•

Inspect the jack before each use; do not use the jack if it’s damaged, altered, or in poor

•

condition.

A load must never exceed the rated lifting capacity of the jack.

•

Use the jack on a hard, level surface.

•

Never move the jack with a load any higher off the ground than necessary. SLOWLY AND

•

CAREFULLY move the jack around corners, because the load could tip.

Do not modify the jack or use adapters unless approved or supplied by OTC.

•

Lower the jack slowly and carefully while watching the position of the load.

•

Use only approved hydraulic fluid (Chevron AW Hydraulic Oil MV or equivalent). The use of alcohol,

•

hydraulic brake fluid, or transmission oil could damage seals and result in jack failure.

This guide cannot cover every situation, so always do the job with safety first.

Parts List & Operating Instructions

Form No. 102737, Sheet 1 of 5, Back

Operating Instructions

This is a two-stage transmission jack. The air stage is designed to quickly move the adapter into position, and

is completed with an automatic lock function that prevents loss of load. The following hydraulic stage is designed

to align the adapter with the transmission.

1. Lift the vehicle on a hoist.

2. Position the jack under the transmission.

3. Connect the air supply to the jack. (90 psi of clean, dry air is required for the capacity of this jack.)

4. Press the pedal marked UP to raise the adapter until the cylinder locks into place (at about 20 inches). The

air hose can be removed at this time.

CAUTION: If a load is transferred to the adapter when the air cylinder is only partially raised, the

cylinder will drop suddenly. To eliminate this problem, always raise the cylinder to the point where the

mechanical lock engages.

5. Check the placement of the jack. The transmission’s center of weight, or balance point, should be centered

over the jack adapter, with the power output end located over the adapter bracket between the chains. The

jack’s mechanical lock must be engaged.

6. Close the hydraulic release valve by turning the knob clockwise (CW).

7. Pump the jack handle to finish raising the adapter to the transmission. Use the controls on the adapter to

roll or tip the adapter as needed to align it with the transmission.

8. Push in the four adapter brackets until they touch the transmission. Use the chains to secure the

transmission to the adapter.

9. Support the engine, and remove the transmission according to instructions in the vehicle service manual.

10. Slowly turn the hydraulic release valve counterclockwise to lower the hydraulic stage. Lower the air stage

by pressing the DOWN foot pedal. If the load is already resting on the mechanical lock, attach the air hose,

and press the UP pedal briefly so the mechanical lock will release. The air stage should then lower when

the DOWN pedal is pressed.

Bleeding Air from the Hydraulic System

Air can accumulate within a hydraulic system during shipment or after prolonged use. This entrapped air causes

the jack to respond slowly or feel “spongy.” To remove the air:

