Leistungsstarke IR-Lumineszenzdiode

High Power Infrared Emitter

Lead (Pb) Free Product - RoHS Compliant

SFH 4200

SFH 4205

SFH 4200 SFH 4205

Wesentliche Merkmale

• Leistungsstarke GaAs-LED (35mW)

• Hoher Wirkunsgrad bei kleinen Strömen

• Homogene Abstrahlung

• Typische Peakwellenlänge 950nm

• IR Reflow und TTW Löten geeignet

Anwendungen

• Schnelle Datenübertragung mit

Übertragungsraten bis 100 Mbaud

Tastatur, Joystick, Multimedia)

(IR

• Analoge und digitale Hi-Fi Audio- und

Videosignalübertragung

• Alarm- und Sicherungssysteme

• IR-Scheinwerfer für Kameras

Typ

Type

Bestellnummer

Ordering Code

Strahlstärkegruppierung 1) (IF = 100 mA, tp = 20 ms)

Radiant Intensity Grouping

Ie (mW/sr)

Features

• High Power GaAs-LED (35mW)

• High Efficiency at low currents

• Homogeneous Radiation Pattern

• Typical peak wavelength 950nm

• Suitable for IR reflow and TTW soldering

Applications

• High data transmission rate up to 100 Mbaud

keyboard, Joystick, Multimedia)

(IR

• Analog and digital Hi-Fi audio an d vi deo s ignal

transmission

• Alarm and safety equipment

• IR spotlight for cameras

1)

SFH 4200 Q65110A2494 10 (>4)

SFH 4205 Q65110A2498 10 (>4)

1)

gemessen bei einem Raumw ink el Ω = 0.01 sr / measu red at a solid angle of Ω = 0.01 sr

