OSTBERG HERU S AC, HERU 19 S AC, HERU 14 S AC, HERU 35 S AC, HERU 52 S AC Installation And Directions For Use

Installation and

directions for use

HERU S AC

UL VERSION. Choose language and unit system in the Setting Menu on page 15.

WARRANTY

Warranty period valid according to purchase contract

calculated from date of purchase.

SCOPE OF WARRANTY

This warranty covers faults occurring during the warranty period, which have been notified to the dealer

or verified by Ostberg Americas Inc. (warrantor) or a

representative of the warrantor, and which concern

design, manufacturing or material defects and consequential damages occurring on the product itself.

The above mentioned faults will be rectified so that

the product is made operational.

GENERAL WARRANTY LIMITATIONS

The warrantor’s responsibility is limited in accordance with these warranty terms and the warranty does

not cover property damage or personal injury. Verbal

promises made in addition to this warranty agreement are not binding for the warrantor.

WARRANTY LIMITATIONS

This warranty applies on condition that the product

is used in a normal fashion or under comparable circumstances for its intended purpose and that the

instructions for use are followed.

- Settings; information on use, care, handling, service

or cleaning that are customarily described in the

instructions for use; or works caused by the user

neglecting to observe warning or installation

instructions; or investigation of such are not

covered by the warranty.

- The warrantor is responsible only for the operation

if approved accessories are used.

- The warranty does not cover product failures

caused by accessories/equipment from other

manufacturers.

The unit’s current settings must be noted in the

installation/mounting instructions at installation to

avoid costs in the event of fault. The warrantor is not

liable for costs such as adjustment costs related to

the replacement of fans and control boards in the

unit.

SERVICE TERMS DURING

THE WARRANTY PERIOD

According to your agreement with your local distributor.

This warranty does not cover faults caused by:

- Transport of the product.

- Careless use or overstraining of the product.

- Failure on the part of the user to follow instructions concerning installation, use, maintenance,

care and handling.

- Incorrect installation or incorrect positioning of

the product.

- Conditions that are not due to the warrantor, e.g.

excessive voltage variations, lightning, fire and

other accidents.

- Repair, maintenance or design changes made by

an unauthorized party.

- Faults that do not impact operation, e.g. surface

scratches.

- Parts that through handling or normal wear are

exposed to greater than average hazard, e.g. lamps,

glass, ceramic, paper and plastic parts, and filters

and fuses are not covered by the warranty.

RECTIFICATION MEASURES

WHEN A FAULT IS DETECTED

When a fault is detected, the customer must notify

this to the dealer. Specify what product this applies

to (part number and manufacture date – year and

week – are listed on the product label), and describe

the fault and how it occurred as accurately as possible. For a warranty repair to be performed, the customer must prove that the warranty is valid by presenting the receipt of purchase. After the warranty

period has expired, warranty claims that have not

been made in writing before the expiration of the

warranty period will not be valid.

In all other respects according to our conditions

of sale.

NOTE!

Ostberg Americas Inc. reserve the right to make

changes without further notice.