1. Tilt the jack onto two casters with the pump handle positioned below the cylinder.

2. Open the release valve by turning the knob counterclockwise (CCW).

3. Pump the handle until resistance is felt.

4. Close the release valve by turning the knob all the way clockwise (CW).

5. Continue pumping the handle while returning the jack to its upright position.

Parts List & Operating Instructions Form No. 102737

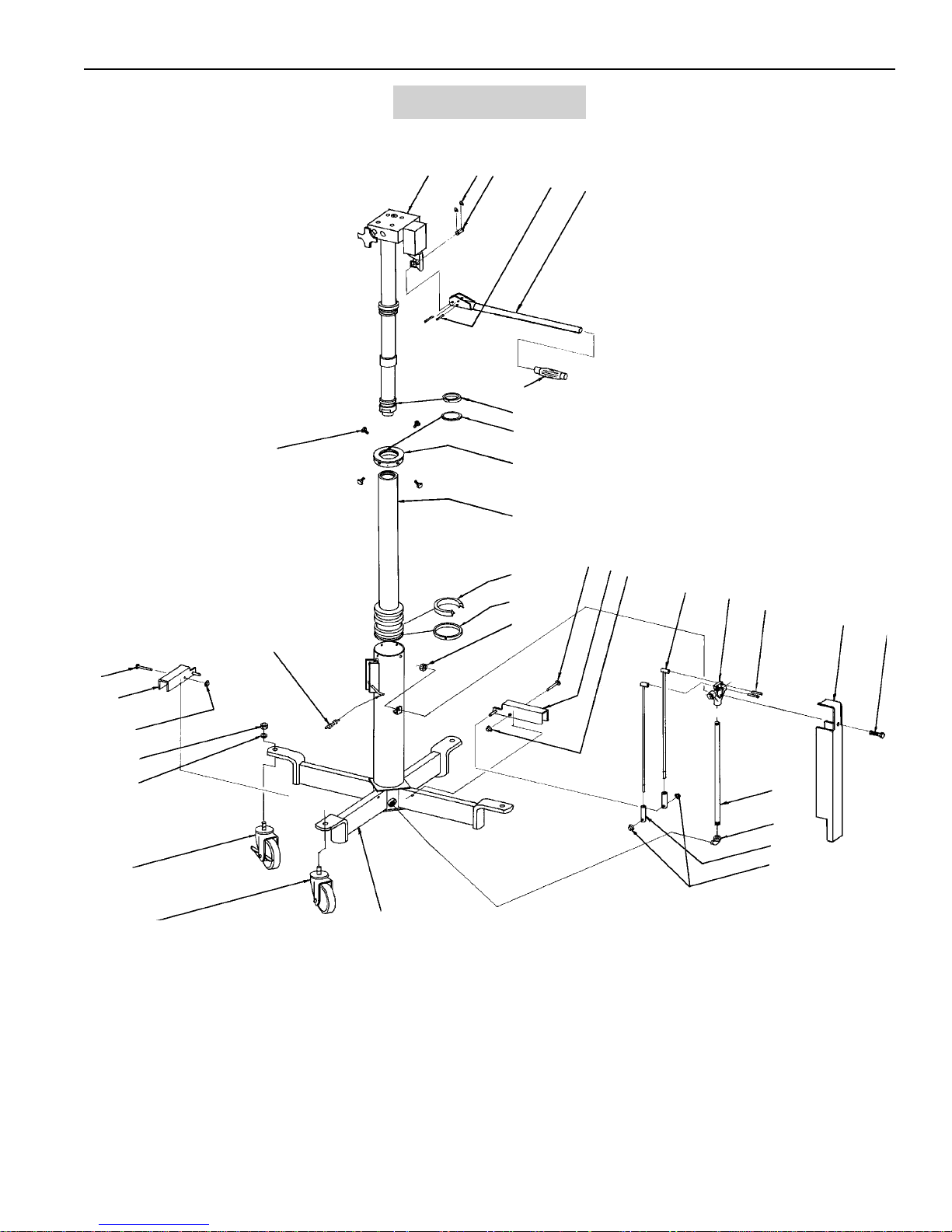

Jack Assembly

57

31

1

2

3

7

10

11

12

13

14

5

6

8

9

16

15

17

18

19

5

21

22

16

30

17

28

55

56

27

23

24

25

17

26

Parts List & Operating Instructions

525197 Head Assembly

Form No. 102737, Sheet 2 of 5, Back

45

46

47

32

29

39

4

44

43

42

41

40

39

38

33

37

36

33

48

34

37

49

50

29

51

54

35

32

34

33

32

47

52

53

33

Shaded areas reflect the last

revisions made to this form.