2005-02-25 1

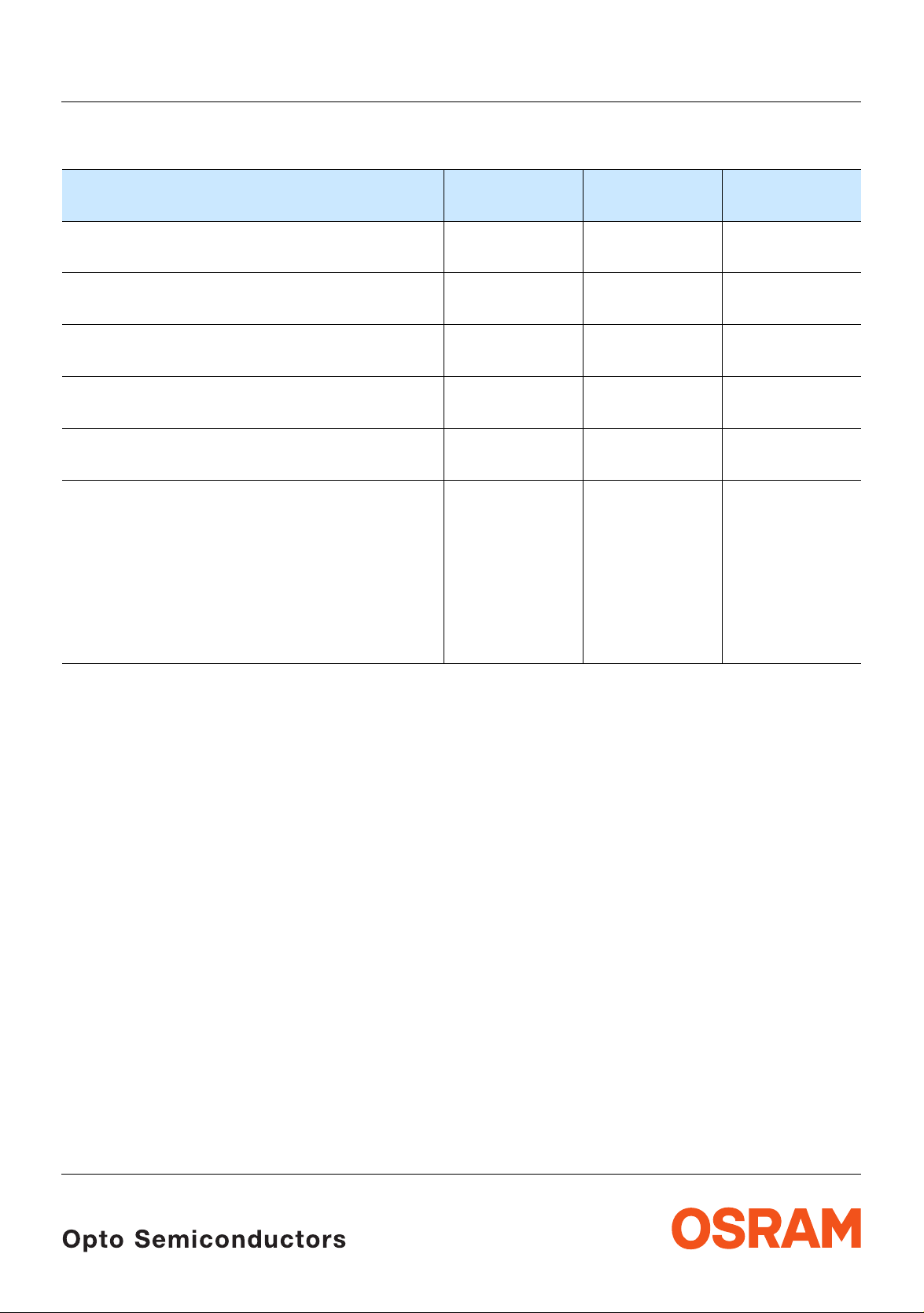

Grenzwerte (TA = 25 °C) Maximum Ratings

SFH 4200, SFH 4205

Bezeichnung

Parameter

Betriebs- und Lagertemperatur

Operating and storage temperature range

Sperrspannung

Reverse voltage

Durchlassstrom

Forward current

Stoßstrom, tp = 10 µs, D = 0

Surge current

Verlustleistung

Power dissipation

Wärmewiderstand Sperrschicht - Umgebung bei

Montage auf FR4 Platine, Padgröße je 16 mm

2

Thermal resistance junction - ambient mounted

2

on PC-board (FR4), padsize 16 mm

each

Wärmewiderstand Sperrschicht - Lötstelle bei

Montage auf Metall-Block

Thermal resistance junction - soldering point,

mounted on metal block

Symbol

Symbol

T

; T

op

stg

V

R

I

(DC) 100 mA

F

I

FSM

P

tot

R

thJA

R

thJS

Wert

Value

– 40 … + 100 °C

3 V

2.2 A

180 mW

450

200

Einheit

Unit

K/W

K/W

2005-02-25 2

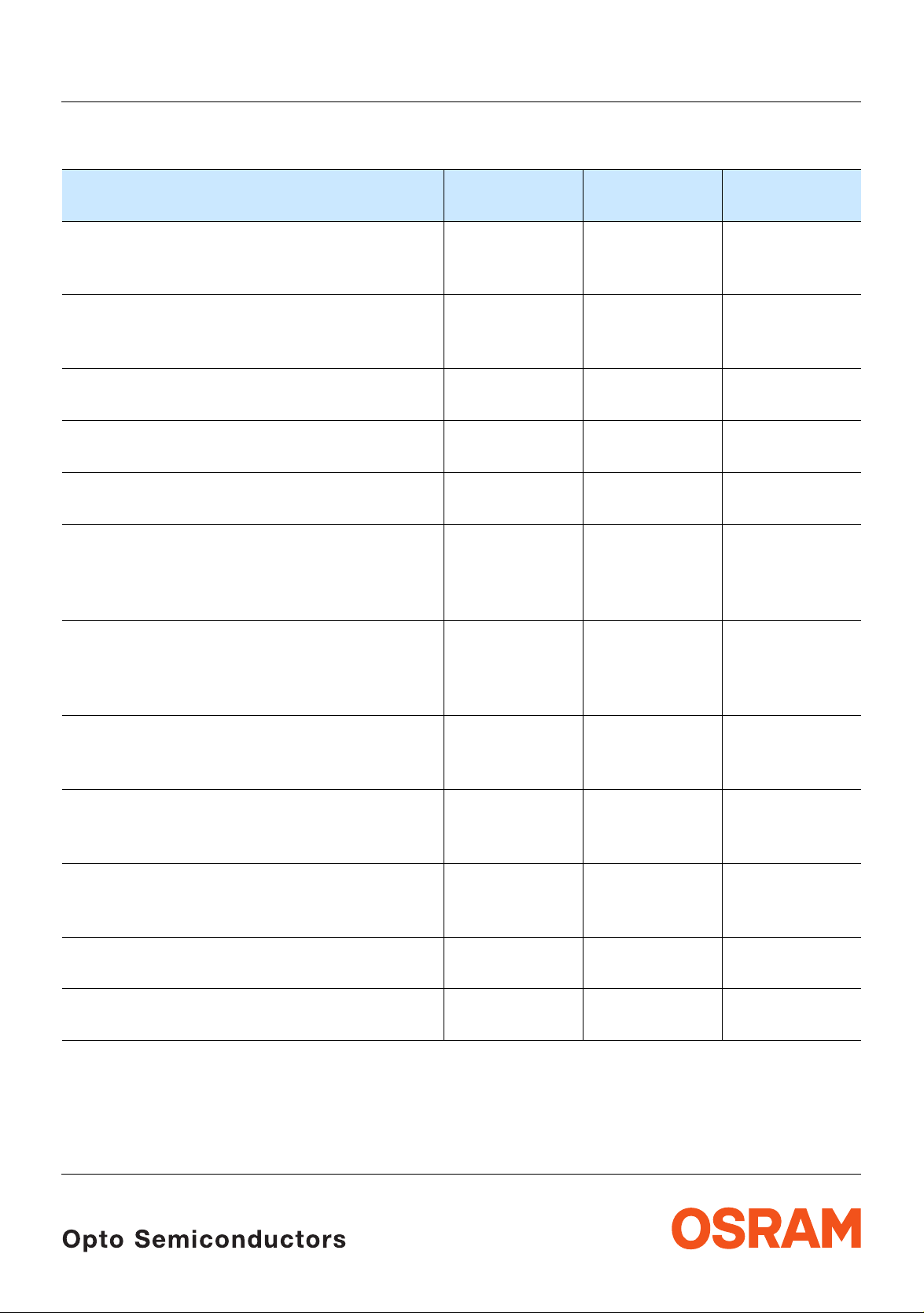

Kennwerte (TA = 25 °C) Characteristics