CONTENTS

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

UNIT DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . .4

INSTALLATION AND SECURITY . . . . . . . . . . . . . .5

”USE” ”SECURITY” ”MOUNTING” . . . . . . . . . . . . . . . . .5

”PLACING” ”FREE SPACE” . . . . . . . . . . . . . . . . . . . . . . .6

”ASSEMBLY INSTRUCTIONS” . . . . . . . . . . . . . . . . . . . . . .6

”SCHEMATIC DIAGRAMS FOR PLACING” . . . . . . . . . . . .6

STARTING UP THE UNIT . . . . . . . . . . . . . . . . . . . .7

CONTROL DIAGRAM . . . . . . . . . . . . . . . . . . . . . .8

REGULATION FUNCTIONS . . . . . . . . . . . . . . . . . .9

OPERATING THE CONTROL UNIT . . . . . . . . . . .10

VIEW MODES 1-3 . . . . . . . . . . . . . . . . . . . . . . . .11

MAIN MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

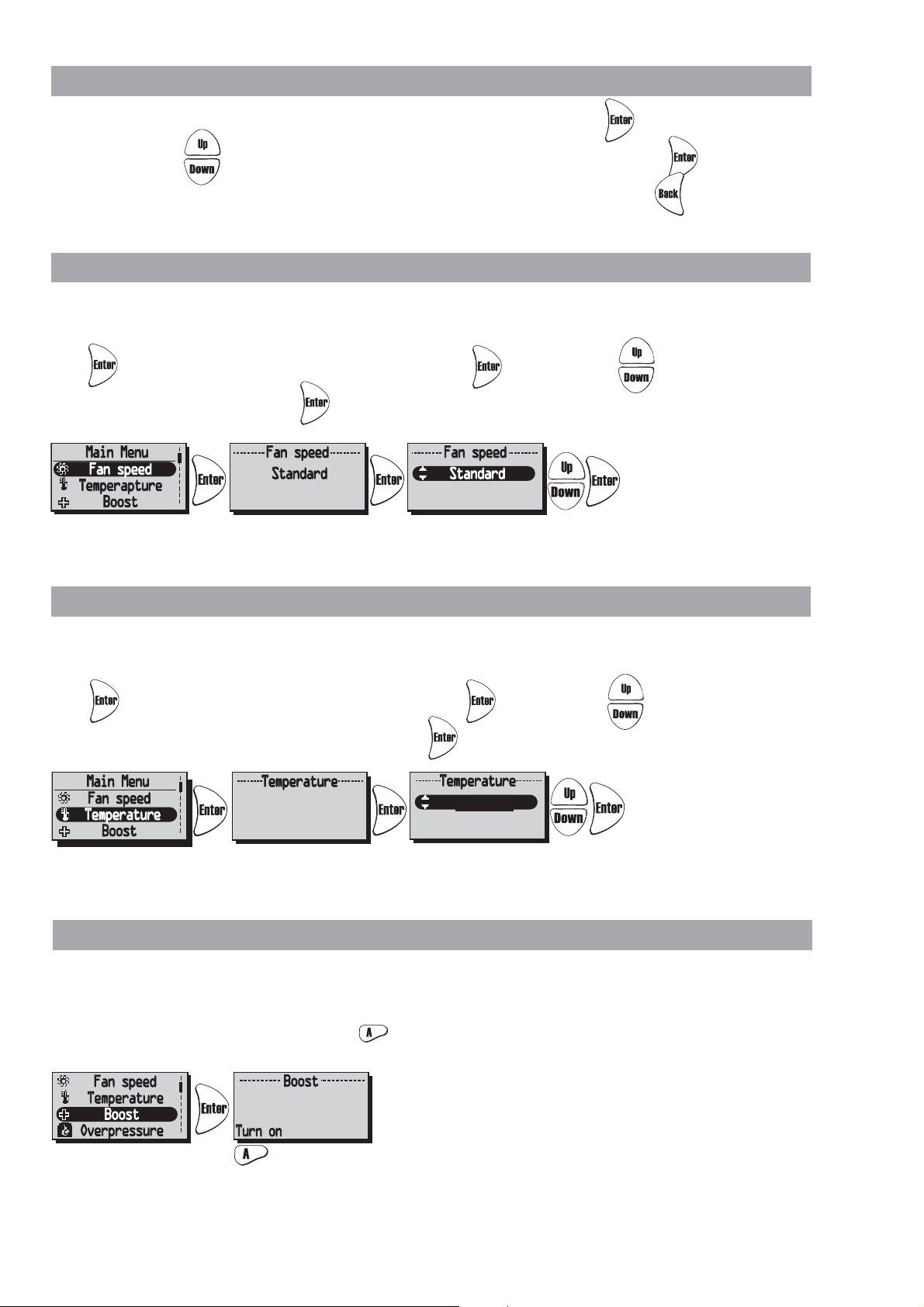

”FAN SPEED” MENU . . . . . . . . . . . . . . . . . . . . . .12

”TEMPERATURE” MENU . . . . . . . . . . . . . . . . . . .12

”BOOST” MENU . . . . . . . . . . . . . . . . . . . . . . . . .12

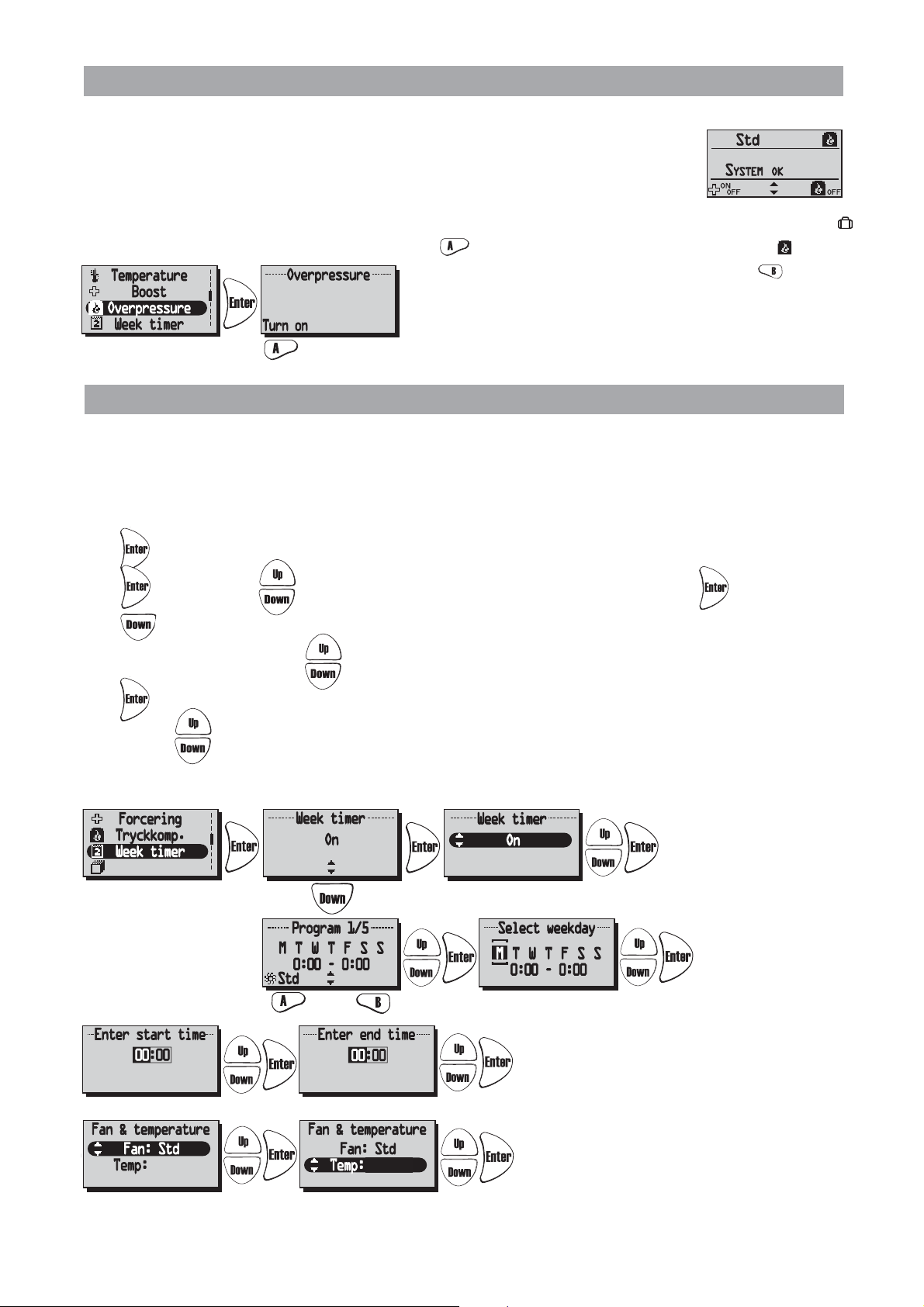

”OVERPRESSURE” MENU . . . . . . . . . . . . . . . . . .13

”WEEK TIMER” MENU . . . . . . . . . . . . . . . . . . . .13

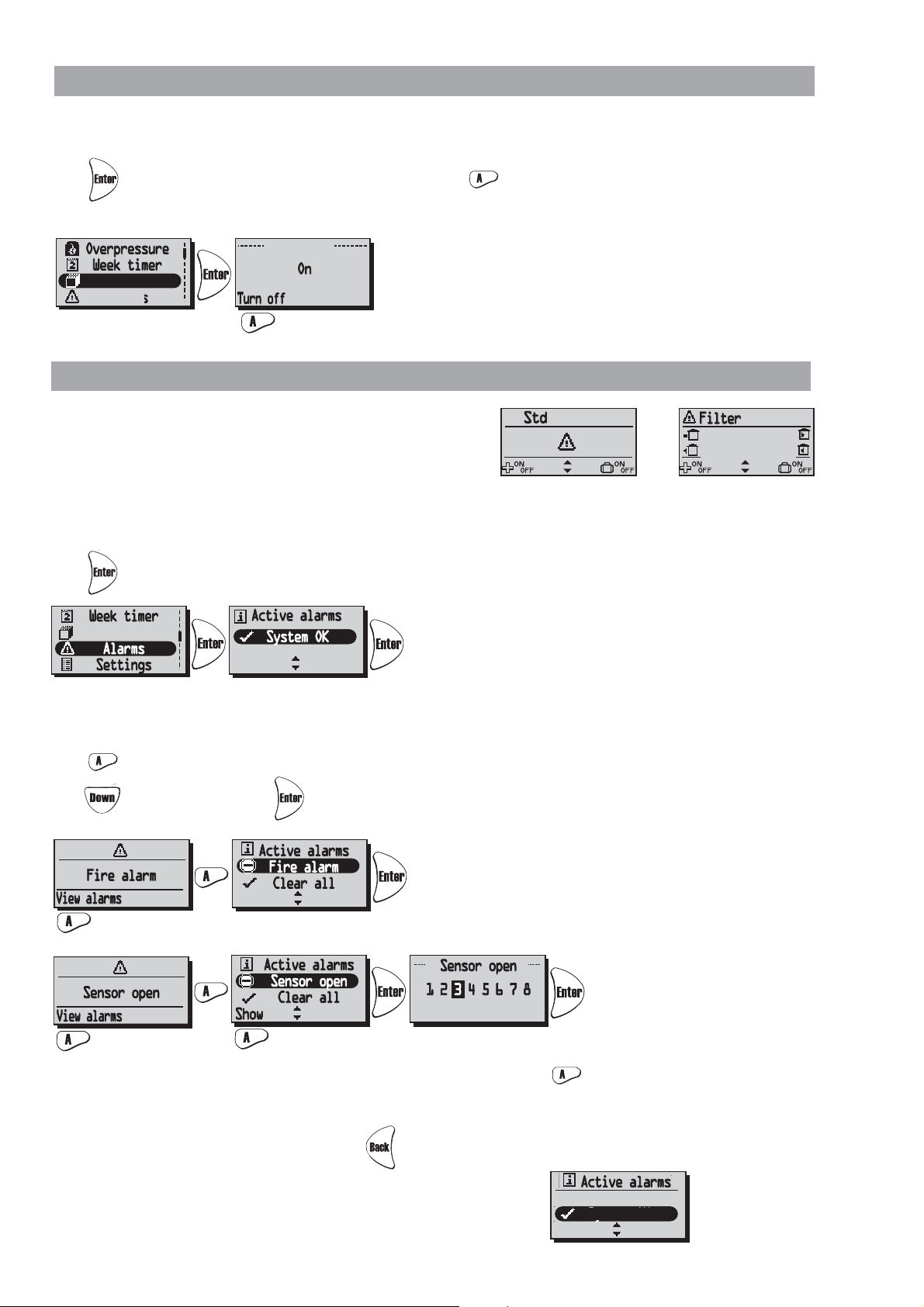

”POWER ON/OFF” MENU . . . . . . . . . . . . . . . . .14

”ALARMS” MENU . . . . . . . . . . . . . . . . . . . . . . . .14

”SETTINGS” MENU . . . . . . . . . . . . . . . . . . . . . . .15

THE ”SERVICE MENU” . . . . . . . . . . . . . . . . . .15-23

”PRESSURE INPUTS” ”FILTER MEASUREMENT”

”AC FAN SETUP” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

”DISPLAY CONTRAST” ”BOOST”

”OVERPRESSURE” ”MAX TEMPERATURE” . . . . . . . . . . .17

”ALARM” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

”CO2” ”RH” ”HEATER” . . . . . . . . . . . . . . . . . . . . . . . .19

”COOLER” ”SUPPLY LIMITS”

”REGULATION MODE” ”MODBUS” . . . . . . . . . . . . . . . .20

”SUMMER COOLING” ”FREEZE PROTECTION”

”FLOW DIRECTION” . . . . . . . . . . . . . . . . . . . . . . . . . . .21

”SENSOR CALIBRATION” ”LOAD/SAVE SETTINGS”

”VERSION INFO” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

”DEVICE PAIRS” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

CHANGING FROM EC TO AC MODE . . . . . . . . .23

OTHER FUNCTIONS . . . . . . . . . . . . . . . . . . . . . .23

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24-25

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . .26

SPARE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . .27

ERROR DETECTION DIAGRAM . . . . . . . . . . .28-29

ERROR DETECTION . . . . . . . . . . . . . . . . . . . . . . .30

INTERNAL SETTINGS . . . . . . . . . . . . . . . . . . . . .31

TECHNICAL INFORMATION

DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . .34

FLOW DIRECTION . . . . . . . . . . . . . . . . . . . . . . . .35

TECHNICAL DATA . . . . . . . . . . . . . . . . . . . . . . . .35

SOUND DATA . . . . . . . . . . . . . . . . . . . . . . . .36-37

PRESSURE/FLOW DIAGRAMS . . . . . . . . . . . .38-39

WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . .40-41

