Page 1

SYLVANIA LED 2x2 RETROFIT KIT INSTALLATION INSTRUCTIONS

INSTALLATION SAFETY INFORMATION

The SYLVANIA LED 2x2 Retrofit Kit uses self-drilling hardware for ground straps and power supply installation. Check for electrical wiring and

components above luminaire housing prior to installation to avoid damage to A/C, sprinkler or other electrical systems.

WARNING—Risk of fire or electric shock. Luminaires wiring, ballasts, or other electrical parts may be damaged when drilling for installation of

reflector kit hardware. Check for enclosed wiring and components.

WARNING—Risk of fire or electric shock. LED Retrofit Kit installation requires knowledge of fluorescent lighting luminaires electrical systems. If

not qualified, do not attempt installation. Contact a qualified electrician.

WARNING—Risk of fire or electric shock. Install this kit only in the luminaires that has the construction features and dimensions shown in the

enclosed photographs and/or drawings.

WARNING—To prevent wiring damage or abrasion, do not expose wiring to edges of sheet metal or other sharp objects.

WARNING—Do not make or alter any open holes in an enclosure of wiring or electrical components during kit installation.

INSTALLATION OF THIS LED RETROFIT KIT ASSEMBLY REQUIRES A PERSON FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF LOW

VOLTAGE LUMINAIRE ELECTRICAL SYSTEMS AND THE HAZARD INVOLVED.

Contact your local OSRAM SYLVANIA representative for any assistance needed with this installation.

LED262 1/2012

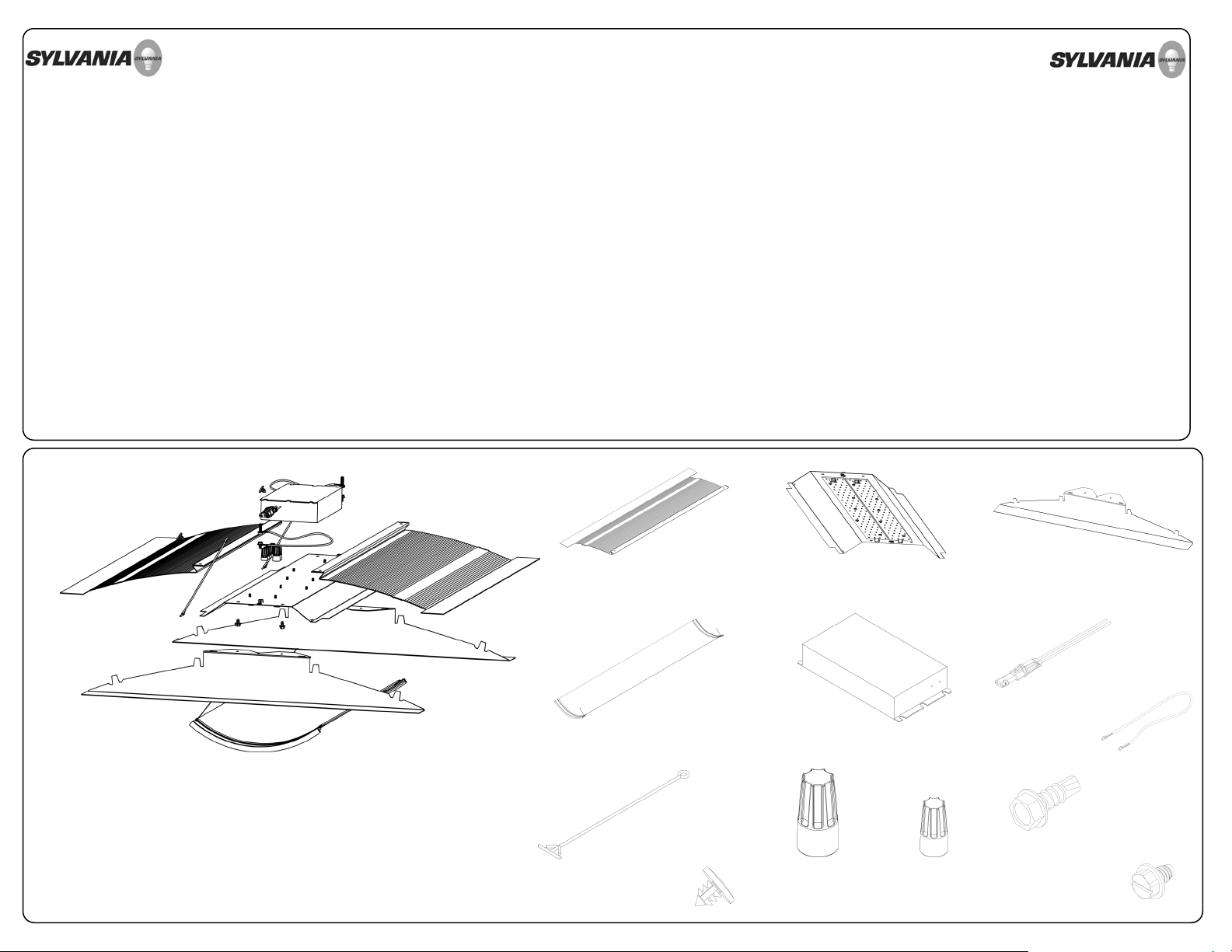

LED RETROFIT KIT EXPLODED VIEW

REFLECTOR BRACKET

QUANTITY: 2

LIGHT ENGINE PANEL

QUANTITY: 1

DIFFUSER LENS ASSEMBLY

QUANTITY: 1

SYLVANIA LED DRIVER

QUANTITY: 4

LED SUB ASSEMBLY

SAFETY TETHER

QUANTITY: 2

PUSH FASTENER

QUANTITY: 2

ORANGE WIRE NUT

QUANTITY: 2

BLUE WIRE NUT

QUANTITY: 5

END BRACKET

QUANTITY: 2

DRIVER QUICK

DISCONNECT

12” 18 GA GREEN

GOUND STRAP

QUANTITY: 2

#8-32 1/2”