SFH 4200, SFH 4205

Bezeichnung

Parameter

Wellenlänge der Strahlung

Wavelength at peak emission

I

= 100 mA, tp = 20 ms

F

Spektrale Bandbreite bei 50% von I

Spectral bandwidth at 50% of I

IF = 100 mA, t

= 20 ms

p

max

max

Abstrahlwinkel

Half angle

Aktive Chipfläche

Active chip area

Abmessungen der aktiven Chipfläche

Dimensions of the active chip area

Schaltzeiten, Ie von 10% auf 90% und von 90%

I

auf 10%, bei

= 100 mA, tp = 20 ms, RL = 50 Ω

F

Switching times, Ιe from 10% to 90% and from

I

90% to10%,

= 100 mA, tp = 20 ms, RL = 50 Ω

F

Durchlassspannung

Forward voltage

I

= 100 mA, tp = 20 ms

F

I

= 1 A, tp = 100 µs

F

Sperrstrom

Reverse current

V

= 3 V

R

Gesamtstrahlungsfluss

Total radiant flux

I

= 100 mA, tp = 20 ms

F

Temperaturkoeffizient von Ie bzw. Φe,

I

= 100 mA

F

Temperature coefficient of Ie or Φe, IF = 100 mA

Symbol

Symbol

λ

peak

Wert

Value

Einheit

Unit

950 nm

∆λ 40 nm

ϕ ± 60 Grad

deg.