This ”Installation and directions for use” contains following products:

HERU 14 S AC, HERU 19 S AC, HERU 35 S AC and HERU 52 S AC.

IMPORTANT! Please read this manual before installing the unit.

HERU 14 S AC

HERU 19 S AC

HERU 52 S AC

UNIT DESCRIPTION

• HERU S is approved according to the standard

UL 1812 ”Ducted Heat Recovery Ventilators” and

CSA-C22.2 No. 113 ”Fans and Ventilators”.

• HERU S is a heat recovery unit (HRV) or an energy recovery unit (ERV). It is designed for supply

and exhaust air ventilation combined with heat

and cool recovery.

• HERU S can be used in both residential and commercial applications such as homes, apartments,

offices and schools etc. where there is a need for:

-clean. filtered and fresh air

-high temperature efficiency

-energy saving

-safe and quiet operation

• HERU S;

- has a rotating heat exchanger, of hygroscopic or

non-hygroscopic type and is manufactured of aluminium, placed centrally in the unit. The ERV exchanger has a humidity efficiency of up to 85%.

The HRV exchanger has a temperature efficiency

of up to 85%.

- has backward curved centrifugal fans with maintenance free external rotor motors, which are connected with quick contacts, and are easy to

remove for cleaning.

HERU 35 S AC

- has built-in control for heating/cooling.

- can be fitted with a built-in electric heater.

- has as standard, disposable bag filters,

class MERV 13.

- has a wireless remote controller for the operation

and monitoring of the unit.

- has as standard, Modbus communication via

RS485.

- has a double skinned galvanised sheet steel casing

with intermediate insulation.

• The HERU S can be mounted in either warm or

cold space.

• The HERU S is delivered galvanized.

• All HERU S are operated via a wireless remote

controller which can operate and to preset the required parameters as well as monitor the unit’s

status. The operating range is approximately 50

meters/164 feet.

The antenna which is placed next to the unit can

have the range reduced if there are heavy reinforcing bars in the concrete structure and it should

then be moved either to a position where the signal is not shielded or nearer to the controller.

4

INSTALLATION AND SECURITY

USE

• To achieve as comfortable indoor climate as possible and to avoid moisture damage to the property, the house needs a continuous and adequate ventilation. The unit must run continuously and only

be stopped for maintenance.

The air flow is controlled by settings in the wireless control unit:

Away – Reduced airflow, can be used when no one

is at home.

Normal – This is adjusted by the installer and

should not be changed by the user.

Boost – A higher air flow than normal, selectable

medium/max. Should be used when there is a need

for a higher air flow than the default mode is

adjusted for, such when cooking, drying laundry,

shower and sauna.

Recommendations for drying laundry: Because of

the high moisture content, an exhaust air tumbler

or a drying cabinet should not be connected to the

system. We recommend a condensing tumbler

without duct connection.