Parts List & Operating Instructions Form No. 102737

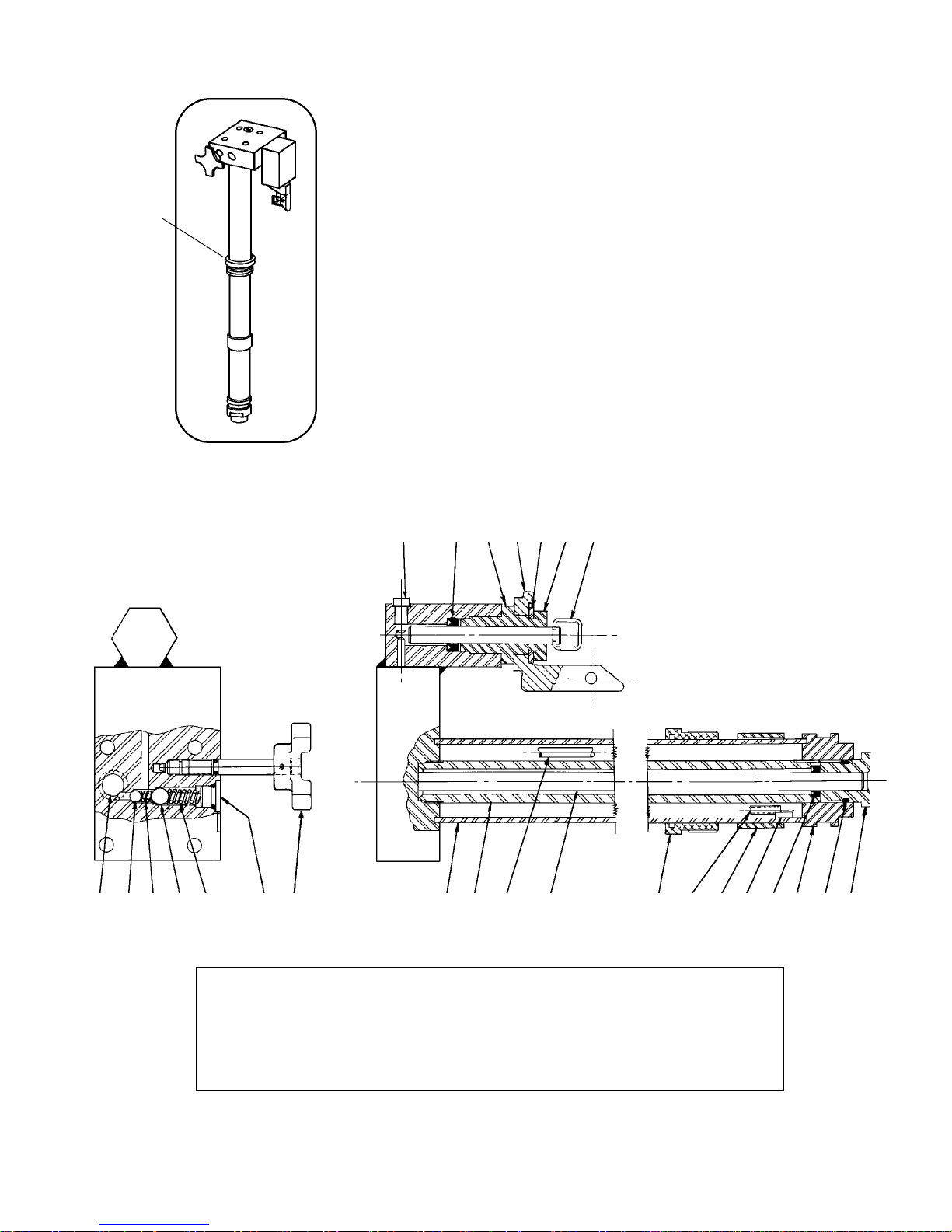

Hydraulic Unit

If the hydraulic unit needs service, it can be removed easily for repair or

shipment to a manufacturer-approved service center. If the unit is

Gland Nut

shipped, remove the platform assembly and handle to minimize package

size and weight. The hydraulic unit will separate from the jack by

removing the gland nut.

Hydraulic Unit Detail

65,66 63 62 61 60 59 64

85 84 83 82 81 85 80 79 78 77 76 74,75 73 72 71 70 69 68 67

Refer to any operating instructions included with the product for detailed information about

operation, testing, disassembly, reassembly, and preventive maintenance.

Items found in this parts list have been carefully tested and selected by OTC. Therefore: Use

only OTC replacement parts!

Additional questions can be directed to the OTC Technical Services Department.

Parts List & Operating Instructions

Item

No.

Part

No.

No.

Req'd

Description

1 1728-01 1 Hydraulic Unit

2 1728-02 2 Retaining Ring (1/8")

3 1728-03 1 Pump Shaft

4 1728-04 1 Transmission Bracket

5

1728-05 4 Roll Pin (1/4" x 1-1/2")

4

6 1728-06 1 Pump Handle Rod

7 1728-07 1 Handle Grip (7/8" ID)

8

9

10 1728-10 1 Gland Nut (4" bore;

11 1728-11 1 Piston Rod

12

13

1728-08 1 Wiper Ring (2")

u

1728-09 1 Felt Ring (2-3/4" OD)

u

507530 1 Gland Nut (4" bore;

(for serial no. 83-225639 and below)

507531 1 Piston Rod

1728-12 1 Seal (4" dia.)

u

1728-13 1 Ring Wiper (4" bore)

u

(for serial no. 83-225640 and above)

for serial no. 83-225639 and below)

for serial no. 83-225640 and above)

14 1728-14 1 Self-locking Nut (1/4"-20)

