SMD Kippsensor mit digitalem Ausgang (SFH 7710)

SMD Orientation-Sensor with digital output (SFH 7710)

Lead (Pb) Free Product - RoHS Compliant

SFH 7710

Wesentliche Merkmale

• optische Erkennung der Verkippung durch

gravitationsabhängige Position einer

Stahlkugel

• Niedriger Stromverbrauch

• digitaler Ausgang, open drain

• definierter Schaltwinkelbereich

• sehr kleines SMD Gehäuse

• IC gesteuerter Sensor

Anwendungen

• Digitalkameras

•Camcorder

• Mobiltelefone

• Computer Zubehör

Typ

Type

SFH 7710 Q65110A4407

Features

• optical detection of orientationby gravity

dependent position of a steel ball

• Low current consumption

• digital output, open drain

• defined range of switching angle

• very small SMD package

• IC controlled sensor

Applications

• Digital cameras

• Camcorders

• Mobile phones

• Computer peripherals

Bestellnummer

Ordering Code

2007-10-16 1

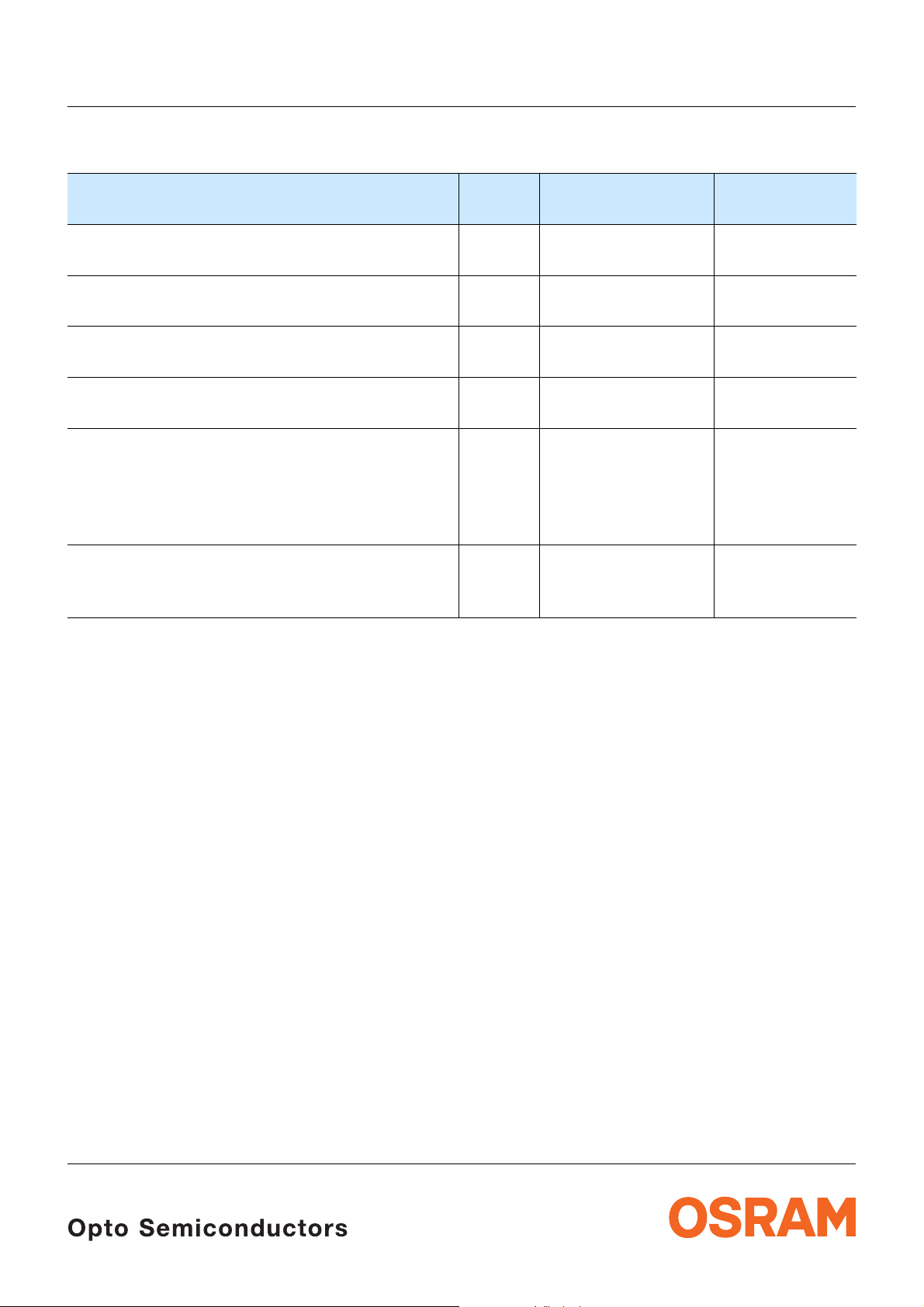

Grenzwerte

Maximum Ratings

SFH 7710

Bezeichnung

Parameter

Versorgungsspannung

Supply voltage

Ausgangsspannung

Output voltage

Ausgangsstrom

Output current

Lagertemperatur

Storage temperature range

Elektrostatische Entladung

Electrostatic discharge

- human body model (according to: Class I)