• When installing HERU consideration must be

given to any approval authority requirements and

recommendations concerning siting, accessibility,

electrical connections, etc.

• The HERU unit is accessible for the user, according to IEC 60335-2-40, to by themselves do the

service and maintenance, according to this

Directions for use. But before this work the unit

must be currentless.

With reservation according to IEC 60335-2-7.12

”This appliance is not intended for use by persons

(including children) with reduced physical, sensory or metal capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning use of the appliance

by a person responsible for their safety.”

”Children should be supervised to ensure that they

do not play with the appliance.”

• The HERU unit should be storage in a sheltered

and dry place before installation.

• Dimensioned air flow should not exceed 60% of

the unit's maximum capacity.

• Check at regular intervals that supply air and exhaust air works.

• To avoid condensation in the unit during the cold

season, the unit should not be turned off for a

longer period. When installed in warm moisturre

environment as e.g. bathroom and utilityroom condense may appear on the outside of the unit at low

outside temperatures.

currentless. If there is a need of changing or complement any electrical components, it should be

done by a qualified person.

• The HERU unit includes rotating parts that could

cause serious danger on the occasion of contact.

This is why the unit must be duct connected and

the lid closed with the screws tightened, before

starting up the unit.

• After the current is cut for service and maintenance the electric heater may still be warm.

• Make sure that the access cable is not damage

when mounting and installation.

• HERU must be equipped with residual-current

device (RCD).

• The HERU S needs a permanent electrical supply.

• The unit must be connected via a safety switch.

Any electrical connections must be made by a qualified electrician.

• Keep in mind that rotating, warm and electrical

components can cause serious damage.

MOUNTING THE HERU S

• HERU S should be installed according to the

assembly instructions. See picture on next page.

• Place the unit on a insulation board, min. 2 inch.

• Supply and exhaust air must be duct connected on

the same side of the unit.

• Acoustic silencer should be planned with the help

of sound data and required sound levels.

• Use duct clamp or flange with encompassing insulation when connecting to duct.

• If the supply and the exhaust air ducts are installed

in a cold space they should be insulated. To prevent condensation the supply air duct should also

be insulated if installed in warm space at low supply air temperatures.

• The fresh air and extract air duct should always be

condense insulated.

• The ducts should be insulated all the way towards

the unit.

• The duct sensor GT7 should be mounted in the

supply air duct, and the antenna on a suitably position beside the unit (not against metal).

• If a heating coil is connected a cut off damper must

be mounted in the fresh air duct.

• Cooker hoods must not be connected to the

HERU S because of the increased cleaning demand.

• Ducting must be conntected to external ground on

the unit, see picture.

SECURITY

Caution! Do not apply electric power until after

completion of the installation. Ensure the installation

and wiring is in accordance with CEC, NEC and

local electrical codes..

• Attention, look out for sharp edges and corners on

the HERU unit and fans.

• Consider the weight of the unit. See page 35.

• Before maintenance work the HERU unit must be

External

ground.

5

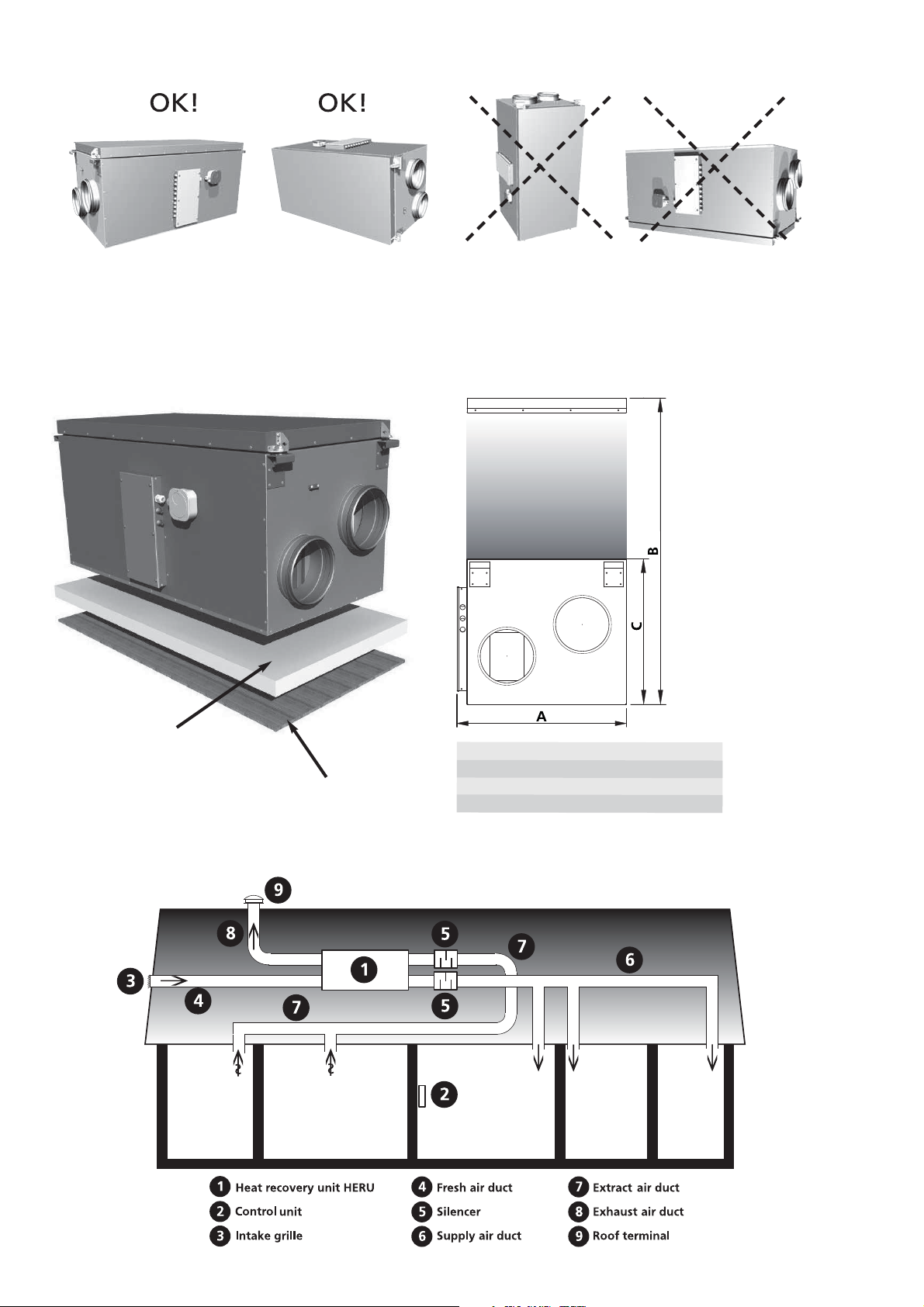

PLACING THE HERU S UNIT

A B C D

The HERU S should be installed with the lid upwards (A) or on the side (B). Because of the risk of injury

we do not recommend installing the unit vertically (C) or with the lid downwards (D). Allowances must be

made to access the unit for servicing or maintenance.