15 1728-15 1 Pedal (UP)

517189 1 Pedal (UP)

(for serial no. 48-020001 and above)

16 1728-16 2 Rivet (1/4" x 1-3/4")

17 1728-17 4 Palnut (1/4")

517190 4 Palnut (1/4")

(for serial no. 48-020001 and above)

18 1728-18 2 Control Rod

517186 2 Control Rod

(for serial no. 48-020001 and above)

19 1728-19 1 Air Valve

21 1728-21 1 Valve Cover

22 1728-22 1 Cap Screw (1/4" x 1-3/4")

23 1728-23 1 Pipe (1/4" x 14-3/4")

24 1728-24 2 Street Elbow (1/4")

25 1728-25 2 Rod End

517187 2 Rod End

(for serial no. 48-020001 and above)

26 1728-26 1 Base Weldment

27 1728-27 2 Caster (4")

28 1728-28 2 Caster w/ Brake (4")

29 1728-29 2 Self-locking Nut (1/2"-13)

30 1728-30 1 Pedal (DOWN)

517188 1 Pedal (DOWN)

(for serial no. 48-020001 and above)

31 1728-31 1 Spring

32 1728-32 3 Drilled Spacer

33 1728-33 5 Roll Pin (3/16" x 7/8")

34 1728-34 2 Cap Screw

35 1728-35 1 Side Tilt Crank

36 1728-36 1 Spacer (not drilled)

37 1728-37 2 Tilt Nut

38 1728-38 4 Ratchet Assembly

39 1728-39 2 Transmission Bracket (long)

40 1728-40 1 Chain & Snap Assembly

517191 1 Strap Assembly

(for serial no. 48-020001 and above)

41 1728-41 1 Transmission Bracket (short)

42 1728-42 1 Chain (1/0; 42 links)

517192 1 Cap Screw & Washer

(for serial no. 48-020001 and above)

43 1728-43 4 Roll Pin (1/4" x 7/8")

44 1728-44 1 Adapter Weldment

45 1728-45 3 Angle Stop

Parts List & Operating Instructions Form No. 102737

Item

No.

Part

No.

No.

Req'd

Description

46 1728-46 1 Side Tilt Shaft

47 1728-47 2 Tilt Trunnion

48 1728-48 1 Pivot Bracket

49 1728-49 4 Cap Screw (3/8" x 1)

50 1728-50 4 Lockwasher (3/8")

51 1728-51 1 Hydraulic Unit Bracket

52 1728-52 1 Long Tilt Shaft

53 1728-53 1 Crank (lower)

54 1728-54 1 Tow Handle

55 1728-55 4 Hex Jam Nut (1/2")

56 1728-56 4 Lockwasher (1/2")

57 1728-57 4 Self-locking Cap Screw (3/4" long)

59

60

1728-59 1 Jam Nut (3/4"-l 6 UNF)

4

1728-60 1 Rim Washer

4

61 1728-61 1 Swivel Pivot

62

63

64

1728-62 1 Pump Sleeve

4

1728-63 1 Seal (13/16" OD x 7/16" ID x 1/4" deep)

4ju

1728-64 1 Plunger Weldment

4j

65 1728-65 1 Soc. Hd. Cap Screw (5/16"-18 UNC)

66 1728-66 1 Metallic Gasket

67 1728-67 1 Ram Guide

68

1728-68 1 O-ring (1" OD x 3/16" ID x 3/32" dia.)

u

69 1728-69 1Cap

70

1728-70 1 Seal (11/16" OD x 7/16" ID x 3/16" deep)

u

71 1728-71 1 Magnet

72 1728-72 1 Spacer

(for serial no. 83-225639 and below; not needed for

serial no. 83-225640 and above)

73 1728-73 1 Suction Tube (22-5/8" long)

74

75 1728-75 1 Packing Gland (2" bore;

1728-74 1 Felt Packing Gasket

u

507532 1 Packing Gland (2" bore;

for serial no. 83-225639 and below)

for serial no. 83-225640 and above)

76 1728-76 1 Ram

77 1728-77 1 Suction Tube (6" long)

78 1728-78 1 Cylinder Tube

79 1728-79 1 Reservoir Tube

80 1728-80 1 Release Knob Sub-assembly

81 1728-81 1 Compression Spring (.406 OD)

82 1728-82 1 Ball (3/8" dia. RC)

83 1728-83 1 Compression Spring (.250 OD)

84 1728-84 1 Ball (1/4" dia. RC)

85 1728-85 2 Plug w/ o-ring

221089 1 Two-piece Plunger Kit (items marked with

221088 1 Complete Plunger Kit (items marked with

221090 1 Soft Seal Kit (3") (items marked with u)

525797 1 Head Assembly

Available Kits

4

j)

)

Parts List & Operating Instructions

221598 Adapter Set

(used on 014-00942)

Form No. 102737, Sheet 4 of 5, Back

1

6

5

4

Item

No.