- machine model (according to:

AEC-Q100-003-REV-D, classification M3)

latch up Schutz

latch-up protection

(according to: EIA/JESD78 Class I)

Symbol

Symbol

V

cc

V

o

I

10 mA

o

T

-40...100 °C

s

V

ESD

Wert

Value

-0.2...6 V

-0.3...4.5 V

2

200

20 mA

Einheit

Unit

kV

V

2007-10-16 2

Empfohlener Arbeitsbereich

Recommended Operating conditions

SFH 7710

Bezeichnung

Parameter

Symbol

Symbol

Wert

Value

Einheit

Unit

Min Max

Betriebstemperatur

Τ

A

-20 +65 °C

Full operational ambient temperature range

Versorgungsspannung

V

cc

2.3 3.6 V

Supply voltage

Versorgungsspannungsstörungen *

dV

cc pp

0.2 V

(Frequenzbereich: 0...20kHz)

Supply voltage noise

(frequency range: 0...20kHz)

Ausgangsspannung

V

o

1.7 3.6 V

Output voltage

Pull-up Widerstand

R

pull up

10 100 kOhm

Pull-up resistance

* Der Emitter wird mit 10mA gepulst betrieben; das bedeutet, dass jeder Widerstand in Serie zu V

cc

einen Spannungsabfall in der Versorgungsleitung verursacht. Daher wird empfohlen, diesen

V

Serienwiderstand kleiner 10 Ohm zu halten. Die minimale Versorgungsspanung (

) darf keinesfalls

cc min

unterschritten werden.

V

* The emitter is driven with 10 mA in pulsed mode; this means that any series resistor to

causes a

cc

voltage drop on the power line. It is recommended to keep the series resistor below 10 Ohm. The supply

voltage may not fall below

V

cc min

2007-10-16 3

Kennwerte

Characteristics

(TA=25°C)

SFH 7710

Bezeichnung

Parameter

Minimale Betriebsspannung für Startphase(

siehe Figure 3)

Minimum required supply bvoltage for start-up (

Länge der Startphase

Start up time

(see Figure 3

Durchschnittlicher Stromaufnahme

mean current consumption

Spitzenstromaufnahme

peak current consumption

(siehe Figure 3)

)

1)

1)

2)

1)

Ausgangsleckstrom „high“

Output leakage current „high“

O = 3,6V

V

Ausgangsleckstrom „low“

Output leakage current „low“

Ol = 10mA (V

I

Aktualisierung des Ausgangssignals

Refresh of output signal

= 2,3V)

cc

1)

1)

see Figure 3)

Symbol

Symbol

Wert

Value

Einheit

Unit

Min. Typ. Max.

V

cc,start

t

start 60 120 ms

mean

I

0.8 2.0 V

50 µA

Ipeak 20 mA

OH 5µA

I

V

OL 0.5 V

trefresh 90 ms

Kippwinkel mit Ausgangszustand „low“

Tilt angle with output state „low“

(see Figure 1)

Kippwinkel mit Ausgangszustand „high“

Tilt angle with output state „high“

1)

gepulster Betrieb: Dauer LED an: ~44µs / Dauer LED aus: ~90ms

pulsed operation mode: LED on time: ~44µs / LED off time: ~90ms

2)

gepulster Betrieb: Dauer LED an: ~44µs / Dauer LED aus: ~90ms

pulsed operation mode: LED on time: ~44µs / LED off time: ~90ms

2007-10-16 4

(siehe Figure1)

(siehe Figure1)

(see Figure 1)

α

t 70 200 °

α

u 250 20 °

Funktionsdiagramm

Functional diagram

y

V

SFH 7710

αβ

y

20˚

out

= high

Switching Range

70˚

y

60˚-60˚

x

α

z

β

250˚

Switching Range

200˚

Figure1:

Erfassungscharakteristik / Detecting characteristics

(Unter extremen Bedingungen (hohe Temperatur und/oder hohe relative Feuchte) kann vorübergehend eine grössere

Schaltwinkeltoleranz auftreten)

(Under extreme conditions (high temperature and/or high relative humidity) a wider switching angle tolerance can occur

temporarily)

x

= low

V

out

Sensing Range

z

OHF03942

2007-10-16 5

Blockdiagramm

block diagram

V

CC

ASIC

R

SFH 7710

pull up

LED Anode

(must not be

connected)

Figure2:

Blockdiagramm (empfohlener Pull-Up-Widerstand R

Block diagram (recommended Pull up resistance R

LED

Phototransistor

GND

pull up = 10kOhm...100kOhm)

pull up = 10kOhm...100kOhm)

V

O

Device

boundaries

OHF03939

2007-10-16 6

SFH 7710

Startverhalten und Ablaufdiagramm

Start-up behavior and Timing diagramm

Der Ausgang ist immer hochohmig, wenn an Vcc keine Spannung angeschlossen ist. Wenn die Versorgungsspannung

V

cc , start erreicht, bleibt der Ausgang für 60ms <tstart <120ms auf „low“. Anschließend findet etwa alle 90ms eine

Messung der Orientierung statt und der Ausgang wird entprechend geschalten.