A

L × B

0.09 mm

0.3 × 0.3 mm

2

L × W

t

, t

r

V

V

I

R

Φ

TC

f

F

F

e

I

10 ns

1.5 (≤ 1.8)

3.2 (≤ 4.3)

V

V

0.01 (≤ 10) µA

35 mW

– 0.44 %/K

Temperaturkoeffizient von VF, IF = 100 mA

TC

Temperature coefficient of VF, IF = 100 mA

Temperaturkoeffizient von λ, IF = 100 mA

TC

Temperature coefficient of λ, IF = 100 mA

2005-02-25 3

V

λ

– 1.5 mV/K

+ 0.2 nm/K

Strahlstärke Ie in Achsrichtung

gemessen bei einem Raumwinkel Ω = 0.01 sr

Radiant Intensity Ie in Axial Direction

at a solid angle of Ω = 0.01 sr

SFH 4200, SFH 4205

Bezeichnung

Parameter

Strahlstärke

Radiant intensity

I

= 100 mA, tp = 20 ms

F

Strahlstärke

Radiant intensity

I

= 1 A, tp = 100 µs

F

Symbol Werte

Values

I

e min.

I

e typ.

I

e typ.

4

10

60 mW/sr

Einheit

Unit

mW/sr

mW/sr

2005-02-25 4

Relative Spectral Emissi on

I

= f (λ)

rel

100

Ι

erel

80

OHF00777

I

e

Radiant Intensity

I

e

100 mA

= f (I

F

Single pulse, tp = 20 µs

OHF00809

Ι

e

Ι

e (100 mA)

2

10

SFH 4200, SFH 4205

)

Max. Permissible Forward Current

I

= f (TA)

F

120

mA

Ι

F

100

OHF00359

60

40

20

0

850 900 950 1000 1100

Forward Current IF = f (VF)

single pulse, tp = 20 µs

4

10

mA

Ι

F

3

10

2

10

1

10

0

10

-1

10

OHF00784

0

10

-1

10

-2

10

-3

10

nm800

10 10110

23

10

λ

mA

Ι

40

10

F

80

60

40

20

0

0

20 40 60 80 100 120

R

thJA

= 375 K/W

˚C

T

A

Permissible Pulse Handling

I

Capability

= f (τ), TA = 25 °C,

F

duty cycle D = parameter

1

10

A

I

F

5

0

10

5

t

P

=

D

T

t

P

T

D

=

0.005

0.01

0.02

0.05

0.1

0.2

0.5

1

OHF00040

I

F

-2

10

-3

10

0

0.5 1 1.5 2 2.5 3 3.5 4.5

Radiation Characteristics I

V

V

F

rel

= f (ϕ

-1

10

-5

10

10-410-310-210-110010

0˚10˚20˚40˚ 30˚

ϕ

1.0

50˚

60˚

70˚

80˚

90˚

0.8

0.6

0.4

0.2

0

100˚

1.0 0.8 0.6 0.4

0˚ 20˚ 40˚ 60˚ 80˚ 100˚ 120˚

2005-02-25 5

1 2

t

p

OHL01660

10s

Maßzeichnung Package Outlines

SFH 4200

3.0 (0.118)

2.6 (0.102)

2.3 (0.091)

2.1 (0.083)

0.1 (0.004) (typ.)

SFH 4200, SFH 4205

2.1 (0.083)

1.7 (0.067)

0.9 (0.035)

0.7 (0.028)

SFH 4205

3.0 (0.118)

3.4 (0.134)

Cathode marking

2.8 (0.110)

Cathode

(2.4 (0.094))

2.4 (0.094)

2.54 (0.100)

spacing

(2.4) (0.095)

3.7 (0.146)

0.18 (0.007)

0.12 (0.005)

1.1 (0.043)

0.9 (0.035)

Anode

4˚±1

3.3 (0.130)

0.5 (0.020)

1.1 (0.043)

4.2 (0.165)

3.8 (0.150)

0.7 (0.028)

(2.85 (0.112))

A

C

0.6 (0.024)

0.4 (0.016)

GPLY6724

Cathode marking

(2.9 (0.114))

(1.4 (0.055))

(R1)

4.2 (0.165)

3.8 (0.150)

(0.3 (0.012))

3.4 (0.134)