ASSEMBLY INSTRUCTION

INSULATION BOARD

min. 2 inch

FLOOR

CLEARANCEE FOR SERVICING

AND MAINTENANCE

Clearance for servicing

and maintenance

Inch A+D B C

H E R U 14 S/19 S 21

H E R U 35 S 24 39

H E R U 52 S 28 48 24

7/8

1/2

31

16

3/8

1/2

20

7/8

SCHEMATIC DIAGRAM FOR HERU S PLACED IN AN ATTIC

6

STARTING UP THE UNIT

NB! Important information before starting!

WARNING!

Improper installation, adjustment, alternation, service or maintenance can cause property damage, per-

sonel injury or loss of life.

Installation and service must be performed by a

qualified installer or service agency.

Carefully read through the manual before starting

up the unit.

• NB! Always mount the temperature sensor GT7 in

the supply air duct. See page 8. GT7 is connected at the relay card.

• The antenna should be mounted outside the unit.

The antenna for HERUS is connected ans is located in the connection box when delivered.

NB! The antenna should not

any metal area or metal items as this will shield

the signal.

The antenna should be mounted as central as

possible. This to achieve the best signal all over

the house. If needed an extension cord is available

as an accessorie.

• Install the 3 AA batteries in the wireless control

unit that are placed inside the HERU

vered.

• HERU starts automatically (with a few minutes delay) when the power is switched on, or

alternative with the wireless control unit. At power

outage, always check so the unit is starting up

again.

be mounted against

®

when deli-

• HERU S is supplied for right handed application,

see picture below. If the unit is installed left

handed, and no electrical heater is fitted, changes

can be made in the ”Service Menu” and in the submenu ”Flow Direction”. See page 20.

• Important when adjusting the flow: Go to Service

Menu (password 1199), choose “AC -motor setup”.

This disable functions such as Summer cooling or

Boost during flow adjustment. The fan speed is

standard. See page 21.

When adjusting the airflow of AC-fans there is a

possibility to change the voltage for the different

fan speeds via the separate transformers for supply

resp. exhaust fan. Normal operation should be

done in standard mode. Wiring diagrams with trans-

former steps see pages 40-41.

All HERU S has 7-step transformers. See wiring

diagrams on pages 40-41.

Note! When ajusting fan speed manully, make

sure that the speed keeps the sequences.

• All HERU can be fitted with a built-in electric

heater. Choose heater ”On/Off” according to the

instruction on page 19. For a heating coil see

instruction on page 19.

• Set the temperature according to the instruction

on page 12.

• Save settings according to the instruction on page

22.

• Note! The unit must not be operating without

filter.

EXHAUST

AIR

FRESH

AIR

EXTRACT

AIR

SUPPLY

AIR

CONTROL CABINET

7

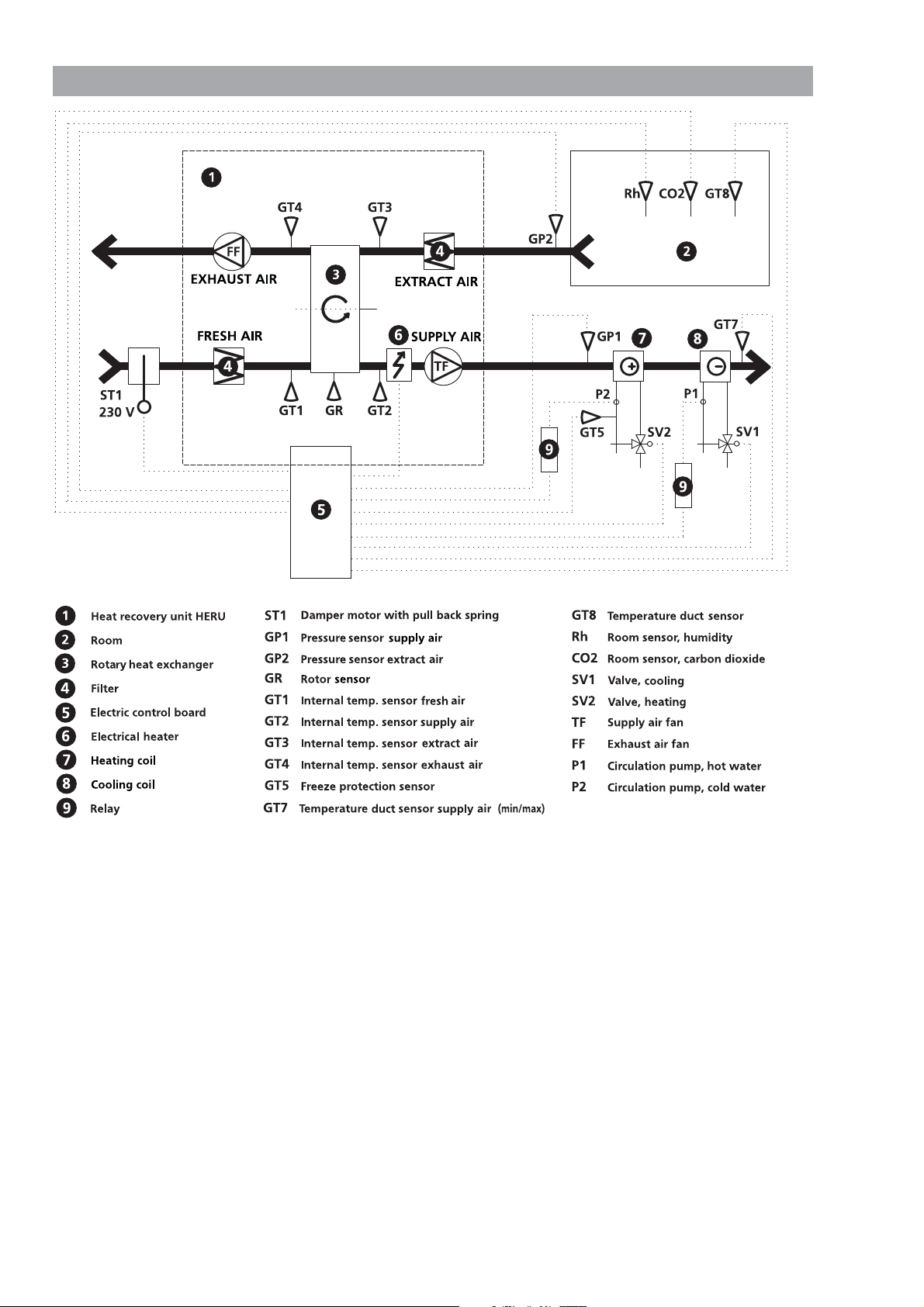

CONTROL DIAGRAM HERU S

shows all sensors, flow direction right

*Accessories

*

*

*

*

*

*

*

*

*

*

*

*

*

8

REGULATION FUNCTIONS

REGULATE THE TEMPERATURE

The air temperature can be regulated either for constant supply air temperature, constant room temperature or constant exhtract air temperature.