The Output is always high ohmic when voltage at V

sensor output stays low for 60ms <t

the output is set accordingly.

CC

V

V

CC, min

V

CC, start

start <120ms. Subsequently approx. every 90ms the orientation is measured and

Supply Voltage

LED

I

I

peak

cc is not connected. When supply voltage reaches Vcc, start the

t

start

t

start

t t

refresh

refreshtrefresh

t

LED Current

O

V

V

Output Voltage

V

OH

V

for α = 250˚...20˚= 70˚...200˚

OL

O

V

OH

αfor

V

Output Voltage

Figure 3:

Startverhalten und Ablaufdiagramm des Sensors

Start-up behavior and Timing diagram of sensor

OL

t

t

t

start

t

start

t

OHF03938

2007-10-16 7

Maßzeichnung

Package Outlines

23

R0.5 (0.020)

Orientation mark

4.6 (0.181)

4.2 (0.165)

(2.3 (0.091))

SFH 7710

4.7 (0.185)

(2.35 (0.093))

4.4 (0.173)

1

GPLY7039

(3.82 (0.150))

(0.4 (0.016))

Maße in mm (inch) / Dimensions in mm (inch)

Anschlußbelegung

Pin configuration

Pin # Description

4

2.0 (0.079)

1.6 (0.063)

4.6 (0.181)

4.2 (0.165)

GPLY7037

(4.1 (0.161))

GPLY7038

1GND

2Vcc

3

LED Anode

(must not be connected)

4Out

2007-10-16 8

Empfohlenes Lötpaddesign

Recommended Solderpad Design

SFH 7710

1.9 (0.075)

2.0 (0.079)

Maße in mm (inch) / Dimensions in mm (inch)

Gurtung und Lage

Method of taping and orientation

+0.1

1.5

0

4

1.2 (0.047)

2

1.3 (0.051)

OHPY3459

1.75

5.5

4.7

12

1.5

0.3

±0.05

4.85

Maße in mm (inch) / Dimensions in mm (inch)

2007-10-16 9

2.25

OHA03983

SFH 7710

Lötbedingungen Vorbehandlung nach JEDEC Level 4

Soldering Conditions Preconditioning acc. to JEDEC Level 4

300

˚C

250

T

255 ˚C

240 ˚C

Maximum Solder Profile

Recommended Solder Profile

Minimum Solder Profile

217 ˚C

200

10 s min

OHLA0687

260 ˚C

245 ˚C

235 ˚C

+0 ˚C

-5 ˚C

±5 ˚C

+5 ˚C

-0 ˚C

30 s max

150

120 s max

100 s max

Ramp Down

6 K/s (max)

100

Ramp Up

50

3 K/s (max)

25 ˚C

0

0

50 100 150 200 250 300

s

t

FFigure 8: Temperaturprofil für Reflow-Löten (Der Sensor darf nach dem Löten nicht gewaschen werden.)

Temperature profile for Reflow-soldering (Do not wash the sensor after soldering)

Published by

OSRAM Opto Semiconductors GmbH

Wernerwerkstrasse 2, D-93049 Regensburg

www.osram-os.com

© All Rights Reserved.

The information describes the type of component and shall not be considered as assured characteristics.

Terms of delivery and rights to change design reserved. Due to technical requirements components may contain

dangerous substances. For information on the types in question please contact our Sales Organization.

Packing

Please use the recycling operators known to you. We can also help you – get in touch with your nearest sales office.

By agreement we will take packing material back, if it is sorted. You must bear the costs of transport. For packing

material that is returned to us unsorted or which we are not obliged to accept, we shall have to invoice you for any costs

incurred.

Components used in life-support devices or systems must be expressly authorized for such purpose! Critical

components

1

A critical component is a component usedin a life-support device or system whose failure can reasonably be expected

1

, may only be used in life-support devices or systems 2 with the express written approval of OSRAM OS.

to cause the failure of that life-support device or system, or to affect its safety or effectiveness of that device or system.

2

Life support devices or systems are intended (a) to be implanted in the human body, or (b) to support and/or maintain

and sustain human life. If they fail, it is reasonable to assume that the health of the user may be endangered.

2007-10-16 10

Loading...

Loading...