3.8 (0.150)

AC

GPLY6880

Maße werden wie folgt ange geben: mm (inch) / Dimensions are specified as follows: mm (inch)

2005-02-25 6

Empfohlenes Lötpaddesign IR-Reflow Löten

Recommended Solder Pad IR Reflow Soldering

SFH 4200

2.6 (0.102)

2.6 (0.102)

SFH 4200, SFH 4205

SFH 4205

1.5 (0.059)

Padgeometrie für

verbesserte Wärmeableitung

Paddesign for

improved heat dissipation

4.5 (0.177)

Padgeometrie

für verbesserte

Wärmeableitung

Lötstopplack

Solder resist

3.7 (0.146)

3.0 (0.118)

1.2 (0.047)

4.5 (0.177)

1.5 (0.059)

Cu-Fläche > 16 mm

Cu-area > 16 mm

2

2

OHLPY970

Paddesign

for improved

heat dissipation

Cu-Fläche > 16 mm

Cu-area > 16 mm

2

2

Lötstopplack

Solder resist

OHLPY965

Maße werden wie folgt ange geben: mm (inch) / Dimensions are specified as follows: mm (inch)

2005-02-25 7

SFH 4200, SFH 4205

Lötbedingungen Vorbehandlung nach JEDEC Level 2 Soldering Conditions Preconditioning acc. to JEDEC Level 2 IR-Reflow Lötprofil für bleifreies Löten (nach J-STD-020B) IR Reflow Soldering Profile for lead free soldering (acc. to J-STD-020B)

300

˚C

250

T

255 ˚C

240 ˚C

Maximum Solder Profile

Recommended Solder Profile

Minimum Solder Profile

217 ˚C

200

150

120 s max

100

min. condition for IR Re f low Solderin g:

solder point temperature ≥ 235 °C for at least 10 sec.

50

Ramp Up

3 K/s (max)

25 ˚C

0

0

50 100 150 200 250 300

Wellenlöten (TTW) (nach CECC 00802)

TTW Soldering (acc. to CECC 00802)

30 s max

100 s max

260 ˚C

245 ˚C

235 ˚C

10 s min

Ramp Down

6 K/s (max)

t

OHLA0687

+0 ˚C

-5 ˚C

±5 ˚C

+5 ˚C

-0 ˚C

s

300

C

250

T

200

150

100

235 C

CC... 130100

50

0

0

C... 260

1. Welle

1. wave

ca 200 K/s

50 100 150 200 250

2 K/s

10 s

5 K/s

Zwangskühlung

forced cooling

2005-02-25 8

2. Welle

2. wave

OHLY0598

Normalkurve

standard curve

Grenzkurven

limit curves

2 K/s

s

t

SFH 4200, SFH 4205

Published by

OSRAM Opto Semiconductors GmbH

Wernerwerkstrasse 2, D-93049 Regensburg

www.osram-os.com

© All Rights Reserved.

The information describes the type of component and shall not be c ons idered as assured characteristics .

Terms of delivery and rights to change design reserved. Due to technical requirements components may contain

dangerous substances . For in fo rmation on the types in question pleas e c ont ac t our Sales Organization.

Packing

Please use the recycling operators k nown to you . We can als o help you – get in touch wit h your near est sales offic e.

By agreement we will take p acking material back, if it is sorted. You m ust bear the costs of transport. For packing

material that is returned to us unsorted or which we are not obliged to accept, we shall have to invoice you for any costs

incurred.

Components used in life-su pport devices or systems must be expressly authorized fo r such purpose! Critical

components

1

A critical component is a co mponent usedin a l ife-support devi ce or system whose failure can re asonably be expec ted

1

, may only be used in life-support devices or systems 2 with the express written approval of OSRAM OS.

to cause the failure of that life-support device or system, or to affect its safety or effectiveness of that device or system.

2

Life support devices or systems are intend ed (a) to be impl anted i n t he human b ody , or (b ) to supp ort a nd/or ma inta in

and sustain human life. If th ey fail , it is rea so nable to assume that the health of the user m ay be endangered.

2005-02-25 9

Loading...

Loading...