For constant room temperature a sensor should be

placed in the room for room regulation (this is also

suitable when a cooling coil is incorporated in the

system).

Extract air regulation functions in a similar way

but with the difference being that the sensor is

placed at the extract air of the unit.

The temperature can be regulated in 5 sequences:

1.Cooling recovery + After cooling: The regulation

unit can regulate a cooling coil (e.g. cooling water

from bedrock), when the cooling recovery from

the rotor is not enough.

2.Cooling recovery or regulated after cooling: The

rotary heat exchanger starts if the extract air tem-

perature is lower than outside temperatur.

Regulated after cooling: The aftercooling starts

when the outside temperature is lower than de-

sired room temperature and is not enough to lower

the room temperature.

3.Outside temperature = desired temperature: When

the outside temperature is the same as desired sup-

ply air temperature the rotor stops.

4.Heat recovery: The rotary heat exchanger starts to

recover the warmer room temperature.

5.Heat recovery + heat: In climate conditions where

the rotary heat exchanger, in spite of its high effi-

ciency, is not sufficient to reach the desired supply

air temperature, the controller can regulate either

the built-in electric duct heater or a heating coil.

FAN CAPACITY

Airflow (fan speed) is regulated via the week timer

that can be programmed for specific time points

when the fan speed should change from one speed to

antoher (e.g. home or away setting). A special feature

is that you can pressure compensate when supplementary heating, using an open fire or stove (the

extract air fan then drops to a lower speed).

With the weektimer function it is possible to

schedule different fan speeds e.g away/boost or

standby. The fan speed can also be controlled by a

carbon dioxide (CO

that the unit gives a higher airflow (boost) when the

maximum limit value has been exceeded.

”Summer Cooling” is a function where you can use

the cool outside temperature to cool down the inside

air. The fan speed is boosted when the ratio between

the outside temperature and the extract air temperature is within the programmed criteria.

Via the wireless control unit the HERU can be put in

an ”Off mode”, which means that the motors for fans

and rotor are ”Off” but the unit is ”Stand by”. If there

is a requirement of totally cut off power, a disconnect switch must be mounted on the main electrical

feed.

Boosting the airflow for a specified time can be done

via the wireless control, there is also a opportunity to

do that via a timer connected to the ”0” and ”Boost”

connection on the PCB. With the connectors closed

the boost function will be ”On”.

) and humidity (RH) sensor so

2

Regulated

after cooling

0-100%

Rotor 100%

1.

Cooling recovery

+

After cooling

Regulated rotor

0-100%

2.

Cooling recovery

Regulated rotor

0-100%

4.

Heat recovery

or After cooling

3.

Outside temperature = Desired temperature

9

Regulated

after heating

0-100%

Rotor 100%

5.

Heat recovery

+

After heat

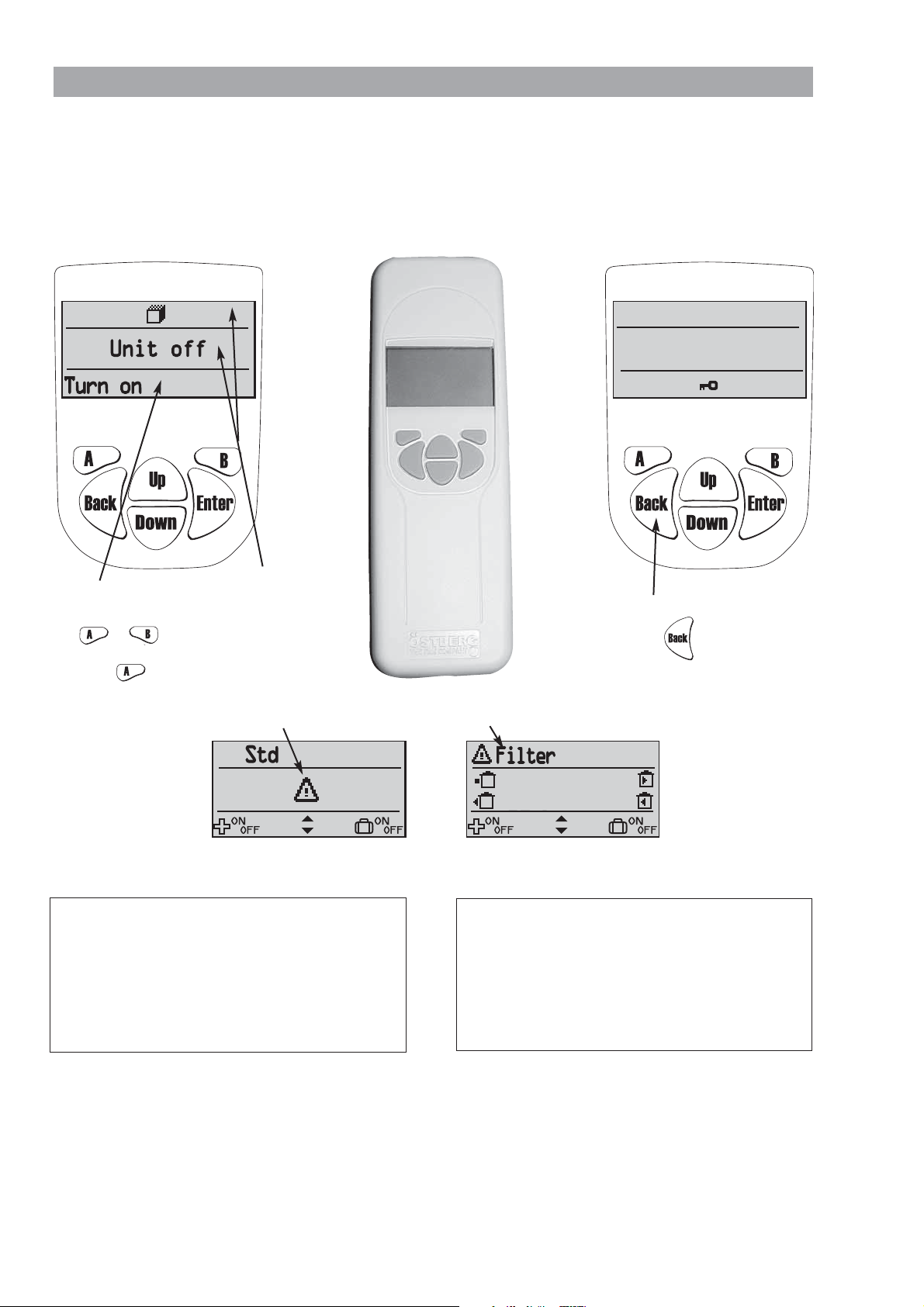

OPERATING THE CONTROL UNIT

StdStd

SYSTEMSYSTEM OK

......

50°F

54°F

70°F

72°F

Information of the units current status such as temperature, fan speed, the rotor temperature efficiency when

operating, heat respectively cooling needs is shown in the VIEW MODE 1, 2, 3 and 4. These menus is normally

not lit up for battery-saving purposes but is lit up after the first press of the button and is switched off after

about 2 minutes of not being in use.