1 54370 1 Adapter

2 313559 1 Mounting Bracket

3 16469 4 Cap Screw

4 10204 2 Hex Nut

5 221597 1 Stem

6 10208 1 Hex Nut

Part

No.

No.

Req'd

3

Description

2

Parts List & Operating Instructions Form No. 102737

Maintenance

Adding Oil to the Hydraulic Stage

1. Position the jack upright with all four casters on the floor. Lower the hydraulic

(See Figure 1)

Mounting Bolts

stage.

2. Remove the transmission adapter by removing the four bolts holding it to the

jack.

3. Clean the top of the jack, concentrating on the area around the filler plug.

Filler

Plug

4. Remove the release knob. This serves as a vent while the reservoir is being

filled.

5. Remove the filler plug.

6. Slowly add Mobile DTE #11 oil (or equivalent) until the reservoir overflows.

7. Install the release knob.

8. Install the filler plug, and mount the adapter.

Cleaning the Air Control Valve

(Item numbers refer to Figure 2)

Figure 1

Release

Knob

1. Remove the fittings (1) from the ends of the air control valve. Clean the screen.

2. Insert a nail or stiff wire into the center of the control body (3), and push each valve spool (2) out of the body.

3. Look for foreign matter embedded in the valve seals (4). If this is the case, remove the screw (5) and cup

(6) from the end of the spool, clean the seat, turn it over, and reassemble.

4. Lubricate the valve spool with light chassis grease.

5. Assemble the valve in this order: insert the valve spools; insert the springs; assemble the hexagon fittings

into the body.

1

5

6

4

Air Valve (1728-19)

1 Fitting

2 Spool

3 Body

2

4 Seal

5 Screw

3

Figure 2

6 Cup

2

4

6

5

1

Parts List & Operating Instructions

Preventive Maintenance

IMPORTANT: The greatest single cause of failure in hydraulic units is dirt. Keep the transmission jack

clean and well lubricated to prevent foreign matter from entering the system. If the jack has been exposed to

rain, snow, sand, or grit, it must be cleaned before it is used.

1. Store the jack in a well-protected area where it will not be exposed to corrosive vapors, abrasive dust, or

any other harmful elements.

2. Lubricate moving parts at least once per month.

3. Regularly wipe the cylinder columns with a clean cloth to remove dirt and abrasives.

4. Replace the oil in the reservoir at least once per year.

5. Inspect the jack before each use. Take corrective action if any of the following problems are found:

a. Cracked or damaged housing d. Scored or damaged piston rod

b. Excessive wear, bending, or other damage e. Loose hardware

c. Leaking hydraulic fluid f. Modified or altered equipment

Troubleshooting Guide

Repair procedures must be performed in a dirt-free environment by qualified personnel who are familiar with

this equipment.

Trouble Cause Solution

Air Stage - Air leak causes 1. Air valve is dirty

mechanical lock to engage or

erratic cylinder action

Air Stage - Cylinder does not 1. Mechanical lock is engaged

lower when DOWN pedal is

pressed

Hydraulic Stage - Cylinder does 1. Jack is out of prime

not raise

Hydraulic Stage - Cylinder lifts 1. Release valve is not sealing

load, but doesn’t hold

2. System oil is dirty

Hydraulic Stage - Cylinder does 1. Low oil level

not raise to full height

1. Follow instructions to

clean air valve.

1. Attach air hose and

press UP pedal until

cylinder is at full line

pressure. Press DOWN

pedal and mechanical

lock should release.

1. Follow instructions

on bleeding air from the

hydraulic system.

1. Clean or reseat

release valve ball.

2. Replace hydraulic oil.

1. Check oil level.

Follow instructions

on adding oil.

OTC puts everything within reach.

Learn more about garage accessories we have.

Loading...

Loading...