HEX HEAD

SELF DRILLING SCREW

QUANTITY: 3

#8-32 3/8”

SLOTTED HEX HEAD

SELF THREADING SCREW

QUANTITY: 7

QUANTITY: 1

Page 2

PREPARE EXISTING FIXTURE FOR INSTALLATION

1

REMOVE EXISTING:

LENS / LENS FRAME

PARABOLIC LOUVER

REFLECTORS / BALLAST COVERS

BRACKETS

LAMPS / LAMP HOLDERS

Prior to installation, remove all electrical parts and the

ballast compartment cover leaving only the supply and

grounding leads.

INSTALL LED DRIVER AND DRIVER DISCONNECT

2 3

2X

DANGER—RISK OF SHOCK—DISCONNECT POWER BEFORE

INSTALLATION.

Using the provided self-drilling screws, properly affix specified

LED Driver to fixture. When drilling for installation of retrofit kit

hardware, please check for enclosed wiring and

components. Properly install Driver Disconnect to driver; black

to black and white to white.

NOTE: LED driver location will depend on troffer depth. The LED

driver may need to be off centered when installing in a

shallow troffer.

INSTALL REFLECTOR BRACKETS INTO EXISTING FIXTURE

2X

The LED Retrofit Kit is designed to rest between the existing

fixture body and the T-grid. Remove protective coating from

brackets before installing. Lift one side of the existing fixture

and place Reflector Bracket between the existing Fixture

body and T-grid . Lower the fixture body onto the Reflector

Bracket. Repeat procedure to install the second Reflector

Bracket.

INSTALL GROUND STRAPS & END BRACKETS

4 5

2X

2X

2X

+

Remove PVC film from End Brackets before installing. Use

3/8” slotted screws to secure one end of the green ground

strap to the small hole found on End Bracket. Lift one end

of the existing fixture and place End Bracket between the Tgrid and the existing Fixture body. Position the Reflector

Bracket so that the slots on the Reflector Bracket mate with

the tabs on the End Brackets. Repeat the procedure for the

second End Bracket. DO NOT bend the tabs yet.

Bond the retrofit assembly to the existing fixture by

connecting a Green Ground Strap directly to mains ground.

BEND TABS TO SECURE ASSEMBLY GROUND & SECURE RETROFIT KIT INTO EXISTING FIXTURE

6

+

With both Reflector Brackets and both End Brackets installed

and correctly positioned, secure the assembly by folding over

the two inner locking tabs applying finger pressure. The

remaining outer tabs are for alignment only. There should be

Four tabs in total that are folded over.

Page 3

ASSEMBLE SAFETY TETHERS TO LIGHT ENGINE PANEL

7

+

ASSEMBLE LIGHT ENGINE PANEL TO FIXUTRE

8

WIRE LIGHT ENGINE PANEL TO LED DRIVER

9

2X

Locate the rectangular slots on the edge of the Light Engine

Panel. Insert the circular end of the Light Engine Panel Safety

Tethers into the slots and pull until the barbs fasten. Verify

that the tethers are locked into place.

INSTALL LIGHT ENGINE PANEL TO FIXTURE

10

+

4X

Install the Light Engine Panel to the fixture buy setting the end

flanges into the ‘Z’ shaped recesses in the Reflector Brackets.

The Light Engine Panel should positively snap into place.

Secure the Light Engine Panel to the fixture by using the

provided self drilling screws.

2X

To assemble the Light Engine Panel to the fixture, locate

the rectangular slots on the End Brackets. Insert the

circular end of the Light Engine Panel Safety Tether into the

rectangular slots. Using the black plastic Push Fastener,

lock the circular end of the Light Engine Panel Safety

Tether into the End Bracket. Repeat the steps for the

second Light Engine Panel Safety Tether.

INSTALL DIFFUSER LENS ASSEMBLY

11

A

A Prior to installing the Diffuser Lens Assembly, pinch the ends

of the nylon tethers so that the fastening ends form a barb.

Refer to corresponding image A.

B With the nylon tethers ready to install, locate the two slots on

the Reflector Brackets where the nylon tethers will insert. Push

the end of the nylon tether into the slot and check that the

tethers secure into the Reflector Brackets. This is shown in B.

C With the nylon tethers secure into the Reflector Bracket,

insert one edge of the lens assembly into the lens groove in

the Reflector Bracket. Refer to image C for lens groove

location.

5X

2X

Using the provided Wire nuts, correctly wire the driver leads

to the LED input connector harnesses.

NOTE: Above image and all images with wires are for

illustration purposes only. Please follow driver wiring

instructions.

B

D When the first edge of the lens assembly is properly seated

into the lens groove, place the second edge of the lens

assembly into the other Reflector Bracket’s lens groove. The

lens groove locations are visible in image D. The gasket will

expand to fit the lens groove. Outward pressure from the

lens and friction from the gasket expanding will serve to

secure the lens assembly into the retrofit kit.

E Image E shows the finished assembly of the retrofit kit.

C

D E

Loading...

Loading...