The control unit automatically returns to VIEW MODE 1 after one minute when one has viewed other submenus.

NB! At new setting a delay of 15 seconds should be taken into consideration.

Top row and

Bottom row shows the

possible choices with

key or .

E.g turn on/off the unit

middle field

displays current

values and

activities.

with the key.

VIEW MODE 1 shows alarm and VIEW MODE 2 shows what kind of alarm.

USER INFORMATION FOR RF DEVICE:

FCC ID: A8W-4020528

This device complies with part 15 of the FCC Rules

and RSS-210 of IC Rules. Operation is subject to

the following two conditions: (1) This device may

not cause harmful interference, and (2) this device

must accept any interference received, including

interference that may cause undesired operation of

the device.

Changes or modifications not expressly approved by the

party responsible for compliance could void the user’s authority to operate the equipment.

This exuipment has been tested and found to comply

with the limits for Class B digital device, pursuant to part

15 of the FCC Rules. These limits are digned to provide

reasonable protection against harmful interference in a

residential installation. This equipment generates, uses and

can radiate radio frequency energy and, if not installed and

used in accordance with the instruction, may cause harmful interference to radio communications. However, there

To activate or disable the keylock;

press down the key for 3 seconds.

This device complies with part 15 of the FCC Rules

and RSS-210 of IC Rules. Operation is subject to

the following two conditions: (1) This device may

not cause harmful interference, and (2) this device

must accept any interference received, including

interference that may cause undesired operation of

the device.

is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be

determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or

more of the following measures: -Reorient or relocate the

receiving antenna. -Increase the separation between the

equipment and receiver. -Connect the equipment into an

outlet on a circuit different from that to which the receiver is connected. Consult the dealer or an experienced

radio/tv technician for help.

FCC ID: ASW-4020527

10

CO2

+

CO2

+

5

50°F

54°F

70°F

72°F

50°F

54°F

70°F

72°F

72°F

68°F

68°F

...

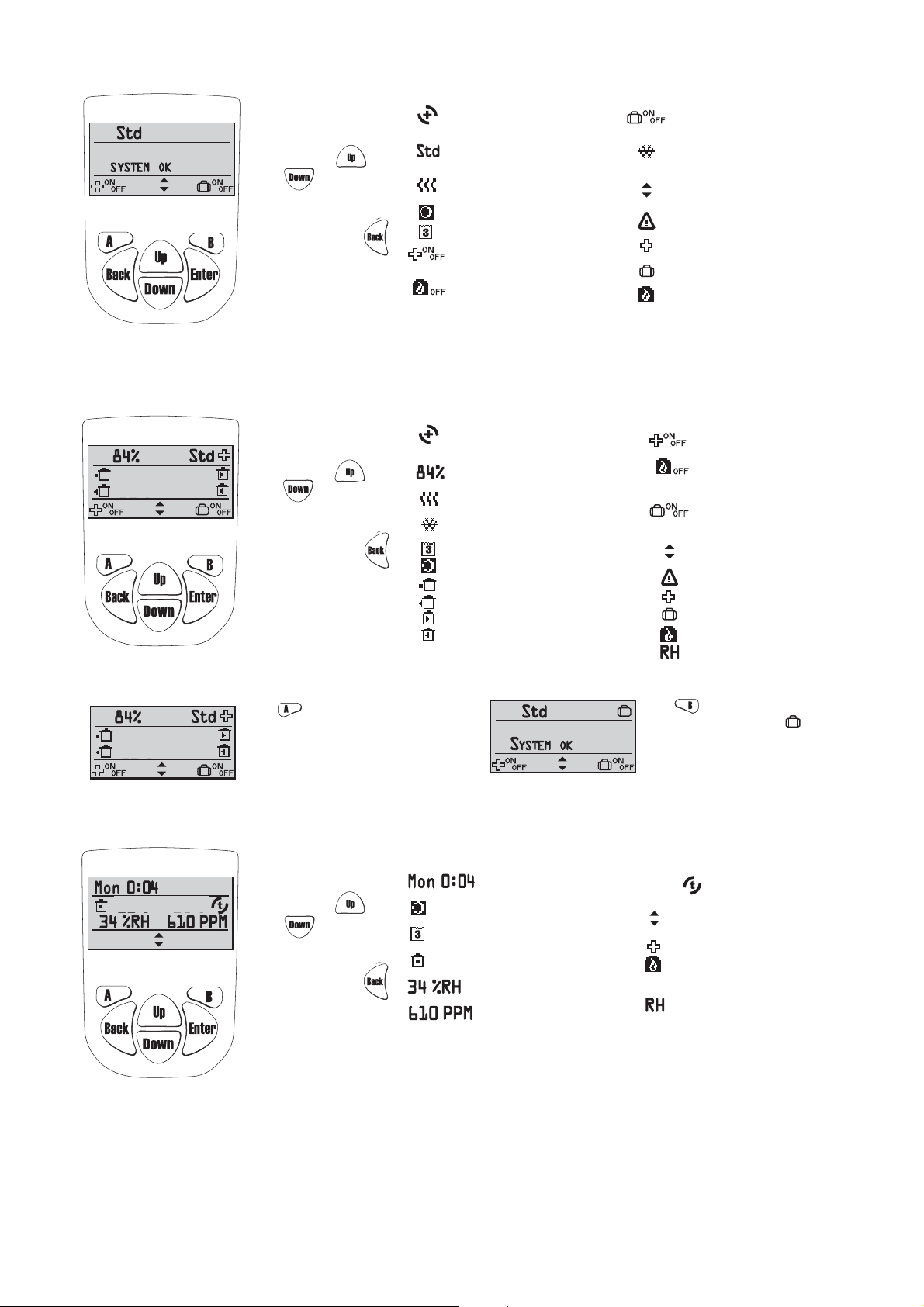

In order to go

view mode 2, 3

or 4 press

or .

In order to

return to view

mode 1, press .

In order to go

view mode 3

or 4 press

or .

In order to

return to view

mode 1, press .

VIEW MODE 1

SYMBOLS THAT CAN BE DISPLAYED IN VIEW MODE 1:

= Indicates that the rotor is operating.

++= heat recovery

- = cooling recovery

= Fan speed. Choose from min,

standard, medium, max.

= Symbol indicates that

the heating coil is on.

= Summer cooling is active.

= Week timer is active.

= Function of A-key.

Press A-key to regulate ”boost”

of supply & exhaust air flow.

= Function of B-key.

Press B-key to turn off

pressure compensation.

VIEW MODE 2

SYMBOLS THAT CAN BE DISPLAYED IN VIEW MODE 2:

= Indicates that the rotor is operating.

= heat recovery

- = cooling recovery

= Temperature efficiency.

= Symbol indicates that

the heating coil is on.

= Symbol indicates that

the cooling coil is on.

= Week timer is active.

= Summer cooling is active.

= Outside temperature.

= Exhaust air temperature.

= Supply air temperature.

= Extract air temperature.

= CO

C

compensation is active.

2

= Function of B-key.

Press B-key to choose

”Away” on or off.

= Symbol indicates that

the cooling coil is on.

= Function of keys up and down

for view mode 2, 3 and 4.

= Alarm

= Indicates Boost is active.

= Indicates Away is active.

= Pressure compensation is active.

= Function of A-key.

Press A-key to regulate ”boost”

of supply & exhaust air flow

= Function of B-key.

Press B-key to turn off

pressure compensation.

= Function of B-key.

Press B-key to choose

”Away” on or off.

= Function of keys up and down

for view mode 1, 3 and 4.

= Alarm

= Indicates Boost is active.

= Indicates Away is active.

= Pressure compensation is active.

= RH compensation is active.

IN VIEW MODE 1 AND 2 BOOST OFF/ON AND AWAY OFF/ON CAN BE CHOOSEN.

Press key to choose

supply & exhaust air flow for a specific time

(time and fan speed settings during the boost

is made in the Service menu ”Boost” page 69).

When the ”plus”

right corner, the boost is activated.

Boost off/on

+

symbol is displayed in the

of the

VIEW MODE 3

In order to go

view mode 2

or 4 press

or .

In order to

return to view

mode 1, press .

SYMBOLS THAT CAN BE DISPLAYED IN VIEW MODE 3:

= Display weekday and time.

= Indicates that Summer

cooling is active.

= Indicates that week timer

is active.

= Room temperature.

Sensor placed in room.

= Relative air humidity in per cent.

= Carbon dioxide level in PPM

(part per million).

Press key to choose

When the symbol ”suitcase” is

displayed in the right corner, the away

mode is activated, i.e. the fan speed is

minimum.

= Supply air temperature

after the rotor.

= Function of keys up and down

for view mode 1, 2 and 4.

= Indicates Boost is active.

= Pressure compensation is active.

compensation is active.

= CO

2

= RH compensation is active..

Away off/on

.

11

”MAIN MENU”

Off

70°F

70°F

In order to go forward in the menu from the View mode to the Main Menu press .

In the Main Menu is used to select the desired menu, after the choice is made with .

The procedure is the same in the submenu. In order to return to the previous page press .

”FAN SPEED” MENU (Only for HERU

In this menu desired fan speed is chosen. You can choose from 4 speeds: Min, Standard, Medium and Max.

Normal operation should be done in standard mode

Press in order to go forward from the Main Menu. Press again and then in order to choose

the desired fan speed. Confirm with .

Made settings is overridden if Week Timer is activated.

®

AC)

”TEMPERATURE” MENU

In this menu desired temperature is chosen (supply air, extract air or room temperature) depending on what

kind of regulation that is choosed, see page 20.

Press in order to go forward from the Main Menu. Press again and then in order to choose the

desired temperature (15-30°C/59-86°F). Confirm with .

Made settings is overridden if Week Timer is activated.

”BOOST” MENU

In this menu Boost On/Off is chosen. The time has the factory setting of 30 min. and fan speed Medium.

To adjust the fan speed and time, see page 17.

Boost is activated/disable (On/Off) with the key.

O

The Boost function can also be activated with an external switch with double pressure or timer.

See wiring diagram page 40-41. The Boost is On as long as the breaker is closed.

12

“OVERPRESSURE” MENU

Off

Power On/Off

70°F

70°F

70°F

Overpressure is a special feature were you can pressure compensate when supplementary

heating using an open fire or stove. The exhaust air fan then drops to a lower speed

during set time.

In this menu Overpressure On/Off is chosen. The time has the factory setting of 15 min.

To adjust the time, see page 17.

Overpressure is activated/disable (On/Off) with the key.

O

When pressure compensate is

activated the symbol ”Away”

will be change to the symbol

”Overpressure” in View

mode 1 and 2.

Than press directly in the

View mode to turn off Overpressure.

“WEEK TIMER” MENU

When in normal operation the unit runs with the fan speed that was choosen in the “Fan Speed” menu and

the temperature that was choosen in the “Temperature” menu. A departure from these programmed values that

you periodically want to recall is done in this menu. For example if you want to have a lower flow/temperature

during the daytime when nobody is at home then there is the possibility to adjust this here.

Week timer. If end time is the same or less than start time the program will end the following day.

Press in order to go forward from the Main Menu.

Press again and then in order to choose off/on of the week timer. Confirm with .

Press to choose/adjust the desired program. There are 5 programs for the adjustment of the fan speed

and temperature available. Press to choose a program.

Press in order to go forward to choose a weekday, start time, end time, fan speed and temperature.

Use the keys to choose the settings of weekday, start time, and end time, fan speed (Min, Standard,

Medium, Max, Standby*) and temperature (15-30°C/59-86°F).

Cont. next line.

Cont.

Cont. next line.

Cont

* Standby mode must only be used if a motorized damper is mounted on the exhaust and fresh air duct, in order to

protect from condensation inside the unit. The dampers should be connected to the control board "Duct valve".

N.B! The activated Week Timer over-

rides the manuel settings of fan speed

and temperature.

Program with the lowest index has

priority when two programs overlap

each other. E.g. Program 1 has priority

over program 2 when overlapped.

13

“POWER ON/OFF” MENU

! Filtertimer

Reset

Power On/Off

Settings

Power On/Off

Power On/Off

50°F

54°F

70°F

72°F

In the ”Power On/Off” Menu you have the possibility of turning off the unit via the wireless control unit.

NB! The unit must be currentless during service and maintenance.

Press in order to go forward from the Main Menu. Press in order to choose on/off of the unit.

When "On" is displayed in the center of the display, the unit is on. When "Off" is displayed the unit is off.

To avoid condensation in the unit during the cold season

the unit should not be turned off for a longer period.

“ALARMS” MENU (Displayed only if an alarm is triggered)

This meny displayes triggered alarms.

View mode 1 shows alarm and

View mode 2 shows what kind of alarm.

Alarms is shown for:

• ”Fire alarm” • ”Sensor open” • ”Sensor shorted” • ”Overheating”• ”Freeze alarm” • ”Supply temp. low”

• ”Rotor temp. low” • ”Rotor failure” • ”Filter” • ”Filter timer” • ”Supply fan alarm” • ”Exhaust fan alarm”

Press in order to go forward from the Main Menu and to view status.

When alerting a dialogue box for the alarm is shown in the Main Menu and the display will flash.

“View alarms” is shown and the possibility for equalization is given.

Press to see the cause of alarm in Submenu. Control the cause and remedy the alarm.

Press to ”Clear all” and than .

Current alarm is viewed. When "Sensor open" and "Sensor shorted" press "Show"

to view which sensor GT 1-8 is alerting.

See Control diagram on page 8.

In order to return to the previous pages press .

When alarm for Filter timer is triggered it can be equalized with Reset.

A reminder to change filter comes in a seven-day interval.

To restart the timer see ”Service Menu Alarm” page 18.

14

!

Loading...

Loading...